#Biofilter

Explore tagged Tumblr posts

Text

Odour Control in Fish and Shrimp Feed Manufacturing: Strategies for a Cleaner Production Process

Introduction

The fish and shrimp feed manufacturing industry plays a vital role in aquaculture, providing essential nutrition for farmed species. However, one of the major challenges faced by feed producers is odour emissions during processing. Strong, unpleasant odours can arise from raw materials like fishmeal, fish oil, and other protein-rich ingredients, leading to environmental concerns and potential regulatory issues.

Effective odour control is crucial not only for maintaining a healthy work environment but also for ensuring compliance with environmental regulations and fostering good community relations. In this blog, we will explore the sources of odour in fish and shrimp feed production and discuss practical strategies to mitigate them

Common Sources of Odour in Fish and Shrimp Feed Manufacturing

1. Raw Materials

Fish Meal: Made from whole fish or fish byproducts; has a strong, pungent odour due to the presence of volatile nitrogen compounds like trimethylamine.

Shrimp Shell meal: Often contains chitin, protein residues, and fats that decompose quickly and emit foul smells.

Other Marine Ingredients: Algae, krill, squid, and crustacean byproducts all contribute to the distinctive odour due to high protein and oil content.

Animal Fats and Oils: These can oxidize and emit rancid smells.

2. Processing Stages

Grinding and Mixing: Releases dust and odorous particles from protein-rich materials.

Cooking/Extrusion: High temperatures volatilize amines, sulfur compounds, and fatty acids, leading to a cooked or burnt protein smell.

Drying: Moisture evaporation carries volatile organic compounds (VOCs) into the air, intensifying odour.

Cooling and Packaging: Residual heat and exposed feed particles can continue to release odours if not quickly cooled or sealed.

3. Storage and Waste Handling

Spoiled Raw Materials: Decomposition of ingredients in storage can produce ammonia, hydrogen sulfide, and VOCs.

Wastewater and Solid Waste: Effluents from wash water and organic solids (like sludge or leftover ingredients) decay and emit unpleasant odours.

4. Microbial Activity

Bacteria and fungi acting on proteins and fats in raw materials and waste streams produce odorous compounds such as:

Ammonia

Hydrogen sulfide

Volatile fatty acids

Putrescine and cadaverine (from protein decay)

Environmental and Community Impact of Odour in Fish and Shrimp Feed Manufacturing

Odour emissions from fish and shrimp feed manufacturing plants are a significant environmental concern affecting air quality and local communities. These odours, mainly caused by volatile organic compounds (VOCs) and nitrogenous compounds released during processing, contribute to air pollution and can lead to frequent community complaints. Persistent and strong odours from aquafeed production can also negatively impact local biodiversity by disturbing nearby ecosystems and sensitive wildlife.

Effective odour control in fish feed manufacturing not only reduces these environmental impacts but also helps improve relations with surrounding communities. By managing odour emissions proactively, feed manufacturers can prevent complaints, avoid costly fines, and reduce the risk of legal action. Strong odour management practices enhance a company’s reputation and demonstrate a commitment to sustainable and responsible aquaculture production.

Regulatory Framework and Compliance for Aquafeed Odour Control

The fish and shrimp feed manufacturing industry must comply with strict environmental regulations related to odour emissions and air pollution control. In India, agencies like the Central Pollution Control Board (CPCB) enforce standards for odour limits and air quality that feed producers must meet. Globally, regulations from bodies such as the United States Environmental Protection Agency (EPA) and the European Union (EU) provide guidelines for industrial odour control and emissions management in aquafeed production.

Compliance with these odour regulations is essential for legal operation and plays a vital role in corporate social responsibility (CSR) and sustainability reporting. Meeting regulatory requirements helps aquafeed manufacturers avoid penalties, ensures operational continuity, and supports environmental stewardship goals. Integrating advanced odour control technologies and following regulatory frameworks enable companies to reduce volatile organic compounds (VOCs) and improve air quality, fostering sustainable fish and shrimp feed production.

Proven Odour Control Strategies in Aquafeed Production

To address these challenges, manufacturers can adopt the following strategies:

1. Optimize Raw Material Handling

Proper Storage: Store fish meal and oil in sealed, temperature-controlled environments to minimize oxidation and VOC release.

Quality Control: Use fresh, high-quality raw materials to reduce the presence of odorous compounds.

Inventory Management: Implement first-in, first-out (FIFO) systems to prevent spoilage.

2. Install Odour Control Systems

Biofilters: These use microorganisms to break down odourous compounds. They are cost-effective and environmentally friendly for treating exhaust air from processing areas.

Scrubbers: Wet scrubbers can neutralize odours by passing exhaust gases through a liquid solution, capturing VOCs and amines.

Thermal Oxidizers: For high-odour loads, thermal oxidizers burn off volatile compounds, converting them into less harmful substances like carbon dioxide and water.

3. Enhance Processing Techniques

Low-Temperature Processing: Use lower temperatures during drying and extrusion to reduce the release of volatile compounds.

Enclosed Systems: Design processing equipment with enclosed systems to contain odours and direct them to treatment units.

Ventilation: Install high-efficiency ventilation systems to capture and treat odourous air before release.

4. Waste Management

Effluent Treatment: Treat wastewater and processing byproducts promptly to prevent odor generation. Anaerobic digesters can convert waste into biogas, reducing odour and generating energy.

Regular Cleaning: Clean equipment and storage areas regularly to prevent residue buildup, which can contribute to odours.

5. Monitor and Maintain

Odour Monitoring: Use sensors to detect and measure odour levels in real-time, allowing for quick adjustments to control systems. Electronic noses and gas sensors such as Odosnese of Oizom provide continuous monitoring, enabling rapid response to odour spikes.

Maintenance of Equipment: Regularly maintain odour control systems like biofilters and scrubbers to ensure optimal performance.

Case Study: How Elixir Enviro Systems Helped a Shrimp Feed Plant Achieve 4 OU/m3 at outlet

A leading shrimp feed manufacturer with a production capacity of 400 tons per day was facing persistent and intense odour emissions at its facility. The primary raw materials—fishmeal, fish oil, soybean meal, vitamins, and minerals—generated strong, fishy odours, particularly during cooking, drying, and cooling phases. Additional odour sources included the grinder unit and material conveying systems.

The company approached Elixir Enviro Systems Pvt. Ltd. for an end-to-end odour control solution. After a detailed site audit and airflow assessment, Elixir designed and installed a high-performance odour abatement system consisting of:

Dust scrubbers to remove particulates and pre-condition the exhaust air

Two high-rate Ultrafil biofilters in parallel to biologically treat odourous compounds like trimethylamine, diamines, and ammonia

A blower system rated at 75,000 CMH, equipped with a Variable Frequency Drive (VFD) for optimal flow control

The system was engineered to handle a process airflow of 75,000 CMH, blending hot air from the dryer and directing it efficiently into the biofilters. Performance testing revealed a remarkable odour removal efficiency with final odour concentration at the outlet measuring just 4 OU/m3 (Odour Units), when tested using field olfactometry—well below industry standards

💡 Outcomes:

✅ Extremly high odour reduction, ensuring environmental compliance

✅ Drastic improvement in workplace air quality

✅ Fewer complaints from neighbouring communities

✅ Enhanced brand reputation and community relations

✅ System designed for scalability and long-term operational efficiency

This successful implementation not only eliminated odour-related complaints but also helped the client align with environmental norms, boosting their sustainability credentials.

Elixir Enviro Systems – Experts in Aquafeed Odour Control

If you’re seeking reliable odour control solutions for fish and shrimp feed manufacturing, Elixir Enviro Systems is your trusted partner. We specialize in industrial odour treatment, wastewater management, and biofiltration systems for factories and processing plants.

With years of experience, Elixir offers complete turnkey solutions—from design and installation to testing and long-term maintenance. Whether your facility requires wet scrubbers, biofilters, regenerative thermal oxidizers (RTOs), or real-time odour monitoring systems, Elixir has you covered.

Why Choose Elixir Enviro?

✅ Pioneer in Industrial Odour Control in India

✅ Largest player in India, treating about 1 Million cubic meters of air per hour

✅ Experts in aquafeed manufacturing odour control

✅ Custom solutions tailored to your industrial odour challenges

✅ In-house R&D and advanced simulation tools

✅ Onsite odour audits and pilot testing for optimized solutions

✅ Solutions designed to meet all local and global environmental regulations

Our expertise and innovative technology ensure your facility operates with minimal odour impact while maintaining productivity and compliance

Conclusion

As the aquafeed industry continues to grow, so does the responsibility to operate sustainably and sensitively—especially when it comes to odour emissions. Effective odour control in fish and shrimp feed manufacturing is not just about meeting regulations; it’s about protecting the health and well-being of plant workers, maintaining good relationships with surrounding communities, and upholding your company’s environmental integrity.

By implementing smart engineering controls, modern treatment technologies, and best operational practices, facilities can significantly reduce their odour footprint while improving overall efficiency and compliance.

At Elixir Enviro Systems, we specialise in designing and delivering tailored odour control solutions that work—from raw material intake to final air discharge. Whether you’re upgrading an existing system or planning a new facility, we’re here to help you create a cleaner, safer production environment.

📞 Ready to tackle odour challenges at your aquafeed plant?

💬 Contact Elixir Enviro Systems today for expert consultation, onsite assessment, or a custom solution that meets your regulatory and operational goals.

FAQ

Q1: Why is odour control important in fish and shrimp feed manufacturing?

Odour control helps reduce environmental pollution, ensures compliance with regulations, protects worker health, and maintains good relations with nearby communities.

Q2: What are the main sources of odour in aquafeed production?

Odour mainly originates from raw materials like fishmeal and shrimp meal, processing stages (grinding, cooking, drying), storage of raw materials and waste, and microbial activity breaking down organic compounds.

Q3: Which technologies are effective for odour control in feed plants?

Common technologies include biofilters, wet scrubbers, thermal oxidizers, enclosed systems, and advanced ventilation combined with real-time odour monitoring.

Q4: How can wastewater treatment help with odour control?

Treating wastewater and organic solids promptly prevents decomposition that generates odours. Methods like anaerobic digestion reduce odours and produce useful biogas.

Q5: How often should odour control equipment be maintained?

Regular maintenance is essential and should be conducted based on manufacturer guidelines and site-specific needs to ensure continuous effective performance.

0 notes

Text

BioClear Solutions

BioFilter

Filters in Aquariums

Aquarium filters play a vital role in maintaining the health and cleanliness of aquatic ecosystems. They remove harmful toxins, debris, and waste from the water, ensuring a balanced environment for fish and plants to thrive. For aquarium owners, filters reduce the need for frequent water changes, simplify tank maintenance, and protect aquatic life, making them indispensable tools for both beginners and seasoned hobbyists.

Introducing the BioFilter

Our BioFilter is an innovative biological filter designed to revolutionize aquarium care. Unlike conventional filters, it uses advanced biofiltration technology to efficiently break down harmful ammonia and nitrites, promoting a healthier aquatic environment. Its unique design enhances water clarity, reduces maintenance requirements, and is eco-friendly. Compared to commercial filters, the BioFilter stands out for its cost-effectiveness, durability, and superior filtration performance, making it a valuable investment for aquarium enthusiasts.

The BioFilter offers a game-changing solution for aquarium owners seeking effective and sustainable filtration. Its innovative design and exceptional advantages over conventional filters ensure healthier aquatic ecosystems while simplifying maintenance tasks. With the BioFilter, maintaining a thriving aquarium has never been easier.

0 notes

Text

4 more hours I can do this I'm so brave and strong and pretty

20 notes

·

View notes

Note

id also like a happy meal with extra happy

Of course!!

1 note

·

View note

Text

O822.4577.1975 | Jual Media Sarang Tawon IPAL Surabaya

Hub : O822-4577-1975 (AUROZA TEKNIK), Kami jual media sarang tawon untuk IPAL di Surabaya - Sidoarjo. Menerima pemesanan jual sarang tawon septic tank, harga sarang tawon septic tank, biofilter sarang tawon surabaya, sarang tawon septic tank surabaya, sarang tawon honeycomb surabaya, sarang tawon ipal sidoarjo, harga sarang tawon ipal, jual media sarang tawon sidoarjo, sarang tawon untuk ipal

Untuk info dan pemesanan, silakan hubungi :

0822-4577-1975 (Telp/WA)

#jual media sarang tawon ipal surabaya#jual sarang tawon septic tank#harga sarang tawon septic tank#biofilter sarang tawon surabaya#sarang tawon septic tank surabaya#sarang tawon honeycomb surabaya#sarang tawon ipal sidoarjo#harga sarang tawon ipal#jual media sarang tawon sidoarjo#sarang tawon untuk ipal

1 note

·

View note

Note

hey. hey. ever think about how ax knows how to combine DNA on the fly and only does it once to create his humansona. and then as far as I'm aware this is never brought up again.

(also do you think K.A.A. was Aware they were creating a straight up intersex character, or)

the frolis maneuver is actually brought up one other time, when elfangor makes his human morph and becomes a nothlit to stay with loren on earth. i do think it's weird that i'd only have two nickels, though, because you'd think this kind of insane tech would be explained more or used in other contexts, but i guess there were just. not enough applications for it to matter??? i guess??? even though ax's human morph is commented on in pretty much every book he uses it in.

i feel like, using the frolis maneuver, you could pose as a random controller pretty easily for like, spy-work, at least outside the pool, but who knows. i also wonder how the gleet biofilter exactly works in the books, because from what i'm seeing from a gloss-through (i meant for it to be brief, but it just left me with more questions and now ive been at this for an hour), in the tv show it can sniff out the lack of yeerk in your brain, and in the books the biofilter can't actually detect anything inside the body of anything else??? even though cassie goes through the biofilter with tidwell in her brain, and says it detected "only yeerk and human", exactly ONE book before that the animorphs, confusingly, successfully negate it by sneaking in through the nostrils of a cow...! which seems weird, to me. if the biofilter can detect a yeerk through the scalp and skull of a human, why can't it detect a fly in a cow nose??

anyway, i think you could make potentially infinite random guys to morph into and pose as to sneak past the biofilter. depending on whether it allows non-infested humans through or not. which seems to be a big fat question mark. if so, more "fun" missions to drag tidwell and aftran into!

and as for applegate Knowing she was creating an intersex character, i think that's something you'd have to ask her. super cool that it turned out that way though!

#ask#animorphs#andalite#txt#the answer may just be that the ghostwriter for book 28 phoned it in. not a very good book anyway woops#and the frolis maneuver just never got super explained or used anytime else because that would require EVEN MORE rules#and there are already so many to keep track of. two hour limits and allergies and distractions and exhaustion and#not to mention all the bullshit that had to be made up for scenarios you'd never ever find yourself in. like looking through fly eyes#or morphing a flea when you've been hit with a shrink ray#or seeing erek's metal chassis through a hologram with spider eyes Y'know. theres a lot going on here#andalite tech#tagging because i might want to do a proper deep dive into the inconsistencies of andalite tech and its yeerk offshoots

30 notes

·

View notes

Note

anitv Jake did WHAT

OP refers to these tags #4d chess psychological warfare#like that time in anitv jake acquires tom and successfully talks a bunch of controllers into shooting the real tom

The episode "Face/Off Pt. 3" is a classic combination of AniTV having some plot ideas with fascinating potential... and then executing those ideas so badly the show is nigh-unwatchable.

Various Animorphs are running around the yeerk pool in the season finale. (Rachel is in Tobias's brain as a yeerk to defeat the Gleet Biofilter, speaking of cool ideas that got wasted.) Jake drags Tom into a back room, and when the controllers break down the door, there are two identical copies of Tom standing there. It's kinda cool that the audience also doesn't know which one's Tom and which is Jake, because both of them immediately start shouting about how the other one is an imposter and the controllers should shoot that guy.

For the rest of the episode — which switches to focus on how Marco collapses the entire yeerk pool cavern by pulling down a single ceiling tile and throwing it against a pillar — there are two copies of Tom running around. There's some dramatic tension when we see one of the Toms get crushed to death by falling rubble and don't know if Jake just died, as well as in a later scene where one of the Toms walks in on Cassie mid-morph. That Tom demorphs into Jake, with the honestly funny line "Phew! My parents were about thirty seconds away from having a set of identical twins." Original flavor Tom is dead in the basement, but that's fine, because the Animorphs are off to a dance party. Also, Tom's back two episodes later with no explanation because Melissa Chapman needs a boyfriend. Sigh. So much potential, so badly wasted.

#animorphs#anitv#jake berenson#tom berenson#yes i know there are *glaring* plot holes and character inconsistencies in this concept#including tom not recognizing jake as jake is standing six inches away and talking directly to him#including jake casually trying to get tom killed after proving willing to let cassie maybe-die to save tom in an earlier episode#but i still think it's a really cool idea that i wish we'd seen k.a. applegate explore in animorphs canon#with good writing and coherent plotting and all

208 notes

·

View notes

Text

Day Twelve - Kinktober 2024

Day 12: Breeding / Collars / Sex Pollen Male Sole Survivor/Paladin Danse Rating: Explicit | Word Count: 1451 Warnings: Sex pollen, dubcon, oral sex, rough oral sex, come eating

Ghost of a Boy Kinktober Prompt List | Kinktober '24 Masterlist Divider by @saradika-graphics

The trap had gone off unexpectedly. One moment Nate and Danse had been walking down a corridor, heading back towards the exit of the long-forgotten bunker they had stumbled on, their packs filled with salvage, ammo, and a brand new bobblehead to add to Nate’s collection. The next moment the entire area was filled with a strange purple mist that left Nate spluttering and running for the main doors.

“It’s breached my power armor’s biofilters!” He heard Danse call out, before feeling the large armored hand of the paladin pushing him forward. “Keep moving soldier! We need to get out of this enclosed environment!”

Coughing and wheezing, Nate fell to his knees as soon as they got outside, the twinkling stars of the Commonwealth sky never looking more welcoming. Turning back to the bunker doors Nate watched as Danse finally appeared in a swirl of purple. Pulling off his helmet, Danse’s eyes were streaming with tears, as the larger man dropped to one knee while a hacking cough wracked his body.

“What the hell was that?” Nate choked out between coughs. “We passed through there on the way in. There was nothing to trigger. We cleared it.”

“Clearly a secondary security system we missed.” Danse frowned, standing back up and offering Nate a hand. “Perhaps designed to trigger as people were leaving.”

“Assholes.” Nate brushed specks of purple dust off his shoulders and collected a small amount on his fingertips. Carefully he held it up to his Pip-Boy’s sensor.

“Indeed.”

“Well, I’ve no idea what that shit was, but hopefully my Pip-Boy will be able to figure it out.” Looking around the area, Nate pointed off into the distance to the familiar red glow of an old Red Rocket station. “In the meantime, we should get somewhere safe, or you know, safer.”

“Affirmative.” Danse nodded, blinking his eyes with a shake of his head. “Lead on.”

The Red Rocket couldn’t have been more than fifteen minutes away from the bunker, but the journey felt like forever. At first, they had walked in silence, as night was especially dangerous in the Commonwealth. But soon the cramps had hit and both men had let out involuntary groans, Nate dropping to his knees once more until the pain subsided. From there it had only gotten worse.

By the time the two men stumbled through the doors of the dilapidated gas station, they were both pouring with sweat. Danse looked pale with a constant expression of intense pain and determination on his handsome face. Nate’s head was swimming and he was struggling to focus. His attention was constantly shifting between trying to be aware of his environment and the dull throbbing ache between his legs.

The heat and arousal had started not long after the cramps, beginning with an intense thrum that seemed to spread through his entire body sending goosebumps dancing across his skin. With each wave of pain, the tingling got worse, until Nate’s cock was hard and heavy. It ached and throbbed with each movement, pulling soft moans from him as he walked.

Danse knew; he had to. There was no hiding Nate’s erection in his condition. His dust-covered jeans obviously tented as he leaned against the cool wall of the building. And glancing over Nate could see Danse’s eyes flicking between the door and Nate’s crotch.

“Any indiction… ahhh… any…” Danse tried to speak, his face twisting in a mixture of pain and ecstasy. “What the hell was that stuff?”

Nate’s arm had never felt so heavy as he lifted his Pip-Boy. The progress bar of the analysis had moved, but not by much. Shaking his head, Nate let out a long sigh.

“No idea yet. Come on, we need to get into the office. We can secure the door better and get you out of that armor.”

Danse just nodded, following Nate into the small back office of the Red Rocket, before closing the heavy door behind him. Danse paused, resting his head against the door, before slowly opening his power armor and climbing out.

It occurred to Nate that he’d never seen Danse outside his power armor in all the months they’d known each other. And as that strange thought struck him, his eyes were immediately drawn to the very obvious erection straining against Danse’s orange flight suit. Palming his own hardness Nate felt as though his whole body was on fire, and the only way to extinguish it was Danse’s cock.

“Danse…” Nate’s mouth felt dry as he approached the panting man. “I need… fuck…I need…”

“I think it’s safe to assume that… damn it… that the substance was an aphrodisiac,” Danse growled, his eyes fixed on Nate’s groin. “We may have to… act… on these urges to purge them.”

“Fuck me then.” Nate staggered over to Danse, burying his face in the paladin’s neck as he bucked against his leg. Danse’s hands roamed over his body, pulling open and off his shirt while Nate fumbled with his fly to free his aching dick.

“Negative.” Danse groaned, cupping Nate’s ass. “As much as I might want to, we don’t have any suitable lubricant.”

“Just fuck me raw,” Nate whined, dropping to his knees to mouth at Danse’s erection through the flight suit, pulling off the remains of his clothes and armor. “I can take it.”

“No.” Danse began to pull off his clothes, throwing his hood to the floor, before tugging open the suit. “I won’t be able to stop and… and I don’t want to hurt you.”

“Fuck my mouth then.” Nate pleaded, pulling and yanking at Danse’s uniform until it was around the larger man’s knees. Almost immediately Danse’s cock sprang free, the angry red tip dripping precum as it twitch in front of Nate’s face.

“That’s my plan.” Danse nodded, taking his cock by the base and guiding it past Nate’s lips. “Open wide soldier.”

Nate didn’t need to be told twice, opening his mouth as wide as he could to take Danse’s girth. As the paladin’s fingers wove into his hair, Nate began to stroke his own cock in time with Danse’s thrusts.

The length of the other man easily hit the back of Nate's throat and Nate gagged and drooled as Danse bucked into his waiting mouth. With Danse's hand firmly holding his head in place all Nate could do was take it. Take every thrust, every jerk, every jolt as Danse used him. And he loved it. He needed it. This is what he was for, right?

All sense of self melted away, until all Nate was, all he became, was the hot needy hole for Danse to use. Danse's pace was merciless, leaving Nate breathless. Nate's eyes watered as he choked around the thick cock in his mouth, each hungry roll of Danse's hips hitting his gag relax.

But Nate could take it. The fog was easier to see through while he was on his knees, cock in hand, pumping in time with Danse. Each snap of the paladin's hips chasing away any doubt, sending sparks of pleasure directly to Nate's core.

With a hoarse moan, Danse came, flooding Nate's mouth with thick, salty release which he greedily swallowed. Nate could feel it spilling from the corners of his stretched lips, as his own climax hit. Still sucking and milking Danse, Nate emptied himself onto the floor, his hips bucking into his fist making ropes of cum spatter over Danse's feet.

The small dimly lit office stank of sweat and sex as the shrill beeps of the Pip-Boy jolted Nate from his sleep. His jaw ached and he instinctually rubbed it as he glanced down at his cum splattered body. He lost count of how many times he and Danse made each other climax. Time after time pulling and forcing each other to the edge until finally collapsing on the floor. The fever, the pain, and the urges finally subsiding and allowing them to sleep.

Crawling over to his discarded equipment Nate blinked at the bright light of the Pip-Boy. It seemed it had finally finished analyzing the strange purple dust that had triggered the night’s lustful activities.

[Unknown aphrodisiac. Traces of bufotenin. Proceed with caution.]

“No shit.” Nate rolled his eyes, throwing the Pip-Boy back down onto his clothes pile.

His whole, sticky body ached as he crawled back over to Danse’s sleeping form. He’d tell him later when he woke up. They’d need to be checked over by Knight-Captain Cade later, so perhaps he’d known more and be able to tell them about any long-term consequences. But that was something for later. Right now Nate was content to curl up in Danse’s arms and drift off back to sleep.

24 notes

·

View notes

Text

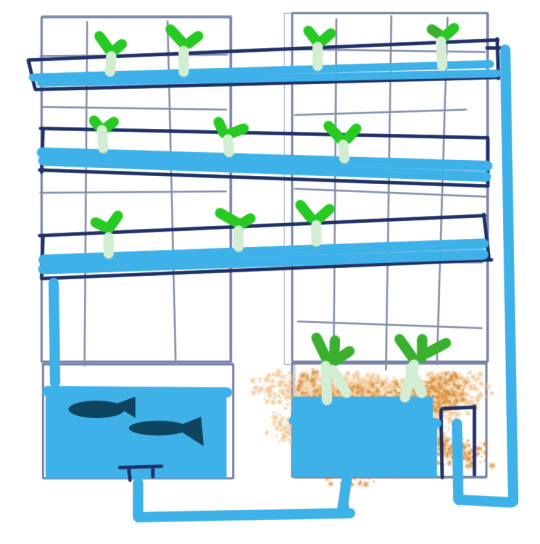

Thinking about Aquaponics!

Sorry im about to get technical and might not make much sense but i need to rave about this for a moment.

I've been thinking about Aquaponics as a sustainable gardening technique since my new garden hates me. I has a set up idea uwu

I want to use the media bed ebb and flow style (box full of rocks that fills with water then drains out perodically) as a biofilter (home for beneficial bacteria that turn fish waste into nutrition for the plants.) and NRT Nutrition river technique (the pipes half full of water) (no not NFT Nutrition film technique) to basically make a Kratky (mostly submerged roots system) that gets water changes from the bell siphon in the media bed.

I'm not sure this will work tho. mostly cuz I'm wondering if a botton drain that uses gravity to equalize the two tanks, could work with a bell siphon to make an electric free set up or not, idk if the bell siphon will be powerfull enough to reach the top of the pipes and idk if the bottom drain will work along side the bell siphon. Maybe I'm just stupid for thinking this could work, but it would be super cool if it did XDD

I could just add a pump and/or a sump tank but this would be way cooler.

8 notes

·

View notes

Text

Unnatural Selection

oh no this was really bad

quite likely the worst episode of tng so far

(except for Code of Honor for its racism)

so this episode is held together by poor judgment, spit and technobabble.

The basic plot is as follows: They find out about some new disease that fast-forwards your aging and kills you. They quarantine the station that it's on, but they have children there, that they say have been in isolation and are definitely not infected, so the Enterprise beams one aboard, and of course they are infected, doctor Pulaski also gets infected and has to quarantine on the station, but then Data looks at some graphics and finds the cause of the disease and then they technobabble so hard that they figure out how to undo it all.

And in case it wasn't clear enough from that summary. The Enterprise finds a station full of people dying from a disease and the medical staff makes seemingly no effort at all to figure out what's going on. All they do is beam the children aboard, who are in absolutely no danger, beyond starving to death in a few weeks when all the adults are dead. It makes absolutely no sense to be concerned with the children, before trying to heal these adults.

And the medical problem was extremely solvable. Data did it within two scenes of being on the station. Did no one think "maybe we should request all data that the station has and give it to literally Data to look at?" Did no one think "Maybe the fast-aging children and the illness that makes you age fast could be connected?" (Ironically they were connected in a much more convoluted way)

But from there on it only gets worse. In my opinion, this is the most significant episode yet for technobabble. Of course we had some jargon here or there, but here have three dedicated scenes of people talking about poorly defined concepts like biofilters and transporter traces and genetic make-up (literally the worst kind!) and these are absolutely vital to the plot progression. I will always take a quick and simple "bad space weather, no transporter/sensors/warp" over any of this bullshit.

And the worst part is that after multiple experts in medicine and engineering (La Forge, O'Brien, Data, Pulaski) did not come up with the ultimate solution. It is instead Picard who thinks of "let's give the transporter Pulaski's DNA, so it can rebuild her to normal levels". Obviously none of the experts thought of it, because it was a contrived explanation, there to finally end this shit show.

But the glaring structural issues aside, what good is there here?

O'Brien has a name now, and he got quite a bit to do so that's nice.

Data and Pulaski get to interact a bit more.

Data initially believing that Pulaski is going rogue is great.

Maybe I'm reading too much into it, but there's a scene on the shuttle with the infected child where Pulaski tells Data that he doesn't have to worry, because he's a machine, and Data retorts (quite correctly, see The Naked Now) that he very much could be infected, but that he was concerned with Pulaski's safety, to which Pulaski replies that medical research is risky and it's all part of being human. And like, that kinda implies that she thinks of Data as more human, right? Like he is also taking a risk here.

The Picard arc reads really horribly here. He basically calls Pulaski's old captain for some plot-relevant info, which he doesn't have. Instead the old captain tells Picard that Pulaski is like Picard's number one fan, and that's the point where he shifts from disliking her to trying to save her. And it comes across as really self-agrandizing, like I thought she sucked before, but now that I know she has good taste in captains I guess she isn't so bad.

Also Jean-Luc "Shut Up Wesley" "Stop Babbling Data" Picard has absolutely no business being snippy to Pulaski about interrupting him. Picard probably interrupts other people more frequently this episode than Pulaski ever interrupts him.

Two notes on the genetic engineering: It is very funny to watch this episode post-DS9 (and more recently post-SNW) and see just how freely it features genetic engineering in the Federation. Although the episode is pretty clearly in the critical camp, if only vaguely.

I do think that the idea of "genetically engineered children that are immune to every disease but will still carry and mutate it"a would be a great basis for like a dystopian horror sci fi series. Where the remnants of the human race are monster, to be clear.

Also I did rather like the scene at the end, where they destroy the quarantined starship. It feels super wrong to see, in a way that was reasonably well done.

#the next generation rewatch#star trek#star trek tng#tng#star trek the next generation#this post was exiled by the queue continuum

3 notes

·

View notes

Text

what everyone absolutely needs to know is that it’s by no means a glamorous or ‘dignified’ job lmfao when our probes get stuck we smack them with hammers and/or yank on the casing with all our strength or use our weight as leverage and it’s not uncommon to get mineral build-up or biofilter sludge or grease or other such assorted substances all over oneself in the process. doing maintenance on pumps and skimmers and ozone injectors (and other adjacent equipment) is a very physical and sweaty and loud job. not uncommon to have to stop what i’m doing to stretch / drop a layer of uniform before going back in to take another shot at unsticking that lever or unscrewing that probe casing. ive built more muscle doing this job for the past handful of months than i did in four years of stocking 50lb bags of dog food and 80lb boxes of saltwater 7hrs a day. what i’m saying is that loids job is not all scanning papers and taking notes and sitting at a desk looking pretty he’s also climbing around in the bowels of whatever plumbing or piping there is and prying shit open with his bare hands and hauling heavy equipment around and hitting stubborn switches or casings with a mallet hard enough to flake rubber off the thing and regularly have to replace it. just so everyone knows. working as part of a very small technician team in a facility with any amount of large, delicate, specialized equipment that sees heavy use, be it life support systems like air or water filtration or specific instruments for void research, you end up wearing several hats just to keep everything moving smoothly and safely, so while on paper you might be there to do ‘assorted maintenance tasks’, in reality you’re part mechanic, HVAC tech, electrician, janitor, inventory manager, secretary, IT guy, the list goes on and on ON TOP OF whatever science you’re also doing. i ran out of time to type i ahve tasks to be doing i’m just going to post this as is hang on

13 notes

·

View notes

Text

How to Manage Odour in Pet Food Manufacturing: Proven Technologies & Regulatory Insights

Introduction

The pet food manufacturing industry has grown significantly in recent years, driven by increasing pet ownership and demand for high-quality, specialized pet nutrition. However, one of the persistent challenges in this sector is managing odours generated during production. The processing of animal proteins, fats, and other organic materials creates volatile organic compounds (VOCs), sulfur compounds, and amines, which produce strong, often unpleasant odours. These odours can affect worker safety, community relations, and regulatory compliance. Effective odour control is thus critical for operational success, environmental responsibility, and maintaining a positive public image.

This article explores the sources of odours in pet food manufacturing, their impact, and the technologies and strategies available for effective odour management. It also examines Regulations, industry best practices, and emerging innovations, providing a comprehensive guide for manufacturers seeking to mitigate odour-related challenges.

What Causes Odours in Pet Food Manufacturing?

Pet food manufacturing involves several processes that contribute to odour emissions, including raw material handling, cooking, extrusion, drying, and packaging. Understanding these sources is the first step in designing effective control measures.

1. Raw Material Handling

Pet food production often begins with the receipt and storage of raw materials such as meat, fish, poultry by-products, grains, and fats. These materials, particularly animal-based ingredients, can emit odours during unloading, storage, and preprocessing. Decomposition of organic matter, especially if storage conditions are suboptimal, exacerbates the issue.

2. Batching and Grinding

The raw materials or all the ingredients defined based on the formulation of the company, including protein sources such as fishmeal, chicken-meal etc. are grinded along with the other materials. During this time there will be VOC and dust generation, which will be handled in a bag filter. The dust gets trapped in the bag filter but the exhaust air after the bag filter will be having VOCs and that causes odour emission from the process.

3. Cooking

A key process in which animal by-products are cooked at high temperatures (often exceeding 120°C), leading to the release of VOCs, including aldehydes, ketones, and sulfur-containing compounds like hydrogen sulfide (H₂S). These compounds have low odour thresholds, meaning even small concentrations are detectable and potentially offensive.

4. Extrusion and Drying

Extrusion involves mixing, cooking, and shaping pet food under high pressure and temperature. The process releases steam and volatile compounds, contributing to odour emissions. Drying, used to reduce moisture content in kibble or treats, further volatilizes organic compounds, releasing them into the exhaust air.

5. Packaging and Storage

While less intense, odours can also arise during packaging if residual volatile compounds are released from freshly processed products. Improperly sealed storage areas may allow odours to escape into the surrounding environment.

Why Odour Control Matters in the Pet Food Industry

Odour emissions from pet food manufacturing have wide-ranging implications:

Community Relations: Facilities located near residential areas often face complaints from neighbors about unpleasant smells. Persistent odours can strain relationships with local communities and harm a company’s reputation.

Regulatory Compliance: Many countries have strict regulations governing odour emissions to protect public health and the environment. Non-compliance can result in fines, operational restrictions, or legal action.

Worker Health and Safety: Prolonged exposure to odorous compounds, especially those like H₂S, can pose health risks to employees, including respiratory irritation and headaches.

Environmental Impact: Some odorous compounds contribute to air pollution or greenhouse gas emissions, necessitating control to align with sustainability goals.

Given these impacts, effective odour control is not just a technical necessity but a strategic priority for pet food manufacturers.

Regulations Governing Odour Emissions

Odour regulations vary by region but generally aim to limit nuisance and protect air quality. In the United States, the Environmental Protection Agency (EPA) and state-level agencies enforce standards under the Clean Air Act, which may include limits on VOCs and hazardous air pollutants (HAPs). Facilities must also comply with local zoning laws and nuisance ordinances.

In the European Union, the Industrial Emissions Directive (2010/75/EU) sets guidelines for managing emissions, including odours, from industrial processes. Member states often have additional requirements, such as Germany’s Technical Instructions on Air Quality Control (TA Luft), which specify odour thresholds.

In Australia, the Environmental Protection Authority (EPA) in each state regulates odour emissions, often requiring facilities to conduct odour impact assessments and implement control measures. Similar frameworks exist in Canada, where provincial governments oversee compliance.

Pet food manufacturers must stay informed about applicable regulations and engage with regulatory bodies to ensure compliance. This often involves monitoring emissions, modeling odour dispersion, and reporting to authorities.

Top Odour Control Technologies for Pet Food Manufacturing

A range of technologies is available to control odours in pet food manufacturing, each suited to specific processes and compounds. These can be broadly categorized into physical, chemical, and biological methods, often used in combination for optimal results.

1. Physical Methods

Ventilation and Containment: Proper ventilation systems capture odorous air at the source, preventing it from escaping into the environment. Capturing Fugitive emissions, especially from the extruder area, Enclosed processing areas and negative pressure systems help contain emissions.

Adsorption: Activated carbon filters adsorb VOCs and odorous compounds from exhaust streams. These systems are effective for low-concentration odours but require regular replacement of carbon media.

Thermal Oxidation: Thermal oxidizers and catalytic oxidizers combust VOCs at high temperatures, converting them into carbon dioxide and water. Regenerative thermal oxidizers (RTOs) are energy-efficient options widely used in pet food facilities.

Condensation: Cooling exhaust gases condenses volatile compounds into liquid form, reducing odour emissions. This method is often used in saturated air treatment. Also used in pet food manufacturing plants having rendering plants for the raw material pre-treatment.

2. Chemical Methods

Scrubbers: Wet scrubbers use water or chemical solutions (e.g., sodium hydroxide or Acids or chlorine dioxide or combination of other chemicals) to neutralize and remove odorous compounds like H₂S and amines. Packed-bed scrubbers are particularly effective for high-intensity odours.

Ozonation: Ozone generators oxidize odorous compounds, breaking them down into less offensive molecules. This method is suitable for treating exhaust air but requires careful control to avoid ozone-related health risks and to destruct the unused ozone after the treatment, as ozone has it own distinctive smell and also due to its high Global Warming Potential (GWP).

3. Biological Methods

Biofilters: Biofilters use microorganisms to degrade odorous compounds in a bed of organic material. They are cost-effective and environmentally friendly, ideal for treating large volumes of low-concentration odours.

Bioscrubbers: Similar to wet scrubbers, bioscrubbers use a liquid medium containing microorganisms to break down odorous compounds. They are compact and effective for continuous operation.

Biotrickling Filters: These combine elements of biofilters and bioscrubbers, using a synthetic medium irrigated with water to support microbial activity. They are highly efficient for treating sulfur compounds.

Best Practices for Pet Food Manufacturing Odour Management

Beyond installing control technologies, pet food manufacturers can adopt operational and strategic practices to minimize odours:

1. Process Optimization

Temperature Control: Lowering cooking temperatures where possible reduces the release of volatile compounds.

Material Handling: Prompt processing of raw materials and proper storage to avoid decomposition and odour generation.

Cleaning Protocols: Regular cleaning of equipment and processing areas minimizes residual organic matter that can produce odours.

2. Facility Design

Enclosed Systems: Designing facilities with enclosed processing units and sealed transfer systems reduces fugitive emissions.

Stack Height and Placement: Exhaust stacks should be tall enough to disperse odours above ground level and positioned away from residential areas to minimize impact.

Buffer Zones: Maintaining a distance between facilities and sensitive receptors (e.g., schools, homes) reduces odour complaints.

3. Monitoring and Modeling

Odour Sampling: Regular sampling and analysis of emissions using olfactometry or gas chromatography identify problem areas and verify control effectiveness.

Dispersion Modeling: Software tools like AERMOD or CALPUFF predict how odours will spread, helping manufacturers assess their impact on nearby communities.

Real-Time Sensors: Electronic noses and gas sensors such as Odosnese of Oizom provide continuous monitoring, enabling rapid response to odour spikes.

4. Community Engagement

Transparency: Communicating with local communities about odour control efforts builds trust and reduces complaints.

Odour Logs: Encouraging residents to report odour incidents helps manufacturers correlate emissions with weather conditions or operational issues.

Public Tours: Inviting community members to visit facilities demonstrates commitment to environmental stewardship.

5. Training and Maintenance

Employee Training: Educating workers on odour control systems and best practices ensure consistent operation and early detection of issues.

Preventive Maintenance: Regular inspection and servicing of scrubbers, oxidizers, and biofilters prevent malfunctions that could lead to odour releases.

Elixir Enviro Systems – Experts in Pet Food Odour Control

If you’re looking for reliable pet food odour control, Elixir Enviro Systems is your trusted partner. We specialize in industrial odour treatment, wastewater management, and biofiltration systems for factories and processing plants.

With years of experience, Elixir offers complete solutions—from design and installation to testing and maintenance. Whether your facility needs scrubbers, biofilters, RTOs, or real-time odour monitoring, we’ve got you covered.

Why Choose Elixir Enviro?

✅ Pioneer in Industrial Odour Control in India

✅ Largest player in India having treating about 1 Million cubic meter of air each hour

✅ Experts in pet food manufacturing odour control

✅ Custom solutions for industrial odour problems

✅ In-house R&D and simulation tools

✅ Onsite odour audits and pilot testing

✅ Solutions that meet all local and global regulations

Visit www.elixirenviro.in to learn more or contact us for a custom consultation on odour control for your facility.

Conclusion

Odour control in the pet food manufacturing industry is a multifaceted challenge requiring a combination of advanced technologies, operational best practices, and community engagement. By understanding the sources of odours—raw materials, batching-Grinding, extrusion, and wastewater—manufacturers can deploy targeted solutions like scrubbers, biofilters, and oxidizers. Regulatory compliance, worker safety, and environmental sustainability further underscore the importance of effective odour management.

As industry continues to grow, so too will the need for innovative, cost-effective, and eco-friendly odour control strategies. Manufacturers that invest in these solutions will not only mitigate risks but also strengthen their reputation as responsible corporate citizens. By prioritizing odour control, the pet food industry can ensure a harmonious coexistence with communities and a sustainable future for pet nutrition.

📌 FAQ Section

Q1. What causes odour in pet food manufacturing?

A: Odours are primarily caused by raw material handling, grinding & batching of ingredients, extrusion, drying, and improper wastewater management. These processes release VOCs, sulfur compounds, and amines.

Q2. How can odour emissions be controlled in pet food factories?

A: Odour control can be achieved using technologies like biofilters, wet scrubbers, regenerative thermal oxidizers (RTOs), and proper ventilation systems. Process optimization and regular maintenance also play a crucial role.

Q3. Are odour control systems mandatory for pet food manufacturers?

A: In many regions, yes. Regulatory bodies like the US EPA, EU’s Industrial Emissions Directive, and local environmental agencies require odour emissions to be controlled and monitored. Other locations around the globe mostly have nuisance law, meaning if the neighborhood complains, the factory might need to shut down until the issue is rectified. Considering this, the cost of installation of the Odour Control Unit surpasses the disadvantages of legal penalties, factory-closures and poor neighborhood relationships.

Q5. What role does Elixir Enviro Systems play in odour control?

A: Elixir Enviro Systems offers turnkey odour control solutions tailored to pet food manufacturing, including biofilters, scrubbers, oxidizers, and real-time monitoring. They also provide audits and pilot testing to ensure effectiveness.

#blog#environment#odourcontrol#elixirenvirosystems#sustainability#airpollution#ecofriendly#biofilter#pet food#pet food manufacturing

0 notes

Text

The Business Model Canvas

Tank filters are essential for maintaining a healthy and balanced environment in aquariums. In a contained water system, waste products from fish, uneaten food, and decaying plant matter accumulate quickly, releasing harmful toxins such as ammonia, nitrites, and nitrates. Filters play a critical role by removing these pollutants, promoting water clarity, and supporting a balanced nitrogen cycle. This keeps the water safe and healthy for fish and other aquatic organisms. Additionally, tank filters enhance oxygen circulation, which is vital for fish respiration. Without effective filtration, aquariums would require frequent water changes to maintain water quality, making filters indispensable for aquarium hobbyists looking to ensure a thriving aquatic ecosystem.

Here's Froilan Fiel, an aquarium enthusiast. He keeps many aquatic pets in his aquarium. The common issue he frequently encounters is keeping his aquariums clean and providing a safe habitat for his aquatic pets. That's why choosing a reliable and efficient tank filter is a big deal for him. That's why I introduced to him our innovative BioFilter. I asked a series of questions to him after trying out the Bio Filter.

Questions Asked

a.) How important is it for you to have a reliable filtration system in place for your aquarium? b.) What specific challenges do you encounter when using your aquarium filter? c.) What benefits do you expect to experience if you use biological pebbles in your current filtration system?

Interviewee's Response

a.) "It's extremely important because a reliable filtration system ensures clean water and keeps my fish healthy by maintaining the right balance in the tank."

b.) "The main challenge I face is frequent clogging, which slows down water flow and forces me to clean the filter more often than I'd like."

c.) "I would feel more confident knowing that biological pebbles support the natural balance in my aquarium, providing a healthier environment for my fish."

Insights

High Value on Reliable Filtration for Fish Health The interviewee places high importance on having a reliable filtration system to maintain a healthy environment for their fish. This underscores the value that aquarium owners place on the stability and efficiency of their filters. Insight: Positioning your natural filter as a reliable solution that ensures optimal water balance will resonate well with aquarium owners who prioritize their fish's health.

Maintenance Challenges with Current Filters Frequent clogging emerged as a primary issue, leading to slow water flow and increased cleaning frequency. Many aquarium enthusiasts encounter this challenge, which adds to maintenance costs and time. Insight: Emphasize the low-maintenance aspect of your natural filter, especially if it effectively minimizes clogging or requires less frequent cleaning. Reducing maintenance could be a strong selling point for your target market.

Interest in Natural, Biological Filtration for a Balanced Environment The interviewee expressed confidence in biological filtration, such as biological pebbles, to support natural balance. This suggests a preference among aquarium owners for eco-friendly and biological methods over purely mechanical solutions. Insight: Highlight the ecological and natural benefits of your filter. Marketing it as an eco-conscious choice that complements the aquarium’s natural ecosystem will likely attract users interested in sustainable, healthy filtration solutions.

Desire for Confidence in Aquarium Management The interviewee indicated that using biological pebbles would make them feel more confident about the health of their aquarium. This desire for peace of mind reflects the need for products that not only perform well but reassure users that they’re providing the best for their aquatic life. Insight: Position your filter as a product that offers peace of mind by actively contributing to a stable, thriving environment, reducing the need for constant monitoring and maintenance.

0 notes

Text

Getting the ol' Kandrona-starvation for installing a Gleet BioFilter across the drive-thru window of this Starbucks. I know it's a breach of covert operations, but damn were there a fuckton of flies making their way past the air curtain

5 notes

·

View notes

Text

Lower Decks' cheesy museum exhibit Voyager was pretty much as I imagined the Starfleet Museum years ago when I wrote my forever-in-progress I Survived Kirk

There are multiple Fleet museums, one in San Francisco, one around Pluto, another at Memory Alpha, one at Copernicus, one at Andor etc. We walked the San Francisco one. I got to visit Enterprise NX-01, which had been equipped with little plaques everywhere giving backstory to everything from the mess to the warp reactor to what the Captain liked to watch in his quarters. The plaques all had buttons which played various Captain’s Log excerpts. The staff wore period-appropriate Starfleet uniforms (navy blue boiler suits with Enterprise patches on the shoulders), which I questioned the legality of since they’re not Starfleet officers. I was told it was okay because they were period costumes, not actual uniforms.

I’d buddied up with Morgan Bateson. I really liked his sense of humour. And neither of us knew our fathers, although Morgan was pretty convinced he’d meet his in space one day, perhaps as head of some evil empire or other. Oddly specific and statistically impossible, but weirder shit would happen in my time in Starfleet.

We visited the engine nacelle the crew hid in during an ion storm, the mess hall where they ate sandwiches and watched a movie every Friday night. The Captain’s Quarters where Admiral Archer probably masturbated a thousand times, a section of corridor where the chief engineer died in what they called a heroic act of self sacrifice but read more like a suicide, the sickbay where the captain’s dog was treated when it contracted an alien disease (and upon the underside of one of the cabinets, someone had crudely engraved “BR+DS 4EVA” which I doubt was part of the recreation), and the decon chamber.

Oh god, the deacon chamber. Before transporters had biofilters (which screen out potentially harmful stuff and prevent us from bringing back deadly diseases), the crew had to strip down in a room and rub antibacterial lotion (which smelled like a mint julep, there was a sample for us all to sniff) all over themselves and/or each other’s bodies. Sounds nice and wholesome and definitely didn’t fuel my sexual fantasies for the rest of my academy tenure and adult life.

Engineering had the second most little plaques with buttons after the bridge. Most of them were about the warp five engine and how revolutionary and amazing it supposedly was. Of mild interest was a video clip of an old Zefram Cochrane made shortly before his disappearance, where he said what became the Captain’s Oath.

The bridge was spammed with plaques and buttons, which played countless audio clips of the crew doing crew-y stuff. The communications officer speaking Klingon slowly and awkwardly, the helmsman had exactly one soundbyte: “aye, sir” (seriously, couldn’t they get anything better for that guy?) and the Captain saying heroic-sounding things which sounded weird out of context. The captain’s chair was actually missing, being repaired after a member of the public broke it. Instead there was just the mounting pole sticking up in the middle of the room, which we all made obscene comments about sitting on.

The Captain had a tiny ready room just off the bridge, which had a century-old game of water polo playing on loop on a TV, a desk, a stack of music minidisks and not much else besides lots more buttons and soundbytes. There was a single cargo transporter nestled halfway along a corridor. The crew used it to beam themselves to and from alien ships and worlds believing it to be safe, but it really wasn’t and many of them suffered sterility and health issues in later life.

It was a fun little excursion. I didn’t learn much more than I’d already absorbed as a kid growing up, but actually being on the iconic vessel-turned-tourist-trap made it all seem real.

42 notes

·

View notes

Note

So, the nicknames "Roses" for comic!Hobie came from Moxie painting them. It's the thing of they don't people, physical bodies or the shit infront of them. They are distantly native, and with that comes the belief that everything that lives has a soul. Moxie doesn't paint their muses faces, they paint the soul of their muses. Hobie is a complicated ass character, with many complicated ass things to him. He's a dork, but if you meet him in the street he'll only threaten to beat your ass. He cares like hell about everything, but he's the quietest in the room until you start fucking up and he has to step in to beat your ass. When the social climate fucked up that people couldn't have the means to live, and that's pretty fucked up ngl, He beat the president's ass. All while hiding under his little punk song references. You're catching Moxie's vibe here? There's one main consistency in behavior and emotion with him. He's a sweet dreamer who has a big ass chip on his shoulder in a capitalist hellhole that wants to kill him for caring about anything other then himself and money. That's a rose. No fucking seriously, think about it. Roses (At-least in america) are no longer a commonly wild plant. Their roots are so weak that they need to be grafted new ones just to survive through growing. They're beautiful, sure. It's the fact that they are beautiful that gets them killed. We only want to farm and chop them down to make shit like Ornament gifts or plucked their petals for people to fuck on. Yes, we also use them for a food produce, but is that your working class experience? The working class is most a country's people. They get farmed and butchered for the fact they had the misfortune of being pretty to another species. The only thing they did was exist. That fucking sucks, man. The tools that they use to keep themselves safe are stripped (thorns) and they are put on display just to watch the life they have left wither away in a day. If you can't tell, Moxie considers plant life apart of important life. They also find it very disrespectful themselves to be gifted flowers because they have the opinion it's basically saying "These were pretty, so I murdered life for you!" Thank you, Ted Bundy. (Still the character's opinion) What they painted the first time Hobie came to them was a willow tree, full of colorful roses. The willow part is because many animals in an ecosystem rely on them to rest, to make homes. They were ancient pollinators for bees, they are known in tribe's for pain relievers. Typically historically they are known as biofilters for important water sources to filter out pollution and shit. Put both of those together and you have something beautiful and dangerous, yet important for a living environment. Something that single-handedly makes the water run clean for animals to drink. Something entire cultures build their wonder around because of it's ability to exist. Admiration was always there, from day one. Mutually. Hobie is a wild-grown rose. Something that defied all systems in place to prevent them from flourishing. Here he stands, Beautiful. (Moxie speaking)

(Yes this painting is the one hobie stole, that lead to moxie being able to inter-dimensionally teleport and lead to them re-meeting. It's a very important narrative painting.) (No, they don't have a ship name but we'll make one up and pretend like we always had one in our back pocket. Bullshitting, GO!)

IM FINALLY GETTING TO THIS WOOOO

GO COFFEE ADRENALINE

OOOOOO love that for them. The essence of the soul is captured by their brush and not their physical form. That's wicked.

OMG THE SYMBOLISM OF HOBIE BEING A ROSE. Putting a show of being beautiful and harmless but underneath it all lies thorns. LIKE UGHHHH.

Oh my God I should've kept reading before I wrote that paragraph because your thought process is even better than what I came up with. DAMNNNNN just putting that into perspective is amazing. We give so many things value and yet instead of enjoying its presence and just leaving it be we exploit it.

Bro not you not having a ship name 💀. (Idk man paintpunk, colorpunk, soulpunk, the punk and the painter just spitballing here.

#AHHHHHH#sorry this took so long#i never have an attention span ever 😭#moxie#comic hobie#hobie x oc#my fuzzy friends [🕷️]#jay webs words

4 notes

·

View notes