#AHU controllers

Explore tagged Tumblr posts

Text

Enhancing AHU Performance with PLC-Based Control Systems

Imagine a world where your building breathes in oxygen. Where comfort meets air quality, and where energy is saved. It is the world where AHUs and PLC control systems are the starting point of everything in the domain of Energy management systems.

These AHU controllers (Air Handling Units) are the primary components of any new HVAC system. They serve as the lungs. But to make those lungs breathe better, smarter, and cleaner, you need a brain—enter the Programmable Logic Controllers (PLC).

We at Messung Industrial Automation are not just manufacturing PLC automation systems. We engineer intelligence. Smart PLC control is our ambition, and we aim to revolutionize the way AHU controllers operate, using a range of technologies, including Modbus, MQTT, compact PLCs, or IOT-enabled PLC.

What is a PLC-Based AHU Control System?

A PLC-based AHU control system is the ultimate HVAC master conductor. The flow, cooling, heating, and energy consumption of air are all controlled by real-time logic and precision through automation controllers.

Decision-making is the primary responsibility of a IoT enabled PLC (programmable logic controller), not just following instructions. Your AHU is designed to respond to data, adjust to changing surroundings, and function like a finely tuned machine with the help of intelligent controllers.

Whether it’s a mini PLC for a compact setup or a modular PLC for a multi-zone building, this IEC 61131-3 standard controller is the heartbeat of your air management system.

Core Functions of PLC Automation in AHU Controllers Applications

Sensor Integration

Temperature, humidity, CO2, and differential pressure are all sensors that your AHU controllers are equipped with. When it comes to Energy management systems, PLC control systems are necessary for reading, interpreting, and operating raw data.

Our intelligent PLCs work together with sensors to capture every detail of your indoor environment.

Data Analysis & Decision Making

After submitting the data, the PLC Automation magic begins. Our IEC 61131 based PLCs utilize advanced logic and maintain monitoring of variables such as:

Room occupancy

Outdoor air quality

Return air temperature

The intelligence in this scenario is not confined to automation alone it expands to the action of the PLC Control Systems.

Control Actions via Actuators

Now let's talk about the muscle of the operation. By utilizing PLC and Modbus TCP/IP, your automation controllers can dynamically control VFDs (Variable Frequency Drives) to regulate fan speeds while minimizing energy usage.

Actuated Dampers

Want zoned cooling in your building? Each damper is given precise guidance on when and where it should be opened or closed by our compact PLC, down to the second.

Valves

Our PLC automation system manages both hot and chilled water circuits, ensuring thermal comfort with accuracy.

Humidifiers & Dehumidifiers

System Overview: The NX-ERA JET Advantage

NX-ERA JET PLC is a digital command centre that is agile, adaptive, and always on alert as the AHU controllers. We have developed an intelligent and IEC 61131-3 standard PLC Control Systems that combine advanced logic, seamless connectivity, and flexible scalability. The NX-ERA JET is the key to ensuring that every component of your AHU system, including sensors and actuators, operates in perfect harmony.

Features of this IoT enabled PLC at a Glance

Modular PLC architecture is flexible and can be easily scaled for multi-zone management in large or changing infrastructure

The utilization of PLC with TCP/IP facilitates fast and secure communication between devices, including devices connected to remote systems

The integration of MODBUS RTU, Modbus TCP, and MQTT with BMS, SCADA, or cloud-based IoT platforms is facilitated by the native support provided by these protocols.

An integrated HMI that provides real-time, intuitive monitoring, diagnostics, and manual overrides.

Benefits of IoT enabled PLC for AHUs

In modern air handling, the focus isn’t just on moving air but moving it forward. Why? Integrating PLC control systems into AHUs can offer a transformative advantage in performance, sustainability, and adaptability for buildings. We should examine why PLC automation is the primary driving force behind intelligent HVAC solutions.

Improved Energy Efficiency

The value of energy is high, and PLC for energy systems with IEC 61131-3 standards optimizes every kilowatt. We can use our IoT enabled PLCs to save energy - up to 30% a time with intelligently controlled fan speeds, valve positions and damper angles that are real-time. Measurable reductions through these intelligent controllers help to reduce operational costs and greener footprints are not just numbers.

High Precision Control

AHU controllers equate performance with precision. Why? Our IEC 61131-3 compliant PLCs provide precise control over airflow, temperature and humidity. The result? Consistent comfort, efficient performance and strict environmental regulations.

Advanced Diagnostics

The use of intelligent PLCs with IoT systems means that problems can be prevented rather than delayed. With real-time monitoring and fault detection, teams can receive predictive maintenance insights to minimize downtime and maximize up time.

Scalability and Modularity

Our modular PLCs are designed to accommodate the growth of your building, offering compact systems and multi-zone installations. Do you require an immediate upgrade or expansion? These intelligent controllers can scale without complexity.

BMS Integration

Our PLC Control Systems with IEC 61131-3 standard integrates seamlessly with Building Management Systems, creating one intelligent ecosystem. Whether it’s HVAC, lighting, fire alarms, or access control—everything talks to everything for smoother operations.

In a world where data and efficiency are the primary drivers of change, PLC-controlled AHU controllers provide more than just automation; they also offer confidence. Our IoT enabled PLCs enable buildings to thrive rather than just functioning.

Intelligent PLC Control Systems for Smart Buildings

HMI with PLC Controllers - An HMI with PLC controller enables the observation of invisible areas. The entire package, including fan speed and filter life, is conveniently located at your fingertips.

MQTT based PLC and IoT Systems - The integration of IoT enabled PLC and MQTT support enables your AHU to communicate with the cloud, apps, and analytics platforms, simplifying the process of achieving predictive control and remote access.

Real-World Applications

Through PLC-based AHU control systems, we at Messung are changing the possibilities of environments from sterile labs to busy malls. With precision, adaptability, and unparalleled reliability, our intelligent automation controllers tackle the challenges associated with every application.

Pharma Cleanrooms - The precision of pharmaceutical products is essential in their application. The strict GMP standards are adhered to by our PLC control systems, which involve managing temperature, humidity, pressure differentials. The result? Zones that are sterile, upholding drug integrity and safety.

Commercial Buildings - Employee comfort drives efficiency. Our HVAC automation enables seamless climate management of all floors and departments. By utilizing intelligent design, efficient air circulation, and real-time monitoring, our IoT enabled PLCs enhance the productivity and satisfaction of customers in spaces.

Data Centers - Servers demand a stable climate 24/7. Even minor temperature fluctuations can compromise data. Our intelligent PLC Control Systems with IEC 61131-3 standard ensure uninterrupted cooling performance, reducing thermal risk and operational downtime.

Energy-Efficient Manufacturing - Today's manufacturers must strike a balance between sustainability and production. Without compromising comfort or compliance, our PLCs maximize AHU performance to reduce energy footprints, reduce emissions, and guarantee stable internal environments.

Wherever there's air to manage and performance to perfect, our Compact PLCs lead the way with intelligent control.

Messung’s Expertise in HVAC Automation

We at Messung lead the way in HVAC automation innovation for organizing smart air movement. Our legacy is created on trust, performance, and innovative control systems that transform indoor environments, not only on technology

Why Choose Messung PLC Automation?

We design smart automation systems rather than only selling PLC Control Systems. With more than four decades of engineering expertise, our PLCs are the favoured option of architects, MEP consultants, HVAC contractors, and facility managers across India and globally. Our internal R&D, field-tested dependability, and quick support system turn us into a progress partner rather than just a supplier.

Built on IEC 61131-3 Standard

To ensure every Messung programmable logic controller is consistent, dependable, and compatible with worldwide systems—today and tomorrow — our automation controllers follow this internationally recognized IEC 61131-3 standard.

Flexible Form Factors

Whether you are managing many air zones throughout a smart high-rise or automating a small rooftop AHU, our compact and modular PLCs meet every architectural and functional requirement.

Comfort, control, and conservation are not optional but rather vital in the quickly changing realm of smart infrastructure of today. Furthermore, realizing this potent triad calls for smart, adaptive control rather than just automation. That is what Messung's PLC-based AHU systems precisely provide. Our programmable logic controllers redefine air handling performance for buildings of all sizes with real-time responsiveness, easy BMS integration, IoT readiness, and IEC 61131-3 standard. Our intelligent controllers offer precision, dependability, and next-generation energy efficiency from sterile zones to skyscrapers. Should excellence be your goal, our IoT enabled PLC guarantees you lead rather than merely follow. Why settle for fundamentals when you may automate brilliance with our smart automation controllers?

FAQs

What makes a PLC suitable for AHU control?

Real-time processing, sensor compatibility, actuator control, and smooth BMS integration define good automation controllers. Messung's smart PLCs with IoT systems check every box

Can a modular PLC (Programmable logic controllers) handle multiple AHU zones?

Absolutely. Modular PLCs like Messung’s NX-ERA JET are great for big buildings since they can span levels and zones.

How does Messung's IoT enabled PLC enhance building performance?

Connecting to cloud systems and providing remote access help our IoT enabled PLCs to maximize energy efficiency and real-time maintenance cycles.

Why is Messung’s NX-ERA JET the ideal, affordable PLC choice for midscale operations compared to traditional compact or mini PLCs?

Messung’s NX-ERA JET offers advanced performance at an affordable price, making it perfect for midscale operations. It outperforms mini PLCs with better speed, scalability, and flexibility, without breaking the budget.

Are MQTT based Programmable logic controllers better than traditional protocols?

MQTT-based PLCs offer faster, lighter, and more effective communication than conventional systems like MODBUS RTU for remote and IoT-intensive applications.

#messing 1st blog ahu link#PLC control systems#Programmable Logic Controllers (PLC).#Messung Industrial Automation#PLC automation systems#Smart PLC control#PLC-based AHU control system#modular PLC#Energy management systems#AHU controllers#IEC 61131 based PLCs#compact PLC#IEC 61131-3 standard PLC Control Systems#MODBUS RTU#Modbus TCP#AHU controllers systems#NX-ERA JET#HVAC solutions#PLC for energy systems#IEC 61131-3 compliant PLCs#modular PLCs#HMI with PLC controller#Pharma Cleanrooms#Commercial Buildings#Data Centers#smart automation systems#programmable logic controller#BMS integration#smart PLCs#Modular PLCs

0 notes

Text

https://posts.gle/diiFZq

Pressure Independent Control

Pressure Independent Control (PIC) valves are advanced control devices designed to maintain a constant flow rate in hydronic heating and cooling systems, regardless of variations in pressure. These valves are essential for optimizing energy efficiency and ensuring consistent temperature control in various applications, including commercial buildings, industrial processes, and residential systems.

Pressure Independent Control valves represent a significant advancement in HVAC technology, offering numerous benefits such as energy efficiency, simplified design, and enhanced comfort. Their ability to maintain constant flow rates under varying pressure conditions makes them an ideal choice for modern heating and cooling systems across various sectors. As industries continue to prioritize sustainability and efficiency, the adoption of PIC valves is expected to grow significantly in the coming years.

0 notes

Text

Infectious Diseases Treatment Room: A Vital Component in Healthcare

Infectious diseases pose significant challenges to public health and medical care. The ability of these diseases to spread from person to person, especially in healthcare settings, demands stringent infection control measures to protect patients, healthcare workers, and visitors. Tuberculosis (TB) serves as a prime example of how infectious diseases can rapidly spread. The disease is airborne and is transmitted when a healthy individual inhales tubercle bacilli expelled by a person with pulmonary TB. The bacteria can spread easily, making it crucial to isolate infected individuals to prevent further transmission.

To address this, healthcare facilities have developed specialized treatment rooms to manage and contain infectious diseases effectively. These rooms play a pivotal role in limiting the spread of dangerous pathogens. One company at the forefront of this development is Utopia, offering advanced solutions for infectious disease treatment room, commonly referred to as isolation rooms.

Utopia-Aire Isolation Room: Advanced Protection Against Contagious Diseases

Utopia-Aire Isolation Rooms are designed with cutting-edge technology to provide a safe and secure environment for treating patients with contagious diseases. These rooms serve the primary function of separating individuals with infectious conditions from the general population, thereby preventing the spread of disease. The rooms cater to a wide range of infectious diseases, including TB, influenza, and other airborne infections that pose significant health risks.

One of the most notable features of Utopia-Aire isolation rooms is the use of negative air pressure technology. In a negative pressure environment, the air pressure inside the room is lower than the pressure outside, meaning air constantly flows into the room but not out. This system effectively prevents infectious pathogens from escaping into other areas of the hospital, reducing the risk of cross-contamination.

The air within the isolation room is drawn into the room through openings such as under the door or through a small crack in a window. This air is then filtered, typically using HEPA filters, before it is expelled outside the hospital. This advanced filtration system ensures that any harmful particles are removed from the air, making it safe to be released into the environment.

Patients in Utopia-Aire Isolation Rooms are treated in a controlled setting where strict infection control protocols are followed, minimizing the risk of spreading diseases both within and beyond the hospital. The rooms are equipped with essential medical equipment to ensure that patients receive the necessary care while being securely contained within an environment designed for their safety and that of others.

The Role of Infection Control in Healthcare

Effective infection control is essential in any healthcare setting, especially when dealing with infectious diseases that can spread rapidly. The goal of infection control is to minimize the risk of transmission between patients, healthcare workers, and visitors. Hospitals must implement strict procedures to limit the spread of diseases, particularly in situations where patients are being treated for highly infectious conditions.

Infection control practices include hand hygiene, the use of personal protective equipment (PPE), and the design of healthcare facilities, such as isolation rooms, that cater specifically to infectious disease treatment. The design of an infectious disease treatment room plays a critical role in ensuring that patients are properly isolated from others.

Utopia understands the importance of infection control and has developed their isolation rooms to meet stringent safety and health standards. These rooms not only separate patients but are also designed to make infection prevention and control more efficient. The effectiveness of such rooms depends on several factors, including airflow, ventilation, and surface cleaning protocols.

By utilizing negative pressure and proper ventilation systems, Utopia-Aire Isolation Rooms help healthcare facilities maintain a safe environment, reducing the risk of disease transmission. The importance of these rooms cannot be overstated, as they provide a controlled environment where patients can receive medical care without endangering the health of others.

Key Elements of Infectious Disease Treatment Rooms

When designing a treatment room for infectious diseases, several key elements must be considered to ensure its effectiveness:

1. Airflow and Ventilation: The room must maintain a constant flow of air to prevent the accumulation of infectious particles. Negative air pressure helps ensure that air flows into the room, minimizing the chances of contaminated air escaping.

2. Filtration Systems: High-efficiency particulate air (HEPA) filters are commonly used to remove harmful pathogens from the air. These filters ensure that any air leaving the room is free from contaminants.

3. Surface Materials: The surfaces inside the isolation room must be easy to clean and disinfect. This helps prevent the spread of infectious diseases through contact with contaminated surfaces.

4. Personal Protective Equipment (PPE): Healthcare workers entering isolation rooms must wear appropriate PPE to prevent the transmission of infectious diseases.

5. Monitoring and Maintenance: Isolation rooms require regular maintenance to ensure that the ventilation and filtration systems are functioning correctly. Additionally, monitoring devices should be in place to track air pressure and other critical factors.

Conclusion

Infectious diseases continue to be a global health concern, making it essential for healthcare facilities to be equipped with the necessary tools to manage and contain outbreaks. Utopia-Aire Isolation Rooms provide an essential solution by offering a safe environment for treating patients with contagious diseases. By using advanced negative air pressure technology and adhering to strict infection control protocols, these rooms play a crucial role in preventing the spread of infectious diseases in hospitals.

As healthcare systems worldwide strive to improve their capabilities in managing infectious diseases, the role of companies like Utopia becomes increasingly important. Their innovative solutions help ensure that patients receive the care they need while safeguarding the health of others, making them a vital component in the fight against infectious disease outbreaks.

In Order To Find Out More Details On Infection Control Singapore Please Be Touch With Us Today Onwards..!

#cleanroom products#cleanroom construction materials#cleanroom equipments#infection control#cleanroom chairs & furnitures#bsc bio-safety laboratory equipments#bio-decontamination#cleanroom equipments singapore#operating room/ surgical room#airconditioning & humidity control#Infection Control#Infection Control Singapore#Infectious Disease Treatment Room#Hospital Ahu & Hvac Equipments#Cleanroom Products#Cleanroom Products Singapore#Cleanroom Construction Materials#Airtech Equipments#Airtech Equipments Singapore

0 notes

Text

X's glasses almost never catch any glare when he's in 3D, while it does so very often when he's in 2D (most notably in his Unlock PV). And it reflects so harshly off the glasses that he's practically doing it on purpose, or at least subconsciously. Almost like he's doing this while he's in the domain he can more overtly control. He ends up being surprisingly easy to read with that added dimension than without. But we still can't read beyond what he chooses to show us in 3D (I say "us" because we're practically the only audience to his 3D-self so far, besides Ahu)

#4k hd detail in 3D mode and we still can't tell shit besides him being a cutie patootie and a smug asshole#10/10 mysterious character#would obsess over again#to be hero x#tbhx#tbhx x#tbhx hero x

105 notes

·

View notes

Text

NEED to know how the powers affect all the other heroes' daily lives.

Is Queen a control freak considering her motto/thing about rules (and ofc her hero name referring to her as a ruler)?

Does E-Soul constantly feel energetic because of the seeming electric powers?

What. is going on with Ahu. Does he like, fail the mirror test all the time because of how he constantly changes shape/appearance?

I would add more but we don't know all that many hero abilities....

44 notes

·

View notes

Text

HFSB

Holy-Fucking-Shit-Batman

So I just reviewed the email of all the things that are wrong with the property in New Orleans:

AHU / RTU Replacement

Temp Air required

Chiller Replacement

AHU #2 caught fire

Forward Lift station controls

Mid ship lift station is missing 1 pump entirely

Main tank pumps are located in a confined space area. Property can’t even inspect this without 3rd party confined space supervision (hole watch, air quality, rescue systems, etc.)

AVS wrote them up on a water heater; property is in the process of replacing this unit located down in the hold.

They’re over plating some areas of bad corrosion per the AVS report.

The potable water system is in need of some repairs.

Siding is deteriorated off of the 2nd floor exterior wall leading to water intrusion and wasp infestations…

So imagine a stationary barge, with poor (if any) air conditioning, makeshift/ modifications/ repairs done over the years, lift stations pump shit/ sewage uphill, if those fail you have bilge alarms going off, you can’t even access the pumps and tanks without supervision (meaning the space is bad), steel plates are being added to cover corrosion, siding is bad/ falling apart, and how could I forget…the potable water system is bad.

Fuck me sideways.

I think I’m about to raise my hourly rates for this project.

7 notes

·

View notes

Text

Top Air Handling Unit Manufacturers in India

Air Handling Units Manufacturers are one of the significant things that ensure air can be efficiently handled in commercial and industrial states. These units help control and circulate air while taking care of clean and hygienic indoor environmental concerns. Since the industry places a lot of importance on AHUs, must power down technology that seems to be the mainstream select as characteristic in hospitals, offices, factories, and malls for Air Handling Unit manufacturers in India.

What is the Role of AHUs? Air Handling Units are responsible for filtering, cooling, heating, and distributing the circulation of air in any given building. By doing so, a sufficient amount of ventilation is guaranteed with the removal of unwanted materials, thus improving the health aspects of our official surroundings. Industries such as pharmaceuticals, IT, food processing, and health make use of AHU to filter the air we breathe. Features of a High-Quality AHU Top manufacturers in India design their AHU with up-to-date technology and durable materials. Some salient features include: - Energy Efficiency – Modern AHUs consume less working power while providing maximum performance - Quality Filters – Effectively remove dust, allergens, and other pollutants thereby shuttering in clean air - Custom-Made Designs – Manufacturers usually provide AHU designs that fit in diverse space requirements and make provision for different airflows. - Durability and Reliability – Made with corrosion-resistant materials, these units last a long time with less maintenance. Aerotech Fans – A Trusted Name in AHU Manufacturing Aerotech Fans holds the pride of being one of the leading Air Handling Unit manufacturers in India and satisfying quality expectations with timely delivery of AHU relevant to indoor air quality and energy efficiency. Its UHUs include customized systems relevant to a small range for offices and high-range for major industry setups. Why Should One Choose Aerotech Fans? - High quality and performance - Custom-built solutions - Low-cost and Energy-efficient Models - Exceptional After-Sales Service Aerotech Fans is your partner in case you look for reliable manufacturers of Air Handling Unit in India. Contact us today to get the best available AHU as per your business needs.

visit- https://www.aerotechfans.in/air-handling-unit/ Address- Plot No. 189, Ecotech Extensions-1, Kasana Greater Noida-201301, (Near Asian Paint) Uttar Pradesh, India

2 notes

·

View notes

Text

The Tragic Love Story of Aurangzeb & Hirabai Zainabadi Mahal

Aurangzeb's portraits may depict an austere man reading the Quran, but there once lurked in him a passionate young man who had considered the "world well lost" for the love of his life.

This story is not an average Valentine’s Day tale. It is about a love affair of a different kind, of a prince known today only as strong-willed, calculating and devoid of a loving bone in his body. It is about Aurangzeb falling in love at first sight.

In 1636, Aurangzeb was a prince and the Governor of Deccan. En route to Aurangabad, he stopped at Burhanpur to pay his respects to his maternal aunt, who was married to Saif Khan, the Governor of Burhanpur. What followed varies in detail in different tellings. But all of them agree that the austere prince fell in love at first sight with one of the women in his uncle’s harem. Her name was Hirabai.

Ma’asir al-Umara, written by Nawab Shams ud Daula Shah Nawaz Khan and his son Abdul Hai Khan, in the 18th century provides a detailed description of the episode:

“One day the prince went with the ladies of his harem to the garden of Zainabad Burhanpur, named Ahu-khanah [Deer Park], and began to stroll with his chosen beloved ones. Zainabadi, whose musical skill ravished the senses, and who was unique in blandishments, having come in the train of Khan-i-Zaman’s wife (the prince’s maternal aunt), on seeing a fruit-laden mango tree, in mirth and amorous play advanced, leaped up and plucked a fruit, without paying due respect to the prince’s presence. This move of hers robbed the prince of his senses and self-control.”

Despite his extremely religious bent, Aurangzeb was a connoisseur of music and a proficient Veena player. Hirabai’s looks, combined with her musical accomplishments, proved irresistible for the prince. He is said to have been so infatuated with her that he gave in to her demand that he taste wine. But before he could, Hirabai revealed that she was just testing his love for her.

A religious prince ready to taste wine, that shows the extent of his feelings for her.

Akbar, in his bid to regulate the harem, had ordered that all concubines should be named after the place they belonged to. So once Hirabai entered Aurangzeb’s harem she was called Zainabadi.

Grieving in solitude

In Ahkam e Aurangzeb, written in 1640, Aurangzeb’s biographer Hamiduddin Khan Nimchah recounts the Burhanpur encounter differently. According to him, the meeting took place when the prince entered the harem unannounced. He fell into a swoon and, on being asked by his aunt, described the reason for the malady and asked for a remedy. He was given Hirabai in exchange for one of his concubines.

The ensuing passion and infatuation is described the same way in Nimchah’s account.

It is said in Ma’asir al-Umara that Aurangzeb’s love affair proceeded to such lengths as to reach Shah Jahan’s ears. Dara Shikoh, who had no love lost for his brother Aurangzeb, is said to have remarked to their father Shah Jahan, “See the piety and abstinence of this hypocritical knave! He has gone to the dogs for the sake of a wench of his aunt’s household.”

But as destiny would have it, Hirabai did not live for long. Her death affected the prince greatly. She is buried in Aurangabad.

Ma’asir al-Umara records that Aurangzeb was so upset by the death of his beloved that he left the palace to go on a hunt. When reproved by the poet Mir Askari (Aqil Khan) for risking his life in that agitated state, the prince replied:

“‘Lamentation in the house cannot relieve the heart,

In solitude alone you can cry to your heart’s content.”

Aqil Khan then recited this couplet of his own composition:

“How easy did love appear, but alas how hard it is!

How hard was separation, but what repose it gave to the beloved!”

The prince could not check his tears. He committed the verses to memory after vainly trying to learn the modest poet’s name.

Incomplete portraiture

Niccolao Manucci, the Italian traveller and writer (1639–1717), too describes this period in Aurangzeb’s life:

“Aurangzeb grew very fond of one of the dancing-women in his harem, and through the great love he bore to her he neglected for some time his prayers and his austerities, filling up his days with music and dances; and going even farther, he enlivened himself with wine, which he drank at the instance of the said dancing-girl. The dancer died, and Aurangzeb made a vow never to drink wine again nor to listen to music. In after-days he was accustomed to say that God had been very gracious to him by putting an end to that dancing-girl’s life, by reason of whom he had committed so many iniquities, and had run the risk of never reigning through being occupied in vicious practices.”

Source: https://scroll.in/article/706290/how-the-heartless-emperor-aurangzeb-fell-in-love-at-first-sight

Picture: Mughal paintings

#desi aesthetic#desi tag#desiblr#desi#desi culture#desi dark academia#desi stuff#desi academia#desi romance#mughal#mughals#akbar#aurangzeb#hirabai zainabadi mahal#zainabadi mahal#tragedy#love story#indian story#indian aesthetic#mughal empire#mohabbat#urdu shayari#shayari#quotes#story#urdu literature

38 notes

·

View notes

Text

The Lonely Worldbuilder Volume I: Vicaria

Welcome to the Hazard Desert, a dusty valley of steam-powered gunslingers, vicious capitalist overlords and all the humble folk in between. This, is my steampunk/western setting, set mainly in a great big dusty valley known as the Great Vicarian Dust Bowl, or colloquially as the Hazard Desert. Vicaria is the greater nation that the Hazard Desert sits in, but realistically there's not much else to the nation. Or, at least not much more important to the nation, for one reason only, the steam crystal. The steam crystal is formed from the highly compressed steam that bursts out of geysers deep under the red sands of the Hazard. These crystals, have very interesting uses, namely their tendency to ignite quite easily, creating a burst of steam. So, these crystals have used in the manufacturing of weapons, revolvers, repeaters, rifles, pistols, shotguns as well as vehicles such as the monowheel: a single-wheeled steam-powered bike, the steam balloon: an enhanced hot air balloon, and much later in their use, to raise a city into the sky. Valve, the capital of Vicaria, soars over the desert. A set of colossal steam vents below the city jet out huge vaporous clouds of steam into the sky. It looks like a steampunk version Attilan, the inhuman city from Marvel (just search the name up and look at image's you'll know what I mean). In order for Valve to continue its flight over the desert, it requires fuel. A constant stream of steam crystals, which come from the many mining towns of the desert. So, Valve circuits the mining towns, hovering over them each for a few days per year, collecting all of the crystals mined over the previous year, before departing to the next town. One of such mining towns, is where my current D&D campaign using this setting takes place. Juggertown, what was once the premier crystal mining town, now lies as a husk of forgotten dreams of false riches. A few decades ago, the town was known as Crystal Rock, and being situated next to the crystal-rich Cogwright Mines, the mining business was booming. Especially in the middle of the Great Steam War, a civil war on the precipice of steam-combustion weapon invention, and a time where the demand for crystals was heavy. However, at the end of the war, the leftover steam-powered tanks known as juggernauts, were repurposed into mining vehicles, bringing terrifying efficiency to the mining trade as the giant drills mounted on them harvested crystals at incredible paces. So, as the constant trundling hum of juggernaut treads became a mainstay in Crystal Rock, and the rock that it was named after was drilled into extinction, the settlement garnered a new name, Juggertown. As a final part on this setting, here are some of the characters my players made. Marrow - Fighter - Gunslinger A gunslinger with a pair of mechanical arms and a very rebellious attitude towards the Valvean Government. Marrow was a former goon for the Mayor of Juggertown but had a harsh change of heart and is an anarchist against the state. Dr. Nick Copperfield - Cleric - Life Domain The former town doctor of Juggertown now relegated to backstreet operations in the shantytown tents of the town outskirts. Dr. Copperfield was outcompeted by a new pharmacy backed by the seemingly-infinite funds of a Valvean businessman that seems to have ill intentions with his business in the town. Ahusaka - Sorcerer - Storm Sorcery An outcast whose body is covered in steam-crystal growths that give him innate control over the steam that powers many contraptions in the desert. As a result of Ahu's affliction, he was raised in his village until around the age of twelve, before being cast out into the desert. Ahu was rescued by a bandit, who took Ahu back to his town and, taking pity on the boy, welcomed Ahu into his gang, raising him an outlaw.

And that's about it. If you made it this far into the post, I don't believe you, and also please ask me questions about and give me feedback on the setting. That is all, thank you and goodbye.

#I HAD TO EDIT THIS POST DOWN UNDER THE CHARACTER LIMIT SO IT IS VERY LONG#ttrpg#dnd#worldbuilding#steampunk#western#fantasy#yapping

2 notes

·

View notes

Text

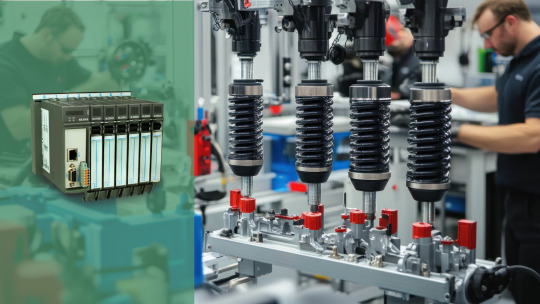

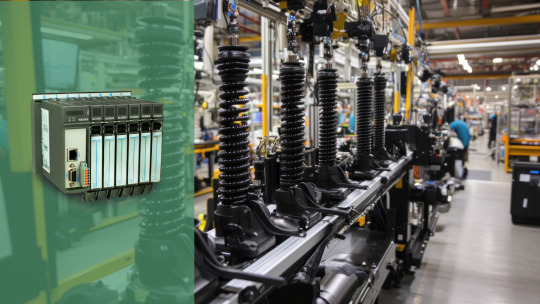

Precision Redefined – PLC-Controlled Shock Absorber Testing Machines

Precision – a word that keeps on getting thrown around often in the world of engineering. However, when it comes to shock absorber testing, precision isn’t a luxury—it’s survival. Every curve, every jolt, every rebound of a shock absorber must be captured, tested, and analysed to microscopic exactness. Gone are the days when manual testing could keep up.

The role of shock absorbers in today’s high-speed automotive innovation and precision engineering is to provide safety, comfort, and performance protection. But how can we make sure that these absorbers meet the high standards required by modern vehicles? This is where PLC automation becomes a useful tool.

The old-fashioned testing methods, which were cumbersome, unreliable, and laborious, have been replaced by PLC-based automation systems. Imagine a testing line with the capacity to think, adapt and respond in real time. The precision of Programmable Logic Controllers (PLCs) is not solely a promise, but rather adherence to standardised protocols.

How PLCs Enhance Shock Absorber Testing

There has been an evolution in the science of testing shock absorbers. Let’s understand how smart and compact PLCs can automate and optimise critical testing stages by providing consistency, control, and clarity.

Centralised Control with High Reliability

A robust industrial PLC is the foundation of our testing machines. The real-time control systems embedded in our automation design enable seamless functioning of all sensor, actuator, and motorised components.

Multiple sensors? Check.

Complex test sequences? Seamlessly handled.

From servo motion controllers managing high-speed vertical displacements to compact PLCs managing individual test stations, the formation is digital, deliberate, and dependable.

Real-Time Data Acquisition & Analysis

Here's where things get exciting. Tests on shock absorbers are more than just passing or failing. It's about quantifiable performance with our automation controllers:

Damping force curves

Displacement maps

Velocity and resistance profiles.

The data is gathered by high-resolution sensors and then processed through HMI with PLC controllers. The integration of this with databases is achieved through integrated PLC-based software, resulting in predictive maintenance and long-term performance insights

Feedback Loops for Adaptive Control

Ever wondered what would happen if the test differs? What would be the outcome? Well, with the use of real-time PLC communication protocols (like MODBUS and Ethernet/IP) and closed-loop control enable our systems to identify anomalies mid-test while enabling automatic correction.

Additionally, dynamic adjustment of actuator velocity in a system is possible when the response rate of the unit is slower than the tolerance. Or if temperatures spike? After a system shutdown, it sends an alert via the web server PLC and logs the fault. This requires more than just testing -- intelligent testing.

NX-ERA JET PLC System Architecture

Now let’s explore the engine room that fuels our innovation. The NX-ERA JET PLC, the foundation of our automated testing platform, undergoes a thorough architecture and connectivity analysis.

Core Hardware Components

With its compact size, modular design, and future scalability, the NX-ERA JET PLC is a formidable beast. It houses:

Simple servo systems designed for precise motion control

Energy-efficient motors can be powered by Variable Frequency Drives (VFDs)

HMI interfaces that enable the creation of visual dashboards and manual overrides

I/O modules for interfacing with third-party equipment.

Its modular design makes it suitable for both high-volume testing environments and small-batch production lines that use Micro PLCs or Mini PLCs

Communication & Connectivity

Connectivity should be a fundamental aspect of the entire setup, not an extra one.

Modbus PLC Interface is responsible for ensuring device-to-device communication

High-speed data relays are made possible with Ethernet-based controller systems

PLC with TCP/IP can be used for remote data logging and system control, as well as firmware updates

IoT-ready PLCs enable the integration of the testing machine with ERP, MES, and SCADA

Key Benefits of PLC-Controlled Testing Machines

Indeed, inefficient processes are not easily exploited in the fast-paced manufacturing industry. Your requirements include testing devices that don't blink even when pressured, systems that guarantee high quality, and technology that evolves as your business grows. Our PLC-based automation solutions are precisely in tune with that.

They offer:

Repeatability and Precision - One unit can be tested with ease and accuracy. But what about testing thousands with zero deviation? Our automation solutions that utilize PLCs accomplish this objective. You get:

Identical test cycles

Calibrated control parameters

Automated calibration routines

It implies improved quality control and enhanced audit accessibility.

High Throughput with Reliability - Traditional systems often require individuals to choose between speed and accuracy. Not here. The configurations of our NX-ERA JET PLC enable:

Sub-second test cycles

Parallel station control

Integrated logic and safety layers

All without compromising test integrity.

Reduced Manual Intervention - By utilizing HMI integration, and adaptive PLC programming, operators can not only monitor and but control:

Reduced human error

Faster changeovers

Safer work environment

Safety and Compliance – Safety is crucial for any industrial setup. With our smart PLCs, you can easily:

Emergency stop circuits

Real-time fault diagnostics

Layered safety logic

PLCs are designed to provide timely and effective alerts and shutdowns, complying with international standards such as ISO and CE.

Adaptable and Future-Ready - Different testing may be required for tomorrow's shock absorber. Good news: you won’t need a new machine.

Reprogram testing logic

Add new motion profiles

Update firmware via PLC with IoT

That’s the power of modular PLCs.

Whether you're chasing precision, throughput, or transformation, our PLC-controlled shock absorber testing machines deliver across the board. These benefits aren’t just technical specs—they’re business advantages, engineered to give you control, confidence, and a competitive edge.

Why Choose Messung’s Programmable Logic Controllers for Automation Solutions

Your choice of controller can determine your plant's success in a world propelled by data-driven decision-making, agility, and accuracy. We offer complete PLC-based automation solutions meant to grow with your demands rather than just supply PLCs. Our PLCs are not only intelligent but also necessary for the following reasons:

Smart and Connected PLCs - Our smart PLCs dynamically optimise by adjusting to handle changes. Embedded intelligence enables them to learn from repeated tests, predict component failures, and optimize actuator profiles automatically. Moreover, our edge-computing enabled PLCs help for quicker decisions by lowering cloud dependence.

HMI Integration for Better User Control - No more enigmatic command-line interfaces. With our smart PLCs, you get touchscreen HMIs, customised dashboards and real-time analytics displays.

Compact and Versatile PLC (Programmable Logic Controller) Options - Squeezed on space? You can get the complete power of a typical controller, without worrying about the size, with our compact PLC, micro PLC, and mini PLC range.

From intelligence that anticipates, to interfaces that simplify, to form factors that adapt—Messung’s PLC Programming range is designed not just to meet your automation goals, but to exceed them. Because when you choose Messung, you don’t just adopt automation; you embrace transformation.

Applications Beyond Shock Absorbers

Although shock absorber testing is where our PLC automation solutions show their power, that's just one section in our automation playbook. Beyond the same technology, fine-tuned for real-time control, precision, and adaptability, extends far. Messung's intelligent PLC solutions provide flexibility and value across a range of sectors, whether you are forming metal or transporting materials.

Let's explore how our PLC Control Systems have a range much outside the damping zone:

Motion Control Systems - Conveyor automation and actuator-driven systems all fall under our motion control solutions. Through synced servo motion controllers, we guarantee millisecond-level accuracy.

Machine Tool Controllers - Integrated with smart CNC tools, our machine tool controllers use feedback to adjust cutting speeds, minimise tool wear and even optimise material usage.

Advanced Automation – Through this end-to-end automation, sending raw material to finished parts, fully automated quality checks and centralized command via connected PLCs can easily become possible.

One shouldn't limit automation to just one purpose. Whether it is in high-speed assembly lines or precise machining at Messung, our PLC automation systems are flexible enough to meet the demands of many industries. Beyond shock absorbers, our solutions usher in intelligent manufacturing possibilities one motion at a time.

Conclusion

Accuracy is a standard, not only a specification. If you are still using obsolete testing configurations, it's time to change course. Designed to bring not just performance but also purpose to your production floor, Messung's PLC-controlled shock absorber testing equipment helps you to achieve this.

Testing has to be quick, adaptable, and flawless, whether you are creating luxury cars or robust trucks. That is precisely what Messung's PLC control systems promise—and deliver.

We do not just automate; we elevate, from servo-tight control to smart data acquisition, from seamless integration to Industry 4.0-based controllers.

At Messung, accuracy is not just redefined. It has changed everything. Hence, go for it. Redefine accuracy. One test at a time!

FAQs

What makes Messung’s PLC Control Systems ideal for shock absorber testing?

Messung’s PLCs (Programmable Logic Controller) offer centralised control, real-time data capture, adaptive feedback loops, and ensure peak accuracy and speed.

Can Messung’s PLC Programming integrate with existing equipment?

Yes. With protocols like MODBUS, TCP/IP, and Ethernet-based controllers, our PLCs are designed for easy retrofitting and compatibility.

How do PLC Control Systems improve the testing process?

PLCs provide real-time emergency stop functionality, error detection, and ensure the equipment runs within safe operational parameters.

Do you offer remote access features?

Absolutely. With web server PLC (Programmable Logic Controller) capabilities and HMI with PLC controllers, you can monitor and manage testing remotely.

Is your PLC solution scalable?

Yes. With modular PLCs and IoT-ready systems, you can scale your setup to match your growth.

#PLC control systems#Programmable Logic Controllers (PLC).#Messung Industrial Automation#PLC automation systems#Smart PLC control#PLC-based AHU control system#modular PLC#Energy management systems#IEC 61131 based PLCs#compact PLC#IEC 61131-3 standard PLC Control Systems#MODBUS RTU#Modbus TCP#NX-ERA JET#PLC for energy systems#IEC 61131-3 compliant PLCs#modular PLCs#HMI with PLC controller#smart automation systems#programmable logic controller#smart PLCs#Modular PLCs

0 notes

Text

How do PICV Valves contribute to energy efficiency in HVAC systems

We offer Pressure Independent Control Valves with matching Actuators or incorporate these in a prefabricated PICV Valve Arrangement. The ½" or ¾" PICV Valve Arrangement is widely used on Fan Coil Units. The larger-size threaded or flanged PICV Valve Arrangement is well-suited for Zone, AHU, branch connection and Plantroom applications. Are you looking for a one stop shop for your fit out? Enquire about our PICV Valve Package, which includes all PICV Valves, General and Public Health Valves as specified on your drawing!

0 notes

Text

What to Look for When Choosing a Cleanroom Solutions Provider

In sectors like pharmaceuticals, hospitals, electronics, and diagnostics, where hygiene, safety, and regulatory compliance are non-negotiable, choosing the right cleanroom solutions provider becomes a critical decision. A subpar installation can compromise not just product quality and patient safety, but also business continuity and compliance with regulatory bodies such as NABH, GMP, WHO, and USFDA.

Whether you’re setting up a modular OT in a private hospital, expanding a pharmaceutical unit, or upgrading a clean zone in an electronics plant, you need a provider who offers turnkey cleanroom infrastructure with deep domain expertise.

In this comprehensive guide, we will explore what buyers should look for in a cleanroom solutions provider, based on insights gathered from top-performing projects across India.

Why the Right Cleanroom Partner Matters

Cleanroom environments are highly sensitive and regulated. An error in design, materials, airflow control, or installation could result in:

Product contamination or rejection

Failed audits by NABH, GMP, or USFDA

Equipment malfunction

Costly retrofits or repairs

Delayed go-to-market timelines

Hence, your provider must offer not just components, but a fully integrated, future-ready solution—from design and engineering to fabrication and compliance support.

Key Factors to Consider When Choosing a Cleanroom Solutions Provider

1. Proven Experience in Regulated Sectors

Cleanroom construction is not like typical interior or civil work. It requires an understanding of environmental control, air changes per hour (ACH), clean zoning, and ISO classifications.

Choose a provider with verifiable experience in:

Pharmaceutical cleanrooms (GMP compliant)

Modular operation theatres (Class 100 or ISO 5)

IVF labs, ICUs, and diagnostic labs

Electronic assembly units (ESD-sensitive)

Food and cosmetic manufacturing clean zones

A provider with sector-specific experience will understand your industry's pain points and regulatory expectations.

2. Turnkey Capabilities

Is your provider offering only panels and doors? Or do they deliver end-to-end turnkey solutions?

Look for companies that can deliver:

Design & layout planning (AutoCAD/3D)

HVAC & AHU systems integration

Cleanroom paneling (PUF, HPL, SS)

Ceiling systems (walkable/non-walkable)

Flooring (epoxy, PU, vinyl)

HEPA filtration systems & LAF units

Electrical, lighting, and smart control panels

Validation documentation & compliance checklists

A turnkey approach ensures better coordination, single-point responsibility, and cost efficiency.

3. In-House Manufacturing Capability

Providers with their own manufacturing units for panels, doors, AHUs, and filters can ensure:

Faster project turnaround

Quality consistency

Custom-built components for unique site needs

Reduced dependence on third-party vendors

In contrast, contractors who only “buy and install” tend to lack control over timelines and quality.

4. Compliance With International & Indian Standards

Your provider should demonstrate strict adherence to major compliance standards:

NABH – For Indian hospitals and surgical units

WHO-GMP – For pharma and biopharma setups

USFDA & MHRA (UK) – For global export readiness

ISO 14644-1 – Cleanroom classification system

IEC & CE compliance – For electrical components and air handling units

Ask for certificates, project references, and third-party audit reports.

5. Technical Depth: HVAC, HEPA, and More

Air purity, pressure, temperature, and humidity control are central to cleanroom performance.

Ensure your provider has expertise in:

Air Handling Units (AHUs) – DX or chiller-based; single/double skin

HEPA Filters (0.3 Micron) – Terminal boxes, LAF units, and risers

Airflow design – Laminar flow, turbulence control, return air risers

Insulations – Thermocol, XLPE, nitrile rubber for Class ‘O’ fire ratings

Ducting systems – GI, SS, or aluminum with MS flange systems

6. Custom Engineering & Flexibility

Every site and use case is different. A good provider should offer tailor-made configurations, such as:

PUF panel thickness options (50mm / 80mm / 100mm)

Flush or glazed doors (single/double)

Manual or remote blinds for observation windows

Modular ICUs with nurse control stations

Touch panels to control lighting, oxygen, AHUs, etc.

Custom engineering ensures your cleanroom integrates seamlessly with existing infrastructure.

7. Project Management & Installation Team

Ask about the team who will execute the job.

A competent turnkey cleanroom provider should have:

On-site engineers and supervisors

Skilled fabricators and installers

NABH/GMP consultants

Commissioning and validation support team

Also verify whether the provider offers pan-India support—a must for large hospital chains and pharma units.

8. Post-Installation Support & AMC

Cleanrooms need ongoing maintenance. Ensure the provider offers:

Preventive Maintenance Contracts (PMC)

Annual Maintenance Contracts (AMC)

Replacement filters, lights, and wear parts

Emergency breakdown services

Validation and documentation support for audits

Frequently Asked Questions (FAQs)

Q1: How do I verify if a cleanroom provider is NABH compliant? Check for project case studies in NABH-accredited hospitals. Ask for documentation and site references.

Q2: What’s the difference between epoxy and PU flooring in cleanrooms? Epoxy is glossy, antimicrobial, and chemical-resistant—ideal for pharma and OTs. PU is matte, impact-resistant, and used in ICUs or food processing areas.

Q3: Are modular cleanrooms better than conventional construction? Yes. Modular cleanrooms are faster to install, easy to modify, and offer better contamination control.

Q4: How important is HEPA filtration in a cleanroom? HEPA filters remove 99.97% of airborne particles ≥0.3 microns. They are crucial for ISO-classified environments.

Q5: Can I get HVAC, cleanroom panels, and flooring from one vendor? Yes. Leading turnkey cleanroom companies offer all systems under one roof—design, manufacture, and install.

Final Thoughts: Build Clean with AUM Industries

When hygiene, efficiency, and compliance are paramount, partnering with a trusted provider like AUM Industries can make all the difference. With a state-of-the-art facility in Gujarat and a pan-India execution team, AUM Industries delivers turnkey cleanroom and modular OT solutions that meet the strictest global and Indian standards.

From cleanroom paneling and modular OT setups to HVAC, HEPA filtration, and epoxy flooring, AUM Industries offers everything under one roof—with unmatched customization, technical support, and post-installation service.

Let’s build clean. Let’s build smart. Let’s build together.

#CleanroomSolutions#ModularOT#TurnkeyProjects#PharmaInfrastructure#HealthcareConstruction#HEPAFilters#HVACSystems#EpoxyFlooring#NABHCompliance#AUMIndustries

0 notes

Text

Hospital Equipment: Stretcher with Physical Containment by Utopia

In today’s world, medical facilities demand advanced equipment that can ensure patient safety, especially when handling infectious diseases or hazardous materials. One such essential piece of equipment is the Stretcher with Physical Containment, designed for the safe transportation of patients, particularly in high-risk environments such as hospitals, research labs, and disaster response situations.

Among the leaders in innovative medical technology is Utopia, a globally recognized company known for its flexible containment systems. Utopia has extensive expertise in designing and supplying integrated containment systems across various industries, including pharmaceuticals, chemicals, medical, and food. Their unmatched knowledge and practical experience with flexible containment technology enable them to offer solutions that meet the highest safety and efficiency standards. One of their standout products is the Stretcher with Physical Containment, designed to safely transport patients while minimizing contamination risks.

What Is a Stretcher with Physical Containment?

A stretcher with physical containment is a specialized piece of medical equipment engineered to transport patients in isolation, preventing the spread of infectious diseases or exposure to hazardous substances. In high-risk environments such as hospitals, especially when dealing with infectious diseases or chemical exposure, traditional stretchers may not suffice. The addition of physical containment ensures the safety of healthcare workers, the environment, and other patients by encapsulating the patient in a controlled, sealed environment.

Key Features of Utopia’s Stretcher with Physical Containment

Utopia’s stretcher sets itself apart due to its robust design, effective containment measures, and ease of operation. Below are the key features and specifications that make this product a leader in its category:

1. Efficiency of 99.9% at 0.3 µm

The physical containment provided by the stretcher ensures an impressive filtration efficiency of 99.9% for particles as small as 0.3 µm. This level of efficiency is critical when dealing with highly contagious pathogens, ensuring that potentially harmful particles are kept inside the containment zone, protecting both the patient and medical staff.

2. HEPA Filter for Enhanced Safety

The main filtration element in the stretcher is a HEPA filter, which is scan-tested to guarantee its effectiveness. HEPA filters are renowned for their ability to trap fine particles such as bacteria, viruses, and allergens, making them ideal for situations where air purification is essential. The HEPA filter on this stretcher ensures that the air circulating within the containment unit is continuously cleaned, minimizing the risk of airborne transmission.

3. Air Volume

The stretcher is designed to handle an air volume of approximately 2.0 m3/min, ensuring efficient air circulation within the containment unit. This air volume capacity allows for quick filtration and air exchange, maintaining a stable environment for the patient without compromising safety.

4. Versatile Power Operation

Utopia’s stretcher offers versatile operation modes, powered by both AC and battery. The dual power option enhances its usability in various settings, including those with limited access to electricity. It can be operated using AC100V 50/60Hz power or DC12V for battery use, ensuring continuous operation in emergency scenarios or during patient transport in ambulances.

5. Transparent PVC Hood

The stretcher comes with an aluminum hood fitted with a transparent PVC cover. This material choice ensures durability while allowing medical staff to continuously monitor the patient without compromising the containment. The transparency also offers psychological comfort for the patient, as they can maintain visual contact with their surroundings.

6. Compact Design and Mobility

Measuring W02090 x D650 x H830, Utopia’s stretcher is compact yet spacious enough to accommodate patients comfortably. The aluminum frame ensures that the stretcher is lightweight, weighing around 92 kg, yet robust enough to support a maximum patient load of approximately 85 kg. The design is optimized for easy maneuverability in hospital hallways, isolation wards, and ambulances.

7. Battery Backup for Uninterrupted Operation

In critical medical environments, continuous operation is essential. Utopia’s stretcher includes a reliable battery backup system to ensure seamless functioning during transport or in case of power outages. The battery-operated system ensures that the filtration and containment functions remain active at all times, even when the stretcher is not connected to an AC power source.

Utopia’s Expertise in Containment Solutions

Utopia is not only a leader in the design and manufacture of containment systems but also has extensive experience in providing practical solutions for the pharmaceutical industry. Their flexible containment systems are used globally, providing safety and security when working with potent materials. Their expertise extends to both new and existing equipment, ensuring that their containment technology can be easily integrated into a variety of medical and industrial settings.

For healthcare facilities handling biosafety level 4 (BSL4) pathogens, Utopia’s expertise in containment is invaluable. The company’s advanced technology and innovative approach allow them to cater to the stringent safety standards required by these high-security environments.

Conclusion

Utopia’s Stretcher with Physical Containment represents the pinnacle of patient transportation safety. Combining advanced filtration technology, efficient air circulation, and a robust, compact design, this stretcher offers peace of mind to healthcare providers dealing with highly infectious or hazardous materials. The attention to detail and commitment to excellence that Utopia has brought to the design and manufacturing process ensures that this product is a reliable and essential tool in any hospital’s arsenal.

With a strong global presence and unmatched experience in containment systems, Utopia continues to push the boundaries of medical technology, making them a trusted partner for hospitals and healthcare providers worldwide.

In Order To Find Out More On Details Cleanroom Construction Materials Kindly Checkout Our Site Today..!

#Stretcher with Physical Containment#Cleanroom Products#Cleanroom Products Singapore#Cleanroom Construction Materials#Infection Control#Infection Control Singapore#Hospital Ahu & Hvac Equipments#Hospital Ahu & Hvac Equipments Singapore#bio-decontamination#bsc bio-safety laboratory equipments#operating room/ surgical room#airconditioning & humidity control#cleanroom equipments singapore#cleanroom equipments#cleanroom chairs & furnitures

0 notes

Text

HVAC Innovations in 2025 – What Clients in Gurgaon Are Asking For

The expectations from HVAC systems in 2025 have gone far beyond cooling and heating. In Gurgaon, where high-rise offices, premium apartments, and mixed-use developments continue to dominate the skyline, clients — from builders to corporate tenants — are demanding more from their HVAC investments.

No longer satisfied with basic functionality, they’re now looking for energy efficiency, intelligent automation, indoor air quality, and systems that align with green building goals. This shift has led the Top HVAC Companies in Gurgaon to rethink design, execution, and after-sales support in order to stay relevant.

Let’s take a closer look at what’s shaping the HVAC conversation in Gurgaon this year.

1. Smart HVAC Systems with Real-Time Control

Gurgaon is a tech-forward market. Many clients, especially corporate tenants in Cyber City, DLF Phase V and Golf Course Road, now expect smart control capabilities — not as an add-on, but as a standard feature.

From smartphone-controlled thermostats to centralised Building Management System (BMS) integrations, automation is in demand. Clients want the ability to monitor and adjust:

Room-wise temperatures

Energy consumption

CO₂ levels and ventilation rates

System faults and alerts

HVAC systems are being connected to the Internet of Things (IoT) for predictive maintenance and data-backed decisions. The Best HVAC Company in Gurgaon today is the one offering not just equipment — but smart, connected climate solutions.

2. Demand for Energy Efficiency and Green Compliance

With rising energy costs and stricter sustainability guidelines, energy-efficient HVAC solutions are top of the list for developers and facility managers. As per a recent CREDAI report, nearly 40% of a building’s energy usage in India comes from HVAC systems.

Clients are now actively asking for:

High ISEER-rated equipment (Indian Seasonal Energy Efficiency Ratio)

Variable Refrigerant Flow (VRF) systems for zoned cooling

Heat recovery ventilation systems

Demand-controlled ventilation using occupancy sensors

These systems not only lower running costs but are also essential to secure certifications like LEED, IGBC, and GRIHA — which are fast becoming market differentiators in Gurgaon’s real estate segment.

3. Indoor Air Quality (IAQ) Is Now a Deal-Breaker

The air quality in NCR remains a serious concern, and post-COVID awareness has made indoor air quality a core decision-making factor for clients. Office tenants, co-working operators, hospitals, and even premium homebuyers are asking how HVAC systems:

Filter PM2.5 and PM10

Regulate humidity levels

Circulate fresh air

Prevent microbial growth in ducts and coils

As a result, there’s a growing push for integrated air purification, UVGI (ultraviolet germicidal irradiation) lamps in AHUs, and advanced filtration systems. Clients want assurance that the air their teams or families are breathing indoors is significantly safer than what’s outside.

4. Noise Reduction and Acoustic Comfort

With the rise of open office layouts and luxury living spaces, acoustic performance of HVAC systems is under the spotlight. Traditional systems often overlook the impact of duct design, grille placement, and unit vibration on noise levels.

Innovative duct silencers, vibration isolators, and silent fan coil units are now being specifically requested. In some cases, clients even ask for acoustic simulation during the design phase — a service now being offered by forward-thinking HVAC consultants.

5. Customisation for Mixed-Use Developments

Gurgaon has seen a surge in integrated developments — retail, commercial, co-living and co-working spaces under one roof. These require HVAC systems that are:

Modular and scalable

Designed to handle varied peak loads

Capable of operating 24/7 in some zones and intermittently in others

This level of complexity demands HVAC partners who can tailor solutions rather than follow a one-size-fits-all approach. It’s one of the key reasons developers are turning only to Top HVAC Companies that have proven experience across sectors.

6. Strong After-Sales Support and Remote Monitoring

Clients are also prioritising post-installation service. With real-time monitoring becoming the norm, many facility heads in Gurgaon now demand:

Remote diagnostics and system health checks

AMCs that include sensor calibration and IAQ reporting

Fast response times in the event of faults

The HVAC partner is expected to not only install but also manage and optimise the system’s performance year after year. The trend clearly shows that best-in-class HVAC providers are investing in tech-enabled service infrastructure.

Final Thoughts

The HVAC industry in Gurgaon is undergoing a quiet revolution — one driven not by suppliers, but by clients who are far more informed and forward-thinking than ever before. They don’t just want cool air. They want clean, efficient, quiet, adaptable systems that evolve with their spaces and support their sustainability goals.

For HVAC firms, staying ahead means embracing innovation, offering smart custom solutions, and becoming long-term partners in performance.

#HVAC contractor in gurgaon#HVAC Consultants in Gurgaon#HVAC Company in Gurgaon#Best HVAC company in gurgaon#Top HVAC companies in gurgaon#Unique Engineers

0 notes

Text

Air handling units (AHUs) are essential components in HVAC systems that regulate and circulate air within buildings. An air handling unit typically contains fans, heating and cooling coils, filters, and dampers to condition and distribute clean, comfortable air. These systems are widely used in commercial, industrial, and residential environments to maintain indoor air quality and thermal comfort. Air handling units play a key role in energy efficiency and occupant health by controlling temperature, humidity, and air cleanliness. Proper maintenance of air handling units ensures consistent performance and helps extend the lifespan of HVAC equipment.

#climategrip#ahu unit#air haldling unit#best in class ahu unit#ahu manufactures#top ahu manufactures in punjab#best ahu manufactures in maharastra

0 notes

Text

HVAC Course in Hyderabad | Rite Academy

In the ever-evolving world of infrastructure, climate control systems are no longer a luxury—they are a necessity. Whether it's a high-rise office building, a modern residential complex, or a manufacturing unit, HVAC systems play an essential role in maintaining a comfortable, energy-efficient, and healthy indoor environment. For individuals who aspire to be a part of this growing industry, enrolling in an HVAC Course in Hyderabad could be the key to unlocking a rewarding and future-ready career. Among the numerous institutions offering this training, Rite Academy stands out as a premier destination for HVAC education.

In this blog post, we will explore the significance of HVAC systems in modern construction, the scope of the HVAC industry, what an HVAC course typically includes, and why Rite Academy is the ideal place to pursue an HVAC Course in Hyderabad.

Understanding HVAC: The Backbone of Modern Comfort

HVAC stands for Heating, Ventilation, and Air Conditioning. It refers to the different systems used for moving air between indoor and outdoor areas, along with heating and cooling both residential and commercial buildings. HVAC systems regulate temperature, humidity, and air quality to create a comfortable environment.

With rising global temperatures, rapid urbanization, and increased focus on indoor air quality, the demand for trained HVAC professionals is skyrocketing. From designing and installing HVAC systems to maintaining and troubleshooting them, the opportunities in this field are vast and varied.

Why Choose an HVAC Course in Hyderabad?

Hyderabad is one of India's fastest-growing cities, renowned for its infrastructure development, IT hubs, and expanding real estate sector. The surge in commercial and residential constructions has directly impacted the demand for climate control solutions, thereby boosting the requirement for certified HVAC technicians and engineers.

Here’s why pursuing an HVAC Course in Hyderabad makes strategic sense:

High Demand for Skilled Professionals: Hyderabad's booming industries need HVAC experts for designing, installing, and maintaining systems in malls, hospitals, tech parks, and more.

Competitive Salary Packages: With the right skillset, HVAC professionals can command lucrative salaries in both the domestic and international job markets.

Diverse Career Opportunities: Roles range from HVAC technician and system designer to energy auditor and project manager.

Modern Training Facilities: Top institutions like Rite Academy offer state-of-the-art laboratories, experienced trainers, and industry-aligned curriculum.

What Does an HVAC Course in Hyderabad Cover?

A comprehensive HVAC Course in Hyderabad like the one offered at Rite Academy typically includes both theoretical knowledge and hands-on training. Here’s an overview of the modules:

1. Fundamentals of HVAC

Introduction to Heating, Ventilation, and Air Conditioning systems.

Understanding thermodynamics, psychrometry, and fluid mechanics.

Basic electrical and mechanical concepts related to HVAC.

2. HVAC System Components

Air handling units (AHU), chillers, compressors, ducts, and filters.

Control systems, sensors, and automation in HVAC.

Refrigeration principles and their applications in HVAC.

3. Design and Installation

Heat load calculations.

Duct sizing and layout.

Equipment selection and system design.

4. Maintenance and Troubleshooting

Preventive and corrective maintenance techniques.

Diagnosing system failures and rectification methods.

Safety protocols and energy efficiency practices.

5. Advanced Topics

Green building concepts and sustainable HVAC.

Building Management Systems (BMS).

Recent technological advancements like IoT in HVAC.

The course duration typically ranges from 3 to 6 months, depending on the level (basic, diploma, or advanced diploma), and includes projects, site visits, and internships.

Career Opportunities After Completing an HVAC Course

Upon successful completion of an HVAC Course in Hyderabad, students can explore several career paths:

HVAC Technician: Installation, repair, and maintenance of HVAC systems.

System Designer: Planning and designing HVAC systems for various infrastructures.

Energy Auditor: Assessing energy consumption and recommending energy-efficient solutions.

Project Engineer: Managing HVAC-related construction or renovation projects.

Service Manager: Overseeing a team of technicians and ensuring client satisfaction.

Industries that recruit HVAC professionals include construction, real estate, manufacturing, pharmaceuticals, data centers, and hospitality, among others.

Why Choose Rite Academy for Your HVAC Training?

If you're looking to enroll in an HVAC Course in Hyderabad, choosing the right institute can make all the difference. Rite Academy has established itself as a leading name in technical and vocational training, particularly in the field of HVAC.

1. Industry-Relevant Curriculum

Rite Academy designs its curriculum in consultation with industry experts to ensure students are trained in the latest techniques, tools, and technologies used in the field.

2. Experienced Faculty

The academy boasts a team of seasoned trainers with hands-on experience in HVAC design, maintenance, and project management.

3. State-of-the-Art Infrastructure

With modern labs, simulation tools, and access to real-world equipment, students at Rite Academy get the best practical exposure possible.

4. Placement Support

One of the key strengths of Rite Academy is its strong network of industry connections. The academy provides end-to-end placement assistance, including resume preparation, interview training, and direct job referrals.

5. Flexible Learning Options

The academy offers both weekday and weekend batches, enabling working professionals to upskill without compromising their current jobs.

How to Enroll in the HVAC Course at Rite Academy

Enrolling in the HVAC Course in Hyderabad at Rite Academy is straightforward:

Visit the Official Website: Learn more about the course details, syllabus, and upcoming batch schedules.

Fill Out the Application Form: Provide your basic details and education background.

Attend a Counseling Session: A career advisor will help you choose the right level of HVAC training.

Start Learning: Begin your training with hands-on sessions, real-time projects, and expert guidance.

Eligibility: 10th, 12th pass, ITI, diploma holders, or even graduates looking to enter a specialized technical field can apply.

Future Trends in HVAC and the Need for Training

The HVAC industry is constantly evolving with new technologies and innovations. Some emerging trends include:

Smart HVAC Systems: Integration with IoT and AI for remote control and predictive maintenance.

Sustainable HVAC Solutions: Focus on reducing carbon footprints through energy-efficient systems.

Modular HVAC Units: Easy-to-install units gaining popularity in commercial buildings.

Demand for Certified Professionals: Employers prefer candidates with verified training and practical exposure.

Staying updated with these trends through structured education like the HVAC Course in Hyderabad at Rite Academy ensures a competitive edge in the job market.

Final Thoughts

If you're looking for a career that combines technical skills, real-world applications, and a high earning potential, HVAC is a smart choice. With the increasing demand for climate-controlled environments and energy-efficient buildings, trained HVAC professionals are more in demand than ever before.

Choosing to enroll in an HVAC Course in Hyderabad will not only provide you with in-depth knowledge and skills but also open up career opportunities across India and abroad. And with Rite Academy as your training partner, you're assured of quality education, hands-on experience, and strong placement support.

CONTACT US;

9121921999

EMAIL ID;

ADDRESS;

Flat No 402, 11-4-659, Bhavya Farooqi Splendid Towers, Red Hills, Lakdikapul, Hyderabad, Telangana 500004.

0 notes