#CFD Simulation for EV Batteries

Text

How Can Computational Fluid Dynamics (CFD) Be Used For Designing Better EV Battery And Thermal Management Systems (BTMS)

Introduction

Electric vehicle batteries are transforming how we move, live, and work. Architects and engineers have a crucial role in shaping the future of EVs and their integration with buildings and infrastructure. By understanding electric vehicle batteries’ challenges and opportunities, they can create innovative and sustainable solutions that benefit both people and the planet. However, EVs…

View On WordPress

#Battery Heat Dissipation#BTMS#BTMS Optimization#CFD#CFD for Battery Design#CFD in BTMS#CFD Simulation for EV Batteries#Computational Fluid Dynamics#Computational Fluid Dynamics for EV Batteries#Computational Fluid Dynamics for Thermal Management#Designing Better EV Battery#EV Battery Cooling#EV Battery Cooling Solutions#EV Battery Design#EV Battery Efficiency#Thermal Management in EV Batteries#Thermal Management Systems

0 notes

Text

Industry Developments in Thermal Management of Electric Vehicle Batteries

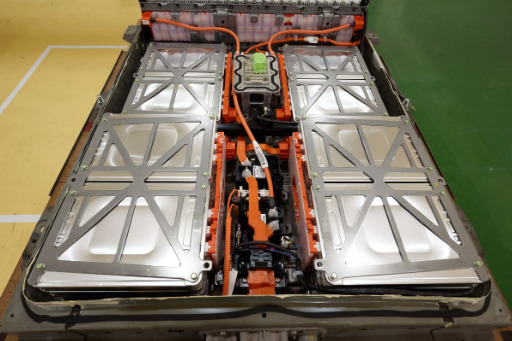

Electric vehicles (EV) fall into two main categories: vehicles where an electric motor replaces a combustion engine and vehicles that feature a combustion engine assisted by an electric motor. All EV contain large, complex, rechargeable batteries, sometimes called traction batteries, to provide all or a portion of the vehicle’s propelling power.

In EV batteries, current flow, both charge and discharge, generates heat inside the cells and in their interconnection systems. This heat is proportional to the square of the flowing current multiplied by the internal resistance of the cells and the interconnect systems. The higher the current flow the more the heating will be produced. [1]

Battery manufacturers and researchers routinely investigate how the rate of heat generation in cells varies over the course of charging and discharging. Heat can be generated from multiple sources including internal losses of joule heating and local electrode overpotentials, the entropy of the cell reaction, heat of mixing, and side reactions. [2]

Proper thermal management of EV batteries (lithium-ion is the most common) is essential to maintain adequate and consistent performance of the battery and the vehicle. Excessive temperature will negatively affect an EV’s battery and its performance. Features that can be impacted include its electrochemical system, charge acceptance, power output, safety and life cycle/replacement cost and the vehicle’s driving distance.

From a thermal point of view, there are three main aspects to consider when using lithium-ion batteries in an EV:

At temperatures below 0°C (32°F), batteries lose charge due to slower chemical reactions taking place in the battery cells. The result is a significant loss in power, acceleration and driving range, and higher potential for battery damage during charging.

At temperatures above 30°C (86°F) the battery performance degrades, posing a real issue if a vehicle’s air conditioner is needed for passengers. The result is an impact on power density and reduced acceleration response.

Temperatures above 40°C (104°F) can lead to serious and irreversible damage in the battery. At even higher temperatures, e.g. 70-100°C, thermal runaway can occur. This is triggered when the runaway temperature is reached. The result is a self-heating chain reaction in a battery cell that causes its destruction while propagating to adjacent cells.

The ideal temperature range for an EV’s lithium-ion battery is akin to that preferred by human beings. To keep it in this range, the battery temperature must be monitored and adjusted. A battery thermal management system (BTMS) is necessary to prevent temperature extremes, ensure proper battery performance, and achieve the expected life cycle. An effective BTMS keeps cell temperatures within their allowed operating range. [1]

As defined by engineers at the U.S. Department of Energy’s NREL (National Renewable Energy Laboratory), EV battery pack thermal management is needed for three basic reasons: [5]

To ensure the pack operates in the desired temperature range for optimum performance and working life. A typical temperature range is 15-35°C.

To reduce uneven temperature distribution in the cells. Temperature differences should be less than 3-4C°.

To eliminate potential hazards related to uncontrolled temperature, e.g. thermal runaway.

Various cooling agents and methods are in use today as part of the thermal management of EV batteries. Among these are air cooling, the use of flowing liquid coolants, or direct immersion.

Air Cooling

The lowest cost method for EV battery cooling is with air. A passive air-cooling system uses outside air and the movement of the vehicle to cool the battery. Active air-cooling systems enhance this natural air with fans and blowers. Air cooling eliminates the need for cooling loops and any concerns about liquids leaking into the electronics. The added weight from using liquids, pumps and tubing is also avoided.

The trade-off is that air cooling, even with high-powered blowers, does not transport the same level of heat as a liquid system can. This has led to problems for EV in hot climates, including more temperature variation in battery pack cells. Blower noise can also be an issue.

Still, air-cooling solutions have their roles and value. An example is the custom-built Volkswagen EV race car that finished first in the Pikes Peak International Hill Climb in Colorado Springs, Colo. To optimize performance, the car was designed to combine minimum weight, as much downforce as possible, and maximum power. Volkswagen used air-cooling systems to reduce weight. It used thermal software in virtual driving tests along the entire race to ensure the air-cooling system would perform sufficiently. [10]

Liquid Cooling

Piped liquid cooling systems provide better battery thermal management because they are better at conducting heat away from batteries than air-cooling systems. One downside is the limited supply of liquid in the system compared with the essentially limitless amount of air that can flow through a battery.

Tesla’s thermal management system (as well as GM’s) uses liquid glycol as a coolant. Both the GM and Tesla systems transfer heat via a refrigeration cycle. Glycol coolant is distributed throughout the battery pack to cool the cells. Considering that Tesla has 7,000 cells to cool, this is a challenge. [11]

The Tesla Model S battery cooling system consists of a patented serpentine cooling pipe that winds through the battery pack and carries a flow of water-glycol coolant; thermal contact with the cells is through their sides by thermal transfer material.

General Motor’s Chevrolet Volt features a liquid cooling system to manage battery heat. Each rectangular battery cell is about the size of a children’s book. Sandwiched between the cells is an aluminum cooling plate. There are five individual coolant paths passing thru the plate in parallel, not in series as the Tesla system does. Each battery pouch (cell) is housed in a plastic frame. The frames with coolant plates are then stacked longitudinally to make the entire pack. [12]

Thermodynamic engineers at Porsche develop and optimize each vehicle’s entire cooling system. This includes the battery, of course, and one example is the liquid-filled cooling plate from the traction battery in the Boxster E. [13]

Based on the results of the analysis in the thermal model described above, the cooling plate was designed geometrically and optimized using computational fluid dynamics (CFD). The result is a highly efficient and lightweight heat exchanger, optimally tailored and adapted to the battery pack, with low pressure losses, high cooling performance and a very even distribution of temperature.

Liquid Immersion

Instead of snaking coolant through lines and chambers within a battery pack’s case, XING Mobility takes a different approach by immersing its cells in a non-conductive fluid with a high boiling point. The coolant is 3M Novec 7200 Engineered Fluid, a non-conductive fluid designed for heat transfer applications, fire suppression and supercomputer cooling.

XING’s batteries take the form of 42 lithium-ion-cell modules that can be put together to build larger battery solutions. The complete XING battery houses 4,200 individual 18,650 lithium-ion cells encased in liquid-cooled module packs. [14]

Simulation Technologies

Design of thermal management solutions requires extensive knowledge of cooling systems and the amount of heat generated by cells throughout the battery pack. Engineers must also weigh various tradeoffs and factors such as cost, packaging, manufacturability, efficiency, reliability of heat dissipation components, and battery pack as an integrated, modular system.

Batteries require a unique range of issues be taken into consideration. First, detailed models and sub-models are needed to simulate the chemical and physical phenomena inside battery cells. Then, these models need to be tied into a system-level model of a battery pack, which can comprise hundreds of cells and cooling circuits. Finally, the battery pack model needs to be integrated with the system model of the entire powertrain and vehicle.

Engineers must consider the physical placement of the battery pack within the EV, not only to minimize the effects of ambient temperatures and maximize heat dissipation but also to avoid excessive mechanical stresses, structural fatigue from road vibrations, and potential impact from road debris. The team also must consider crash scenarios in which passengers must be protected from toxic acids released from the battery pack.

References:

1. https://avidtp.com/what-is-the-best-cooling-system-for-electric-vehicle-battery-packs/

2. Hu, X., Battery Thermal Management in Electric Vehicles. Ansys, Inc., 2011.

3. https://www.mpoweruk.com/chemistries.htm

4. Wang, Q., Jiang, B., Xue, Q., Sun, H., Li, B., Zou, H. and Yan, Y., Experimental Investigation on EV Battery Cooling and Heating by Heat Pipes, Applied Thermal Engineering, 2015.

5. Rugh, J., Pesaran, A. and Smith, K., Electric Vehicle Battery Thermal Issues and Thermal Management Techniques, NREL, SAE Alternative Refrigerant and System Efficiency Symposium, 2011.

6. https://www.hybridcars.com/chevy-bolt-evs-battery-is-as-big-as-a-teslas/

7. https://cleantechnica.com/2018/07/08/tesla-model-3-chevy-bolt-battery-packs-examined/

8. https://www.greencarreports.com/news/1064332_nissan-leafs-battery-pack-should-last-as-long-as-the-car

9. http://synergyfiles.com/2016/07/battery-thermal-management-system-review/

10. https://www.theverge.com/2018/6/24/17078544/volkswagen-ev-race-car-pikes-peak-hill-climb-record https://media.vw.com/en-us/releases/1008

11. https://insideevs.com/tesla-or-gm-who-has-the-best-battery-thermal-management-bower/

12. https://www.youtube.com/watch?time_continue=113&v=h4nM7rXpsJg

13. Thermal Management in Vehicles with Electric Drive System, Porsche Engineering Magazine, January 2011.

14. https://www.greencarreports.com/news/1114188_new-approach-to-electric-car-battery-cooling-immerse-cells-in-coolant

Advanced Thermal Solutions, Inc. (ATS) is hosting a series of monthly, online webinars covering different aspects of the thermal management of electronics. This month’s webinar will be held on Thursday, Oct. 25 from 2-3 p.m. ET and will cover the cooling of automotive batteries. Learn more and register at https://qats.com/Training/Webinars.

For more information about Advanced Thermal Solutions, Inc. (ATS) thermal management consulting and design services, visit https://www.qats.com/Consulting/Custom-Cooling-Solutions or contact ATS at 781.769.2800 or [email protected].

0 notes