#Automotive Testing

Explore tagged Tumblr posts

Text

TSM - Technocrat Systems & Measurements | Automotive Testing Excellence | LinkedIn

https://www.linkedin.com/company/tsm-systems-measurement-analysis

Partner with TSM for precision and innovation in automotive testing. From sensors to data loggers, we deliver accurate, reliable, and cost-effective solutions to redefine testing standards. Drive safety, reliability, and performance with TSM!

0 notes

Text

#Crankshaft#Crank Shaft Testing#hardness tester#Multitek Technologies#Automotive Testing#Universal hardness tester#Micro Vickers Hardness tester#Vickers Hardness Tester#Brinell Hardness Tester#Rockwell Hardness Tester

0 notes

Text

Unleashing Peak Performance: Revolutionize Your Workflow with LabVIEW Test Automation

In today’s fast-paced technological landscape, businesses are constantly seeking ways to streamline their processes, reduce errors, and enhance productivity. One powerful solution that has emerged to meet these demands is LabVIEW test automation.

What is LabVIEW Test Automation?

LabVIEW, short for Laboratory Virtual Instrument Engineering Workbench, is a system-design platform and development environment ideal for applications that require test, measurement, and control with rapid access to hardware and data insights. Test automation, within the LabVIEW framework, refers to the process of using software to execute pre-scripted tests on software applications and compare the actual results with expected results.

Benefits of LabVIEW Test Automation

Enhanced Efficiency: By automating repetitive testing processes, LabVIEW test automation significantly reduces the time and effort required to validate software functionality. This allows teams to focus their energy on more strategic tasks, ultimately accelerating time-to-market for products and services.

Improved Accuracy: Human error is inevitable, especially during manual testing procedures. However, with LabVIEW test automation, the risk of errors is greatly minimized. Automated tests execute precisely as programmed, ensuring consistent and reliable results with every run.

Cost Savings: While initial setup costs for test automation may be higher, the long-term savings are substantial. By reducing manual labor hours and mitigating the risk of defects slipping into production, businesses can experience significant cost savings over time.

Scalability: As businesses grow and evolve, so do their testing needs. LabVIEW test automation offers scalability, allowing organizations to easily expand their testing capabilities to accommodate new features, platforms, and technologies.

Transitioning to LabVIEW Test Automation

Transitioning to LabVIEW test automation requires careful planning and execution. Here are some key steps to consider:

Assessment: Evaluate your current testing processes and identify areas that would benefit most from automation. Prioritize tests based on frequency, complexity, and potential impact on business objectives.

Tool Selection: Choose the right tools and frameworks that align with your testing requirements and technology stack. LabVIEW offers a comprehensive suite of tools specifically designed for test automation, ensuring seamless integration and maximum efficiency.

Training and Resources: Invest in training programs and resources to empower your team with the knowledge and skills required for successful test automation implementation. Encourage collaboration and knowledge sharing to foster a culture of continuous learning.

Integration: Integrate LabVIEW test automation into your existing development and deployment pipelines. Establish clear communication channels between development, testing, and operations teams to streamline workflows and ensure smooth transitions.

Continuous Improvement: Test automation is not a one-time endeavor but rather a continuous journey of refinement and optimization. Regularly evaluate your automated tests, identify areas for improvement, and iterate accordingly to maximize ROI.

Conclusion

LabVIEW test automation offers a myriad of benefits, including enhanced efficiency, improved accuracy, cost savings, and scalability. By embracing automation, businesses can streamline their testing processes, accelerate time-to-market, and drive overall performance and competitiveness in today’s dynamic market landscape.

#automation#labview#technology#labviewsoftware#software development#labviewtestautomation#ROI#engineering#automotive testing

0 notes

Text

#Automotive Testing#Inspection and certification (TIC) Market Size#Inspection and certification (TIC) Market Scope#Inspection and certification (TIC) Market Trend#Inspection and certification (TIC) Market Growth

0 notes

Text

Ford GT ( 2006 ) 😎😎. I've added a quick Video at the end 😉

youtube

#ford gt40#gt40#american cars#supercars#fun cars#sports cars#ford cars#muscle cars#car photography#automobile photography#car pics#images of cars#fast cars#great cars#sporty cars#cool cars#classic cars#pictures of cars#images of automobiles#coolest cars#look at this#car show#show car#great automobiles#automotive#test drive#car video#youtube#pics of cars#Youtube

128 notes

·

View notes

Text

Unlocking the Secrets of Engine Health: Vacuum Tests Explained

Vacuum tests are among the most effective tools for diagnosing engine performance issues. By measuring the vacuum in the intake manifold, technicians gain valuable insights into engine health, pinpointing problems like compression, valve timing, ignition, or fuel delivery.

What Are Vacuum Tests?

A vacuum test measures the vacuum created by the pistons during their intake stroke. This reading reveals factors like compression, valve sealing, and ignition timing. Technicians use a vacuum gauge to connect to the intake manifold and observe the needle’s movement in inches of mercury (in. Hg).

How to Perform a Vacuum Test:

1. Prepare Engine: Get the engine to normal temperature.

2. Connect Gauge: Attach the vacuum gauge to the manifold.

3. Start Engine: Let it idle and observe the readings.

4. Record and Analyze: Note the readings and compare them with expected results.

What Do Vacuum Readings Reveal?

• Normal (17-22 in. Hg): Good engine condition.

• Low (below 17 in. Hg): Possible valve timing, ignition, or vacuum leaks.

• Fluctuating Needle: May indicate stuck/burned valves or uneven compression.

• Sharp Drop on Acceleration: Indicates a restricted exhaust system.

Common Issues Diagnosed:

• Stuck/Burned Valves

• Vacuum Leaks

• Compression Issues

• Exhaust Blockages

Conclusion:

Vacuum tests are an efficient, cost-effective method to diagnose engine issues. Whether you’re a professional or a DIY enthusiast, these tests offer quick and reliable insights into your engine’s performance.

17 notes

·

View notes

Text

This La Ferrari test mule is Maranello’s forbidden fruit

While not conventionally beautiful by any means, there’s something brutally attractive about test mule prototypes. Never intended to be seen by the general public, they’re clad with camouflage to deceive onlookers and hide the next-generation technology hiding under their skin. Of all the test mules you could hope to track down, arguably none are as impressive as this La Ferrari test mule; the creme de la creme of the Holy Trinity. Ferrari is well-known for rewarding its most loyal customers, and this La Ferrari test mule was just that when it was sold in 2016, after it was clear that it was no longer required for testing.

Known internally as ‘M6’, this first-phase test mule prototype was based on a Ferrari 458, albeit with a modified aluminium chassis to accommodate the prototype hybrid LaFerrari powertrain, which includes Ferrari’s Type F140FB V12 engine. While virtually unrecognisable when equipped with the detachable test-mule panels that will accompany the car, without them its 458 base is immediately evident, although here a massive roof scoop has been added to compensate for the lack of side-intakes. Although not homologated and therefore not suitable for use on the road or public race tracks, M6 is fully functional and can be enjoyed on private land. Lacking the usual polish one would expect from a Ferrari road car, the rough edges, exposed wires, and mismatched interior panels only add to this prototype’s raw appeal. Certified by Ferrari Classiche with accompanying Yellow Book, this is a unique opportunity to acquire a supremely cool piece of Ferrari history. If this test mule is actually your ideal prancing horse, then be sure to mark rmsothebys Monaco 2022 sale on May 14th in your calendar.

#ferarri#ferarri f1#ferarri racing#supercars#hypercars#prototype#automobiles#testing#test mule#automotive#2000s#fast cars#fast#ugly#cars

8 notes

·

View notes

Text

Honestly, SRS Airbags are kinda cool.

Like, we managed to fit a safety system in a car in the early 2000s that can, in less than the blink of an eye, detect if your buckled, where you're sitting on the seat, where the seat is positioned, how fast the car is going, how fast the opposing car is colliding, and how much you weight.

In that same "less than a blink of the eye" it then weighs all these variables and decides which of the two airbag explosives it should fire, if either.

Like that's pretty damn cool, and the fact that we did in the 2000s shows you that enshitified tech in cars isn't the norm when automakers actually put a genuine effort forward.

#and fun fact#you can actually see this advanced airbag system in action#the NHTSA has required all new cars undergo a 25 mph unbelted full overlap crash test for years now#the YouTube channel CarPro1993 uploads a lot of them from the NHTSA database#in a lot of tests you can see how the car fires the second (much harder) explosive to prevent the dummies from pushing though the airbags#they also release the steering column adjustment mechanism#so the steering wheel can travel back and up out of the driver's way#it's pretty neat#| | |#rambles#cars#car#safety#airbags#automotive safety

6 notes

·

View notes

Text

How WhistlinDiesel Revolutionized Car Reviews

With automotive content, traditional car reviews have long followed a familiar formula: polished shots of vehicles, technical specifications, and reserved commentary on performance. However, with the rise of platforms like YouTube and social media, this formula has been challenged. One creator who stands out in this shift is WhistlinDiesel. Known for his unconventional and often extreme approach,…

#audience engagement#authentic reviews#authenticity#Automotive#automotive brands#automotive creator#automotive industry#automotive journalism#automotive trends#Car Culture#car enthusiasts#car reviews#cars#Cody Detwiler#Community#content creator#content evolution#content strategy#destruction testing#digital content#Durability#entertainment#extreme content#extreme testing#influence#innovation#new media#off-road#online reviews#raw reviews

4 notes

·

View notes

Text

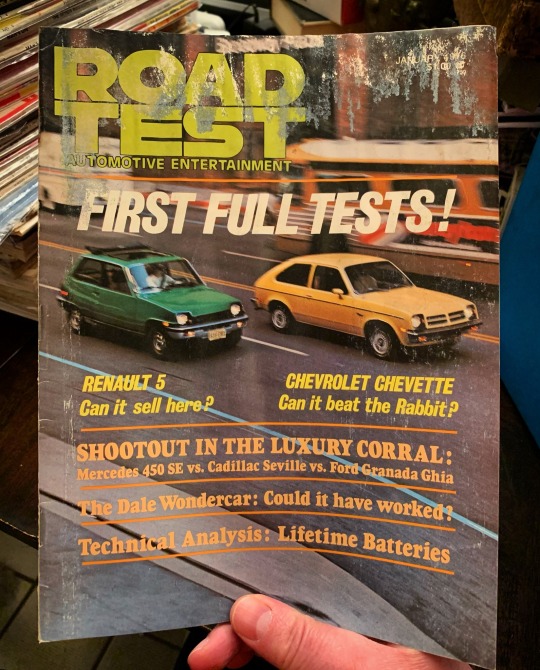

If you remember “Le Car”, that’s the one on the left. I grew up in a Chevette-owning family, so I’m regretfully familiar with the one on the right.

6 notes

·

View notes

Text

Semiconductor & Remote Testing Boost Auto Testing Services

The Mexico automotive testing market is projected to grow at a compound annual growth rate (CAGR) of 3.7% from 2023 to 2030. This upward trend is driven by increasingly stringent vehicle emissions and safety standards, expanding demand for electric vehicle (EV) testing, and growing adoption of advanced Testing, Inspection, and Certification (TIC) services in the country.

Mexico plays a strategic role in the global automotive supply chain, and as vehicle production accelerates, so does the demand for high-quality testing to ensure compliance, performance, and safety.

To Get Free Sample Report : https://www.datamintelligence.com/download-sample/mexico-automotive-testing-market

Key Market Drivers

1. Stricter Emission and Safety Regulations Mexico has tightened its regulatory framework in alignment with global standards, enforcing rigorous emissions controls and safety mandates. This includes the enforcement of soot-free vehicle emission norms and more stringent crash-testing protocols, prompting automakers and parts suppliers to expand testing operations.

2. Growth in TIC Services The automotive TIC (Testing, Inspection, and Certification) market in Mexico was valued at approximately USD 635 million in 2022 and is expected to exceed USD 1.3 billion by 2030. Rising demand for emissions testing, component validation, and homologation processes is fueling this segment’s rapid growth.

3. Rise of Electric and Connected Vehicles The expansion of electric and connected vehicle production has introduced new testing requirements, such as high-voltage battery certification, electromagnetic compatibility (EMC) testing, and ADAS system verification. The EV testing market alone is projected to grow at over 13% CAGR, supporting battery durability and charging system validation.

4. Increase in Automotive Production Mexico remains one of the top vehicle-producing nations globally, with strong exports to North America and Europe. The growth in vehicle output especially in SUVs, EVs, and light trucks is increasing the need for robust local testing capabilities.

5. Industry 4.0 and Digitalization Automotive testing in Mexico is increasingly powered by automation, data analytics, and cloud-based platforms. These technologies streamline quality checks, accelerate certification, and improve data-driven insights for both OEMs and regulators.

Market Segmentation

The automotive testing market in Mexico is broadly segmented by:

Test Type: Engine and transmission testing, chassis testing, durability and vibration analysis, emissions testing, electrical and electronics testing.

Product Type: Emission analyzers, battery testers, chassis dynamometers, alignment systems, and digital diagnostic tools.

Vehicle Type: Passenger cars, commercial vehicles, and electric vehicles.

Engine and transmission testing accounts for the largest share, while EV-related testing is the fastest-growing segment due to increasing vehicle electrification and regulatory requirements.

Regional & Industry Trends

North American Integration Under trade agreements such as USMCA, Mexico aligns its automotive testing standards with the U.S. and Canada. This harmonization ensures products meet stringent export requirements and drives demand for localized testing labs.

EV Component Testing Expansion Mexico’s growing role in the EV supply chain especially in battery and power electronics has created a surge in testing facilities dedicated to thermal safety, high-voltage stress, and software validation.

Underinvestment in R&D Infrastructure Despite strong production capabilities, many Mexican OEMs and Tier 1 suppliers lack advanced R&D labs. This gap presents opportunities for third-party testing providers and international TIC firms to expand service offerings.

Market Challenges

1. Limited In-House Capabilities Many domestic automotive manufacturers depend on external partners for emissions and safety testing due to underdeveloped internal facilities.

2. Capital Intensive Equipment Needs Modern test benches, EMC chambers, and battery validation systems require substantial investment, creating barriers for small-to-medium testing service providers.

3. Regulatory Complexity Automotive testing in Mexico must meet both domestic standards and international certification protocols, which can increase the cost and complexity of compliance.

Get the Demo Full Report : https://www.datamintelligence.com/enquiry/mexico-automotive-testing-market

Future Outlook

EV Testing Growth The demand for electric vehicle testing services particularly battery certification, charger compliance, and motor control system validation is expected to accelerate sharply by 2030.

Digital TIC Platforms AI-driven diagnostics, cloud-based monitoring, and remote inspection capabilities are emerging as core features of next-generation testing services in Mexico.

Government Support and Investment As the Mexican government encourages local automotive innovation, public-private partnerships may fund R&D labs, skill development, and infrastructure upgrades to meet growing testing demand.

Cybersecurity and Software Validation As connected and autonomous vehicle systems expand, there will be a growing emphasis on secure software validation, over-the-air update testing, and data protection protocols.

Competitive Landscape

Key players in Mexico’s automotive testing and TIC ecosystem include:

SGS

TÜV Rheinland

Intertek

DEKRA

Robert Bosch

Siemens

Rohde & Schwarz

AVL

UL Solutions

Anritsu

These firms are expanding their local footprint by offering integrated mechanical, electrical, and digital testing solutions tailored to OEM needs and regulatory requirements.

Conclusion

Mexico’s automotive testing market is undergoing a transformation, driven by tighter regulations, increasing EV adoption, and the rise of smart vehicle technologies. As the country reinforces its position as a key player in global automotive manufacturing, demand for high-quality testing services is set to grow steadily through 2030. With targeted investment, digital innovation, and strategic partnerships, Mexico can not only meet domestic testing needs but also serve as a testing hub for the broader Latin American and North American regions.

0 notes

Text

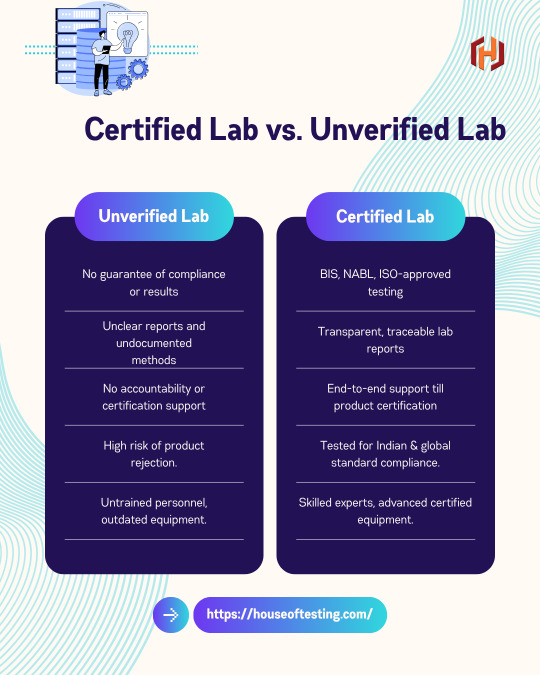

What’s the real difference between a certified testing lab and just a local one?

This project aimed to visually contrast Certified Testing Labs against Unverified ones, assisting manufacturers and startups in grasping the significance of NABL, BIS, and ISO-approved testing services.

Central to this effort is House of Testing, a reliable and NABL-accredited lab, aiding brands in adhering to India's stringent compliance standards.

🎯 Goal Boost brand recognition of the value of certified testing

Inform clients about the hazards associated with unverified labs

Establish House of Testing as the primary BIS/TEC/ISI testing partner

Incorporate SEO keywords into the project's visuals and wording

Visual Approach Two-part layout: Left side = Unverified, Right side = Certified

Red and Green color scheme to represent warnings versus approvals

Simple icons: ❌ versus ✅ for quick visual recognition

Content designed for Instagram, Behance, and LinkedIn

🔑 SEO Keywords: NABL accredited lab

Certified lab versus unverified lab

BIS certified testing

NABL lab near me

ISI mark testing

product testing India

House of Testing

testing for BIS/TEC/ISI certification

📈 Outcomes Enhanced social interaction and content dissemination

Achieved higher rankings for search terms such as “NABL lab near me” and “certified testing labs”

Shared by over 10+ tech manufacturers for their internal onboarding

Reused in carousel posts and certification webinars

📞 About House of Testing House of Testing is a prominent NABL-accredited and BIS-recognized product testing lab located in Noida. We deliver electrical, environmental, and compliance testing services across various sectors, providing accurate reporting, expert support, and complete certification assistance.

Phone: 9899994387 Website: https://www.houseoftesting.com/ Address: B-78, B Block, Sector 5, Noida, Uttar Pradesh 201301 Instagram : https://www.instagram.com/houseoftesting?igsh=ZXoyZzMweXMxOHI3&utm_source=qr facebook : https://www.facebook.com/share/1ajhbTkGp7/?mibextid=wwXIfr

0 notes

Text

Growth of the EV Battery Testing Equipment Market

The EV Battery Electrical Testing Equipment Market plays a critical role in ensuring the safety, performance, and reliability of electric vehicle batteries. The necessity of stringent testing, inspection, and certification procedures has been highlighted by the rise in EV battery component failures. Additionally, the emergence of digital technologies is changing testing practices and making real-time, more accurate diagnosis possible. Manufacturers are investing in cutting-edge testing apparatus that supports battery cells, modules, packs, and Battery Management System (BMS) Hardware-in-the-Loop (HIL) simulation as battery technologies advance, opening the door for improved quality control and market expansion.

Key Growth Drivers

Increase of EV Battery Issues: High-accuracy testing solutions are in greater demand as the failure rate of EV battery components rises. To guarantee long-term safety, dependability, and battery life, these instruments are crucial for identifying even the smallest defects.

Testing's Digital Transformation: Battery testing is becoming much more accurate and efficient thanks to technologies like artificial intelligence (AI), machine learning, and real-time analytics. The market's growth is further supported by these tools, which make predictive maintenance, more intelligent diagnostics, and quicker decision-making possible.

Market Challenges

Regulatory Standards Are Changing: Manufacturers are constantly under pressure to upgrade their testing procedures and equipment due to changing testing laws, which can be expensive and time-consuming.

Connecting Legacy Systems: There may be financial and technical challenges when integrating cutting-edge testing technology with outdated infrastructure. This intricacy could increase implementation costs and hinder market penetration.

Key Market Players

Arbin Instruments

Tektronix

Keysight Technologies

Rohde & Schwarz

Dynamic Manufacturing, Inc.

ATEC

Chroma ATE

Fluke Corporation

Yokogawa Electric Corporation

Market Segmentation

By Application

Battery Cell

Battery Module and Pack

BMS HIL

By Product

Oscilloscopes

Digital Multimeters

Source Measure Units (SMUs)

Battery Management System Testers

By Region

North America

Europe

Asia-Pacific

Rest of the World

Download TOC for this report!

Learn more about Automotive Vertical. Click Here!

Conclusion

The need for dependable battery testing equipment is anticipated to increase significantly as the global shift to electric vehicles picks up speed. Stricter regulations, quick technological breakthroughs, and a quest for safer, better-performing batteries are all influencing the industry. The emphasis on digital precision and innovation places this market as a pillar of the EV industry's future success, despite obstacles including legacy system integration and standardization.

#EV Battery Testing Equipment Market#EV Battery Testing Equipment Industry#EV Battery Testing Equipment Report#automotive

0 notes

Text

LabVIEW Data Acquisition System

Data acquisition is a critical aspect of various industries, from scientific research to industrial automation. LabVIEW, developed by National Instruments, offers a powerful platform for designing and implementing data acquisition systems efficiently. In this article, we'll delve into the intricacies of LabVIEW data acquisition systems, exploring their components, setup, programming, benefits, applications, case studies, challenges, and future trends.

Introduction to LabVIEW Data Acquisition System

Understanding Data Acquisition Systems

Data acquisition systems are instrumental in collecting and processing data from physical phenomena or systems. These systems typically consist of sensors, signal conditioning hardware, and software for data processing and analysis.

Importance of LabVIEW in Data Acquisition

LabVIEW stands out as a premier software tool for data acquisition due to its user-friendly graphical programming interface and extensive library of functions for signal processing, analysis, and visualization.

Components of a LabVIEW Data Acquisition System

Hardware Components

A LabVIEW data acquisition system comprises various hardware components, including sensors, signal conditioning modules, data acquisition devices (DAQ), and interfaces for connecting with external devices.

Software Components

LabVIEW software provides the programming environment for configuring, controlling, and monitoring data acquisition processes. It offers a wide range of built-in functions and libraries for seamless integration with hardware components.

Setting Up a LabVIEW Data Acquisition System

Installation Process

Setting up LabVIEW involves installing the software on a compatible computer system and configuring it to communicate with the hardware components of the data acquisition system.

Configuring Hardware

Once the software is installed, users need to configure the hardware components by selecting appropriate drivers and setting up communication protocols within the LabVIEW environment.

Programming in LabVIEW for Data Acquisition

Basics of LabVIEW Programming

LabVIEW programming involves creating virtual instruments (VIs) using a graphical programming language known as G, which utilizes a block diagram approach for visual representation of code.

Data Acquisition Techniques

LabVIEW offers various data acquisition techniques, including analog and digital input/output, voltage measurements, frequency measurements, and waveform generation, all of which can be implemented through intuitive programming constructs.

Benefits of Using LabVIEW for Data Acquisition

Versatility and Flexibility

LabVIEW provides a versatile and flexible platform for designing custom data acquisition systems tailored to specific application requirements.

Integration with Other Systems

LabVIEW seamlessly integrates with other systems and software tools, allowing for interoperability and compatibility with existing infrastructure.

Scalability and Customization

LabVIEW offers scalability, enabling users to expand their data acquisition systems as per evolving needs, along with extensive customization options for optimizing performance.

Applications of LabVIEW Data Acquisition System

Industrial Automation

LabVIEW data acquisition systems find extensive applications in industrial automation for monitoring and controlling processes in manufacturing, quality assurance, and product testing.

Scientific Research

In scientific research, LabVIEW facilitates data collection and analysis in diverse fields such as physics, chemistry, biology, and environmental science, enabling researchers to conduct experiments and gather insights efficiently.

Medical Monitoring

LabVIEW-based data acquisition systems play a crucial role in medical monitoring applications, including patient monitoring, diagnostic equipment, and biomedical research, aiding in the advancement of healthcare technologies.

Environmental Monitoring

LabVIEW is utilized for environmental monitoring tasks such as weather forecasting, pollution detection, and ecological research, contributing to the preservation and sustainability of natural resources.

Case Studies: Real-World Implementations

Case Study 1: Automotive Testing

LabVIEW data acquisition systems are employed in automotive testing facilities for evaluating vehicle performance, conducting crash tests, and analyzing vehicle dynamics under various conditions.

Case Study 2: Weather Monitoring

Meteorological agencies utilize LabVIEW-based data acquisition systems for collecting and analyzing weather data, including temperature, humidity, wind speed, and precipitation, to forecast weather patterns accurately.

Case Study 3: Biomedical Research

In biomedical research laboratories, LabVIEW facilitates the acquisition and analysis of physiological data, imaging data, and genetic data, supporting advancements in disease diagnosis, treatment, and drug development.

Challenges and Solutions in LabVIEW Data Acquisition

Compatibility Issues

One challenge in LabVIEW data acquisition is compatibility issues between hardware components and software versions, which can be mitigated through careful selection and configuration of compatible components.

Data Processing Challenges

Processing large volumes of data in real-time poses another challenge, requiring efficient algorithms and hardware optimization techniques to ensure timely and accurate data acquisition and analysis.

Calibration and Maintenance

Regular calibration and maintenance of hardware components are essential to maintain the accuracy and reliability of LabVIEW data acquisition systems, requiring adherence to best practices and standards.

Future Trends in LabVIEW Data Acquisition

Advancements in Hardware Technology

Future advancements in hardware technology, such as faster processors, higher-resolution sensors, and wireless connectivity, will enhance the performance and capabilities of LabVIEW data acquisition systems.

AI Integration

Integration of artificial intelligence (AI) algorithms into LabVIEW data acquisition systems will enable predictive analytics, anomaly detection, and autonomous decision-making, revolutionizing data acquisition processes.

IoT Integration

LabVIEW data acquisition systems will increasingly integrate with the Internet of Things (IoT) ecosystem, leveraging cloud computing, edge computing, and wireless sensor networks for enhanced connectivity, scalability, and interoperability.

Conclusion

LabVIEW data acquisition systems offer a comprehensive solution for collecting, processing, and analyzing data across various industries and applications. With its user-friendly interface, robust functionality, and versatility, LabVIEW continues to empower engineers, researchers, and scientists in their quest for innovation and discovery. If you want to read more blogs/articles so visit on PujaControls

#automation#labview#technology#software development#iot#iot integration#ai integration#automotive testing#industrial automation

0 notes

Text

Understanding ISO Standards for Automotive Textiles Testing

In the automotive industry, textiles used for vehicle interiors must meet stringent quality, safety, and performance requirements. From seat covers and airbags to door panels and carpets, automotive textiles play a vital role in passenger comfort, safety, and vehicle aesthetics. To ensure these textiles meet global benchmarks, rigorous testing aligned with internationally recognized standards is essential.

Among these, ISO standards hold a prominent position, providing clear guidelines and procedures for testing automotive textiles. This blog explores key ISO standards relevant to automotive textiles testing, their significance, and how they support manufacturers in delivering reliable, high-quality automotive textile products.

Why ISO Standards Matter in Automotive Textiles Testing

The International Organization for Standardization (ISO) develops standards that unify testing methods across industries worldwide. In automotive textiles, ISO standards help:

Ensure consistent product quality irrespective of geography or manufacturer

Facilitate compliance with international regulations and customer requirements

Enhance safety by specifying flammability, durability, and performance criteria

Support innovation by providing clear testing protocols for new materials

Build consumer trust through verified and certified textile performance

By adhering to ISO standards, automotive manufacturers and suppliers can confidently offer products that meet or exceed industry expectations.

Key ISO Standards for Automotive Textiles Testing

Here are some of the most important ISO standards widely used in automotive textiles testing:

1. ISO 105 – Textiles: Tests for Color Fastness

Color fastness is crucial for automotive textiles to maintain their appearance despite exposure to sunlight, washing, rubbing, and chemicals.

ISO 105-B02: Color fastness to artificial light (Xenon arc lamp) simulating sunlight exposure

ISO 105-X12: Color fastness to rubbing (crocking)

ISO 105-C06: Color fastness to domestic and commercial laundering

Testing ensures fabrics retain their color integrity, crucial for aesthetic and branding purposes.

2. ISO 13934-1 – Tensile Properties of Fabrics

This standard specifies methods to measure the maximum force that a textile fabric can withstand before breaking (tensile strength). For automotive textiles, tensile strength is vital to:

Ensure seat covers and airbags withstand mechanical stress

Prevent fabric tearing under prolonged use

ISO 13934-1 provides procedures to test tensile strength and elongation, essential for durability assessments.

3. ISO 12947 – Martindale Abrasion Test

Abrasion resistance testing, under ISO 12947, assesses how well automotive textiles endure surface wear due to rubbing or friction.

Essential for seat upholstery, carpets, and door trims exposed to constant use

Measures the number of cycles before fabric damage

High abrasion resistance ensures longer-lasting interiors with maintained appearance.

4. ISO 15025 – Protection Against Heat and Flame

Automotive textiles must meet strict flammability requirements to ensure passenger safety in case of fire.

ISO 15025 outlines methods to determine if fabrics resist ignition and burning

Helps evaluate materials for airbags, seat covers, and interior linings

Passing ISO 15025 tests is critical for meeting global safety regulations.

5. ISO 2076 – Textile Fibers: Generic Names and Codes

Understanding fiber composition is key for automotive textiles testing. ISO 2076 standardizes fiber identification, allowing:

Precise labeling of textile materials

Easier compliance checks with chemical and environmental regulations

Correct fiber identification supports targeted testing for durability, chemical resistance, and environmental impact.

6. ISO 2556 – Tear Resistance of Fabrics

Tear resistance testing measures the force required to propagate a tear once initiated.

Important for assessing automotive textiles exposed to sharp objects or sudden stresses

Ensures fabric integrity under real-world conditions

ISO 2556 helps manufacturers select materials that minimize the risk of sudden failure.

7. ISO 9073 – Test Methods for Nonwovens

Nonwoven textiles are increasingly used in automotive applications like filters, insulation, and interior panels. ISO 9073 series provides test methods to evaluate:

Tensile strength

Bursting strength

Thickness and density

Testing nonwoven textiles ensures they meet the specific performance needs in vehicles.

How ISO Standards Support Automotive Industry Needs

Quality Assurance and Consistency

Using standardized ISO testing methods guarantees that automotive textiles consistently meet defined performance levels. This reduces variability between batches and suppliers, ensuring uniform quality across global production lines.

Regulatory Compliance

Many countries incorporate ISO standards into their automotive safety and environmental regulations. Meeting these standards facilitates market entry and acceptance, avoiding costly delays or product recalls.

Enhancing Product Safety

By rigorously testing flammability, strength, and durability as per ISO guidelines, manufacturers ensure that automotive textiles contribute to vehicle safety and passenger protection.

Facilitating Innovation

ISO standards offer clear protocols that accelerate the development of new textile materials and composites by providing reliable test methods to verify performance claims.

Role of Accredited Labs in ISO Automotive Textiles Testing

ISO testing requires specialized equipment and expertise. Accredited laboratories, certified under ISO/IEC 17025, offer:

State-of-the-art instruments and standardized procedures

Skilled professionals trained in automotive textile testing

Reliable and internationally recognized test reports

Support for certification and regulatory submissions

Collaborating with accredited labs ensures credible testing results that can be confidently used to validate automotive textiles.

Conclusion

Understanding and applying ISO standards in automotive textiles testing is essential for manufacturers aiming to deliver safe, durable, and high-quality vehicle interiors. From assessing color fastness and tensile strength to verifying flammability resistance, these standards provide a global benchmark for performance and safety.

Adherence to ISO standards not only ensures regulatory compliance but also enhances product reliability, consumer confidence, and innovation. Automotive companies that invest in comprehensive ISO-based textiles testing position themselves strongly in the competitive and evolving automotive market.

#automotive textile testing#textile testing lab#textile testing#testing lab near me#testing lab in delhi

0 notes

Text

0 notes