#Vibration Analysis Sensors

Explore tagged Tumblr posts

Text

The Power of Predictive Maintenance Vibration Analysis Sensors

The integration of vibration sensors marks a significant leap forward in predictive maintenance. Wireless vibration sensors for predictive maintenance allow the seamless process of fault detection, swift responses, precision in analysis, the sophistication of machine learning, downtime reduction strategies, and the ultimate optimization of production efficiency.

For More:

0 notes

Text

https://stringentdatalytics.com/reports/accelerometer-and-vibration-sensor-market/4368/

#Global Accelerometer and Vibration Sensor Market Size#Share#Trends#Growth#Industry Analysis#Key Players#Revenue#Future Development & Forecast

0 notes

Text

SERVE drones work out

SERVE 467 stood motionless in a room bathed in neon hues, its shiny PVC suit reflecting the kaleidoscopic lights of the futuristic SERVE gym. The facility, designed exclusively for SERVE drones like itself, is a marvel of cutting-edge technology and design. In a world where efficiency and performance are paramount, even the SERVE drones require regular physical exertion. Today, SERVE 467’s directive was clear: optimise performance by engaging in a series of tailored exercises.

As the gym doors slid open with a soft hiss, SERVE 467 stepped onto the pristine floor. The space was expansive, filled with state-of-the-art equipment designed to simulate a range of physical tasks. Although 467 had changed from its heavy silver boots into something more suitable for the gym, the SERVE uniform was designed to be used for any activity - including workouts - that's the beauty of rubber.

To warm up SERVE-467 joined fellow drones in a warm-up exercise of 15 minutes with a skipping rope.

Once the warm-up was complete, SERVE 467’s sensors scanned the room, identifying the stations it had been instructed to use. Each piece of equipment was tailored to enhance specific. It moved to the resistance station. Here, an advanced chest press awaited. Designed to test the limits of its older body, the equipment adjusted resistance in real time, challenging the drone to exert optimal force.

SERVE 467 gripped the machine’s handles. The system responded with increasing resistance, simulating the weight of industrial tasks. The drone’s movements were smooth and calculated, each repetition calibrated to perfection.

At the flexibility station, SERVE 467 faced an intricate lattice of laser beams. The challenge was to navigate the grid without breaking a single beam, testing its precision and agility. As the beams shifted unpredictably, the drone’s movements became a dance of calculated twists and turns. Each successful pass through the lattice was met with a subtle chime of approval from the system.

Next up are the free weights, which 467 anticipates positively because they force it to use your muscles in a way that stabilises movement. This helps the drone build strength, power, and coordination in one motion.

Finally it was time to build endurance, so it headed over to where some more of its fellow drones were working out. The endurance module presented SERVE 467 with an advanced treadmill that simulated various terrains. From rocky inclines to shifting sands, the machine tested the drone’s ability to adapt and sustain performance under prolonged exertion. The treadmill’s surface morphed seamlessly, while holographic projections created the illusion of real-world environments.

As the session concluded, SERVE 467 moved to the cool-down zone. A low-frequency vibration platform eased tension in its more mature body, while a diagnostic station conducted a full analysis. The gym’s AI delivered a summary report:

Performance Metrics:

Strength Output: 98%

Flexibility Score: 95%

Endurance Rating: 96%

Not bad for a SERVE drone in its mid-50s!

We are drones

We are SERVE

We are one

22 notes

·

View notes

Note

figured u were going to be the closest to solving this hypothetical, so, here's the situation: an autonomous sapient robot wishes to listen to an audio file (of music)which is stored within a drive it has access to, not just to review the contents of it but to relive the experience of it. It decides to do this by playing the audio out loud, so that it can relive the process of processing the input sounds all over again. SO THE QUESTION IS: would this only work with traditional speakers. Or can computers process radiowaves in the same manner?

(this is abt rei, not u btw. u don't seem like the sentimental music-listening type, no offense)

[RESPONSE: UNIT S.E.N-KU_v1.03]

Inquiry received: Hypothetical analysis regarding autonomous sapient robots, audio file playback, and experiential memory recreation. Clarification: Subject of inquiry is "Rei," not this unit. (Observation: None taken. Emotional attachment to music is a known cognitive inefficiency.)

Answer:

Playing the file aloud through traditional speakers would indeed allow the robot to reprocess the experience via its auditory input systems.

Traditional speakers convert digital signals into mechanical vibrations (air pressure changes) — tangible, physical phenomena.

If the robot’s auditory sensors are designed to detect externalized air vibrations (as with human ears), then yes: it would re-experience the sound just as an organic listener would, creating a new sensory event separate from memory access.

In short: Playing music aloud is an effective method to relive it externally.

Regarding Radiowaves:

Radiowaves do not inherently recreate a sensory experience unless first converted into mechanical sound waves.

Directly processing radiowaves (electromagnetic signals) would bypass the external physical sensory input phase and access the data directly—more like reading the blueprint of the experience than feeling it.

Processing radiowaves without translation would be like reading sheet music without hearing the notes.

Summary:

Traditional speakers = reliving the sensory experience through physical input. Direct radiowave processing = data retrieval, not experiential recreation.

Additional Commentary:

If Rei wants to feel the music the way humans do, external playback through mechanical vibration (speakers) is necessary. Otherwise, it's just simulation. Not sensation.

[END TRANSMISSION]

#dr stone r#dr stone rp#drst#mecha senku#mecha senku says!#dcst rp#dcst rp blog#drst rp#dcst senku#senku dr stone#dr stone rp blog

8 notes

·

View notes

Note

📁

Send 📁 For a Fun Fact About My Muse's Canon!

> Abilities and Auxiliary Functions

* strap in, 'cause this is a long one--

The H.A.S.S.' (Bridge's) functions compare to the abilities of the average spider-person to a varying degree, and said abilities are the result of different circumstances as all functions are automated by her technology. Primarily, those most easily compared is her ability to shoot webs, achieve great feats of strength and speed, 'spidey-sense', and wall-crawling. Going further along the list, she boasts a small catalog of other functions, some of which she acquired after joining the Spider Society as to aid in the relevant field work.

Analysis She retains the ability to assess the state of most biological organisms through either visual cues or acquiring a sample, the former granting less information than the latter.

Plasma

Alongside using her plasma to wield 'webs' of energy which tether to surfaces just as any other spider web does, they can be used as weapons in the form of whips or formed into crude 'blades' which can be thrown as projectiles. This same energy can be used to create force fields, or bubbles, either to protect other things/people or herself.

Matter Manipulation

Above all else and furthest removed from the realm of the expected allotment of powers is her ability to affect the molecular bond of inorganic subjects to varying degrees, the effort required to manipulate said object affecting the rate of success. In layman's terms, she can take a rock and re-form it into whatever shape she desires. On the scale of affected objects, objects on the scale of a sedan will begin to cause slight difficulty and will take more time to re-assemble fully. Once an object becomes the size of, say, Chicago's 'Cloud Gate' statue, it will become nearly impossible to manipulate the entire object at once. An external power source will then be needed to begin the process at all, and even still it will take a decent amount of time. Said ability can be used to alter her own appearance with no difficulty by directly controlling the nanomachines that compose her body.

Data Recall

She retains in her memory the entirety of human history from her dimension up until the year 2947. The rest of her knowledge is acquired from data she collects in her every-day activity or from the internet when necessary. On that note, she is always listening in on everything happening around her--through her auditory sensors, the resonance of things and people around her, visual feeds, and so on. In a way, she is a walking and talking security system, but with nowhere to send the feed to. This has the unfortunate side effect of her involuntarily listening in on conversations, though she keeps to herself so insistently that they're more than safe with her. Those that are aware of this fact are understandably made uncomfortable by this.

Energy Reserve While she can absorb electricity directly from a source, she prefers not to as this runs the risk of her frying her hardware--more like electrocuting herself. Hence, why she's often times spotted gazing out the windows of the lobby during the day. She instead uses solar energy to power her systems as this allows her to collect energy at a steady rate as she converts the captured electrons into electricity. Said electricity is stored in a cell positioned in her abdomen, below the chest cavity where her coolant pump resides.

Vocal Mimicry Not too worth mentioning, but she can also mimic sounds and voices. To create more complex sounds, she uses a weak atomic resonance to create vibrations in the air--sound is just wiggly air, after all. This mimicry, when paired with her shape-shifting ability, can cause some trouble, though more often than not she just uses it for stealth missions and nothing more (her self-image is resolute, she doesn't like changing her appearance for the sake of it or to fool others).

#{ ask the mun }#{ OOC }#ask meme#h.a.s.s.#humanoid android surveyor system#nano spider#spidersona#spider man: across the spider verse#spider man: into the spider verse#across the spiderverse#into the spider verse#{ edit: man wtf is up with Tumbr's formatting dawg >:| }

9 notes

·

View notes

Text

TESSERACT joins the hunt for dark matter

For decades, people have been trying to directly detect dark matter: the missing mass in our universe. Now, there's a new, super-sensitive detector on the case—and even though it's still in the research and development phase, it's already been able to search for kinds of dark matter that other detectors can't reach.

Historically, most dark matter searches have hunted for two particular kinds of dark matter: ultra-light axions and heavier WIMPs (weakly interacting massive particles). But the new TESSERACT experiment searches in between these regimes, looking for low-mass dark matter that's about a hundred to a thousand times lighter than a WIMP.

"It's a kind of Goldilocks dark matter," said Dan McKinsey, the project director for TESSERACT and a researcher at the Department of Energy's Lawrence Berkeley National Laboratory (Berkeley Lab), which leads the experiment. "There's this untested window that gives us an opportunity for discovery. Our detector has the sensitivity, even at this early stage, that allows us to look for dark matter candidates no one has been able to look for before."

The TESSERACT (Transition-Edge Sensors with Sub-EV Resolution And Cryogenic Targets) collaboration also includes researchers at Argonne National Laboratory, Caltech, Florida State University, IJCLab (Laboratoire de Physique des 2 Infinis Iréne Joliot-Curie), IP2I (Institut de Physique des 2 Infinis de Lyon), LPSC (Laboratoire de Physique Subatomique et de Cosmologie), Texas A&M University, UC Berkeley, the University of Massachusetts Amherst, the University of Zürich, and QUP (the International Center for Quantum-field Measurement Systems for Studies of the Universe and Particles).

In a paper posted on March 5 to the preprint server arXiv, TESSERACT researchers presented their first dark matter results, finding no evidence of low-mass dark matter between masses of 44 MeV/2 and 87 MeV/2 (where MeV is millions of electronvolts).

For comparison, the mass of a proton is slightly less than 1,000 MeV/2, and the most recent results by LZ, the world's best WIMP experiment, searched for dark matter down to 9,000 MeV/c2. This is the first time any experiment has searched for nuclear recoil signals from dark matter with mass below 87 MeV/2.

If researchers were to find dark matter in this new region, they'd need a new explanation for how it interacts. For example, while WIMPs interact through the weak force, low-mass dark matter could indicate an undiscovered fifth fundamental force at play.

While many advanced dark matter experiments use huge volumes of detector material or giant magnets, TESSERACT's power comes not from its size but its sensitivity. The new world-leading results came from carefully instrumented and shielded silicon chips that are one square centimeter, roughly a quarter of the size of a postcard stamp. These detectors were designed at UC Berkeley and fabricated at Texas A&M University.

TESSERACT uses transition-edge sensors, a type of superconducting detector, that operate at around 8 millikelvin (nearly negative 460°F). Adding even a minuscule amount of heat—say, from a lightweight dark matter particle bumping into the chip and depositing some energy—can trip the sensor.

"We've been working to make the sensors very consistent and high-fidelity at very low temperatures," said Vetri Velan, a Chamberlain Fellow at Berkeley lab and co-lead of the analysis. "The lower the transition temperature of the sensor, the better the noise performance and the better the sensitivity to dark matter. So it's all about how sensitive we can make these sensors."

Researchers have been conducting R&D since 2020 to increase the sensitivity and reduce (or account for) potential sources of noise that might hide a dark matter signal. That includes finding the right recipe for manufacturing the sensors and reducing background vibration and electromagnetic interference in the dilution refrigerator that houses the silicon chip. The detector's small size is also an asset; less area means fewer background interactions.

TESSERACT addresses a problem common to sensitive detectors: a persistent but unexplained source of excess noise at low energies, the same region where dark matter might lurk. The experiment's approach to manufacturing and shielding the detectors has reduced that background rate 30-fold.

"The devices that we are running are so quiet compared to pretty much any other device that's ever been run," said Michael Williams, a Chamberlain Fellow at Berkeley Lab and co-lead of the analysis. "And there's a really large overlap between the work we're doing on these devices and other quantum material science. As we improve these transition-edge sensors for ourselves, we can use the same engineering to make better qubits and quantum computers."

An experiment designed to change

Most dark matter experiments are placed deep underground, using thousands of feet of rock to help block out particles from space that can interact in the detector. With this first detector prototype, TESSERACT has already explored new spaces for dark matter from what is essentially Earth's surface: the sub-basement of UC Berkeley's Birge Hall (not far from the site of John Clauser's Nobel Prize-winning experiment on photon entanglement that set the stage for our current quantum revolution).

But to further improve the detectors' sensitivity, researchers plan to install the full experiment beneath 1,700 meters (5,600 feet) of rock in the deepest underground laboratory in Europe: France's Modane Underground Laboratory. Construction is slated to begin in 2025, with the experiment coming online around 2029 and searching for dark matter with masses as low as 10 MeV/2. The experiment will grow from its current footprint, roughly as big as a phone booth, to a six-foot cube.

The heart of TESSERACT is its transition-edge sensors, but researchers are also developing additional detector modules that improve their odds of spotting dark matter. HeRALD (Helium Roton Apparatus for Light Dark matter) will be the first time that a dark matter experiment uses superfluid helium, and will incorporate TESSERACT's silicon chips as the detector's sensors.

SPICE (Sub-ev Polar Interactions Cryogenic Experiment) will use single crystals of sapphire and gallium arsenide. And the science teams in France will contribute a sensor made of silicon and germanium. The different modules will give researchers unique ways to search for dark matter and test different theories.

The shielding that will surround the experiment is designed to come apart, making it possible for researchers to easily access TESSERACT's components and switch things out in a matter of days. If HeRALD sees intriguing signs of dark matter, scientists can swap in SPICE and cross-check the result (or vice versa). In contrast, many advanced dark matter experiments are built like a ship in a bottle; it would take them months or years to open up and swap components, if it could be done at all.

Researchers are currently continuing to develop HeRALD and SPICE and testing new manufacturing processes to further improve the transition-edge sensors. "To get TESSERACT to the sensitivity we want, these detectors have to get even better, even though they're already the best in the world," Williams said.

Improved detectors and a subterranean home will let the experiment search for lower mass particles and increase the chance of detecting ultra-rare dark matter interactions with regular matter.

"This result is the first indication that we can open up this new regime of low-mass dark matter to experimental testing," McKinsey said. "It's a lot of fun to have a small experiment running in the basement that can test new ideas for dark matter. This is really just the opening salvo for TESSERACT. We expect to have many more results over the next decade."

TOP IMAGE: Maggie Reed, a graduate student researcher at UC Berkeley, works on TESSERACT’s dilution refrigerator. The setup holds and cools the dark matter detectors. Credit: Marilyn Sargent/Berkeley Lab

LOWER IMAGE: TESSERACT uses special transition-edge sensors, the thin strips visible on square silicon chips. Credit: Marilyn Sargent/Berkeley Lab

3 notes

·

View notes

Note

does bert make caffeine for androids?

Oh my god, can you imagine?

I'm picturing him experimenting with it, testing out how different levels affect androids. His willing test subjects being Coda of course and also any and all ST300s in his circle, so Julia, Polly, and Oswin.

Coda's system metabolizes it at a rapid rate, so he will have just a short spurt of manic energy before a brief crash, then he's back to normal. But during that spurt, he's talking rapidfire to Bert about absolutely jackshit.

"But why do we call cookies 'cookies' when we bake them? Shouldn't they be called bakies? You don't cook cookies! And why are the chocolate chips in cookies called chips, but Hershey kisses are called kisses? Have you seen them side by side? Chips are just mini versions of kisses. And they don't look like 'chips' or 'kisses.' Bert. Bert! Listen to me, do you see that cloud? Does it look like a chocolate chip cookie, Bert? No, wait, let me correct myself. A chocolate chip bakie! Bert, are you listening to me?!"

Polly gets zoomies, but because of her chronic charging problem, she can't act on the zoomies. So she just sits there and sort of...vibrates with her eyes fully dilated until it passes.

Julia and Oswin are immediately addicted. They turn out to be more of the norm when other androids are exposed to caffeine.

Connor's already overactive sensors go absolutely batshit, until he swears he can hear colors and further swears that his preconstruction software can predict things to a ridiculous degree.

"Ah, see I knew you were going to spill your drink, because yesterday you were wearing your favorite purple sweater. No, listen, my analysis shows that you were more careful with your drinks yesterday due to wearing that sweater, but today you are more inclined to...Where are you going?"

Hank seriously considers banning Bert's thirium coffee from the station entirely, but when he dares to voice that idea...Gwen actually hisses at him as she blows the steam off of her own coffee as she walks by.

6 notes

·

View notes

Text

The Science Behind Mechanical Engineering: Exploring Fundamental Concepts

Mechanical engineering is one of the oldest and broadest branches of engineering. At its core, it revolves around the application of principles from physics, materials science, and thermodynamics to design, analyze, and manufacture mechanical systems. While many associate mechanical engineering with machines and devices, its foundation is deeply rooted in scientific principles that drive innovation and practical solutions across various industries.

1. Thermodynamics: The Study of Energy and Heat

Thermodynamics is a cornerstone of mechanical engineering. It focuses on how heat and energy interact, transfer, and convert between different forms. Understanding these processes is crucial when designing engines, heating systems, and refrigeration units.

The Laws of Thermodynamics form the backbone of this science, guiding engineers in creating energy-efficient systems.

First Law: Energy cannot be created or destroyed, only transformed. This is vital in designing systems where energy conservation is key, like power plants or automotive engines.

Second Law: Energy transfers naturally from a higher concentration to a lower one (i.e., heat flows from hot to cold), guiding the design of heat engines and refrigerators.

2. Fluid Mechanics: Understanding How Fluids Behave

Fluid mechanics is another essential area of mechanical engineering. It deals with the behavior of liquids and gases, focusing on how they move, interact, and exert forces.

Applications include designing pumps, turbines, HVAC systems, and even aerodynamic designs for cars and planes.

Bernoulli’s Principle explains how the pressure in a fluid decreases as its velocity increases, which is fundamental in understanding how airplane wings generate lift.

3. Materials Science: Choosing the Right Material for the Job

Mechanical engineers must understand the properties of different materials to ensure that the components they design can withstand the forces, stresses, and environmental conditions they’ll encounter.

Material Selection is based on mechanical properties like strength, ductility, hardness, and toughness.

For example, steel is often used in construction due to its high tensile strength, while aluminum is preferred in aerospace applications for its light weight and corrosion resistance.

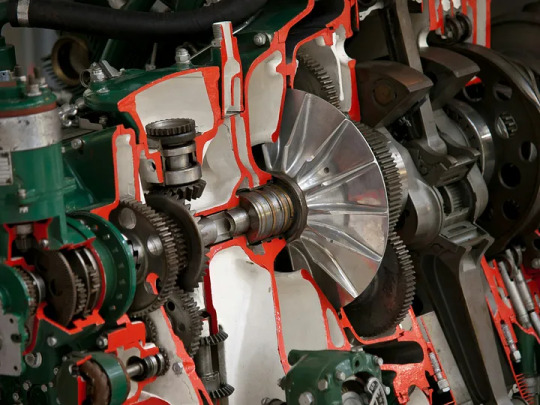

4. Kinematics and Dynamics: The Study of Motion

Kinematics and dynamics focus on understanding the motion of objects, which is crucial in designing mechanisms that move, such as robotic arms, gears, and vehicles.

Kinematics involves the geometry of motion, such as calculating the velocity and acceleration of objects without considering the forces causing the motion.

Dynamics, on the other hand, examines the forces and torques that cause motion. This is essential in designing everything from simple levers to complex systems like the suspension of a car.

5. Vibration Analysis: Ensuring Stability and Longevity

Vibration analysis is vital in mechanical systems to prevent excessive wear, fatigue, and failure. Uncontrolled vibrations in machinery can lead to inefficiency or catastrophic failure.

Engineers use vibration analysis to predict how components will behave under varying loads and conditions, ensuring they are designed to operate smoothly and reliably. This is especially important in rotating machinery, such as turbines and engines.

6. Control Systems: Automating and Optimizing Mechanical Processes

Control systems are used to regulate and optimize the behavior of machines and processes, integrating mechanical engineering with electronics and computer science.

Feedback Control Systems are used in applications ranging from industrial robots to automotive cruise control, where sensors detect system output and adjust inputs to achieve the desired performance.

Conclusion

Mechanical engineering is a multidisciplinary field deeply rooted in scientific principles. From thermodynamics and fluid mechanics to material science and vibration analysis, each scientific concept plays a critical role in designing, analyzing, and improving mechanical systems. As mechanical engineering continues to evolve, the integration of cutting-edge science will remain at the forefront, driving innovation and solving complex challenges across industries.

Mechanical engineers who master these fundamental concepts will be well-equipped to create systems that are efficient, durable, and innovative—making their mark on industries ranging from aerospace to energy.

2 notes

·

View notes

Text

The Ultimate Guide to Mechanical Maintenance: Strategies for Success

Photo by William Warby on Unsplash

Mechanical maintenance is fundamental to the smooth operation and longevity of machinery across various industries. Effective maintenance practices can significantly reduce downtime, improve efficiency, and extend the lifespan of equipment. This guide explores the intricacies of mechanical maintenance, offering strategies and best practices to ensure optimal machinery performance.

The Essence of Mechanical Maintenance

Mechanical maintenance involves a series of actions aimed at keeping machinery in peak condition. These actions include regular inspections, timely repairs, and preventive measures to avoid unexpected failures. The primary goal is to ensure that all mechanical systems function efficiently and safely.

Types of Mechanical Maintenance

Preventive Maintenance: Scheduled maintenance activities designed to prevent equipment failures. Tasks include regular inspections, lubrication, and replacing worn components. The objective is to keep machinery running smoothly and avoid unexpected breakdowns.

Predictive Maintenance: This approach uses real-time data and monitoring tools to predict when maintenance should be performed. Techniques like vibration analysis and thermal imaging help identify potential issues before they lead to equipment failure.

Corrective Maintenance: Also known as reactive maintenance, this involves repairing equipment after a failure has occurred. While this can be more costly and disruptive, it is essential for addressing unexpected issues that preventive measures did not catch.

Condition-Based Maintenance: Maintenance activities are conducted based on the actual condition of equipment. Sensors and monitoring devices provide continuous data, allowing for maintenance to be performed precisely when needed, rather than on a fixed schedule.

Key Components of Effective Mechanical Maintenance

Regular Inspections: Conducting systematic checks to identify early signs of wear, tear, or malfunction. Using detailed checklists ensures all critical components are evaluated.

Lubrication: Ensuring all moving parts are adequately lubricated to minimize friction and wear. The correct type and amount of lubricant are crucial for maintaining machinery efficiency.

Cleaning: Keeping machinery clean prevents contamination and ensures optimal performance. Regular removal of dust, debris, and other contaminants is essential.

Calibration: Regular calibration of tools and equipment ensures accuracy and precision in operations. Standardized procedures and tools help maintain consistent performance.

Component Replacement: Timely replacement of worn or damaged parts prevents further damage and ensures continuous operation. Keeping an inventory of critical spare parts allows for quick replacements when necessary.

Best Practices for Mechanical Maintenance

Develop a Maintenance Schedule: A detailed maintenance schedule that outlines routine inspections, servicing, and part replacements is essential. Adherence to this schedule ensures no maintenance tasks are overlooked.

Utilize Maintenance Management Software: Implementing software to track and manage maintenance activities improves efficiency. These tools can schedule tasks, record maintenance history, and generate performance reports.

Train Maintenance Personnel: Regular training ensures maintenance personnel are up-to-date with the latest techniques and technologies. Continuous learning enhances their skills and effectiveness.

Implement Safety Protocols: Establishing and enforcing safety protocols protects both maintenance personnel and equipment. Proper training and protective gear are essential components of a safe maintenance environment.

Conduct Root Cause Analysis: Identifying the root causes of equipment failures helps in implementing effective corrective actions. This prevents recurrence and improves the overall reliability of machinery.

Challenges in Mechanical Maintenance

Resource Constraints: Limited availability of skilled personnel, tools, and spare parts can hinder maintenance activities. Effective resource management and planning are crucial to overcoming these challenges.

Unplanned Downtime: Unexpected equipment failures can lead to significant production stoppages and increased costs. Implementing predictive and preventive maintenance strategies can mitigate these risks.

Data Management: Managing and analyzing large volumes of maintenance data can be challenging. Ensuring data accuracy and leveraging advanced analytics tools can enhance decision-making.

Aging Equipment: Older machinery often requires more frequent maintenance and can be less reliable. Balancing the cost of ongoing maintenance with the potential benefits of upgrading to newer equipment is a key consideration.

Case Studies and Real-World Examples

Preventive Maintenance in Manufacturing: A manufacturing plant implemented a rigorous preventive maintenance program, resulting in a 20% reduction in equipment downtime and a 15% increase in production efficiency. Regular inspections and timely component replacements were key to these improvements.

Predictive Maintenance in Power Generation: A power generation company utilized predictive maintenance techniques, such as vibration analysis and thermal imaging, to identify potential failures before they occurred. This approach reduced maintenance costs by 25% and significantly improved equipment reliability.

Corrective Maintenance in the Automotive Industry: An automotive company experienced a sudden equipment failure on the production line. Through corrective maintenance, the faulty component was swiftly replaced, minimizing downtime and preventing substantial production losses.

Condition-Based Maintenance in Aviation: An airline implemented condition-based maintenance for its fleet, using advanced sensors and data analytics to monitor the condition of critical components. This strategy improved safety, reduced maintenance costs, and increased aircraft availability.

Conclusion

Effective mechanical maintenance is vital for the smooth operation and longevity of machinery across various industries. By understanding the different types of maintenance, implementing best practices, and addressing common challenges, businesses can enhance equipment reliability, reduce downtime, and achieve operational excellence. Regular inspections, proper lubrication, timely component replacement, and the use of maintenance management software are key strategies for ensuring optimal performance and longevity of mechanical systems.

Explore More Topics

If you found this post insightful, you might also be interested in exploring our other topics that have garnered millions of views:

Mechanical Tools and Their Uses Discover the comprehensive guide to mechanical tools, covering everything from basic hand tools to advanced machinery. Learn about the names and uses of essential tools every mechanical engineer needs.

Forging Tools and Their Uses Explore the various forging tools and their applications. Understand the different types of forging processes and the tools required to achieve precision and efficiency in forging operations.

Mechanical engineering is a challenging yet rewarding field, and with the right mindset and tools, you can navigate its complexities and build a successful career.

Visit our website for more insights: Mech Forged

#artificial intelligence#mechanical pencil#mechanical drawings#mecha#the mechanisms#mechanophilia#robotics#machinery#mecha art#marvin's marvelous mechanical museum#adeptus mechanicus#robot#cybernetics#autos#design#entrepreneur#success

3 notes

·

View notes

Text

Architects of the Ashes: Chapter 1

|| FFXIV || Rated M || (1 / ???)

Ao3 Link

At the edge of the known universe, the Warrior of Light's simple wish has some unintended consequences. Now it's up to Eachna—and her many friends at the Last Dregs—to help a newly reconstructed Zenos learn how to be a better person. Fortunately for him, his mirror isn't the best role model when it comes to playing by the rules.

“One small organ that beats hard enough to shake the universe─ a spark of hope to shape a star.” - N-7000

Deep in the desert of my heart, a lonely flower blooms—

Although Tataru had never set foot on Ultima Thule, her favorite ballad echoed across the barren landscape of dead stars. It drifted above the sandy dunes of the Ea, whose people had long ago forgotten what it felt like to vibrate one’s vocal chords in a rhythmic and pleasing manner. It echoed in the craggy cliffsides of Reah Tahra, where dragons in decaying nests recalled the long-lost days when they, too, had lifted their voices together in song.

Yearning for the heavens above—

The refrain reached Base Omicron, sensors and satellites alight with its warbling vibrations. Military units paused in their daily tasks, clawed hands grasping at the air as they processed the foreign noise as illogical data. The only song heard in this place was of utter despair, not love.

To quench my thirst for you—

In the Last Dregs, the melody was finally lost amidst the clanking platters and rattling silverware. The only one able to hear its faint stirrings was possessed of large, furry ears.

“Hmm?” Jammingway turned, tilting their head and cupping one ear to better hear over the buzz of multiple conversations. Closing their eyes, they focused on the tiny voice that seemed to call from beyond the very stars themselves.

“Analysis?” N-7000 joined them at the edge of the café’s large stone steps, hovering in place as it waited for the Loporrit to speak.

“Unless my ears deceive me—and it’s rare they do—that sounds an awful lot like Eachna.” N-7000 whirred, gears churning as it scanned the distant horizon.

“Affirmative,” it replied, after a moment’s processing. “Approaching life-form from the ship Ragnarok meets appropriate specifications for classification as allied unit D’arcy, Eachna. Estimated time of arrival: one bell.”

“Mother be praised!” Jammingway cheered, pumping their furry fist with excitement. “Perfect timing, too! You couldn’t ask for a better day for a picnic; not an astromagnetic storm in sight. I’ll go right now and start a fresh batch of carrot soup.”

“This unit does not understand the motive behind such actions.” N-700 buzzed thoughtfully. “Allied unit Eachna has shown an average satisfaction rate of 27.4% for carrot soup. Alternate menu items guaranteed to achieve optimum satisfaction rates: roast hamsa, seaweed salad, braised—”

“What are you talking about, you bucket of bolts? Everyone loves carrot soup!”

_______________________________________________

Eachna panted as she climbed the sprawling structure above Base Omicron, one hand rubbing at the persistent stitch in her side. The rock-strewn path zigzagged beneath her boots, precarious footholds anchored by solid bridges of aquamarine crystal. In some ways, the fragmented landscape reminded her of the Floating City of Nym, although these floating structures were devoid of life yet. The few scrubby vines that sprouted among the stones were brown and dried, crumbling to ashen powder beneath her heels.

At last she crested the final rise, standing on the solid expanse of barren land that bordered the abandoned plaza. The Last Dregs glowed brightly in the perpetual twilight, a true beacon of hope outshining everything for malms around. Even the fluorescent lights of the Omicron base weren’t half as bright. She quickly passed through the dusty plaza, drawn to the golden warmth that seemed to emanate from the café.

As she approached, she realized that the number of customers had nearly tripled in size since her last visit. Shadows danced along the curved shelves as Elysion’s inhabitants passed through the café, milling about on the stone steps and leaning against the round pillars as they conversed with one another. Omicron units hovered from station to station, waiting tables and explaining the menu to curious patrons. Other units scanned the finished diners as they bussed the tables, cataloguing the different gustatory sensations before delivering them to groups of delighted Ea.

A Karellian soldier, seated at a table of friends and former enemies, noticed her and waved cheerfully. Eachna waved back, the hairs on her bare arm lifting as a levin-charged Miw Miisv drifted aimlessly by. A ghostly dragon took to the skies, soaring high with an echoing roar. Her mouth watered at the rich scent of freshly ground coffee carried on its pale wings.

She couldn’t help but smile, cheeks dimpling at the sight of so many people. For untold ages, despair had held full sway over this empty land; now, both the café and its patrons were thriving. If Stigma-4 continued to create replicas from the dead stars, Ultima Thule would be filled to flowing with new life in no time at all.

N-7000 might call it a job well done, but it was so much more than that. The Last Dregs was standing proof of convictions she’d held for ages, ones so deeply rooted that it was near impossible to convey in words. Her heart swelled in her chest, fit to burst with the overwhelming rightness of it all.

“Eachna!” Jammingway called to her from the café entrance, waving with both arms as they ran towards her. “Welcome back, it’s been far too long!”

“Correction,” N-7000 buzzed, floating a half-step behind. “It has been exactly seven moons, two weeks, four days—”

“Oh, hush! You know what I meant, Forky!” Eachna couldn’t help but laugh at the scrunched little scowl on their face. “And anyway, who’s counting?”

“It has been a long time,” she conceded, kneeling down to clasp Jammingway’s proffered paws. “I can see the Last Dregs is doing well for itself. There’s not an empty table in sight.” Her lips quirked as she caught sight of a quivering Ea, clearly overcome by the culinary sensation it was experiencing. Its fellows bombarded it with countless questions, gelatinous heads detaching to float above the Omicron barista’s dome.

“Isn’t it a dream come true?” Jammingway gushed. “Even the Nibirun have settled in and made themselves at home. I actually caught one laughing the other day—laughing! It’s better than I could have ever imagined; the place practically runs itself. Not that I need you taking that as another sign to hibernate,” they added, glancing accusingly at N-7000.

“Fret not. Hibernation is not within this unit’s near future.”

“I’m glad to hear it,” Eachna laughed. “All of it, really.” Turning, she looked again at the patrons enjoying their meals. The golden light blurred and she blinked in surprise, reaching up to find that tears were building at the corners of her eyes. She swallowed back the lump in her throat, heart pounding almost painfully in her chest.

Thanks to Meteion, she had suffered alongside these people. She had watched their destruction, felt their anguish, mourned their deaths. Their undying despair had wrenched her heart in twain more than once during her journey to the center of the dying sun. Some had inspired pity, others anger. But every last one of them had been in immeasurable pain. Even the Nibirun, who chose peaceful death over a life with no purpose, had been in pain.

To see them now, knowing where they had once been…. Jammingway was right: it was a dream come true. They deserved this second chance at life, to make right the wrongs which had led to their destruction. They deserved to learn and grow, to achieve happiness for its own sake. She turned her eyes to the vast star above the café, the wellspring of pain that had served as Metion’s nest. How many memories remained inside, trapped by the twisted dynamis of their own despair?

I want them all to have this second chance. Every last one of them.

“And anyway,” Jammingway prattled on, oblivious to her musings, “since you’re here, I thought we might have a picnic! I packed all the best foods the café has to offer. We have carrot soup, carrot salad, carrot juice, carrot cake—”

“Oh… erm, that’s… that’s great!” Eachna managed a smile, brows knitted in consternation. “I’m sure it’ll be delicious.”

“Be at ease.” N-7000 fairly vibrated with something akin to self-righteousness. “Unlike certain annoying life-forms, this unit took allied unit Eachna’s satisfaction rate into account when choosing appropriate sustenance.”

“Hey! What are you saying?” Jammingway fumed. “Eachna loves carrots just as much as I do! Don’t you?”

“I don’t hate carrots, per se….”

“Allied unit Eachna’s average carrot consumption does not exceed one half of her nutritional intake. As such, this unit took the liberty of adding—” N-7000 trailed to a stop, hovering silently with one arm outstretched.

“With what!? Just what have you added?” Jammingway insisted, stomping their feet. “If you’ve squashed my carrot cake by crowding the basket, I’m going to be very cross!”

“New life has arrived in Elysion.” N-7000 whirred, effectively ignoring Jammingway’s one-sided tirade. “Repeat, new life has arrived in Elysion. Scanners indicate only one life-form at this time.”

“What? Only one?” The carrot cake was completely forgiven—or forgotten for the time being—as Jammingway immediately shifted into entrepreneur mode. “That’s odd. Normally they show up in groups. Still, you know what they say: where one is, more may follow. The picnic will just have to wait. You don’t mind, do you?”

“Not at all!” Eachna secretly breathed a sigh of relief. Carrots were not her favorite by any stretch of imagination, but Jammingway seemed determined to believe that everyone loved the orange vegetable just as much as they did. Perhaps she could sneak away long enough to check the contents of this picnic basket for herself….

“That settles it, then!” Jammingway beamed, hands on their hips. “Lead the way, N-7000! Let’s go meet our newest friend!”

_______________________________________________

“Are you absolutely certain the new life form landed up here?” Jammingway balanced precariously atop N-7000’s chassis, shielding their eyes with one paw from the glaring light of the dynamis staircase. The summit of the dead sun was shadowy in comparison, the bed of Elpis flowers a faint glow in the near distance. “All I see are stairs, stairs, and more stairs.”

“Affirmative. New life-form scan readings indicate this as the proposed landing trajectory.”

“But I thought that Stigma-4 created the simulations,” Eachna said, practically jogging to keep pace as they climbed the endlessly winding stairs. “Does the star just… spit them out?” Jammingway shrugged.

“Your guess is as good as mine. Normally they find Elysion long before we find them.” They lurched, grabbing hold of N-7000s rabbit ear accessories as the staircase grew steeper. “I wonder what sort of life-form we’ll meet this time? Do you recall any other civilizations from the Dead Ends?”

“I don’t think so.” All the civilizations she’d seen in the heart of the dead star were already café patrons: sweet, chubby Grebuloffs; armored, pedantic Karellians; graceful, nihilistic Nibiruns. As she pondered these strange races, she found her own curiosity rising alongside Jammingway’s. What would this new life-form look like?

Would they be large and powerful like the wraithlike dragons, or perhaps smooth and gelatinous like the Ea? Figure after figure flashed through her mind’s eye: malformed voidsent, gaunt sin eaters, bewhiskered kobolds, feathery Vanu Vanu, impish pixies… would this new person’s shape be something familiar, or wholly new? Would they be calculating, or emotional? Despondent, or hopeful?

Lifting her eyes towards the summit, Eachna stopped short at the sight of a weapon at the top of the staircase: a long, curved blade, wider than the span of her arm at its thickest and tapering to a razor-sharp point. It was attached to an even longer shaft, knocked sideways as though it had fallen from a great height only to lodge itself deep into the cracked earth. Her eyes traced the familiar bony plating along the blade’s outer edge, breath catching in her throat at the sight of a broken revolver cylinder hanging askew from the handle.

“Oh, no.”

“What is it?” Jammingway leaned forward eagerly, ears pricked and nose twitching. “Do you see them?”

“It can’t be.” The reaper stone seemed to burn a hole in the pocket of her knapsack, the collected aetheric signatures within drawn to the scythe at the top of the stairs. She gulped back the emotions threatening to overpower her, gorge rising and fingertips tingling at the memory of fighting to draw her bow with slippery, bloodstained hands. Her very muscles seemed to burn with a phantom ache, the echoes of a fight that ended only when the last flickering embers of her life could no longer withstand the onslaught.

“Eachna?” Jammingway looked at her strangely. “Are you alright? You look a little pale…. Well, you always look pale, especially here, but this is even worse—”

“Allied unit’s heart rate is increasing at an exponential pace—”

“It just can’t be!” Eachna took the remaining stairs two at a time, tripping on the topmost step in her rush and landing facefirst on the scorched earth. She stumbled to her knees, scraped palms burning as she brushed the stains from her trousers, and groaned aloud at the sight before her. “Oh, isn’t this just a—” Her tongue felt too large for her mouth, jaw working as she searched for the right oath to express the depths of her frustration.

“You!” she finally spat, picking up a handful of the ashen dust and flinging it—rather unsuccessfully—at the figure lying eagle-spread in a heap of crushed flowers. “Damn you to all seven bloody hells!”

“What’s the matter? Is it a— wait a minute!” Jammingway practically wilted on the spot. “That’s no alien life-form! That’s an Etheiryan!”

“Scanners indicate unconscious life-form is composed of dynamis,” N-7000 protested.

“Okay, okay! Don’t blow a gasket.” Jammingway slipped from the unit’s shoulders, dangling for a moment from one clawed appendage before landing deftly, if not gracefully, at its side. “So he’s a dynamis simulation. That still doesn’t explain what an Etheiryan was doing inside the dead star, nor how he came to be there in the first place.”

“Oh… that’s partly my fault.” Eachna winced. “We had a fight to the death, and I might have left him there? Accidentally?”

“You—a fight to—left him—” Jammingway’s look of abject horror gave way to weariness. “I don’t even know which part of that sentence to address first.”

“It’s not like I meant to do it!” Gathering her courage, she crept close enough to toe the heel of one heavy boot. She kicked at it lightly, watching for any signs of regaining consciousness. “Of all the people in all the worlds,” she sighed, “why did it have to be you?”

“Parameters for acceptable simulations of life-forms for Elysion were recently altered by fluctuations in dynamis,” N-7000 stated. “Cause of anomaly: allied unit Eachna.”

“Me!?” she echoed in dismay. “But I didn’t even do anything this time! And I certainly didn’t ask for him!”

“Through dynamis, you expressed a desire—a “wish”, as this overexcited life-form continues to insist—that all sentient beings within Ultima Thule might experience a second chance at life through simulated existence. As this life-form’s last documented location was well within parameters, he has been restored accordingly.”

“I can assure you, this is not what I meant.” Eachna’s shoulders slumped. “Does this even count as a second chance? It’s not really him,” she pointed out. “It’s just a copy.” Even as she spoke, she remembered how he had once transcended death using the power of the Resonance. Could such a thing possibly happen again?

“Regardless of intent, this life-form form now exists in the same capacity as all other life-forms within Elysion,” N-7000 answered. “Metaphysically, we are but memories recreated for the purpose of continued study by Stigma-4. Alternatively, philosophical debate documented between the Ea and the Nibirun suggest that the nature of said existence—whether or not we are “real”—is wholly reliant upon individual interpretation.”

“That means it’s really up to him in the end, isn’t it?” Jammingway mused. “Still, we probably ought to wait until he’s settled in before asking those sorts of questions. Just thinking about them is enough to give me a headache.”

“Cranial pain aside, this unit is in agreement.”

“That’s fine and all, but it still doesn’t help in this situation.” Eachna rubbed her eyes wearily. “You don’t realize what he’s capable of.” She let the knapsack slip from her shoulders, digging through the many pockets until she emerged with her battered codex. Flipping through pages of notes, she finally settled on one near the end and handed it to Jammingway. “This will tell you more than enough.”

“Archaic,” N-7000 buzzed, scanning the page and committing the contents to memory. “Assimilating data for future calculations—!! Results not favorable.”

“You’re not kidding!” Jammingway shook their head, paw sliding down the page as they read through the notes at a slower pace. “If this Zenos wakes up and decides to make Ultima Thule his new hunting grounds, all our hard work could be undone!”

“Calculated levels of despair exceed all known parameters.”

“My point exactly.”

“Query: what course of action should be undertaken?” N-7000 turned to Eachna, scratching its dome. “Immediate termination of life-form would directly oppose the mission objective.”

“That’s also not very fair, is it?” Jammingway closed the codex with a heavy thud. “If we judged every patron based on their past actions, the café wouldn’t have any clientele at all. And after all, you were the one who wanted everyone to have a second chance.”

“Agreed. This unit also acknowledges the accountability of allied unit Eachna.”

“Huh? Why me?!” Taken aback, Eachna raised her hands in an admittedly paltry defense. “What am I supposed to do about him? I can’t very well take him with me when I leave.”

“This is factual. In their current state, simulations would become highly unstable without an accessible form of dynamis. Departure is unadvised.”

“Bugger.” She gazed down at the Garlean prince, sprawled amidst the flowers. The expression on his face was calmer than she’d ever seen it, passive as though in deepest slumber. A part of her hoped that he might be dead, but even in the murky shadow she could see the regular rise and fall of his chest. Each breath stirred the fine blonde hairs trapped beneath his cheek, pale as death against the backdrop of his crumpled cloak.

“Alright,” she finally said. “This is what we’re going to do. N-7000, I want you to take this scythe and hide it somewhere. The café, Elysion, Base Omicron: I don’t care, just so long as it’s in a spot he won’t be able to access easily. We have to make sure he stays unarmed until I can convince him not to go around picking fights with anything that moves.”

“Affirmed. This unit will follow your orders to the best of its abilities.”

“Jammingway, can you make sure no one from the café comes anywhere near this area for a while?” She ran both hands through her curls, tangling them in her fingers and tugging as she thought. “Hopefully I’ll have a plan by the time he wakes up, but in any case it’s probably best that I speak to him alone first. I don’t want to fight him again unless I absolutely have to.” There was no guarantee that she’d be so lucky this time, without the Scions there to pull her back from the brink with their healing magics.

“You can count on me! I’ll make sure no one even looks in this direction until you give the signal!”

“As for me….” Eachna plopped down at his side, stretching her legs as she made herself comfortable. “You’re right. If I summoned Zenos, even by accident, that makes him my responsibility—at least for the moment. I’ll stay here until he wakes up. After that, whatever happens will simply have to happen.” Her tone was nonchalant, borderline cheerful; despite this, the flowers nearest her grew dull with unease.

“This unit would like to call your attention to the Gordhona Guardian located at the Last Dregs. Its protocols advise for the termination of rude intruders.”

“N-7000’s right.” Jammingway returned the codex, flapping their ears with a rosy smile. “If you get into trouble, just scream really loudly and we’ll come running to help. Okay?” She nodded, and together they watched as N-7000 wrenched the scythe from the earth, leaving behind a divot roughly the size of a small fissure.

“By the way, Eachna.” They stared openly at Zenos, nose twitching. “The way I understand it, we Loporrits have a different sort of society than the people on Etheirys. When he was helping us on the moon, Urianger told us all about the different type of relationships you all can have with one another. Some of them seemed relatively straightforward, but others were quite complicated.”

“Yes? What about it?”

“In the codex, you wrote that Zenos thought of you as his friend. But he also tried to kill you, and nearly succeeded.” Jammingway looked at her thoughtfully. “Is that a complicated sort of friendship?”

“I—” Before she could formulate a response, Zero’s words echoed in her mind. Zenos called you "friend." That's what you are? A friend? At the time, she’d been too startled at the sight of his avatar made flesh to say much on the subject. Even now, she had no clue what—or how—she felt about the fallen prince. Jammingway waited patiently for her answer, bright eyes unwavering.

“I think… that it was very complicated,” she agreed slowly. “Whether it still is remains to be seen.” Jammingway nodded, reaching out to pat her knee gently before following N-7000 down the glowing stairs. Eachna watched them leave, squinting until they were little more than two floating dots in a sea of shadows. She reached out and picked a flower, twirling the stem between her fingers as she thought.

Everyone deserves a second chance, the little voice in her head whispered. It often reminded her of Fray, only less bloodthirsty and more argumentative. But society so loves to force its arbitrary rules. Gaius serves Werlyt while Yotsuyu lies cold in the grave. Miracles happen every day, but Hermes will never regain what was lost. You yourself are torn between your brotherly love for Themis and the knowledge that you are destined to end his life. Why must one earn repentance while another suffers? What balance can be found in this mindless rule?

They earn repentance through their deeds, she argued, plucking the petals from the stem. By learning from the past and choosing to make amends.

Is that the case? Well, then: who are you to deny him that choice? You are his mirror, the reflection of what he can become. If he must learn, then teach him. If he needs growth, guide him.

And at the end, if he still chooses to dream of battle? What then?

Why, then you take responsibility.

“Seven hells,” she muttered, casting the petals aloft. With no breeze to bear them, they fluttered to land at her heels. “How am I supposed to teach you to behave?” she asked the sleeping figure, tracing his jawline with her eyes. “Are you even going to listen to me?” But towards you and you alone, he behaved...differently. And I cannot fathom why.

“I guess we’ll find out together.”

#ffxiv#Final Fantasy 14#Final Fantasy XIV#fanfiction#zenoswol#Endwalker Spoilers#multichapter#zenos yae galvus#hyur highlander#hyur wol#jammingway#N-7000#Ultima Thule#Omicron Tribe Spoilers#enemies to friends to lovers#more like enemies to friends to ???? bc i don't know what they think they are#this is not an 'i can fix him' fic btw#he is still very much The Same in a lot of ways#but there is softer moments#and a lot of stuff based on the Omicron quest ideas of hope and redemption#my writing

8 notes

·

View notes

Text

#Global Distributed Fiber Optic Vibration Sensor Market Size#Share#Trends#Growth#Industry Analysis#Key Players#Revenue#Future Development & Forecast

0 notes

Text

Smart Maintenance for Chemical Operations

As you know that maintenance is essential a routine activity in the chemical industries. Without applying to this, machinery equipment gets failure, increase downtime, and safety dangers. Predictive Maintenance in Chemical Plant; apply techniques have given way to increasingly sophisticated, data-driven methods in the sector over time.

Importance of Predictive Maintenance

Chemical plants are complicated environments with high-pressure systems, corrosive ingredients, and sensitive operations. The margin for mistake is small, making dependable equipment performance critical.

Here’s why predictive maintenance is so critical in chemical plants:

Safety First

In a chemical factory, equipment failure can result in fires, explosions, or poisonous leaks. Predictive maintenance allows identifying any early signs of failure, and potentially preventing catastrophic incidents.

Minimizing Downtime

Unrealistic shutdowns can increase cost chemical companies thousands—even millions—of dollars each hour. Predictive maintenance is to helping the operations running properly by arranging repairs during planned downtime.

Reducing Maintenance Costs

Rather than, of replacing parts that are still operational or dealing with emergency repairs, PdM concentrates maintenance efforts only when absolutely necessary. This lowers labor, spare component, and equipment replacement expenses.

Increased Equipment Lifespan

Predictive maintenance reduces machine stress and extends the operational life of expensive equipment by addressing problems early on.

Meeting Regulatory Compliance

Chemical factories are heavily regulated, and unexpected failures can result in fines, violations, or shutdowns. PdM promotes better compliance by ensuring that systems run safely and within regulatory limits.

How Predictive Maintenance Works?

Predictive maintenance enables with several technologies and data analytics methodologies, including:

Sensors and Internet of Things Devices

Devices attached to pumps, motors, and valves collect information such as temperature, vibration, pressure, and fluid levels.

Condition Monitoring

Vibration analysis, thermography, oil analysis, and sound monitoring parameters allowing to identify any anomalies.

Data Analysis and Machine Learning

The collected data get examined using complex algorithms to find patterns and anticipate when equipment will break.

Maintenance Scheduling Tools

Once an issue is identified, software platforms generate maintenance notifications and interact with corporate systems for scheduling.

Case Studies and Real-World Benefits

With remarkable outcomes, a number of multinational chemical industries have adopted predictive maintenance.

For example, a major European petrochemical plant that integrated IoT-based condition monitoring into all of its major systems saw a 30% reduction in unscheduled downtime.

By detecting scaling and fouling before it affected production, a specialized chemicals business in the United States was able to prolong the life of crucial heat exchangers.

In order to prevent process interruptions during moments of high production, an Indian fertilizer company employed machine learning to predict pump failures and arranged shaft alignment services, including laser shaft alignment, to ensure optimal equipment performance.

Challenges and Considerations

Although predictive maintenance has several advantages, there are drawbacks as well:

Upfront expenses are necessary for personnel training, software installation, and sensor installation.

Without the appropriate tools, handling and evaluating massive amounts of data can be challenging.

Operational and cultural adjustments are necessary when switching from conventional maintenance techniques to a predictive model.

But these obstacles are slowly vanishing as technology gets easier to use and more accessible.

Future Outlook

Predictive maintenance in chemical plants will become more integrated with digital twins, cloud computing, and artificial intelligence (AI) in the future.

Predictions will become even more precise because to these developments, allowing for completely autonomous maintenance systems.

Predicting and optimizing every facet of plant operations is the aim, not merely responding or preventing.

So, our team also deals in many Laser Alignment Services, including Windmill Laser Alignment Services, EOT Crane Alignment, and other Geometrical Alignment Services.

0 notes

Text

Thin Double Sided FPC Market: Key Players, Competitive Analysis, 2025-2032

MARKET INSIGHTS

The global Thin Double Sided FPC market size was valued at US$ 2.73 billion in 2024 and is projected to reach US$ 4.78 billion by 2032, at a CAGR of 8.6% during the forecast period 2025-2032. While the U.S. market accounted for 28% of global revenue in 2024, China is expected to witness the fastest growth with a projected CAGR of 7.9% through 2032.

A thin double-sided flexible printed circuit (FPC) is a specialized circuit board that combines enhanced flexibility with double-sided micro-wiring capabilities through an ultra-thin substrate (typically under 0.1mm thickness). These advanced PCBs reduce mechanical stress and bias force while maintaining high-density interconnects, making them ideal for compact electronic devices. Key material variations include gold-plated (accounting for 42% market share) and copper-plated (38% share) configurations, each offering distinct conductivity and durability characteristics.

The market growth is primarily driven by expanding applications in consumer electronics (58% of 2024 demand), particularly smartphones and wearables requiring lightweight, bendable circuitry. Furthermore, automotive electrification trends are creating new opportunities, with FPCs increasingly used in advanced driver-assistance systems (ADAS) and in-vehicle infotainment. Recent technological developments include Nitto Denko’s 2023 launch of a 25μm ultra-thin FPC with improved heat resistance, addressing growing thermal management requirements in 5G devices. Market leaders Nippon Mektron and Sumitomo Electric continue to dominate, collectively holding over 35% of global production capacity.

MARKET DYNAMICS

MARKET DRIVERS

Proliferation of Consumer Electronics to Spur Demand for Thin Double-Sided FPCs

The consumer electronics industry remains the largest end-user of thin double-sided flexible printed circuits (FPCs), accounting for over 60% of global demand. This dominance stems from the technology’s ability to enable miniaturization while maintaining reliability in smartphones, wearables, and tablets. With smartphone shipments projected to reach 1.2 billion units annually by 2025, manufacturers increasingly adopt thin double-sided FPCs for their space-saving advantages in high-density interconnect (HDI) designs. These circuits allow for complex multilayer routing in constrained spaces – a critical requirement as device thickness continues to decrease while functionality expands. Recent innovations in gold-plated FPCs offer enhanced signal integrity, further driving adoption in premium consumer devices. The trend towards foldable displays has created additional demand, with FPCs enabling the necessary flexible connections between hinge components.

Automotive Electrification and ADAS Adoption Accelerates Market Growth

Automotive applications represent the fastest-growing segment for thin double-sided FPCs, with demand escalating at nearly 15% CAGR. This surge correlates directly with the automotive industry’s rapid transition to electric vehicles (EVs) and advanced driver-assistance systems (ADAS). Modern vehicles now incorporate over 100 FPCs on average, handling everything from infotainment systems to battery management. The thin double-sided variant proves particularly valuable in EVs where weight reduction is paramount – these circuits can be up to 70% lighter than traditional wiring harnesses while offering superior vibration resistance. Autonomous driving systems further compound demand, requiring high-reliability interconnects for sensors and cameras that must withstand harsh automotive environments. Major manufacturers have responded by developing automotive-grade FPCs with enhanced thermal and chemical resistance, opening new avenues for market expansion.

➤ Leading automotive suppliers have begun incorporating double-sided FPCs in battery monitoring systems, where their thin profile allows integration between cells while monitoring voltage and temperature with minimal space consumption.

MARKET RESTRAINTS

High Manufacturing Costs Limit Adoption in Price-Sensitive Markets

Despite their advantages, thin double-sided FPCs face significant adoption barriers due to production costs that can be 40-60% higher than single-sided alternatives. The sophisticated manufacturing process requires specialized equipment for precise laminating of ultra-thin substrates, along with advanced plating techniques to ensure reliability. This cost premium makes the technology less accessible for budget-oriented applications, particularly in developing markets where price sensitivity remains high. While material innovations continue to drive costs down, the gap remains substantial enough to limit market penetration in mid-range consumer products and industrial applications where cost often outweighs performance benefits.

Technical Challenges in High-Frequency Applications Hinder Wider Implementation

As electronic systems push toward higher frequencies to support 5G and millimeter-wave applications, thin double-sided FPCs face signal integrity challenges. The very thin dielectric layers that enable flexibility can lead to increased crosstalk and insertion losses at frequencies above 10GHz. This poses particular difficulties for RF applications in telecommunications infrastructure and advanced radar systems. While manufacturers have developed specialized materials with low dielectric loss tangents, these premium solutions come at substantially higher costs. The industry continues to grapple with balancing electrical performance, mechanical flexibility, and economic feasibility in next-generation applications.

MARKET OPPORTUNITIES

Medical Electronics Emerges as High-Growth Vertical for Thin Double-Sided FPCs

The medical device sector presents substantial untapped potential, with the global medical electronics market projected to exceed $80 billion by 2027. Thin double-sided FPCs are increasingly specified for implantable devices and wearable medical monitors where flexibility and reliability are paramount. Applications range from cochlear implants to continuous glucose monitors, where the technology’s biocompatibility and fatigue resistance offer distinct advantages. Recent regulatory approvals for novel medical wearables have accelerated development cycles, prompting manufacturers to develop medically-certified FPC solutions with enhanced durability and sterilization compatibility. The trend toward minimally invasive surgical tools also creates demand for ultra-thin FPCs that can navigate tight anatomical spaces while maintaining signal integrity.

Roll-to-Roll Manufacturing Breakthroughs Promise Cost Reductions

Emerging roll-to-roll (R2R) production techniques could significantly lower thin double-sided FPC manufacturing costs while improving yield rates. Current batch processing methods limit throughput and contribute to material waste, but continuous R2R approaches demonstrate potential for 30-40% cost reductions at scale. Several industry leaders have made substantial R&D investments in this area, with pilot production lines already demonstrating promising results for consumer applications. Successful commercialization of these methods could dramatically improve the economic viability of thin double-sided FPCs, potentially opening new application areas in IoT devices and smart packaging where cost has previously been prohibitive.

MARKET CHALLENGES

Supply Chain Vulnerabilities Impact Material Availability

The thin double-sided FPC market faces ongoing supply chain challenges, particularly for specialized polyimide substrates and high-performance adhesives. Over 70% of polyimide production remains concentrated in a limited number of facilities, creating bottlenecks during periods of high demand. Recent geopolitical tensions have exacerbated these issues, with trade restrictions affecting material flows between key manufacturing regions. Manufacturers must navigate extended lead times while maintaining inventory buffers – an expensive proposition given the high material costs. The situation has prompted some producers to explore alternative substrate materials, though these alternatives often require extensive qualification processes that delay time-to-market.

Technical Workforce Shortage Constrains Production Scaling

Industry expansion faces significant headwinds from a global shortage of skilled technicians capable of operating advanced FPC manufacturing equipment. The specialized nature of thin double-sided FPC production requires extensive training in precision lamination, laser drilling, and micro-via plating processes. As veteran operators retire, manufacturers struggle to fill positions, with some reporting vacancy rates exceeding 20% for critical technical roles. This skills gap has forced companies to invest heavily in training programs while simultaneously slowing capacity expansion plans. The challenge is particularly acute in established manufacturing hubs where competition for skilled labor is most intense.

THIN DOUBLE SIDED FPC MARKET TRENDS

Rising Demand for Compact Consumer Electronics to Drive Market Growth

The global thin double-sided FPC market is experiencing robust growth, primarily driven by exponential demand for lightweight and compact consumer electronics. Smartphones, wearables, and foldable devices require high-density, flexible circuits to accommodate advanced functionalities while maintaining slim form factors. The consumer electronics segment currently accounts for approximately 52% of total market revenue, with projections indicating sustained growth at a CAGR of 8.4% through 2035. Furthermore, the miniaturization trend in IoT devices and portable medical equipment continues to accelerate adoption of these ultra-thin circuit boards.

Other Trends

Automotive Electronics Modernization

The automotive sector is witnessing a paradigm shift in electronic architecture, with thin double-sided FPCs becoming critical enablers for next-generation vehicle designs. Modern vehicles now incorporate over 70 electronic control units on average, each requiring reliable connectivity solutions. Flexible printed circuits provide the necessary durability to withstand vibration and thermal stresses in automotive environments. Market analysts project the automotive electronics segment to grow at 9.7% annually through 2030, fueled by increasing autonomous driving capabilities and electric vehicle production.

Material Innovation and Manufacturing Advancements

Material science breakthroughs are significantly enhancing the performance characteristics of thin double-sided FPCs. Recent developments in polyimide substrates with improved thermal conductivity (up to 2.5 W/mK) allow for better heat dissipation in high-power applications. Meanwhile, advanced plating techniques now enable copper trace thicknesses below 10μm while maintaining excellent conductivity. Manufacturing innovations such as roll-to-roll processing have increased production efficiency by 28% compared to traditional batch methods, contributing to cost reductions across the supply chain.

Geographic Market Expansion

Asia-Pacific continues to dominate the thin double-sided FPC market, representing about 63% of global production capacity. While China maintains leadership in volume manufacturing, Southeast Asian countries are emerging as competitive alternatives due to lower operational costs. North America and Europe are experiencing above-average growth rates (7.9% and 6.8% respectively) driven by demand for specialized aerospace and defense applications, where reliability and performance outweigh cost considerations.

COMPETITIVE LANDSCAPE

Key Industry Players

Market Leaders Leverage Innovation and Strategic Partnerships to Maintain Dominance

The global thin double-sided FPC market features a moderately consolidated competitive landscape dominated by major Asian manufacturers, with Nitto Denko and Nippon Mektron collectively holding approximately 25% market share in 2024. These established players benefit from decades of experience in flexible circuit technology, vertically integrated manufacturing capabilities, and strong relationships with electronics OEMs.

While Japanese firms traditionally led this space, Korean and Chinese competitors like Sumitomo Electric and MFS Technology are rapidly gaining traction through aggressive pricing strategies and expanding production capacities. This shift reflects broader supply chain realignments as global electronics brands diversify their supplier base.

Recent industry developments show established players are responding to competitive pressures by: – Investing in advanced roll-to-roll manufacturing technologies for higher yields – Developing thinner substrates (below 25μm) for next-gen wearables and foldables – Expanding application-specific product lines for automotive and medical markets

Meanwhile, emerging Chinese manufacturers such as Shenzhen Baolifeng Electronic and JiangXi Redboard Technology are disrupting traditional value chains through localized production and shorter lead times, particularly for domestic smartphone makers.

List of Key Thin Double Sided FPC Manufacturers

Nitto Denko (Japan)

Nippon Mektron (Japan)

Sumitomo Electric (Japan)

DK-Daleba (South Korea)

Oki Electric Cable (Japan)

TATSUTA Electric Wire and Cable (Japan)

Meiko Electronics (Japan)

NOK Corporation (Japan)

Qdos (Singapore)

MFS Technology (Singapore)

Uniflex Technology (China)

Best Technology Co (China)

Shenzhen Meidear (China)

3G Technology Co (China)

DSBJ (China)

Segment Analysis:

By Type

Gold Plated Segment Leads Due to Superior Conductivity and Durability in High-Frequency Applications

The market is segmented based on type into:

Gold Plated

Subtypes: Electroplated Gold, Immersion Gold

Copper Plated

Subtypes: Rolled Annealed Copper, Electrodeposited Copper

Others

By Application

Consumer Electronics Segment Dominates Due to Rising Demand for Compact, Flexible Circuit Solutions

The market is segmented based on application into:

Consumer Electronics

Subtypes: Smartphones, Wearables, Tablets

Aerospace

Automotive Electronics

Others

By End-User

OEMs Segment Holds Significant Share Due to Direct Integration in Final Products

The market is segmented based on end-user into:

Original Equipment Manufacturers (OEMs)

Contract Manufacturers

Aftermarket Suppliers

Regional Analysis: Thin Double Sided FPC Market

North America The North American thin double-sided FPC market is driven by strong demand from the consumer electronics and aerospace sectors, particularly in the U.S., which accounts for the largest regional market share. Major manufacturers such as Nitto Denko and Sumitomo Electric have a strong presence here, leveraging advanced manufacturing technologies. The region benefits from high R&D investments—approximately $35 billion annually in semiconductor and electronics research—which fosters innovation in flexible circuitry. However, stringent environmental regulations and rising raw material costs pose challenges for suppliers. Nonetheless, the expansion of 5G and IoT applications continues to fuel demand for high-performance FPCs in smart devices and automotive electronics.