#Computational Fluid Dynamics for Thermal Management

Text

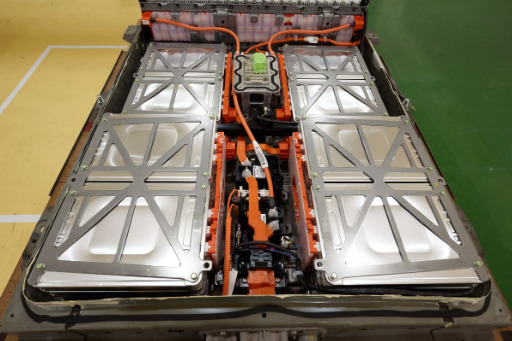

How Can Computational Fluid Dynamics (CFD) Be Used For Designing Better EV Battery And Thermal Management Systems (BTMS)

Introduction

Electric vehicle batteries are transforming how we move, live, and work. Architects and engineers have a crucial role in shaping the future of EVs and their integration with buildings and infrastructure. By understanding electric vehicle batteries’ challenges and opportunities, they can create innovative and sustainable solutions that benefit both people and the planet. However, EVs…

View On WordPress

#Battery Heat Dissipation#BTMS#BTMS Optimization#CFD#CFD for Battery Design#CFD in BTMS#CFD Simulation for EV Batteries#Computational Fluid Dynamics#Computational Fluid Dynamics for EV Batteries#Computational Fluid Dynamics for Thermal Management#Designing Better EV Battery#EV Battery Cooling#EV Battery Cooling Solutions#EV Battery Design#EV Battery Efficiency#Thermal Management in EV Batteries#Thermal Management Systems

0 notes

Text

A Complete Guide for Mechanical Engineers Taking the CIL Exam

One of the biggest producers of coal in the world, Coal India Limited (CIL), holds recruiting tests for mechanical engineering among other engineering specialties. For mechanical engineers, landing a position at CIL provides a great chance to work in the public sector with professional progression, competitive income, and job stability. This comprehensive resource offers an in-depth analysis of the test structure, syllabus, preparation techniques, and success recommendations for mechanical engineers hoping to ace the CIL exam.

1. Recognizing the Format of the CIL Exam For mechanical engineers, the CIL exam usually includes of two sections: Section 1: General Knowledge and Skill General knowledge, critical thinking, numeracy, and English language proficiency are all covered in this part. It assesses your capacity for critical thought, problem-solving, and comprehension of fundamental ideas from a range of academic areas. Section 2: Technical Expertise in Mechanical Engineering The topics covered in this section include mechanical engineering. The questions center on fundamental ideas in mechanical engineering, including heat transport, thermodynamics, fluid mechanics, material strength, machine design, and production procedures. This section is very important since it has a big impact on the final score.Typically, the test is administered online using multiple-choice questions. Although the test's duration varies, it usually lasts two to three hours. Since wrong responses frequently result in a lower score, precision is crucial.

2. Comprehensive Mechanical Engineering Syllabus The following is included in the CIL test syllabus for the mechanical engineering section: Thermodynamics Basic concepts of thermodynamics, laws of thermodynamics, heat engines, refrigeration and air conditioning, gas power cycles, and thermodynamic relations. Fluid Mechanics and Machinery Fluid properties, fluid dynamics, flow through pipes, hydraulic turbines, pumps, and dimensional analysis. Strength of Materials Stress and strain, mechanical properties of materials, bending moment and shear force, deflection of beams, torsion, and columns. Heat Transfer Modes of heat transfer (conduction, convection, and radiation), heat exchangers, and thermal insulation. Manufacturing Processes Casting, forming, welding, machining processes, production planning and control, and computer-integrated manufacturing. Machine Design Design of machine elements, bearings, gears, springs, and brakes. Engineering Mechanics Statics and dynamics, force systems, friction, and kinematics of rigid bodies. Engineering Materials Properties of materials, heat treatment, and material testing. Having a clear understanding of this syllabus is crucial as it helps in focusing your preparation on the relevant topics.

3. CIL Exam Preparation Technique An organized study plan is necessary in order to pass the CIL test for mechanical engineers. Take into consideration these crucial steps: Recognize the syllabus and format of the test Start preparing by familiarizing yourself with the syllabus and format of the test. Pay closer attention to the subjects that are more important in the test. Make a study schedule. Your preparation time should be divided into small study periods. Set up dedicated time periods for every topic, making sure to cover everything in a methodical manner. Don't forget to factor in time for practice exams and review.

Examine standard books For mechanical engineering courses, use standard textbooks and study guides. P.K. Nag's "Thermodynamics," R.K. Bansal's "Fluid Mechanics," and R.S. Khurmi's "Strength of Materials" are a few suggested works. Practice papers from previous years Understanding the exam's difficulty level and question format requires solving prior years' question papers. It also improves time management abilities throughout the test and aids in selecting key subjects. Take Practice Exams Take online practice exams frequently to gauge your degree of readiness. By assisting you in determining your strengths and shortcomings, mock exams enable you to concentrate on your areas of weakness.Put an emphasis on aptitude and general awareness The sections on ability and general awareness should not be overlooked. Read newspapers every day, keep up with current events, and work on your mathematical thinking and aptitude skills.

4. Crucial Advice for Managing Your Time on Exam Day Use your time wisely during the test. Avoid devoting excessive time to a single question. Go on to the next question and come back to it later if you have time, even if you're not sure about the answer. Precision Above Velocity Because of the exam's negative grading, precision must be maintained. Refrain from speculating and respond only when you are quite certain of the right response.Remain composed and assured. Success requires having a collected and tranquil mentality. Your exam performance will improve if you have confidence in your preparation.

5. Selection Process After Exam Depending on CIL's recruiting procedure, qualified applicants are contacted for additional steps after the written exam, which may include a group discussion or in-person interview. The ultimate decision is made by combining the results of the written test with the other phases. In summary Focused study, a solid grasp of fundamental mechanical principles, and regular practice are necessary to pass the mechanical engineering CIL test. You may improve your chances of landing a great job at Coal India Limited by adhering to a disciplined study plan, rehearsing past papers, and keeping an optimistic outlook. Remember, dedication and smart work are the keys to success in this competitive exam.

Start Your Preparation With: https://gameacademy.in/ / https://clppenny.page.link/cTBm

Recommended: https://www.youtube.com/@gblions / https://www.youtube.com/@gblionsaeje

0 notes

Text

Catia vs NX: Which Is Better Choice in 2024

When it comes to sophisticated computer-aided design (CAD) software for complex engineering and design projects, CATIA and Siemens NX are two of the leading names in the industry. Both tools are renowned for their robust capabilities, but choosing the right one for your needs can be challenging. In 2024, both CATIA and NX continue to evolve, offering advanced features and functionalities. This blog will compare CATIA vs NX, highlighting their strengths, differences, and which might be the better choice for you.

What is CATIA?

CATIA (Computer Aided Three-Dimensional Interactive Application) is developed by Dassault Systèmes and is widely used in industries such as aerospace, automotive, and industrial machinery. Known for its comprehensive suite of tools, CATIA is renowned for its robust modeling capabilities and strong support for complex assembly designs.

Key Features of CATIA:

Surface and Solid Modeling: CATIA excels in creating complex surfaces and solid models, making it ideal for industries where precision is crucial.

Parametric Design: The parametric design capabilities allow for flexible modifications and easy updates to design models.

Integration: CATIA integrates well with other Dassault Systèmes solutions, such as ENOVIA and DELMIA, providing a seamless experience for product lifecycle management (PLM) and manufacturing.

Collaboration: CATIA's collaborative tools support team-based design, allowing multiple users to work on the same project simultaneously.

What is NX?

NX, developed by Siemens, is another leading CAD software with extensive capabilities for product design, engineering, and manufacturing. It is used across various sectors, including automotive, aerospace, and industrial machinery. NX is known for its advanced technology and integration capabilities.

Key Features of NX:

Integrated Design and Engineering: NX provides a unified environment for design, engineering, and manufacturing, ensuring consistency across the entire product development process.

Advanced Simulation: NX offers powerful simulation tools for structural, thermal, and fluid dynamics analysis, helping users optimize their designs for performance and reliability.

Generative Design: The generative design feature enables the creation of innovative design solutions by leveraging artificial intelligence and advanced algorithms.

Manufacturing Integration: NX integrates seamlessly with Siemens' manufacturing solutions, providing a comprehensive approach to product development from design to production.

Comparing CATIA and NX: Key Differences

Industry Focus:

CATIA: Strongly favored in industries like aerospace and automotive due to its advanced surface modeling capabilities and extensive support for complex assemblies.

NX: Popular in industries requiring tight integration between design, engineering, and manufacturing, such as aerospace, automotive, and consumer goods.

User Interface and Usability:

CATIA: Known for its extensive feature set, which can be overwhelming for new users but offers a high level of control for experienced designers.

NX: Features a more modern and intuitive user interface, designed to improve usability and streamline workflows.

Integration and Collaboration:

CATIA: Integrates seamlessly with other Dassault Systèmes tools, providing a strong PLM solution for managing complex projects and collaboration.

NX: Offers extensive integration with Siemens’ other products and third-party applications, facilitating collaboration across different stages of product development.

Simulation and Analysis:

CATIA: Provides powerful simulation tools, but its analysis capabilities are often considered less advanced compared to NX.

NX: Known for its cutting-edge simulation tools, including advanced generative design capabilities and robust analysis features.

Cost and Licensing:

CATIA: Generally has a higher cost of ownership, which may include licensing fees for various modules and support services.

NX: Offers flexible licensing options, which can be tailored to specific needs, potentially reducing overall costs for users.

Which Is the Better Choice in 2024?

Choosing between CATIA and NX largely depends on your specific needs and industry requirements. If your work involves complex surface modeling and you need strong integration with PLM systems, CATIA might be the better choice. On the other hand, if you require advanced simulation capabilities, generative design, and tight integration with manufacturing processes, NX could be more suitable.

Conclusion:

Both CATIA and NX are exceptional CAD tools, each with its unique strengths and capabilities. As of 2024, CATIA remains a powerful choice for industries with a focus on complex design and assembly, while NX stands out for its integrated approach to design, engineering, and manufacturing. Evaluate your specific requirements, industry needs, and budget to determine which software will best meet your needs.

Ultimately, the choice between CATIA and NX should align with your project goals, workflow preferences, and long-term objectives. Both platforms offer robust solutions that can significantly enhance your design and engineering processes.

0 notes

Text

Unlocking Efficiency: The Power of Hydraulic Analysis Software

In today's rapidly evolving industrial landscape, efficiency and accuracy are more important than ever. With complex systems and processes in industries such as oil and gas, water treatment, and chemical manufacturing, understanding and optimizing fluid dynamics is crucial. Hydraulic analysis software has emerged as an indispensable tool for engineers and managers seeking to enhance system performance and reliability. This article delves into the capabilities and benefits of hydraulic analysis software, offering insights into its applications and advantages.

Understanding Hydraulic Analysis Software:

Hydraulic analysis software is designed to model, simulate, and analyze fluid flow within various systems and infrastructures. By utilizing advanced algorithms and computational techniques, this software helps engineers visualize fluid dynamics, identify potential issues, and optimize system performance. Whether dealing with pipelines, pumps, or valves, hydraulic analysis software provides a comprehensive view of how fluids behave under different conditions.

Key Features and Capabilities:

Hydraulic analysis software offers a range of features tailored to meet the needs of diverse industries. Here are some of the most significant capabilities:

Flow Simulation and Modeling: The software allows users to create detailed simulations of fluid flow within complex networks. By accurately modeling the behavior of fluids, engineers can predict how systems will respond to various conditions and design changes.

Pressure Analysis: Understanding pressure dynamics is essential for ensuring the safety and efficiency of hydraulic systems. Hydraulic analysis software helps identify pressure drops, surges, and other anomalies that could lead to operational challenges.

Heat Transfer Analysis: In systems where temperature changes impact fluid behavior, the software can simulate heat transfer processes, helping engineers optimize energy efficiency and manage thermal conditions.

Leak Detection: Identifying leaks quickly and accurately is crucial for maintaining system integrity. Hydraulic analysis software can pinpoint potential leak points, reducing downtime and minimizing environmental impact.

Optimization and Design: The software facilitates the optimization of system components and layouts. Engineers can experiment with different configurations to find the most efficient and cost-effective designs.

Applications Across Industries:

Hydraulic analysis software is used across a wide range of industries, each benefiting from its unique capabilities:

Oil and Gas: In the oil and gas sector, accurate hydraulic analysis is vital for designing efficient pipeline networks, managing pressure fluctuations, and ensuring safe transportation of resources.

Water Treatment: Municipalities and industries rely on hydraulic analysis software to optimize water distribution systems, manage pressure variations, and enhance the efficiency of treatment plants.

Chemical Processing: In chemical manufacturing, precise fluid management is essential for maintaining process stability and ensuring product quality. Hydraulic analysis software aids in designing and optimizing fluid handling systems.

Renewable Energy: Hydraulic analysis is critical in renewable energy projects, such as hydroelectric and geothermal systems, where fluid dynamics play a key role in energy generation.

Benefits of Hydraulic Analysis Software:

The adoption of hydraulic analysis software offers numerous benefits, contributing to improved operational efficiency and cost savings:

Enhanced System Reliability: By identifying potential issues before they become critical, hydraulic analysis software helps prevent costly downtime and equipment failures.

Cost Savings: Optimizing system designs and reducing energy consumption lead to significant cost savings over time. The software enables engineers to make informed decisions that minimize operational expenses.

Environmental Impact: By reducing the likelihood of leaks and optimizing energy usage, hydraulic analysis software contributes to a more sustainable and environmentally friendly operation.

Improved Safety: Accurate pressure analysis and leak detection enhance the safety of hydraulic systems, protecting both personnel and the environment.

Data-Driven Insights: The software provides valuable data and insights that inform decision-making and drive continuous improvement.

Selecting the Right Hydraulic Analysis Software:

Choosing the right hydraulic analysis software is essential to achieving the desired outcomes. Here are some factors to consider when making your selection:

Ease of Use: Look for software that offers an intuitive user interface and comprehensive support resources, ensuring that both novice and experienced users can navigate the system effectively.

Scalability: Consider whether the software can accommodate your current needs and adapt to future requirements as your operations grow and evolve.

Integration: Evaluate the software's compatibility with existing tools and systems, ensuring seamless integration and data sharing.

Support and Training: Opt for a provider that offers robust customer support and training resources to help your team maximize the software's capabilities.

Implementation and Best Practices:

Successful implementation of hydraulic analysis software requires careful planning and execution. Here are some best practices to consider:

Define Objectives: Clearly outline your goals and objectives for using the software, ensuring alignment with your organization's strategic priorities.

Data Collection: Gather accurate and comprehensive data on your hydraulic systems, including flow rates, pressure levels, and system configurations.

Training: Provide thorough training for your team to ensure they are well-equipped to use the software effectively and interpret its outputs.

Iterative Approach: Use the software iteratively, continuously refining your models and analyses based on new insights and data.

Collaboration: Foster collaboration among cross-functional teams, leveraging the expertise of engineers, operators, and analysts to optimize system performance.

Conclusion

Hydraulic analysis software is revolutionizing the way industries approach fluid dynamics, offering powerful tools for optimizing system performance, enhancing safety, and driving cost savings. By understanding the capabilities and benefits of hydraulic analysis software, organizations can unlock new levels of efficiency and reliability. As technology continues to evolve, embracing these innovations will be essential for staying competitive in today's dynamic industrial landscape.

For more information on how hydraulic analysis software can transform your operations, feel free to contact us at CEPL. Our experts are here to help you explore the possibilities and achieve your strategic goals.

0 notes

Text

CATIA vs SolidWorks: Making the Right Choice with Dynamic CAD CAM CAE in Chennai

Choosing the right CAD (Computer-Aided Design) software is crucial for engineering professionals and organizations that aim to excel in design, simulation, and manufacturing processes. Two of the most popular and powerful CAD software options available today are CATIA and SolidWorks. Both are developed by Dassault Systèmes and offer extensive features tailored to various industries and applications. However, each software has its unique strengths and caters to different user needs. In this blog, we will explore the key differences, advantages, and applications of CATIA and SolidWorks to help you make an informed decision. Additionally, we will highlight the best training institutes for both software in Chennai, such as Dynamic CAD CAM CAE, to support your learning journey.

Introduction to CATIA

CATIA (Computer-Aided Three-dimensional Interactive Application) is a comprehensive multi-platform suite developed by Dassault Systèmes. It is widely recognized for its robust capabilities in 3D design, engineering, and product lifecycle management. CATIA is extensively used in industries like aerospace, automotive, shipbuilding, and industrial equipment, where complex and high-precision designs are essential.

Key Features of CATIA

Advanced 3D Modeling: CATIA excels in creating highly detailed and complex 3D models. It supports a wide range of design processes, from conceptualization to detailed engineering.

Multidisciplinary Approach: CATIA integrates multiple disciplines within a single platform, including mechanical engineering, systems engineering, and electrical design. This holistic approach enables seamless collaboration among various engineering teams.

Product Lifecycle Management (PLM): CATIA is known for its strong PLM capabilities, allowing organizations to manage the entire lifecycle of a product from inception through engineering design and manufacturing.

Simulation and Analysis: The software provides advanced simulation tools for stress analysis, kinematics, and fluid dynamics, helping engineers validate designs and optimize performance.

Surface Modeling: CATIA offers powerful surface modeling tools, making it ideal for industries that require complex surface designs, such as automotive and aerospace.

Introduction to SolidWorks

SolidWorks is another powerful CAD software developed by Dassault Systèmes, designed primarily for mechanical engineering and product design. It is widely used in industries such as consumer products, machinery, and electronics due to its user-friendly interface and robust design capabilities.

Key Features of SolidWorks

User-Friendly Interface: SolidWorks is known for its intuitive and easy-to-use interface, which significantly reduces the learning curve for new users.

Parametric Design: The software uses parametric design principles, allowing designers to easily make changes and updates to their models. This feature is particularly beneficial for iterative design processes.

Extensive Library of Components: SolidWorks offers a vast library of pre-built components and parts, saving time and effort in the design process.

Simulation and Analysis: Similar to CATIA, SolidWorks provides powerful simulation tools for stress analysis, motion analysis, and thermal analysis, enabling engineers to test and validate their designs.

Integration with CAM: SolidWorks integrates seamlessly with Computer-Aided Manufacturing (CAM) tools, facilitating the transition from design to manufacturing.

Comparing CATIA and SolidWorks

While both CATIA and SolidWorks are highly capable CAD software, their distinct features and functionalities make them suitable for different types of projects and industries. Let’s compare some key aspects to help you determine which software is the right fit for your needs.

Complexity and Scope

CATIA: Designed for large-scale and complex projects, CATIA is ideal for industries that require high precision and intricate designs. Its advanced surface modeling and PLM capabilities make it the preferred choice for aerospace, automotive, and industrial equipment sectors.

SolidWorks: Best suited for small to medium-sized projects, SolidWorks is widely used in industries like consumer products, machinery, and electronics. Its user-friendly interface and parametric design capabilities make it an excellent choice for mechanical engineering and product design.

Learning Curve

CATIA: Due to its extensive features and advanced functionalities, CATIA has a steeper learning curve. It requires more time and effort to master, making it essential for users to undergo comprehensive training.

SolidWorks: Known for its intuitive interface, SolidWorks has a shorter learning curve. Users can quickly become proficient with the software, making it a popular choice for beginners and those who need to start designing without extensive training.

Cost

CATIA: As a more complex and feature-rich software, CATIA tends to be more expensive than SolidWorks. The cost includes not only the software license but also potential training and implementation expenses.

SolidWorks: Generally more affordable than CATIA, SolidWorks offers a cost-effective solution for small to medium-sized businesses. The lower cost makes it accessible to a wider range of users and organizations.

Industry Applications

CATIA: Primarily used in aerospace, automotive, shipbuilding, and industrial equipment industries, CATIA’s advanced features and capabilities make it the go-to choice for companies involved in complex and large-scale projects.

SolidWorks: Widely used in consumer products, machinery, and electronics industries, SolidWorks is ideal for mechanical engineering, product design, and manufacturing processes that require a straightforward and efficient design tool.

Training and Certification

Proper training is essential to maximize the potential of any CAD software. In Chennai, Dynamic CAD CAM CAE is a renowned training institute offering comprehensive courses for both CATIA and SolidWorks. Let’s explore the training programs offered by this institute.

CATIA Training at Dynamic CAD CAM CAE

Dynamic CAD CAM CAE provides in-depth CATIA training programs designed to equip students with the knowledge and skills required to excel in the industry. The training covers:

Introduction to CATIA: Basics of the software, interface navigation, and essential tools.

3D Modeling: Techniques for creating detailed 3D models, including part design and assembly design.

Surface Modeling: Advanced surface design tools and techniques for creating complex shapes.

Simulation and Analysis: Utilizing CATIA’s simulation tools for stress analysis, kinematics, and more.

PLM Integration: Understanding CATIA’s PLM capabilities and how to manage product lifecycles effectively.

SolidWorks Training at Dynamic CAD CAM CAE

Dynamic CAD CAM CAE also offers specialized SolidWorks training programs tailored to meet industry standards. The training includes:

Introduction to SolidWorks: Basics of the software, interface, and core functionalities.

Part and Assembly Design: Techniques for creating parametric models, assemblies, and detailed drawings.

Simulation and Analysis: Using SolidWorks simulation tools for stress analysis, motion analysis, and thermal analysis.

CAM Integration: Understanding the integration between SolidWorks and CAM tools for seamless manufacturing processes.

Advanced Features: Exploring advanced design features, such as sheet metal design, weldments, and surfacing.

Choosing between CATIA and SolidWorks depends on your specific needs, industry requirements, and project complexity. CATIA is the preferred choice for industries that require advanced 3D modeling, surface design, and PLM capabilities, such as aerospace and automotive. On the other hand, SolidWorks is ideal for mechanical engineering, product design, and manufacturing processes in industries like consumer products, machinery, and electronics.

For those looking to gain expertise in either software, Dynamic CAD CAM CAE in Chennai offers top-notch training programs to help you master CATIA and SolidWorks. Whether you are an individual seeking to enhance your skills or an organization looking to train your team, Dynamic CAD CAM CAE provides comprehensive training solutions to meet your needs.

By understanding the key differences and advantages of CATIA and SolidWorks, and with proper training from a reputable institute like Dynamic CAD CAM CAE, you can make an informed decision and excel in your CAD projects. Embrace the right CAD software and unlock your potential in the world of design and engineering.

Choosing Between CATIA and SolidWorks: FAQs to Guide Your Decision with Dynamic CAD CAM CAE in Chennai

1. What are the primary differences between CATIA and SolidWorks?

CATIA and SolidWorks are both powerful CAD software developed by Dassault Systèmes, but they cater to different needs and industries. CATIA is designed for large-scale and complex projects, particularly in aerospace, automotive, shipbuilding, and industrial equipment industries. It excels in advanced 3D modeling, surface modeling, and product lifecycle management (PLM). SolidWorks, on the other hand, is best suited for small to medium-sized projects in consumer products, machinery, and electronics industries. It is known for its user-friendly interface, parametric design capabilities, and cost-effective solutions.

2. How do the learning curves of CATIA and SolidWorks compare?

CATIA has a steeper learning curve due to its extensive features and advanced functionalities. It requires more time and comprehensive training to master, making it essential for users to undergo in-depth courses. SolidWorks is known for its intuitive and easy-to-use interface, which significantly reduces the learning curve. Users can quickly become proficient with the software, making it a popular choice for beginners and those who need to start designing without extensive training.

3. What industries are CATIA and SolidWorks most suitable for?

CATIA is primarily used in industries that require high precision and intricate designs, such as aerospace, automotive, shipbuilding, and industrial equipment. Its advanced features and PLM capabilities make it the preferred choice for companies involved in complex and large-scale projects. SolidWorks is widely used in consumer products, machinery, and electronics industries. It is ideal for mechanical engineering, product design, and manufacturing processes that require a straightforward and efficient design tool.

4. How much does it cost to get trained in CATIA and SolidWorks in Chennai?

The cost of training in CATIA and SolidWorks can vary based on the training institute and the depth of the course. At Dynamic CAD CAM CAE in Chennai, comprehensive training programs are offered for both software. While the exact costs can vary, investing in quality training ensures that you gain the necessary skills to excel in your career. It is advisable to contact Dynamic CAD CAM CAE directly for detailed pricing and course information.

5. Why should I choose Dynamic CAD CAM CAE for CATIA and SolidWorks training in Chennai?

Dynamic CAD CAM CAE is a renowned training institute in Chennai, offering in-depth courses for both CATIA and SolidWorks. The institute provides specialized training programs designed to meet industry standards and equip students with the knowledge and skills required to excel in their careers. With comprehensive courses covering everything from basic to advanced features, simulation and analysis, and integration with other tools, Dynamic CAD CAM CAE ensures that you receive top-notch training and are well-prepared for the demands of the industry.

0 notes

Text

The Power of Computational Fluid Dynamics: Real-World Applications and Benefits

Enhance vehicle performance with Computational Fluid Dynamics solutions for the automotive industry from CFD Support. Our CFD analysis services cover aerodynamics, thermal management, and fluid flow optimization, helping you improve fuel efficiency, reduce emissions, and enhance overall performance. Trust our experts to deliver reliable and accurate CFD solutions for your automotive projects. Contact us now to discuss your requirements!

1 note

·

View note

Text

Europe Immersion Cooling Market: Unlocking Efficiency and Sustainability in Data Centers with Immersion Cooling Technologies

Introduction:Immersion cooling is an innovative thermal management technique that involves submerging electronic components, such as servers and computing equipment, in a thermally conductive dielectric liquid. This method effectively dissipates heat, enhancing the efficiency and performance of high-density data centers. As the demand for cloud services, artificial intelligence, and big data analytics grows, immersion cooling emerges as a sustainable and cost-effective solution for managing the escalating heat loads in modern data centers.

Major Vendors: ➲ Asperitas, ➲ DCX — The Liquid Cooling Company, ➲ DUG Technology, ➲ Engineered Fluids, ➲ Green Revolution Cooling Inc, ➲ LiquidStack Holding B.V., ➲ Schneider Electric, Submer, ➲ TEIMMERS, ➲ GlobalConnect, ➲ Cordis, Grundfos, ➲ Submer, ➲ and others

Rising Demand for High-Performance Computing (HPC)

The Europe Immersion Cooling Market is poised for significant growth due to the increasing demand for high-performance computing (HPC) solutions across various industries. As organizations strive to handle complex computations and process massive amounts of data, traditional air-cooling methods are becoming inefficient and costly.

Immersion cooling technology provides an innovative solution by submerging IT components directly into a non-conductive liquid, enhancing cooling efficiency and reducing energy consumption.

Research Methodology:This report is based on a robust research methodology that combines primary and secondary research. Primary research includes interviews with industry experts, key stakeholders, and market participants, providing firsthand insights into market dynamics.

Secondary research involves a thorough review of industry reports, white papers, academic journals, and reputable news sources. The data collected is analyzed using quantitative and qualitative methods to ensure accuracy and reliability. Market size estimations, growth projections, and trend analyses are derived from a comprehensive analysis of historical data, current market conditions, and prospects.

The Report Offers:✤ Market Overview: A detailed overview of the Europe Immersion Cooling Market, including market size, growth trends, and key drivers.✤ Technology Insights: In-depth analysis of immersion cooling technologies, their applications, and benefits.✤ Market Segmentation: Comprehensive segmentation by type, application, and region, providing a granular view of the market.✤ Competitive Landscape: Analysis of the competitive landscape, including profiles of leading companies, their market strategies, and recent developments.✤ Market Forecasts: Accurate market forecasts for the next five years, highlighting growth opportunities and potential challenges.✤ Regulatory Insights: Information on regulatory frameworks and standards influencing the market.✤ Investment Opportunities: Identification of potential investment opportunities and key areas for market expansion.

Recent Developments:

In March 2023, DCX unveiled the PRO10 Immersion Mining System, introducing a groundbreaking system architecture specifically designed for scale-out crypto mining. Compared to the industry standard, the new DCX High-Density Immersion Containers offer a remarkable 70% improvement in heat transfer performance, 2.5 times higher power density, and double the capacity for hosting miners.

Conclusion:

The Europe Immersion Cooling Market is poised for significant growth, driven by the increasing demand for efficient and sustainable data center cooling solutions. This report provides a comprehensive analysis of market trends, technologies, and competitive dynamics, equipping stakeholders with the knowledge needed to navigate the evolving landscape. By accessing this report, you gain valuable insights that will help you make informed decisions and leverage the opportunities in the immersion cooling market to achieve long-term success.

0 notes

Link

2 min readPreparations for Next Moonwalk Simulations Underway (and Underwater) A wireframe image of an aircraft being designed.NASA The Hypersonic Technology project is divided into four research topic areas. The first research topic is system-level design, analysis, and validation, which explores the impacts of technologies on vehicle performance. The second and third topics focus more specifically on propulsion technologies and vehicle technologies enabling hypersonic flight. The fourth topic area explores material technology that can survive and be reused in high-temperature hypersonic flight. System-Level Design and Analysis The System-Level Design, Analysis, and Validation research topic (RT-1) investments are focused on computational tool development and validation for hypersonic propulsion and vehicle system analysis methods including uncertainty quantification. RT-1 coordinates and performs definitive systems analysis studies to clarify the potential benefits of hypersonic vehicles and technologies for both high-speed civilian travel and space access and will use these studies to drive a technology portfolio focused on reusability, affordability, and reliability. An illustration of a hypersonic vehicle.NASA Propulsion Technologies The Propulsion Technologies research topic (RT-2) focuses on turboramjet, ramjet, integrated combined-cycle, dual-mode, and scramjet propulsion systems and associated propulsive mode transitions, combustor operability, fuels, controls, and sensors. RT-2 develops computational fluid dynamic technologies to enable predictive simulations of these systems. Hypersonic model test in the 8-Foot High Temperature Tunnel at NASA Langley.NASA Vehicle Technologies The Vehicle Technologies research topic (RT-3) investments focus on understanding aerodynamic and aerothermodynamic phenomena, such as high-speed boundary-layer transition and shock-dominated flows, to further technologies that improve aerodynamic performance as well as reduce aerodynamic heating. A model of a hypersonic vehicle and sensor in NASA’s 20-Inch Mach 6 Air Tunnel in the Langley Aerothermodynamic Lab.NASA High Temperature Materials The High Temperature Durable Materials research topic (RT-4) investments focus on advanced propulsion and vehicle materials research. Due to the operating conditions of hypersonic vehicles, most of the structures and materials are shared between propulsion and vehicle components, which include aeroshell, control surface, leading edge, propulsion, and sealing concepts. RT-4 examines the design and evaluation of potential structure and material concepts through component development and testing under relevant environments. In addition, because of the extreme environments the materials and structures must endure, RT-4 also includes development of advanced thermal and structural measurement methods. Read More About Hypersonic Technology About the AuthorShannon EichornShannon Eichorn is the Strategic Engagement Lead for NASA’s Advanced Air Vehicles Program. She is a former test engineer in supersonic wind tunnels and former engineer managing facilities, such as the Aeroacoustic Propulsion Lab, Glenn Extreme Environments Rig, and Creek Road Cryogenics Complex. Facebook logo @NASA@NASAaero@NASA_es @NASA@NASAaero@NASA_es Instagram logo @NASA@NASAaero@NASA_es Linkedin logo @NASA Explore More 3 min read NASA Launches Rocket to Study Hypersonic Aircraft Article 2 years ago 1 min read AETC Hypersonic Facilities Article 8 years ago 2 min read Rocket Launch Scheduled March 21 from NASA’s Wallops Flight Facility Article 2 years ago Keep Exploring Discover Related Topics Technology Transfer & Spinoffs Small Business Innovation Research (SBIR) / Small Business Technology Transfer (STTR) Manufacturing and Materials Why Go to Space Share Details Last Updated Jun 21, 2024 EditorJim BankeContactShannon [email protected] Related TermsHypersonic TechnologyAdvanced Air Vehicles Program

0 notes

Text

How Ebara pumps help reduce energy consumption

Ebara pumps are designed with advanced technologies and engineering principles to enhance energy efficiency and reduce energy consumption. Here are several ways Ebara pumps achieve these goals:

1. High-Efficiency Motors

Optimized Motor Design: Ebara submersible pumps are equipped with high-efficiency motors that convert electrical energy into mechanical energy more effectively. These motors operate at higher efficiencies, reducing energy losses.

Energy-Efficient Ratings: Many Ebara pumps meet or exceed international energy efficiency standards, such as NEMA Premium efficiency in the U.S. or IE3/IE4 in Europe, ensuring they consume less power while delivering the same performance.

2. Advanced Hydraulic Design

Optimized Impellers: The impellers in Ebara pumps are designed using advanced computational fluid dynamics (CFD) to minimize hydraulic losses and maximize fluid flow efficiency. This design reduces the energy required to pump fluids.

Streamlined Flow Paths: The internal flow paths of the pumps are engineered to minimize turbulence and friction losses, resulting in more efficient energy use.

3. Variable Frequency Drives (VFDs)

Speed Control: Ebara pumps can be equipped with variable frequency drives (VFDs) that adjust the pump speed to match the demand. This ensures that the pump operates only at the necessary speed, reducing energy consumption during periods of low demand.

Soft Start and Stop: VFDs provide a soft start and stop for the pump, reducing the inrush current and avoiding energy spikes, which also helps in lowering energy costs.

4. Precision Engineering

Tight Manufacturing Tolerances: Ebara pumps are manufactured with precise tolerances to ensure all components work together seamlessly, reducing mechanical losses and enhancing overall pump efficiency.

Quality Materials: High-quality materials reduce wear and tear, maintaining efficiency over the pump’s lifespan and avoiding the energy loss associated with degraded components.

5. Energy-Saving Features

Thermal Protection: Many Ebara pumps include thermal protection features that prevent overheating and ensure the pump operates within its optimal temperature range, reducing energy wastage.

Auto Shut-off: Some models have an automatic shut-off feature that turns the pump off when not needed, preventing unnecessary energy consumption.

6. System Optimization

Right-Sizing Pumps: Ebara provides a range of pump sizes and models, allowing users to select the right pump for their specific application, avoiding the energy inefficiencies associated with over-sized or under-sized pumps.

Consultative Approach: Ebara often works with customers to assess their system needs and recommend the most efficient pump setup, ensuring the overall system operates at peak efficiency.

7. Maintenance and Reliability

Long Service Intervals: Ebara pumps are designed for long service intervals, reducing downtime and maintaining high efficiency over time.

Easy Maintenance: Simplified maintenance procedures ensure that pumps are kept in optimal condition, preventing the energy losses associated with poorly maintained equipment.

8. Innovative Technologies

Permanent Magnet Motors: Some Ebara models feature permanent magnet motors, which offer higher efficiency compared to traditional induction motors.

Smart Monitoring Systems: Ebara pumps can be integrated with smart monitoring systems that track performance metrics and alert users to inefficiencies or maintenance needs, allowing for proactive energy management.

By incorporating these advanced technologies and design principles, Ebara pumps help users significantly reduce energy consumption, leading to lower operating costs and a smaller environmental footprint. Whether through high-efficiency motors, advanced hydraulic designs, VFD integration, or smart system optimization, Ebara pumps are engineered to provide energy-efficient solutions across a wide range of applications. For more info contact Ebara Pump Suppliers in UAE or call us at +971 4 2522966.

0 notes

Text

The Impact of iPhone 15 on Mobile Gaming: A Gamer’s Perspective

The release of Apple's iPhone 15 marks another leap forward in the evolution of mobile technology, promising significant enhancements that could reshape the landscape of mobile gaming. For gamers, the iPhone 15 brings a host of new features that enhance performance, graphics, and overall gaming experience. Let's delve into how the iPhone 15 impacts mobile gaming from a gamer's perspective.

Cutting-Edge Performance

A17 Bionic Chip: The Heart of Performance

At the core of the iPhone 15 is the new A17 Bionic chip. This advanced processor boasts a significant increase in performance and efficiency over its predecessors. With a 5-nanometer architecture, it delivers faster processing speeds and improved graphics capabilities, which are crucial for high-end gaming.

The A17 Bionic chip includes a 16-core Neural Engine capable of performing up to 30 trillion operations per second. This not only enhances the performance of AI-driven game features but also ensures smoother gameplay, reduced latency, and more responsive controls. For gamers, this means a more immersive and enjoyable gaming experience, especially in titles that demand high computational power.

Enhanced Graphics

The iPhone 15's GPU has been upgraded to support more complex graphics with better efficiency. The six-core graphics processor allows for higher frame rates and more detailed textures. Games like "Genshin Impact," which rely on intricate graphics and seamless animations, will run more smoothly and look more stunning than ever before. This enhanced GPU is a boon for developers, too, as it provides the tools needed to create more graphically rich games without compromising performance.

Advanced Cooling System

Heat management is a critical factor in maintaining consistent performance during extended gaming sessions. The iPhone 15 introduces an advanced cooling system that dissipates heat more effectively than previous models. This allows gamers to enjoy prolonged sessions without experiencing thermal throttling, which can reduce performance over time. With the new cooling system, gamers can play demanding titles for longer periods without worrying about their device overheating.

Display Enhancements

ProMotion Technology

The iPhone 15 features ProMotion technology, which supports refresh rates up to 120Hz. This means that the display can refresh up to 120 times per second, providing a much smoother visual experience compared to the standard 60Hz display. For gamers, this translates to more fluid motion, reduced motion blur, and a more responsive gaming experience. Fast-paced games, such as first-person shooters and racing games, will particularly benefit from this higher refresh rate.

OLED Display with HDR

The new OLED display offers better contrast, deeper blacks, and more vibrant colors. Combined with HDR (High Dynamic Range) support, this enhances the visual fidelity of games, making them more immersive and visually appealing. Games with rich, detailed environments, such as "The Witcher: Monster Slayer," will benefit significantly from this technology, providing players with a more lifelike and captivating experience.

Battery Life and Efficiency

Longer Gaming Sessions

One of the perennial concerns for mobile gamers is battery life. The iPhone 15 addresses this with a larger battery and more efficient power management. The A17 Bionic chip is designed to be power-efficient, ensuring that even the most demanding games don’t drain the battery excessively. Gamers can expect longer uninterrupted sessions, which is a significant improvement over previous models.

Fast Charging

In addition to improved battery life, the iPhone 15 supports faster charging speeds. This means that even if you run low on battery during an intense gaming session, you can quickly recharge and get back to playing. This is a practical enhancement for gamers who are always on the go and need their devices to be ready for action at a moment’s notice.

Connectivity and Multiplayer Gaming

5G and Wi-Fi 6E

The iPhone 15 supports the latest connectivity standards, including 5G and Wi-Fi 6E. These technologies provide faster internet speeds and more reliable connections, which are crucial for online multiplayer games. With 5G, gamers can enjoy low-latency gaming experiences even when they are away from home. Wi-Fi 6E offers better performance in congested areas, ensuring a stable connection during critical gaming moments.

Seamless Cloud Gaming

With the rise of cloud gaming services like Xbox Cloud Gaming and NVIDIA GeForce Now, the need for a powerful and reliable internet connection has never been greater. The iPhone 15's enhanced connectivity options make it an excellent device for cloud gaming. Gamers can stream high-quality games directly to their phones without worrying about lag or buffering, opening up a world of gaming possibilities that were previously limited to high-end PCs and consoles.

Augmented Reality (AR) and Virtual Reality (VR)

Enhanced AR Capabilities

The iPhone 15 continues to push the boundaries of Augmented Reality (AR) with its improved ARKit framework and advanced sensors. The combination of the A17 Bionic chip and enhanced AR capabilities means that AR games will run more smoothly and look more realistic. Games like "Pokémon GO" and "Harry Potter: Wizards Unite" will benefit from these enhancements, providing a more engaging and interactive experience.

Potential for VR

While VR is still in its nascent stages on mobile devices, the iPhone 15’s hardware advancements lay the groundwork for future developments in this area. With its powerful processor, advanced graphics capabilities, and improved sensors, the iPhone 15 could potentially support more complex VR applications and games, offering gamers a taste of immersive virtual environments.

Ecosystem and Compatibility

Apple Arcade and Beyond

Apple Arcade, Apple’s gaming subscription service, stands to benefit from the iPhone 15’s advancements. The service offers a wide range of exclusive games that are optimized for iOS devices. With the iPhone 15’s enhanced performance and graphics, Apple Arcade games will look and play better than ever. Additionally, the seamless integration with other Apple devices means that gamers can easily switch between playing on their iPhone, iPad, or Apple TV.

Controller Support

The iPhone 15 offers robust support for external controllers, including those from major console manufacturers like Sony and Microsoft. This allows gamers to enjoy a console-like experience on their mobile devices. The improved Bluetooth capabilities ensure a stable connection between the phone and the controller, reducing input lag and enhancing the overall gaming experience.

Conclusion

The iPhone 15 represents a significant step forward for mobile gaming. Its powerful A17 Bionic chip, advanced graphics, improved display, and enhanced connectivity options all contribute to a superior gaming experience. For gamers, this means smoother gameplay, more immersive visuals, and longer gaming sessions without interruption. Whether you are a casual gamer or a hardcore enthusiast, the iPhone 15 offers features that can enhance your mobile gaming experience in numerous ways.

As the mobile gaming industry continues to grow, the iPhone 15 positions itself as a leading device capable of meeting the demands of modern gamers. Its combination of hardware and software advancements ensures that it can handle the most demanding games on the market, while also providing a platform for future innovations in AR and VR. For those looking to take their mobile gaming to the next level, the iPhone 15 is a device worth considering.

0 notes

Text

Mastering the Art of Silicon Carbide Nozzles: Engineering Marvels for Extreme Environments

In the ever-evolving landscape of high-temperature applications and extreme environments, silicon carbide (SiC) nozzles have emerged as true engineering marvels, offering unparalleled performance and durability. These exceptional components have revolutionized various industries, from aerospace and defense to manufacturing and energy production, enabling unprecedented advancements and pushing the boundaries of what is possible. This comprehensive guide delves into the intricacies of silicon carbide nozzles, exploring their unique properties, applications, and the cutting-edge technologies that make them an indispensable asset in extreme environments.

The Extraordinary Properties of Silicon Carbide

Silicon carbide, a remarkable ceramic compound composed of silicon and carbon, is renowned for its exceptional thermal, mechanical, and chemical properties. With a melting point exceeding 2700ᄚC (4892ᄚF), SiC boasts outstanding thermal stability, enabling it to withstand extreme temperatures without compromising its structural integrity. Its hardness, second only to diamond, translates into exceptional wear resistance, making it an ideal material for applications involving abrasive environments or high-velocity particle flows.

Moreover, silicon carbide exhibits remarkable chemical inertness, resisting corrosion and oxidation even in the most demanding conditions. This characteristic ensures prolonged service life and minimizes maintenance requirements, contributing to cost-effectiveness and operational efficiency. The unique combination of these properties makes SiC an ideal choice for high-temperature nozzle applications, where performance and reliability are paramount.

Precision Engineering: Crafting Perfection

The design and manufacturing of silicon carbide nozzles are intricate processes that demand precision engineering and cutting-edge technologies. These nozzles are typically manufactured through advanced techniques such as chemical vapor deposition (CVD), reaction bonding, or hot isostatic pressing (HIP), ensuring consistent quality and performance.

Intricate geometries and complex internal channels are meticulously crafted to optimize fluid dynamics, ensuring precise control over flow patterns and minimizing turbulence. Advanced computational fluid dynamics (CFD) simulations are employed to analyze and refine nozzle designs, enabling engineers to achieve optimal performance tailored to specific application requirements.

Furthermore, advanced surface treatments and coatings can be applied to silicon carbide nozzles, enhancing their performance and tailoring them to specific operating conditions. These coatings may include erosion-resistant materials, thermal barrier coatings, or specialized coatings designed to improve chemical resistance or thermal management.

Applications Pushing the Boundaries

Silicon carbide nozzles have found widespread applications across diverse industries, enabling unprecedented advancements and pushing the boundaries of what is possible in high-temperature environments. Here are some of the most prominent applications:

Aerospace and Defense:

Rocket nozzles: SiC nozzles are instrumental in solid rocket motors and liquid rocket engines, withstanding the extreme temperatures and erosive conditions during rocket firing. Their exceptional thermal stability and wear resistance ensure reliable performance and extended service life, making them a critical component in space exploration and defense applications.

Plasma spray nozzles: Used in plasma spray systems for thermal barrier coatings, these nozzles endure the high-temperature plasma jet without degradation, enabling the deposition of advanced protective coatings on critical components.

Manufacturing:

Sand blasting nozzles: The hardness and wear resistance of SiC make it ideal for sandblasting applications, ensuring prolonged service life and consistent performance. These nozzles enable efficient surface preparation and finishing processes in various manufacturing industries.

Cutting nozzles: SiC nozzles are employed in high-temperature cutting processes like oxy-fuel cutting and plasma cutting, enabling precise and efficient material processing. Their ability to withstand extreme temperatures and abrasive environments ensures accurate cuts and extended tool life.

Energy Production:

Furnace components: Silicon carbide is utilized to manufacture burner nozzles, thermocouple protection tubes, and other high-temperature furnace components, ensuring reliable operation and extended service life in demanding environments.

Gasification processes: SiC nozzles find applications in gasification systems, facilitating the conversion of solid or liquid feedstocks into syngas under extreme conditions. Their chemical inertness and thermal stability make them ideal for handling corrosive and high-temperature gases.

Research and Development:

High-temperature testing: SiC nozzles play a crucial role in research and development efforts involving high-temperature environments, enabling scientists and engineers to push the boundaries of material science and engineering. Their exceptional performance allows for accurate data collection and reliable testing under extreme conditions.

Advancements and Future Prospects

The field of silicon carbide nozzles is continuously evolving, driven by advancements in material science, manufacturing techniques, and application-specific requirements. Ongoing research efforts are focused on optimizing nozzle designs for improved flow dynamics, enhanced thermal management, and increased durability.

The integration of additive manufacturing technologies, such as 3D printing, is paving the way for innovative nozzle designs with complex geometries and internal structures tailored to specific applications. This synergy between cutting-edge manufacturing techniques and material science promises to unlock new potentials, driving efficiency, precision, and cost-effectiveness in various industries.

Furthermore, the development of new coating materials and surface treatments holds the promise of further enhancing the performance and lifespan of SiC nozzles. Researchers are exploring advanced coating systems that can provide additional protection against erosion, corrosion, and thermal degradation, extending the operational envelope of these nozzles in even more extreme environments.

As computational power and simulation capabilities continue to advance, the use of sophisticated computational fluid dynamics (CFD) simulations will become increasingly prevalent in the design and optimization of silicon carbide nozzles. These simulations will enable engineers to accurately predict fluid flow patterns, thermal gradients, and potential areas of wear or erosion, allowing for proactive design improvements and optimizations.

Leveraging Synergies for Groundbreaking Innovations

The future of silicon carbide nozzles lies in the seamless integration of cutting-edge technologies and multidisciplinary collaborations. By fostering synergies between material science, computational modeling, advanced manufacturing techniques, and application-specific expertise, engineers and researchers can unlock groundbreaking innovations in nozzle design and performance.

One exciting area of exploration is the development of hybrid nozzle systems, combining the exceptional properties of silicon carbide with other advanced materials or composites. These hybrid designs could leverage the strengths of multiple materials to create nozzles with tailored properties, such as enhanced thermal management, improved erosion resistance, or optimized fluid dynamics.

Additionally, the integration of smart sensing technologies and real-time monitoring systems could revolutionize the way silicon carbide nozzles are utilized and maintained. Embedded sensors could provide valuable data on operating conditions, wear rates, and potential failure points, enabling predictive maintenance strategies and proactive interventions to maximize service life and minimize downtime.

Conclusion: Mastering the Art of Extreme Engineering

Silicon carbide nozzles have proven to be true engineering marvels, enabling unprecedented performance and reliability in high-temperature and extreme environments. Their exceptional thermal stability, wear resistance, and chemical inertness make them indispensable components in applications ranging from aerospace and defense to manufacturing and energy production.

As technology continues to advance, the demand for silicon carbide nozzles is expected to grow, driving further innovation and advancements in material science and manufacturing techniques. By harnessing the extraordinary properties of these exceptional components, industries can push the boundaries of what is possible, enabling new frontiers in innovation and technological progress.

Through precision engineering, cutting-edge manufacturing processes, and continuous research and development, silicon carbide nozzles will continue to redefine the limits of what is achievable in extreme environments, empowering engineers and scientists to tackle ever-more challenging applications and unlocking new realms of possibility.

By mastering the art of silicon carbide nozzle design and manufacturing, visionary engineers and researchers will shape the future of extreme engineering, propelling humanity's ability to explore, create, and push the boundaries of what was once deemed impossible.

0 notes

Text

Pioneering Sustainable Building Solutions with Comprehensive Energy Assessment and Consulting Services

In the dynamic world of building construction and design, sustainability is no longer a luxury but a necessity. As architects, builders, and developers increasingly focus on green building standards, the demand for specialized consulting and assessment services in energy efficiency and sustainability is growing. At Green Energy Assessment, we offer a suite of services designed to meet these needs, including NatHERS energy rating assessment services, Green Star certification consulting, Section J compliance reports, JV3 assessment services, mechanical design consultancy for commercial buildings, and CFD modelling consulting services. Our aim is to provide our clients with the expertise needed to achieve not only compliance but also performance and sustainability in their building projects.

NatHERS Energy Rating Assessment Services

The Nationwide House Energy Rating Scheme (NatHERS) provides a standard measure of a home's potential energy consumption for heating and cooling. Our expert assessors at GEA utilize advanced software tools to model your building’s thermal performance, providing you with a detailed energy rating that helps in making informed decisions about thermal comfort and energy efficiency. Our services ensure that your project meets or exceeds Australia’s stringent energy regulations, optimizing your building's design for sustainability and cost-effectiveness.

Green Star Certification Consulting Services

Achieving Green Star certification signifies a building’s achievement in environmental sustainability. Our green star certification consulting services guide you through the complex process of certification, from the initial design stages to the final application. We focus on sustainable design practices, helping you incorporate elements such as energy and water efficiency, materials selection, and indoor environmental quality into your project. Our consultants are experienced in navigating the Green Star rating system, ensuring your building achieves its highest potential certification.

Section J Compliance Report and JV3 Assessment Services

For commercial building projects, compliance with Section J of the National Construction Code (NCC) is crucial. Our services include detailed Section J compliance reports that analyze your building's design against the Deemed-to-Satisfy (DtS) provisions and suggest enhancements for energy efficiency. Additionally, we offer JV3 assessment services, an alternative solution to Section J compliance, using thermal simulation methods to demonstrate that your building's energy performance meets or exceeds the DtS provisions. This tailored approach allows for more design flexibility while ensuring compliance.

Mechanical Design Consultancy for Commercial Buildings

Our mechanical design consultancy services are tailored to commercial buildings, focusing on HVAC systems, piping, and energy management systems that meet both the operational needs and sustainability goals of your project. Our team of mechanical engineers designs systems that optimize energy use, enhance indoor air quality, and reduce overall environmental impact. We integrate the latest technologies and sustainable practices to deliver systems that are not only efficient but also cost-effective in the long run.

CFD Modelling Consulting Services

Computational Fluid Dynamics (CFD) modelling is essential for understanding and optimizing the airflow, temperature distribution, and contaminant dispersal in buildings. Our CFD modelling consulting services provide detailed analyses that support the design of ventilation systems and environmental controls. This service ensures that your building provides comfort while maintaining the highest standards of energy efficiency and environmental health.

At Green Energy Assessment, we are committed to leading the charge in sustainable building practices through our comprehensive consulting and assessment services. Whether you are aiming for NatHERS compliance, Green Star certification, or innovative mechanical designs, our team is here to support your project’s success with expert guidance and cutting-edge solutions. Visit our website https://green-ea.net/ to learn more about how we can assist in bringing your sustainable building ambitions to fruition.

#NatHERS energy rating assessment services#green star certification consulting services#section J compliance report and JV3 assessment services#mechanical design consultancy for commercial buildings#CFD modelling consulting services

0 notes

Text

Revolutionizing Product Development: Harnessing AI-Driven CAD Simulation in 2024

In the ever-evolving landscape of product development, innovation reigns supreme. As we navigate through the complexities of design, prototyping, and manufacturing, one technology stands out as a game-changer: AI-driven Computer-Aided Design (CAD) simulation. In 2024, this revolutionary approach is transforming how we conceive, refine, and produce products, optimizing efficiency, reducing costs, and pushing the boundaries of what's possible.

The Evolution of CAD Simulation

CAD simulation has long been a cornerstone of product development, allowing engineers and designers to test concepts virtually before investing time and resources into physical prototypes. However, traditional simulation methods often fall short in accurately predicting real-world behavior due to simplifications and assumptions inherent in their algorithms.

Enter Artificial Intelligence (AI). With advancements in machine learning and computational power, AI-driven CAD simulation has emerged as a disruptive force, enabling engineers to simulate complex scenarios with unprecedented accuracy and efficiency. By learning from vast datasets and iteratively improving models, AI empowers simulations to mimic real-world conditions with remarkable fidelity.

The Power of AI in CAD Simulation

At the heart of AI-driven CAD simulation lies its ability to adapt and evolve. Unlike static simulation models, AI algorithms continuously refine themselves, learning from each iteration to deliver more accurate results. This adaptive approach not only enhances predictive capabilities but also reduces the need for manual intervention, accelerating the design iteration cycle.

Moreover, AI-driven CAD simulation excels in handling complexity. Whether it's simulating fluid dynamics in aerodynamic designs, predicting structural integrity under varying loads, or optimizing thermal management in electronic devices, AI algorithms can tackle multifaceted problems with ease. By simulating intricate interactions between components and subsystems, engineers can uncover insights that would be impossible to glean through traditional methods.

Streamlining Design Iterations

In traditional product development workflows, iterating on design iterations can be a time-consuming and resource-intensive process. Each iteration requires modifications to CAD models, followed by simulation runs to evaluate performance—a cycle that can stretch on for days or even weeks.

AI-driven CAD simulation revolutionizes this process by automating and accelerating design iterations. By leveraging AI to generate and evaluate design alternatives, engineers can explore a vast design space in a fraction of the time. With AI acting as a virtual assistant, suggesting optimizations and highlighting potential pitfalls, designers can focus their expertise on creative problem-solving rather than mundane tasks.

Enhancing Collaboration and Knowledge Sharing

In today's interconnected world, collaboration is key to innovation. AI-driven CAD simulation facilitates collaboration by providing a common platform for engineers, designers, and domain experts to converge and share insights. By centralizing simulation data and results, teams can collaborate in real-time, seamlessly exchanging feedback and ideas to drive the design process forward.

Furthermore, AI-driven CAD simulation democratizes knowledge sharing by capturing and codifying expertise within simulation models. As AI algorithms learn from the collective experience of engineers, they become repositories of domain knowledge, capable of guiding less experienced practitioners through complex design challenges. This democratization of expertise not only accelerates skill development but also fosters a culture of continuous learning and improvement within organizations.

Optimizing Manufacturing Processes

Beyond the design phase, AI-driven CAD simulation plays a crucial role in optimizing manufacturing processes. By simulating manufacturing operations, such as machining, molding, or additive manufacturing, engineers can identify potential bottlenecks, optimize tool paths, and minimize material waste. This holistic approach to product development ensures that designs are not only functional and aesthetically pleasing but also manufacturable at scale.

Moreover, AI-driven CAD simulation enables predictive maintenance, allowing manufacturers to anticipate and address equipment failures before they occur. By analyzing real-time sensor data and historical performance trends, AI algorithms can identify early warning signs of impending failures, enabling proactive maintenance interventions to minimize downtime and maximize productivity.

Overcoming Challenges and Ethical Considerations

While the potential of AI-driven CAD simulation is immense, it's not without its challenges and ethical considerations. Chief among these is the issue of bias in AI algorithms, which can inadvertently perpetuate existing disparities and inequalities. Addressing bias requires a concerted effort to diversify datasets, interrogate algorithmic decision-making processes, and implement safeguards to mitigate potential harms.

Furthermore, the widespread adoption of AI-driven CAD simulation raises questions about data privacy and security. As simulation models become increasingly reliant on proprietary data, safeguarding intellectual property and sensitive information becomes paramount. Robust encryption protocols, access controls, and audit trails are essential components of a comprehensive data security strategy.

Looking Ahead: The Future of Product Development

As we look ahead to the future of product development, the role of AI-driven CAD simulation will only continue to expand. From autonomous vehicles to sustainable infrastructure, AI-powered simulations will drive innovation across industries, unlocking new possibilities and pushing the boundaries of what's achievable.

However, realizing this vision requires a collective effort from stakeholders across academia, industry, and government. By fostering collaboration, investing in research and development, and prioritizing ethical considerations, we can harness the full potential of AI-driven CAD simulation to build a better, more sustainable future for all.

Conclusion

AI-driven CAD simulation represents a paradigm shift in product development, revolutionizing how we conceive, design, and manufacture the products of tomorrow. By leveraging the power of AI to simulate complex scenarios, streamline design iterations, and optimize manufacturing processes, we can unlock new opportunities for innovation and drive positive change on a global scale.

Outsourcing CAD simulation services optimizes product design by tapping into specialized expertise and resources beyond internal capabilities. Skilled professionals conduct simulations, detecting flaws and enhancing performance. This streamlined approach reduces costs and time-to-market by swiftly addressing design issues. Access to cutting-edge tools and diverse perspectives enhances design robustness and efficiency, fostering innovation and competitiveness.

#product development#product design#CAD simulation#Artificial Intelligence (AI)#machine learning#computational power#AI-driven CAD simulation#Outsourcing CAD simulation services

0 notes

Text

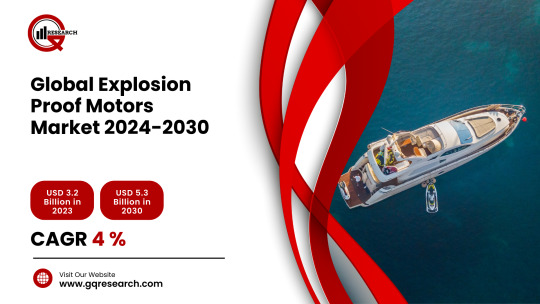

Explosion Proof Motors Market Huge Growth in Future Scope 2024-2030 | GQ Research

The Explosion Proof Motors market is set to witness remarkable growth, as indicated by recent market analysis conducted by GQ Research. In 2023, the global Explosion Proof Motors market showcased a significant presence, boasting a valuation of USD 3.2 Billion. This underscores the substantial demand for Explosion Proof Motors technology and its widespread adoption across various industries.

Get Sample of this Report at: https://gqresearch.com/request-sample/global-explosion-proof-motors-market/

Projected Growth: Projections suggest that the Explosion Proof Motors market will continue its upward trajectory, with a projected value of USD 5.3 Billion by 2030. This growth is expected to be driven by technological advancements, increasing consumer demand, and expanding application areas.

Compound Annual Growth Rate (CAGR): The forecast period anticipates a Compound Annual Growth Rate (CAGR) of 4 %, reflecting a steady and robust growth rate for the Explosion Proof Motors market over the coming years.

Technology Adoption:

In the Explosion Proof Motors market, technology adoption is crucial for enhancing safety and performance standards. As industries such as oil and gas, chemical processing, and mining demand robust and reliable motor solutions, manufacturers continuously integrate cutting-edge technologies to meet stringent safety regulations and operational requirements. Advancements in motor design, insulation materials, and protective enclosures contribute to the development of explosion-proof motors capable of withstanding hazardous environments while maintaining efficient operation.

Application Diversity:

Explosion-proof motors find application across a wide range of industries where the presence of flammable gases, vapors, or combustible dusts poses a risk of ignition. From powering equipment in petrochemical plants and offshore platforms to driving ventilation systems in grain silos and pharmaceutical facilities, these motors play a critical role in ensuring operational safety and compliance with hazardous area classifications. The versatility of explosion-proof motors extends to various environments, including classified hazardous locations such as Class I, II, and III divisions, as well as Zone 0, 1, and 2 areas, providing solutions tailored to specific industry needs.

Consumer Preferences:

Consumer preferences in the Explosion Proof Motors market are heavily influenced by safety considerations, reliability, and compliance with industry standards. With a heightened awareness of workplace safety and regulatory requirements, end-users prioritize the selection of explosion-proof motors that adhere to international certifications such as ATEX, IECEx, and UL, ensuring compatibility with regional safety regulations. Additionally, preferences for energy-efficient motor designs and maintenance-friendly features contribute to the overall value proposition for consumers seeking long-term performance and cost-effectiveness.

Technological Advancements:

Technological advancements drive innovation in explosion-proof motor design, enhancing performance, efficiency, and reliability. Integrated features such as advanced thermal monitoring, fault diagnostics, and condition monitoring systems enable predictive maintenance strategies, reducing downtime and optimizing asset lifecycle management. Furthermore, the use of advanced materials, precision manufacturing techniques, and computational fluid dynamics (CFD) simulations facilitate the development of motors with improved cooling capabilities and mechanical robustness, enhancing their suitability for demanding operating environments.

Market Competition:

The Explosion Proof Motors market is characterized by intense competition among global and regional manufacturers striving to differentiate their product offerings based on performance, quality, and value-added services. Established players leverage their extensive experience and technical expertise to maintain market leadership, while emerging entrants focus on niche applications or technology specialization to gain market share. Price competitiveness, product customization, and aftersales support are key factors influencing purchasing decisions in this competitive landscape, driving continuous innovation and market expansion.

Environmental Considerations:

Environmental considerations in the Explosion Proof Motors market revolve around mitigating the risks associated with hazardous materials and minimizing environmental impact during motor operation and maintenance. By employing efficient motor designs and reducing energy consumption, manufacturers contribute to sustainability initiatives aimed at lowering greenhouse gas emissions and minimizing resource consumption. Additionally, the proper disposal and recycling of motor components at the end of their lifecycle ensure compliance with environmental regulations and promote responsible stewardship of natural resources, aligning with the industry's commitment to environmental sustainability.