#Computational Fluid Dynamics for EV Batteries

Text

How Can Computational Fluid Dynamics (CFD) Be Used For Designing Better EV Battery And Thermal Management Systems (BTMS)

Introduction

Electric vehicle batteries are transforming how we move, live, and work. Architects and engineers have a crucial role in shaping the future of EVs and their integration with buildings and infrastructure. By understanding electric vehicle batteries’ challenges and opportunities, they can create innovative and sustainable solutions that benefit both people and the planet. However, EVs…

View On WordPress

#Battery Heat Dissipation#BTMS#BTMS Optimization#CFD#CFD for Battery Design#CFD in BTMS#CFD Simulation for EV Batteries#Computational Fluid Dynamics#Computational Fluid Dynamics for EV Batteries#Computational Fluid Dynamics for Thermal Management#Designing Better EV Battery#EV Battery Cooling#EV Battery Cooling Solutions#EV Battery Design#EV Battery Efficiency#Thermal Management in EV Batteries#Thermal Management Systems

0 notes

Text

Final work by Juliana Giraldo

With a long-time fascination for storytelling and character design and a newfound interest in GIFs, I made the goal of creating comics that incorporated kinetic elements within their one- to two-page compositions for the final project. Pursuing that goal, I created a slice-of-life webcomic series titled JJ Cafe Comics, which currently has three comics of four to six panels for viewers to enjoy.

The series follows the life of Milo, a cat-obsessed young man with robotic arms who tries to make it through the end of the day as a barista in an often-crowded local cafe in a futuristic city. Once the cafe closes for the day, Milo dons a robotic cat attire and sets out to the city streets to do what he considers his true passion—graffiti art. The first comic, Battery Kit-ten: Recharge, centers on Milo experiencing a full day of mishaps before returning home and receiving the uplifting comfort of his cat, Klim. The second comic, Lots of Latte: Show-Off, concentrates on Milo and coworkers Eve and Melody showing off each other's latte art after Eve begins the challenge—much to the others' initial confusion. Finally, the third comic, Stray Entree: Delight, focuses on Milo packing up before becoming distracted by a hungry stray cat, which he came prepared for.

When it comes to the techniques and tools of the work, I utilized Krita, Photoshop, and Illustrator throughout the process. At first, I used Krita to draw the comics in a simple cartoon style and a predominantly vibrant color palette to encompass a lighthearted mood for these slice-of-life moments. Once I made the static portions of the comics, I incorporated speech bubbles, effects, changing expressions, and moving body parts into the panels to achieve the dynamic energy needed for the GIF format. That said, I made a total of three frames for each comic. Afterward, I uploaded the frames of each comic into Photoshop to convert them into an animation and, eventually, a GIF. As for the title banners, I used Illustrator to write the titles in two select fonts and arrange them within a gradient color plane.

For where I presented JJ Cafe Comics, I opened a secondary Tumblr account—not only because it is the platform I am the most accustomed to but also because I often see other artists post their comics and GIFs there. Another aspect I appreciate about Tumblr is its option for users to customize their blogs with coding or adjustable themes, which I did. Regarding layout choices, I went with a theme called Pixelution that presents the blog items as what I describe as a minimalistic computer desktop. I decided to change the theme colors into a grey, orange, and teal palette to align with the colors of Milo's graffiti attire.

If I had more time on the webcomic series, I would have focused on the animation aspect of each comic. For one thing, I would make more frames for elements like the speech bubbles to have a more natural and fluid motion rather than abruptly appearing within the frames. Moreover, I would play around with creating proper animations of the characters' and objects' movements so that I do not have some panels that look too stiff or static—such as the first panel of Battery Kit-ten: Recharge (part 1) where Milo is running after the public transportation.

0 notes

Text

Paradigm shift in ‘Virtual Validation’ with the emergence of EVs

The automotive industry has undergone a remarkable transformation over the past decade. In an era where global environmental consciousness has become a paramount concern for the well-being of future generations, the electric vehicle (EV) sector has surged in prominence across the globe. This growth isn’t confined solely to two and three-wheelers but extends to encompass commercial vehicles as well.

Traditional original equipment manufacturers (OEMs) have been compelled to reassess their vehicle development strategies, pushing for rapid turnarounds, particularly within the EV sector. Moreover, startup companies worldwide, whether situated in Western North America or Eastern ASEAN nations, have demonstrated remarkable audacity by challenging established engineering norms and achieving the development of EVs in as little as 24 months, from the initial design phase to the showroom floor.

EV landscape

While EVs may boast a simpler mechanical structure when compared to their internal combustion engine (ICE) counterparts, it’s crucial to note that safety requirements, compliance standards, and validation criteria remain as robust as ever. In fact, EVs introduce a set of unique challenges due to their distinctive architecture, featuring high-capacity electric batteries (HEV) and all-wheel-drive systems equipped with two motors, one in the front and another in the rear. These intricacies compound the difficulties in meeting the ever-escalating safety standards such as US NCAP, ENCAP, and ASEAN NCAP, which are well-recognised by consumers worldwide.

In this dynamic landscape characterised by swift turnarounds and the unwavering commitment to stringent safety norms, the utilisation of Virtual Validation tools, commonly referred to as Computer-Aided Engineering (CAE), assumes an even more pivotal role. While this necessity undeniably benefits the Virtual Validation industry, it simultaneously exerts pressure on the established knowledge base and standard operating procedures that have endured for over three decades. The wealth of expertise accrued by OEMs and service providers underscores the growing importance of effectively addressing the unique challenges presented by EVs.

The reliability and effectiveness of Virtual Validation tools and methodologies have been consistently demonstrated, owing to the advancement of high computing power. Engineers have steadily built confidence over the years by methodically bridging the gap between virtual and physical testing. This ongoing progress provides a sturdy foundation for navigating the ever-evolving EV landscape, marked by accelerated development cycles, exacting safety regulations, and distinctive architectural demands.

Virtual Validation in the past and recently

In recent years, a notable shift has been observed in the practices of testing agencies, exemplified by ARAI (Automotive Research Administration of India, Pune), responsible for certifying vehicles as roadworthy. These agencies have increasingly shown receptivity to Virtual Validation reports submitted by OEMs for various test cases. While this acceptance is not yet ubiquitous among testing bodies, it serves as compelling evidence of the pivotal role that Virtual Validation plays in the development of both ICE and EV vehicles. This process not only expedites development timelines but also yields substantial cost savings for new vehicle programs and facelifts.

Virtual Validation finds application across a diverse spectrum of domains, encompassing Noise, Vibration, and Harshness (NVH), Durability, Structural Crash and Occupant Safety, Multi-body Dynamics (MBD), Computational Fluid Dynamics (CFD), and Mold Flow, among other major areas. Numerous companies have made substantial investments over the decades in the development of Virtual Validation tools, with the singular objective of enhancing accuracy and streamlining development timelines while curbing testing expenditures — a pressing need within the automotive industry. These tools have undergone a remarkable evolution, progressing from 1D (one-dimensional) and 2D methodologies to sophisticated 3D models that closely mirror the actual design and functionality of vehicles. Following the generation of Computer-Aided Design (CAD) data during the styling phase, Virtual Validation can be applied in the early stages of a program to evaluate various domain-specific feasibility requirements and provide invaluable feedback to design engineers, ultimately fostering a ‘first-time-right’ approach.

The strength of a Virtual Validation team, whether it resides within an OEM’s CAE department or is provided by a specialised service supplier with expertise in meeting the demands of the EV industry, directly correlates with the competitive advantage enjoyed by the car manufacturer. The significance of Virtual Validation in conferring a competitive edge becomes even more pronounced for EV startups. These startups are at the forefront of innovation, relentlessly pushing the boundaries of rapid turnaround times.

Unlike well-established OEMs burdened by decades-old legacy systems and development procedures, EV startups are agile in their adoption of Virtual Validation tools and processes. They not only embrace these tools but also actively seek ways to minimise their reliance on prototype testing. Building prototype vehicles is a costly endeavor, often running into the millions of dollars. Consequently, Virtual Validation tools play a pivotal role in significantly reducing the number of required test vehicles, with some OEMs achieving remarkable reductions ranging from 40 percent to 60 percent. Their ultimate vision is to eliminate the need for prototypes in the years to come.

Future of Virtual Validation

Virtual Validation has a track record of utilising intelligent tools like Design of Experiments (DOE) and optimisation techniques, which have consistently proven their worth in uncovering optimal design solutions amid the intricate web of permutations and combinations. However, with the advent of Artificial Intelligence (AI) and Machine Learning (ML), the Virtual Validation industry is poised for a transformative revolution in the field of automotive engineering. AI/ML holds the potential to significantly expedite the advancement of EV programs, especially when coupled with adaptable modular approaches.

Beyond AI/ML, the proliferation of versatile computer platforms is set to further propel the acceleration of EV development in the years to come. These platforms offer an array of advantages, including digital twinning, Universal Scene Description (USD), and the availability of in-house Virtual Validation tools catering to various domains. These advancements will empower engineers from diverse domains, encompassing CAD, CAM, and CAE, to seamlessly collaborate, leading to swift problem-solving.

Furthermore, harnessing the capabilities of cloud computing within this multiverse will facilitate rapid data sharing, computing, and analysis, ultimately amplifying the momentum of the leftward shift in EV development. This transformation promises to confer a substantial competitive edge and facilitate the creation of exceptional products that cater to the ever-discerning demands of consumers.

Original Source: https://tatatechnologies.com/media-center/paradigm-shift-in-virtual-validation-with-the-emergence-of-evs/

Gopal Musale, Regional Manager, Virtual Validation Centre of Excellence, Tata Technologies

0 notes

Text

EV Virtual Prototyping Market to See Booming Growth 2019-2030

A virtual prototype, also known as a digital mock-up, is a computer simulation of a physical product that may be displayed, evaluated, and tested as if it were a real physical model from product life-cycle elements like design/engineering, production, service, and recycling. Virtual prototyping is the process of creating and testing a virtual prototype (VP).

Report Overview: https://bisresearch.com/industry-report/satellite-earth-observation-market.html

In recent years, virtual prototyping has evolved as a computer-based simulation of systems with realism and accuracy to improve the design and, in some cases, to replace the physical prototype to save time and money. One of the primary objectives of automobile manufacturers is to enhance the design process and obtain a more realistic model before producing a prototype, which is expensive and often must be made multiple times before the design is complete. The usage of a virtual prototype is one solution to the problem. The focus is on enhancing suspension systems and introducing advanced active suspension systems, as one of the key objectives for upgrading design is to increase handling and comfort.

Most of the active suspension research has been based on physical principles, with a control algorithm applied to a quarter car model using simulation software. Using techniques known as hardware on the loop is another way to evaluate active suspension. Any upgrades or improvements necessitate replacing the hardware, which can be quite costly. A thorough investigation can be carried out by obtaining a virtual prototype. Having a virtual prototype of a complete car model makes it easy to experiment with different scenarios, swiftly animate the vehicle's behavior and plot the dynamic outcomes.

Increasing demand for effective solutions to reduce production and training costs and increasing capabilities of electric vehicle virtual prototyping toward advanced technologies such as AR/VR, digital twins, and 3D printing are fueling the growth of the global electric vehicle virtual prototyping market.

The ADAS and autonomous system segment held the major share of $XX million in the global electric vehicle virtual prototyping market in 2020. As autonomous vehicle technology becomes more widely used on public roads, verifying and testing the systems' safe operation becomes increasingly important. Each of these three difficulties must be examined to see how algorithms respond. By reducing prototype costs, enhancing accessibility, and increasing virtual integration steps, adding a virtual development layer can help prepare safe systems for launch. Virtual Test Drive (VTD), a product by MSC (Hexagon), overcomes challenges by allowing engineers to test code and stack adjustments almost instantly, quickly record and access data, and perform a variety of scenarios.

Request for the Sample Report at: https://bisresearch.com/requestsample?id=1236&type=download

Based on deployment, the global electric vehicle virtual prototyping market has been categorized into on-premises and cloud. Several large enterprises have moved or shown intent to move toward a on-premises -based infrastructure. In competitive and regulated marketplaces, engineering teams produce high-tech equipment for demanding users. As a result, they must incorporate high-performance technology into ever-smaller yet durable enclosures, accessories, and packages. Under time pressure, this frequently results in difficult trade-offs.

#Electric Vehicle Virtual Prototyping Market#EV Virtual Prototyping Market#Virtual Prototyping#ECU#Electronic Systems#Sensor#Battery System#Charging Systems#ADAS and Autonomous System#Designing#Simulation#Validation#On-Premises#Cloud#Finite Element Analysis#Computational Fluid Dynamics#Computer-Aided Manufacturing#Computer-Aided Design#Computer Automated Design

0 notes

Text

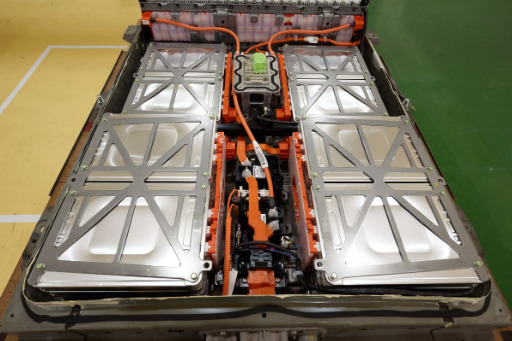

Industry Developments in Thermal Management of Electric Vehicle Batteries

Electric vehicles (EV) fall into two main categories: vehicles where an electric motor replaces a combustion engine and vehicles that feature a combustion engine assisted by an electric motor. All EV contain large, complex, rechargeable batteries, sometimes called traction batteries, to provide all or a portion of the vehicle’s propelling power.

In EV batteries, current flow, both charge and discharge, generates heat inside the cells and in their interconnection systems. This heat is proportional to the square of the flowing current multiplied by the internal resistance of the cells and the interconnect systems. The higher the current flow the more the heating will be produced. [1]

Battery manufacturers and researchers routinely investigate how the rate of heat generation in cells varies over the course of charging and discharging. Heat can be generated from multiple sources including internal losses of joule heating and local electrode overpotentials, the entropy of the cell reaction, heat of mixing, and side reactions. [2]

Proper thermal management of EV batteries (lithium-ion is the most common) is essential to maintain adequate and consistent performance of the battery and the vehicle. Excessive temperature will negatively affect an EV’s battery and its performance. Features that can be impacted include its electrochemical system, charge acceptance, power output, safety and life cycle/replacement cost and the vehicle’s driving distance.

From a thermal point of view, there are three main aspects to consider when using lithium-ion batteries in an EV:

At temperatures below 0°C (32°F), batteries lose charge due to slower chemical reactions taking place in the battery cells. The result is a significant loss in power, acceleration and driving range, and higher potential for battery damage during charging.

At temperatures above 30°C (86°F) the battery performance degrades, posing a real issue if a vehicle’s air conditioner is needed for passengers. The result is an impact on power density and reduced acceleration response.

Temperatures above 40°C (104°F) can lead to serious and irreversible damage in the battery. At even higher temperatures, e.g. 70-100°C, thermal runaway can occur. This is triggered when the runaway temperature is reached. The result is a self-heating chain reaction in a battery cell that causes its destruction while propagating to adjacent cells.

The ideal temperature range for an EV’s lithium-ion battery is akin to that preferred by human beings. To keep it in this range, the battery temperature must be monitored and adjusted. A battery thermal management system (BTMS) is necessary to prevent temperature extremes, ensure proper battery performance, and achieve the expected life cycle. An effective BTMS keeps cell temperatures within their allowed operating range. [1]

As defined by engineers at the U.S. Department of Energy’s NREL (National Renewable Energy Laboratory), EV battery pack thermal management is needed for three basic reasons: [5]

To ensure the pack operates in the desired temperature range for optimum performance and working life. A typical temperature range is 15-35°C.

To reduce uneven temperature distribution in the cells. Temperature differences should be less than 3-4C°.

To eliminate potential hazards related to uncontrolled temperature, e.g. thermal runaway.

Various cooling agents and methods are in use today as part of the thermal management of EV batteries. Among these are air cooling, the use of flowing liquid coolants, or direct immersion.

Air Cooling

The lowest cost method for EV battery cooling is with air. A passive air-cooling system uses outside air and the movement of the vehicle to cool the battery. Active air-cooling systems enhance this natural air with fans and blowers. Air cooling eliminates the need for cooling loops and any concerns about liquids leaking into the electronics. The added weight from using liquids, pumps and tubing is also avoided.

The trade-off is that air cooling, even with high-powered blowers, does not transport the same level of heat as a liquid system can. This has led to problems for EV in hot climates, including more temperature variation in battery pack cells. Blower noise can also be an issue.

Still, air-cooling solutions have their roles and value. An example is the custom-built Volkswagen EV race car that finished first in the Pikes Peak International Hill Climb in Colorado Springs, Colo. To optimize performance, the car was designed to combine minimum weight, as much downforce as possible, and maximum power. Volkswagen used air-cooling systems to reduce weight. It used thermal software in virtual driving tests along the entire race to ensure the air-cooling system would perform sufficiently. [10]

Liquid Cooling

Piped liquid cooling systems provide better battery thermal management because they are better at conducting heat away from batteries than air-cooling systems. One downside is the limited supply of liquid in the system compared with the essentially limitless amount of air that can flow through a battery.

Tesla’s thermal management system (as well as GM’s) uses liquid glycol as a coolant. Both the GM and Tesla systems transfer heat via a refrigeration cycle. Glycol coolant is distributed throughout the battery pack to cool the cells. Considering that Tesla has 7,000 cells to cool, this is a challenge. [11]

The Tesla Model S battery cooling system consists of a patented serpentine cooling pipe that winds through the battery pack and carries a flow of water-glycol coolant; thermal contact with the cells is through their sides by thermal transfer material.

General Motor’s Chevrolet Volt features a liquid cooling system to manage battery heat. Each rectangular battery cell is about the size of a children’s book. Sandwiched between the cells is an aluminum cooling plate. There are five individual coolant paths passing thru the plate in parallel, not in series as the Tesla system does. Each battery pouch (cell) is housed in a plastic frame. The frames with coolant plates are then stacked longitudinally to make the entire pack. [12]

Thermodynamic engineers at Porsche develop and optimize each vehicle’s entire cooling system. This includes the battery, of course, and one example is the liquid-filled cooling plate from the traction battery in the Boxster E. [13]

Based on the results of the analysis in the thermal model described above, the cooling plate was designed geometrically and optimized using computational fluid dynamics (CFD). The result is a highly efficient and lightweight heat exchanger, optimally tailored and adapted to the battery pack, with low pressure losses, high cooling performance and a very even distribution of temperature.

Liquid Immersion

Instead of snaking coolant through lines and chambers within a battery pack’s case, XING Mobility takes a different approach by immersing its cells in a non-conductive fluid with a high boiling point. The coolant is 3M Novec 7200 Engineered Fluid, a non-conductive fluid designed for heat transfer applications, fire suppression and supercomputer cooling.

XING’s batteries take the form of 42 lithium-ion-cell modules that can be put together to build larger battery solutions. The complete XING battery houses 4,200 individual 18,650 lithium-ion cells encased in liquid-cooled module packs. [14]

Simulation Technologies

Design of thermal management solutions requires extensive knowledge of cooling systems and the amount of heat generated by cells throughout the battery pack. Engineers must also weigh various tradeoffs and factors such as cost, packaging, manufacturability, efficiency, reliability of heat dissipation components, and battery pack as an integrated, modular system.

Batteries require a unique range of issues be taken into consideration. First, detailed models and sub-models are needed to simulate the chemical and physical phenomena inside battery cells. Then, these models need to be tied into a system-level model of a battery pack, which can comprise hundreds of cells and cooling circuits. Finally, the battery pack model needs to be integrated with the system model of the entire powertrain and vehicle.

Engineers must consider the physical placement of the battery pack within the EV, not only to minimize the effects of ambient temperatures and maximize heat dissipation but also to avoid excessive mechanical stresses, structural fatigue from road vibrations, and potential impact from road debris. The team also must consider crash scenarios in which passengers must be protected from toxic acids released from the battery pack.

References:

1. https://avidtp.com/what-is-the-best-cooling-system-for-electric-vehicle-battery-packs/

2. Hu, X., Battery Thermal Management in Electric Vehicles. Ansys, Inc., 2011.

3. https://www.mpoweruk.com/chemistries.htm

4. Wang, Q., Jiang, B., Xue, Q., Sun, H., Li, B., Zou, H. and Yan, Y., Experimental Investigation on EV Battery Cooling and Heating by Heat Pipes, Applied Thermal Engineering, 2015.

5. Rugh, J., Pesaran, A. and Smith, K., Electric Vehicle Battery Thermal Issues and Thermal Management Techniques, NREL, SAE Alternative Refrigerant and System Efficiency Symposium, 2011.

6. https://www.hybridcars.com/chevy-bolt-evs-battery-is-as-big-as-a-teslas/

7. https://cleantechnica.com/2018/07/08/tesla-model-3-chevy-bolt-battery-packs-examined/

8. https://www.greencarreports.com/news/1064332_nissan-leafs-battery-pack-should-last-as-long-as-the-car

9. http://synergyfiles.com/2016/07/battery-thermal-management-system-review/

10. https://www.theverge.com/2018/6/24/17078544/volkswagen-ev-race-car-pikes-peak-hill-climb-record https://media.vw.com/en-us/releases/1008

11. https://insideevs.com/tesla-or-gm-who-has-the-best-battery-thermal-management-bower/

12. https://www.youtube.com/watch?time_continue=113&v=h4nM7rXpsJg

13. Thermal Management in Vehicles with Electric Drive System, Porsche Engineering Magazine, January 2011.

14. https://www.greencarreports.com/news/1114188_new-approach-to-electric-car-battery-cooling-immerse-cells-in-coolant

Advanced Thermal Solutions, Inc. (ATS) is hosting a series of monthly, online webinars covering different aspects of the thermal management of electronics. This month’s webinar will be held on Thursday, Oct. 25 from 2-3 p.m. ET and will cover the cooling of automotive batteries. Learn more and register at https://qats.com/Training/Webinars.

For more information about Advanced Thermal Solutions, Inc. (ATS) thermal management consulting and design services, visit https://www.qats.com/Consulting/Custom-Cooling-Solutions or contact ATS at 781.769.2800 or [email protected].

0 notes

Text

BMW Technical Abbreviations

New Post has been published on https://dragonauto.works/blog/bmw-technical-abbreviations/

BMW Technical Abbreviations

BMW like most automotive manufacturer like acronyms. Here is a list of Technical acronyms, abbreviations and terminology as used in BMW manuals and BMW service documents.

A

AAR – Automatic Air Recirculation.

AB – Airbag (airbag system).

ABL – Brake system warning Lamp.

ABS – Anti-lock Braking System.

AC – Air Conditioning.

ACC – Active Cruise Control.

ACS – Active Comfort Seats.

ACSM – Advanced Crash Safety Module.

ADB / ADB-X – Automatic Differential Braking.

ADAS – Advanced Driver Assistance System.

ADS – Engine intake air control.

ADV – Windshield wiper pressure control.

AEGS – Automatic Electronic Gearbox Control (also EGS).

AFM – Air Flow Meter.

AGD – Suction silencer.

AGR – Emission reduction.

AGS – Adaptive transmission control.

AG – Automatic Gearbox (transmission).

AHL – Adaptive Headlights.

AHK – Active rear-axle Kinematics.

AHK – Trailer hitch.

AHM – Trailer Module (not US models).

AHPS – Advanced HPS.

AIC – Automatic Interval Control (rain sensor).

AKF – Activated carbon canister.

AKS – Active head restraint.

AKS – Pressure regulating device.

ALC – Automatic Light Control.

ALR – Automatic Lamp Range Adjustment.

ALR – Automatic-locking retractors.

AMM – Air Mass Meter.

AMP – Radio system AMPlifier.

ARI – Car radio information system.

ARRB – Automatic Rear Roller Blind.

ARS – Active Roll Stabilization.

ASC – All Season traction.

ASC – Automatic Stability Control.

ASC-EZA – ASC w/ engine timing and injection intervention.

ASC+T – ASC+ Traction control.

ASK – Audio System controller (Kontroller).

ASR – Self starter block relay.

AST – Automatic Slip control (marketing term).

AST – All Season Traction.

AT – Antenna.

ATF – Automatic Transmission Fluid.

ATL – Exhaust gas turbo charger.

AS – Active Steering.

AUC – Automatic air recirculation.

AUT – AUTomatic transmission.

AVT – Antenna amplifier Tuner.

AZD – Tightening torque specifications.

A/D – Analog/Digital.

B

B – Benzene (petrol, gasoline).

BAT – BATtery.

BC – Board Computer.

BC1 – Body Controller (#1).

BL – Brake Light.

BLS – Brake Light Switch.

BMBT – Board Monitor.

BMW – Bavarian Motor Works (Bayerische Motoren Werke).

BS – Block diagram.

BST – Battery Safety Terminal.

BVA – Brake pad wear indicator.

BZM – Center console control center.

BZMF – Center console control center, rear.

C

CA – Comfort Access, also Client Advisor.

CAN – Controller Area Network (Multiple ECU Controller).

CAN-Bus – Controller Area Network (bus).

CANH-Bus – CAN bus, High.

CANL-Bus – CAN bus, Low.

CANP – Fuel tank ventilation valve.

CAS – Car Access System.

CBC – Corner Braking Control.

CBC – Cornering Brake Control.

CBS – Condition Based Service.

CCC – Car Communications Computer.

CCM – Check Control Module.

CD – Control Display.

CDC – Compact Disk Changer.

CDS – CD player.

CDV – Clutch Delay Valve.

CEL – CELsius.

CID – Central Information Display.

CIM – Chassis Integration Module.

CIP – Coding, Individualization, Programming.

CO – Carbon monOxide.

COMBI – Electronic Instrument Cluster.

CON – CONtroller.

CPO – Certified Pre-Owned.

CSL – Club Sport Lightweight (Club Sport Leicht).

CU – Copper.

CVM – Convertible top Module.

CVT – Constantly Variable Transmission.

CW – Drag coefficient.

CWP – Cold Weather Package.

D

D-Bus – Diagnosis bus (same as TXD).

D1 – Xenon light/ gas discharge.

DBC – Dynamic Brake Control.

DBS – Dynamic Braking System.

DCC – Dynamic Cruise Control.

DCS – Dealer Communication System.

DD – Dynamic motor Drive.

DDE – Digital Diesel Electronics.

DE – Diagnostic Unit.

DIN – German industrial standards.

DIS – Diagnosis and Information System.

DISA – Differential air intake control.

DIVA – Continuously variable length intake runners.

DK – Throttle housing/valve.

DKB – Throttle w/ brake intervention.

DKE – Throttle Increase.

DKI – Throttle position.

DKR – Throttle reduction.

DKT – Throttle position signal.

DKV – Preset throttle position value.

DM-TL – Diagnostic Module Tank Leakage.

DME – Digital Motor Electronics.

DOHC – Double Over Head Camshafts.

Double VANOS – Steplessly variable intake and exhaust valve timing.

DRL – Daytime Running Lights.

DS – gasket set.

DSC – Dynamic Stability Control.

DSP – Digital Sound Processing.

DTC – Diagnostic Trouble Code (SAE).

DTC – Dynamic Traction Control.

DWA – Theft deterrent system.

DWS – Tire pressure Warning System.

DZM – Revolution counter.

E

E-KAT – Electrically heated catalytic converter.

EBV – Electronic Brake force proportioning.

ECE – European market version.

ECM – Engine Control Module (SAE term).

ECO – Controller for I-Drive system.

ECU – Electronic Control Unit.

ED – European Delivery.

EDC – Electronic Dampening Control.

EDC-K – Electronic Dampening Control – Continuous.

EDK – Electronic throttle valve.

EDR – Electronic throttle control.

EDS – pressure regulator.

EFH – Electric window lifter.

EGS – Electronic transmission control.

EH – Electronic-Hydraulic.

EHC – Electronic Height Control.

EKM – Electronic body Module.

EKP – Electric fuel Pump.

ELV – Electronic steering lock.

EM – Electro-Mechanical.

EMF – Electro-Mechanical parking brake.

EML – Electronic Motor Load regulation.

EMV – Electro-Magnetic sensitivity.

EO – Component location.

EPC – Electronic Parts Catalog (also ETK).

EPROM – Erasable/ Programmable chip Memory.

ESS – Electronic anti-theft device.

ETK – Electronic parts catalog (also EPC).

ETM – Electrical Troubleshooting Manual.

EV – Injection Valve.

EWS – Electronic drive-away protection.

EZA – Same as ASC-EZA.

F

FB – Function description.

FBC – Fading Brake Control.

FBD – Remote control services.

FBZV – Radio frequency locking system.

FDRS – Fold Down Rear Seats.

FGR – Vehicle Speed Control (Cruise Control).

FH – Window lifter.

FHK – Rear Heater/ air conditioner.

FLC – Automatic Light Control.

FRU – Flat Rate Unit.

FS – Crash Sensor.

FTM – Flat Tire Monitor.

FZV – Central lock receiver.

G

GAL – Speed dependent sound volume.

GM – General Module.

GMR – Yaw moment control.

GPS – Global Positioning System.

GRII – Cruise control.

GRS – Rotation Rate Sensor.

GS – Belt Tensioner.

GWK – Torque converter lock-up control.

H

H2 – Xenon headlights.

HA – Rear Axle.

HC – Hydro Carbon.

HD – Heavy Duty.

HDC – Hill Decent Control.

HFM – Hot Film air mass Meter.

HG – Manual Gearbox (transmission).

HKL – Hydraulic trunk lid Lift.

HLM – Hot Wire Air Mass Meter.

HPS – Head Protection System.

HR – Heater control.

HU – Head Unit.

HUD – Heads Up Display.

HVA – Hydraulic Valve Adjuster.

HWS – Headlight Washer System.

Hz – Hertz (Cycle).

I

I-Bus – Information bus.

IB – Interior lighting control signal.

IHKA – Automatic Heating and A/C.

IHKAF – IHKA w/ micro filter.

IHKR – Regulated Heating and A/C.

IHKRF – IHKR w/ micro filter.

IHKS – Standard Heating and A/C.

IHPD – Internal High Pressure Deformation.

IHR – Integrated Heater control.

IKE – Instrument cluster Electronics.

ILH – Interior Lighting, rear.

ILV – Interior Lighting, front.

IMS – Instant Mobility System.

IR – Infrared.

IRS – Infrared Locking System.

ISC – Idle Speed Control.

ISIS – Intelligent Safety and Information System.

ISN – Individual Serial Number.

ISOFIX – Standardized mounts for child restraints.

ITS – Head airbag assembly/ Inflatable Tubular Structure.

IVM – Integrated power supply Module.

J

#

K

K-Bus – Body bus (Karosserie).

KAT – Catalytic converter.

KATON – Converter creating (signal).

KD – Kick-Down.

KHI – Interface for headphones.

KL – Terminal designation.

KL15 – Run bus (ignition switch run position).

KL30 – Battery bus (hot at all times).

KL31 – Ground bus (chassis ground).

KL50 – Start bus (ignition start position).

KLR – Accessory bus.

KO – Compressor ON signal.

KOMBI – Instrument cluster.

KOREL – Compressor relay signal.

KR – Contact Ring.

KSK – Knock Sensor.

KVA – Fuel consumption signal/value.

KW – Crankshaft.

KW – KiloWatt.

L

LCM – Lamp Check Module.

LDP – Leak Diagnosis Pump.

LEV – Low Emissions Vehicle.

LEW – Lateral acceleration sensor.

LHD – Left-Hand Drive.

LKM – Lamp control Module.

LL – Closed throttle.

LM – Light Module.

LMM – Air flow meter/sensor.

LMR – Light alloy wheel.

LRA – Vertical headlight aiming.

LSM – Steering column memory.

LSZ – Lamp Switching center.

LVA – Air supply system (for EHC system).

LVDS – Low Voltage Differential Signaling.

LWR – Vertical headlight aim control.

LWRT – Low Weight Reinforced Thermoplastics.

LWS-5 – Steering angle sensor.

M

M-Bus – IHKA/IHKR stepper motor bus.

MAL – Center armrest.

MBC – Maximum Brake Control.

MDK – Motorized throttle valve/system.

MFC – Multi-Function Controller.

MFL – Multi-Function steering wheel.

MFS – Multi-Function Steering Wheel.

MFU – Multi-Function Clock.

MID – Multi-Information Display.

MIL – Malfunction Indicator Lamp (SAE), “check engine”.

MIR – Multi-Information Radio.

MMC – Multi-Media Changer.

MoDiC – Mobile Diagnostic Computer.

MOST-Bus – Media Oriented System Transport bus.

MRS – Multiple Restraint System.

MSR – Engine drag torque Regulation.

MV – Magnetic Valve (solenoid Valve).

N

n-ab – Rotational speed, transmission (rpm).

n-mot – Rotational speed, engine (rpm).

NAVI – Navigation module.

NG – New Generation (N73 engine).

NG – Tilt sensor.

NOX – Nitrogen Oxides/ exhaust gas recirculation.

NSD – Rear muffler.

NSL – Rear fog Lamp.

NSW – Fog lamp.

NTC – Negative Temperature Coefficient.

NW – Camshaft.

O

OBC – On-Board Computer.

OBD – On-Board Diagnosis.

OEM – Original Equipment Manufacturer.

P

P-Bus – Periphery bus.

P/N – Park/Neutral position.

PB – Pin assignments.

PBS – Parts Bulletin System (in TIS).

PCD – Performance Center Delivery.

PDC – Park Distance Control.

PDI – Pre-Delivery Inspection.

PGS – Passive Go System.

PM – Power Module.

PP – Impact Pad.

PTC – Positive Temperature Coefficient.

PuMA – Product and Measures Management in After sales.

PWG – Pedal position sensor/ potentiometer.

Q

#

R

RA – Repair instructions.

RAL – Aluminum wheels.

RAL – Standard color.

RAM – Random Access Memory.

RDC – Tire pressure Control.

RDS – Radio Data-broadcast System.

RDW – Tire pressure Warning.

RFT – Run Flat Tires.

RHD – Right-Hand Drive.

RLS – Rain-Light Sensor.

RM – Relay Module.

ROZ – Research Octane rating/ fuel grade.

RPA – Tire puncture warning.

RPS – Rollover Protection System.

RS – Repair kit.

RSC – Run flat System Components.

RSW – Back-up lamp.

RXD – Wake-up Diagnosis line.

RZV – Direct stationary ignition.

S

SA – Sales Advisor or Service Advisor.

SASL – Satellite, A-pillar left.

SASR – Satellite, A-pillar right.

SAV – Sport ACTIVITY Vehicle.

SB – Fuse assignments.

SBE – Seat occupancy detector/sensor.

SBFH – Seat module, passenger-side rear.

SBK – Safety Battery Terminal Clamp (???).

SBSL – Satellite, B-pillar left.

SBSR – Satellite, B-pillar right.

SBT – SI techniques/ tech reference information (in TIS).

SCA – Soft Close Automatic/Actuator.

SD – Silencer/ muffler.

SD – Sliding roof.

SE – Special Equipment.

SES – Voice Recognition System.

SFAH – Seat module, driver’s side rear.

SFZ – Satellite, vehicle center.

SG – Control unit.

SGS – Seat integrated belt System.

SHD – Sliding/ lifting roof.

SHD – Sunroof module (also SHDM).

SI – Service Information (in TIS).

SIA – Service Interval system (ver. I, II, III, IV, etc.).

SII – Service Interval Indicator.

SIL – SILicon.

SIM – Safety Information Module.

SINE – Siren/tilt sensor.

SKD – Steel sliding roof.

SKHD – Steel sliding/ lifting roof.

SM – Seat Module.

SM/SPM – Seat/Mirror Memory.

SMBF – Seat Module, passenger side.

SMFA – Seat Module, driver’s side.

SMG – Sequential Manual Gearbox.

SP – Schematic.

SRA – Headlight/fog light cleaning.

SRS – Supplemental Restraint System.

SSD – Steel sliding roof.

SSH – Seat Satellite, rear seat.

ST – Connector views.

Steptronic – Transmission shift control.

STVL – Satellite, left front door.

STVR – Satellite, right front door.

SULEV – Super Ultra Low Emissions Vehicle (not coined by BMW).

SVS – Speech processing System.

SWR – Headlamp cleaning system.

SWZ – Special tool listings (in TIS).

SZL – Switch center, steering column.

SZM – Central switch center Module.

T

TAGE – Door handle Electronics.

TCM – Transmission Control Module.

TD – Engine speed signal (ignition pulse).

TD – Technical Data (in TIS).

TDD – Technical Documentation Disk.

TE – Fuel evaporation control.

TEL – TELephone control unit.

TEV – Evaporative purge control.

THZ – Tandem master cylinder.

ti – Injector ON Time (duration).

TIS – Technical Information System.

TL – Part throttle / load signal.

TLEV – Transitional Low Emission Vehicle.

TMBFT – Door Module, passenger side.

TMBFTH – Door Module, passenger side rear.

TMC – Traffic Message Channel.

TMFAT – Door Module, driver’s side.

TMFATH – Door Module, driver’s side rear.

TP – Tandem Pump.

TP – Traffic Program.

TPC – Tire Pressure Control.

TPM – Tire Pressure Monitor.

TPS – Throttle Position Switch/Sensor.

TR – Engine speed signal (rpm).

TR – TRansistor.

TRG – Fuel level sensor.

TRI – Technical Reference Information (also SBT).

TRS – Battery isolation Switch.

TSB – Technical Service Bulletin.

TSD – Torsional vibration dampener.

TSH – Door lock Heating.

TSZI – Transistorized coil Ignition system.

TU – Technical Update (as in M50tu).

TXD – Transmitting Diagnosis line.

U

U-batt – Battery voltage.

U-vers – Supply voltage.

UERSS – Rollover bar.

URS – Rollover protection System.

USIS – Ultrasonic passenger compartment Sensor.

V

V – Vorn (front).

V – Vehicle road speed.

VA – Front Axle.

VAC – Voice Activated Control.

VANOS – Variable camshaft timing.

VAT – Front axle support.

VDC – Vehicle Distribution Center.

VEP – Distributor-type injection Pump.

VID – VIDeo module.

VL – Full load (wide open throttle).

VPC – Vehicle Preparation Center.

VSD – Front muffler.

VVT – Valve tronic.

W

WBG – Hazard warning switch.

WIM – Wiper control Module.

WK – Torque converter lock-up clutch.

WSS – Wind Shield.

WT – Valve tronic control unit.

X

#

Y

#

Z

ZAB – Ignition fade-out (reduction).

ZAE – Central Airbag Electronics.

ZAS – Ignition starter switch.

ZCP – Competition Package (M3).

ZCW – Cold Weather Package.

ZGM – Central Gateway Module.

ZHP – Performance Package (Available on US-Market e46 330i/Ci/Cic Only).

ZK – Cylinder head.

ZKE – Central body Electronics.

ZKH – Cylinder head cover.

ZMS – Dual-Mass flywheel.

ZPP – Premium Package.

ZS – Central lock.

ZSD – Center muffler.

ZSP – Sport Package.

ZV – Central locking system.

ZVM – Central locking Module.

ZWD – Idle control valve.

0 notes