#Thermal Management in EV Batteries

Text

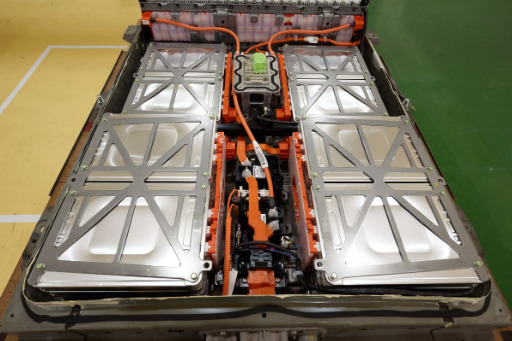

How Can Computational Fluid Dynamics (CFD) Be Used For Designing Better EV Battery And Thermal Management Systems (BTMS)

Introduction

Electric vehicle batteries are transforming how we move, live, and work. Architects and engineers have a crucial role in shaping the future of EVs and their integration with buildings and infrastructure. By understanding electric vehicle batteries’ challenges and opportunities, they can create innovative and sustainable solutions that benefit both people and the planet. However, EVs…

View On WordPress

#Battery Heat Dissipation#BTMS#BTMS Optimization#CFD#CFD for Battery Design#CFD in BTMS#CFD Simulation for EV Batteries#Computational Fluid Dynamics#Computational Fluid Dynamics for EV Batteries#Computational Fluid Dynamics for Thermal Management#Designing Better EV Battery#EV Battery Cooling#EV Battery Cooling Solutions#EV Battery Design#EV Battery Efficiency#Thermal Management in EV Batteries#Thermal Management Systems

0 notes

Text

0 notes

Link

0 notes

Text

0 notes

Text

EV Battery Thermal Management System

EV battery thermal Management system market 2022 report provides key analysis of the market status of the market with best facts, figures, meaning, definition, SWOT analysis, expert opinions, and the latest developments across the globe. The report also calculates the market size, price, revenue, gross margin, market share, cost structure and growth rate.

Top key players involved in EV battery thermal management system are:

Modine Manufacturing Company

Continental AG

Gentherm

Dana Limited

Hanon Systems

To download the sample copy of the report:

https://introspectivemarketresearch.com/request/16279

0 notes

Text

LTO 60Ah M6 18kW 14.8V-16.2V Battery Kit

Revolutionizing Energy Storage: The LTO 60Ah M6 18kW Battery Kit

What Makes LTO Special?

Lithium Titanate Oxide batteries distinguish themselves from traditional lithium-ion batteries through their unique chemical composition. This innovation results in rapid charging, enhanced safety, and a significantly longer lifespan, making LTOs an excellent choice for various applications.

Key Features of the LTO 60Ah M6 18kW Battery Kit

Impressive Capacity and Power Output:

60Ah Capacity: Offers substantial energy storage, catering to high-demand applications.

18kW Power Output: Supports quick charging and discharging, ensuring optimal performance in various scenarios.

2. Flexible Voltage Range:

Operating within a range of 14.8V to 16.2V, this battery kit is compatible with a wide array of systems, providing versatility for users.

3. Ultra-Fast Charging:

One of the standout benefits of LTO technology is its ability to charge in mere minutes. This feature is particularly advantageous for electric vehicles and public transport systems that require rapid turnaround.

4. Exceptional Cycle Life:

With a cycle life surpassing 10,000 cycles, the LTO 60Ah M6 kit outperforms conventional batteries, reducing the frequency of replacements and lowering long-term costs.

5. Enhanced Safety Features:

LTO batteries are renowned for their thermal stability and low risk of thermal runaway, providing peace of mind for users in various applications.

Applications of the LTO 60Ah M6 Battery Kit

The versatility of the LTO 60Ah M6 18kW Battery Kit makes it suitable for a wide range of applications:

Electric Vehicles: Ideal for EV manufacturers looking for rapid charging solutions and longevity.

Renewable Energy Storage: Perfect for solar and wind energy systems, facilitating effective energy management and consumption.

Grid Energy Support: Enhances grid stability, especially in regions with a high integration of renewable sources.

Backup Power Solutions: Ensures reliable energy supply for homes and businesses during outages.

Conclusion

The LTO 60Ah M6 18kW Battery Kit is a powerful solution at the forefront of energy storage technology. With its high capacity, rapid charging capabilities, and impressive lifespan, it addresses the pressing energy needs of today’s users. Whether you’re enhancing electric vehicles, storing renewable energy, or ensuring backup power, this battery kit offers a reliable and efficient option.

As we continue to move towards a more sustainable energy future, innovations like the LTO 60Ah M6 battery kit will play a crucial role. Discover the potential of this advanced energy storage solution and take the first step toward a greener tomorrow!

Contact

+𝟭 𝟳𝟳𝟵-𝟳𝟳𝟬-𝟯𝟭𝟬𝟵

1585 Beverly CT, Unit 121, Auror

0 notes

Text

600KW DC Liquid — cooled Super EV Chargers

The 600KW DC liquid — cooled super charger stations are game — changers. They shorten charging time and have liquid — cooling tech, solving thermal issues during high — power charging and promoting EV popularity.

AEAUTO’s 600KW charger can have 10 terminals (3 liquid — cooled with 600A max current, 7 air — cooled with 200A max).

Advantages:

High Power Output: 600KW output gets EVs charged quickly. Advanced tech ensures safe energy transfer.

Liquid Cooling System: It’s crucial for heat management. High — power charging generates heat; liquid — cooling uses coolant to keep the battery at the best temperature for efficiency and longevity.

Application Scenarios:

Highway Service Areas: For long — distance EV users, these chargers in service areas improve efficiency, reduce waiting time for inter — city travel.

Urban Fast — charging Stations: Built in busy urban areas, they meet the needs of operating and private vehicles, promoting EV use in cities.

Commercial and Residential Areas: As EV numbers rise, these areas value charging facilities. Liquid — cooled chargers enhance project attractiveness and promote green lifestyles.

Future Prospects:

600KW chargers have great potential. As technology matures and costs fall, they’ll be used more widely, upgrading charging infrastructure. This will also drive the coordinated development of the EV industry chain, making the industry greener, smarter, and more sustainable.

AEAUTO’s charger meets various needs. In the future, AEAUTO will keep innovating to lead the industry in green travel.

#ev charger#electric car charger station#600KW chargers#600KW DC liquid — cooled super charger stations

0 notes

Text

Automotive Engine Cover Market: Key Trends, Growth Drivers, and Future Prospects in Vehicle Design and Performance

The automotive engine cover market is an important segment of the automotive industry, focusing on components that enhance the engine's performance, protection, and aesthetic appeal. Engine covers are designed not only to shield the engine from external elements like dust, water, and debris but also to reduce noise, improve thermal management, and contribute to the overall visual design of the engine bay. With the increasing demand for lightweight, high-performance vehicles and the rise of electric vehicles (EVs), the automotive engine cover market is poised for steady growth.

Read the Full Report Here:

https://www.reportprime.com/automotive-engine-cover-r11751

This article explores key market trends, growth factors, and future opportunities in the automotive engine cover market, optimized with SEO-friendly, high-volume keywords to provide comprehensive insights into this vital component of vehicle design.

Market Overview

Automotive engine covers serve multiple purposes in modern vehicles. They protect the engine from external elements, reduce vibrations and engine noise, and improve thermal insulation to maintain optimal engine temperatures. Engine covers also play an aesthetic role by enhancing the visual appearance of the engine bay, particularly in high-performance and luxury vehicles where design is critical.

Traditionally made from materials like steel or aluminum, engine covers are now increasingly produced using lightweight materials such as composites, carbon fiber, and thermoplastics, which help improve fuel efficiency and meet stringent emissions regulations. With the ongoing shift toward electric and hybrid vehicles, engine covers are also evolving to accommodate electric motors and advanced battery systems, making them a critical component in vehicle electrification.

Key Market Drivers

Growing Demand for Lightweight Materials: Automotive manufacturers are increasingly focused on reducing the overall weight of vehicles to improve fuel efficiency and reduce emissions. Lightweight engine covers made from materials such as polypropylene, carbon fiber, and thermoplastics are becoming more popular as they provide the necessary protection while contributing to weight reduction. This trend is particularly important for electric and hybrid vehicles, where minimizing weight is essential to extend battery range.

Aesthetic and Design Appeal: Engine covers play a significant role in the aesthetics of a vehicle's engine bay, especially in high-performance, luxury, and sports cars. Automakers are using customized engine covers to enhance the visual appeal of the engine compartment, with premium materials, branded logos, and sleek designs. As consumer preferences shift towards vehicles with enhanced aesthetics, the demand for visually appealing engine covers is growing.

Noise Reduction and Thermal Management: Modern engine covers are designed to improve NVH (Noise, Vibration, Harshness) characteristics by reducing engine noise and vibrations. Additionally, they provide thermal insulation, helping to regulate engine temperatures and improve overall performance. These functional benefits are driving the adoption of advanced engine covers in both internal combustion engine (ICE) vehicles and electric vehicles (EVs), where thermal management is crucial for battery health.

Shift Toward Electric Vehicles (EVs): As the automotive industry shifts towards electrification, engine covers are being reimagined to suit electric motors and battery systems. EVs require engine covers that provide protection and thermal insulation for electric components while maintaining lightweight properties to maximize range. The rise of EVs is expected to drive significant demand for innovative engine cover designs in the coming years.

Market Segmentation

The automotive engine cover market can be segmented based on material, vehicle type, and sales channel:

By Material:

Plastic/Composites: Engine covers made from lightweight plastics and composites, such as polypropylene and polyamide, are popular for their durability, low weight, and cost-effectiveness.

Carbon Fiber: Known for its strength and lightweight properties, carbon fiber is used in high-performance and luxury vehicles to enhance both performance and aesthetics.

Aluminum and Steel: Traditional engine covers made from metals like aluminum and steel offer excellent durability and thermal resistance but are heavier than plastic and composite alternatives.

By Vehicle Type:

Passenger Cars: The largest segment, driven by the demand for noise reduction, thermal management, and design aesthetics in both mass-market and luxury vehicles.

Commercial Vehicles: Engine covers in commercial trucks, buses, and vans focus on durability and protection against harsh operating conditions.

Electric and Hybrid Vehicles: With the rise of electric and hybrid vehicles, specialized engine covers are needed to protect electric motors and battery systems, contributing to the growing demand in this segment.

By Sales Channel:

OEM (Original Equipment Manufacturer): Engine covers sold directly to automakers for installation in new vehicles during production.

Aftermarket: Replacement engine covers and custom-designed covers sold to consumers and repair shops for vehicle maintenance or aesthetic upgrades.

Key Market Players

Several leading companies dominate the automotive engine cover market, offering a range of innovative solutions to meet the demands of automakers and consumers. Key players in the market include:

Magna International Inc.: Magna is a global leader in automotive components, including engine covers made from lightweight materials. Their products are known for their durability and advanced noise-reducing properties.

Polytec Group: Polytec specializes in plastic-based engine covers, offering innovative solutions that focus on lightweight design and noise reduction for both internal combustion and electric vehicles.

Montaplast GmbH: Montaplast is known for its high-quality, lightweight plastic components, including engine covers used in premium and high-performance vehicles. Their covers are designed for both functionality and aesthetic appeal.

Mahle GmbH: Mahle produces advanced engine covers with a focus on thermal management and noise reduction, catering to both passenger and commercial vehicle segments.

Valeo: Valeo is a key player in the automotive components industry, offering innovative engine covers that incorporate lightweight materials and advanced engineering to improve vehicle performance and fuel efficiency.

Challenges in the Market

High Cost of Advanced Materials: While lightweight materials such as carbon fiber and composites offer significant advantages in terms of weight reduction and performance, they are also more expensive than traditional materials like aluminum or steel. This can limit the adoption of high-end engine covers in mass-market vehicles, where cost constraints are a major factor.

Durability and Heat Resistance: Engine covers must withstand high temperatures, vibrations, and exposure to harsh environmental conditions. Ensuring that lightweight materials such as plastics and composites can provide the necessary durability and heat resistance remains a challenge for manufacturers.

Complexity in Customization: While customized engine covers are in demand for their aesthetic appeal, offering a wide range of options can increase manufacturing complexity and costs. Balancing customization with cost-effectiveness is a challenge for manufacturers, especially in the aftermarket segment.

Opportunities in the Market

Growth of Electric and Hybrid Vehicles: The rise of electric and hybrid vehicles presents a significant growth opportunity for the engine cover market. As EV manufacturers look for innovative ways to protect electric components and improve thermal management, there is increasing demand for specialized engine covers tailored to the unique needs of EVs.

Advancements in Sustainable Materials: As the automotive industry moves towards more sustainable practices, there is an opportunity for manufacturers to develop engine covers made from eco-friendly and recycled materials. This shift towards sustainability could appeal to both automakers and consumers looking for greener alternatives in vehicle production.

Aftermarket Customization: The growing trend of vehicle customization offers opportunities in the aftermarket segment. Consumers are increasingly seeking engine covers that not only enhance performance but also add a personalized touch to their vehicles. Manufacturers that focus on offering customizable, premium engine covers can tap into this lucrative market.

Future Outlook

The automotive engine cover market is expected to experience steady growth in the coming years, driven by advancements in materials technology, increasing demand for electric vehicles, and the ongoing focus on lightweight and efficient vehicle components. According to market forecasts, the global automotive engine cover market is projected to grow at a compound annual growth rate (CAGR) of 5-7% over the next five years.

As automakers continue to prioritize fuel efficiency, noise reduction, and aesthetics, the demand for innovative engine covers made from advanced materials will increase. The rise of electric vehicles and the shift towards sustainable materials will further shape the future of this dynamic market.

Conclusion

The automotive engine cover market is a crucial component of modern vehicle design, providing protection, performance, and aesthetic appeal. As the automotive industry evolves with the rise of electric vehicles, advancements in lightweight materials, and growing consumer demand for customized components, the market for engine covers is set to grow. Manufacturers that invest in innovation, sustainability, and customization will be well-positioned to capitalize on the opportunities in this dynamic and evolving market.

Explore similar Reports for valuable insights:

https://www.reportprime.com/turn-indicators-r11745

https://www.reportprime.com/aircraft-tachometers-r11746

https://www.reportprime.com/aircraft-fuel-gauges-r11747

https://www.reportprime.com/boat-bearings-r11748

https://www.reportprime.com/track-bike-r11749

https://www.reportprime.com/automotive-suspension-components-r11750

https://www.reportprime.com/drum-brake-r11752

https://www.reportprime.com/automotive-cabin-filters-r11753

https://www.reportprime.com/medical-silicone-r11754

https://www.reportprime.com/vehicle-alarm-system-r11755

0 notes

Text

Where Can I Buy an EV Fire Blanket? A Comprehensive Guide

As electric vehicles (EVs) gain popularity worldwide, safety considerations have become increasingly important. One critical safety tool that has emerged is the EV fire blanket, which can effectively contain and control fires that may occur in electric vehicles, especially battery fires. This article will provide a comprehensive guide on where to buy an EV fire blanket, with a specific recommendation to purchase from LI-FIRE.

Table of Contents

Introduction to EV Fire Blankets

Why Are EV Fire Blankets Important?

How Do EV Fire Blankets Work?

Features to Look for in an EV Fire Blanket

Where to Buy EV Fire Blankets?

Why Choose LI-FIRE for EV Fire Blankets?

Types of EV Fire Blankets Available at LI-FIRE

Steps to Purchase an EV Fire Blanket from LI-FIRE

Customer Reviews and Testimonials for LI-FIRE

Pricing and Shipping Information

How to Use an EV Fire Blanket Safely?

Maintenance and Care for EV Fire Blankets

Comparing EV Fire Blankets with Other Fire Suppression Tools

FAQs About EV Fire Blankets

Conclusion

1. Introduction to EV Fire Blankets

An EV fire blanket is a safety device specifically designed to suppress fires in electric vehicles. These blankets are made from fire-resistant materials that can withstand extremely high temperatures and are effective in isolating the fire from oxygen, which is essential to controlling and extinguishing it. As the number of EVs on the road continues to grow, having an EV fire blanket on hand can be a crucial safety measure.

2. Why Are EV Fire Blankets Important?

Electric vehicle fires, particularly those involving lithium-ion batteries, can be highly challenging to control. Unlike traditional fires, battery fires can reignite due to the thermal runaway process. An EV fire blanket is essential because it can help contain the fire, prevent it from spreading, and minimize damage to property and harm to individuals.

3. How Do EV Fire Blankets Work?

EV fire blankets work by smothering the fire and cutting off its oxygen supply. When deployed over a burning vehicle, the blanket traps the flames and smoke, reducing heat and preventing oxygen from reaching the fire. This method is highly effective for controlling battery fires and preventing further escalation.

4. Features to Look for in an EV Fire Blanket

When choosing an EV fire blanket, several features should be considered:

Size and Coverage: The blanket should be large enough to cover the entire vehicle.

Heat Resistance: High-temperature resistance is essential for effectively handling battery fires.

Material Quality: Look for blankets made from high-quality, durable, and fire-resistant materials.

Ease of Deployment: The blanket should be easy to deploy and handle, even in emergency situations.

Certification: Ensure the product is certified by relevant safety standards and authorities.

5. Where to Buy EV Fire Blankets?

There are several suppliers of EV fire blankets, but not all offer the same level of quality and reliability. For those looking for a trusted and reliable source, LI-FIRE is an excellent choice. They specialize in high-quality fire safety solutions designed to manage EV fires effectively.

6. Why Choose LI-FIRE for EV Fire Blankets?

LI-FIRE is a reputable company known for its specialization in fire safety solutions, particularly for electric vehicles. Here are some reasons to consider buying an EV fire blanket from LI-FIRE:

Quality Assurance: Their products undergo rigorous testing to ensure they meet the highest safety standards.

Wide Range of Options: LI-FIRE offers various sizes and types of EV fire blankets to suit different needs.

Customer Support: They provide excellent customer service and support to help you choose the right product.

Easy Purchase Process: Their website is user-friendly, making it easy to find, compare, and purchase products.

7. Types of EV Fire Blankets Available at LI-FIRE

At LI-FIRE, there are several types of EV fire blankets available:

Standard EV Fire Blankets: Suitable for personal use or small-scale applications.

Heavy-Duty EV Fire Blankets: Designed for industrial use, suitable for workshops and EV service centers.

Customized Fire Blankets: Tailored solutions for specific vehicle types or unique requirements.

8. Steps to Purchase an EV Fire Blanket from LI-FIRE

Buying an EV fire blanket from LI-FIRE is simple:

Visit the LI-FIRE website.

Browse through their product offerings.

Select the EV fire blanket that best suits your needs.

Add the product to your cart and proceed to checkout.

Complete the payment process and await confirmation and shipping details.

9. Customer Reviews and Testimonials for LI-FIRE

LI-FIRE has garnered positive reviews from customers worldwide. Many users appreciate the durability and reliability of their EV fire blankets. Testimonials often highlight the ease of use and effectiveness in emergency situations, making LI-FIRE a preferred choice for many.

10. Pricing and Shipping Information

LI-FIRE offers competitive pricing for their range of EV fire blankets. Prices vary based on the size, type, and specific features of the blanket. They provide shipping to various locations and have a straightforward return policy for added customer assurance.

11. How to Use an EV Fire Blanket Safely?

Using an EV fire blanket requires careful handling:

Ensure Safety First: Wear protective gear if available.

Deploy the Blanket Over the Vehicle: Ensure the blanket fully covers the burning vehicle.

Leave the Blanket in Place: Do not remove the blanket immediately; allow it to suppress the fire completely.

Follow Emergency Protocols: Contact emergency services for further assistance.

12. Maintenance and Care for EV Fire Blankets

Proper maintenance is key to ensuring the longevity and effectiveness of an EV fire blanket:

Regular Inspections: Check for any damages or wear.

Proper Storage: Keep the blanket in a cool, dry place, away from direct sunlight.

Clean When Necessary: Follow manufacturer guidelines for cleaning the blanket.

13. Comparing EV Fire Blankets with Other Fire Suppression Tools

While there are other fire suppression tools like extinguishers and sprinklers, EV fire blankets are uniquely effective for vehicle fires. They provide immediate coverage and are specifically designed to handle the complexities of battery fires.

14. FAQs About EV Fire Blankets

Q: What is an EV fire blanket?

A: An EV fire blanket is a specialized blanket designed to suppress fires in electric vehicles by cutting off oxygen and containing the flames.

Q: Can an EV fire blanket be reused?

A: Most EV fire blankets are single-use, especially after exposure to high-intensity fires.

Q: How big should an EV fire blanket be?

A: It should be large enough to cover the entire vehicle, typically around 6x8 meters or more.

Q: Are EV fire blankets mandatory for electric vehicle owners?

A: While not mandatory, they are highly recommended for added safety.

Q: What materials are used in EV fire blankets?

A: High-temperature resistant fabrics like fiberglass and silica are commonly used.

Q: Where can I buy a reliable EV fire blanket?

A: You can purchase a high-quality EV fire blanket from LI-FIRE.

15. Conclusion

As electric vehicles become more common, ensuring safety through appropriate fire suppression tools is crucial. EV fire blankets provide a reliable solution for managing battery fires, helping to contain and control potential hazards effectively. For those looking to purchase a high-quality EV fire blanket, LI-FIRE offers a range of options that cater to various needs.

By choosing LI-FIRE, you are investing in safety, reliability, and peace of mind.

0 notes

Text

Impact of Battery Testing on EV Manufacturing Quality Standards

As the electric vehicle market grows, demands for high-quality batteries become more critical. A battery is the heart of an EV; its performance, range, and safety features are directly related to it. Quality and reliability is crucial, which is where battery testing comes into play. In this blog, we look into how battery testing affects the quality standard in EV manufacturing, including what an EV battery assembly line is, what the role of Battery Testing Equipment for EVs might be, and what Lithium-Ion Battery Testing for EVs entails.

The Role of Battery Testing in EV Manufacturing

Battery testing is just a part of testing the whole manufacturing process for EVs and ensures that the batteries completely meet the required quality and safety standards. With the emerging trends of EVs, the producers face huge pressure in producing batteries that are not only of high performance but also safe and reliable. Testing allows the manufacturer to identify defects or low-performance capacity before installing the batteries in vehicles, hence reducing the chances of field failures.

EV Battery Assembly Importance

The place where the battery cells will be going into modules and packs is the EV battery assembly line. Each phase of the assembly must go through stringent quality checks for the final product to come out to specifications. A well-organized assembly line incorporates testing at various stages: from incoming cell testing, through module testing to final Battery Pack Testing for an EV. By this means, integrating such tests into an assembly line ensures that defective units are caught on time to ensure quality across units.

Battery Testing Equipment for EVs: The Backbone of Quality Assurance

Invest in the right Battery Testing Equipment for EVs to ensure only quality EVs leave the production line. Testing equipment and technologies will be designed to test capacity, charge/discharge rates, thermal stability, and safety under various conditions. Advanced testing equipment with an enriched set of features will ensure that each pack will meet the needed performance and safety requirements, building trust among consumers in EV technology.

Lithium-Ion Battery Testing for EVs: Making Sure Safety and Performance

Lithium-ion battery testing of EVs is an increasingly important process that more and more manufacturers are considering since the adoption of this technology is increasing in the industry as a result of its high energy density and efficiency. However, lithium-ion batteries are equally prone to thermal runaway and other safety issues in case they are not tested and handled properly. Their testing incorporates a set of intensive tests, which range from mechanical and electrical to thermal. Due to this thorough testing, manufacturers ensure that batteries will operate in various conditions and minimize the possibility of failures that could result in costly recalls or even safety hazards.

EV Battery Pack Testing: Quality's Last Check

Once the individual cells and modules are built into a complete battery pack, the last step for EVs to ensure that the entire system works as specified is Battery Pack Testing for EVs. It will include a wide variety of tests: electrical integrity, thermal management, and overall system performance under various load conditions. The goal of this test campaign is to confirm that the battery pack performs as expected without any compromise on safety.

Conclusion

Battery testing is not only a part of manufacturing processes but also an extremely important factor in determining the quality and safety of electric vehicles. The manufacturer can ensure the highest quality standards for his batteries by introducing strict testing protocols right from the EV battery assembly line up to the final Battery Pack Testing for EVs. Advanced battery testing equipment for EVs and comprehensive Lithium-Ion Battery Testing for EVs play an important role in the construction of safer, more reliable electric vehicles that consumers believe in. Moving forward, continuing these high standards will be the epitome of sustaining growth and innovation in this industry.

#ev battery assembly line#Battery Testing Equipment for EVs#Lithium-Ion Battery Testing for EVs#Battery Pack Testing for EVs

0 notes

Text

Electric Vehicle Propulsion Systems: How Does MCU Drive Efficiency?

September 4, 2024

by dorleco

with no comment

eMOBILITY CONTROLS

Edit

Introduction

The Electric Vehicle Propulsion System of an electric vehicle is made up of various components that combine to transform electrical energy into motion to move the vehicle. Increasing the efficiency of the EV requires the Motor Control Unit (MCU). Let’s take a closer look at how the MCU of an EV propulsion system increases efficiency:

1. Motor Planning and Control:

The MCU controls factors including voltage, current, and frequency to manage the operation of the electric motor to maintain optimal performance and efficiency. It minimizes energy loss by ensuring that the motor runs within its most efficient range.

2. Regenerative Braking Control:

When braking and accelerating, the car can regain energy thanks to regenerative braking. It is under MCU management. Based on input from the driver and the condition of the road, it determines the proper amount of regenerative braking force to maximize energy recovery and boost efficiency.

3. Battery Control:

Optimizing battery management is critical to the overall functionality of the system. The MCU keeps an eye on the battery’s temperature, condition, and charge level. It maximizes battery performance and lifespan by reducing overcharging and over-discharging and by modifying charging and discharging rates by this data.

4. Temperature Control:

Overheating can cause components in an EV to lose some of their effectiveness. To prevent overheating, the MCU regulates power supply and monitors the temperature of essential components including the battery and electric motor. This ensures that the parts stay within their designated temperature limits and continue to work correctly.

5. Powertrain Coordination:

When an EV has many motors, like separate motors for the front and rear axles, the MCU regulates the power transmission between the motors. In particular, all-wheel drive (AWD) electric cars (EVs) ensure the optimal power distribution for optimal traction and efficiency.

6. Adaptive Algorithms:

Adaptive control algorithms are found in many MCUs, which respond instantly to changing driving conditions. These algorithms consider variables including load, vehicle speed, and road conditions. The MCU regulates power supply and motor performance to optimum economy in a range of driving scenarios.

Advantages of Electric Vehicle Propulsion Systems

There are various advantages when comparing the propulsion of electric vehicles to those of traditional internal combustion engine (ICE) vehicles. The driving efficiency of electric vehicles (EVs) is one of their primary benefits, and the Motor Control Unit (MCU) has a significant impact on this. The following are advantages of electric vehicle (EV) propulsion systems, and the MCU increases their efficiency:

1. Energy Effectiveness:

EVs are inherently more energy-efficient than ICE vehicles. The MCU plays a major role in optimizing the process of converting electrical energy from the battery into mechanical energy to propel the vehicle.

It regulates the electric motor’s performance to ensure that it maximizes energy conversion while consuming the least amount of energy.

2. Efficiency and Instant Torque:

Electric motors can accelerate quickly and provide torque instantly. To maximize efficiency and responsiveness and create a driving experience that is both efficient and enjoyable, the MCU ensures that the motor receives power accurately.

3. Battery Management:

The MCU monitors and controls the battery’s charging and discharging rates optimally. It protects against overcharging and severe discharge, two situations that might reduce the battery’s useful life.

The MCU supports the battery’s continuous ability to store energy by preserving ideal working conditions.

4. Temperature Regulation:

Efficient thermal management is critical to EV efficiency. The MCU monitors critical component temperatures and modifies power delivery as needed to avoid overheating.

Ensuring that the motor, battery, and power electronics operate within acceptable temperature limits, enhances their efficiency and longevity.

5. Intelligent Control Systems:

Adaptive control algorithms are found in many MCUs, which respond instantly to changing driving conditions. They adjust power delivery and engine performance based on factors like load, road conditions, and vehicle speed.

These adaptable algorithms optimize performance in a range of driving scenarios.

6. Updates and Enhancements to Software:

The MCU’s software can be updated progressively with manufacturer updates to increase efficiency. These upgrades could improve functionality, effectiveness, and modifications according to data and user input.

7. Combined Powertrain:

An essential component of the integrated powertrain in an EV is the MCU, which permits precise coordination between the electric motor, power electronics, and other components. This integration makes the system more effective.

Disadvantages of Electric Vehicle Propulsion Systems

In addition to their many advantages, electric vehicle (EV) propulsion technology has several serious disadvantages. It’s important to keep in mind that many of these flaws are being fixed and enhanced as EV technology develops. The Motor Control Unit (MCU) helps to somewhat offset some of these disadvantages, particularly about driving efficiency. The following are some issues with electric vehicle propulsion systems and the MCU’s fixes for them:

1. Limited Range:

One of the primary disadvantages of EVs is their limited driving range on a single charge. The MCU can optimize the power supply of the electric motor, resulting in efficient energy use and an increase in the vehicle’s range.

With accurate power output regulation and adaptive algorithms, the MCU contributes to maximizing the miles per kilowatt-hour (kWh) of energy stored in the battery, extending the total range.

2. Infrastructure for Charging:

Locating infrastructure for EV charging that is both comfortable and easily accessible may prove to be challenging. The MCU can assist with fast charging by maximizing charging rates, reducing charging times, and alerting drivers to charging stations that are close by.

3. Charging Time:

It could take longer to charge an electric vehicle (EV) than it does to refuel with gasoline or diesel. The MCU can regulate charging to lessen overheating and battery degeneration, allowing for a safe and efficient battery charging process.

4. Initial Cost:

When comparing EVs to traditional ICE cars, an EV’s initial cost is typically higher. However, by optimizing energy use and prolonging the life of essential components like the battery, the MCU can eventually contribute to cost savings.

5. Performance in Cold Weather:

Cold weather may cause electric vehicles to function less well and have a shorter range due to its effect on battery efficiency. By controlling the battery’s temperature using thermal management techniques, the MCU can lessen the negative effects of cold weather on efficiency.

6. Charging accessibility:

Due to restricted access to charging infrastructure, EV owners may find it challenging to conveniently charge their vehicles in some places. The MCU can help by optimizing the use of available charging resources and offering recommendations for efficient charging schedules based on the accessibility of charging stations.

7. Effects of Battery Production on the Environment:

The process used to make lithium-ion batteries, which are used in EVs, may have negative environmental implications. The MCU can help solve this issue by prolonging battery life and reducing the need for battery replacements by improving battery usage and charging practices.

8. Discarding and reusing:

EV battery recycling and disposal can be difficult processes. The MCU may be able to prolong the batteries’ usable life and lessen the requirement for early removal by controlling their life and health.

Conclusion:

To sum up, electric vehicle (EV) propulsion technologies offer a viable and environmentally friendly option to traditional internal combustion engine cars. A Motor Control Unit (MCU), which is essential for effectiveness and overall performance, is required for these systems.

Longer driving distances, more energy efficiency, and a reduced environmental impact are the outcomes of the MCU’s contribution to driving efficiency, notwithstanding the advantages and disadvantages of electric vehicle propulsion systems. As technology advances, these solutions should become much more accessible and effective, making EVs a more appealing and ecologically beneficial mode of transportation.

#autonomousVehicle#electricvehicle#EVPropulsion#Vehiclecontrolunit#VCU#EVSoftwareservices#CANKeypads#CANDisplays

0 notes

Text

Motorcycle Lead Acid Battery Market 2024-2033 : Demand, Trend, Segmentation, Forecast, Overview And Top Companies

Overview and Scope

A motorcycle lead acid battery is a rechargeable battery used in motorcycles to provide the electrical power needed for starting the engine and running the vehicle's electrical systems. These batteries are known for their reliability and cost-effectiveness. They come in various sizes and capacities to match different motorcycle models and requirements.

Sizing and Forecast

The motorcycle lead acid battery market size has grown strongly in recent years. It will grow from $5.06 billion in 2023 to $5.39 billion in 2024 at a compound annual growth rate (CAGR) of 6.3%. The growth in the historic period can be attributed to growing urbanization, increasing consumer awareness and education, growth of ride-sharing and delivery services, increasing electrification of motorcycle fleets for public, and growth in the charging infrastructure.

The motorcycle lead acid battery market size is expected to see strong growth in the next few years. It will grow to $6.91 billion in 2028 at a compound annual growth rate (CAGR) of 6.4%. The growth in the forecast period can be attributed to increasing focus on improving the energy density and power density, introduction of battery leasing programs for consumers, use of lead acid batteries in conjunction with renewable energy sources, high replacement rates for lead acid batteries in motorcycles, and establishment of battery swapping stations. Major trends in the forecast period include innovations in sealing technologies, adoption of greener manufacturing processes, development of safety features, nanotechnology applications, and advanced thermal management systems.

Order your report now for swift delivery, visit the link:

https://www.thebusinessresearchcompany.com/report/motorcycle-lead-acid-battery-global-market-report

Segmentation & Regional Insights

The motorcycle lead acid battery market covered in this report is segmented –

1) By Product Type: Valve Regulated Lead Acid Battery (VRLA) Battery, Flooded Lead-Acid (FLA), Absorbed Glass Mat (AGM), Vented Battery, Other Product Types

2) By Technology: Internal Combustion Engine (ICE), Hybrid, Electric

3) By Sales Channel: Original Equipment Manufacturers (OEMs), Aftermarket

North America was the largest region in the motorcycle lead acid battery market in 2023, and is expected to be the fastest-growing region in the forecast period. The regions covered in the motorcycle lead acid battery market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa.

Intrigued to explore the contents? Secure your hands-on a free sample copy of the report:

https://www.thebusinessresearchcompany.com/sample.aspx?id=16744&type=smp

Major Driver Impacting Market Growth

The increasing demand for two-wheeled EV motor vehicles is expected to propel the growth of the motorcycle lead acid battery market going forward. A two-wheeled motor vehicle, also known as a motorcycle or motorbike, is a motorized vehicle designed to travel on two wheels. The increasing demand for two-wheelers is rising due to affordability, fuel efficiency, ease of navigation in urban congestion, and flexibility in urban and rural settings. Lead-acid batteries benefit two-wheeled electric vehicles by offering a cost-effective, durable, and reliable energy storage solution. For instance, according to the Society Of Manufacturers Of Electric Vehicles, an India-based association representing Indian manufacturers of electric vehicles (EV), in 2021-2022, the number of electric two-wheeler sales was 2,52,641, which rose to 7,28,054 in 2022-2023. Therefore, the increasing demand for two-wheeled motor vehicles drives the motorcycle lead acid battery market growth.

Key Industry Players

Major companies operating in the motorcycle lead acid battery market are Panasonic Holdings Corporation, Johnson Controls International plc, Clarios International Inc., Chaowei Power Holdings Limited, GS Yuasa Corporation, EnerSys, East Penn Manufacturing Co., Exide Industries Limited, Leoch Leoch International Technology Limited, The Amara Raja Group (Amaron), Shuangdeng Group Co Ltd , Coslight Technology International Group Ltd., Trojan Battery Company LLC, Power Sonic Corporation, HBL Power Systems Limited, Mutlu Battery and Materials Industry Inc., Hawker Powersource Inc., FIAMM Energy Technology S.p.A., MK Battery International, CSB Energy Technology Co. Ltd., EverExceed Industrial Co. Ltd., Thai Energy Storage Technology PLC, C&D Technologies Inc., Deltran USA LLC, HAZE Power Company Ltd.

The motorcycle lead acid battery market report table of contents includes:

1. Executive Summary

2. Motorcycle Lead Acid Battery Market Characteristics

3. Motorcycle Lead Acid Battery Market Trends And Strategies

4. Motorcycle Lead Acid Battery Market - Macro Economic Scenario

5. Global Motorcycle Lead Acid Battery Market Size and Growth

..........

32. Global Motorcycle Lead Acid Battery Market Competitive Benchmarking

33. Global Motorcycle Lead Acid Battery Market Competitive Dashboard

34. Key Mergers And Acquisitions In The Motorcycle Lead Acid Battery Market

35. Motorcycle Lead Acid Battery Market Future Outlook and Potential Analysis

36. Appendix

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

0 notes

Text

Sistema de enfriamiento de batería eléctrica, previsión del tamaño del mercado mundial, clasificación y cuota de mercado de las 9 principales empresas

Según el nuevo informe de investigación de mercado “Informe del Mercado Global del Sistema de enfriamiento de batería eléctrica 2024-2030”, publicado por QYResearch, se prevé que el tamaño del mercado mundial del Sistema de enfriamiento de batería eléctrica alcance 18.93 mil millones de USD en 2030, con una tasa de crecimiento anual constante del 15.7% durante el período de previsión.

Figure 1. Tamaño del mercado de Sistema de enfriamiento de batería eléctrica global (US$ Millión), 2019-2030

Según QYResearch, los principales fabricantes mundiales de Sistema de enfriamiento de batería eléctrica incluyen Mahle, Valeo, etc. En 2023, las tres principales entidades mundiales tenían una cuota de aproximadamente 13.0% en términos de ingresos.

Figure 2. Clasificación y cuota de mercado de las 9 principales entidades globales de Sistema de enfriamiento de batería eléctrica (la clasificación se basa en los ingresos de 2023, actualizados continuamente)

The power battery cooling system market, integral to maintaining the optimal performance and safety of batteries used in electric vehicles (EVs) and energy storage systems, is driven by several key factors:

1. Growth of the Electric Vehicle (EV) Market: The exponential increase in EV adoption globally is a primary driver. As more automotive manufacturers produce EVs to meet consumer demand and regulatory mandates, the need for effective battery cooling systems grows to ensure battery longevity and performance.

2. Advancements in Battery Technology: As battery energy densities increase to provide longer driving ranges, managing thermal performance becomes more critical. Enhanced cooling systems are necessary to handle the higher heat generation associated with advanced battery chemistries and configurations.

3. Stricter Safety Regulations: Governments and regulatory bodies are imposing more stringent safety standards to prevent battery overheating, fires, and explosions. Compliance with these regulations necessitates the incorporation of reliable and efficient cooling systems in battery-powered vehicles and storage units.

4. Environmental and Efficiency Standards: Emission reduction and efficiency improvement initiatives drive the development and adoption of efficient battery cooling systems, which can improve overall vehicle performance and reduce environmental impact.

5. Consumer Expectations: As consumer awareness and expectations regarding vehicle safety, performance, and reliability increase, manufacturers are compelled to integrate superior thermal management systems to meet market demands.

6. Growth in Renewable Energy Storage: The expansion of renewable energy projects, such as solar and wind, requires robust energy storage solutions. Efficient battery cooling systems are essential in these storage applications to ensure consistent performance and longevity.

7. Technological Innovations: Ongoing R&D activities lead to innovations in battery cooling technologies, such as liquid cooling, air cooling, phase-change materials, and immersive cooling. These advancements improve the efficiency, reliability, and cost-effectiveness of cooling systems.

8. Government Incentives and Subsidies: Financial incentives, subsidies, and grants provided by governments to promote the adoption of EVs and renewable energy storage systems also drive the market for battery cooling systems.

These drivers collectively enhance the focus on and investment in advanced power battery cooling systems, crucial for the evolution of various battery-reliant industries.

Sobre QYResearch

QYResearch se fundó en California (EE.UU.) en 2007 y es una empresa líder mundial en consultoría e investigación de mercados. Con más de 17 años de experiencia y un equipo de investigación profesional en varias ciudades del mundo, QY Research se centra en la consultoría de gestión, los servicios de bases de datos y seminarios, la consultoría de OPI, la investigación de la cadena industrial y la investigación personalizada para ayudar a nuestros clientes a proporcionar un modelo de ingresos no lineal y hacer que tengan éxito. Gozamos de reconocimiento mundial por nuestra amplia cartera de servicios, nuestra buena ciudadanía corporativa y nuestro firme compromiso con la sostenibilidad. Hasta ahora, hemos colaborado con más de 60.000 clientes en los cinco continentes. Trabajemos estrechamente con usted y construyamos un futuro audaz y mejor.

QYResearch es una empresa de consultoría a gran escala de renombre mundial. La industria cubre varios segmentos de mercado de la cadena de la industria de alta tecnología, que abarca la cadena de la industria de semiconductores (equipos y piezas de semiconductores, materiales semiconductores, circuitos integrados, fundición, embalaje y pruebas, dispositivos discretos, sensores, dispositivos optoelectrónicos), cadena de la industria fotovoltaica (equipos, células, módulos, soportes de materiales auxiliares, inversores, terminales de centrales eléctricas), nueva cadena de la industria del automóvil de energía (baterías y materiales, piezas de automóviles, baterías, motores, control electrónico, semiconductores de automoción, etc.. ), cadena de la industria de la comunicación (equipos de sistemas de comunicación, equipos terminales, componentes electrónicos, front-end de RF, módulos ópticos, 4G/5G/6G, banda ancha, IoT, economía digital, IA), cadena de la industria de materiales avanzados (materiales metálicos, materiales poliméricos, materiales cerámicos, nanomateriales, etc.), cadena de la industria de fabricación de maquinaria (máquinas herramienta CNC, maquinaria de construcción, maquinaria eléctrica, automatización 3C, robots industriales, láser, control industrial, drones), alimentación, bebidas y productos farmacéuticos, equipos médicos, agricultura, etc.

0 notes

Text

LTO 30Ah M6 9kW 14.8V-16.2V Battery Kit

Unlocking the Future of Energy: LTO 30Ah M6 9kW Battery Kit

In today’s fast-paced world, efficient energy storage solutions are more critical than ever. Among the leading technologies, the LTO (Lithium Titanate Oxide) 30Ah M6 9kW Battery Kit stands out for its innovative design and outstanding performance. Let’s dive into what makes this battery kit a game-changer for both personal and commercial use.

What is LTO?

Lithium Titanate Oxide (LTO) batteries utilize a unique chemistry that allows for rapid charging and discharging. Unlike traditional lithium-ion batteries, LTOs offer a longer lifespan, increased safety, and better thermal stability, making them ideal for various applications.

Key Features of the LTO 30Ah M6 9kW Battery Kit

High Capacity and Power Output:

30Ah Capacity: Provides ample energy storage for various needs, from electric vehicles to renewable energy systems.

9kW Power Output: Ensures high performance, allowing for quick charging and discharging without compromising efficiency.

Wide Voltage Range:

Operating between 14.8V and 16.2V, this battery kit is versatile and compatible with numerous systems, providing flexibility for users.

Rapid Charging:

One of the standout features of LTO technology is its ability to charge in minutes. This makes it a perfect choice for applications requiring quick turnaround times, like public transportation or emergency power systems.

Long Cycle Life:

With a cycle life exceeding 10,000 cycles, the LTO 30Ah M6 kit outlasts conventional lithium-ion batteries, ensuring longevity and reduced replacement costs.

Safety and Stability:

LTO batteries are known for their exceptional thermal stability and low risk of thermal runaway, making them a safer option for various applications.

Applications

The LTO 30Ah M6 9kW Battery Kit is suitable for:

Electric Vehicles: Its rapid charging capabilities and long lifespan make it ideal for EV manufacturers and users.

Renewable Energy Storage: Perfect for solar and wind energy systems, allowing for effective energy management and usage.

Grid Energy Storage: Enhancing the stability and reliability of power grids, especially in areas with renewable energy integration.

Backup Power: Providing reliable backup solutions for homes and businesses during power outages.

Conclusion

The LTO 30Ah M6 9kW Battery Kit is at the forefront of energy storage technology. With its high capacity, rapid charging, and long lifespan, it meets the diverse needs of modern energy users. Whether you’re looking to enhance your electric vehicle, store renewable energy, or secure backup power, this battery kit offers a robust solution that aligns with today’s energy demands.

As we continue to embrace cleaner, more efficient energy solutions, innovations like the LTO 30Ah M6 battery kit will pave the way for a sustainable future. Explore the possibilities and make the shift to smarter energy storage today!

Contact

+𝟭 𝟳𝟳𝟵-𝟳𝟳𝟬-𝟯𝟭𝟬𝟵

1585 Beverly CT, Unit 121, Auror

0 notes

Text

0 notes