#5 axis cnc machine

Text

As a leading company in the manufacturing and processing field, DADESIN hopes to become your manufacturing and supplier partner for CNC customized machining parts.

0 notes

Photo

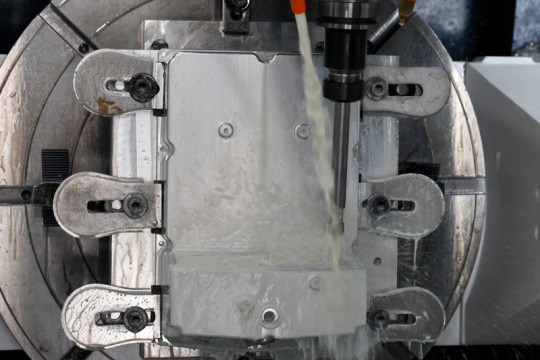

Russian customers visited our factory and felt the charm of Yornew Small CNC Machine.We showed our MX220 Desktop 5 Axis CNC Milling Machine and won their trust. Reached a cooperation intention and create a better future together.If you want to know more about Yornew Desktop 5 Axis CNC Milling Machine. Please visit https://www.miumachine.com/mx220.asp

0 notes

Text

We provide precision CNC machining services, CNC Milling and Turning (3 axis, 4 axis, 5 axis), can manufacture complex and multi-structure plastic and metal parts.

#cncmachining#5 axis machining#cnc milling services#cnc machining parts#rapid prototyping#precision machining

2 notes

·

View notes

Text

Maintenance Tips for Your CNC Turning Machine by MechPlus China

As a leading CNC turning machine manufacturing, MechPlus China understands the importance of proper maintenance to ensure precision and efficiency. Regular upkeep not only extends the machine's lifespan but also maximizes productivity and quality. Here are essential maintenance tips from MechPlus China to keep your CNC turning machine running smoothly and efficiently.

Keeping your CNC turning machine in top condition is crucial for optimal performance. Regular maintenance not only extends the machine's lifespan but also ensures precision and efficiency in your operations. Here are essential maintenance tips to keep your CNC turning machine running smoothly.

Daily Inspection and Cleaning

Start each day with a thorough inspection of your CNC turning machine. Check for any signs of wear and tear, and ensure all components are in good working order. Clean the machine daily to remove any debris, chips, and coolant residue. This prevents buildup that can affect performance and accuracy.

Lubrication

Proper lubrication is vital for the smooth operation of your CNC turning machine. Lubricate all moving parts as recommended by the manufacturer. This includes the spindle, guideways, and ball screws. Regular lubrication reduces friction, prevents wear, and extends the machine’s life.

Coolant Maintenance

Maintaining the coolant system is essential for the longevity of your CNC machine. Regularly check the coolant level and concentration. Replace or refill the coolant as needed. Also, clean the coolant tank and filters to avoid contamination that can damage the machine and workpieces.

Alignment and Calibration

Ensure that your CNC turning machine is properly aligned and calibrated. Misalignment can lead to inaccuracies in your machining processes. Regularly check and adjust the machine’s alignment and calibration according to the manufacturer’s guidelines. This ensures precision in your operations.

Check Electrical Components

Inspect the electrical components of your CNC turning machine regularly. Look for any loose connections, worn-out wires, or faulty switches. Address any electrical issues immediately to prevent machine downtime and potential safety hazards.

Monitor Machine Vibration

Excessive vibration can lead to poor machining quality and damage to your CNC turning machine. Monitor the machine for any unusual vibrations or noises during operation. Identify and address the source of the vibration to maintain optimal performance.

Regular Software Updates

Keep your CNC machine’s software up to date. Manufacturers often release updates that improve functionality and fix bugs. Regularly updating the software ensures your machine operates efficiently and takes advantage of the latest technological advancements.

Tool Maintenance

Regularly inspect and maintain the cutting tools used in your CNC turning machine. Sharp and well-maintained tools are crucial for high-quality machining. Replace worn or damaged tools promptly to ensure precise and efficient operation.

Preventive Maintenance Schedule

Implement a preventive maintenance schedule for your quick response machining tool. Follow the manufacturer’s recommended maintenance intervals for all components. Regular preventive maintenance helps identify potential issues before they become major problems, reducing downtime and repair costs.

Training and Safety

Ensure that all operators are properly trained in the maintenance and operation of the CNC turning machine. Regular training updates and adherence to safety protocols are crucial for preventing accidents and ensuring smooth operations.

Document Maintenance Activities

Keep detailed records of all maintenance activities performed on your CNC turning machine. Documenting maintenance helps track the machine’s condition over time and provides valuable information for troubleshooting and repairs with all types of customized machining parts.

In conclusion, regular maintenance of your CNC turning machine is essential for its longevity and performance. By following these tips, you can ensure your machine operates efficiently, reducing downtime and improving the quality of your machining processes. Implement these maintenance practices to keep your CNC turning machine in optimal condition.

#Prototyping solutions#SLA Rapid Prototyping manufacturing#SLS Rapid machining manufacturing#5 Axis CNC machining manufacturing#3D metal printing manufacturing

2 notes

·

View notes

Note

Bro just straight up pouring molten bronze like it's not the coolest thing in the world wtf

Right now I work in a wood & metals fabrication shop and As a man of many hats if I see a piece of machinery I make it my life goal to get my dirty little hands on operating it at least once (when i was on the pour team i did most jobs but pouring from the big crucible of metal was my favorite and i was pretty good at it. never did the crane bc i have a bad sense of direction and you have to be pretty quick when pouring molten metal)

My next target is this thing:

#5 axis cnc i will get you.#i currently specialize in the 3 axis but i havent been able to learn to toolpath this thing bc its significantly more complicated#and also our shop's is kind of .broken#but i toured a shop that had 7 axis cncs in enclosed cabinets and shit literally the most insane precision machining#idk if i would be able to work in a shop like that but a man can dream#m#answers

5 notes

·

View notes

Text

The Applications of 5 axis machining Across Industries

The keys to success in the field of advanced manufacturing are accuracy and effectiveness. 5 axis machining services are a ground-breaking strategy that has expanded the potential for producing complicated and sophisticated components. In this article, we explore the realm of 5-axis machining, examining its advantages, uses, and the radical changes it has brought about across several sectors.

5-axis Machining: Beyond Traditional Boundaries

To obtain the required form, traditional machining techniques frequently entail moving the workpiece along many axes. However, these techniques have drawbacks when it comes to creating intricate geometries. This is where 5-axis machining comes into play, expanding the realm of what is feasible.

5-axis machining adds two rotating axes (usually A and B), in contrast to 3-axis machining, which moves the workpiece along three linear axes (X, Y, and Z). This gives the tool an unmatched degree of flexibility in its movement, allowing it to approach the workpiece from several angles and orientations. A capacity for producing complex designs, speeding up production, and requiring fewer setups overall is the outcome.

5-axis Machining Shining Applications

· Aerospace: The aircraft sector requires complex, lightweight, yet robust components. In materials like titanium and aluminum, 5 axis machining enables the production of complicated geometries that are essential for airplane and spacecraft parts.

· Medical: The medical industry benefits from the accuracy of 5-axis machining in generating patient-specific components and sophisticated designs that support greater biocompatibility. This includes orthopedic implants and medical gadgets.

· Automobile: Precision 5-axis machining is utilized to create molds, prototypes, and crucial engine components in the highly competitive automobile industry, improving performance and reducing weight.

· Even in the creative sectors, such as art and design, 5-axis machining has a role. By using technology, designers, and artists can bring their imaginative ideas to life by producing elaborate sculptures, molds, and architectural models.

The Challenges and Innovations Ahead

5-axis machining is a constantly evolving field, much like any cutting-edge technology. Its capabilities are being further improved by advancements in automation, real-time monitoring, and adaptive toolpaths, which are turning it into a crucial resource in the industrial environment. Nevertheless, there are still issues like programming complexity and greater startup costs. To fully utilize the potential of 5-axis machining services at the 5 axis CNC machining center, it is imperative to understand the complexities of programming and engage in training.

Follow our Facebook and Twitter for more information about our product.

#5 axis machining#5 axis machining services#5 Axis CNC Machining Center#Custom 5 Axis Machining services#5 Axis CNC Machine Shop#5 Axis Machining Center

3 notes

·

View notes

Text

How 5 Axis CNC Machining Produces Unmatched Flexibility and Precision

0 notes

Text

How 5-Axis CNC Machining Transforms Aerospace Manufacturing?

This blog delves into the game-changing role of 5-axis CNC machining in the aerospace industry. Unlike traditional methods, which often struggle with complex designs and tight tolerances, 5-axis CNC machining provides unparalleled precision and efficiency. Aerospace manufacturers can now create intricate parts with fewer setups, reducing both time and cost while ensuring the highest standards of quality. This technology plays a crucial role in enhancing aircraft performance and safety by delivering parts that meet stringent aerospace requirements.

Additionally, the blog emphasizes the adaptability of 5-axis CNC machining for handling various materials such as aluminum, titanium, and composites, commonly used in the aerospace sector. By minimizing material waste and optimizing production workflows, this advanced machining technique has become indispensable for manufacturers aiming to remain competitive in the ever-evolving aerospace market.

For a deeper understanding of how 5-axis CNC machining is revolutionizing aerospace manufacturing, read the full blog here.

0 notes

Text

CNC / VMC Machining Job Work & CNC Machining Components in India— Pitrukrupa Engineering

Pitrukrupa Engineering is country’s leading Manufacturer, Exporter and Supplier firm offering high performing CNC Milling and Turning Components since its inception in 2009.

Our CNC Machining Work

We are offering CNC Machining job Work to our clients. For accomplishing this work, experts bank on innovative machines and important tools.

CNC Machining Work

CNC Job Work

Precision Machining Work

VMC Machining Work

Milling Machining Work

HMC Machining Work

CNC Turning Machining Work

EDM Wire Cutting Work

CNC laser Cutting Work

CNC Bending Work

CNC Machining Components & Parts

We are offering CNC Components to our clients. For accomplishing this work, experts bank on innovative machines and important tools.

CNC Lathe Machining Component

5 Axis Milling Components

4 Axis Milling Components

CNC Turn Mill Components

CNC Turn Mill Machining Parts

Aerospace and Defence Machining Parts Manufacturing

Aluminium And Steel Precision Welding Fabrication

Aluminium High Pressure Die Casting

Aluminium Extrusion

For More Details

Click Here : https://www.pitrukrupaengineering.com/

#Machining Job Work#CNC Machining Work#CNC Job Work#5 Axis Milling Components#4 Axis Milling Components#CNC Turn Mill Machining Parts

0 notes

Text

CNC precision machining parts

#design#autos#business#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#cnc precision machining#cnc precision#high precision#precision cnc machining#5axismachining#5 axis cnc machining#5 axis cnc#5 axis

0 notes

Text

Simultaneous 5-axis CNC milling is an advanced processing technique that can manufacture high-precision and complex part. Every part will be perfectly splendid machined by 5 axis milling.

0 notes

Text

cut out the inner rectangle on the countertop using milling cutter

0 notes

Text

The Benefits Of Using 5-Axis CNC Machining

5-axis CNC machining is a highly specialized process that utilizes advanced machine tools to produce complex components and parts with incredible precision.

5-axis CNC machining centers are available easily and throughout the world. Even if your machine gets broken, the 5 Axis Machining Manufacturer services are so professional and efficient that they can repair your machine quickly in no time.

Compared to more traditional manufacturing methods, 5-axis CNC Machining offers several key advantages, including:

Greater Control Over Part Geometry

Increased Accuracy And Repeatability

Faster Production Times

Greater Flexibility In Design

Improved Surface Finish Quality

Reduced Setup Time And Costs

Increased Material Utilization

Greater Part Complexity And Size

Increased Production Efficiency

Greater Safety For Workers

To view more information visit here - https://www.tirapid.com/5-axis-machining/

1 note

·

View note

Text

The Top 4 Benefits of CNC 5 Axis Machining

When it comes to machining, having a rotary table that can tilt is a major advantage. This is because it allows for multi-axis machining, which means that more complex parts can be produced with greater accuracy and precision. Silver CNC is a leading manufacturer of CNC 5 axis tilting rotary tables, and in this infographic, we'll explore some of the benefits of using a tilting rotary table for your next project. Here are four benefits of CNC 5 Axis Machining.

For more information about 5 axis rotary table, visit here: https://www.silvercnc.com/product/5-axis-rotary-table/

#CNC 5 Axis Machining#Benefits of CNC 5 Axis Machining#5 axis rotary table#CNC 5 axis tilting rotary tables

0 notes

Text

5 axis CNC machining PC parts

11 notes

·

View notes

Text

CNC precision machining part

#design#autos#business#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#cnc precision machining#precision cnc machining#cnc precision#5 axis cnc#5 axis#5 axis machining#5 axis cnc machining#metal machining#metal products#metal cnc

1 note

·

View note