#Advanced pcb

Explore tagged Tumblr posts

Text

Advanced PCB Manufacturing Cost Effective Solutions Partnership

Introducing a one-stop solution for all your advanced PCB manufacturing needs such as rigid-flex pcb. We're not just a provider; we're your partner in innovation, serving customers globally with top-notch fabrication, solutions, and services. Join our Advanced PCB Manufacturing cost effective solutions for USA, EU, Germany, Switzerland.

#Advanced pcb#pcb manufacturer#usa#europe#germany#switzerland#technology#printed circuit board#affiliate program#partnership#electronic

1 note

·

View note

Text

Navigating the Future of Electronics with Rigid-Flex and Taconic PCB Manufacturers

Today’s Printed Circuit Boards (PCBs) are much more flexible and advanced than the first rigid versions. Compact devices with great capabilities and multiple features have earned popularity in the electronics industry, leading to the rise of Rigid-Flex PCBs and Taconic PCBs. The use of these technologies enables unique designs, improves how long the device works, and maintains good electricity flow. Rigid-flex PCB Manufacturers can move and also keep their form, similar to how rigid boards function. They particularly shine in high-speed or RF and microwave applications. Dependable and effective products rely greatly on what electronics do.

Rigid-Flex PCBs: Hybrid Structure with High Functionality

Rigid-Flex PCBs take attributes from both stiff and flexible PCBs and merge them into one board. As a result, rigid and flexible boards no longer need connectors and cables, letting us make assemblies that are lighter and more space-saving. You can find these boards in smartphones, medical devices used on patients, military systems and aerospace devices. They are suited for use in places that require resistance to vibration and bending due to machines. In manufacturing, various layers are made and bonded together using very accurate methods. Therefore, it is only experienced manufacturing companies that can keep products of constant quality and performance.

Key Advantages of Rigid-Flex PCB Manufacturers

Important benefits of using well-known Rigid-flex PCB Manufacturers are their excellent design aid and advanced methodologies. They depend on laser direct imaging for precise work and optical inspection that finds problems in the early stage. Tests using temperature fluctuation and electrical overload guarantee that the product will function in any extreme condition. Manufacturers typically boost efficiency by assisting with design changes that lower the number of components and simplify assembly. In addition, they guarantee that flexible circuit boards meet all IPC standards for quality. Because they are involved in developing products and moving them into mass production, they help make the process more efficient.

Taconic PCBs: High-Frequency Performance Excellence

Taconic PCB Manufacturers are produced from proprietary PTFE-based laminates designed by Taconic with low dielectric loss and thermal stability. These boards are the preferred option for RF, microwave, and high-speed digital designs. They are most prevalent in satellite communications, radar systems, 5G base stations, and aerospace communication modules. Taconic laminates have low signal attenuation and superior dimensional stability. They exhibit moisture resistance as well as heat tolerance, which makes them dependable in extreme working environments. Production using these laminates demands proficiency in drilling, plating, and multilayer bonding because of their special properties.

What to Expect from a Taconic PCB Manufacturers

The best Taconic PCB Manufacturers must possess extensive experience in working with high-frequency laminate material. It involves strict impedance control, surface preparation, and low-loss transmission line engineering. Cleanroom facilities, specially designed PTFE-compatible equipment, and precise lamination procedures are necessary for high-quality output. The producers may perform RF testing and thermal profiling to ensure circuit integrity. They also guide customers on stack-up selection as well as PCB layout according to end-use frequency requirements. By maintaining compliance with IPC and MIL-spec specifications, these companies ensure the critical applications' performance and safety.

Comparing Rigid-Flex and Taconic PCBs

Although both are sophisticated PCBs, Rigid-Flex and Taconic PCBs are for different technical applications. Rigid-Flex is prized for mechanical flexibility, whereas Taconic leads for signal transmission at high speeds. Rigid-Flex boards simplify systems and minimize space utilization in cramped enclosures, while Taconic boards maintain signal purity in communication networks. The components and manufacturing methods are quite different, as are the final-use applications. The two are chosen based on physical space, frequency range, and exposure to the environment. Designers will often talk to both varieties of manufacturers to match their circuit requirements with the appropriate solution.

Conclusion

As innovation speeds up in electronics, the need for Rigid-flex PCB Manufacturers and Taconic PCBs keeps increasing. Such technologies facilitate the development of lighter, faster, and more efficient devices across industries. With increasingly sophisticated design challenges, collaborating with an experienced manufacturer is crucial. BS Interconn Hong Kong Co., LIMITED differentiates itself by providing quality-oriented, customer-centric PCB manufacturing services. Whether you're creating a next-generation medical wearable or a state-of-the-art RF device, selecting a reliable Rigid-Flex or Taconic PCB producer guarantees that your product will outperform and outlast the competition.

#Rigid-flex PCB Manufacturers#Taconic PCB Manufacturers#flexible circuit boards#high-frequency PCB#RF PCB solutions#microwave PCBs#PTFE laminates#hybrid PCB design#aerospace PCB#medical device PCBs#5G PCB manufacturer#signal integrity PCB#low dielectric PCB#high-speed PCB#multilayer PCB assembly#IPC compliant PCBs#MIL-spec PCBs#advanced PCB manufacturing#Taconic laminate PCB#Rigid-Flex technology

1 note

·

View note

Text

Negative Photoresists: Tailored Solutions for Complex Designs

Explore how negative photoresists deliver precision, durability, and high aspect ratio patterning for electronics, MEMS, photonics, and PCB manufacturing. Discover tailored solutions for microfabrication excellence with A-Gas Electronic Materials. Contact us today to learn more.

#negative photoresists UK#microfabrication photoresists#high aspect ratio photoresists#photolithography resists#PCB photoresist materials#microfluidic device photoresists#optical device photoresists#advanced microfabrication solutions#A-Gas Electronic Materials

0 notes

Text

Superior American Circuits for Advanced Electronic Systems

ASC-I offers cutting-edge American circuits designed to elevate the performance of electronic systems. Our circuits are crafted with precision and built to meet the highest standards of quality and durability. Whether for industrial, automotive, or consumer electronics, ASC-I's American circuits provide reliable solutions that enhance innovation and ensure seamless functionality. Trust in our expertise to deliver custom circuit designs that cater to your specific needs. Choose ASC-I for American circuits that drive efficiency, reliability, and success in every application.

#american circuits#asc inc#advanced circuit boards#circuits board#advanced circuit board#thermal circuits inc#us pcb manufacturers#advanced printed circuit board#advanced printed circuits#american pcb manufacturers#american circuit

0 notes

Text

"As the world grows “smarter” through the adoption of smartphones, smart fridges, and entire smart houses, the carbon cost of that technology grows, too.

In the last decade, electronic waste has become one of the fastest-growing waste streams in the world.

According to The World Counts, the globe generates about 50 million tons of e-waste every year. That’s the equivalent of 1,000 laptops being trashed every second.

After they’re shipped off to landfills and incinerated, the trash releases toxic chemicals including lead, cadmium, arsenic, mercury, and so much more, which can cause disastrous health effects on the populations that live near those trash sites.

Fortunately, Franziska Kerber — a university student at FH Joanneum in Graz, Austria — has dreamed up a solution that helps carve away at that behemoth problem: electronics made out of recyclable, dissolvable paper.

On September 11, Kerber’s invention “Pape” — or Paper Electronics — earned global recognition when it was named a national winner of the 2024 James Dyson Awards.

When she entered the scientific competition, Kerber demonstrated her invention with the creation of several small electronics made out of paper materials, including a fully-functional WiFi router and smoke detector.

“Small electronic devices are especially prone to ending up in household waste due to unclear disposal systems and their small size, so there is significant potential to develop a more user-friendly end-of-life system,” Kerber wrote on the James Dyson Award website.

“With this in mind, I aimed to move beyond a simple recycling solution to a circular one, ensuring long-term sustainability.”

Kerber’s invention hinges on crafting a dissolvable and recyclable PCB board out of compressed “paper pulp.”

A printed circuit board (PCB) is a board that can be found in nearly all modern electronic devices, like phones, tablets, and smartwatches.

But even companies that have started incorporating a “dissolution” step into the end life of their products require deconstruction to break down and recover the PCB board before it can be recycled.

With Kerber’s PAPE products, users don’t need to take the device apart to recycle it.

“By implementing a user-friendly return option, manufacturers can efficiently dissolve all returned items, potentially reusing electronic components,” Kerber explained.

“Rapidly advancing technology, which forms the core of many devices, becomes obsolete much faster than the structural elements, which are often made from plastics that can last thousands of years,” Kerber poses.

PAPE, Kerber says, has a “designed end-of-life system” which anticipates obsolescence.

“Does anyone want to use a thousand-year-old computer?” Kerber asks. “Of course not. … This ensures a sustainable and reliable system without hindering technological advancement.”"

-via GoodGoodGood, September 13, 2024

#ewaste#e waste#e waste recycling#e waste management#e waste solutions#paper#sustainability#green tech#tech news#sustainable technology#recycling#good news#hope

586 notes

·

View notes

Note

great ragebait. who’s your idea of a smart person?

idolizing anyone as "smart" in the general sense is going to inevitably lead to embarrassment when they do or say something stupid. building up an expertise in any one field to the extent that you serve as an inspiration for others in that field will result in shortcomings and blind spots elsewhere. great authors are going to have dogshit takes on IP laws. great political theorists are going to make dumbass points about technology. one of my coworkers at my old job could practically rework PCBs blindfolded and also regularly forgot to include water when microwaving cup noodles. Herman Cain was a genuinely groundbreaking neurosurgeon who invented novel procedures to separate the brains of cojoined twins and also thought that the Great Pyramids were used as grain silos.

the reason i'm so dismissive of people who ever held a positive opinion of Elon Musk is because the only things he's ever been held up as "smart" about are things that he's very obviously (to anyone with actual expertise in that field) a dumbass about. he's not good at "technology"; all of his press events featured untested and faked demos (like an "autonomous" humanoid robot being puppetted from the next room over or his brain implants killing test subjects) and listening to him talk about potential future advancements belies a complete lack of experience in the field. he's not good at urban planning: every suggestion he makes in that field is transparently motivated by his desire to sell more cars. he's not good at making cars: they blow up, catch fire in special ways that require FULL IMMERSION IN WATER to put out, have their autopilot fail fatally, and are only cheaper than the competition because of government contracts. he's not good at aerospace: his rockets blow up, are worse than what NASA has been doing by every conceivable metric, and all of his "advances" in that field are focused around fulfilling contracts for the US military centered around sending arbitrary payloads anywhere on earth really fast (which they also can't do). you can't even fall back on the "well at least he knows how to run a business" argument because he's been running Tesla into the ground since buying it from the original inventors with stunts like getting rid of OSHA-mandated yellow safety markings because he doesn't like yellow, to the extent that literally any other human being on Earth would have been forced out by the board of directors years ago. even if you narrow your focus to any one field, Elon Musk has never been anything other than a fraud to anyone who cared to investigate

189 notes

·

View notes

Note

Cactus fascinates me, does it run on code similar to an existing instruction set or is it completely original on that front?

What can you do with it? What's it's storage?

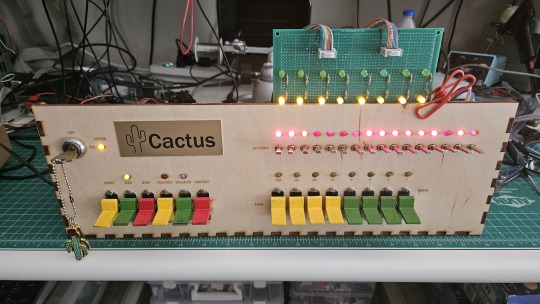

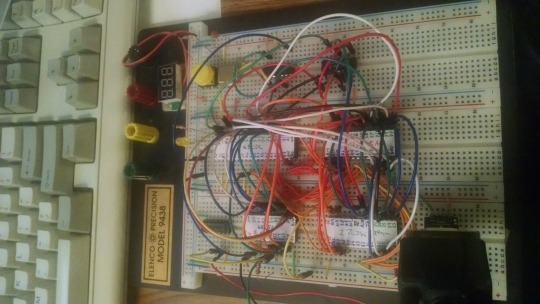

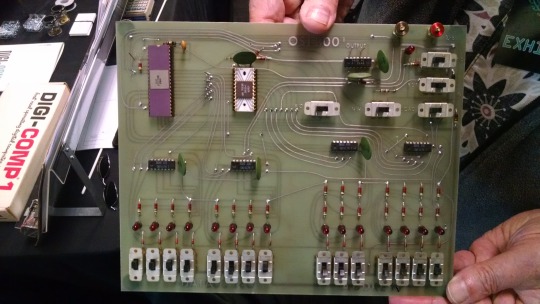

Both the Cactus (the original wooden prototype from years ago) and the new PCB Cactus(es) are essentially derived from a minimal 6502 computer design by Grant Searle for their core logic. Here's what that would look like on a breadboard:

There isn't much to it, it's 32K of RAM, 16K of ROM containing Ohio Scientific's version of Microsoft BASIC, a 6850 ACIA for serial interaction, some logic gates, and of course a 6502 microprocessor (NMOS or CMOS, doesn't matter which). You hook it into a terminal and away you go.

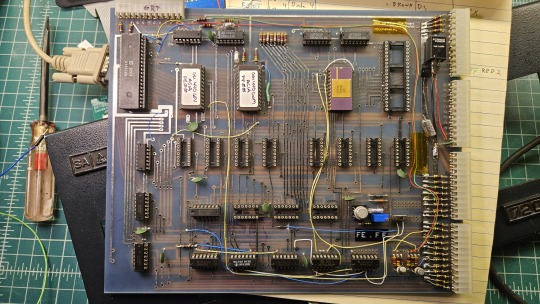

Grant's design in turn can be best described as a distilled, modernized version of the OSI Challenger series of computers. Here's an OSI-400 and a Challenger 4P respectively:

The left one is a replica of the 400 circa 1976, also called the Superboard. It was affordable, endlessly reconfigurable and hackable, but ultimately very limited in capabilities. No BASIC, minimal monitor ROM you talk to over serial, but you could connect it to a bus to augment its features and turn it into a more powerful computer.

Whereas the OSI C4P on the right from about 1979 has more RAM, a video card, keyboard, BASIC built in, serial interface, cassette tape storage, and that's just the standard configuration. There was more room to expand and augment it to your needs inside the chassis (alot changed in 3 years for home computer users).

Grant's minimal 6502 design running OSI BASIC is a good starter project for hobbyists. I learned about the 6502's memory map decoding from his design. I modified and implemented his design on a separate cards that could connect to a larger backplane.

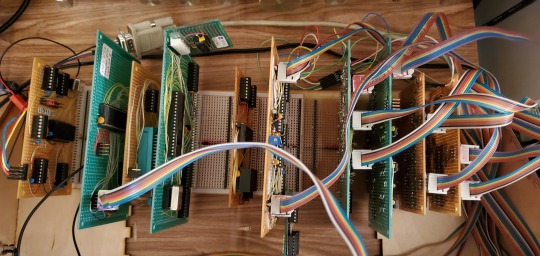

Here are the serial, ROM, RAM, and CPU cards respectively:

Each one is 100% custom, containing many modifications and fixes as I developed the design. However, that's only half of the computer.

I really wanted a 6502 machine with a front panel. People told me "nobody did that", or couldn't think of examples from the 1970s but that seemed really strange to me. Especially since I had evidence to the contrary in the form of the OSI-300:

This one I saw at VCF West back in 2018 illustrates just how limited of a design it is. 128 bytes of RAM, no ROM, no serial -- just you, the CPU, and toggle switches and LEDs to learn the CPU. I was inspired the first time I saw one in 2015 at VCF East, which is probably when this whole project got set in motion.

Later that year I bought a kit for a miniature replica OSI-300 made by Christopher Bachman, and learned really quickly how limited the design philosophy for this particular front panel was. It was a major pain in the ass to use (to be clear, that's by OSI's choice, not any fault of Christopher in his implementation)

So... I designed my own. Took awhile, but that's the core of what the Cactus is: my attempt at experiencing the 1970s homebrew scene by building the computer I would have wanted at the time. Over half of the logic in the Cactus is just to run the front panel's state machine, so you can examine and modify the contents of memory without bothering the 6502. I added in all of the things I liked from more advanced front panels I had encountered, and designed it to my liking.

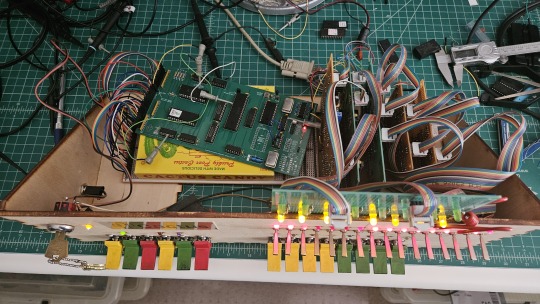

Here's the original front panel, accompanying logic, and backplane connected to the modern single board computer (SBC) version of the machine:

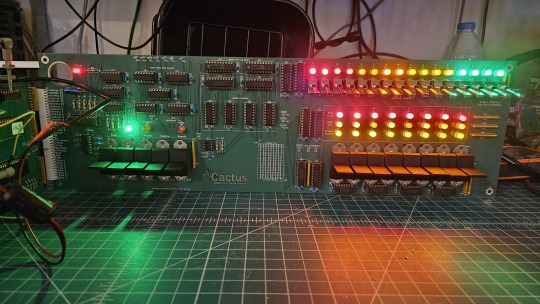

And here's the new Cactus SBC working with the new front panel PCB, which combines the logic, physical switch mountings, and cabling harnesses into a single printed circuit board.

So, what can you do with it? Pretty much the same things I do already with other contemporary 1970s computers: play around in BASIC, fire up the occasional game, and tinker with it.

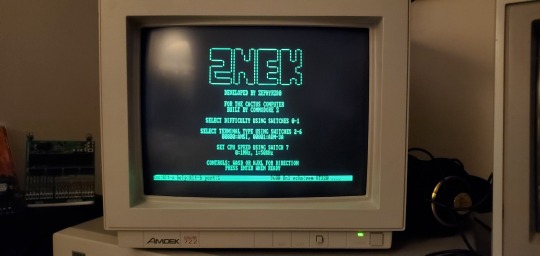

I've got no permanent storage designed for the Cactus as yet, it's been one of those "eventually" things. The good news is that a variety of software can be ported to the hardware without too much trouble for an experienced hobbyist. A friend of mine wrote a game called ZNEK in 6502 assembly which runs from a terminal:

Right now, you have to either toggle in machine programs from the front panel from scratch, burn a custom ROM, or connect it to a serial terminal to gain access to its more advanced features:

Here's it booted into OSI BASIC, but I have also added in a modern descendant of Steve Wozniak's WOZMON software for when I need to do lower level debugging.

I've also got a video card now, based on the OSI-440. I have yet to implement a keyboard, or modify BASIC to use the video board instead of the serial connection. Even if I did, screen resolution is pretty limited at 24x24 characters on screen at once. Still, I'm working on that...

Anyway, I hope that answers your question. Check the tags below to see the whole process stretching back to 2017 if you're curious to learn more of the project's history. I'm also happy to answer any more questions you might have about the project.

267 notes

·

View notes

Text

I know I say a lot “Copia wishes he had Phantom from birth” but what if he did…

Maybe Phantom was born topside and their dam didn’t want them. A summoning gone wrong that brought up a kit instead of a fully grown Ghoul. Or wandering Ghouls not tethered to any Ministry or anything leave the unwanted kits on the Abbey steps so they’ll still be cared for.

However it happened, as soon as Copia had that little kit in his arms, he knew they’d become his world.

He was the one who raised them, soothed them as their fangs and horns grew in, watching them take their first steps and say their first words.

It wasn’t always easy, juggling his rapidly advancing stations and caring for his autistic kit that when they needed their Papa, they needed him.

But they both made it work and Phantom had the best childhood an orphaned kit could ever ask for.

They missed their Papa so terribly on tours and would call constantly or arrange days to be able to come out and see them.

When Aether retired and Phantom could play the whole discography from memory, they knew it was the perfect opportunity to spend even more time with Copia and travel the world with him.

They never really wonder about their dam and sire, and they only thank them for whatever they did to make it so they could always be in Copia’s arms.

Ig this would have to be another au to the #pcb cinematic universe but the thought is cute~

#phanter cuddle buddies#the band ghost#ghost band#ghost ghouls#nameless ghouls#phantom ghoul#papa emeritus iv#cardinal copia#copia emeritus#frater imperator#ghoul headcanons#phantom ghost#nameless ghoul phantom

80 notes

·

View notes

Text

Opinion: Reusing old computers is more practical and environmentally friendly then producing new environmentally friendly computers at the moment but I doubt that will always remain the case especially with advances in pcb production to that end

23 notes

·

View notes

Text

#pcb#pcb manufacturer#united states#europe#switzerland#germany#advanced circuit#partnership#branding#contract#business#printed circuit board#ttm#scc

0 notes

Text

Mind you, just the CPU. We're not talking about fancy-ass graphics or anything here. Assume something simple like a Z80 or 6501, or a fully custom design that's at most as advanced as either of those. It doesn't even need to have any means of communication beyond some blinkenlights.

14 notes

·

View notes

Text

Inspired by nature: Leaftronics pave way for biodegradable electronics

A research team headed by Prof. Karl Leo at TUD Dresden University of Technology have developed an innovative, nature-inspired solution that could revolutionize the electronics industry: "Leaftronics." This innovative approach leverages the natural structure of leaves to create biodegradable electronic substrates with enhanced properties and offers a sustainable, efficient, and scalable solution to the global-waste problem. These findings have now been published in the journal Science Advances. Electronic devices, from toys to smartphones, consist of circuits. Specific substrates are used to manufacture these circuits. In commercial electronics, these are printed circuit boards (PCBs) made of glass fiber-reinforced epoxy resin.

Read more.

#Materials Science#Science#Biomaterials#Electronics#Plants#Dresden University of Technology#Biodegradable

14 notes

·

View notes

Text

When it comes to ensuring the quality and performance of printed circuit boards (PCBs), the right testing equipment is essential. PCB Test Fixtures play a critical role in validating and troubleshooting PCBs during manufacturing.

0 notes

Text

Giving Tuesday – KiCad open-source design #GivingTuesday 💻🔧🌍❤️🤝

KiCad is an open-source software suite for electronic design automation (EDA), enabling users to design schematics and printed circuit boards (PCBs). KiCad is a great, free, open tool for creating complex designs, from hobbyist projects to professional-grade hardware. As an open-source initiative, KiCad promotes accessibility and collaboration, making advanced EDA tools freely available. Supporting KiCad helps the development of features, bug fixes, and community-driven improvements, empowering engineers, educators, and hobbyists worldwide. Consider donating to KiCad to strengthen the open-source hardware community and help make high-quality EDA tools accessible to everyone.

In the past year, they posted this nifty chart that shows what your support can help accomplish.

If KiCad is valuable to you, please consider donating to help make it even better.

#kicad#kicadpcb#electronics#eda#schematic#pcbdesign#pcblayout#opensource#edatools#openhardware#donatetoday#engineeringdesign#communitysupport#openedsystems#opensourcecommunity#pcbtools#givingback#generositymatters#techforgood#makercommunity#electronicsdesign#designsoftware#kicaddonation#hardwaredesign#opensourceinitiative#techcommunity#sharekindness

11 notes

·

View notes

Text

For future reference (my own and others), if your TI SilverLink USB cable stops working and starts showing up as "TUSB3410 Boot Device" or similar under device manager (AKA this issue on TI's help page), this is how you can fix it:

Download the TUSB3x10 EEPROM Burner. This is a Windows-only program, but to my knowledge will work on basically any windows machine from XP on -- so long as it's got USB ports. No clue if it'll work in a VM. (You might want to consult this user's manual.)

Download the SilverLink firmware. I got it from here, and compiled it from their de-compilation. It's just a standard 'make' to build. The output file you're looking for is called "ti_graph_link_silver.eep".

Rename "ti_graph_link_silver.eep" to "ti_graph_link_silver.bin".

Open the TUSB3x10 EEPROM Burner, click on the options dropdown and click "Show the 'Program Full Binary Image' button". (page 7 of the manual).

Select the entry under "Computer" labeled "TUSB3410 EEPROM Burner Instance (1.00)".

Set EEPROM size to "64Kb".

Set "File Path" to point to "ti_graph_link_silver.bin". (The renamed .eep, not the original .bin)

I don't know if the VID, PID, Manufacturer string, Product string and Serial # need to be set manually or not with a 'Full Binary Image' burn. Just to be safe, I set VID to 0451, PID to e001, Manufacturer to "Texas Instruments", Product to "TI-GRAPH LINK USB", and checked "Not Serialized"*.

Click the "Program Full Binary Image" button (yellow triangle with the exclamation point), and proceed with the write.

Unplug and re-plug your cable, and it should show up as a SilverLink again!

Additional notes:

The reason that this happens is because the SilverLink cable (revision b, at least) is based on the TUSB3410 microcontroller. That microcontroller's boot process involves checking for an I2C EEPROM containing program code. If it finds that EEPROM and its contents are properly formatted, it'll copy that code into internal RAM and start executing it. If it can't find the EEPROM, or its contents aren't properly formatted, it'll fall back to looking for boot code over USB. Thus: "TUSB3410 Boot Device". Your cable has, in essence, forgotten who it is and and is begging for you to give it a purpose.

The default page-write buffer size (32 bytes) and I2C bus speed (400 KHz) in the burner app are already correct, so no need to change them.

*I don't remember exactly what the Manufacturer string, Product string, or serial number fields were set to pre-corruption. Likewise, no idea about the advanced descriptor options. If someone wants to send the output of lsusb -v -s [whatever their silverlink's bus/id numbers are], I'd really appreciate it!

You might be able to skip the header rigamarole by taking the ti_graph_link_silver.bin file directly ("directly coming from the compiler") -- but I again I don't know exactly what information is in the .eep file and what isn't. Are the PID and VID encoded somewhere in there? I peeked with a hex editor but have no clue. If someone has hardware lying around they're willing to experiment with/potentially brick, I'd love to hear your results!

If you mess up and accidentally forget to do a "Full Binary Image" write, or otherwise brick the firmware, you can force the TUSB3410 to fall back to USB boot mode by opening the plastic shell around the PCB (one Torx screw under the sticker, then just normal plastic tabs) and shorting the right-bottom (Vss) and right-top (SDA), or right-bottom (Vss) and center right-top (SCL) pins of the EEPROM (the chip labeled "24LC64") as you plug it into the USB port. You may need multiple attempts. This works because it temporarily convinces the TUSB3410 that the EEPROM is missing/corrupt, and thus it decides to fall back into USB boot mode -- until you reset it. It might be better to do this with a ~1k resistor instead of a jumper wire, but IDK I'm not an electrical engineer. All I know is that shorting Vss and SDA worked for me. Again, would love feedback.

No clue what causes the corruption in the first place, or how long this fix will last. It might be because the EEPROM's write protect pin is set to "write enable"? It could also just be degrading hardware, for all I know, so no idea how long the fix will last. All I do know is that everything seems nominal right now (immediately after performing this procedure).

10 notes

·

View notes

Text

Comrades of the Classist Feminist Collective Ana Montenegro participated in the VIII PCB National Political Conference, held last month in Fortaleza. Militants from several states and also comrades of the National Coordination, elected delegates at the state levels were present.

On the occasion, we held a meeting with all the presents that make up the CFCAM, where we exchanged information and reports on the situation of our collective in different regions of the country, and collectively thought about suggestions to be sent to the PCB Central Committee, in order to advance our organization and widening and ensuring the militancy of more and more women in the party and collectives.

The 8th PCB National Political Conference was an important moment in the history of our party and its collectives, contributing to advance important debates and resolutions. Spaces like this, which bring together militants from all over the country, strengthen us and renew our energy to continue firmly in the feminist and anti-capitalist struggles in our venues. We salute the Brazilian Communist Party for the completion of the conference and, especially, comrades from Fortaleza who ensured the excellent structure for carrying out the work of the conference.

Long live the Brazilian Communist Party!

Long live the Classist Feminist Collective Ana Montenegro!

15 notes

·

View notes