#Components of Pressure Lubrication System

Explore tagged Tumblr posts

Text

Aohong NBR Sealing Rubber Gaskets: The Cost-Effective Workhorse for Demanding Applications

Let's face it—when that hydraulic system starts leaking after just six months and you're knee-deep in oil-soaked components, you realize not all rubber gaskets are created equal. NBR Sealing Rubber Gaskets from Aohong solve what generic elastomers can't: delivering reliable sealing performance without breaking the bank. Here's why our nitrile rubber solution outperforms the competition where it matters most.

The Science Behind Superior Sealing

That 34% acrylonitrile content in Aohong's formulation isn't just a random number—it's the sweet spot for balancing oil resistance and flexibility. While cheaper NBR compounds cut corners with 28% content (and pay the price in swelling), we've optimized our material to deliver:

70±5 Shore A hardness (ASTM D2240 verified)

<10% oil swell after 1,000 hours in ASTM #3 oil

-40°C to 120°C service range—no brittle fractures in cold climates

85% compression set resistance at 100°C (beats EPDM in hot oil)

Pro Tip: That matte black finish isn't for looks—it's our proprietary carbon black reinforcement that adds 30% more tear strength versus standard NBR.

Real-World Proof: Hydraulic Cylinder Case Study

Take this OEM mining equipment application we solved last quarter:

Problem: Competitor's gaskets swelled 25% after 3 months

Conditions: 1,500 psi hydraulic fluid + 80°C continuous operation

Solution: Aohong's NBR gasket with enhanced oil swell resistance

After 18 months of brutal service: ✓ Zero leaks (pressure tested monthly) ✓ Only 8% thickness variation ✓ Saved $14,000 in downtime costs

Their maintenance supervisor called it "the only gasket that lasts through our service interval."

Installation: Do It Right the First Time

Surface Prep

32-64 RA surface finish (too smooth causes slippage)

Clean with isopropyl alcohol—never WD-40 (leaves silicone residue)

Torque Sequence

30% less torque than FKM gaskets

Criss-cross pattern for even compression

Break-In Period

Allow 24 hours for full compression set

Retorque after first thermal cycle

❌ $8,000 Mistake Using petroleum grease as lubricant—it degrades NBR over time. Silicone-based only.

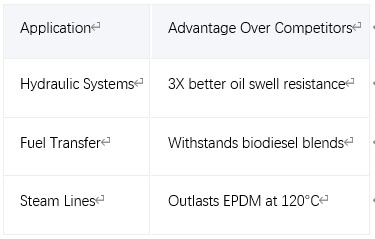

Where Aohong's NBR Excels

Safety Note: Never use with ketones or esters—they'll dissolve the material in weeks.

The Bottom Line

When your application needs oil resistance without fluoropolymer prices—whether it's a construction equipment hydraulic system or a biodiesel transfer line—Aohong's NBR Sealing Rubber Gasket delivers proven performance where generic rubber fails.

Why gamble with inferior materials? Contact Aohong's engineering team today for application-specific solutions—because in industrial sealing, "good enough" usually fails at the worst possible moment.

3 notes

·

View notes

Note

For the writing requests.

Sunstreaker, nsfw, G1 and the prompt is something to do with his narcissism (Mirror, clones, get creative)

A Solo Session | Sunstreaker Solo

Sunstreaker checked his appearance one last time in the mirrors. He’d set them up so he’d have a view from all angles to ensure he was always in the best position. They were on a pulley system that could safely be retracted and adjusted now thanks to Wheeljack’s assistance. A necessity so Sunstreaker didn’t have to spend his setup time herding a grumbling Sideswipe into helping him.

His polish, as always, was perfect and his paint touch up had dried without a hint of difference. He had been worried about mixing in human paint but they’d done an admirable job helping get the right shade. He brushed his digits over his chassis, enjoying the smoothness that showed no hint of the nasty scratch he’d had only days prior from Skywarp. He glanced upwards towards the ceiling where a full body mirror hung and slid down on the luxurious pile of pillows to a more splayed-out position, moving one to directly under his lower back to give a more pronounced arch.

A side mirror showed how prettily the curved lined made his body and the way it allowed his chassis to hit the lighting better.

He smiled. Perfect. He took the time to watch himself, languidly tracing the lines of his body, enjoying both the feeling of his silky-smooth bodywork under his servos and the sight he made caressing himself. The camera should start the stream automatically, and the playlist started with a ping from his system. A thrumming, lyricless rhythm that he could feel vibrating sensually against his system.

As he moved his servos downwards, grasping the round curves of his hips and stroking inward to nudge his legs into parting, he found himself humming along with the familiar music. His body reacted to it from habit, having long associated it with appreciation. He looked in front of himself, watching his blue optics darken at the sight of the view of his long legs spread with servos teasing closer to his panel, pausing to trace his seams and dig into them to tease the wires underneath, starting up the first sparking charges within him.

His fans came on with a vengeance and the sound and touches triggered his array, though he kept it firmly shut, watching intently as he started to move his hips to the rhythm of the music. He wasn’t the dancer Jazz was, lacked the practiced sensuality, but he moved with the rhythm smooth and assured and the thrusting roll of his hips as his servos followed the movement only further got him in the mood.

His array pinged again to open, this time with a distinct wetness starting to gather behind one panel and pressurization alerts behind another. He dismissed it again, optics dimmed to focus on his fingers, digging into the opening in his hips pulling at the wires barely able to be caught inside them. The sharpness of the sensation made his mouth drop open to pant and he darted his optics upwards to admire how his lips looked open and plush, slightly damp from the oral lubricant gathering there.

His tongue darted out licking over the softness of them and he shivered from both the sight and the slow sensation.

This time when his array pinged he didn’t deny it, gasping as the cooler air made contact with his warmed up components.

Sunstreaker couldn’t have stopped himself from planting his feet to spread himself as wide as he could, making certain he had the perfect view of his carefully constructed array. His engine turned over at the vision he made.

Plush gold lips with the inside peaking out with how they spread with arousal, the inside stripped black to map out the calipers of the paler yellow soft insides visibly clenching and rippling, glistening pink stained fluid dripping down his thighs, a perfect white-gold bright node lit up and peaking outside of the hood.

"Perfect," he breathed out angling his hips in a way to share the sight. "And all mine."

He felt a wonderful throb at the sound of alert pings popping up from the computer he left open and smirked. Oh, it would be fun to read later and the heat building in him felt all the sweeter for all the envy he knew his fans felt. It was going to be a long session, he could already tell.

-

Sorry for the delay it took me a bit to get the flow going, though it was fun. Hope you enjoy!

17 notes

·

View notes

Text

Why Your Porsche Macan Might Vibrate When Accelerating

Have you been experiencing vibration when driving your Porsche Macan at high speeds lately?

Macan is one of the most popular Porsche models… known for its impressive handling and performance. If it is vibrating when you press the gas pedal, it is trying to communicate with you about an issue. An issue that, if left undiagnosed, can translate into expensive repairs. Today’s blog post discusses some of the prominent reasons why such a high-performing vehicle might shudder during acceleration.

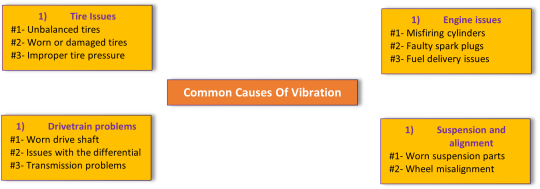

Common Causes of Vibration

Tire Issues

#1- Unbalanced tires: If your Macan’s tires are not properly balanced, you will experience a wobbling sensation when driving at high speeds. The intensity of the sensation will only increase over time. Vibration is the least that you’ll need to be worried about. Unbalanced tires can contribute to an array of drivability issues including decreased handling, increased tire wear, and a rougher ride.

#2- Worn or damaged tires: You might sense vibration as you accelerate your Porsche if there is a bulge in its tire sidewall… It is not safe to drive with such a tire deformity. It can contribute to a bunch of performance-related issues―ranging from traction loss to poor handling. You might also have to deal with issues such as sudden blowouts, premature tire replacement, and suspension malfunctions.

#3- Improper tire pressure: Inflating tires beyond the recommended range can also cause vibration. It is therefore important that you have your Porsche Macan’s tire pressure checked routinely and inflate it according to the manufacturer’s guidelines.

Drivetrain problems

#1- Worn drive shaft: The drive shaft is an essential component of a vehicle’s drivetrain… entrusted with the task of facilitating power transfer from the engine to the wheels. If your Porsche’s drive shaft gets damaged because of corrosion, contamination, or physical impact, you’ll encounter all sorts of drivability issues… including intense vibration under acceleration.

#2- Issues with the differential: The differential is yet another power-distributing component of your vehicle’s drivetrain… responsible for enabling the wheels to turn at different speeds. If there is something off with your Porsche Macan’s differential, you may feel vibration… especially during acceleration. Address the issue promptly if you don’t want the issue to escalate into an expensive repair.

#3- Transmission problems: When was the last time you had your Porsche Macan’s gearbox fluid changed? The gearbox is an important component of any vehicle… the sole purpose of which is to make the engine a controlled source of power. If your vehicle’s transmission system acts up because of low lubricant or a damaged component, its performance will suffer. And your vehicle might shudder under acceleration.

Engine issues

#1- Misfiring cylinders: Your Porsche engine will vibrate violently if some of its cylinders are not firing properly. From ignition system issues to faulty sensors… there can be many reasons why a car engine may misfire. Find out what’s going on with your Porsche and why some of its cylinders are not firing the way they should.

#2- Faulty spark plugs or ignition coils: Electric sparks generated by these tiny components ensure controlled combustion of the air-fuel mixture inside the cylinders. Prolonged exposure to repeated heating and cooling cycles, accumulation of carbon deposits, and improper gap between spark plug electrodes can influence spark plug operation… As a result, the engine might run rough and vibrate violently.

#3- Fuel delivery issues: If your Porsche Macan engine is not getting the correct amount of fuel at the right time, its performance will suffer. It may run unevenly and vibrate during acceleration.

Suspension and alignment

#1- Worn suspension components: The suspension system does much more than just damping road shocks. It distributes the vehicle’s weight across all four wheels. It prevents body roll during turns. Most importantly… it enables better steering response. Your Porsche will vibrate during acceleration if its suspension system is not in good shape.

Wrapping Up

So, there you have it…

A list of reasons why you might experience vibration when accelerating your Porsche Macan. Such an issue should not go undiagnosed… as it could lead to expensive repairs down the road. Have your vehicle checked by certified professionals if it’s wobbling too much under acceleration. Whether the culprit is a faulty suspension part or a defective drivetrain part… have it fixed before its too late.

#porsche macan#porsche service center#porsche maintenance#porsche car mechanic#porsche car suspension

4 notes

·

View notes

Text

Guide to Maintaining Rexroth Hydraulic Pumps: Insights from NN Hydraulic India

Hello fellow engineers and hydraulic system enthusiasts,

At NN Hydraulic India, we've accumulated extensive experience in maintaining and servicing Rexroth hydraulic pumps.

We'd like to share some best practices to help you ensure optimal performance and longevity of your equipment.

1. Regular Inspection:

Leak Detection: Periodically inspect for fluid leaks around seals, valves, and connections. Even minor leaks can indicate underlying issues that may lead to pump failure if not addressed promptly.

Noise Monitoring: Unusual sounds, such as whining or grinding, can signal cavitation or mechanical problems within the pump. Investigate any abnormal noises during operation.

2. Maintain Cleanliness:

Contaminant Control: Keep the pump and surrounding area free from dirt, dust, and metal particles. Contaminants can cause wear and tear on internal components.

Fluid Quality: Regularly check and replace hydraulic fluid as per the manufacturer's recommendations to maintain optimal performance.

3. Proper Lubrication:

Ensure the lubrication system is functioning correctly. Refer to the Rexroth hydraulic pump manual for recommended lubrication intervals and suitable oil types.

4. Valve Maintenance:

Regularly inspect Rexroth valves for leaks, buildup, or damage. Faulty valves can disrupt flow regulation, leading to system inefficiencies.

5. Preventive Maintenance:

Adhere to the maintenance schedule outlined in the Rexroth hydraulic pump manual.

Use genuine Rexroth parts for replacements to ensure compatibility and performance.

Train your maintenance team to handle Rexroth pumps properly, preventing common issues arising from improper handling.

6. Timely Repairs:

Address any signs of malfunction, such as pressure irregularities or unusual noises, promptly to prevent minor issues from escalating.

We hope these insights assist you in maintaining your Rexroth hydraulic pumps effectively.

Feel free to share your experiences or ask any questions related to hydraulic pump maintenance.

— NN Hydraulic India

2 notes

·

View notes

Text

Signs Your Engine Oil Pressure Transmitter Needs Replacement

n Engine Oil Pressure Transmitter is a crucial component in ensuring the smooth operation of your vehicle’s engine. It monitors the oil pressure and sends this information to the car's electronic control unit (ECU), allowing you to stay informed about the engine's health. One popular model, the 64279-004-1, is known for its reliability, but even the best parts can wear out over time. Here are some key signs that your engine oil pressure transmitter needs replacement.

1. Fluctuating Oil Pressure Gauge Readings

If you notice that your oil pressure gauge is providing erratic readings, it could be a sign that your Engine Oil Pressure Transmitter is failing. The gauge might swing wildly from high to low pressure without any apparent reason, indicating that the transmitter is sending inconsistent signals to the ECU.

2. Oil Pressure Warning Light

The oil pressure warning light on your dashboard is designed to alert you when there’s a problem with your engine’s oil pressure. If this light comes on frequently or stays illuminated, it’s a strong indication that your 64279-004-1 Engine Oil Pressure Transmitter might be malfunctioning. Ignoring this warning can lead to serious engine damage.

3. Unusual Engine Noises

A failing Engine Oil Pressure Transmitter can lead to incorrect oil pressure readings, which in turn can cause inadequate lubrication of engine components. This may result in unusual noises such as knocking, ticking, or tapping from the engine. If you hear such sounds, it’s advisable to check your oil pressure transmitter.

4. Engine Performance Issues

When the Engine Oil Pressure Transmitter isn’t working correctly, it can affect the overall performance of your engine. You might experience reduced power, poor acceleration, or even stalling. These performance issues are often linked to incorrect oil pressure readings, leading to improper engine lubrication and increased friction.

5. Oil Leaks

Sometimes, physical damage to the Engine Oil Pressure Transmitter can cause oil leaks. If you notice oil puddles under your vehicle or see oil seeping from around the transmitter, it’s a clear sign that it needs to be replaced. Oil leaks can lead to low oil levels and inadequate lubrication, posing a significant risk to your engine.

6. Fault Codes

Modern vehicles equipped with onboard diagnostics (OBD) can detect issues with components like the 64279-004-1 Engine Oil Pressure Transmitter. If your vehicle’s OBD system registers fault codes related to oil pressure, it’s essential to have the transmitter inspected and potentially replaced. These codes can be read using an OBD scanner, helping you pinpoint the issue quickly.

Conclusion

Maintaining proper oil pressure is vital for the longevity and performance of your engine. The Engine Oil Pressure Transmitter plays a critical role in monitoring and regulating this pressure. If you notice any of the signs mentioned above, it’s important to address the issue promptly. Replacing a faulty oil pressure transmitter can prevent more severe engine damage and ensure your vehicle runs smoothly. Regular maintenance and timely replacement of worn-out components are key to keeping your engine in optimal condition.

2 notes

·

View notes

Text

How to Maintain and Care for Your Rollator

Rollators have become indispensable mobility aids for many seniors and individuals with mobility challenges. With their ease of use and stability, rollators provide the necessary support to maintain an active and independent lifestyle. For residents of The Villages, Florida, where outdoor activities and social gatherings are abundant, a well-maintained rollator is crucial. This guide offers essential tips on how to maintain and care for your rollator in The Villages, Florida, ensuring it remains reliable and functional throughout your daily adventures.

Regular Cleaning and Inspection

Regular cleaning and inspection are fundamental to maintaining the longevity of your rollator. Depending on how frequently you use it and the terrain you navigate, debris and dust can accumulate on the wheels and frame. Use a damp cloth to wipe down the entire rollator, paying close attention to the wheels, brakes, and hand grips. Avoid using harsh chemicals that may damage the surface. Additionally, inspect the rollator for any signs of wear or damage, such as loose bolts, bent frames, or frayed cables. Addressing these issues promptly can prevent further damage and ensure your rollator's safety and reliability.

Lubrication of Moving Parts

To keep your rollator running smoothly, regular lubrication of moving parts is essential. Apply a silicone-based lubricant to the wheel axles, pivot points, and any movable components. This prevents excessive friction, reduces wear and tear, and ensures a more comfortable and efficient rolling experience. Regular lubrication also helps prevent squeaking noises, which can be a nuisance during your walks around The Villages, Florida.

Tire Maintenance

Proper tire maintenance is critical for ensuring optimal performance and traction on various surfaces. Check the tire pressure regularly and ensure it matches the manufacturer's recommended specifications. Underinflated tires can make maneuvering difficult, while overinflated tires can lead to reduced shock absorption. Also, inspect the tires for any signs of wear or damage, such as cracks or punctures. If you notice any issues, replace the tires promptly to avoid potential accidents and maintain a smooth ride around The Villages.

Battery Care (For Rollators with Electric Features)

For rollators equipped with electric features like powered wheels or height adjustment, proper battery care is essential. Follow the manufacturer's guidelines for charging the batteries and avoid overcharging. Regularly check the battery's condition and replace it if needed. In the warm Florida climate of The Villages, battery performance can be affected, so ensure the rollator is stored in a cool and dry place to extend battery life.

Brake Maintenance

The brake system of your rollator is vital for ensuring safety during use. Regularly inspect the brake cables, pads, and levers for any signs of wear or damage. Adjust the brake tension if needed, following the manufacturer's instructions. If you notice any issues with the brakes, such as decreased stopping power or squeaking sounds, have them checked and repaired by a professional as soon as possible.

Storage and Transportation

When not in use, store your rollator in a dry and clean environment. Avoid leaving it outdoors for extended periods, as exposure to the elements can accelerate wear and rusting. If you need to transport your rollator, fold it properly according to the manufacturer's instructions. Consider using a protective cover or bag to shield it from scratches and damage while in transit.

7 notes

·

View notes

Text

GIGABYTE Introduces AMD Radeon RX 7600 XT 16GB GPU

GIGABYTE TECHNOLOGY releases an AMD RDNA 3 graphics card today. GIGABYTE’s best-in-class WINDFORCE cooling system comes with the AMD Radeon RX 7600 XT GAMING OC 16G graphics card. Its superior performance, stunning visual effects, and efficiency make it ideal for 1080p gaming and streaming.

GIGABYTE AMD Radeon RX 7600 XT Gaming Performance

With its three distinct blade fans that spin alternately, its composite copper heat pipes that come into direct contact with the GPU, its three 3D active fans, and its screen cooling, the GIGABYTE WINDFORCE cooling system is designed with gamers in mind. By rotating the central fan in the opposite direction from the side fans, the Alternate Spinning technology directs airflow in the same direction, doubling air pressure and lowering turbulence. This design improves overall cooling performance by efficiently dissipating heat from the graphics card’s top and bottom.

Using graphene nano lubricant, three of the WINDFORCE fans have a 2.1-fold longer lifespan than the double ball bearing design, with a quieter operation that nevertheless yields nearly the same durability. The protective back plate keeps the PCB from bending or getting damaged in addition to strengthening the graphics card’s overall structure. With customizable LED lighting on the side that can be displayed in a personalized manner using software, the graphics card boasts a gaming-style design.

The graphics card’s superior performance can be attributed to its power design and utilization of ULTRA DURABLE certified components. With their superior computational performance and extended lifespan, ULTRA DURABLE certified high-quality materials like metal chokes, all-solid capacitors, and low-resistance MOSFETs allow gamers to fully immerse themselves in 1080p gaming and vivid virtual worlds.

The 16GB of GDDR6 memory and next-generation technologies that enable a smoother, better-looking, and ultra-fast gaming experience at 1080p and beyond give the GIGABYTE AMD Radeon RX 7600 XT GAMING OC 16G graphics card the promise of great gaming for years to come. You can adjust your game settings to achieve the highest level of immersion and responsiveness, and in certain crucial situations, you can even increase the resolution to 1440p, thanks to next-generation technologies like AMD FidelityFX Super Resolution 3 and AMD HYPR-RX with AMD Fluid Motion Frames.

With 16GB of lightning-fast RAM, games will be ready for years to come, and workloads involving creation and Al can be completed with greater freedom and inventiveness. Future-ready performance and next generation technologies are what gamers care about most, and the GIGABYTE AMD Radeon RX 7600 XT GAMING OC 16G graphics card delivers on both fronts.

Read more on Govindhtech.com

#GIGABYTE#AMDRadeonRX7600XT#16GBGPU#AMDRDNA3#graphicscard#WINDFORCE#RAM#technews#technology#govindhtech#gpu

2 notes

·

View notes

Text

Zero Friction Coatings Market: Charting the Course for Enhanced Performance and Sustainable Solutions

The global zero friction coatings market size is estimated to reach USD 1,346.00 million by 2030 according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 5.6% from 2022 to 2030. Growth can be attributed to the fact that these coatings reduce friction and wear resulting in low fuel consumption and less heat generation. According to the European Automobile Manufacturers' Association, 79.1 million motor vehicles were produced across the globe in 2021 which was up by 1.3% as compared to 2020. Zero friction coatings can extend the time between component maintenance and replacement, especially for machine parts that are expensive to manufacture.

Zero Friction Coatings Market Report Highlights

In 2021, molybdenum disulfide emerged as the dominant type segment by contributing around 50% of the revenue share. This is attributed to its properties such as low coefficient of friction at high loads, electrical insulation, and wide temperature range

The automobile & transportation was the dominating end-use segment accounting for a revenue share of more than 35% in 2021 due to the rapid growth of the automotive industry across the globe

The energy end-use segment is anticipated to grow at a CAGR of 5.7% in terms of revenue by 2030, owing to the excessive wear on the drill stem assembly and the well casing during the drilling operations in the oil and gas sector

In Asia Pacific, the market is projected to witness the highest CAGR of 5.8% over the predicted years owing to the presence of car manufacturing industries in the countries such as Japan, South Korea, and China

For More Details or Sample Copy please visit link @: Zero Friction Coatings Market Report

Several applications in the automobile industry use wear-resistant plastic seals that require zero tolerance for failure and lifetime service confidence. Increasing demand for the product from the automotive industry across the globe for various applications including fuel pumps, automatic transmissions, oil pumps, braking systems, and others is expected to drive its demand over the forecast period.

Low friction coatings can be used in extreme environments comprising high pressure, temperatures, and vacuums. These coatings can provide improved service life and performance thereby eliminating the need for wet lubricants in environments that require chemicals, heat, or clean room conditions. The product containing molybdenum disulfide (MoS2) are suitable for reinforced plastics while those free from MoS2 are suitable for non-reinforced plastics.

Zero friction coatings are paint-like products containing submicron-sized particles of solid lubricants dispersed through resin blends and solvents. The product can be applied using conventional painting techniques such as dipping, spraying, or brushing. The thickness of the film has a considerable influence on the anti-corrosion properties, coefficient of friction, and service life of the product. Its thickness should be greater than the surface roughness of the mating surfaces.

ZeroFrictionCoatingsMarket #FrictionlessTechnology #CoatingInnovations #IndustrialEfficiency #ZeroFrictionSolutions #AdvancedMaterials #SurfaceCoatings #ManufacturingAdvancements #GlobalIndustryTrends #InnovativeCoatings #PerformanceOptimization #MechanicalSystems #SustainableTechnology #IndustrialApplications #FutureTech #InnovationInMaterials #EfficiencySolutions #ZeroFrictionMarket #TechnologyInnovation #EngineeringMaterials

#Zero Friction Coatings Market#Frictionless Technology#Coating Innovations#Industrial Efficiency#Zero Friction Solutions#Advanced Materials#Surface Coatings#Manufacturing Advancements#Global Industry Trends#Innovative Coatings#Performance Optimization#Mechanical Systems#Sustainable Technology#Industrial Applications#Future Tech#Innovation In Materials#Efficiency Solutions#Zero Friction Market#Technology Innovation#Engineering Materials

2 notes

·

View notes

Text

Discover the Ultimate JIFFY LUBE SIGNATURE SERVICE Oil Change Package and Grab Exclusive Discounts!

Welcome to JIFFY LUBE, where convenience meets exceptional automotive care. The JIFFY LUBE SIGNATURE SERVICE Oil Change package is renowned for its quality and efficiency, ensuring your vehicle runs smoothly and efficiently. In this article, we'll explore the comprehensive oil change package offered by JIFFY LUBE and reveal where you can find exclusive discounts to keep your engine purring without breaking the bank.

Why Choose JIFFY LUBE for Your Oil Change?

Expertise: With decades of experience in the automotive industry, JIFFY LUBE has become a trusted name for oil changes and vehicle maintenance. Their certified technicians are well-trained to handle a wide range of car makes and models.

Comprehensive Service: The JIFFY LUBE SIGNATURE SERVICE Oil Change package goes beyond just changing the oil. It includes a 14-point inspection to identify any potential issues, ensuring your car stays in top condition.

Quality Products: JIFFY LUBE uses high-quality motor oils that meet or exceed the manufacturer's specifications, providing optimal performance and protection for your engine.

Quick and Convenient: As the name suggests, JIFFY LUBE is all about getting your oil change done quickly without compromising on quality. They understand the value of your time and strive to provide a hassle-free experience.

Exploring the JIFFY LUBE SIGNATURE SERVICE Oil Change Package

The JIFFY LUBE SIGNATURE SERVICE® Oil Change package includes the following essential services:

Oil Change: Expert technicians will drain the old oil from your engine and replace it with high-quality motor oil that meets your car's requirements.

Oil Filter Replacement: The oil filter will be replaced with a new one to ensure maximum filtration and protection for your engine.

Check/Fill Fluids: JIFFY LUBE technicians will inspect and top up essential fluids like transmission fluid, power steering fluid, brake fluid, and windshield washer fluid as needed.

Engine Air Filtration System Inspection: The air filter will be inspected, and if necessary, it will be replaced to maintain optimal engine performance.

Serpentine Belt Inspection: The serpentine belt, responsible for powering essential engine components, will be checked for wear and tear.

Wiper Blade Inspection: The condition of your wiper blades will be evaluated, and if required, new blades will be installed to ensure clear visibility during inclement weather.

Exterior Light Inspection: The functioning of your headlights, taillights, brake lights, and turn signals will be assessed to guarantee your safety on the road.

Battery Test: JIFFY LUBE technicians will test your car battery's performance and inform you if it needs to be replaced.

Chassis Lubrication: Selected fittings will be lubricated to reduce friction and ensure smooth vehicle operation.

Tire Pressure Check: Tire pressure will be inspected and adjusted to the recommended levels to promote even tire wear and improved fuel efficiency.

Cleaning of Exterior Windows: Exterior windows will be cleaned to enhance visibility and overall driving experience.

Where to Find Exclusive Discounts

Official Website or Coupon Websites: Start your search for exclusive JIFFY LUBE discounts on their official website. Look for promotions and special offers on the online coupon website.

Social Media: Follow JIFFY LUBE on social media platforms like Tumblr, Facebook, Twitter, and Instagram to stay updated on their latest deals and discounts.

JIFFY LUBE App: Download the JIFFY LUBE app to access exclusive mobile-only discounts and promotions. You can also conveniently schedule your appointments through the app.

Local Flyers and Newspapers: Keep an eye on local flyers and newspapers, as JIFFY LUBE often distributes coupons and discount codes in these publications.

Email Subscriptions: Sign up for JIFFY LUBE's email newsletter to receive exclusive discounts and promotions directly in your inbox.

Partnerships and Affiliates: Check if JIFFY LUBE has any partnerships or affiliations with automotive clubs, organizations, or credit card companies that offer special discounts to members.

Conclusion

JIFFY LUBE SIGNATURE SERVICE Oil Change package is the ultimate solution for maintaining your vehicle's engine health and performance. With a comprehensive range of services, expert technicians, and high-quality products, JIFFY LUBE stands out as a leader in the automotive care industry. To make your oil change experience even more delightful, explore their official website, social media channels, and email subscriptions to uncover exclusive discounts and promotions. Drive with confidence, knowing your engine is in expert hands with JIFFY LUBE!

2 notes

·

View notes

Text

A Comprehensive Guide to Hydraulic Paver Block Making Machine

Welcome to "A Comprehensive Guide to Hydraulic Paver Block Making Machine." In the ever-evolving world of construction and infrastructure development, the significance of efficient and eco-friendly building materials cannot be overstated. Paver blocks have emerged as a popular choice due to their durability, versatility, and aesthetic appeal. At the heart of this revolution lies the Hydraulic Paver Block Making Machine – a game-changing technology that has transformed the production of paver blocks.

This article aims to delve into the intricacies of Hydraulic Paver Block Making Machine, providing a detailed exploration of their working principles, key components, and various types available in the market. We will uncover tips and some troubleshooting steps.

Moreover,we will highlight essential considerations for selecting the right machine that aligns with specific project requirements. Whether you are an industry professional seeking to optimize production processes or an enthusiast eager to grasp the mechanics behind paver block manufacturing, this guide will equip you with invaluable insights.

Understanding Hydraulic Paver Block Machine Specifications

When it comes to hydraulic paver block machines, understanding their specifications is crucial for making informed decisions. These machines are essential for producing high-quality, durable, and aesthetically pleasing paver blocks used in various construction projects.

Hydraulic paver block machine specifications encompass a range of key features. The capacity, which determines the number of blocks produced per hour, directly impacts productivity. The molding area size affects the dimensions and shapes of the blocks. Additionally, the power and pressure rating influence the machine's efficiency and performance.

Moreover, it's essential to consider the automation level and control system, as advanced automation ensures precision and ease of operation. The type of molds compatible with the machine allows for versatility in block design. Understanding these specifications empowers buyers to select the ideal hydraulic paver block machine that aligns with their specific project requirements, resulting in cost-effective and successful paving solutions.

Choosing the Right Paver Type: Interlocking vs. Non-interlocking

When it comes to selecting the right paver type for your project, the choice between interlocking and non-interlocking pavers plays a crucial role in determining the overall outcome. Here are some key points to consider for each option:

Interlocking Pavers:

Interlocking pavers are designed to fit tightly together, creating a durable and stable surface.

They offer excellent load-bearing capabilities, making them ideal for driveways, walkways, and high-traffic areas.

The interlocking design provides flexibility, allowing them to withstand ground movement without cracking.

These pavers come in various shapes, colors, and patterns, enabling versatile and visually appealing designs.

Installation is relatively easier due to the interlocking system, reducing labor time and costs.

Repairs are simple, as individual pavers can be replaced without affecting the entire surface.

Non-Interlocking Pavers:

Non-interlocking pavers are more affordable compared to their interlocking counterparts.

They are suitable for light to moderate traffic areas like patios, garden pathways, and decorative landscape elements.

Installation may require more precision and skill as they do not have the interlocking mechanism.

Although repairs are possible, they might be more labor-intensive and could involve replacing larger sections.

Pro Tips for Maintaining Your Paver Block Making Machine

Regular Cleaning: Clean the machine daily to remove any residual concrete and debris that can cause blockages or malfunctions.

Lubrication: Keep all moving parts well-lubricated to reduce friction and prevent wear and tear.

Inspection: Conduct routine inspections to identify and address any signs of wear, damage, or misalignment promptly.

Tighten Bolts: Check and tighten all bolts and nuts regularly to maintain stability and prevent vibrations.

Replace Worn Parts: Replace worn-out parts immediately to prevent further damage and ensure optimal performance.

Calibration: Calibrate the machine regularly to ensure accurate and consistent block dimensions.

Electrical Connections: Inspect and secure electrical connections to prevent electrical issues.

Professional Maintenance: Schedule periodic maintenance by qualified technicians to address complex servicing and extend the machine's lifespan.

Operating Guidelines: Train operators on proper machine operation and safety protocols to prevent mishandling or accidents.

Store in Shelter: Store the machine in a sheltered area to protect it from weather conditions and extend its longevity.

Troubleshooting Hydraulic Paver Block Making Machine

Low Block Quality: Adjust the hydraulic pressure and ensure proper alignment of molds to improve block quality.

Block Disintegration: Check the mix proportions of raw materials and the curing process for better block strength.

Oil Leaks: Inspect hydraulic hoses and connections, repair or replace damaged parts, and refill hydraulic oil as needed.

Excessive Noise/Vibrations: Tighten loose components and bolts, and ensure proper leveling of the machine.

Uneven Block Height: Verify uniform material distribution in the mold and calibrate the machine for consistent block height.

Machine Not Starting: Check power supply, fuses, and safety switches; repair or replace faulty electrical components.

Insufficient Block Production: Clean and maintain the machine regularly, and optimize the production process for efficiency.

Irregular Block Shapes: Inspect mold condition, ensure proper vibration, and adjust mold settings to achieve uniform shapes.

Safety Hazards: Implement strict safety protocols, provide training to operators, and display safety guidelines prominently.

Seek Professional Help: If issues persist, consult experienced technicians or manufacturers for advanced troubleshooting and repairs.

Conclusion

A Comprehensive Guide to Hydraulic Paver Block Making Machine highlights the indispensable role of perfect hydraulic machines in revolutionizing paver block production. The detailed exploration of working principles, types, and maintenance underscores their efficiency and eco-friendly advantages. By embracing these cutting-edge technologies, the construction industry gains a competitive edge in creating durable and visually appealing infrastructure. As Perfect Hydraulic Machines continue to shape the future of paver block manufacturing, their impact on sustainable construction practices remains unparalleled.

#Hydraulic Paver Block Making Machine#perfect hydraulic machines#hydraulic machines#Fly Ash Brick Machine

2 notes

·

View notes

Text

Floating Ball Valve: A Comprehensive Guide to Optimal Fluid Control

Floating Ball Valves are essential components in fluid control systems, offering reliable shut-off and excellent sealing capabilities. In this comprehensive guide, we will explore the features, benefits, and applications of floating ball valves, providing valuable insights to help you make informed decisions for your fluid control needs.

Section 1: Understanding Floating Ball Valves Floating ball valves are designed with a Floating Ball that is not fixed to the valve stem. This unique design allows the Ball to float and move with the fluid pressure, ensuring optimal sealing and minimizing the risk of leakage. These valves are commonly used in various industries for their versatility and reliable performance.

Section 2: Advantages of Floating Ball Valves

Excellent Sealing: Floating ball valves provide exceptional sealing performance due to the pressure exerted on the ball by the fluid, ensuring tight shut-off and preventing leakage.

Wide Range of Applications: Floating Ball Valves are suitable for a wide range of applications, including oil and gas, petrochemicals, chemical processing, water treatment, and many more. Their versatility makes them a popular choice in various industries.

Easy Operation and Maintenance: Floating Ball Valves are designed for ease of operation and maintenance. The simple structure and fewer components contribute to quick and efficient maintenance, reducing downtime and overall costs.

Section 3: Types of Floating Ball Valves

Two-Piece Design: This type of floating ball valve consists of two main parts—the body and the Ball. It offers ease of maintenance and is commonly used in low-pressure applications.

Three-Piece Design: Three-piece floating ball valves feature a detachable body, allowing easy access to the internals for maintenance. They are suitable for high-pressure and high-temperature applications.

Section 4: Selecting the Right Floating Ball Valve Consider the following factors when choosing a Floating Ball Valve:

Material Compatibility: Ensure that the valve materials are compatible with the fluid being handled, considering factors such as corrosion resistance and temperature limitations. Pressure and Temperature Rating: Select a valve with the appropriate pressure and temperature ratings to ensure optimal performance and safety. End Connection Type: Choose the correct end connections (flanged, threaded, or welded) based on your piping system requirements.

Section 5: Maintenance and Safety Tips Proper maintenance and safety practices are crucial for the optimal performance and longevity of floating ball valves. Regular inspection, lubrication, and adherence to safety guidelines are essential to ensuring reliable and safe operation.

Floating Ball Valves are reliable and versatile components for fluid control applications. Their excellent sealing capabilities, a wide range of applications, and ease of operation make them a popular choice in various industries. By understanding the advantages, types, and selection criteria for floating ball valves, you can make informed decisions and optimize your fluid control systems for efficient and reliable performance.

2 notes

·

View notes

Text

Why Regular Garage Door Service Can Save You Money in the Long Run

Your garage door might not be something you think about every day, but it plays an important role in the safety, security, and convenience of your home. Whether you use your garage for parking, storage, or as an entryway to your house, the door must operate smoothly and reliably. Just like any mechanical system, your garage door requires regular maintenance to function properly—and investing in regular garage door service can actually save you a lot of money in the long run.

In this blog, we’ll break down why regular garage door service is essential, what it involves, and how it can prevent unexpected repair costs and extend the life of your garage door system. If you're in an area like Santa Clarita, where weather changes and frequent use can take a toll on your garage door, keeping up with maintenance becomes even more important.

The Importance of Regular Garage Door Service

A garage door is one of the largest moving parts in your home, and it often gets used multiple times a day. Over time, parts can wear down, become misaligned, or simply stop working. If these issues aren’t addressed early, they can lead to major malfunctions or even complete system failures. That’s where regular Garage Door Service comes in.

Routine maintenance checks can help identify problems early on. Think of it like getting regular oil changes for your car—preventative care keeps everything running smoothly and reduces the risk of costly repairs.

What Does Garage Door Service Include?

A standard garage door service usually involves a full inspection of the door’s components, including:

Springs: Checking for signs of wear, tension adjustment, or corrosion

Cables: Inspecting for fraying or damage

Rollers: Lubricating and checking for wear

Tracks: Cleaning and aligning for smooth operation

Hinges and hardware: Tightening loose screws and checking for cracks

Sensors: Making sure safety sensors are aligned and functioning

Motor and opener: Testing the garage door opener and its remote controls

Professionals performing Garage Door Service will ensure that everything is running efficiently and safely. These minor tweaks and checks can make a big difference in the long-term performance of your garage door.

How Regular Service Prevents Costly Repairs

One of the biggest advantages of scheduled garage door maintenance is that it can help you avoid expensive repairs. Here’s how:

1. Catching Problems Early

Small issues like a squeaky hinge or slightly off-balance door may not seem like a big deal, but they can escalate quickly. What starts as a minor noise could turn into a snapped spring or a burned-out motor. Regular service ensures that these small issues are fixed before they get worse—and more expensive.

2. Preventing Emergency Situations

A malfunctioning garage door can become a serious inconvenience, especially if it refuses to open when you're trying to leave for work or pick up your kids. Worse, it could even pose a safety risk. Regular servicing keeps everything in working order and reduces the chances of a breakdown at the worst possible time.

3. Reducing Wear and Tear

When parts aren't properly lubricated or aligned, they wear out faster. Misaligned tracks can put unnecessary pressure on the rollers and opener, while loose bolts can strain the hinges and frame. Regular maintenance reduces overall wear and tear, keeping the system working longer.

Extending the Lifespan of Your Garage Door

Garage doors are built to last, but they won’t last forever without a little help. With proper Garage Door Service, your door could last 15-30 years depending on its material and usage. Without it, that lifespan could be cut in half.

Replacing a garage door is a major investment. By scheduling regular maintenance, you're essentially protecting that investment. Even better, many components like the opener, springs, and cables can last much longer with just a bit of routine care.

Energy Efficiency and Cost Savings

You may not realize it, but a poorly maintained garage door can impact your home’s energy efficiency. Gaps, broken seals, or a door that doesn’t close properly can let in cold air in winter or hot air in summer. This makes your HVAC system work harder, which can increase your energy bills.

Regular service ensures that your garage door seals properly and is well-insulated, helping you maintain a comfortable indoor temperature and lower your utility costs over time.

Enhancing Safety and Security

A faulty garage door isn’t just inconvenient—it can also be dangerous. Worn-out springs or frayed cables can snap unexpectedly, potentially causing injury or damage. Misaligned safety sensors can fail to detect obstacles, posing a risk to pets, children, or vehicles.

Additionally, a malfunctioning garage door can be a security risk. If your door doesn’t close or lock correctly, it could provide easy access to burglars. Regular Garage Door Repair makes sure all safety and security mechanisms are working as they should, giving you peace of mind.

Compliance with Warranties

Some garage doors and opener systems come with warranties that require regular maintenance. Skipping service could void your warranty, leaving you responsible for the full cost of any repairs or replacements.

If your warranty coverage is important to you, be sure to read the fine print and stick to a regular maintenance schedule to stay compliant.

Professional vs. DIY Maintenance

While there are some basic maintenance tasks you can do yourself—like lubricating moving parts or checking for visual signs of damage—most garage door servicing is best left to professionals. Tension-loaded parts like springs and cables can be dangerous to handle without proper training and tools.

Trained technicians can perform a thorough inspection and take care of any adjustments safely. For homeowners in Santa Clarita, choosing a local expert for Garage Door Repair Santa Clarita means you’re getting service from someone who understands the unique demands of your climate and community.

Signs That You Need Garage Door Service

Not sure if your garage door needs servicing? Here are a few warning signs to look out for:

Unusual noises during opening or closing

Slow or jerky movement

Door doesn’t open or close completely

Sagging sections

Remote control or keypad not working properly

Gaps under the door when closed

Visible rust, fraying cables, or worn rollers

If you notice any of these issues, it’s a good idea to schedule a Garage Door Repair Santa Clarita inspection before the problem worsens.

How Often Should You Service Your Garage Door?

For most homes, once a year is a good rule of thumb for professional maintenance. However, if your garage door gets heavy daily use or you live in an area with extreme weather conditions, you might benefit from servicing it every six months.

Also, if your door is older or has been previously repaired, more frequent checks might be necessary to ensure everything stays in working order.

Conclusion: A Smart Investment in Your Home

When it comes down to it, regular Garage Door Service is not just about keeping things running—it's about avoiding unnecessary costs, protecting your home, and ensuring safety. It’s an affordable, proactive approach that can prevent expensive repairs, extend the lifespan of your garage door, and even reduce energy bills.

If you're in the Santa Clarita area and want to make sure your garage door is in top condition, consider reaching out to a trusted local expert like Spark Garage Door Repair Santa Clarita. With experienced technicians and a commitment to quality, they can help you keep your garage door working like new for years to come.

A little attention today can save you from big expenses tomorrow—because when it comes to your garage door, prevention truly is the best cure.

Spark Garage Door Repair Santa Clarita 22777 Lyons Ave #201, Santa Clarita, CA 91321, United States (661) 485–4280 https://sparkgaragedoorssantaclarita.com/

0 notes

Text

The Unseen Workhorse: How Compressor Felt Drives Efficiency and Longevity

In the industrial world, air and gas compressors are indispensable machines, powering everything from manufacturing lines and pneumatic tools to refrigeration systems and medical equipment. They are the lungs of many operations, converting power into compressed air or gas. But lurking within these robust machines, often unnoticed, is a critical component that ensures their smooth, efficient, and long-lasting operation: Compressor Felt.

Far from being a mere piece of fabric, compressor felt is a highly engineered nonwoven material, specifically designed to perform vital functions such as filtration, sealing, sound dampening, and absorption. Its quality directly impacts the performance, lifespan, and maintenance costs of your valuable compressor systems.

At PARKNONWOVEN, with our state-of-the-art manufacturing facilities in Gurugram, Haryana, India, we are a leading producer of high-quality nonwoven felts, precisely engineered to meet the demanding requirements of various compressor applications.

The Unsung Workhorse: What is Compressor Felt?

Compressor felt refers to specialized nonwoven felt materials that are integrated into various parts of air and gas compressors. Unlike woven fabrics, felt is produced by mechanically or thermally interlocking fibers into a dense, matted structure. This unique construction provides specific properties essential for compressor functionality.

These felts are not a one-size-fits-all solution; they are meticulously designed based on their intended role within the compressor system, serving as:

Filtration Media: Capturing airborne particulates, oil mist, or moisture.

Sealing Elements: Creating tight seals between components to prevent leaks.

Acoustic Dampeners: Absorbing noise and vibration.

Absorption Pads: Wicking or holding lubricants, or absorbing contaminants.

Beyond the Machine: Why Compressor Felt is Indispensable for Performance

The precise function of compressor felt is critical for several reasons:

Protecting Internal Components: High-quality filtration felt prevents abrasive particles from entering and damaging sensitive moving parts like pistons, rotors, and valves.

Ensuring Clean Air/Gas Output: For applications requiring pure, uncontaminated air (e.g., medical, food processing, electronics manufacturing), the felt filter ensures that the output is free from dust, oil mist, and other impurities.

Noise Reduction: Compressors can be noisy machines. Felt materials serve as effective acoustic insulation, dampening vibrations and reducing operational noise levels, contributing to a better working environment.

Enhancing Efficiency & Longevity: Proper filtration reduces wear and tear, leading to less friction, lower energy consumption, and significantly extending the overall service life of the compressor.

Preventing Leaks: As gasket material, felt provides a reliable seal under various pressures and temperatures, preventing expensive air or gas loss and maintaining system integrity.

Engineered for Demanding Environments: Key Properties of Effective Compressor Felt

The performance requirements for compressor felt are rigorous, demanding specific material properties:

High Filtration Efficiency: The ability to consistently capture a wide range of particle sizes without excessive pressure drop.

Oil/Moisture Absorption & Retention: For oil mist separation or lubrication wicking, the felt must effectively absorb and hold liquids without degradation.

Excellent Acoustic Dampening: A porous, dense structure that can effectively absorb sound waves and vibrations.

Superior Sealing & Gasketing: The ability to conform to surfaces, withstand compression, and maintain a tight seal under varying temperatures and pressures.

Temperature Resistance: Capable of operating consistently within the compressor's specific temperature range, from ambient intake air to high-temperature compressed gas.

Chemical Compatibility: Resistance to various compressor oils, refrigerants, and atmospheric contaminants encountered during operation.

Durability & Resilience: Withstanding continuous mechanical stress, compression, and airflow without degradation, tearing, or shedding fibers.

Consistent Thickness & Density: Uniformity across the material ensures predictable and reliable performance in critical applications.

The Fabric of Functionality: Materials and Types of Compressor Felt

The choice of fibers and the manufacturing process are crucial for tailoring compressor felt to its specific role. Common materials used include:

Polyester (PET) Felt: A versatile and widely used synthetic fiber known for its strength, durability, good temperature resistance, and chemical compatibility with many compressor oils. It's often needlepunched to achieve desired density and porosity for filtration and dampening.

Polypropylene (PP) Felt: Offers excellent chemical resistance, especially to acids and alkalis, and is often used where moisture absorption is critical or for lower temperature applications.

Blends and Specialty Fibers: For highly specific requirements, blends of synthetic fibers or even natural fibers like wool (known for excellent oil absorption and acoustic properties in certain traditional applications) might be considered, though modern compressors heavily favor engineered synthetics.

The needlepunching process is particularly effective for creating compressor felts, as it allows for precise control over the felt's density, thickness, and porosity, enabling customization for specific filtration or acoustic dampening performance.

Where Felt Makes a Difference: Key Applications within Compressors

Compressor felt finds diverse applications within various types of compressors:

Air Intake Filters: Essential for capturing dust, dirt, and other airborne particulates before they enter the compressor's delicate internal mechanisms.

Oil Separator Elements: In oil-lubricated compressors, felt layers are crucial for separating oil mist from the compressed air/gas stream, ensuring cleaner output.

Gaskets and Seals: Used around flanges, covers, and other mating surfaces to prevent air/gas leaks and maintain system pressure.

Acoustic Insulation & Liners: Applied within compressor enclosures or around noisy components to absorb sound and reduce operational noise levels.

Vibration Dampening Pads: Placed under mounting points or between vibrating components to absorb mechanical vibrations and prevent their transmission.

Lubrication Wicks: In some smaller compressors, felt can be used to wick and distribute lubricants to bearing surfaces.

The Hidden Benefits: Investing in High-Quality Compressor Felt

Choosing the right, high-quality compressor felt offers a cascade of advantages:

Improved Air/Gas Purity: Ensures the compressed medium meets stringent quality standards for various industrial and sensitive applications.

Extended Compressor Lifespan: Reduces wear and tear on expensive internal components, delaying costly repairs and replacements.

Reduced Maintenance Costs: Fewer breakdowns, less frequent filter changes, and longer component life lead to significant savings.

Quieter Operation: Creates a more comfortable and compliant working environment by effectively dampening noise.

Enhanced Energy Efficiency: Clean components and proper sealing mean the compressor doesn't have to work harder than necessary, leading to lower energy consumption.

PARKNONWOVEN: Precision-Engineered Nonwoven Felts for Compressor Excellence

At PARKNONWOVEN, we understand that the performance of your compressor systems hinges on the quality of every component, no matter how small. As a leading manufacturer of high-quality nonwoven felts in Gurugram, Haryana, India, we are uniquely equipped to meet the precise demands of compressor applications.

Our capabilities in compressor felt manufacturing include:

Customized Material Solutions: We produce nonwoven felts from a variety of synthetic fibers (e.g., polyester, polypropylene) in various densities, thicknesses, and GSMs (Grams per Square Meter) to match specific filtration, sealing, or acoustic requirements.

Engineered Performance: Our felts are designed with controlled porosity, compressibility, and resilience to ensure optimal airflow, effective sealing, and superior acoustic dampening under operational conditions.

Robust Durability & Compatibility: We ensure our felts exhibit excellent resistance to oils, chemicals, and temperature fluctuations, providing long-lasting performance in demanding compressor environments.

Consistent Quality: Through stringent manufacturing processes and quality control, we guarantee uniform felt products that deliver reliable and predictable performance.

By partnering with PARKNONWOVEN, you secure a foundation of excellence for your compressor systems, ensuring cleaner air, longer lifespan, and more efficient operation.

Conclusion: Small Component, Big Impact

Compressor felt may be a relatively small and often overlooked component, but its role in the efficiency, longevity, and safety of air and gas compressors is undeniable. Investing in high-quality, engineered compressor felt is a proactive step towards optimizing your industrial operations, reducing costs, and ensuring reliable performance.

Optimize Your Compressor Performance. Partner with PARKNONWOVEN for Advanced Nonwoven Felt Solutions!

Don't let subpar components compromise your valuable compressor systems. For robust filtration, reliable sealing, and effective noise reduction, the right compressor felt makes all the difference. PARKNONWOVEN is your trusted expert in manufacturing precision-engineered nonwoven felts tailored for the demanding world of compressors.

Choose the expertise, cutting-edge technology, and unwavering quality that define PARKNONWOVEN.

Contact our dedicated team of nonwoven specialists NOW! Let's discuss your specific compressor felt requirements and explore how our advanced nonwoven solutions can enhance the efficiency, longevity, and operational excellence of your compressed air and gas systems. Your path to superior performance starts here, in Gurugram, Haryana.

#CompressorFelt#NonwovenFelt#FiltrationMedia#IndustrialMachinery#PARKNONWOVEN#AirCompressor#GasCompressor#IndustrialFelt

0 notes

Text

Understanding Gasket Compatibility With Different Types Of Fluids

Gaskets are essential components in sealing systems, as they prevent leaks and ensure the safe and efficient functioning of machinery and pipelines. The effectiveness of gaskets is significantly influenced by their compatibility with the fluids they encounter, such as oils, gases, and chemicals. Utilizing an inappropriate gasket material can result in early failure, leaks, or potentially dangerous situations. This article examines the interactions between various gasket materials and different fluids, highlighting the importance of material compatibility for achieving optimal performance.

Gasket material compatibility

Gasket compatibility refers to a material’s capacity to retain its sealing properties when exposed to various fluids. Key factors that influence effectiveness include chemical resistance, temperature stability, and pressure tolerance. The gasket must be able to resist swelling, degradation, or adverse reactions with the fluid, endure temperature fluctuations without becoming too hard or soft, and maintain its sealing capability under different pressure conditions. Choosing the appropriate gasket material based on the type of fluid is crucial to avoid leaks, prevent equipment damage, and minimize costly downtime.

Gasket compatibility with oils

Oils, such as engine oils, hydraulic fluids, and industrial lubricants, necessitate gaskets that can endure swelling, softening, or degradation from extended exposure.

Nitrile rubber (NBR) is a commonly utilized material for oil sealing, recognized for its superior resistance to petroleum-based oils and fuels, making it suitable for both automotive and industrial uses. Viton (FKM) is another favoured option, as it can withstand elevated temperatures and aggressive oils, making it ideal for high-performance sealing applications. Additionally, cork and rubber composites are frequently employed in engine gaskets, providing both flexibility and resistance to oil infiltration.

A significant challenge in oil-sealing applications is the selection of a gasket material that remains stable over time. Natural rubber and EPDM gaskets should be avoided for use with petroleum-based oils, as they are prone to rapid deterioration when exposed to hydrocarbons. Furthermore, the gasket material must be capable of withstanding the complete operating temperature range, particularly in high-heat environments like engine compartments.

Gasket compatibility with gases

Gases, including steam, natural gas, and compressed air, necessitate gaskets that can sustain an airtight seal across a range of pressures and temperatures.

Graphite gaskets are particularly well-suited for applications involving steam and high-temperature gases, thanks to their superior heat resistance and ability to preserve sealing integrity in extreme conditions. PTFE (Teflon) gaskets also serve as a dependable alternative, being chemically inert and capable of effectively sealing aggressive gases and highly reactive materials without deterioration over time. In the context of high-pressure gas pipelines, metallic gaskets, such as ring-type joint (RTJ) and spiral-wound designs, are frequently employed due to their robustness and ability to maintain effective seals even when faced with fluctuating pressure levels.

A significant challenge in gas-sealing applications is the potential for gas permeation through inferior gaskets, which can result in gradual leaks over time. In high-pressure settings, the use of metal-reinforced gaskets is strongly advised, as they resist deformation and ensure a durable seal.

Gasket compatibility with chemicals

Chemical processing facilities and laboratories handle highly corrosive fluids that can quickly deteriorate inappropriate gasket materials.

PTFE (Teflon) stands out as one of the most chemically resistant gasket materials, making it particularly suitable for sealing acids, solvents, and aggressive chemicals. Its inert properties guarantee stability even in extremely corrosive conditions. Viton (FKM) is another commendable option, providing resistance to hydrocarbons, acids, and various chemicals commonly encountered in fuel and oil applications. For water-based chemicals, acids, and alcohols, EPDM (Ethylene Propylene Diene Monomer) is an appropriate choice, although it is not advisable for use with petroleum-based fluids.

A significant challenge in chemical sealing applications is ensuring that the gasket material is compatible with the specific chemicals it will encounter. Some materials may withstand certain acids but may fail when exposed to strong bases or oxidizers. Furthermore, rubber-based gaskets should typically be avoided for highly aggressive chemicals unless they are specifically designed to offer enhanced chemical resistance.

Common gasket failures due to fluid incompatibility

Utilizing inappropriate gasket materials can result in significant failures, including leaks, contamination, and damage to equipment. Common types of failures include swelling and softening, where rubber gaskets absorb liquids and consequently lose their structural integrity; hardening and cracking, which occur due to extended exposure to elevated temperatures; and chemical degradation, where incompatible gaskets are compromised by corrosive substances, leading to swift failure. To mitigate these risks, it is crucial to perform compatibility testing prior to selecting a gasket material, opt for high-quality gaskets tailored to the specific fluid and application, and carry out regular maintenance to inspect and replace gaskets before they reach the point of failure.

Choosing the appropriate gasket material is essential to achieve safe and effective sealing in a variety of industrial settings. Whether dealing with petroleum oils, gases, or aggressive chemicals, ensuring gasket compatibility with the fluid is essential to prevent leaks and uphold equipment integrity. By evaluating factors such as chemical resistance, temperature stability, and pressure tolerance, industries can enhance their gasket selection for improved performance and longevity. For professional advice on fluid-compatible gasket solutions, reach out to Vrushabh Engineering, a prominent high-quality gaskets supplier in India, whose gasket solutions are designed to deliver enduring performance even in the most challenging environments. Resource - Read More

0 notes

Text

Maintenance Tips for Long-Lasting Stainless Steel Clamps

Ladhani Metal Corporation is a leading Stainless Steel Clamp Manufacturer in India, Stainless steel clamps are essential components used in various industries for securing pipes, hoses, cables, and other materials. They are valued for their corrosion resistance, strength, and durability. Whether used in plumbing, automotive, marine, or industrial settings, proper maintenance of stainless steel clamps ensures their long-term performance and reliability. In this blog, we’ll explore helpful maintenance tips and provide useful resources like the Stainless Steel Clamp Weight Chart in Kg, PDF & mm for better handling and planning. We’ll also introduce you to reliable sources like leading Stainless Steel Clamp Manufacturers and Suppliers in India.

Why Stainless Steel Clamps Need Maintenance

Stainless steel clamps are known for their resistance to rust and harsh environments, but even the best products need care to maintain their lifespan. In areas with high moisture, chemical exposure, or temperature changes, clamps can wear out over time. Proper cleaning, inspection, and replacement when needed can prevent failures and save you from costly downtimes.

Tip 1: Clean Clamps Regularly

One of the easiest and most effective maintenance tips is to clean your clamps regularly. Use a soft brush or cloth with mild soap and warm water to remove dirt, grease, or chemicals that may accumulate. Avoid using harsh cleaners or wire brushes as they may damage the stainless steel surface.

Tip 2: Inspect for Signs of Wear

Check clamps regularly for signs of cracking, deformation, or corrosion—especially around the screw or bolt area. This is crucial for systems operating under pressure or movement. Replace any damaged clamp immediately to avoid failure.

Tip 3: Lubricate Moving Parts

If your stainless steel clamp includes a screw or bolt mechanism, lubricate it with a light anti-corrosion oil. This helps in smoother tightening and prevents thread seizure over time.

Tip 4: Store in a Dry Place

When not in use, store your clamps in a dry and clean environment. Even stainless steel can corrode if exposed to harsh chemicals or saltwater for prolonged periods without proper care.

Stainless Steel Clamp Weight Chart in Kg, PDF & mm

To help with planning and installation, it’s important to refer to a Stainless Steel Clamp Weight Chart in Kg, PDF & mm. This chart provides the standard dimensions and weights of various clamp sizes, making it easier for engineers, fabricators, and buyers to choose the right product. It ensures compatibility with pipes and other fittings, and helps in estimating load requirements and shipping costs. Always refer to the chart provided by your Stainless Steel Clamp Manufacturer for accurate data.

Choosing the Right Stainless Steel Clamp Manufacturer in India

India is home to several trusted Stainless Steel Clamp Manufacturers who provide high-quality products suitable for domestic and international use. we manufacturers follow global standards and often supply to the plumbing, construction, automotive, and industrial sectors. As a reputed Stainless Steel Clamp Manufacturer in India we ensures the clamps are made from certified grades like SS304, SS316, or SS202, and go through rigorous testing for strength and durability.

When selecting a Stainless Steel Clamp Supplier in India, always check if they provide technical support, customized sizes, and reliable delivery timelines. Some top Stainless Steel Clamp Suppliers also offer downloadable resources like the perforated sheet standard size chart PDF and clamp weight charts for engineers and procurement teams.

Conclusion

Maintaining stainless steel clamps doesn’t require much effort, but it does require consistency. Regular cleaning, inspection, and proper storage will ensure your clamps last longer and perform at their best. By sourcing from a reputable Stainless Steel Clamp Manufacturer and referring to tools like the Stainless Steel Clamp Weight Chart in Kg, PDF & mm, you can ensure long-term efficiency in your projects. Whether you're dealing with industrial pipelines or simple home installations, stainless steel clamps are reliable — and with proper care, they’ll serve you well for years to come.

#StainlessSteelClampsManufacturerInIndia#StainlessSteelClampsManufacturer#StainlessSteelClampsSupplierInIndia#StainlessSteelClamps

0 notes

Text

Garage Door Repair Beachwood Problems and Ways to Fix Them

The garage door is both the most often used and highly overlooked feature of your home. It is possible you and your family open and close the door several times in a day. However, you begin noticing something is not working when the door starts making noises and stops working. Garage door is like any other mechanical system that can wear down with time. Garage door repair Beachwood requires regular maintenance and repair. You must understand the common garage door problems identified by the repair services and find ways to fix them. These would help you avoid expensive repairs and enhance the safety of the doors.

Here are all the frequent issues you are likely to face with garage doors and all the ways in which you can fix them.

1. The biggest issue that can cause the garage door to stop working would be worn out or damaged rollers. Rollers are the small wheels that move along the metal tracks along either side of the garage door. They help open and close the door smoothly. However, with time, these rollers can wear out and get damaged. This can happen due to dirt, friction or lack of lubrication. The squeaking and grinding noises along the door rollers can be sign that they are worn out. You will feel jerky and shaky movements when you open/close the door, and it indicates issues with the rollers. Similarly, when the door gets stuck halfway, you might be facing roller issues. Lastly, visible cracks and wear could also indicate issues with the rollers, according to the garage door service Solon. There are easy ways to fix these worn out rollers. You must disconnect the opener and unplug it. Next, lift the door manually and relieve the pressure. You should then remove the roller brackets and slide the old rollers out to insert the newer ones. Lastly, reattach the brackets to test the door’s performance. In case multiple rollers are damaged call for a professional service. 2. The next issue you are likely to face is off-track garage door. The garage doors can derail when there is an accidental impact or obstruction, according to garage door repair Beachwood. It can also happen if there are worn out components along the track like lift cables and rollers. You will notice that the doors are crooked and uneven in this case. There is a loud screeching noise or scraping noise that can occur. Lastly, your door doesn’t open or close fully if there is a track issue. You must turn the power off and disengage the opener to get started. Next, move the door manually so that it is derailed. You should use pliers to open the track slightly and put the roller back in its place. Lastly, close the track to test the door manually before you reconnect it with an opener. 3. The next issue you may face with garage door is the faulty safety sensor. The safety sensors can prevent the door from closing, especially when there is something on its path. The sign that indicates this issue includes a door that reverses as soon as you attempt to close it. You will notice flashing lights on the opener and the door doesn’t close till you hold the wall button. Start by cleaning the sensors with a cloth and then check for alignment. You should adjust the brackets and then tighten them slightly. Call a professional garage door service Solon when the sensors wont remain aligned or the wires are damaged.

0 notes