#Automated Material Handling machines

Explore tagged Tumblr posts

Text

Automated Material Handling Equipment Market Insights The Rise of Robotics in Supply Chain Operations

The Automated Material Handling Equipment (AMHE) market has gained remarkable traction in recent years, driven by the increasing need for efficiency, productivity, and safety across various industries. AMHE includes systems like conveyors, automated guided vehicles (AGVs), robotics, and sorting systems, all designed to optimize the handling and transportation of materials in warehouses, distribution centers, and manufacturing plants. The market is poised for further growth as companies invest in advanced technologies to streamline operations and reduce labor costs.

Growth Factors in the AMHE Market

Several key factors are driving the growth of the Automated Material Handling Equipment market. One of the main contributors is the increasing demand for faster, more efficient operations, particularly in industries such as e-commerce, logistics, automotive, and manufacturing. Automation helps companies meet these demands by reducing human error, minimizing downtime, and improving overall productivity. Additionally, advancements in robotics, artificial intelligence (AI), and the Internet of Things (IoT) are enhancing the functionality of AMHE systems, making them more intelligent and adaptable.

Automation in Warehousing and Distribution Centers

Warehouses and distribution centers are among the biggest adopters of automated material handling systems. The rising demand for quick delivery times in the e-commerce sector has forced companies to implement automated solutions to keep up with order volumes. Automated systems such as sorting, packaging, and AGVs help reduce operational bottlenecks and improve throughput. These systems can move goods more efficiently, leading to faster order fulfillment and improved customer satisfaction.

Technological Advancements Shaping the AMHE Market

Technological advancements play a significant role in shaping the AMHE market. Automation technologies such as AI, robotics, and machine learning are being integrated into material handling systems to improve efficiency and reduce human involvement. AI-powered robots can sort, transport, and pick items with greater precision, while machine learning allows systems to adapt and optimize processes based on real-time data. These advancements are not only making AMHE systems more efficient but also enabling greater flexibility in adapting to different types of products and warehouse layouts.

Adoption of Robotics and Smart Systems

Robotics is a central element of the AMHE market, with robots being increasingly deployed to handle materials in warehouses and production lines. Robotic arms, autonomous mobile robots (AMRs), and drones are improving the speed, accuracy, and safety of material handling operations. These robots are capable of performing repetitive tasks such as lifting, sorting, and packaging, freeing up human workers for more complex tasks. The adoption of robotics is expected to increase as companies strive to reduce labor costs and improve operational efficiency.

The Role of AI and IoT in Automation

Artificial intelligence (AI) and the Internet of Things (IoT) are transforming the AMHE market by enabling smarter systems. AI allows for predictive maintenance, optimizing workflows, and enhancing decision-making, while IoT enables real-time monitoring of operations. The integration of these technologies helps businesses track materials and equipment performance, anticipate problems, and streamline supply chain processes. As these technologies become more advanced, the level of automation in material handling systems will continue to rise, offering greater flexibility and efficiency.

Benefits of AMHE: Improving Efficiency and Reducing Costs

The primary benefits of automated material handling systems are improved efficiency and reduced operational costs. These systems enable faster processing of goods, minimize human error, and reduce labor costs. In addition, automated systems can operate around the clock, which leads to better utilization of resources and maximized productivity. The long-term cost savings from adopting AMHE solutions are driving companies to invest in these technologies, despite the high initial installation costs.

Impact of E-Commerce Growth on AMHE Demand

E-commerce has had a significant impact on the demand for automated material handling systems. As online shopping continues to grow, logistics companies are increasingly relying on automation to meet the rising demand for faster and more efficient order fulfillment. Automated systems can handle large volumes of orders, process returns, and manage inventory more effectively. As e-commerce companies expand their operations, they are expected to continue investing in AMHE systems to stay competitive in a rapidly evolving market.

Regional Insights: Global Adoption of AMHE

The AMHE market is experiencing rapid growth in various regions around the world. North America and Europe are leading the market due to the presence of key players, advanced technological infrastructure, and a strong focus on automation across industries. The Asia-Pacific region, particularly China and Japan, is also witnessing significant growth, driven by the rapid industrialization and the rise of e-commerce in these countries. Emerging economies in Latin America and the Middle East are also expected to contribute to the market's expansion as they increasingly adopt automation to enhance productivity and efficiency.

Challenges Facing the AMHE Market

Despite its growth, the Automated Material Handling Equipment market faces several challenges. The high upfront costs associated with the installation of automated systems can be a barrier for small and medium-sized enterprises (SMEs). Moreover, the complexity of integrating automation with existing infrastructure and the need for skilled labor to operate and maintain these systems can pose difficulties. However, as the technology matures and becomes more affordable, these challenges are expected to diminish, making AMHE solutions more accessible to a wider range of businesses.

Conclusion

The Automated Material Handling Equipment market is set for significant growth, driven by technological innovations, the rise of e-commerce, and the need for greater efficiency in industrial operations. Robotics, AI, and IoT are transforming material handling systems, making them smarter, faster, and more adaptable. As industries continue to embrace automation, the AMHE market will play a crucial role in reshaping supply chain management and operational processes in the years to come.

#Automated Material Handling Equipment Market#Automated Material Handling Equipment Market trends#Automated Material Handling Equipment#Automated Material Handling machines#Automated Material#Automated Material services

0 notes

Text

#Truck loading conveyor system manufacturer#Vertical lift for material handling manufacturer#Flow wrap machine for FMCG packaging manufacturer#Vertical reciprocating conveyor (VRC) manufacturer#Goods lift manufacturer India#Industrial conveyors for packaging lines manufacturer#End-of-line packaging solutions manufacturer#Smart packaging and conveyor integration manufacturer#Heavy-duty goods lifts manufacturer#Automated truck loading and unloading system manufacturer#Conveyor belt manufacturer#Horizontal flow wrap machine India manufacturer#Horizontal packaging machine for high-speed wrapping manufacturer#Industrial palletizing and packaging line manufacturer#Intralogistics solutions manufacturer#Telescopic boom conveyor manufacturer#Telescopic conveyor for truck loading manufacturer#Warehouse automation manufacturer#FMCG packaging machinery manufacturer

0 notes

Text

How Automation Is Changing the Game for Extrusion Machine Manufacturers?

The extrusion manufacturing industry is evolving rapidly, driven by the rising need for speed, precision, and scalable production. As industries demand more complex and customized aluminium components, manufacturers are turning to automation to meet these expectations efficiently.

Automation is redefining how extrusion machines operate enhancing productivity, reducing errors, and delivering consistent quality. For sectors relying on aluminium sections for machining & machine building, automation is not just a technological upgrade but a game-changing shift toward smarter, leaner production.

What Is Automation in Extrusion Manufacturing?

In the context of modern production, automation in extrusion manufacturing refers to the integration of intelligent control systems, robotics, and advanced software to streamline the aluminium extrusion process. This includes automating everything from billet loading and die changeovers to profile cutting, cooling, and quality inspection.

For aluminium extrusion machine manufacturers, automation isn’t just about reducing labor—it's about enhancing precision, consistency, and throughput. By adopting cutting-edge technologies, automation machines manufacturers help reduce human error, increase efficiency, and maintain uniform product quality across large-scale production runs.

As industries demand faster turnaround and higher performance, automation is no longer optional. It’s a competitive advantage reshaping the future of aluminium extrusion manufacturing.

Different Types of Automation Used in Machine Manufacturing Units

To stay competitive and deliver consistent quality, top aluminium extrusion profile manufacturers are embracing advanced automation technologies that streamline production and enhance precision. Here are the key types of automation revolutionizing extrusion machine manufacturing:

1. PLC-Controlled Extrusion Lines

Programmable Logic Controllers (PLCs) ensure precise control over the extrusion process, allowing manufacturers to maintain consistent temperature, pressure, and speed—critical for delivering high-performance output with minimal waste.

2. Automated Material Handling Systems

From raw material loading to finished product stacking, automated handling systems reduce manual intervention, speed up workflow, and improve workplace safety—an essential move for large-scale production.

3. Smart Sensors & Real-Time Data Collection

By integrating IoT-enabled smart sensors, manufacturers can monitor performance, detect anomalies, and gather actionable insights in real-time. This not only increases uptime but also supports predictive maintenance strategies.

Key Features of Machine Design Manufacturing and Automation Manufacturers

In the rapidly evolving landscape of machine design manufacturing and automation, the integration of smart systems is revolutionizing how extrusion machine manufacturers operate. With the rise of aluminium extrusion automation & material handling, companies are achieving unprecedented levels of efficiency, accuracy, and scalability.

1. Improved Efficiency and Productivity

Automation enables reduced cycle times, maximizing throughput and operational speed.

With 24/7 production capability, manufacturers meet high demand without compromising quality or consistency.

2. Enhanced Product Quality

Advanced automation ensures consistent aluminium extrusion profiles with precision engineering.

Real-time defect detection systems enhance quality control, reducing the need for manual inspection.

3. Cost-Effectiveness

While the initial investment may be significant, lower labor costs over time offer long-term savings.

Automation minimizes waste and rework, optimizing material usage and reducing overall production costs.

4. Workforce Optimization

Modern systems promote safer working environments, reducing human exposure to hazardous conditions.

Skilled workers transition into system monitoring and analysis roles, increasing the demand for technical expertise over manual labor.

This given blog was already published here

#aluminium sections for machining & machine building#aluminium extrusion automation & material handling#aluminium extrusion machine manufacturers#automation machines manufacturers#top extrusion machine manufacturers#aluminium extrusion machine manufacturers in india

0 notes

Text

Energy Power automate in pune | India

An inverter, charge controllers, a battery that stores energy, and solar panels that gather sunlight are the essential components of a solar power system. If these were absent, it would be inaccurate to state that the system is functioning well. Your smart house will be energy-efficient and optimized for usage thanks to energy automation, which links the solar power system to the primary energy operations.

#Energy and Power Automation Solutions#Special Purpose Machine Automation | AI-based vision sensors#Warehouse Automation Solutions#Material Handling Processes#Partner in Factory Automation#Electrical & software solutions#Process Automation Partner

0 notes

Text

Factorio: Space Age introduces the "quality" system, which you can technically play without, though I'm not sure it's balanced around that. I've now played with it enough that I have some thoughts on it.

First, I think it's kind of stupid that machines cannot naively use mixed-quality materials. It means that if you put a quality module in a single furnace, the lines will get "polluted" by the plates that are produced, and the whole factory will eventually gum up. Ask me how I know. I would vastly have preferred that it not matter: use a rare gear in a belt, and either it has no special benefit, or gives a chance to grant quality or something. But if it did that, I suppose it wouldn't be much of a gameplay challenge.

There are a few other pain points. One of them is that bots and the interface in general do not handle quality very well. Quality is almost always a strict upgrade, so it would be nice if there was a setting I could tick that said "hey, go upgrade things if possible". But instead, the UI and mechanics are such that you need to specify it, and this is super annoying, because it means that I have to manually go do the replacement myself, or have an upgrade planner to upgrade quality, then cancel the job once everything that can be replaced is so that the game will stop giving me an alert. I have accumulators and solar panels set up for quality right now, and I can't immediately think of a way to automate the process of upgrading the solar fields. I'm guessing that mods will help with that eventually. I also definitely want a keybind for "increase quality" and "decrease quality" on a machine, though I guess I never went looking to see whether that was a thing, so maybe it exists and I'm ignorant.

So as I see it, there are three main ways to engage with the mechanics:

Put quality modules in a machine that you're going to craft once and hope to roll high. The advantage is that hey, maybe you'll get lucky, and for stuff that goes in the equipment grid, I think this is sensible to do. Probably also wise for infrastructure, so long as you're fine doing some manual finagling that really should be done with bots.

Put quality modules in (some) machines that make intermediates, then use whatever you skim off the top there to make quality things. This does work, but you have to skim off essentially every single production line, and I think over time you end up with too much of certain things, which kind of sucks. It's one of the things that I've been doing, since it can guarantee the higher quality stuff, and ideally all the stuff in a spaceship and your equipment grid is at highest quality available. (You can also "skim" off anything you're making a shit-ton of for science: electric furnaces and yellow inserters are the two most obvious ones. I do wish this were easier to automate so that at some point you could say "actually, don't do the quality thing anymore". Probably some circuit logic could get you there, but you can't replace modules automatically that I know of.)

Use the recycler to "reroll" quality, making a gear over and over and over until it rolls high and can be separated out. The only issue with this is that it requires the recycler, and also is very expensive, but it does mitigate the randomness in its own way.

There's a secret fourth way that I've been noodling, which is that you could essentially build five separate copies of your base, put quality modules in everything, then if you roll high, send the better materials to the other base. This is insane, which is why I like it. So you would have miners mining with quality, which then gets separated onto five different trains and brought to the smelters, which then turn some fraction into higher quality plates that get sent to the "higher" factories. Those plates go into assemblers, which have a chance of upgrade, and so on, until there are five sets of labs, each of which is working with a different set of quality flasks. But I'm pretty sure that this would have a lot of technical problems, and really risk gumming up, as well as being very space inefficient and resource intensive. Still, might be workable end game, if you could deal with the inevitable overflows and imbalances.

Overall, I like it as a problem to chew on, but I think in practice they made a few decisions that I find annoying. Mods seem like they're fix some of it, like having to manually select upgrades, but the "clogging up the inventory" issue isn't going to go away, and in fact seems like one of the basic things that the mechanic is balanced around. I really appreciate that there are many ways to approach it, and that it creates this tradeoff of "go tall" or "go wide".

I'm very curious to see what people do with it, though I think the "throw vast resources into recycling" approach is probably going to be the dominant one unless there's a great blueprint for handling the overhead. And I'm also curious where public opinion is going to land on it, since it seems like the kind of thing that might end up divisive.

17 notes

·

View notes

Text

I am back!

Where have I been?

Well, it's my birthday! So I'm feeling more capable than usual. So I'm here to tell you that the reason I've been away is because I've been working hard to archive and automate the collection of data on Gazavetters campaigns. (No, I'm not working in an official capacity with them. I just appreciate their work immensely.)

The excellent @gazavetters have just hit 350 individually vetted and verified campaigns. That's a lot! In fact it's this many: XXXXX XXXXX XXX0X XXXXX XXXXX - 25 XXXXX XXXXX XXXXX XXXXX 00XXX - 50 X0XXX XXXXX XXXX0 XXXXX X0XXX - 75 XXXXX XXXXX XXXXX XXXXX XXXXX - 100

XXXXX XXXXX 0XXXX XXXX0 XXXXX - 125 XXX0X 00XXX XXXXX X0X0X XXXXX - 150 XXXXX XXXXX XXXXX XXXXX XXXXX - 175 0XXXX XXXXX XXXXX XX0XX XXXXX - 200

XXXXX XXXXX XXXXX XXXXX XX0XX - 225 XXXXX XXXXX XXXXX XXXXX XXXXX - 250 XXX0X XXXXX XXXXX XXXXX XXXXX - 275 XXXXX XXXXX XXXXX XXXXX XXXXX - 300

XXXXX XXXXX XXXXX XXXXX XXX0X - 325 XXXXX XXXXX XXXXX XXXX0 XXXXX - 350 X (351)

I've bolded and linked to campaigns that either have less than 5 donations, or collected less than 50 of their currency. (16 of them)

I've replaced campaigns that have closed with zeroes. (5% of them)

Every single campaign except for two I couldn't catch in time (#47 and #142) has been archived in the Wayback Machine, or archive.is where that wasn't possible.

More details under the cut

I could not have done without the help of my incredible boyfriend, who basically put this tool together for me - here's how long it takes to scan 10 campaigns:

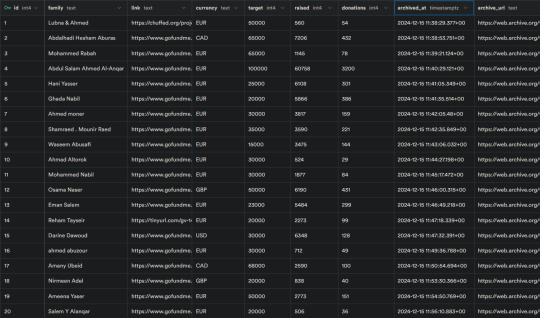

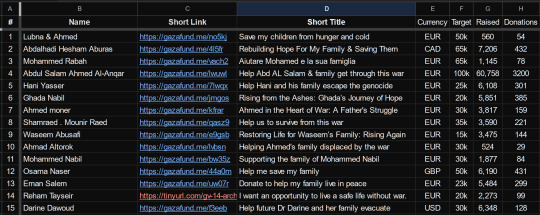

All that data goes into here, Supabase:

Which I can then import directly into a spreadsheet for analysis:

Which is how I created the post "50 campaigns less than 4% funded", etc.

I wanted this to be flexible enough to handle any masterlist of campaign links, not just Gazavetters. Other amazing efforts include el-shab-hussein and nabulsi's spreadsheet, Operation Olive Branch, Bees and Watermelons, the Butterfly Effect project, the Strawberry Seed collective, and definitely more that I don't have in my bookmarks folder. You could absolutely swap out all the names and links for any of theirs and the scraper would do most of the rest.

Kids in Gaza don't have a lot to be happy about. Fortunately, my other talent and hobby is locating and acquiring media. I've managed to obtain a rip of the entire children's section of an Arabic audiobook platform, a decent amount of Iftah Ya Simsim (Sesame Street), and an animated educational series about Muslim scholars and their contributions to science and philosophy. I'm working with a mate to get these as small and accessible as possible, before I share them privately. I've got... oh, about 475GB worth of material so far? Let's see how these projects go, as well as my own fundraisers (Shaima Fatima Aya Asmaa) plus the other 17 I'm advocating for (see my pinned post for details), and we'll see what happens. Peace. Bee out.

#gazavetters#gaza#free gaza#palestine#free palestine#ask received#gofundme#funds needed#go fund them#vetted#github#internet archive#data analytics

9 notes

·

View notes

Text

youtube

Yesterday I saw a few people interested in 3D printers, and then I just saw this video explaining the issues with really cheap 3D printers, and how you can upgrade them with lots of time and money to work properly. That absolutely matches my experience. My first 3D printer was a 150€ machine, not quite as crappy as the one in this video, but still full of flaws and issues and things that didn't work well. I later bought the Bambu Lab A1 mini, also recommended in this video, and it's been problem-free. I don't like recommending a single product like that, but in my experience it really does work that well. I'm sure you can get others that aren't bad as well, but when it comes to price and performance and ease of use, it genuinely seems to be the best option right now.

So a quick buyer's guide if you're interested in that particular model.

First up, watch out for sales. The official price is like 320€ for an A1 mini, but in practice there are usually sales that drop the price to 199€. Don't pay more than that.

Second, they sell multiple printers, but for beginners the interesting ones are the A1 and A1 mini. The A1 is bigger and can print bigger parts, for around 150€ more; apart from that they're basically identical. I got the smaller one and am perfectly happy with it. Instead you can put that money into…

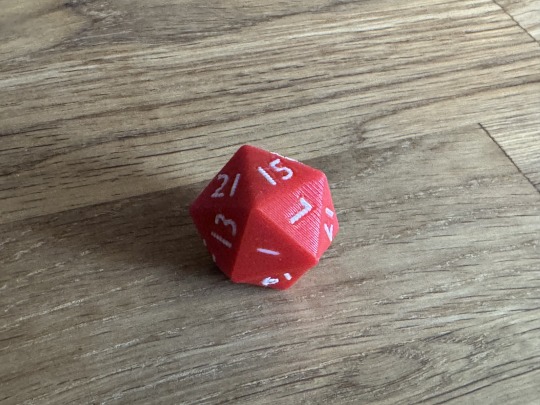

The AMS (Automated Material System), a thing you put next to the printer that can feed it material in different colours. It's included in several bundles, on the Bambu Lab website you specifically need to deselect it to not get it. This is the printer's main party trick, because it can print multiple colours (up to four) at once. This feature isn't actually that great, because on every layer it dumps a bit of the old material and then sucks in new ones, so multicolour prints take forever and produce a lot of scrap material. But you can do them at all, which is great. It's how I printed this D20 for my sister. Can you spot the special feature that she hasn't yet?

And it's useful to swap materials between different prints quickly. E.g. you want to print a gearbox and it takes several tries, but you can change the colours between each iteration so you don't get confused which is the new and old part. I've bought the AMS, I'm happy with it, but if money were tight this would be the first thing I'd get rid of. Note that for the A1 printers, you need the AMS lite, that's the one included in the bundles.

Print material (filament). Bambu Lab sells some, it's good. Lots of other companies sell some and those are also good, there's basically no advantage here, but Bambu Lab sells it for relatively cheaply if you order it with the printer. If you don't know material what you want or need (yet), you'll want PLA in different colours. Note that silk PLA needs to be treated differently (your printer and its software know about that, but you need to tell them you're using silk PLA). PLA-CF or glow-in-the-dark PLA also have special properties that require special handling.

Other additions: A smooth build plate is a nice thing to have for either very small things or things that need to be smooth. Different hot-ends can be useful; you need the hardened ones for PLA-CF or glow-in-the-dark PLA and some other materials; ones with a higher diameter print faster, ones with a lower diameter print more precisely. Glue: I've never used that for anything. These aren't things you need right away, but you do get a bit of a discount if you do order them with the printer.

Obviously I do need to tell you that this is literally a machine for producing plastic trash, there's no way around that. And while you can use the printer offline (or so I heard, I haven't tried it), it's mostly designed to be used with the Chinese manufacturer's cloud service, which does not make me super-happy. Also, the resolution for really tiny stuff is limited; if you want to build e.g. model trains, then you should really get a resin printer, but everything I heard about the chemicals and post-processing and so on there scares me, so I haven't yet. But if you are interested in 3D printing and want to get one for yourself, this is, as of right now, the thing I'd recommend.

15 notes

·

View notes

Text

Theory time :) (spoilers)

Rocket Corp? The close up to the corporation that the new ep brought, can reveal a lot more than you think

How did a random and unknow dude create such thing?... I've talked about this before, but with no large evidence or material to work with. This time will be different.

When we talk about AvA stickfigures, we get something like in the Radgoll short. They are all made of "random" and curved lines. But! What about Agent?

He is made of straight lines almost fully with just one curve and one perfect circle. Still, the curve does not break the ruler rule, bc it is a predictable line that doesn't changes direction. I'm talking about a arc from a circle or a symetrical circular shape.

The point I'm reaching to is: Where is he from? Maybe he could be from any town with a different art style, bc they were shown to exist in the new episode. But aren't these styles all "deffective"? They aren't geometrically perfect, like a human would draw (this last is just an example, not theory related)

But maybe the question isn't where is HE from. It should be, where are THEY from? All the Rocket corp people are the exact same art-style and color. Strange. Unless...

What if they all come from the same place? Another thing to recall... These dudes, atleast most of them, don't have toes. Just like Hollowheads! (I think there are a few exceptions, but still ruler shaped). And isn't a Hollowhead running this corp? Yup

Welp, all of them are like, "born" the same way. And even tho in this world everyone is a stickfigure, they still have differences in art-style, color or anything else...

My theory is: Victim is a Hollowhead and his team includes a "Hollowhead" (kinda). Victim has no toes and (most of) his team don't have them. What if Victim made them??

In the corp, they got the line tools and circle tools. And all of them are "made" the same way... But, didn't Victim have a brush?

If Victim made them. Why did he use lines instead of a brush? I got two theories:

Personality and control

The brush produces hand-made drawings, they're soft, unpredictable. If you put a human to draw a random line, you don't know what he will do. Just as Alan's Hollowheads.

Each of them didn't follow their initial objective and got free, they actions couldn't be predicted. They were made from the brush tool... Meanwhile, a straight line or a geometrical curve, can be predicted. Once it goes on a way, it won't change direction.

The kind of line maybe means a lot more than just an optional tool. Maybe it affects the stick's character

Time and amount

If Victim planned to take control of something big as a corporation. He would need a lot of people.

Let's imagine a machine. The machines follow the same orders over and over again, they do calculations to know where and how do something. It's easier to let a machine follow pre-made orders than create a machine that can innovate and adjust to a lot more of conditions... While the brush needs someone to handle it for drawing (or a really complicated machine). The line can be automated.

If Victim wanted to make a lot of people. He would need to be efficient... Isn't this a better way?

He. this dude has a lot to explain yet

AAaaaaaaghaiushnguianghia. Ha! I made something bigger than two

paragraphs. Lemme dance >:)))

Feel welcome to question anything from the theory.

32 notes

·

View notes

Text

Getting Started with Industrial Robotics Programming

Industrial robotics is a field where software engineering meets automation to drive manufacturing, assembly, and inspection processes. With the rise of Industry 4.0, the demand for skilled robotics programmers is rapidly increasing. This post introduces you to the fundamentals of industrial robotics programming and how you can get started in this exciting tech space.

What is Industrial Robotics Programming?

Industrial robotics programming involves creating software instructions for robots to perform tasks such as welding, picking and placing objects, painting, or quality inspection. These robots are typically used in factories and warehouses, and are often programmed using proprietary or standard languages tailored for automation tasks.

Popular Robotics Programming Languages

RAPID – Used for ABB robots.

KRL (KUKA Robot Language) – For KUKA industrial robots.

URScript – Used by Universal Robots.

Fanuc KAREL / Teach Pendant Programming

ROS (Robot Operating System) – Widely used open-source middleware for robotics.

Python and C++ – Common languages for simulation and integration with sensors and AI.

Key Components in Robotics Programming

Motion Control: Programming the path, speed, and precision of robot arms.

Sensor Integration: Use of cameras, force sensors, and proximity detectors for adaptive control.

PLC Communication: Integrating robots with Programmable Logic Controllers for factory automation.

Safety Protocols: Programming emergency stops, limit switches, and safe zones.

Human-Machine Interface (HMI): Designing interfaces for operators to control and monitor robots.

Sample URScript Code (Universal Robots)

# Move to position movej([1.0, -1.57, 1.57, -1.57, -1.57, 0.0], a=1.4, v=1.05) # Gripper control (example function call) set_digital_out(8, True) # Close gripper sleep(1) set_digital_out(8, False) # Open gripper

Software Tools You Can Use

RoboDK – Offline programming and simulation.

ROS + Gazebo – Open-source tools for simulation and robotic control.

ABB RobotStudio

Fanuc ROBOGUIDE

Siemens TIA Portal – For integration with industrial control systems.

Steps to Start Your Journey

Learn the basics of industrial robotics and automation.

Familiarize yourself with at least one brand of industrial robot (ABB, KUKA, UR, Fanuc).

Get comfortable with control systems and communication protocols (EtherCAT, PROFINET).

Practice with simulations before handling real robots.

Study safety standards (ISO 10218, ANSI/RIA R15.06).

Real-World Applications

Automated welding in car manufacturing.

High-speed pick and place in packaging.

Precision assembly of electronics.

Material handling and palletizing in warehouses.

Conclusion

Industrial robotics programming is a specialized yet rewarding field that bridges software with real-world mechanics. Whether you’re interested in working with physical robots or developing smart systems for factories, gaining skills in robotics programming can open up incredible career paths in manufacturing, automation, and AI-driven industries.

2 notes

·

View notes

Text

Top Benefits of Using Fiber Carding Machines for Fiber Processing

Introduction

A Fiber Carding Machine is an essential tool in the textile and fiber industry, designed to clean, separate, and align fibers for further processing. It plays a crucial role in improving efficiency, reducing labor costs, and ensuring high-quality fiber production. Whether you are processing cotton, wool, or synthetic fibers, investing in a Fiber Carding Machine in India can significantly enhance productivity and consistency.

1. Improved Fiber Quality

One of the biggest advantages of using a Fiber Carding Machine is its ability to enhance the quality of fibers. The machine removes impurities, short fibers, and foreign particles, ensuring a uniform and smooth texture. This process is essential for achieving high-quality final products, whether for yarn production, felting, or textile manufacturing.

2. Increased Efficiency and Production Speed

Manual fiber processing is time-consuming and labor-intensive. A Fiber Carding Machine automates the process, significantly increasing production speed while maintaining consistency. Industries can meet higher demands with less effort, ensuring smooth and efficient operations.

3. Cost-Effective Solution

Investing in a Fiber Carding Machine in India reduces the need for extensive manual labor, lowering operational costs. Additionally, by minimizing fiber wastage and enhancing material quality, businesses can achieve better profitability over time.

4. Versatility in Fiber Processing

Modern Fiber Carding Machines are designed to handle a wide range of fiber types, including natural and synthetic materials. Whether you're working with cotton, wool, polyester, or blends, these machines can efficiently process different fiber compositions, making them ideal for diverse textile applications.

5. Reliable and Durable Technology

With advancements in technology, Fiber Carding Machine Manufacturers in India now offer durable and high-performance machines. They are built with precision engineering, ensuring long-term reliability and minimal maintenance requirements.

Conclusion

For businesses looking to enhance fiber processing efficiency, investing in a Fiber Carding Machine is a smart choice. Terron India, one of the leading Fiber Carding Machine Manufacturers in India, offers state-of-the-art machines that ensure superior performance, cost-effectiveness, and durability for the textile industry.

#Fiber Carding Machine#Fiber Carding Machine in India#Fiber Carding Machine Manufacturers#Fiber Carding Machine Manufacturers in India

2 notes

·

View notes

Text

Summary Analysis of CNC Milling Process

In modern manufacturing, CNC milling technology is widely used for its high precision and flexibility. Whether it's a mechanical part, an automotive component, or a component for a medical device, CNC milling provides excellent machining results.

What is CNC Milling?

CNC milling is a computer-controlled machining process that utilises a rotating tool to cut a workpiece. CNC milling allows for greater accuracy and consistency than traditional manual milling. It is often combined with other machining methods (e.g. turning, drilling) to meet different and diverse manufacturing needs.

Workflow of CNC Milling

Design stage In the initial stages of CNC milling, designers use Computer-Aided Design (CAD) software to create a model of the product. Commonly used software includes SolidWorks and Autodesk, which are tools that help designers accurately draw the shape and dimensions of the desired part.

Programming stage Once the design is complete, the CAD file needs to be converted to G-code, a language that CNC machines can understand. With Computer-Aided Manufacturing (CAM) software, the design files are converted into machine-executable instructions that enable automated machining.

Machine setting During the machine set-up phase, the workpiece needs to be fixed to the table and a suitable tool selected. At the same time, the operator needs to set the initial co-ordinates to ensure accurate positioning during machining.

Advantages of CNC Milling

High precision and dimensional stability CNC milling allows for micron-level machining accuracy, ensuring consistency from part to part.

Complex shapes can be processed Whether it's a simple flat surface or a complex three-dimensional structure, CNC milling can handle it with ease.

Efficient production capacity Due to its high degree of automation, CNC milling can significantly increase productivity and shorten lead times.

Applications of CNC Milling

CNC milling technology is used in a wide range of industries, including:

Mechanical parts: Used in the manufacture of key components in a variety of mechanical equipment.

Automotive parts: High-precision parts for the automotive industry, such as engine components.

Medical device parts: Ensure the reliability and safety of medical devices.

Optical product parts: For the production of optical instruments and related products.

Frequently Asked Questions

What materials can be CNC milling machined? CNC milling is suitable for a wide range of materials, including metals (e.g. aluminium, steel), plastics, wood, and more. However, for some materials, such as ceramics or certain composites, the machining is more difficult and requires special handling.

What are the limitations of CNC milling? Despite its advanced technology, CNC milling has some limitations. For example, machining may be limited for internal vertical angles or very complex small structures.In addition, high hardness materials may lead to faster tool wear, which can affect productivity.

Comparison of CNC milling with other manufacturing technologies The advantages and disadvantages of each can be seen when comparing CNC milling with other manufacturing techniques such as 3D printing. CNC milling is generally superior to 3D printing in terms of accuracy and surface finish, but 3D printing has advantages in rapid prototyping and complex geometries. In terms of cost-effectiveness, the choice of technology depends on specific project needs and budget.

Summary

In summary, CNC milling is an indispensable manufacturing technology that plays an important role in several industries with its efficiency, precision and flexibility.

#prototyping#prototype#rapid prototyping#prototype machining#precision machining#cnc machining#cnc milling#machining parts#cnc milling 5 axis#cnc milling machining#cnc milling turning#precision cnc milling#cnc milling parts

2 notes

·

View notes

Text

#Truck loading conveyor system manufacturer#Vertical lift for material handling manufacturer#Flow wrap machine for FMCG packaging manufacturer#Vertical reciprocating conveyor (VRC) manufacturer#Goods lift manufacturer India#Industrial conveyors for packaging lines manufacturer#End-of-line packaging solutions manufacturer#Smart packaging and conveyor integration manufacturer#Heavy-duty goods lifts manufacturer#Automated truck loading and unloading system manufacturer#Conveyor belt manufacturer#Horizontal flow wrap machine India manufacturer#Horizontal packaging machine for high-speed wrapping manufacturer#Industrial palletizing and packaging line manufacturer#Intralogistics solutions manufacturer#Telescopic boom conveyor manufacturer#Telescopic conveyor for truck loading manufacturer#Warehouse automation manufacturer#FMCG packaging machinery manufacturer

0 notes

Text

Industrial Automation and Control

A manufacturing plant's integration of diverse devices, machinery, and equipment forms the basis of industrial automation control systems. However, as previously indicated, they might go one step further and integrate the manufacturing floor system with the rest of the business.

#Energy and Power Automation Solutions#Special Purpose Machine Automation | AI-based vision sensors#Warehouse Automation Solutions#Material Handling Processes#Partner in Factory Automation#Electrical & software solutions#Process Automation Partner

0 notes

Text

Why Stretch Wrap is Essential for Safe and Secure Shipping in the UK

Shipping products in the UK has always come with its fair share of challenges—from safeguarding goods during transport, to reducing the risk of damage, to maintaining cost efficiency. However, one standout solution that has revolutionized packaging across industries is stretch wrap. Widely recognized for its versatility and effectiveness, stretch wrap plays a vital role in ensuring safe and secure shipping.

Whether you're in logistics, manufacturing, or retail, stretch wrap provides an indispensable way to protect your items and optimize your shipping process. In this blog, we’ll explore what makes stretch wrap essential, its benefits, and why more businesses in the UK are choosing premium solutions like Tilak Polypack stretch films.

What is Stretch Wrap?

Stretch wrap, also referred to as stretch film or stretch wrap roll, is a highly stretchable plastic film made from polyethylene. Its elastic properties allow the material to tightly and securely wrap items or pallet loads without the need for adhesives or heat. It ensures tight containment, reduces risk of shifting during transport, and protects goods from external elements.

Stretch films are available as hand rolls for manual application and machine rolls for automated operations, making them highly versatile for various packaging needs. Advanced versions now also come with additional features like UV resistance or pre-stretching for added convenience and cost savings.

Popular Use Cases for Stretch Wrap:

Logistics and Warehousing: Streamlining palletized shipping and reducing the risk of goods tipping over.

E-commerce and Retail: Efficiently bundling packages together and securing items for delivery.

Food and Beverage Industries: Safeguarding products against dust, moisture, and contamination.

Manufacturing: Containing irregularly shaped items or bundling loose components.

Why Stretch Wrap is Essential for Shipping in the UK

1. Protection from Damage and Moisture

Shipping involves handling, vibrations, and exposure to external factors like rain or humidity. Stretch wraps act as a durable shield, preventing scratches, dents, dust, and moisture from damaging your goods. For sensitive or fragile products, such as electronics or fabrics, this level of protection is critical.

2. Secure Load Stability

Stretch wrap increases the stability of pallet loads, reducing the risk of shifting or toppling during transport. This makes it a reliable choice for the UK’s busy distribution networks, where goods are constantly loaded and unloaded at warehouses, ports, and delivery hubs.

3. Cost-Effective Packaging Solution

Stretch film is not only affordable but also reduces the need for additional packing materials such as strapping or adhesives. Its high conformability ensures that every inch of material is effectively used, minimizing waste while delivering superior results.

4. Ease of Usage for Businesses of All Sizes

From small retailers to large-scale logistics operations, stretch wrap offers scalability. Hand rolls cater to small packaging needs, while machine stretch wraps are perfect for bulk operations. Combined with its lightweight and recyclable nature, stretch wrap becomes a practical addition to any packaging workflow.

5. Sustainability and Eco Friendliness

Many businesses are now adopting more sustainable practices, and using recyclable stretch wraps is a great way to reduce environmental impact. Choosing eco-friendly options from a provider like Tilak Polypack not only ensures high quality but also supports your business’s green initiatives.

Benefits of Stretch Wrap Rolls

Here are some solid reasons why stretch wrap rolls are the go-to packaging choice for UK businesses:

Secure Packaging: Keeps items tightly bound, preventing them from slipping or shifting.

Damage Prevention: Minimizes the risk of scratches, breaks, or exposure to external elements.

Load Stability: Provides excellent grip for stacked pallets, preventing toppling during transport.

Versatility: Ideal for pallets, irregularly shaped loads, or bundling small items.

Transparency: Easy product identification during inventory checks.

Efficiency: Streamlines packaging and unpacking processes, saving time.

Eco-Friendly: Recyclable materials are available, contributing to sustainability goals.

Customizable Options: Different thicknesses, lengths, and features are available to meet unique needs.

Why Choose Tilak Polypack for Your Stretch Film Needs?

When it comes to premium stretch wraps, Tilak Polypack stands out as a trusted manufacturer and supplier. What makes them the ideal choice for UK businesses? Here’s why:

Top-Quality Products

Tilak Polypack offers durable, high-performance stretch film that meet stringent manufacturing and quality standards. You can trust their products to keep your shipments protected at all times.

Eco-Friendly Solutions

Committed to sustainability, Tilak Polypack provides recyclable and eco-conscious wraps that minimize environmental impact—a win for your business and the planet.

Customizable Packaging Options

With a variety of film thicknesses, lengths, and widths available, Tilak Polypack ensures you receive the perfect solution tailored to your needs.

Global Reach and Trusted Expertise

With over 20+ years of experience and a strong presence in global markets like the US, UK, Australia, and Singapore, Tilak Polypack is a reliable partner for businesses worldwide.

Excellent Customer Support

From choosing the right type of stretch film to resolving queries, their attentive team ensures a seamless experience for all their customers.

2 notes

·

View notes

Text

Mastering Woodworking with a CNC Router Machine: Unlocking Precision and Efficiency

The CNC router machine for wood has emerged as an indispensable tool for modern woodworking. Whether crafting intricate designs or scaling up production, this advanced technology brings precision, speed, and creativity to the forefront. Among its many variations, the 5x10 CNC router stands out for its large working area and robust functionality. This article delves into the transformative impact of CNC router machines on woodworking and why they are a must-have in today’s workshops.

What is a CNC Router Machine for Wood?

A CNC (Computer Numerical Control) router machine for wood is a sophisticated device that automates cutting, engraving, and carving processes. By using computer-aided designs (CAD), it translates digital plans into precise physical creations. This machine eliminates the challenges of manual craftsmanship, ensuring flawless results even for the most complex patterns.

Key Benefits:

Unmatched Accuracy: Create intricate details with pinpoint precision.

Time-Saving: Reduce production times significantly without compromising quality.

Versatility: Handle diverse projects, from furniture making to decorative carvings.

Consistency: Deliver identical results across multiple pieces, perfect for bulk production.

Exploring the 5x10 CNC Router

The 5x10 CNC router is a preferred choice for professionals who handle large-scale projects or work with oversized wooden sheets. Its generous 5-foot by 10-foot workspace allows for seamless execution of expansive designs, such as furniture panels, doors, and signage.

Features of the 5x10 CNC Router:

Ample Work Area: Ideal for cutting and engraving large materials without the need for piecing.

Precision Mechanics: Designed to maintain accuracy over extended working hours.

Tool Flexibility: Compatible with various attachments for added functionality, such as automated tool changers or multiple spindles.

This model is particularly useful in industries where size and detail matter, such as interior design and furniture manufacturing.

Applications of CNC Router Machines in Woodworking

CNC router machines have diverse applications across various woodworking domains, including:

Furniture Production: Create tables, chairs, cabinets, and other custom pieces with intricate designs.

Interior Décor: Produce unique wooden wall panels, decorative moldings, and ceiling details.

Architectural Designs: Craft custom doors, frames, and staircases with precision.

Artisanal Creations: Design engraved artwork, personalized gifts, and one-of-a-kind decorative items.

Sign Making: Build durable and aesthetically pleasing wooden signs with precision engravings.

Why Choose a CNC Router Machine for Wood?

Ease of Use: With user-friendly software and automated processes, CNC routers make complex projects manageable.

Material Optimization: Reduce waste with precise cutting and carving.

Scalable Production: Adaptable for one-off creations or large-scale manufacturing.

Cost Efficiency: While an initial investment is required, long-term savings are achieved through reduced material waste and increased productivity.

Conclusion

The CNC router machine for wood is a technological marvel that combines precision, versatility, and efficiency to revolutionize woodworking. Its ability to automate complex tasks while maintaining artistic integrity makes it an invaluable asset for both seasoned professionals and hobbyists. The 5x10 CNC router, with its expansive workspace, is especially suited for tackling large and detailed projects. Whether you aim to craft fine furniture or intricate designs, investing in a CNC router ensures that your woodworking ventures achieve excellence with every cut and carve.

2 notes

·

View notes

Text

Mastering Woodworking with the Router Table 4x8: Elevate Your Craft with Precision and Versatility

In the world of woodworking, achieving professional-grade results relies heavily on having the right tools at your disposal. Among these tools, the router table 4x8 stands out as an essential piece of equipment for both novice and experienced woodworkers. This article explores the features, benefits, and applications of a router table while also comparing it to the increasingly popular desktop CNC machine.

What is a Router Table 4x8?

A router table 4x8 is a large woodworking device designed to support a router, enabling it to make precise cuts and shapes in various materials. The "4x8" designation refers to the dimensions of the tabletop, providing ample space for handling large workpieces. This expansive surface allows for increased stability and control, essential for executing detailed woodworking tasks.

Benefits of Using a Router Table 4x8

Enhanced Stability and Control: The larger size of a router table provides a stable working environment, which helps minimize vibrations and errors during the routing process. This stability is particularly beneficial when working with intricate designs or larger boards.

Versatile Applications: Router tables are incredibly versatile and can perform numerous tasks, such as shaping edges, creating grooves, and making joinery cuts. With adjustable speeds and heights, you can tailor your routing operations to suit various woodworking projects.

Improved Safety: Operating a router table significantly reduces the risk of injury compared to using a handheld router. The secure positioning of the workpiece minimizes kickback and enhances user safety, allowing for a more focused and productive work environment.

Compatibility with Different Router Bits: A router table 4x8 is designed to accommodate a wide range of router bits. This flexibility enables woodworkers to explore diverse techniques and styles, facilitating the creation of unique designs and finishes.

Comparing Router Tables and Desktop CNC Machines

Both the router table 4x8 and desktop CNC machines have their merits, and understanding their differences can help you choose the right tool for your needs.

Precision and Automation

Desktop CNC machines excel in precision and automation, making them ideal for detailed and repetitive tasks. These machines use computer-controlled settings to execute intricate designs with high accuracy, which can be especially beneficial for commercial woodworking applications. However, they often require significant upfront investment and time to master the software.

Hands-On Flexibility

In contrast, a router table 4x8 offers a more hands-on approach, allowing for immediate adjustments and manual control over the routing process. This hands-on experience fosters creativity, enabling woodworkers to experiment with different techniques and designs. The tactile nature of routing can enhance the enjoyment of woodworking and lead to innovative results.

Selecting the Right Router Table 4x8

When choosing a router table, keep these considerations in mind:

Build Quality: Select a router table with a sturdy construction that can handle regular use. A solid base will contribute to the table's durability and stability during operations.

Ease of Use: Look for features like adjustable heights, clear measurements, and intuitive controls that simplify your workflow. A user-friendly design is crucial for maximizing efficiency and effectiveness in your woodworking projects.

Included Accessories: Many router tables come with valuable accessories such as fences, dust collection ports, and miter gauges. These tools can enhance your routing capabilities and improve the accuracy of your cuts.

Conclusion

A router table 4x8 is an invaluable addition to any woodworking shop, providing a perfect blend of stability, versatility, and safety. While desktop CNC machine offer advanced precision and automation, the hands-on experience of using a router table can inspire creativity and innovation in your projects. By understanding the benefits and features of a router table, you can elevate your woodworking skills and bring your creative visions to life. Embrace the possibilities that a router table 4x8 offers, and take your woodworking craft to new heights.

2 notes

·

View notes