#textile waste recycling

Text

#bohostyle#marketing#branding#handmade#quilting#sales#home decor#business#business growth#accounting#rural women crating#rural life#rural women#ruralcore#rural india#rural women artist#recycledmaterials#recycling#reduce reuse recycle#recycled costumes#reducewaste#upcylced#upcycle#textile waste recycling#save environment#avoid fast fashion#slow fashion#clothing recycling#patchwork#kanthawork

0 notes

Text

organizing shampoo bars

Organizing my shampoo and conditioner bars along with my sanitary pads.

I used a cardboard box, covered with leftover cloth that I sewed by hand.

I am far from perfect zero waste, couldn't adapt to menstrual cups or O.B. or menstrual panties.

However, not being perfect doesn't stop me from trying the best I can in all the rest.

#Reduce the waste#zero waste#zerowaste#sustainability#recycling#recycle#reduce reuse recycle#ecofriendly#earthfriendly#reuse#creative reuse#cardboard box#cardboard cutouts#textile design#textile crafts#textile waste#shampoo and conditioner#shampoo bars#Conditioner bars#Organizing#Organization#Eco cosmetics#eco friendly

29 notes

·

View notes

Text

Whoever on here said that work pants aren’t even made to last no more; you are 10^100% right. I just discovered that I have a 2+ inch big hole on my pants along with another parallel to it bc my thighs are mighty. I am able to fix damn near everything cloth related but

my work pants getting holes when they are under a year old is

unacceptable.

#recycled words#planned obsolescence#clothing repair#dumpster stories#reduce reuse recycle#clothing waste#textile waste#work pants#enshittification

18 notes

·

View notes

Text

youtube

Every year, nearly 100 billion items of clothing are produced – and 65% of them end up in a landfill within 12 months. New technologies in textile recycling may be able to curb that waste – while producing a host of sustainable materials.

#planeta #recycling #fastfashion #circulareconomy #textileindustry

We're destroying our environment at an alarming rate. But it doesn't need to be this way. Our new channel Planet A explores the shift towards an eco-friendly world — and challenges our ideas about what dealing with climate change means. We look at the big and the small: What we can do and how the system needs to change. Every Friday we'll take a truly global look at how to get us out of this mess.

Follow Planet A on TikTok: https://www.tiktok.com/@dw_planeta?la...

Credits:

Report: Dave Braneck

Video Editor: Frederik Willmann

Supervising Editor: Michael Trobridge

Fact Check: Alexander Paquet

Thumbnail: Ém Chabridon

Read More:

McKinsey - Scaling Textile Recycling in Europe

https://www.mckinsey.com/industries/r...

NY Times - Will We Ever Be Able to Recycle Our Clothes Like an Aluminum Can?

https://www.nytimes.com/2022/11/30/st...

EU Strategy for Sustainable and Circular Textiles https://environment.ec.europa.eu/stra...

Chapters:

00:00 Intro

00:46 Textile waste's global impact

02:47 How do you actually recycle clothes?

03:50 New approaches to textile recycling

07:41 What else needs solving?

11:41 Can we even recycle all the clothes we make?

#DW Planet A#solarpunk#fashion#fashion industry#fast fashion#fashion waste#circular fashion#recycling#textiles#textile industry#sustainable fashion#sustainable textiles#textile recycling#Youtube

7 notes

·

View notes

Photo

Closed-loop recycling of textile wastes

The apparel industry accounts for 10% of global carbon emissions. The annual amount of fiber production reached 113 million tons in 2021 and the demand is increasing every year. However, almost 90% of post-consumer fiber wastes are disposed of through incineration or deposition in landfills.

Among these forms of waste, synthetic fiber has become a major threat to the environment and human health because, similar to other plastics, it is not biodegradable. Due to its low cost and durability, polyester is the most widely used synthetic fiber on the planet, accounting for more than half of all fabrics annually produced. Comprehensive recycling of polyester is thus a critical challenge for environmental sustainability and the health of future generations.

In practice, crude textile waste is not suitable for reuse or recycling because it is mixed with different fabric materials, colored by different dyes, and contaminated by various other impurities. Sorting it into homogeneous materials is necessary to make the waste recyclable by a chemical or mechanical method. To this end, a research team at the Korea Research Institute of Chemical Technology (KRICT) has developed a new chemical technology referred to as "chemical sorting." Their study is published in the journal ACS Sustainable Chemistry & Engineering.

Read more.

28 notes

·

View notes

Text

The Swedish pulp producer Renewcell has just opened the world's first commercial-scale, textile-to-textile chemical recycling pulp mill, after spending 10 years developing the technology.

While mechanical textiles-to-textiles recycling, which involves the manual shredding of clothes and pulling them apart into their fibres, has existed for centuries, Renewcell is the first commercial mill to use chemical recycling, allowing it to increase quality and scale production. With ambitions to recycle the equivalent of more than 1.4 billion T-shirts every year by 2030, the new plant marks the beginning of a significant shift in the fashion industry's ability to recycle used clothing at scale.

"The linear model of fashion consumption is not sustainable," says Renewcell chief executive Patrik Lundström. "We can't deplete Earth's natural resources by pumping oil to make polyester, cut down trees to make viscose or grow cotton, and then use these fibres just once in a linear value chain ending in oceans, landfills or incinerators. We need to make fashion circular." This means limiting fashion waste and pollution while also keeping garments in use and reuse for as long as possible by developing collection schemes or technologies to turn textiles into new raw materials.

Each year, more than 100 billion items of clothing are produced globally, according to some estimates, with 65% of these ending up in landfill within 12 months. Landfill sites release equal parts carbon dioxide and methane – the latter greenhouse gas being 28 times more potent than the former over a 100-year period. The fashion industry is estimated to be responsible for 8-10% of global carbon emissions, according to the UN.

Just 1% of recycled clothes are turned back into new garments. While charity shops, textiles banks and retailer "take-back" schemes help to keep those donated clothes in wearable condition in circulation, the capabilities of recycling clothes at end-of-life are currently limited. Many high street stores with take-back schemes, including Levi Strauss and H&M, operate a three-pronged system: resell (for example, to charity shops), re-use (convert into other products, such as cleaning cloths or mops) or recycle (into carpet underlay, insulation material or mattress filling – clothing is not listed as an option).

Much of the technical difficulty in recycling worn-out clothes back into new clothing comes down to their composition. The majority of clothes in our wardrobes are made from a blend of textiles, with polyester the most widely produced fibre, accounting for a 54% share of total global fibre production, according to the global non-profit Textile Exchange. Cotton is second, with a market share of approximately 22%. The reason for polyester's prevalence is the low cost of fossil-based synthetic fibres, making them a popular choice for fast fashion brands, which prioritise price above all else – polyester costs half as much per kg as cotton. While the plastics industry has been able to break down pure polyester (PET) for decades, the blended nature of textiles has made it challenging to recycle one fibre, without degrading the other. (Read more about why clothes are so hard to recycle.)

By using 100% textile waste – mainly old T-shirts and jeans – as its feedstock, the Renewcell mill makes a biodegradable cellulose pulp they call Circulose. The textiles are first shredded and have buttons, zips and colouring removed. They then undergo both mechanical and chemical processing that helps to gently separate the tightly tangled cotton fibres from each other. What remains is pure cellulose.

6 notes

·

View notes

Link

Who Are We? YES Full Circle is an international tech-based, climate change, and circular economy platform that supports people and organizations to become global sustainability champions. What Does YES Full Circle Stand For? YES refers to Your Environmental Savings. Full Circle refers to ensuring that material we collect, is not landfilled, but is used back,

#Textile Waste Recycling Services Dubai#Brand Protection in Dubai#Aerosol Recycling services in dubai#Cosmetics Recycling Service in Dubai#Recycling Zero Waste Solutions#Consumer Goods recycling in Dubai#Plastic Recycling Solutions in Dubai#Waste Management services in dubai#Scrap Metal Recycling in Dubai#Cosmetic Recycling Trends#E-waste Recycling Service in Dubai#Plastic recycling dubai

0 notes

Link

What is EPR/PRO? In certain government jurisdictions, producers must comply with EPR requirements for items. This is to promote proper recycling and extensive sustainable recycling for certain materials. Producer organizations must file EPR returns annually. An EPR return for waste is just like ITR or Income Tax Return. As a producer, they must file an

#White-Labelled Csr Solutions#Circular economy in Dubai#Global circle recycling in Dubai#Secure Destruction services in Dubai#Innovative Circular Economy Solutions in Dubai#Textile Waste Recycling Services Dubai#Brand Protection in Dubai#Aerosol Recycling services in dubai#Hazardous Waste Collection#Cosmetics Recycling Service in Dubai#Recycling Zero Waste Solutions#Consumer Goods recycling in Dubai#Community recycling solutions

0 notes

Text

Evolving in Style: Supporting Zero Waste Fashion the Practical Way

View On WordPress

#challenges in sustainability#education in fashion#repurposing clothes#sustainable brand choices#sustainable style#textile recycling#versatile wardrobe#Zero waste fashion

0 notes

Text

How does one upcycle a pile of dirty laundry into a stunning work of modern art?

Laundry day can be a tedious task for many of us, but did you know that your dirty laundry can be upcycled into a stunning work of modern art? With a little creativity and effort, you can transform your mundane laundry pile into something unique and beautiful.

Continue reading Untitled

View On WordPress

#aesthetics#art techniques#artistic expression#artistic vision#creativity#dirty laundry#DIY#eco-friendly#environmentalism#home decor#modern art#repurpose#reuse#sustainability#textile art#textile design#textile recycling#textile waste#upcycling

0 notes

Text

How can we reduce Textile Waste

There are many ways to combat textiles waste and reduce the impact on the environment, like use cotton that is still good but not as soft as before. This will help to reduce textile waste. Try on your clothes before you buy them to see if the fabric is perfect or not. This will help to reduce textile waste too. Know more about Textile waste by Recycling fibers.

0 notes

Text

#bohostyle#marketing#branding#handmade#quilting#sales#home decor#business#business growth#accounting#home improvement#best handmade item#handmade kantha scarf#handmade vintage kantha quilt#handmade kantha quilt#handicraft#handcrafted#hand crafted#recycledmaterials#recycling#reduce reuse recycle#recycled costumes#reuse#upcycle#save environment#reducewaste#reduce textile waste#rural crafting#rural women#rural art

0 notes

Link

The “Recycled Textile Waste Market” research report offers important information about the state of the sector. This research offers in-depth details on the industry’s foundation, productivity, strengths, manufacturers, and current trends that support business expansion and economic strength.

0 notes

Text

Repair regrets? “I wish I could have saved ____ with the right tool(s) or skills.”

I miss my old boots, the ones I found in the dumpster. They were so comfortable and were reasonably water proof for how much they cost- around $45 and from Walmart. They are those cheap kinds that you get when all of the others are out of your range at that moment, the kind that will really start to break down after a year of constant use. Those boots were my #1 choice for everything every single day.

I miss them and I wish there could have been more that I could have done within reason to save them or make them last longer.

Maybe it’s stupid sounding, but sometimes I look back at all of the objects I’ve been given and have owned that I could have put a little more effort into reusing or mending. I’m in my early 20s and still have a lot of skills to learn for later in my life to make sure I don’t generate too much waste.

I happen to think a lot about the hands of the people who’ve crafted my clothes and accessories. I know about the inhumane conditions people are forced to work in and, as a result of the poor pay from that labor, have to live in horrible housing units with (or without) the bare essentials to keep them alive for another day just to labor again. I don’t want to treat their blood sweat and tears like a joke, I don’t want to forget about the treatment these humans have to go through every day to try to feed their families and themselves. Like it or not, every single thing we wear comes from another human who’s being used as a slave for damn near free labor by a big company.

My friends are sewing needles, thread, spare cloth from clothes I no longer wear, stores when I need them, stuffing/filling, E600, patience and creativity. We have created and healed a lot of things that would have been tossed otherwise. There are still regrets about the things we couldn’t work together to save and I think it’s very valid to have those feelings. We as humans have a responsibility to help keep trash and chemical pollution away from where they shouldn’t be.

#recycled words#dumpster diving#reduce reuse recycle#zero waste#freeganism#clothing#clothing waste#zero waste living#low waste#fabric waste#textile waste#plastic waste#waste not want not

6 notes

·

View notes

Text

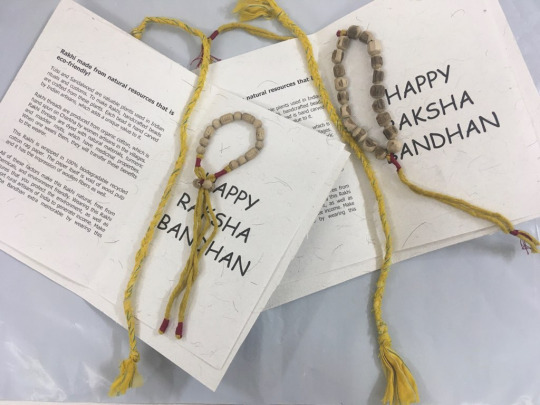

#Tulsi & Sandal Wood Rakhi with Natural Dyed Recycled & Organic Thread#Handmade Lumba Rakhi Set made with recycled yarn made out of post consumer textile waste and hand made coconut shell.#https://www.youtube.com/watch?v=lwu478HxoL8#recycledrakhi#handmadelumbarakhi#recycledlumbarakhi#lumbarakhi#lumbarakhiset#sustainablerakhi#rakhi2022#plasticfreerakhi#recyclablerakhis#ecofriendlyrakhi#handmaderakhi#handmaderakhisonline#ecorakhi#ecorakhis#naturalrakhi#pompomrakhi#coconutshellrakhi#recyclablerakhi#sustainablerakhis#threadrakhi#handcraftedrakhi

1 note

·

View note

Text

Brands are leaning on ‘recycled’ clothes to meet sustainability goals. How are they made? And why is recycling them further so hard?

- By Timo Rissanen , University of Technology Sydney , The Conversation -

Today we make more clothing than ever before. And the driver for this is primarily economic, rather than human need. Over the past decade, the term “circular economy” has entered the fashion industry lexicon, wherein materials are made to be reused and recycled by design.

Yet we haven’t seen the same level of recycling in fashion as we have in other spaces – such as with plastic recycling, for instance. And this is mainly because clothing-to-clothing recycling is much more difficult.

The use of recycled polyester and cotton by brands such as H&M and Cotton On are key aspects of these companies’ sustainability initiatives – but the source of these recycled fibres usually isn’t clothing. Recycled polyester tends to come from plastic bottles, and recycled cotton is usually made from manufacturing waste.

The fact is most clothing is simply not designed to be recycled. Even when it is, the fashion industry lacks the kind of infrastructure needed to really embrace a circular economy model.

Why is recycling clothes difficult?

Recycling clothing isn’t like recycling paper, glass or metal. Clothes are endlessly variable and unpredictable. So they’re not ideal for recycling technologies, which require a steady and consistent source material.

Even a seemingly simple garment may contain multiple materials, with fibre blends such as cotton/polyester and cotton/elastane being common.

Different fibres have different capacities for recycling. Natural fibres such as wool or cotton can be recycled mechanically. In this process the fabric is shredded and re-spun into yarn, from which new fabric can be woven or knitted.

However, the fibres become shorter through the shredding process, resulting in a lower quality yarn and cloth. Recycled cotton is often mixed with virgin cotton to ensure a better quality yarn.

Most fabrics are also dyed with chemicals, which can have implications for recycling. If the original fabric is a mixture of many colours, the new yarn or fabric will likely need bleaching to be dyed a new colour.

A complex garment such as a lined jacket easily contains more than five different materials, as well as trims including buttons and zippers. If the goal of recycling is to arrive at a material as close to the original as possible, all the garment’s components and fibres would first need to be separated.

This requires labour and can be expensive. It’s often easier to shred the garment and turn it into a low-quality product, such as shoddy which is used for insulation.

Industry progress and challenges

Companies such as BlockTexx and Evrnu have developed processes to recycle fibres from blended fabrics, though such recycled fibres aren’t yet widely available.

Through a proprietary technology, BlockTexx separates cellulose (present in both cotton and linen) and polyester from textile and clothing waste for new uses, including in new clothing. And Evrnu has developed a type of lyocell made entirely from textile and clothing waste.

Spain-based company Recover meticulously sorts through different kinds of cotton textile waste to produce high quality, mechanically recycled, cotton fibre.

There’s also biological recycling. Fibre waste from the Rivcott cotton “gin” (or cotton engine) is composted to become fertiliser for a new cotton crop. The same is possible with natural fibres from worn-out clothing, after potentially toxic dyes and chemicals have been eliminated.

Synthetic fibres such as polyester and polyamide (nylon) can also be recycled mechanically and chemically. Chemical recycling through re-polymerisation (where the plastic fibre is melted) is an attractive option, since the quality of the original fibre can be maintained.

In theory it’s possible to use polyester clothing as the source for this. But in practice the source is usually bottles. This is because clothing is usually “contaminated” with other materials such as buttons and zippers, and separating these is too labour intensive.

The plastic problem

Almost all recycled polyester in clothing today comes from recycled plastic bottles, rather than previous polyester clothing. This is significant when you consider polyester accounts for more than 60% of all fibre use.

Given the rapid increase in the production of synthetic fibres, and the as-yet-unknown impact of microplastics (which were documented in human placentas last year) – the question remains whether clothing should be made from biologically incompatible materials at all.

Polyester clothes, regardless of fibre sources, contribute to microplastic pollution by shedding fibres when worn and laundered.

A new generation of synthetic fibres from renewable sources (recyclable and also biodegradable) offers a path forward. For instance, the Kintra fibre is made from corn.

Reduce and reuse before you recycle

There’s plenty of evidence that reducing the consumption of clothing by wearing items longer and buying second-hand is preferable to purchasing recycled fibre clothes.

But even second-hand fashion isn’t without problems when you consider the scale and pace of clothing production today.

Liz Ricketts of the US-based OR Foundation, a charity focused on sustainable fashion, paints a gruesome picture of the Kantamanto market in Ghana, where much of the world’s secondhand clothing ends up (including from Australia).

One path forward is for companies to take responsibility for products at their end of life. US fashion brand Eileen Fisher is a pioneer on this front.

The company has purchased garments back from customers since 2009. These are cleaned and sorted, and mostly resold under the Eileen Fisher Renew brand.

Garments too damaged for resale are given to a dedicated design team, which redesigns them to be sold under the Eileen Fisher Resewn collection. Off-cuts from this process are captured and turned into textiles for further use.

Timo Rissanen, Associate professor, University of Technology Sydney

This article is republished from The Conversation under a Creative Commons license. Read the original article.

--

Read Also

New report: AI in North American fashion market (2019-2027)

0 notes