#vibration sensors

Explore tagged Tumblr posts

Text

3-axis accelerometer, Accelerometer sensor application, vibration sensors

LIS2MDL Series 3.6V 50 Hz High Performance 3-Axis Digital Magnetic Sensor-LGA-12

0 notes

Text

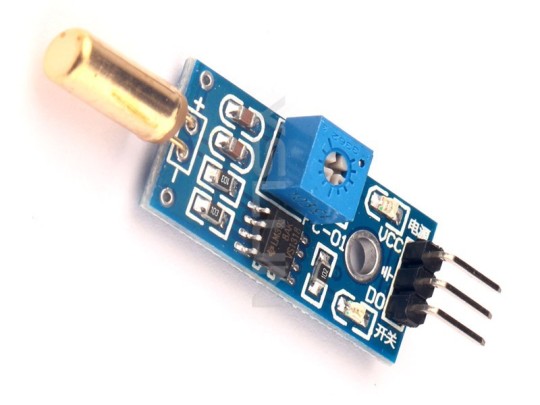

vibration sensors

Unlock unparalleled sensitivity with STI's vibration sensors. Meticulously calibrated for optimal performance, our sensors empower your testing processes by capturing the subtlest vibrations with precision. Trust STI for sensitivity that makes a difference.

0 notes

Text

atrociously sticky adhesive, gone, due to the powers of a heat gun and goo-gone

#all the oils have been stripped from my hands#smart home bullshit#got a pile of tilt/vibration sensors to detect two main things:#did i remember to put the frozen bagels in the oven before i started making coffee?#and: have they picked up the garbage bins yet?#but the fucking things came with so much of the world's most annoying and stubborn adhesive on them for fuck only knows why

36 notes

·

View notes

Text

Application fields of vibration sensors

Industrial field

In the industrial field, vibration sensors are used to monitor the operating status of mechanical equipment, predict equipment failures, and improve production efficiency. For example, in rotating machinery (such as motors, compressors, etc.), by monitoring the speed or acceleration of vibration, it is possible to determine whether the bearing is worn or the rotor is unbalanced.

Construction field

In the construction field, vibration sensors are used to monitor the vibration response of the structure, evaluate the health of the structure, and ensure the safety of the building. By monitoring the vibration caused by natural factors such as earthquakes and wind loads, the natural frequency, damping ratio and other parameters of the structure can be analyzed to provide a basis for the seismic and wind-resistant design of the structure.

Transportation field

In the transportation field, vibration sensors are used to detect damage to roads and bridges. When a vehicle passes by, the speed and acceleration of the vibration will change. By measuring these changes, it can be determined whether the road or bridge has cracks, unevenness and other problems. In addition, vibration sensors can also be used to detect the operating status of transportation vehicles (such as subways, trains, etc.) to ensure traffic safety.

Precautions

When using vibration sensors, the following points should be noted:

Installation method: The installation method of the sensor should be reasonable to ensure full perception of the vibration of the object.

Environmental factors: The performance of the sensor may be affected by factors such as ambient temperature and humidity. The sensor type suitable for the specific environment should be selected.

Signal processing: The signal output by the sensor may require further processing and analysis to ensure the accuracy and reliability of the data.

In short, vibration sensors, as an important measurement tool, play an important role in many fields. By monitoring the vibration state of an object, information such as the operating status and health status of the object can be obtained, providing data support for engineers and scientists.

0 notes

Text

Cw minor health stuff but only tangentially

I had to go to the pharmacy to get some bg strips because my new cgm was being weird and apparently they lock that shit up bc god forbid diabetics who can’t afford them steal the test strips they need to manage a chronic life threatening illness 🙄

But anyway it said to press the assistance button but there wasn’t one at that case and the closest one was on the vibrators and when we pushed it, it made an announcement to the entire store that someone needed “assistance in the personal care aisle” and me and my wife were cracking up

#they actually had some pretty decent looking vibrators tho#but like why lock up the test strips???#they didn’t even lock the sensors you need to use the test strips so like what???#having a chronic illness in the us is so exhausting#this shit should be free#anyway thanks for coming to my ted talk#kj yaps

1 note

·

View note

Text

Choosing the Right Sensor Cables for Your Vibration Sensors

When it comes to monitoring and analyzing vibrations in industrial settings, having the right equipment is crucial. Vibration sensors are the backbone of any predictive maintenance program, but they can't do their job effectively without the proper sensor cables. In this article, we'll explore the importance of choosing the right sensor cables for your vibration sensors.

Understanding Vibration Sensors: They play a vital role in preventing unexpected breakdowns and ensuring the safety and efficiency of operations. However, the performance of vibration sensors depends not only on their quality but also on the cables connecting them to data acquisition systems.

The Role of Sensor Cables: These cables are responsible for transmitting the sensor's data accurately and reliably to the monitoring equipment. Using subpar or incompatible cables can lead to data loss, inaccurate readings, and increased maintenance costs.

Choosing the Right Sensor Cables: Compatibility:Ensure that the sensor cables are compatible with your vibration sensors and data acquisition equipment. Different sensors may require specific cable types. Cable Length: Select the appropriate cable length to reach from the sensor to the data acquisition unit. Avoid excessive cable lengths, which can introduce signal degradation.

Shielding: Look for cables with adequate shielding to protect against electromagnetic interference (EMI) and radio-frequency interference (RFI), which can distort sensor readings. Durability: In industrial environments, sensor cables are exposed to harsh conditions. Choose cables with robust insulation and jacket materials to withstand temperature variations, moisture, and physical wear. Connector Types: Ensure that the connectors on the sensor cables match those on your sensors and data acquisition equipment.

Conclusion: Investing in the rightsensor cables is essential for maintaining the accuracy and reliability of your vibration sensors. By considering factors like compatibility, cable length, shielding, durability, and connector types, you can optimize your vibration monitoring system's performance, reducing down time and maintenance costs. For high-quality sensor cables and vibration sensors, visit to explore a range of options tailored to your specific needs.

0 notes

Text

RED HANDED

Pairing: Damian Wayne x Reader

divider by: @cafekitsune word count: 1.2k synopsis: Damian sneaks you into the manor, only to get caught red handed.

Wayne Manor was supposed to be empty.

That’s what Damian had told you when he pulled you through the back gate, hand clasped tightly in yours, voice low and insistent as he muttered about stealth and nosy family members and “don’t touch that, it’s a pressure sensor.” He’d checked the security logs himself—Bruce was at a board meeting, Alfred out running errands, and the others all scattered across the city on patrol or “adult things,” as Damian called them with no small amount of disdain.

So he brought you home. Quietly. Secretly.

To his room.

The moment the door shut behind you, his shoulders dropped that ever-present tension. His fingers found your wrist, then your waist, tugging you gently toward the bed. No words, just that look he gave you—sharp eyes softening, mouth twitching at the corners in something dangerously close to a smile.

You were the only one who ever got that version of him.

Now the two of you were curled up beneath the covers, the storm outside tapping against the windows while his arm wrapped snug around your waist. Damian’s head rested near yours, nose brushing your temple every so often, breath slow and steady.

“I could get used to this,” you murmured, tracing lazy circles along his chest.

“You will,” he replied, voice quiet and certain. “Once I find a way to keep you here without the others ruining everything.”

You giggled, tipping your head up to meet the small, rare curve of his mouth—the almost-smile he only gave you.

And then the bedroom door slammed open.

“Dami, I need to borrow—OH MY GOD!”

Both of you shot upright like you’d been struck by lightning.

Dick Grayson stood frozen in the doorway, eyes wide as dinner plates, mouth agape in sheer, appalled disbelief. His finger jerked upward, trembling like it couldn’t decide whether to point at Damian, you, or the fact that you were clearly in his bed.

“What the hell, Grayson?!” Damian snapped, scrambling to hide your presence by throwing the blanket over you as you shrieked in surprise and ducked under it. But the damage had already been done.

“You have a GIRL in your BED?!” Dick shouted, scandalized.

Damian looked moments away from lunging across the room. “I swear to Ra, if you say one more word I will end your bloodline—”

But it was too late. The yelling had summoned the wolves.

Heavy footsteps pounded up the stairs.

“What the hell’s going on?” Jason’s voice barked from the hall, followed by a clatter of someone sprinting.

“Did someone die?” That was Tim, out of breath and still chewing toast as he skidded into view.

And then, like the final nail in the coffin, Bruce appeared.

He was dressed for work—pressed suit, tie knotted perfectly, not a single strand of hair out of place—but the look on his face was nothing short of bewildered. He stood in the hallway, staring into the room like he wasn’t quite sure what he’d walked in on, and very much wished he hadn’t.

There was a silence. A very loud, very awkward silence as everyone took in the scene.

“Damian has a girlfriend?” Tim whispered like he’d uncovered an ancient secret.

Jason blinked at you, then back at Damian. “Wait. She’s real?”

Another blink. Then a wild grin. “She’s real!” He turned and punched Dick in the arm. “You owe me twenty bucks.”

“I do not—!”

“You bet she was imaginary!”

“Because she was supposed to be imaginary! He’s fifteen!”

“Seventeen,” Damian growled, practically vibrating with fury under the blanket. “And if any of you take another step into this room, I swear on every god you hold dear, I will bring out my katana.”

But of course, the damage was done.

Slowly, cautiously, you peeked out from beneath the blanket. Your cheeks were burning, your hair a mess, and your heart pounding loud enough to echo in your ears.

Four sets of eyes landed on you.

Jason gave a slow, impressed nod. “Hey there. I’m the hot brother.”

“I swear to—”

Damian made a strangled sound of protest, but before he could lunge across the room, Tim raised a hand with a sheepish half-wave.

“I’m the smart one,” he offered helpfully. “Sorry about… all this.”

“And I,” Dick declared proudly, hands on his hips, “am the fun one. Also the reason you’re all about to get grounded. You’re welcome.”

“OUT!” Damian barked.

That’s when Bruce finally spoke up. “Enough,” he said, calm and quiet— almost immediately it made all three older brothers freeze.

Jason blinked. “We were just—”

“Out,” Bruce repeated, this time with the faintest arch of his brow.

One by one, the boys started backing up like scolded dogs.

Jason grumbled something under his breath and turned.

Tim gave you a quick, apologetic smile and shuffled after him.

Dick lingered the longest, flashing you a grin and a salute. “Still think it’s adorable.”

“Out,” Bruce said again, firmer this time.

With that all three filed out with varying degrees of grumbling and smirking.

Bruce remained in the room for a moment longer. His eyes shifted from you—still half-curled beneath the blanket—to his son, who sat stiff-backed beside you, his jaw tight with embarrassment and defiance.

“I expect a proper introduction at dinner,” Bruce said coolly, turning on his heel. “Six sharp.”

Damian exhaled like it physically pained him. “Yes, Father.”

Bruce nodded once, then turned and left, the door clicking shut behind him.

Damian exhaled sharply through his nose, the breath full of fire and exasperation. He muttered a string of curses in Arabic—low, venom-laced, and fast enough to blur into one hissed syllable—as he collapsed back into the pillows with a dramatic thud. One arm flung over his eyes like he was shielding himself from the humiliation still clinging to the air.

You lay beside him, the warmth of his body still lingering beneath the tangled sheets, a laugh bubbling in your throat despite your best efforts to suppress it.

“Well,” you murmured, voice edged with amusement, “at least they didn’t bring a camera.”

He made a sound—something between a groan and a growl. “You underestimate them. There will be photos. There will be memes. Grayson will narrate the whole scene on the family group chat by noon. I am already doomed.”

You leaned over and pressed a soft kiss to his cheek, the curve of your mouth brushing the flushed skin just beneath his eye. “Guess I better dress nice for dinner, then.”

Another groan, this one muffled by the pillow he dragged down over his face.

But then, without warning, his arm slid around your waist and pulled you in—close, possessive. Like he wasn’t ready to let you go, even if the rest of the world now knew you existed.

“Remind me to kill them later,” he muttered, voice gruff but reluctant.

You laughed and burrowed into the crook of his arm, cheek pressed to his collarbone. “I don’t know… I kind of liked seeing flustered Damian. Might be my favorite version yet.”

He peeked down at you then, dragging the pillow just far enough to reveal a glare that lacked its usual bite. “You’re lucky I like you.”

You tilted your head and gave him a grin, utterly unrepentant, before brushing another kiss to his cheek.

“Yeah,” you said, voice soft and smug. “I know.”

#damian wayne x reader#damian wayne#damian al ghul#damian wayne x you#damian wayne x y/n#damian al ghul x you#damian al ghul x reader#dc robin#dcu#dc universe

3K notes

·

View notes

Text

Cyborg!Caleb and his strange affectionate habits

you love your part-robot boyfriend, but he’s a little strange!

✎ᝰ a/n: he was supposed to be a puppy for this series… but then this happened, so now he’s a cyborg. i think you all will like this one. enjoy!

cat zayne bunny xavier mermaid rafayel dragon sylus

ִ ࣪𖤐

❥ he's always scanning you. day or night, awake or asleep, caleb will take it upon himself to check your vitals and health on a normal basis. just a quick little holo-scan from his eye is all he needs. and from the amount of time he already spends staring at you, this is a pretty easy feat.

he knows things about you that you haven’t even figured out yet. you’re gonna catch a cold soon, but he already knows from your white blood cell count. you might not know your period is coming soon but caleb has always got your back and tells you when you’re ovulating or preparing for a period. of course, you ask him not to do it all the time. and of course, caleb is insane, so he doesn’t listen all the time. it’s very intimate to him to know the inner workings of your body.

❥ he can’t sleep next to you (and he tries to fix it). caleb does not sleep in a normal human bed. instead, he sleeps in a tube where his charging port is and asks (begs) you to sleep with him there. and while you do indulge him, it’s very uncomfortable for your human body. even after he tried to enlarge the tube by rebuilding, it’s still not ideal.

he’s so upset that he can’t sleep with you in your bed that he’ll charge himself during the day just so he can be next to you at night. except, he can’t sleep without his port, so he just stays awake next to you, exhausting his energy by admiring you. he talks to himself and you during this time and if you ever stir awake from his murmurs, he’ll apologize and lull you back to bed.

❥ he makes modifications for you. caleb doesn’t wish to be any less than perfect for you, so he’s constantly making tweaks and refinements to his system and body to better adapt to you. like the time he installed a heating system inside of him because you always flinched at how cold he was. or maybe the time he installed more sensors in his wires just so he could better feel your touch.

and while to an extent it is sad, caleb will find a way to make it more fun. he’ll adjust the size and feel to his appendage for your pleasure and he’ll also install vibrations to his fingers if you really ask. or maybe he’ll do something silly like add confetti to his hands so that he can pop them out at celebratory moments.

❥ he forces himself to eat for you. caleb doesn’t really need to eat to keep alive. in fact, he prefers not to because sometimes it’ll make his metal tummy feel weird. he’ll never tell you that, though. he loves you too much to let you know that all the meals you prepare for the two of you are actually making him a little sick.

but he’s gotten better at keeping them down. he modifies his stomach to hold food better and slowly he’s working up toward more intolerable foods—such as spices. one day he hopes to be able to stomach everything you make, but until then, he’ll lie day and night to keep you happy and to bond with you.

❥ he’s very picky at his face. the face is the only thing caleb has that’s human-like. because of this, he’s constantly picking at it; snipping at his hair, shaving, cleaning the skin there, everything he can do salvage what he can of his human form. he also prefers it when you touch his face rather than any other part of him, simply because that’s where he can feel skin to skin contact.

he’ll constantly ask you if he looks handsome as a joke, but it comes from a deeper insecurity within him. he wants to ensure you still enjoy him even as he is, and once he gets your reassurance, he’ll start to remind himself every day that he doesn’t need to worry as much about his looks. because you love him anyway.

❥ he takes secret recordings and photos of you. there are two sides of this, the sweet side and the suggestive side. he loves recording your laughs and photographing your smiles with his system so he can rewatch them when the two of you apart. especially if he’s on a mission and away from you for an extended period of time, he’ll make to stock up on your beauty before he goes.

the suggestive side is more like… a few cheeky pictures of you dressed down or right after sex. maybe even a video of your butt while you’re walking away from him. he’ll never want to take videos or pictures of you during intimacy without your consent, but these small provocative pictures of you are more than enough to satisfy him. if you ever do give him consent to make what is essentially robo-homemade-porn, he’ll play it holographically and watch with you after the fact.

❥ he flies you everywhere! come with caleb on a joyride in his arms. he’ll fly you across town or just around the neighborhood! not that he can’t drive you, he just thinks this way is more fun and special because you’re clinging to him the whole way through. no need to be scared of heights because he’s got you tight in his grip and has 8 backup protocols in case he malfunctions mid-air.

you found it a little embarrassing at first, being a spectacle in the air for everyone else, but now it’s fun! you’ve grown so accustomed to being in the air because of him. and since you have such a fun time, anytime you’re down in the dumps or need fresh air, caleb is always there to take you on a little ride to cheer you up.

❥ he has you engraved. it was part of his hardware modifications, but he once asked you to write your name on a piece of paper, and a week later, he has that same writing etched onto his nape. you couldn’t believe it at first, but it was an exact copy of your handwriting now just seared into him.

he tells you it’s so that he can feel more comfortable in his “skin”. knowing that you’re a part of his new robotic body makes him much more accepting and happier of it. he doesn’t hate it as much, not when you’re always in the back of his mind. ִ ࣪𖤐 hey gals: @chersyluvs , @otomegamesforlife

#lads#lads x reader#love and deepspace#love and deepspace x reader#lads mc#l&ds#l&ds x reader#lnds#l&ds mc#lads smut#caleb x reader#lads caleb#love and deepspace caleb#caleb#lnds caleb#love and deep space#love and deepspace smut#loveanddeepspace#fluff#caleb lads#caleb love and deepspace#xia yizhou#caleb fluff#love and deepspace headcanons#love and deepspace imagine#love and deepspace scenarios#navydoves

2K notes

·

View notes

Text

Unveiling the Power of Vibration Sensor

Two Switching Outputs

Employs pre-alarm and main alarm outputs for enhanced monitoring and response.

Integrated History Memory with Real-Time Clock

Facilitates seamless data monitoring, display, and recording, bolstering operational efficiency.

Scalable Analogue Current Output

Delivers precise measurements of vibration velocity, optimizing performance analysis.

Versatile Analogue Input

Enables monitoring of additional measurements, expanding its utility beyond vibration detection.

A Multifaceted Guardian

Comprehensive Insights

Provides deep insights into machinery performance and environmental conditions.

Proactive Maintenance

Alerts to potential issues before they escalate, ensuring preemptive actions.

Adaptability Across Industries

Reliable tool for diverse sectors, ensuring optimal functioning and strategic maintenance.

Conclusion: Empowering Proactive Decision-Making

The vibration sensor emerges as a cornerstone in monitoring and control, empowering proactive decision-making and safeguarding critical systems. Its advanced features and adaptability make it indispensable across industries, ensuring optimal performance and preemptive maintenance

#Vibration Sensor#Vibration Sensor automation#Vibration Sensor for industrial agricaltural use#Vibration Sensor for factory#Vibration Sensor india#Vibration Sensor buy online

1 note

·

View note

Text

The Power of Predictive Maintenance Vibration Analysis Sensors

The integration of vibration sensors marks a significant leap forward in predictive maintenance. Wireless vibration sensors for predictive maintenance allow the seamless process of fault detection, swift responses, precision in analysis, the sophistication of machine learning, downtime reduction strategies, and the ultimate optimization of production efficiency.

For More:

0 notes

Text

Vibration Sensor Market Size, Share, Trends, Outlook, Forecast 2024-2032

According to IMARC Group latest report titled “Vibration Sensor Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032”, offers a comprehensive analysis of the industry, which comprises insights on vibration sensor market forecast. The report also includes competitor and regional analysis, and contemporary advancements in the global market.

The global vibration sensor market size reached US$ 4.5 Billion in 2023. Looking forward, IMARC Group expects the market to reach US$ 7.4 Billion by 2032, exhibiting a growth rate (CAGR) of 5.4% during 2024-2032.

Request a Free Sample Report: https://www.imarcgroup.com/vibration-sensor-market/requestsample

A vibration sensor, also known as an accelerometer or vibration transducer, is a device designed to detect and measure vibrations in machinery or structures. It converts mechanical vibrations into electrical signals, providing valuable data for monitoring equipment health and identifying potential issues. Vibration sensors are widely used in various industries, including manufacturing, aerospace, automotive, and infrastructure. They help prevent equipment failure, reduce maintenance costs, and enhance overall operational efficiency by detecting abnormal vibrations that may indicate misalignments, imbalance, or wear. The collected data aids in predictive maintenance strategies, ensuring timely intervention and preventing unexpected breakdowns in machinery or structural components.

Market Trends:

The global market is majorly driven by the increasing emphasis on predictive maintenance. In line with this, industries worldwide are increasingly adopting predictive maintenance strategies, leveraging vibration sensors to monitor equipment health. These sensors play a pivotal role in detecting abnormalities in machinery early on, reducing downtime, and optimizing maintenance schedules. Furthermore, the rise of Industry 4.0 and the broader trend of industrial automation contribute significantly to the market's growth. Vibration sensors are integral components of smart manufacturing systems, enabling real-time monitoring and control of machinery. This facilitates data-driven decision-making, improves overall equipment effectiveness, and supports the transition toward more efficient and connected industrial processes. Besides, the expanding use of vibration sensors in diverse applications, including automotive, aerospace, healthcare, and infrastructure, drives market diversification. In the automotive sector, for example, vibration sensors contribute to vehicle safety and performance monitoring. In healthcare, they play a role in medical diagnostics and monitoring equipment. Additionally, rapid technological advancements, particularly in sensor design and data analytics, enhance the capabilities of vibration sensors. Integrated wireless communication and Internet of Things (IoT) connectivity enable seamless data transmission and remote monitoring, fostering the adoption of these sensors across various industries.

View Full Report with TOC & List of Figure: https://www.imarcgroup.com/vibration-sensor-market

Competitive Landscape

The competitive landscape of the industry has also been examined along with the profiles of the key players operating in the market.

Analog Devices Inc.

Bosch Sensortec GmbH (Robert Bosch GmbH)

Dytran Instruments Inc.

Emerson Electric Corp.

FUTEK Advanced Sensor Technology Inc.

Hansford Sensors Ltd.

Honeywell International Inc.

National Instruments Corporation

NXP Semiconductors N.V.

Rockwell Automation

Safran Colibrys SA

SKF

TE Connectivity Ltd.

Texas Instruments Incorporated.

Key Market Segmentation:

Our report has categorized the market based on region, product, technology, material, and end-use industry.

Breakup by Product:

Accelerometers

Velocity Sensors

Non-Contact Displacement Transducers

Others

Breakup by Technology:

Piezoresistive

Strain Gauge

Variable Capacitance

Optical

Others

Breakup by Material:

Doped Silicon

Piezoelectric Ceramics

Quartz

Breakup by End-Use Industry:

Automotive

Healthcare

Aerospace and Defence

Consumer Electronics

Industrial Machinery

Others

Breakup by Region:

North America (United States, Canada)

Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

Asia Pacific (China, Japan, India, Australia, Indonesia, South Korea, Others)

Latin America (Brazil, Mexico, Others)

Middle East and Africa

Key Highlights of the Report:

Market Performance (2018-2023)

Market Outlook (2024-2032)

Porter’s Five Forces Analysis

Market Drivers and Success Factors

SWOT Analysis

Value Chain

Comprehensive Mapping of the Competitive Landscape

About Us:

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC’s information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company’s expertise.

Contact US:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145 | United Kingdom: +44-753-713-2163

0 notes

Text

Accelerometer and Vibration Sensor Market

0 notes

Text

How to Use Vibration Sensors to Prevent Motor Failures in High Vibration Fans

Introduction: High vibration fans are vital components in various industrial applications, ensuring optimal airflow and temperature control. However, the constant exposure to high vibration levels can significantly impact the performance and longevity of the motors driving these fans. To mitigate potential motor failures and enhance fan efficiency, integrating vibration sensors for motors becomes indispensable.

Utilizing Vibration Sensors for Motor Protection: Vibration sensors are sophisticated devices designed to detect and quantify vibrations within the fan system. When installed strategically, these sensors continuously monitor the motor's vibration levels and promptly alert operators of any unusual patterns. By detecting anomalies at an early stage, maintenance teams can take preemptive actions to prevent severe damage and unexpected downtime.

Predictive Maintenance for Fan Reliability: One of the key advantages of integrating vibration sensors is enabling predictive maintenance practices. Instead of adhering to a reactive maintenance approach, where repairs occur after failure, predictive maintenance empowers operators to schedule maintenance tasks proactively based on actual equipment condition. This approach reduces downtime and optimizes maintenance costs, ensuring that the fan operates at peak performance levels.

The Role of Data Analytics: With vibration sensors in place, a vast amount of data is generated, requiring effective analysis to draw actionable insights. Data analytics tools enable maintenance teams to interpret vibration patterns, identify trends, and establish thresholds for alarm triggers. Leveraging these insights, operators can fine-tune the fan's operation, prolonging the motor's lifespan and overall fan longevity.

Conclusion: Incorporating vibration sensors for motors inhigh vibration fansis a wise investment for any industrial facility. The data-driven approach of predictive maintenance helps prevent motor failures, increase fan efficiency, and reduce operational costs. With the seamless integration of these sensors from reliable manufacturers like STI Web, industries can ensure smooth and reliable fan performance, contributing to enhanced productivity and operational success.

0 notes

Text

How to make a factory smart

The term “SMART FACTORY” is becoming more popular, and is often related to industry 4.0. SMART factories are critical to achieving Industry 4.0 expectations. The strategic importance of SMART FACTORY is undeniable, as early adopters have reported operating more efficiently and driving more to the bottom line.

According to Deloitte, in the United States alone, 86% of manufacturers believe that smart factories will be the main drivers of competition by 2025.Furthermore, 83 percent believe that smart factories will transform the way products are made.

This post will discuss what a smart factory is, its benefits, how to get started, and how solutions provided by CIMCON can help with the process.

What is a SMART FACTORY

SMART FACTORY is a networked industrial facility that combines data, collecting results from devices, processes, machines, and apps to generate actionable insights. The SMART FACTORY transformation highlight the importance of connectivity,the need to connect assets and data across a range of systems, platforms, and data structures, some of which were never meant to be connected. Once a facility and its assets are connected with the use of Sensors and Edge Devices, they unleash a flood of information to be translated and acted upon.

SMART FACTORY Sensors / EDGE devices can be found in a variety of manufacturing environments. CIMCON provides vibration sensor VIBit and the Edge Platform CIM devices. A vibration sensor is a sensitive and calibrated instrument that detects anomalies in the functioning of real-time equipment (motor, pump, etc.). Vibration sensors can provide a warning, allowing the facility to resolve the problem before there is an accidental shutdown. The CIM device can gather data from numerous devices (wired or wireless), using the appropriate protocol and transforming the captured data into a readable format.

Challenges without a SMART FACTORY

In today’s manufacturing industry, organizations are expected to streamline operations, reduce costs, regularly update product formulas, drive supply chain efficiencies, increase employee productivity and maintain business relationships. With expectations so high, the manufacturing industries cannot afford to run into any issues that may interfere with the productivity. But without the implementation of SMART FACTORY, there are some common challenges that may come up with time.

Lengthy implementation period

Costly customization

Inflexibility

Siloed data

Risk of lagging behind new aged technology

The benefit of Smart Factory using CIMCON solutions

Agile production process: SMART FACTORY allows the manufacturer to adapt to changing client needs, budgets, and product quality requirements due to the connectivity of multiple systems, processes, devices, etc., to provide an edge on the delivery of a product.

Enhancing the efficiency and reliability of manufacturing operations: CIM devices and the sensor network will enable the industry to collect data on processes and equipment and provide alerts if there is a deviation. The acquired data is analyzed in near real-time, allowing manufacturers to immediately modify equipment parameters. The analysis of sensor-generated data throughout the manufacturing process aids in identifying trends and scope for improvement. In addition, the likelihood of human error is minimized in production procedures.

Increased visibility into operations on the shop floor: Through IIoT products, SMART FACTORY provides a greater sense of visibility into shop floor operations by providing continuous real-time updates on production operations.

Information safety: In SMART FACTORIES, data priority is necessary. So, the more technologies are involved with sensors and Edge devices, the more secure the factory must be for customers, suppliers and investors.

Predictive maintenance improves uptime: Data regarding the health and performance of equipment is communicated near-real-time to the cloud via IIoT, ensuring advanced planning in maintenance work and boosting machine availability.

Increased worker safety: Sensors are used to communicate information without the physical presence of humans to ensure maximum safety.

Step-by-step instructions for constructing a SMART FACTORY

Establish your goals and needs: To ensure you put your resources in the right places, you must also understand the “WHYs” behind your decision to implement a smart factory.

Get your personnel on board: Legacy systems are still in existence in many production plants, making the deployment of smart technologies difficult. Creating a new solution to replace an existing legacy system may incur costs such as the purchase of a new instrument and the hire of a digitally skilled individual. Because the human workforce is always an important part of the manufacturing process, it must be trained to adapt to changing conditions.

Be cyber secure: In today’s scenario of data-driven technology and usage of increased IIoT devices, data security is a rising concern. Updating security measures should be implemented to provide future-proof security from unwanted threats.

Make a new investment in instruments: To make SMART FACTORY a reality, manufacturing facilities need to invest in IIoT sensors and CIM devices to collect data from legacy machines. IIoT sensors and CIM devices help manufacturing facilities quickly adopt innovative technology for the digital transformation.

Make a new investment in hiring personnel: To adopt the new technology, the manufacturing facility needs to invest in data analysts to turn the data collected into something usable or valuable – one more area to reskill your existing personnel to fulfil the requirement. This is also an area where CIMCON can help provide technical expertise.

Open to change and keep upgrading SMART FACTORY implementation: As you and your staff grow more familiar with innovative technology and its benefits, it will become easier to continue to expand smart technologies to other facility areas. The factory is flexible and responsive and can perform in a dynamic environment.

Implementing smart factory technology with CIMCON’s product and platform

Implementing the SMART FACTORY in any business can be difficult and time-consuming. CIMCON DIGITAL is a company that can provide support for digital transformation in terms of both software and hardware, with vast experience in the development and implementation of automation using various in-house developed products, such as sensors, CIM devices, and so on.

CIMCON devices will address all the issues that will transform the industries and support in converting the factories into smart factories of the future.

Contact us today to begin your smart factory adventure.

#predictive maintenance#iot edge platform#condition monitoring sensors#vibration sensor#digital transformation solutions

0 notes

Text

Bently Nevada Vibration Sensors Supplier - Your Trusted Source: WOC

Your Trusted Bently Nevada Vibration Sensors Supplier. Contact World of Controls today to procure Bently Nevada vibration sensors. We provide worldwide shipping.

0 notes