#Automatic Plastic Injection Moulding Machine

Explore tagged Tumblr posts

Text

AI & ML for Smart Quality Control in Injection Moulding

In the fast paced world of manufacturing, staying ahead of the curve means adopting the smartest tools and nothing is smarter right now than Artificial Intelligence (AI) and Machine Learning (ML). As industries across the globe push toward digital transformation, smart manufacturing with AI and ML is becoming the new norm. One area experiencing a dramatic shift is quality control in plastic injection moulding.

India, being a hub of industrial innovation, is witnessing a rapid adoption of Automatic Plastic Injection Moulding Machine integrated with AI and ML technologies. These advanced systems are helping manufacturers enhance product precision, reduce defects, and speed up production cycles all while minimizing waste.

Why Smart Quality Control Matters

In traditional injection moulding setups, quality control is often a manual or semi automated process. Operators visually inspect parts, measure dimensions, or test batches at specific intervals. While this system works, it's prone to human error, delayed detection of defects, and inconsistency.

Now imagine a setup where machines constantly monitor production in real time. They learn from past data, predict possible flaws, and make adjustments before errors happen. That’s what AI in injection moulding quality control is making possible today.

How AI & ML Are Transforming Injection Moulding Quality

The integration of AI and ML into moulding processes isn’t just about automation it’s about intelligence.

Here’s how it works:

Data Collection Every step of the moulding process generates data: temperature, pressure, injection speed, material type, cooling time, etc. AI algorithms process this data to identify ideal operating conditions.

Real-Time Monitoring Cameras, sensors, and IoT devices gather live production data. AI analyzes it continuously to detect minor deviations that could lead to defects.

Predictive Maintenance ML models can predict machine failures before they happen. This reduces downtime and increases the lifespan of expensive moulding equipment.

Automated Decision Making Based on data, the system can make on-the-fly decisions like adjusting injection speed or cooling time to ensure every product meets quality standards.

This intelligent approach significantly reduces waste, saves energy, and enhances the consistency of manufactured parts.

Benefits of AI-Driven Injection Moulding Process

The shift toward AI-driven injection moulding processes is already delivering measurable results. Here are some of the major benefits:

Higher Precision: With continuous monitoring, the margin for error is drastically reduced.

Faster Time-to-Market: Fewer defects mean less rework and faster delivery timelines.

Reduced Operational Costs: Smart systems optimize energy use and raw material consumption.

Scalability: As production scales, AI adapts without the need for extensive manual intervention.

For manufacturers using Injection Moulding Machines in India, AI and ML are no longer futuristic concepts they're critical tools for global competitiveness.

Real-World Use in Indian Manufacturing

Many companies in India are now investing in smart factories equipped with Automatic Plastic Injection Moulding Machines powered by AI. These machines are not only helping reduce dependency on skilled manual labor but also standardizing product quality across large batches.

The government’s focus on initiatives like Make in India and Digital India is accelerating this transformation. With India poised to become a global manufacturing hub, early adopters of AI in injection moulding quality control are likely to lead the market in terms of innovation, speed, and customer satisfaction.

What to Look for in Smart Injection Moulding Machines

When upgrading to an AI-powered system, manufacturers should consider the following:

Compatibility with sensors and IoT devices

Real-time data analytics dashboard

Integration with MES/ERP systems

Cloud-based monitoring and remote access

Machine learning capabilities for predictive analytics

Whether you're upgrading your existing system or starting fresh, choosing the right Injection Moulding Machine in India that supports smart features can transform your factory floor.

Final Thoughts

The era of smart manufacturing is here, and it’s powered by AI and ML. For plastic product manufacturers, adopting AI-driven injection moulding processes is not just about better quality it's about future proofing your business.

If you're in the market for high performance, automated moulding solutions, now’s the time to invest in Automatic Plastic Injection Moulding Machines that are built for the intelligent future.

#Injection Moulding Machine India#Automatic Plastic Injection Moulding Machine#AI in injection moulding quality control

0 notes

Text

Vishavakarma Hydraulic Machines: Precision Engineering for Diverse Industries

Are you looking for thermoplastic injection moulding machines? Vishvakarma Hydraulic Machines is a leading and trusted plastic injection moulding machines manufacturer and supplier in India. These moulding machines are high in quality.

Why choose us?

Vishavakarma Hydraulic Machines is the best semi automatic injection moulding machine supplier; it aims to provide outstanding and high-quality thermoplastic injection moulding machines in the industry that cater to plastic manufacturing companies in India.

Key features of thermoplastic injection moulding machines

High Precision & Accuracy

Advanced Control Systems

Energy Efficiency

Robust Build Quality

Versatility

As a VS Series Machines manufacturer in India, Vishvakarma Hydraulic Machines is offering different types of hydraulic machines such as direct drive injection moulding machines, VS Series model thermoplastic injection moulding machines, and many more.

For more details, you can call us at +91-9810079823 and email us at [email protected]

#semi automatic injection moulding machine supplier#plastic injection moulding machines manufacturer and supplier#VS Series Machines manufacturer

1 note

·

View note

Text

#PLASTIC BLOW MOULDING#Parison Control Blow Moulding Machine#Double Station Parison Blow Moulding Machine#Automatic Blow Moulding Machine#L-Ring Drums Full Range#Accumulator Parison Full Range#IBC Tank Blow Molding Machine#Water Tank Blow Moulding Machine#Plastic Injection Moulding Machine#PET Bottle Stretch Blow Moulding Machine#Plastic Blow Moulding Machine#Extrusion Blow Moulding Machine#PET Blow Moulding Machine

0 notes

Text

Streamlining Your Business with Labelling Machines

Optimising productivity and efficiency is crucial for success in today’s fast-paced and competitive business landscape. One area where businesses can significantly improve their operations is in the labelling and decorating process. Traditional manual labelling methods are time-consuming and prone to human errors, which can lead to costly mistakes. Thankfully, labelling or decorating machines have emerged as a game-changer, revolutionising how businesses handle their labelling needs. This comprehensive guide will explore the benefits of labelling machines and how they can streamline your business operations while saving time and resources.

Understanding the Power of Labelling or Decorating Machines

Enhanced Productivity and Efficiency

Labelling machines are designed to automate the labelling process, eliminating the need for manual application. These machines can label products at a much higher speed and with greater precision than human workers. For example, a high-speed labelling machine can label hundreds of products per minute, while manual labelling may take considerable time and labour. With increased throughput, businesses can meet higher demands and efficiently handle larger order volumes, ultimately improving productivity.

Reduced Errors and Improved Accuracy

Human errors during labelling can significantly affect businesses, including wasted resources, product recalls, and dissatisfied customers. Labelling machines reduce the likelihood of errors by automating the application process and ensuring precise label placement on each product.

Some labelling machines have built-in sensors that detect product positioning and automatically adjust the label application to match the product’s size and shape. It minimises the risk of misaligned labels and ensures accurate placement every time. Furthermore, labelling machines can integrate with barcode and RFID systems, enhancing product traceability and inventory management, which further reduces the chances of errors and improves overall accuracy.

Cost Savings

While labelling machines require an initial investment, they are cost-effective in the long run. One of the primary cost-saving benefits is the reduction in material wastage. Manual labelling often leads to misprints, label misplacement, and label damage, which results in wasted labels and additional expenses. Labelling machines ensure minimal wastage by applying labels accurately and consistently, optimising the use of label rolls or sheets.

Flexibility and Versatility

Labelling machines are highly versatile and can accommodate various label sizes, shapes, and materials. Whether businesses require adhesive labels, shrink sleeves, wraparound labels, or heat-transfer labels, these machines can handle them all. Some labelling machines offer quick changeover capabilities, allowing businesses to swiftly switch between different products or label designs.

Streamlined Regulatory Compliance

In industries with strict regulatory requirements, compliance with labelling standards is essential. Labelling machines can be programmed to ensure compliance with specific regulations, such as ingredient listings, nutritional information, and hazard warnings. Businesses can avoid legal penalties, maintain consumer trust, and uphold their brand reputation by automating the compliance process.

Improved Branding and Aesthetics

In today’s competitive market, product branding is vital in attracting consumers and building brand recognition. Labelling machines can add decorative elements, brand logos, and appealing designs to product labels, making them more visually appealing to customers.

Adaptability to Industry Demands

Labelling machines cater to various industries, including food and beverage, pharmaceuticals, cosmetics, etc. Different industries have unique labelling requirements, and labelling machines can adapt to meet these specific needs.

Choosing the Right Labelling Machine for Your Business

Label Types and Sizes

Before selecting a labelling machine, businesses should identify the types of labels they need to apply and their sizes. Some labelling machines specialise in specific label types, such as self-adhesive labels. In contrast, others offer greater versatility, accommodating a variety of label materials, including shrink sleeves and in-mould labels.

Production Volume

The production volume is crucial in determining the appropriate labelling machine for a business. High-speed labelling machines are ideal for large-scale production facilities, where a high volume of products needs to be labelled quickly. Conversely, smaller businesses or those with lower production volumes may find more cost-effective solutions in mid-range or semi-automatic labelling machines.

Automation and Integration

Automation features are essential for optimising the labelling process and reducing manual intervention. Advanced labelling machines can feature auto-adjusting settings, label position correction, and label presence sensors. These functionalities ensure that labels are applied accurately and consistently, even when dealing with products of different shapes and sizes.

Maintenance and Support

When selecting a labelling machine, consider the ease of maintenance and the availability of technical support from the manufacturer or supplier. Regular maintenance is essential to keep the machine in optimal working condition and prevent unexpected breakdowns.

Conclusion

Plastics Processing Machinery in Australia have transformed how businesses handle their labelling needs, offering increased productivity, reduced errors, and improved efficiency. By investing in a suitable labelling machine that aligns with their business requirements, companies can streamline their operations, save valuable time and resources, and position themselves for success in today’s competitive market.

Automation and technology continue to shape the future of Plastics Processing Machinery in Australia with advancements in precision, speed, and integration capabilities. As businesses seek to optimise their labelling processes, staying informed about the latest trends and industry innovations is essential to remain competitive and meet consumer demands effectively. Embrace the power of labelling or decorating machines, and take your business to new heights of efficiency and success.

#Granulation Moulding Machines#World’s fastest Automatic Bagging Machines#High Quality Conveying Machines#ISBM Mould Injection Machines Supplier#Plastic Automation machine systems#Plastics Processing Machinery Australia#Labelling or Decorating Machines#Recycling Machines#inspection machines#injection moulding machines#Plastics Processing Machinery#Blow Moulding Machines

0 notes

Text

A trunk door handle serves a fundamental role in a vehicle, enabling easy access to the trunk for storing and retrieving items. It’s a simple but essential component that many often take for granted until it’s in need of replacement. These handles are available in various designs, including manual and automatic options, and they are typically constructed from materials like stainless steel, aluminum, or plastic to ensure durability and ease of use.

Taizhou Huangyan Maorong Plastic Mould Co., Ltd. business: design and manufacture of automotive interior and exterior molds, processing pipe molds, and daily necessities molds. As a famous Custom Chevrolet car handle and Wholesale Chevrolet car handle Factory in China, our company's leading products: automobile bumpers, grilles, side steps, door guards, door sill trims, wheel eyebrows, front cabin trim cover moulds and products.High-end processing equipment: CNC machining centers, injection molding machines, electroplating lines, spraying lines, and other advanced automatic mold processing and mold testing equipment, product surface treatment production lines.

0 notes

Text

Premium and Best Plastic Toys Moulds Manufacturer From Ahmedabad

Shivam Engitech, the leading manufacturer of high-quality plastic toys moulds in Ahmedabad, India. We specialize in toy injection molding, delivering innovative and durable mould solutions for the toy industry. Our expertise, advanced technology, and commitment to excellence make us the preferred choice for toy manufacturers worldwide.

Our plastic toy molding machine has advantages such as completely automatic operation, ease of use, more versatility, consistent toy quality, lower labor consumption, and low power consumption.

Our plastic toy moulds are designed to produce a wide range of toys, including action figures, educational toys, building blocks, and more. These moulds are crafted with precision to ensure smooth and consistent production, resulting in high-quality toys that meet safety standards and delight children.

For More Details 👇

0 notes

Text

Plastic Injection Moulding Machine manufacturer in India

Patel Plastic Machinery Mfrs. is one of the small scale industries in India is located in Ahmedabad, Gujarat.We are glad to inform you to introduce ourselves as a manufacturers of Fully Automatic Screw type PLC Base Servo Plastic Injection Moulding Machine.

#plastic injection moulding machine#plastic injection moulding machine manufacturer#plastic injection moulding machine supplier#plastic injection moulding machine in India#plastic injection moulding machine manufacturer in Ahmedabad

0 notes

Text

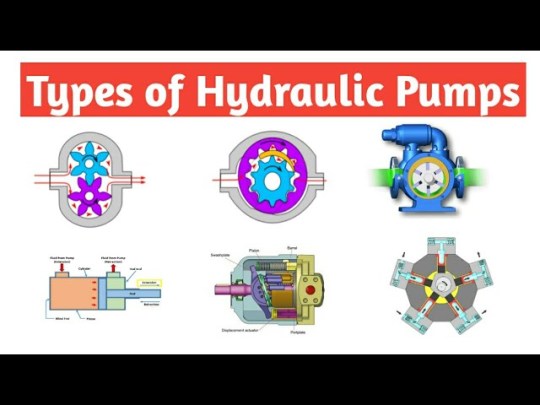

Top Types of Hydraulic Pumps and Their Various Applications

Hydraulic systems are essential components of various industries, providing the power needed to perform a wide range of tasks. At the heart of these systems are hydraulic pumps, which play a crucial role in generating the necessary fluid power.

In this blog, we'll explore the top types of hydraulic pumps and their diverse applications, shedding light on their functionality and significance in different settings.

Understanding Hydraulic Pumps

Before delving into the specific types of hydraulic pumps, it's important to understand their fundamental purpose. Hydraulic pumps are mechanical devices designed to generate flow and provide power to hydraulic systems.

They convert mechanical energy into hydraulic energy by pressurising hydraulic fluid. This pressurised fluid is then utilised to perform various tasks, making hydraulic pumps integral components of a wide array of applications.

Types of Hydraulic Pumps

1. Gear Pumps

Gear pumps are one of the most common types of hydraulic pumps. They operate using the intermeshing of gears to pump fluid.

With their simple design and ability to handle a wide range of viscosities, gear pumps are widely used in applications such as automotive power steering systems, forklifts, and construction equipment.

2. Vane Pumps

Vane pumps utilise vanes to push fluid through the pump. These pumps are known for their quiet operation and ability to handle low-to-medium pressure applications.

They find extensive use in industrial and mobile hydraulic systems, as well as in aerospace and automotive applications.

3. Piston Pumps

Piston pumps use reciprocating pistons to pressurise fluid. They are capable of handling high-pressure applications and are often used in heavy machinery, hydraulic presses, and other industrial equipment where high power density is required.

4. Radial Piston Pumps

Radial piston pumps consist of a set of pistons arranged radially around a drive shaft. These pumps are known for their high efficiency and are commonly employed in high-pressure hydraulic systems, including those used in plastic injection moulding machines, hydraulic presses, and marine equipment.

5. Axial Piston Pumps

Axial piston pumps feature pistons arranged in a circular array within a cylinder block. They are widely utilised in various hydraulic systems, including industrial machinery, agricultural equipment, and construction machinery, thanks to their ability to handle high pressure and provide efficient performance.

Applications of Hydraulic Pumps

Industrial Machinery

In the industrial sector, hydraulic pumps play a critical role in powering heavy machinery such as presses, extruders, and injection moulding machines.

The high pressure and power density provided by piston pumps and radial piston pumps make them well-suited for these demanding applications.

Construction Equipment

Construction and earthmoving equipment rely heavily on hydraulic pumps to provide the power needed for tasks such as lifting, lowering, and manoeuvring heavy loads. Gear pumps and vane pumps are commonly used in hydraulic systems within excavators, dump trucks, and cranes.

Aerospace and Automotive Systems

Vane pumps are often employed in aerospace and automotive applications where quiet operation and efficient fluid handling are essential. These pumps are utilised in aircraft hydraulic systems, as well as in power steering and automatic transmission systems in automobiles.

Agriculture

In the agricultural sector, hydraulic pumps are integral to the operation of various equipment, including tractors, harvesters, and irrigation systems. Axial piston pumps are well-suited for these applications due to their ability to handle high pressure and provide reliable performance in demanding agricultural environments.

Marine Equipment

Radial piston pumps are commonly used in marine hydraulic systems to power steering, winches, and other equipment on ships and offshore platforms. Their high efficiency and ability to handle high-pressure applications make them ideal for these marine applications.

Conclusion

Hydraulic pumps are indispensable components of hydraulic systems across diverse industries. Understanding the various types of hydraulic pumps and their applications is crucial for selecting the right pump for specific tasks and ensuring efficient and reliable operation.

By exploring the functionality and significance of hydraulic pumps, we gain a deeper appreciation for the pivotal role they play in powering a wide range of machinery and equipment.

As we've seen, the versatility and performance of hydraulic pumps make them essential for achieving powerful and precise hydraulic operations across numerous applications. Whether in industrial settings, construction sites, aerospace and automotive systems, agriculture, or marine environments, hydraulic pumps continue to drive innovation and efficiency in hydraulic power systems.

Source URL: https://hydraulicpumpsau.blogspot.com/2024/04/top-types-of-hydraulic-pumps-and-their.html

0 notes

Text

Design of injection mould for guide vane of curtain bead automatic machine

When designing an injection mold, demolding method affects mold structure. Main manifestation is that selection of parting method needs to consider convenient demoulding of plastic part, simple mechanism and convenient processing of mold parts. When plastic part has multiple characteristics and demolding direction is different, if conventional sliding block, inclined push rod and other mechanisms…

View On WordPress

0 notes

Text

Automatic Plastic Injection Moulding Machine Manufacturer in India

KSB Lion is a trusted Automatic Plastic Injection Moulding Machine Manufacturer in India, delivering high-performance, energy-efficient, and durable machines designed to meet the evolving needs of the plastic industry. With advanced technology and precision engineering, KSB Lion offers fully automatic injection moulding solutions ideal for various applications, ensuring consistent quality and productivity.

Contact Us: 9824023849 https://wa.me/919824023849

#automatic plastic injection moulding machine#automatic plastic injection moulding machine manufacturer india#automatic plastic injection moulding machine cost

1 note

·

View note

Text

Plastic Granules Mixing Machine in Chennai

Plastic Granules Mixing Machine in Chennai:z Invoit Plast Machinery: A leading manufacturer, supplier, and exporter of plastic processing machines based in India. Renowned for offering reliable solutions in the plastic processing sector, emphasizing high-quality manufacturing standards. Specializes in providing Plastic Granules Mixing Machines in Chennai, Tamil Nadu, India. Designed for effectively mixing plastic granules to achieve consistent and homogeneous blends. Utilized in the plastics industry to combine raw plastic materials, colorants, and additives for subsequent processing. Equipped with rotating blades or agitators within a mixing chamber for thorough blending. Designs may incorporate adjustable speed controls and temperature regulation to suit different plastic formulations. Features: Robust construction ensures durability and stability during operation. Variable speed control allows adjustment of mixing intensity as per specific requirements. Safety features like emergency stop buttons and protective covers prevent accidents. Easy access for cleaning and maintenance contributes to operational efficiency. Optional features may include programmable settings for automated processes and digital displays for parameter monitoring. Product Details: Minimum Order Quantity: 1 Piece Production Capacity: 200 kg Usage/Application: Mixing Material: M.S. / S.S. Shape: Vertical Screw Mixing Powder Mixing: No Design Type: Standard, Customized Automation Grade: Semi-Automatic Country of Origin: Made in India Machine Functionality: Vertical Granules Mixer machine for Mass Production ensures continuous homogeneous mixing of Plastic Raw Material Granules. Suitable for various applications including Injection Moulding, Blow Moulding, Tape Plant, and Film Plant. Geographical Coverage in Chennai: Provides Plastic Granules Mixing Machine in Chennai, Tamil Nadu, India, and surrounding areas, covering locations such as Provides Plastic Granules Mixing Machines in Chennai, Tamil Nadu, India, and surrounding areas, including Adambakkam, Alapakkam, Alwarpet, Ambattur, Aminjikarai, Arumbakkam, Ayanavaram, Chepauk, Chetput, Ekkaduthangal, Eranavur, Ennore, Guduvancheri, Karapakkam, Kattivakkam, Kattupakkam, Madhavaram, Manali, Manapakkam, Mandaveli, Mangadu, Nanganallur, Pakkam, Palavakkam, Pallavaram, Puzhal, Saidapet, Vyasarpadi, Washermanpet, Sriperumbudur, Kanchipuram, and Thiruvallur. For further details, engage in a professional conversation with the Invoit Plast Machinery team. Read the full article

#Adambakkam#Alapakkam#Alwarpet#Ambattur#Aminjikarai#Arumbakkam#Ayanavaram#Chennai#Chepauk#Chetput#Ekkaduthangal#Ennore#Eranavur#Exporter#Guduvancheri#India#kanchipuram#Karapakkam#Kattivakkam#Kattupakkam#Madhavaram#Manali#Manapakkam#Mandaveli#Mangadu#Manuacturer#ManufacturerofPlasticGranulesMixingMachineinChennai#Nanganallur#Pakkam#Palavakkam

0 notes

Text

What is an Injection Molding Machine? Get to know everything about it!

Injection molding is an important industrial technique. Although it is somewhat similar to die casting, but the raw material used in this case are different. Die casting uses metals that melt at extremely high temperatures, whereas injection molding mostly uses glasses, elastomers, and most frequently thermoplastic and thermosetting polymers. Nevertheless, this process is commonly used to create thermoplastic materials. In this method, raw materials are heated to a certain temperature and then injected under pressure into the mould cavity without changing their composition.

What are the main parts of injection molding machine?

The material hopper, barrel, an injection ram/rotating screw type plunger, heating element (heater), adjustable pattern, ejectors, and a mould inside mould cavity are the key components of an injection molding machine.

Injection molding machines typically operate horizontally. A barrel is part of an injection molding machine (cylindrical pipe). At one end of the barrel, there is a hopper. Inside the barrel is a revolving screw or hydraulic ram powered by an electric motor that provides force. The barrel has a heating element (warmer) attached to it that is used to melt the molding compound when it exits the hopper.

Mold cavity linked to the barrel's opposite side. During the entire production process, a movable pattern is used and the mould is situated inside the mould cavity. Typically, copper, aluminum, and tool steels are used to make mould. Distinct types of material moulds have different life cycles. This can be chosen based on your needs.

How does the injection moulding machine works?

Extrusion and injection molding both function similarly, as implied by their names. Using a feeding apparatus, molding material and raw materials are poured into the hopper. Following that, the molding material falls into the cylinder (barrel) as depicted in the diagram due to gravity. The material is melted using a circumferential heater that is mounted on the barrel. When molding compound in powder form enters the barrel from the hopper, it begins to melt, and a revolving screw or hydraulic ram applies pressure to advance the compound into the mould.

In this split mould, which is attached to the other side of the barrel, molten plastic material is pumped into a closed mould. The revolving screw constantly advances the molding material. The hydraulic system exerts pressure. Normal injection pressure ranges from 100 to 150 MPa. Following injection, pressure is exerted for a while or held in place with some force.

The pieces produced when the entire procedure is complete are appropriately cooled. The mould is then opened, and a few ejectors are utilized to remove the part properly and damage-free. The portion mould is reopened after removal. This process is very fast and automatically repeated. Here, it is simple to make pieces with complex shapes. The injection molding process may produce 12–16,000 components every cycle.

The Procedure

- The process parameter fluctuates based on the circumstances and demands. - The components made with this method typically weigh between 100 and 500 g. - A single part's cycle time ranges from 5 to 60 seconds, depending on how the item is made. - The heating range for molding material is 150 to 350 degrees Celsius. - The molding machine has an injection capacity of 12,000 to 2.2 106 mm3. - 100 to 150 MPa is the injection pressure. - From 0.1 to 8.0 MN is the locking force.

What are the advantages of Injection molding machine?

- The fundamental benefit of this method is that intricately shaped components with thin walls (5–15 mm) may be molded with ease and retrieved from the die without being harmed. - Injection-molded components offer good dimensional tolerance. - The main benefit of this method is that it produces far less scrap than certain other methods. - Investment cast iron and intricately machined pieces compete with parts produced through the Injection Moulding Method. - In comparison to other procedures, this process has a high production rate.

What are the various types of injection molding machines?

Following are the different types of injection molding machines. Have a look:

Hydraulic Injection Molding Machine

Hydraulic injection molding machine were the only types of machine at start. It is the oldest one in the industry. Following are the benefits of this machine-

1. Economical price These machines cost far less at the base level than comparable models.

2. Cheap parts If a machine component needs to be replaced because it has been damaged or has reached the end of its useful life, the replacement parts are less expensive and more readily available.

3. Robust components The machine's hydraulic components are longer-lasting and more resistant to deterioration.

4. Easy to use and maintain High-pressure clamping forces are typically simple to adjust on hydraulic injection devices.

5. Powerful The gripping force on hydraulic molding machines is outstanding.

Electric Injection Molding Machines

In the 1980s, electric injection molding machines were made available and soon gained popularity in the high precision plastic parts production sector. The positioning accuracy of today's full electric servo drive injection molding machines is exceptionally precise (of 0.0001 in), but at a very high cost.

1. Less idle time There is no possibility of oil leaking. Additionally, since no oil is used, there is no need to replace filters, which lowers consumable costs.

2. Efficiency while using energy Electric Injection Molding Machines only consume energy when they are in use, thus their output is limited to what is necessary to support the load.

3. Fast procedure Since these machines are digitally controlled, the procedure can be completely repeated without any oversight.

4. Highly reproducible The injection device can be accurately controlled, the molding conditions can be stabilized, the injection control (such as pressure and speed) can be regulated in fine units, and there is a highly accurate control and monitoring system. It can handle challenging tasks like multi-stage hydraulic system extension and control the extension.

Injection Molding Machine Price

There are various types of machines. The Injection Molding Machine Price will also vary according to the complexity of the machine. Costs for large industrial injection molding equipment can range from $50,000 to $200,000 or more. Additionally, the facilities needed to operate, maintain, and monitor these equipment are more demanding and call for expert staff.

Who are the best injection molding machine manufacturers?

There are many Injection Molding Machine Manufacturers in India; however, some of them offer the exception quality products that last longer. Here is the list of some trusted manufacturer in India-

Milacron

Yizumi Injection Molding Machine

Primex Plastics Pvt. Ltd

Windsor Machines Limited

Haitian

Hikon

ENGEL Global

Indo-MIM

Micro Plastic

Kruger

Vikas Industries

Jagmohan PlaMech Pvt. Ltd

Neelgiri Machinery

These are some of the leading manufacturers offering the best quality Injection Molding Products. If you are looking for someone in your region, you can try to search on Google and write Injection Molding Machine near me. This way, you will find the list of top-rated manufacturers offering top-notch services in your area.

Types of products made with injection molding machine

There are various types of products that can be made with injection molding machines.

Some of them are listed below-

Toys

Plastic bottles

Machinery and automotive components

Household products like molded closures, containers, etc.

Healthcare industry

Agricultural products

Conclusion

Injection moulding may appear to be a complicated procedure, yet it is the most popular manufacturing technique because it can manufacture a wide range of everyday things quickly and effectively. One of the most economical methods for producing both working prototypes and finished goods is injection molding.

#Injection Molding Machine#molding material#raw materials#injection molding process#Injection-molded components#Injection Moulding Method.#hydraulic molding machines#Injection Molding Machine Price#Injection Molding Machine Manufacturers#Injection Molding Products

0 notes

Text

10 Convincing Reasons to Embrace Recycling Machines

In today’s changing world, there’s an ever-growing concern and worry for environmental sustainability. With the global population increasing, waste generation and environmental impact have escalated significantly.

One must undertake recycling as a crucial practice to address these challenges, but conventional methods might not be sufficient. That’s where investing in recycling machines proves to be a smart and forward-thinking choice.

Such advanced machines revolutionise waste management and offer many benefits beyond just being environmentally friendly.

What is a Recycling Machine?

A recycling machine processes recyclable materials into reusable products or raw materials. Its main job is to reduce waste and conserve valuable resources. It is available in multiple sizes and types according to the user’s needs. Also, plastic automation machine systems for recycling are present in the market to ease the process and reduce waste.

Why is a Recycling Machine Crucial?

Cost-Effectiveness

Investing in recycling machines can significantly reduce waste disposal costs for businesses and municipalities alike. By recycling on-site materials, companies can avoid the expenses of transporting waste to distant landfills or recycling centres.

Recycling machines can process various materials, turning them into valuable resources. These include plastics, metals, paper, and glass. These recycled materials provide ample benefits to the manufacturers. They can sell and reuse them, potentially creating a new business revenue stream.

Environmental Advantages

Recycling machines remove waste from landfills. These reduce their environmental impact and preserve valuable land space.

By enabling the recovery and reuse of valuable resources like metals and paper, recycling machines lessen the need for raw material extraction. This conservation of natural resources helps protect biodiversity and minimises habitat destruction.

Energy Efficiency

Extracting raw materials from nature demands significant energy inputs. In contrast, recycling materials generally consume less energy, making it a more sustainable option.

Recycling machines contribute to lower greenhouse gas emissions compared to producing materials from scratch. It plays a crucial role in combating climate change and reducing industries’ carbon footprints.

Waste Volume Reduction

Recycling machines come equipped with features like compaction and shredding, significantly reducing waste volume. This compacting effect results in more efficient storage and transportation of waste materials.

Smaller waste volumes achieved through recycling machines allow businesses and municipalities to optimise waste storage and transportation, leading to cost savings and reduced emissions. Also, the recycling process becomes simpler if you have plastic automation machine systems.

Flexibility and Versatility

Recycling machines can handle various materials, from plastics and paper to glass and electronics. Their adaptability makes them suitable for diverse recycling needs.

Each recycling operation may have unique requirements. Recycling machines come with customisable settings, making it possible to tailor the recycling process to specific materials and goals.

Improved Waste Sorting

Recycling machines incorporate advanced sorting technologies, such as optical sensors and AI-driven algorithms, ensuring precise and efficient separation of recyclable materials.

Contamination in recycled materials can compromise their quality and usability. One can minimise contamination using cutting-edge plastic automation machine systems, resulting in higher-quality recycled products.

Job Creation and Economic Impact

Investing in recycling machines is an excellent way to promote environmental sustainability while stimulating the green economy’s growth. By utilising recycling machines, we can reduce waste and minimise the impact on landfills, which helps preserve natural resources.

We can also strengthen the regional economy by supporting local recycling initiatives through these machines. This is because the machines require skilled labour to operate and maintain, providing employment opportunities for local workers. Furthermore, promoting recycling and sustainability can foster a sense of community responsibility, encouraging individuals to preserve the environment actively.

Compliance with Regulations

Many regions have strict regulations regarding waste management and recycling. Investing in recycling machines helps businesses comply with these regulations and avoid potential penalties.

Recycling regulations are there for every entity to follow. If you do not adhere to the legislature, it will bore hefty fines and legal consequences.

Corporate Social Responsibility

Investing in advanced recycling machines is an example of a company’s unwavering commitment to environmental sustainability. It is pivotal in the present world.

Companies foster a positive reputation and brand image by adopting a solid corporate social responsibility strategy. It is a significant factor in attracting new customers and retaining existing ones.

Additionally, customers will support businesses placing a high value on environmental preservation. When businesses invest in recycling machines, they show their commitment to the environment. Ultimately, by prioritising environmental sustainability, companies can substantially impact their bottom line while contributing to a healthier planet for future generations.

Summing Up

Embracing recycling machines offers a multitude of benefits that extend beyond simple recycling efforts. Incorporating machines into waste management can have numerous benefits. These include cost-effectiveness, environmental advantages, energy efficiency, and job creation. These machines are critical in shaping a better future and can help businesses and communities contribute to a cleaner, greener, and more prosperous world.

#Granulation Moulding Machines#World’s fastest Automatic Bagging Machines#High Quality Conveying Machines#ISBM Mould Injection Machines Supplier#Plastic Automation machine systems#Plastics Processing Machinery Australia#Labelling or Decorating Machines#Recycling Machines#inspection machines#injection moulding machines#Plastics Processing Machinery#Blow Moulding Machines

0 notes

Text

12cavity PET Preform mould The cavity No.: 12cavity and in general, it is for the production capacity is not so big. Because in general, the smallest cavity for lightweightPETpreform mould we choose is: 8cavity. In this way, 12cavity PET preform mould is not so big and it can use the same size injection machine compared to the 8cavity. The arrangement for 12cavity plastic PET preform mold is: 6*2 and the width is the same as 8cavity PET preform mold but the capacity could be higher. So I advise you to choose 12cavity compared to the 8cavity PET preform mould. Also for preform mould, we also have PP preform mould, PC preform mould, Tritan preform mould. The 12 cavity PET preform injection mould can produce a mold with high efficiency, as it can drop preforms automatically. Thank you for your kind reading and new technology is updating.

0 notes

Text

What is an Automatic Injection Moulding Machine?

What is an Automatic Injection Moulding Machine?

In the realm of manufacturing, an automatic injection moulding machine stands out as a pivotal tool. This machine has revolutionized the production of plastic parts, making it a cornerstone in industries ranging from automotive to consumer goods. But what exactly is an automatic injection moulding machine, and how does it function?

The Basics of Automatic Injection Moulding Machines

An automatic injection moulding machine is a complex piece of machinery designed for the mass production of plastic parts. It works by melting plastic pellets, injecting the molten plastic into a mould, and then cooling it to form a solid part. The "automatic" aspect of these machines refers to their ability to perform this process with minimal human intervention, relying on advanced programming and robotics.

Key Components and Functionality

The machine consists of several key components: the injection unit, the clamping unit, the mould, and the control system. The injection unit heats and injects the plastic into the mould. The clamping unit then holds the mould closed under pressure while the plastic cools and solidifies. Once the part is cooled, the mould opens, and the part is ejected, ready for use or further processing.

Advantages of Using Automatic Injection Moulding Machines

There are several advantages to using an automatic injection moulding machine:

Efficiency and Speed: These machines can produce high volumes of parts quickly, significantly reducing production time.

Precision and Consistency: They offer a high degree of accuracy, ensuring that each part is identical to the last.

Reduced Labor Costs: The automation reduces the need for manual labor, lowering overall production costs.

Flexibility: They can produce parts of various sizes, shapes, and complexities.

Material Variety: These machines can work with a wide range of plastic materials.

Applications and Industries

Automatic injection moulding machines are used in numerous industries, such as automotive, medical, consumer electronics, and packaging. They are essential for producing items like plastic bottles, automotive parts, medical devices, and household appliances.

Conclusion

An automatic injection moulding machine is a vital component in modern manufacturing, known for its efficiency, precision, and versatility. As technology continues to advance, these machines will undoubtedly play an even greater role in the production of high-quality plastic parts.

0 notes

Text

Case packer manufacturers | Technorobotic

Technorobotics is a leading manufacturer of packaging machinery in India, specializing in the production of case packers, plastic injection moulding machines, bottle unscrambler machines, and bottle screen printing machines. Their case packer machines are designed to handle various types of packaging materials and can be customized to meet specific customer requirements. Their plastic injection moulding machines are known for their high-speed and efficient production capabilities. Their bottle unscrambler machines are designed to sort and feed bottles to production lines seamlessly, increasing production efficiency. Technorobotics' bottle screen printing machines are equipped with advanced technology for high-quality printing on bottles. With a commitment to innovation and customer satisfaction, Technorobotics is a trusted choice for packaging machinery manufacturers in India.

#injection moulding machine#industrial equipments#linear conveyor system manufacturer in india#bottle screen printing machine#bottle screen printing machine manufacturers#oval glass bottle printing machine

0 notes