#validating CFD

Explore tagged Tumblr posts

Text

rolling road

1 note

·

View note

Text

OK, time for me. It won’t be the last post, because boy do I have lots to say about the last episode, but you gotta start somewhere 😉

I can’t believe I have to say this but two things can be true at the same time.

1. Stellaride adopting a baby feels totally right. Stella lived with her aunt after her parents died. Kelly moved in with April when Benny left and his mum couldn’t take care of him anymore. Both of them know how life changing it is when someone else than your parents opens their home and their heart to you and help you. How much that means - especially when you are a kid (I know Kelly was in high school at this point but he wasn’t an adult, he still needed his family, he still needed support and care and love. Like every kid).

Both of them help people at work. They do it without hesitation - like Stella told Kelly, when someone needs help, he doesn’t ask questions, he does everything he can to help them.

Their relationship helped both of them heal their wounds, showed them that they deserve true love, happiness and peace. Was it an easy road? Nope. Was it worth it? Totally.

Also, another thing that is worth pointing out is the fact that they are actually the first couple who talked about adopting a baby before meeting the baby. Gabby saw Louis on call, same with Cruz, Brett and Burgess. It wasn’t something they considered before - and if they did, they never mentioned it (correct me if I’m wrong). It’s nice to see two people talk about it, take time with it and make decisions based on what feels right to them - because they want to and they are sure of it, not just because they rescued a baby during work (I don’t day it’s not a good thing, but again, repeated storyline has entered the chat).

2. Being mad that we might get another adoption storyline is also totally valid. BTW let’s point out that she said she wanted to know if adoption is something he would consider and want. She didn’t say it’s their only option. And she didn’t say ’absolutely no’ to being pregnant. OK, moving on. We’ve seen adoption so many times already - with Dawsey (I didn’t say it was all successful), Burgess, Cruz and Brett. We’ve seen Casey fostering Darden boys (twice actually), we’ve seen that with Maggie on MED. At this point it feels like it’s the only way for a couple to have a baby. Yeah, Cindy was pregnant, same with Donna and Chloe, but they are not main characters. And their pregnancy was being told from male perspective - their husbands were the ones talking about that, their jobs weren’t at risk because of that, it was there but it wasn’t the centre of attention. By making Stella pregnant they could show how different women are treated, how different is for female firefighter to become a mum than it is for male firefighter to become a dad. Itd make dominated environment, it’s hard as it is, so they had a chance to show how pregnancy make it even harder. And with Stella being the lieutenant? What would that mean for her company? Would they put her behind the desk to do some boring paperwork nobody else wants to do - or would she use that opportunity to make a difference in the department and work to make CFD better place for female firefighters?

And not only that - you have WOC and you don’t use her to shine a light to the reality of how much that impacts her. Nice, you brought up PPD, but what about the fact that pregnancy is way more risky when you are POC? I don’t live in USA, but I’m not blind or stupid, we all know how mortality rates during pregnancy and childbirth are raising lately and how it is worse for people of colour. Perfect opportunity for showing that you are aware what is happening around you.

So, like I said in the beginning of this very long rant (if you made it to the end, thank you - and wow, congratulations, you made through all this rambling), it’s ok to be annoyed at another repeated storyline while being totally happy for two people who wants to expand their family (because two of them are already a family of their own and you won’t change my mind about that).

17 notes

·

View notes

Note

About the post you recently reblogged...

I do rate Carlos high and like him but the race engineer or automotive engineer allegations need to stop. Already being an F1 driver is a life-long investment into understanding many things and honing your skills. Your driving skills.

This is a very complicated team sport and engineering sport, and I think people really downplay just how much engineering work there is behind the cars. Make Carlos use ANSYS software to model the structure of a car, make Carlos run a CFD simulation and analysis, make him generate iso-surfaces in the X velocity and then identify wake regions/flow separation and THEN make him come up with modifications within the regulations that help reduce drag 🙄. And all the shit I'm saying is like the most most basic part that we are taught in a bachelor's mechanical engineering degree. I could not even begin to think or imagine what actual f1 engineers do.

So, please, this man who is a good driver does not need to, nor does he understand the car like the engineers on the williams factory do. He understands it in a different way, and his feedback is very valuable, sure. But god, please, he isn't designing that car. Why can't people understand??

And no he's not creating better strategies. What drivers see and know as they drive is a very very small percentage of all the information the pitwall and strategist have. And even if he was fed that info, he'd have to be a genius to parse all that out. People (rightly) complain about Norris' engineer Will giving him almost a riddle to chose what Tyre he wants, can't imagine what giving a driver ALL the info the team is considering would look like. They wouldn't even have the time 💀.

Sorry my rant is over but this pisses me off badly. The way people will overstate the role of the driver for both positive and negative agendas is such a pet peeve of mine.

I have no recollection of what post i reblogged but yeah, you’re so valid 😅

2 notes

·

View notes

Text

Say Goodbye to Latency: Alltick API Delivers Real-Time Market Data!

In the fast-paced financial market, what does 15 minutes mean? While traditional market data still shows you "historical prices," Bitcoin may have surged by 10%, futures contracts could have triggered margin calls, and forex rates might have experienced wild fluctuations. This is the decision gap created by delayed data—you only see the market's "past."

Alltick API was created to solve this pain point. As a next-generation standardized data interface solution, Alltick redefines how financial data is accessed through technological innovation. Our API delivers real-time market data streams across all asset classes, including stocks, forex, futures, and cryptocurrencies, with millisecond response times. Say goodbye to the traditional 15-minute delay trap, and make every trading decision based on the "now" of the market.

Why Choose Alltick Data Interfaces?

✅ Zero-Latency Direct Exchange Connection Utilizing a distributed data collection architecture, we connect directly to over 50 top exchanges, including NYSE, NASDAQ, and CME, with data update frequencies precise to the microsecond.

✅ Comprehensive Interface Ecosystem We offer various data interface formats, including RESTful, WebSocket, and FIX protocols, perfectly supporting the diverse needs of high-frequency trading systems, mobile apps, and quantitative analysis platforms, with the capacity for billions of API calls daily.

✅ Intelligent Data Cleansing Engine With built-in mechanisms for anomaly filtering, data completion, and multi-source validation, we ensure that every piece of market data transmitted undergoes strict standardization, allowing direct integration with your trading algorithms without the need for secondary cleansing.

✅ Developer-Friendly Design We provide SDKs in Python, Java, C++, and comprehensive technical documentation, allowing you to complete data interface calls in just 3 lines of code. Whether you’re an independent developer or an enterprise user, the 10-minute onboarding experience will completely change your perception of financial data services.

Innovation Scenarios Driven by Data Interfaces

Quantitative Trading Teams: Build high-frequency arbitrage strategies based on real-time tick data.

Smart Investment Platforms: Create an exceptional user experience with millisecond market updates.

Blockchain Projects: Accurately capture signals of cryptocurrency market fluctuations.

Fintech Companies: Rapidly establish proprietary market analysis systems.

“In the world of algorithmic trading, speed is synonymous with excess returns.” — A CTO of a private equity firm remarked after using Alltick API.

Register now to receive a 7-day full-feature trial and experience how a no-latency data interface can inject "time value" into your trading system. Visit the Alltick website for dedicated technical support, and let us help you turn data interfaces into your core competitive advantage!

【Alltick API—Making Real-Time Data Your Second Nature】 Seize the market opportunity by eliminating every millisecond of delay.

0 notes

Text

0 notes

Text

Simcenter Simulation and Test Solutions for Automotive Battery Industries

As the demand for high-performance electric vehicles grows, automotive battery manufacturers face the challenge of delivering safer, more durable, and energy-efficient battery systems. Simcenter, a Siemens solution, offers a powerful combination of simulation and physical testing tools tailored for battery development — from cell to pack level. By integrating advanced multiphysics simulation with real-world validation, Simcenter accelerates innovation while ensuring battery reliability and compliance with global standards.

Key Benefits:

Accelerated Development: Reduce reliance on costly prototypes with virtual testing and model-based engineering.

Improved Battery Safety: Simulate thermal runaway, crush, drop, and abuse scenarios to meet stringent safety requirements.

Extended Battery Life: Optimize design for charge-discharge cycles, temperature control, and material fatigue.

Reduced Costs: Minimize physical testing through accurate virtual simulations and data-driven insights.

Key Features:

Multiphysics simulation (thermal, electrical, structural, CFD)

Electrochemical modeling for battery cell performance

Thermal management system simulation and optimization

Physical test integration for model validation

Battery abuse and crash scenario simulations

Applications in the Automotive Industry:

Battery cell and pack design validation

Thermal and energy efficiency analysis

Structural integrity under vibration and impact

Battery cooling system optimization

Compliance testing for global regulations

Conclusion:

Simcenter equips automotive battery engineers with a complete toolkit to design, simulate, and validate batteries with confidence. It bridges the gap between virtual models and real-world behavior — delivering safer, smarter, and more efficient energy solutions for the next generation of electric vehicles.

0 notes

Text

Bridging Science and Technology: The Benefits of Integrating Histology, Imaging, and Modeling Analysis Services

In the modern landscape of research and development, the integration of multidisciplinary services has become vital for advancing innovation and precision. Among the most transformative approaches is the seamless fusion of Histology and Imaging Analysis Services, Modeling Analysis Services, and Materials Testing Services. This integration not only enhances scientific discovery but also accelerates the development of new materials, medical devices, and treatment strategies by providing a deeper, more holistic understanding of structure-function relationships.

The Role of Histology and Imaging Analysis in Research

Histology, the study of the microscopic structure of tissues, has long been a cornerstone in biomedical and materials research. When combined with advanced imaging technologies such as MRI, CT, and high-resolution microscopy, Histology and Imaging Analysis Services offer unmatched insights into both biological and synthetic samples. These services allow researchers to visualize internal structures with incredible detail, revealing critical information about cellular organization, material porosity, structural integrity, and the impact of various treatments or environmental conditions.

Modern imaging techniques like confocal microscopy, scanning electron microscopy (SEM), and micro-CT scanning provide three-dimensional views of tissues and materials. These detailed visualizations are essential in fields ranging from regenerative medicine and cancer research to biomaterials development and forensic science. Integrating histological data with imaging tools enables the quantification of complex biological processes, such as inflammation, fibrosis, and angiogenesis, and offers visual validation for computational models.

Modeling Analysis Services: Predictive Power Meets Real-World Application

Where imaging and histology offer rich descriptive data, Modeling Analysis Services contribute by simulating and predicting behavior under various conditions. These services involve computational techniques like finite element analysis (FEA), computational fluid dynamics (CFD), and multi-scale modeling to predict how materials or biological tissues respond to mechanical forces, thermal changes, or biochemical interactions.

In engineering and biomedical contexts, modeling can significantly reduce development costs and time. For example, instead of physically testing a prosthetic design across dozens of prototypes, researchers can simulate performance under different loads and anatomical conditions. This accelerates iteration and ensures that the final product is safer and more efficient.

When paired with imaging data, modeling becomes even more powerful. Structural information from MRI or micro-CT scans can be fed directly into computational models to create anatomically accurate simulations. This synergy enables patient-specific modeling in healthcare and precision engineering in materials science.

Enhancing Materials Research Through Integration

Materials Testing Services traditionally involve mechanical testing, thermal analysis, and chemical durability assessments. These tests are crucial for understanding how materials behave in real-world applications, from aerospace components to biodegradable implants. However, these macroscopic tests are greatly enhanced when integrated with microscopic analysis and computational modeling.

For instance, mechanical testing might reveal that a composite material fails under repeated stress. Histological and imaging analysis could then identify internal microfractures or porosity responsible for the failure, while modeling services could simulate stress distributions to predict future performance. This comprehensive view allows scientists and engineers to not only diagnose problems but also design more robust solutions.

In biomaterials research, where new materials are designed to interact with biological systems, integration is even more essential. Testing a new polymer for use in vascular grafts, for example, requires understanding both mechanical resilience and biological compatibility. Imaging can show tissue integration, histology can assess immune response, and modeling can simulate fluid flow within the graft—all contributing to a faster, more effective development process.

Advantages of an Integrated Approach

The convergence of Histology and Imaging Analysis Services, Modeling Analysis Services, and Materials Testing Services delivers a number of strategic advantages:

Comprehensive Insight: Combining macro and micro-scale data with predictive modeling creates a 360-degree view of the system under study.

Reduced Time to Market: By identifying problems earlier and optimizing designs virtually, development cycles are shortened.

Cost Efficiency: Integrated approaches reduce the need for extensive physical prototyping and repeated trial-and-error testing.

Improved Accuracy: Real data from imaging and histology enhances the precision of computational models, resulting in more reliable predictions.

Interdisciplinary Collaboration: This model fosters teamwork between biologists, engineers, data scientists, and material scientists, driving innovation across fields.

Applications Across Industries

The benefits of this integrated analytical approach span a wide array of industries:

Healthcare & Medicine: From designing personalized implants to evaluating drug delivery systems, the combination of histological evaluation, imaging, and modeling ensures safer and more effective medical solutions.

Pharmaceuticals: Drug efficacy and toxicity can be better understood with histological studies, visualized through imaging, and predicted via pharmacokinetic models.

Aerospace & Automotive: Advanced materials are tested for extreme conditions, with failure analysis supported by imaging and stress modeling.

Environmental Science: Materials used in environmental applications, such as biodegradable plastics or filtration membranes, benefit from multi-level analysis to ensure performance and safety.

Conclusion

As science and technology continue to evolve, the demand for comprehensive, accurate, and efficient analysis methods is greater than ever. The integration of Histology and Imaging Analysis Services, Modeling Analysis Services, and Materials Testing Services represents a powerful paradigm shift in how researchers approach complex problems. This fusion allows for deeper understanding, quicker innovation, and more reliable outcomes across both scientific research and industrial applications.

By bridging these disciplines, organizations and institutions can remain at the forefront of discovery—unlocking new capabilities, solving old problems in novel ways, and driving the next generation of scientific and technological advancement.

0 notes

Text

Computational Fluid Dynamics (CFD) Market Report 2034

Computational Fluid Dynamics (CFD) Market Outlook

The global computational fluid dynamics (CFD) market is gaining significant traction owing to its expanding use across diverse industries such as automotive, aerospace, energy, healthcare, and electronics. With the growing need for accurate simulation tools to design efficient and sustainable products, CFD solutions have become indispensable in modern engineering. The integration of high-performance computing (HPC), artificial intelligence (AI), and cloud-based services is transforming the way simulations are conducted, enabling more complex and precise modelling in shorter timeframes. Environmental challenges and the global focus on sustainability are further boosting the relevance of CFD technologies. These tools not only help in improving product performance but also play a pivotal role in reducing emissions and energy consumption, making the market outlook for the computational fluid dynamics market highly promising over the next decade.

In 2024, the global computational fluid dynamics market size attained a value of USD 2.52 billion. This figure encompasses both traditional on-premises software and modern cloud CFD market platforms used for fluid flow simulation, heat transfer, and related processes. The cfd market size reflects the widespread adoption of CFD solutions in various sectors, particularly automotive and aerospace, where fluid dynamics plays a crucial role in vehicle design and fuel efficiency. Furthermore, the growing use of simulation tools in HVAC systems, electronics cooling, and medical devices adds to the overall market volume. As industries shift towards digitised and simulation-based design approaches, the computational fluid dynamics market size is expected to see substantial growth.

Computational Fluid Dynamics (CFD) Market Growth

The computational fluid dynamics (CFD) market is projected to grow at a compound annual growth rate (CAGR) of 11.70% from 2025 to 2034, reaching USD 7.62 billion by 2034. This growth is driven by the increasing complexity of product designs, higher demand for virtual prototyping, and cost pressures associated with physical testing. Automotive companies, for instance, are using CFD to optimise aerodynamics and thermal management systems, while the aerospace sector is leveraging these tools for aircraft design and performance validation. Energy firms are also exploring CFD to improve wind turbine efficiency and cooling in power generation plants. Additionally, the Asia Pacific computational fluid dynamics market is emerging as a key growth driver, with countries like China, Japan, and India investing heavily in industrial automation and advanced engineering solutions. This regional expansion is a vital element in the overall cfd market growth.

Computational Fluid Dynamics (CFD) Market Trends

Current cfd market trends highlight a growing shift toward cloud-based CFD platforms that offer scalable computing resources and remote collaboration capabilities. Cloud CFD market solutions are particularly beneficial for small and medium enterprises that may not have access to high-end computing infrastructure. Another notable trend is the integration of machine learning and AI to enhance simulation speed, predictability, and accuracy. AI-driven CFD systems are able to reduce simulation time and assist in automated optimisation processes. The push for real-time CFD simulation and digital twin technologies is also transforming how engineers approach design and system monitoring. Furthermore, the apac computational fluid dynamics market is witnessing a rise in the adoption of open-source CFD tools, which are reducing entry barriers for new users and promoting innovation. These cfd market insights indicate a future of increased accessibility, accuracy, and efficiency in simulation workflows.

Receive a detailed report, including the Table of Contents: https://www.expertmarketresearch.com/reports/computational-fluid-dynamics-market/requestsample

Opportunities and Challenges

The computational fluid dynamic market presents significant opportunities across several verticals. In the automotive industry, increasing demand for electric vehicles (EVs) has opened new avenues for CFD applications in battery cooling, cabin airflow, and electric motor optimisation. The aerospace sector is focusing on fuel-efficient aircraft and unmanned aerial systems (UAS), where CFD plays a vital role in performance testing. In the energy domain, CFD is crucial for designing efficient wind turbines, cooling systems in nuclear reactors, and optimising combustion in thermal plants. The healthcare sector is also exploring CFD for blood flow simulation and respiratory device development.

Despite these opportunities, the cfd market faces challenges such as the high cost of advanced simulation tools, the need for skilled professionals, and the complexity of integrating CFD with other digital engineering solutions. Additionally, real-time simulation still requires substantial computational resources, which can limit adoption among smaller companies. Addressing these issues requires collaboration between software vendors, hardware providers, and research institutions to make CFD more user-friendly and cost-effective.

Computational Fluid Dynamics (CFD) Market Analysis

The global computational fluid dynamics market is highly competitive, with a mix of established players and emerging solution providers. Major companies such as ANSYS, Siemens Digital Industries Software, Dassault Systèmes, Altair Engineering, and Autodesk dominate the cfd market share, offering a wide range of tools tailored for various industries. These players continue to innovate by integrating cloud computing, automation, and AI capabilities into their offerings.

Regionally, the Asia Pacific computational fluid dynamics market is gaining ground due to industrialisation, smart manufacturing initiatives, and academic collaborations. The APAC computational fluid dynamics market is expected to see rapid adoption in automotive and electronics sectors, where simulation tools are used extensively to enhance product performance and reduce time-to-market. Europe and North America remain mature markets, focusing on sustainability, regulatory compliance, and innovation through digital twins.

In terms of application, the automotive and aerospace segments remain dominant contributors to the cfd market size, followed by energy, electronics, and healthcare. The increased availability of user-friendly CFD platforms and cloud integration is democratising access to simulation tools, expanding their use across startups, research institutions, and mid-sized firms.

The ongoing evolution of computational fluid dynamics tools, combined with growing environmental and performance demands, is positioning the computational fluid dynamics (CFD) market as a vital enabler of next-generation product development across industries. These comprehensive cfd market analysis findings suggest strong potential for continued innovation and global adoption in the years ahead.

Media Contact:

Company Name: Claight Corporation

Email: [email protected]

Toll Free Number: +1-415-325-5166 | +44-702-402-5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au

1 note

·

View note

Text

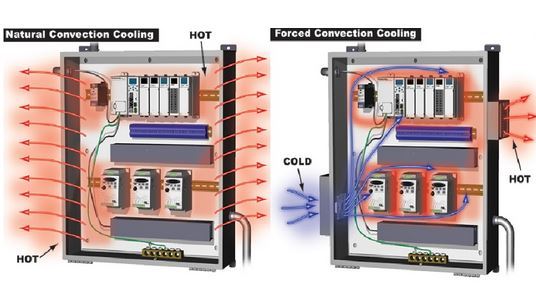

Custom Electrical Cabinet Cooling Fans: Tailored Solutions for Optimal Thermal Management

In industrial automation, renewable energy systems, and power control applications, electrical cabinet cooling fans are critical for maintaining operational stability. As electronic devices grow more powerful and operating environments become increasingly complex, off-the-shelf thermal solutions often fall short. With 20+ years of expertise in industrial thermal management, Cooltron delivers precision-engineered custom cooling fan solutions, system optimization, and full lifecycle support for global clients.

Why Custom Cooling Solutions Matter for Electrical Cabinets?

Industry-Specific Thermal Challenges Demand Specialized Approaches

Different sectors face unique cooling requirements:

EV Charging Stations: Must withstand extreme temperatures (-22°F to 131°F)

Factory Automation Panels: Require IP54+ dust/water resistance

Medical Equipment Enclosures: Need ultra-quiet operation (<35dB)

Offshore Power Cabinets: Require salt spray corrosion certification

Our engineering team combines CFD thermal simulations with real-world validation to create customized cooling models. In a recent semiconductor facility project, optimized fan placement reduced internal temperature variance from ±14.4°F to ±3.6°F, cutting equipment downtime by 67%.

5 Key Customization Factors for Precision Cooling

Case Study: For offshore wind turbines requiring 100,000+ hours in salt spray environments, our titanium-ceramic hybrid bearings with triple-seal architecture tripled service life versus industry standards.

Streamlined Customization Process (14-Day Prototyping)

On-Site Thermal Audit – 23-point inspection including heat mapping & environmental analysis

3D Simulation Modeling – ANSYS Icepak-powered airflow optimization

Functional Prototyping – 72-hour rapid testing with detailed performance report

Production Refinement – Mold adjustments for batch consistency

Smart Integration – Optional Modbus/RS485 connectivity for predictive maintenance

Why Cooltron Leads in Cabinet Cooling Tech?

Energy-Efficient Design: Patented blades achieve 82% aerodynamic efficiency (vs. 68% industry avg)

Military-Grade Durability: Dual ball bearings ensure 80,000-hour MTBF

Universal Compatibility: Supports 12-48VDC & 110-220VAC systems

Fast-Track Service: Standard custom projects ship within 2 weeks

FAQs: Custom Cooling Fans Explained

Q: Are custom fans more expensive than stock models? A: 63% of clients achieve lower TCO through right-sized solutions eliminating over-engineering.

Q: What about rush orders? A: Our 200+ modular designs enable 48-hour expedited shipping for urgent needs.

Q: Will upgrades disrupt existing systems? A: Universal mounting adapters ensure backward compatibility with legacy cabinets.

The Cooltron Advantage

CNAS-Certified Testing Lab (L12345)

Trusted by 300+ Fortune 500 Companies

Industry-Leading 3-Year Warranty

24/7 Technical Support Team

Get Your Free Thermal Analysis: Click the [Online Form] button to request a customized cooling solution and cabinet heat dissipation report.

0 notes

Note

Just read your 13.18 download. It was very interesting.

For me I thought they would be more tension between Boden & Pascal. I thought it would be like a full throw down. Part of me is glad it wasn't but the other part wishes they was more tension there.

I did laugh at how close the camera zoomed into their faces. I understand it was to show how serious it was but did it have to be that close.

Also the scene with the severides & Hermann felt so awkward. I wonder if Damon is going to blame Herrmann,

The look at the end between Hermann & Pascals just shows me they be more tension.

I wish we had a scene of Stella comforting Kelly or them instantly reacting to it be Damon.

Thank you for taking the time to read my episode downloads. I appreciate that.

I felt like the tension between Pascal & Boden was just right. I say that because you can clearly see Pascal is the one who is on the defense and ready to fight the "white shirts" behind his decision-making and those of his officers. He looked insulted a bit that they were even questioning them or trying to place blame & it felt like he brought that disdain to life while not being borderline insubordinate.

I also appreciated how Boden played his role in the investigation as Deputy Commissioner versus as a previous Battalion Chief. Boden has had a TON of run-ins with CFD brass trying to strip him of his command so he knows that feeling. I was actually happy to see that he didn't contribute to that narrative and made it very clear that he was looking for the truth and no matter what that truth was he would do his best to protect the house.

He wasn't trying to pull a gotcha on any of them, including Pascal. He asked valid questions, some more uncomfortable than others, but they needed to be asked. In the end, he told them that he would not have run that scene any other way, and I believe him.

How many times have they referenced their walkies being an issue? They had an entire subplot with it earlier this season. How many times have we seen a call go south because they didn't have the resources there to block off the scene. It just happened in 13x15 when that car blew past the accident, resulting in Stella making that tackle.

I don't think Damon will blame Hermann because ultimately, how was Hermann supposed to know that Damon & Clarence got separated when I don't even think he knew Clarence almost went through the floor. If anything, I'd be curious to know if Damon blames himself for getting separated in the first place.

That look at the end definitely raised my eyebrows because I wasn't sure what Hermann is trying to get at at this point.

Also, yes, I felt like they could have shown the more emotional aspect of it being Damon when they got him to the ambo. However I suppose they didn't want to do that because they wanted to show the scene of him laying in the rubble with his name displayed versus if they would have had a really emotional scene at the ambo it would have given it away potentially?

#chicago fire#kelly severide#stella kidd#ask me anything#always in my stellaride brainrot era#answered#dom pascal#jack damon#christopher hermann#wallace boden

3 notes

·

View notes

Text

Urban physics is a core area being applied in every dimensions of the society, from studying climate change to accessing security and aging. Consequently, it is important to study the aspects the that contribute to the importance of urban physics. Computational fluid mechanics (CFD) is a numerical simulation method used as assessment tool in urban physics, besides various reduced-scale laboratory measurements. In which case, the study of CFD implies the review of engineering of physical processes found in industrial areas in the urban zones. The adoption of computational fluid mechanics has seen it exhibit various fruitful transition, from a mere field to an increasingly developed field in practice and design. This literature review, in form of a position paper, provides a theoretical background of the CFD plus supporting views about its mechanism and its usage within our organization. This will involve studying aspects of technical challenges associated with using the tool within the organization. Further, possibilities and limitations are also presented to further the exploration of how CFD applies to urban physics. Intuitively, this will provide a benchmark for measuring the spatial and temporal scales that can be associated with the position of computational fluid mechanics. Finally, it would be important to scale the position of the review by focusing on the technical aspects of using CFD in the organization. For this reason it would be possible to extensively discover the future of CFD in urban physics. Introduction In mostly urban areas, especially in the industries, urban physics is a core field in facilitating various physical processes. Essentially the field deals with the transmission of heat and mass experienced in the outdoor and indoor for the urban environment. Further, it focuses this concept of heat and mass transmission to its interaction with human and materials used in production. Conclusively, an organization is likely to apply this field ensuring a healthy and sustainable outdoor and indoor environment through encompassing all the associated constraints such as security, energetic and health, all which are considered as grand societal challenges. For this particular reasons, urban physics with all its components is adopted widely across engineering disciplines, scaling from mechanical to electrical engineering. One of the major component that makes urban physics formidable is Computational Fluid Dynamics mainly used in numerical simulation within the particular organization. This technique of numerical simulation, for CFD, makes possible the successful operation of other components of urban physics: field measurement and full-scale or reduced-scale wind-tunnel measurements (Tan et al, 2015, 76). CFD, as numerical simulation tools acts as an effective alternative in the organization given that it can avoid limitations associated with the other tools. This challenges include multitphase flow problems and buoyant flow problems, specifically experienced by both field measurement and wind-tunnel measurement. It can provide thorough data on the pertinent flow variables in the whole calculation domain (“whole-flow field data”), under contained conditions and without similarity limitations (Emmanuel & Kruegler, 2010, 112). However, the accuracy of CFD comes into play as an important aspects which must be put in control. Especially, this must include taking into control geometrical implementation associated with the model and understanding of the results in the event of choosing the proper solution strategies. The selection process including making choices between various options; the steady Reynolds-averaged Navier-Stokes (RANS) approach, the unsteady RANS (URANS) approach, Large Eddy Simulation (LES) or hybrid URANS/LES (Sarrat et al, 2006, 1750). Further, errors arising from numerical and modeling must be taken into consideration through verification and validation to contain them within the system. Further, the validation process might also require the use of high-quality data as compared to other simulation models. The literature review, in form of a position paper, provides a theoretical background of the CFD plus supporting views about its mechanism and its usage within our organization. This will involve studying aspects of technical challenges associated with using the tool within the organization. Further, possibilities and limitations are also presented to further the exploration of how CFD applies to urban physics. Intuitively, this will provide a benchmark for measuring the spatial and temporal scales that can be associated with the position of computational fluid mechanics. Read the full article

0 notes

Text

Say Goodbye to Data Woes! AllTick API Provides Powerful Support for Your Trading System!

Still struggling with data sources for your quantitative trading system? Tired of high latency, instability, and incomplete data? This article will guide you step-by-step in building an efficient and reliable quantitative trading system, highlighting how to leverage the powerful features of AllTick API to solve your data challenges and seize trading opportunities!

Why Do You Need a Quantitative Trading System?

A quantitative trading system is a powerful tool that utilizes computer technology and mathematical models for automated trading. It can overcome human weaknesses, strictly execute predefined strategies, and enhance trading efficiency and profitability. An excellent quantitative trading system can:

Monitor the market 24/7: Never miss a trading opportunity.

Execute strategies quickly: Millisecond response to market changes.

Automate risk management: Avoid losses from emotional trading.

Backtest historical data: Validate strategy effectiveness and optimize parameters.

Core Aspects of Developing a Quantitative Trading System

Building a quantitative trading system involves multiple critical steps:

Data Acquisition and Cleaning: Obtain high-quality, low-latency market data, and perform cleaning and organization.

Tools: AllTick API provides real-time market data for forex, commodities, stocks, and more, covering over 100,000 products globally, with a reliability of 99.95% and extremely low latency, plus high-frequency data updates!

AllTick API: The Powerful Engine of Your Quantitative Trading System

In the data acquisition and cleaning phase, AllTick API is the key to resolving these challenges, offering comprehensive real-time data interfaces to ensure you grasp market dynamics instantly.

Why Choose AllTick API?

Comprehensive Data: Covers various assets including forex, commodities, and stocks to meet diverse trading needs.

High Real-Time Performance: Low-latency interfaces provide real-time updates, ensuring you capture market dynamics immediately.

Strong Reliability: With an SLA of 99.95%, it guarantees stable data supply, avoiding losses from data interruptions.

Easy Integration: Supports popular programming languages like Python and Go, with example code for quick onboarding.

Conclusion

Building a quantitative trading system is complex, but with the right methods and tools, AllTick API’s comprehensive, real-time, and reliable data becomes an indispensable engine for your trading system.

Visit【 AllTick API 】website now to learn more about our products and embark on your quantitative trading journey!

0 notes

Text

Precision CAD/FEA Design and Analysis Expertise at Servotech

Introduction

In the rapidly evolving world of engineering and manufacturing, precision plays a crucial role in product development. Companies require robust tools and methodologies to ensure the accuracy and reliability of their designs. Servotech, a leader in engineering solutions, specializes in Precision CAD (Computer-Aided Design) and FEA (Finite Element Analysis) design and analysis to provide cutting-edge solutions across various industries. Their expertise ensures optimized product performance, cost-efficiency, and a streamlined development process.

Understanding CAD and FEA

What is CAD?

Computer-Aided Design (CAD) is a technology used by engineers and designers to create, modify, analyze, and optimize designs in a digital environment. It facilitates the creation of highly detailed 2D and 3D models with accuracy and efficiency, reducing the time required for traditional drafting and prototyping.

What is FEA?

Finite Element Analysis (FEA) is a computational method used to simulate how products react to real-world forces, vibration, heat, and other physical effects. It helps engineers evaluate product durability, strength, and performance before manufacturing, ensuring that potential issues are identified and addressed at an early stage.

Servotech’s Expertise in CAD and FEA

Advanced CAD Capabilities

Servotech’s team of expert designers and engineers leverage industry-leading CAD software to develop high-precision models for various applications, including:

Mechanical Components: Designing complex mechanical systems with precise detailing.

Automotive and Aerospace Parts: Developing high-performance parts for critical applications.

Industrial Equipment: Creating detailed schematics and assembly models for large-scale machinery.

Architectural and Civil Engineering: Designing structures and layouts with accuracy and compliance with regulations.

Their CAD expertise ensures that every design is optimized for manufacturability and efficiency, minimizing errors and reducing production costs.

Comprehensive FEA Services

Servotech’s FEA services focus on analyzing and improving product performance through simulation and validation techniques. Their capabilities include:

Structural Analysis: Evaluating stress, strain, and deformation to ensure product integrity.

Thermal Analysis: Simulating temperature effects and heat distribution in materials.

Fluid Dynamics (CFD): Assessing fluid flow and heat transfer in designs.

Vibration and Modal Analysis: Understanding how structures respond to dynamic forces.

Fatigue and Failure Analysis: Predicting the lifespan of materials under repeated loading conditions.

By utilizing FEA, Servotech enhances product reliability and ensures compliance with industry standards, preventing costly failures and redesigns.

Industry Applications

Aerospace and Automotive

Servotech’s CAD/FEA expertise plays a critical role in the aerospace and automotive industries by designing lightweight yet durable components, optimizing aerodynamics, and ensuring safety and performance under extreme conditions.

Industrial Manufacturing

For industrial machinery and equipment manufacturers, precision CAD and FEA are essential for developing efficient and durable machines. Servotech’s analysis helps in material selection, load assessment, and structural stability, improving overall equipment performance.

Medical Devices

In the healthcare sector, precision engineering is paramount. Servotech aids in designing complex medical devices, ensuring they meet strict regulatory standards while being functional, safe, and effective.

Consumer Electronics

The development of durable and high-performance electronic enclosures and components is another area where Servotech excels. FEA simulations help in optimizing thermal management and structural integrity for electronic devices.

Benefits of Partnering with Servotech

1. Enhanced Accuracy and Efficiency

Servotech’s CAD/FEA integration ensures high precision, reducing errors in design and improving manufacturability.

2. Cost and Time Savings

By identifying design flaws early, Servotech helps businesses avoid costly modifications, reducing product development cycles.

3. Improved Product Performance

With in-depth simulations and validation, Servotech ensures that every product is optimized for durability, efficiency, and safety.

4. Compliance with Industry Standards

Servotech ensures that designs meet the necessary industry regulations, reducing risks and ensuring product certification with ease.

5. Expert Team and Cutting-Edge Technology

With a team of skilled engineers and access to the latest CAD and FEA software, Servotech provides state-of-the-art design and analysis solutions.

Conclusion

Precision CAD and FEA design and analysis are indispensable for modern engineering and manufacturing. Servotech’s expertise in these domains helps industries develop innovative, reliable, and cost-effective products while ensuring superior performance. By leveraging advanced tools and a skilled team, Servotech continues to lead the way in delivering high-precision engineering solutions to a diverse range of industries.

For businesses seeking top-tier CAD and FEA expertise, Servotech is the trusted partner to enhance product development and bring innovative designs to life.

0 notes

Text

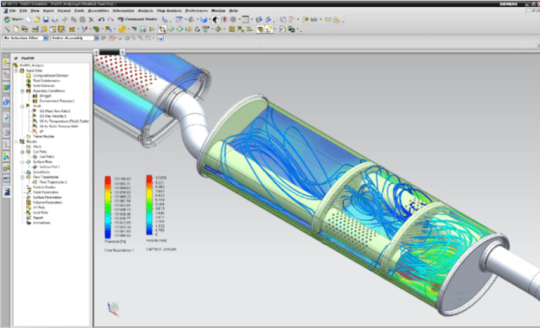

Siemens FloEFD — Revolutionizing Fluid Dynamics Simulation for Manufacturing Industries

Siemens FloEFD is a powerful Computational Fluid Dynamics (CFD) tool embedded in popular CAD platforms like Siemens NX, Solid Edge, and others. It empowers design engineers in manufacturing industries to simulate fluid flow, heat transfer, and other related physical phenomena right within their CAD environment. This seamless integration shortens the simulation process, accelerates design validation, and reduces time-to-market.

Key Benefits

Reduced Design Cycle Time: Integrated directly within CAD, enabling faster iterations and fewer errors.

Cost Efficiency: Reduces the need for physical prototypes by simulating real-world conditions digitally.

Improved Product Quality: Predicts performance early in the design phase to optimize product efficiency and reliability.

Key Features

CAD-Embedded CFD: Direct integration with Siemens NX and other CAD tools.

Intelligent Automation: Automated meshing and solver settings for quicker analysis.

Thermal Analysis: Simulates conduction, convection, and radiation heat transfer.

Multiphysics Capabilities: Accounts for complex interactions like fluid-structure and rotating machinery.

Applications in the Automotive Industry

Thermal Management: Optimize HVAC systems, engine cooling, and battery pack ventilation.

Aerodynamics: Evaluate vehicle drag and lift forces for performance tuning.

Underhood Analysis: Predict airflow patterns and temperature distributions in engine bays.

Brake Cooling & Exhaust Flow: Improve safety and performance through precise flow simulation.

Conclusion

Siemens FloEFD is the go-to CFD solution for manufacturing industries aiming to innovate faster, reduce costs, and deliver reliable, high-performance products. Its CAD-centric approach makes it an essential tool for automotive engineers focused on real-time, design-driven simulation.

0 notes

Text

youtube

🎯 Whether you’re an engineer, student, or CFD enthusiast, this video provides valuable insights into setting up high-fidelity supercharger simulations. In this episode of Advanced Turbomachinery Simulations using CONVERG, we take a critical step in optimizing our Roots-Type Supercharger simulation by refining the computational mesh and running hydrodynamic simulations. 🏎️💨 Ensuring an accurate mesh is essential for capturing the correct flow physics, pressure ratios, and efficiency of the supercharger.

We analyze: ✅ No-Hydro Simulation Results & Mesh Motion Validation ✅ How Dynamic Time Step Selection Works ⏳ ✅ Refinement Strategies for Small Gap Flow Paths ✅ Avoiding Cell Pairing Issues & Ensuring Accurate Torque Predictions ✅ Setting Up Adaptive Mesh Refinement (AMR) for High-Resolution Flow Capture

#youtube#skilllync#mechanicalengineering#engineering#automotiveengineering#turbo#machinery#simulationsoftware

0 notes

Text

The Outo adds CFDS CFDS in UK

Retail FX and CFDS BROKER ORSACE THE QUESTIONS ADDUPS CFD Points In Contens, via FCA that ruled in a small UK. The disasons found soon and Czech Propsation FTMM (Write a valid authorization). The combination of the CFD Part of the UK is a part of the larger changes that make users to sell through the most recent metatrader solution, MT5. This adds a trade that is available to customers, who now…

0 notes