#Composter Machine Manufacturers

Explore tagged Tumblr posts

Text

Best Organic Waste Converter

Transform kitchen scraps into nutrient-rich compost with our innovative solution. The Organic Waste Converter efficiently recycles organic material, promoting sustainability and reducing landfill waste in an eco-friendly way.

0 notes

Text

Organic Waste Composter Machine Manufacturer In India

Are you searching for a fully automatic Organic Waste Composter machine manufacturer in India? Green Aqua Technologies is the perfect choice for you. We are top rated manufacturer and supplier of organic waste composter machines in India, specializing in innovative solutions that convert organic waste into nutrient-rich compost. An organic waste converter is a machine that efficiently transforms kitchen scraps, garden waste, and food processing by-products into high-quality compost. Excel’s OWC not only simplifies the composting process but also promotes sustainable waste management by preventing waste buildup in landfills. Website: https://www.greenaquatechnologies.com/organic-waste-composter/

0 notes

Text

Are you looking for Organic Waste Composter Manufacturer in India? Green Aqua Technologies

Organic waste composting plays a vital role in sustainable waste management, and Green Aqua Technologies leads the way with their innovative organic waste composter manufacturers in India.

Features of Organic Waste Composter Machine

Compact and Robust System

Plug and Play Product

Waste to manure conversion

Best suit for Housing societies, Hotels, Hospitals, Canteens

Importance of Organic Waste Management

Effective management of organic waste reduces landfill pressure, minimizes greenhouse gas emissions, and produces valuable compost for soil enrichment.

Overview of Green Aqua Technologies

Green Aqua Technologies is a renowned provider of organic waste composting solutions, offering state-of-the-art composters for both residential and commercial use.

Key Features of Organic Waste Composter Machine

Their composters are equipped with advanced features such as automated mixing, odor control, and temperature monitoring, ensuring efficient and hassle-free composting.

Types of Composters Offered

Green Aqua Technologies offers a range of composters to suit various needs, including compact home composters for individual households and large-scale commercial composters for businesses.

Advantages of Choosing Green Aqua Technologies

Clients benefit from Green Aqua Technologies' commitment to quality, reliability, and customer satisfaction. Their composters are built to last and deliver superior performance.

Customization Options Available

Clients can customize composters based on factors like capacity, space constraints, and specific waste types, ensuring optimal efficiency and functionality.

Installation and Maintenance Services in India

Green Aqua Technologies provides comprehensive installation and maintenance services to ensure smooth operation and longevity of their composters. Their expert team assists clients every step of the way, from setup to ongoing maintenance.

Success Stories and Client Testimonials

Numerous success stories and positive client testimonials highlight Green Aqua Technologies' excellence in organic waste composting solutions. Their composters have helped countless individuals and businesses achieve their sustainability goals.

Environmental Impact of Organic Waste Composting

Effective organic waste composting reduces greenhouse gas emissions, conserves landfill space, and promotes soil health by producing nutrient-rich compost for agricultural use.

Conclusion

Green Aqua Technologies stands at the forefront of organic waste composting technology, offering innovative solutions to address the growing need for sustainable waste management. With their reliable composters and dedication to customer satisfaction, they continue to make a positive impact on the environment.

FAQs

Are Green Aqua Technologies' composters suitable for all types of organic waste? Yes, their composters can handle a wide range of organic waste, including kitchen scraps, garden waste, and food leftovers.

Do their composters require a lot of space for installation? They offer compact composters suitable for small spaces, as well as larger models for commercial use.

How long does it take for their composters to produce usable compost? The composting process typically takes a few weeks to a few months, depending on factors such as temperature, moisture levels, and waste composition.

Are their composters easy to use for beginners? Yes, their composters are designed for user-friendly operation, with intuitive controls and instructions provided.

Do they offer warranty and support services for their composters? Yes, they provide warranty coverage and ongoing support to ensure the satisfaction and success of their clients.

Contact us right away, if you want to learn more about our wide range of organic waste composter machine products. Call us at +91-9205127088 or send an email to [email protected], We are India’s largest Organic Waste Composter Manufacturers and Suppliers.

#Organic Waste Composter#Organic Waste Composter Machine#Organic Waste Composter Manufacturer#Organic Waste Composter Manufacturers in India#Organic Waste Composter Supplier#Organic Waste Composter Suppliers in India#Organic Waste Composter Machine in Ghaziabad#Organic Waste Composter Machine in Uttar Pradesh#Organic Waste Composter Machine in Noida#Organic Waste Composter Machine in Delhi#Organic Waste Composter Machine in Faridabad#Organic Waste Composter Machine in Gurugram#Organic Waste Composter Machine in Haryana

0 notes

Text

Turning Food Waste into Gold: The Magic of Food Waste Composting Machines

Introduction

In a world where environmental sustainability is gaining paramount importance, managing food waste has become a crucial challenge. One innovative solution that stands out is the Food Waste Composting Machine. This revolutionary technology not only addresses the growing issue of food waste but also transforms it into a valuable resource — compost. In this blog, we’ll delve into the workings, benefits, and environmental impact of these machines.

The Problem of Food Waste

Food waste is a global predicament, with vast amounts ending up in landfills, contributing to environmental degradation. The decomposition of organic waste in landfills releases methane, a potent greenhouse gas that significantly impacts climate change. Food waste composting machines emerge as a beacon of hope, offering a sustainable alternative to traditional waste disposal methods.

How Food Waste Composting Machines Work

These machines operate on the principle of aerobic decomposition, creating an environment that encourages the growth of beneficial microorganisms. Here’s a simplified breakdown of the process:

Collection: Food scraps from kitchens, restaurants, or other food-related establishments are collected and deposited into the composting machine.

Shredding: The waste is shredded into smaller particles, creating an optimal surface area for microbial activity.

Aeration: The machine ensures proper aeration, promoting the growth of aerobic bacteria that thrive in oxygen-rich environments.

Temperature Control: Composting requires specific temperature conditions. These machines regulate temperature to accelerate the composting process.

Maturation: The compost undergoes a maturation phase, allowing it to stabilize and reach a nutrient-rich state suitable for soil enrichment.

Benefits of Food Waste Composting Machines

Reduced Environmental Impact: By diverting food waste from landfills, these machines help cut down methane emissions, mitigating the impact on climate change.

Resource Recovery: The compost produced is a valuable resource, rich in nutrients, and can be used to enhance soil fertility in agriculture or landscaping.

Cost Savings: Waste disposal and landfill fees can be substantial for businesses. Composting machines offer a cost-effective alternative by reducing waste volume and associated disposal costs.

Community Engagement: Implementing food waste composting machines fosters a sense of environmental responsibility within communities, encouraging sustainable practices.

Circular Economy: Embracing composting machines contributes to the development of a circular economy, where waste is viewed as a resource, promoting sustainability and reducing dependence on finite resources.

Conclusion

Food waste composting machines are more than just waste management tools; they represent a paradigm shift towards sustainable living. By transforming food waste into nutrient-rich compost, these machines play a pivotal role in creating a greener, healthier planet. As technology advances and awareness grows, integrating food waste composting machines into our daily lives becomes an essential step towards a more sustainable and environmentally conscious future.

#food waste composting machine#organic waste composting machine#hygienenhuman#rram business corps#food waste composting machine manufacturer#food waste composting machine manufacturer in India

1 note

·

View note

Video

youtube

Organic Waste Composter Machine for hotels, canteens, mess, temples, ind...

#organic waste composter#owc waste management#waste management#organic waste composter machine#organic waste converter#owc machine manufacturer#Natural Composter#Owc Machine manufacturers#Composter manufacturers#Fully Automatic Composting Machine#composting for waste disposal#organic waste for composting#food waste converter machine#OWC Machine Price#semi automatic organic waste composter#Fully Automatic Composting Machine in India

1 note

·

View note

Text

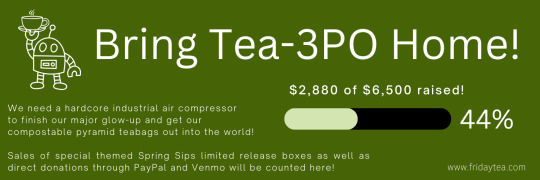

I LOVE ROBOTS AND PROGRESS BARS.

Ok, now for realsies what I actually have to say:

As I've mentioned a few times lately, our air compressor can't keep up with the flow rate of our envelope machine and we gotta upgrade. After consulting with two engineers, a more experienced friend in the bagged tea industry (shoutout to Kelsey at Cliché Tea), and confirmation from our manufacturer, we've found an industrial air compressor which will meet our needs!

Bonus unstressor: the model we ended up selecting costs just over half the one we thought we needed, hell yeah!

So while our original goal set yesterday to sub-crowdfund this aspect of our project was a staggering $11k, we're now able to lower that to $6.5k and we're already nearly halfway there just since last night!

Based on input from our Discord server and Bluesky followers, we found a super fun and adorable way to crowdfund our newest robot friend: a special Spring mini advent release in four variations so you can do a week of surprises or a month as you please!

These are SO CUTE, and I honestly can't wait to put them together. Each box will contain seven surprise loose leaf samples (you open the tag as you go so you can see the ingredients before opening the pouch, don't worry) curated to immerse you in a different Springtime setting. Your options are:

Shire Garden Party

Fae Rainbow Orchard

Cryptid Campout

Parisian Café

Each box is designed to set a mood, and will also include a Teaheart Club sticker and a recipe card for a paired treat crafted by me! Remember how I was a professional chef for fifteen years and also use my synesthesia to give you the most immersive flavor landscapes? Yeah, these boxes are all about both of those things.

There's also just a straight-up donation link set up on our PayPal (boo, hiss, I know) and our venmo handle is @fridaytea if that's your jam. I'll keep our progress bar updated and pinned to our Bluesky profile so you can check in any time!

The biggest, best part of today's news is this: the air compressor we're going to buy is domestically made, already in stock, and will arrive at our warehouse within days of ordering. Hell yes. This is going to resolve more quickly than anticipated, which means compostable high end teabags for nerds everywhere way sooner!

Let's go, rock and roll, kick ass, robot army, hell yes, Friday

#seattle#robot army#tea-3po#industrial machinery#cute box set#sampler#tastyteas#thirstynerds#crowdfunding

15 notes

·

View notes

Text

Bambrew’s range of eco-friendly packaging alternatives

Bambrew, an Indian startup specializing in sustainable packaging, is making strides in the fight against single-use plastics by offering a range of 'eco-friendly' alternatives, says Vaibhav Anant, founder & CEO. The company provides packaging solutions made from renewable, biodegradable materials such as bamboo, seaweed, banana fiber, and agro-waste. According to Anant, these materials are fully compostable and serve as viable alternatives for businesses seeking to reduce their environmental footprint.

“Our solutions are governed by four core principles of sustainability—eco-friendliness, functionality, cost-efficiency, and scalability. These guiding principles enable us to deliver packaging options that are not only environmentally responsible but also commercially viable for businesses of all sizes,” Anant says.

Bambrew offers a range of packaging alternatives, including mailer bags, flexible pouches, rigid boxes, and custom solutions, all designed to meet the functional needs of various sectors while remaining scalable. It has developed solutions for industries such as FMCG, CPG, fresh fruits and vegetables (F&V), food and beverages (F&B), and e-commerce and retail packaging.

Notable clients include Amazon, Nykaa, Hindustan Unilever, Mahindra Logistics, and Tata 1mg.

Material-Agnostic Company

Anant explains that Bambrew is a material-agnostic company, meaning it develops solutions using various materials, all adhering to the four core principles of sustainability as mentioned earlier.

Bambrew prioritizes sustainability not only in its products but throughout the entire product development lifecycle, from sourcing and compounding to conversion processes, says Anant. The company works closely with raw material providers and maintains complete control over production with the latest technology machines for in-house manufacturing. It also operates tech-assisted warehousing and logistics to ensure timely delivery to customers.

“By reducing our reliance on fossil fuels through the use of biofuels and solar energy, we are significantly lowering our carbon footprint. Equally important is the well-being of our workers, and we are committed to maintaining a healthy work-life balance. We adhere to an 8-hour shift structure and offer a range of benefits to ensure a supportive and positive work environment, with a strong emphasis on mental health,” Anant states.

The company has its manufacturing facility in Bangalore and collaborates with several contract manufacturing units across India to expand its reach and capabilities.

Rapid Growth

According to Anant, the company has made big progress over the last 12 months, with growth exceeding 8x.

“This momentum has been incredibly encouraging, and we’re excited to continue building on it in the years to come. As the demand for sustainable solutions grows, we’re committed to scaling responsibly and staying focused on our mission,” he says.

New Offerings

Bambrew is actively working towards the continuous development of advanced meta-materials. It has been extensively researching materials such as Biophil, a home-compostable bioplastic alternative, while also exploring other renewable resources. These materials are designed to offer high performance while being environmentally friendly.

In August of this year, the company introduced a new category of rigid boxes that utilize Kappa boards produced from post-consumer recycled fibers. The product features components like non-animal-based glue, recycled paper cladding, plastic-free Biophil lamination, and plant-based inks. Each element of this product is designed to meet Bambrew's environmental goals and contribute to a fully sustainable manufacturing cycle.

“Additionally, we are actively developing alternative solutions for pharmaceutical packaging, as well as advanced barrier films for food packaging within the FMCG sector. While these are only a few examples, all our efforts are directed towards the broader aim of pushing the envelope of what’s possible within the realm of sustainability and delivering solutions that meet the highest standards of quality while supporting a greener, more sustainable transition into the future,” Anant concludes.

11 notes

·

View notes

Text

Smells That Are Disappearing

Spirit Duplicators

In 1960s and '70s-era classrooms, it was an olfactory treat whenever the teacher passed out fresh-off-the-machine purple print “ditto” sheets to the class. Virtually every student immediately held the page to his face and inhaled deeply. There was something so pleasing about the aroma that emanated from the printing fluid—a 50/50 mix of methanol and isopropanol. The sole company that still manufactures ditto fluid in the U.S. only sells a few thousand gallons per year these days, as opposed to the over 100,000 gallons they delivered during the 1970s.

Burning Leaves

Pollution concerns caused municipalities in the U.S. to enact open burning bans beginning in the 1980s, and today residents are encouraged to either rake and bag their leaves or use them for mulch. Of course, compost piles do have their own aroma, but it’s not particularly enticing.

Diesel Exhaust

City buses and semi-trucks don’t smell quite like they used to when they accelerate on a cold morning. There are a lot of folks that actually enjoyed the old school smell of the black exhaust these vehicles used to belch. But reductions in the sulphur content of diesel fuel, along with selective catalytic reduction, gives today’s diesel burners more of a cat urine-y type of aroma.

Magic Marker

The classic glass bottle-bodied Magic Marker was first marketed in 1952, and until the early 1990s, the ink formula included a mixture of Toluene and Xylene, two solvents which not only had a distinctive and not unpleasant odour, but which also contained intoxicating properties when inhaled. Today’s permanent markers get their colour from less fragrant alcohol-based inks.

Bubble Gum Cards

Topps stopped including a stick of stiff, hard-to-chew bubble gum in their trading cards several years ago when more collectors than kids were buying the product and complaining about the gum sticking to and ruining the bottom card in the pack. So kids today are getting mint-condition cards for their money, but they’re missing out on that distinctive bubble gum smell that wafted from the package when it was opened (and from the cards when they were brand new).

Cap Guns

Even if you didn’t have a toy gun handy, it was easy enough to “shoot off” caps by striking them with a hammer or even a rock. The gunpowder/sulphur smell of an exploded cap is another aroma that immediately propels many minds to summer days spent playing cops and robbers.

(Old) New Car Smell

That aroma we smell today upon delivery of a brand new set of wheels is very different from the new car smell of 30 or so years ago. A lot of that smell comes from off-gassing synthetic materials, plastics and chemical additives that are used in modern vehicles. In 1960, the average American-made car contained 22 pounds of plastics; in 2012, that quantity had increased to 250 pounds. And there’s also matter of the flame retardants and antimicrobials that are now added to the carpeting and upholstery for additional “safety” (even though some of the fumes have been proven toxic).

www.mentalfloss.com

4 notes

·

View notes

Text

Best Food Waste Recycling Machine Manufacturers – Pune

Revolutionize your waste management approach with AGM Enviro Engineers' advanced Organic Waste Composter solutions. Our cutting-edge composting technology efficiently transforms organic waste into nutrient-rich compost, fostering sustainable practices for a greener future. As a leading provider in the industry, we specialize in delivering customized composting solutions for diverse sectors, ensuring efficient organic waste conversion, reduced environmental impact, and compliance with sustainability goals.

Discover how our Organic Waste Composter solutions can optimize your waste management strategy, contributing to a healthier planet and a more sustainable tomorrow. Contact AGM Enviro Engineers for innovative and eco-friendly waste solutions tailored to your unique needs.

2 notes

·

View notes

Text

Mushroom Machinery Manufacturing Pvt. Ltd. Manufacturer of All Kind of Mushroom Machines & Mushroom machinery Equipments for Mushroom Plants & Mushroom Farming. We makes Automation of Mushroom Growing Unit, Composting Unit, Mushroom Cold Room, Mushroom Growing Rooms Unit Machines, Mushroom Project Consultancy, Shed Construction, in India

3 notes

·

View notes

Text

"Well..." Akila raised her hands in a confused matter. It was true that Keilij was a very clever wizard, but his spells often had a major flaw, and now, she had to explain to this hot-headed wizard what it is. "Technology is pretty complicated, but it has the greatest thing to it that it works. In a way, magic is technology when you can use it."

"With due respect, sorceress, this is utter nonsense. Technology is like fax machines, cars, trains and guns."

"Not so fast, Keilij. Consider: if you got no magic, how do you make fire?"

"....I.... I am not sure, actually. Banging two rocks together?" He shrugged, confused now.

"It is not quite true, but let us say it is that easy. Now, you know why these banging works?"

"Don't try to tell me rocks are a technology! They are in nature! Fire is in nature!"

"But how to bang them together is technology." The sorceress smiled, and Keilij huffed.

"Then you did not understand me. This spell can keep the mundanes at bay."

"Okay, I will explain my issue more. When you say it stops technology from working, you are most often go against the laws of reality. That is literally impossible."

"I do not think you understand me." Keilij interrupted her. "Technology is anything that is advanced and manufactured, not just grabbing things and banging them together!"

"Okay.... I can try to explain, or we can test your spell under control in a safe environment. And I know just the place. What would it be?"

"Test it. I am sure it will work."

Akila opener her portal mirror and gently leant forward.

"After you."

The other side was of a rustic cabin in the woods, a small stone-and-wooden log house. It had a few chairs and a table, shelves, but otherwise was empty. Akila walked out with Keilij, dragging the mirror with herself in the chilled, leaf-covered forest.

"Now cast your spell on that house." She said to him. He shrugged and did it, a minute-long ritual that summoned a bubble around them. It expanded and reached the house... which slowly started to dissolve. The wooden planks collapsed to dust, the stone brittled away, then the tiled roof collapsed into ash and mud before they hit the ground. In five minutes, the cabin was just a compost heap.

Keijil turned around to see Akila standing there, naked, her face a slight smug smile. He looked down and realised he was naked as well.

"But... how?"

"Turning cloth into clothing is technology. Sawing logs and cutting stone is technology. Just being able to make sure that the mortar connects them is technology. Oh, and..." she took a step aside. The mirror was just sand and silver dust. Keilij felt a glob of fear in his throat. "And now consider, all you did was a few minutes, and during this time, I could have walked out of your bubble, but I rather sacrifice my dignity and let it demonstrate you how short-sighted you are."

"...it... it is still a spell we can use! We just-"

"If you are about to say 'use offensively', I wish to point out two more things you may not feel. Had you ever had vaccinations? Medication? Anything above 'chew these leaves'? Technology as well."

He started groaning.

"Oh and one more thing, can you cast a spell?"

"What?"

"I had been trying to figure out how to make a portal for us but I can not remember the spell right now. In fact... I am kind of cold and I can't think of anything to warm myself. Can you?"

"Uhhh... we... we..." Keilij stumbled and was red in the face. She leaned forward, waiting with a smug smile.

"Maybe we could bang some rocks together, but make sure we won't burn down the entire forest."

“The anti-technology spell stops technology from working. What’s so confusing about this?”

4K notes

·

View notes

Text

The structural advantages of the large wheel compost turning machine

The large wheel compost turning machine has significant structural advantages in organic fertilizer production. These advantages make it perform well in dealing with organic waste such as livestock and poultry manure, sludge and garbage, sugar factory filter mud, dregs, cake meal and straw sawdust. The following are its main structural advantages:

1. High turning depth and large span: The turning depth of the large disc turning machine can reach 1.5 to 3 meters, capable of handling deeper fermentation materials and suitable for large-span fermentation tanks.

2. Energy-saving and high-efficiency transmission mechanism: It adopts a unique energy-saving and high-efficiency transmission structure, significantly reducing energy consumption compared to traditional turning and throwing equipment under the same operation volume. Equipped with a hydraulic lifting system, it enables the turntable to rise and fall automatically, ensuring that the equipment can move without obstacles.

3. No blind spot turning: The symmetrical design of the wheel disc, in combination with the displacement of the variable-speed transfer trolley, ensures no blind spot turning and guarantees the uniformity of the fermentation materials.

4. High degree of automation: Equipped with a fully automated electrical control system, the organic fertilizer equipment does not require human operation during operation, improving production efficiency and operational safety.

5. Durable and robust: Made of high-quality materials and advanced manufacturing techniques, the equipment is highly durable, reducing maintenance costs.

6. Strong applicability: It is suitable for the fermentation and turning of various organic wastes and is widely used in organic fertilizer plants, compound fertilizer plants, sludge and garbage plants, horticultural farms, and button mushroom cultivation plants, etc.

7. Flexible customization: It can be customized according to the width and length of the fermentation tank to meet the needs of different users.

Through these structural advantages, the large wheel turning machine can not only enhance the efficiency and quality of organic fertilizer production, but also reduce production costs and minimize environmental pollution. It is an indispensable high-efficiency equipment in organic fertilizer production.

0 notes

Text

Organic Waste Composter Machine Manufacturer In India

Are you searching for a fully automatic Organic Waste Composter machine manufacturer in India? Green Aqua Technologies is the perfect choice for you. We are top rated manufacturer and supplier of organic waste composter machines in India, specializing in innovative solutions that convert organic waste into nutrient-rich compost. An organic waste converter is a machine that efficiently transforms kitchen scraps, garden waste, and food processing by-products into high-quality compost. Excel’s OWC not only simplifies the composting process but also promotes sustainable waste management by preventing waste buildup in landfills. Website: https://www.greenaquatechnologies.com/organic-waste-composter/

0 notes

Text

Designing bio-organic fertilizer production lines: Flexible enough for different scales

Bio-organic fertilizer production lines need to balance flexibility, scalability, and cost-effectiveness to meet the needs of businesses of all sizes. Whether it’s a small farm making fertilizer for its own use or a large industrial operation running continuous processing, a well-designed setup ensures efficient and steady output.

1.Small-Scale Production Lines

Perfect for family farms, small co-ops, or organic growing bases. Features include:

Simple equipment: Uses trough composting or windrow piles, paired with small crushers, mixers, and screens.

Low investment: Manual turning with basic compost turning machines keeps startup costs down.

Flexible adjustments: Formulas can be tweaked based on materials (like livestock manure, straw, or mushroom residue) for small-batch production.

2.Medium-Scale Production Lines

Suited for fertilizer processing plants or mid-sized farms. Core setup includes:

Turning equipment: Trough turners or crawler compost turners to speed up fermentation.

Crushing and mixing: Chain crushers + double axis mixers for even blending.

Optional granulation: Disc or flat die granulators for powdered or pelletized fertilizer.

Automated control: Temperature and humidity sensors + PLC systems to optimize fermentation.

3.Large-Scale Production Lines

Built for professional fertilizer manufacturers. Features include:

High-efficiency fermentation: Smart fermentation tanks or continuous turning systems cut down the composting cycle.

Smart ingredient dosing: Automated weighing and mixing systems for precise NPK and microbial inoculant blending.

Versatile granulation: Drum or extrusion granulators to suit different market needs.

Automated packaging: Weighing, sealing, and palletizing done by machine to reduce labor costs.

Bio-organic fertilizer production line designs should match equipment combinations to the production scale, material types, and budget—ensuring efficient, low-cost, and sustainable operations.

0 notes

Text

An organic waste composter is a device designed to break down organic waste materials such as food scraps, leaves, and other biodegradable substances. These composters use natural processes like decomposition and microbial activity to turn organic waste into nutrient-rich compost. They're great for reducing landfill waste and producing compost that can be used to enrich soil in gardens, farms, and even urban spaces.

Here are the key benefits of an Organic Waste Composter:

Environmental Benefits

Soil Health & Agriculture

Economic Benefits

Household & Community Benefits

Versatility & Adaptability

Mob- +919812241001

0 notes

Text

Precision and Productivity: A Deep Dive into Bag Making Machines

Bag making machines play a pivotal role in the global packaging industry, transforming flat materials into functional containers used in countless sectors—from retail and food services to industrial shipping. As consumer demand for convenience and sustainability grows, the bag making machine industry has responded with more versatile, efficient, and environmentally friendly technologies.Get more news about paper bag making machine,you can vist our website!

What is a Bag Making Machine? A bag making machine is a highly specialized piece of equipment that automates the production of various types of bags, including plastic bags, paper bags, woven sacks, and biodegradable alternatives. These machines typically handle processes such as feeding raw material, folding, sealing, cutting, and sometimes even printing or punching. The automation not only accelerates production but also ensures consistency and precision, which is crucial in large-scale manufacturing.

Types and Applications There are numerous types of bag making machines, each suited for a specific application:

Plastic Bag Making Machines: These can produce T-shirt bags, garbage bags, zip-lock bags, and more. Some machines are engineered to handle biodegradable plastics in response to environmental regulations.

Paper Bag Making Machines: As many companies shift toward paper to reduce plastic waste, these machines are gaining popularity in retail and food packaging.

Non-woven Bag Making Machines: Ideal for reusable shopping bags, these have seen a surge in demand due to bans on single-use plastics in many regions.

Each category has subtypes equipped with options for side sealing, bottom sealing, or center sealing, depending on the design and purpose of the bag.

Key Features Driving Innovation Modern bag making machines are equipped with programmable logic controllers (PLCs), touch screen interfaces, and servo motors for greater accuracy and user-friendly operation. Some high-end models come with online printing and lamination systems, integrating multiple processes into a single production line. Energy efficiency and material flexibility are also top priorities in today's designs, enabling manufacturers to work with different substrates like PE, PP, kraft paper, and recycled materials.

Sustainability and Market Trends One of the most significant developments in the bag making machine industry is the pivot toward eco-friendly materials and processes. Governments across the globe are regulating plastic usage, which has led to a sharp increase in demand for machines that handle recyclable or compostable materials. As a result, manufacturers are redesigning equipment to accommodate thinner films and recyclable blends without compromising on strength or seal quality.

China, India, and Southeast Asia remain key manufacturing hubs due to lower labor costs and expanding domestic demand. However, Western markets are increasingly investing in automation to reduce dependency on imports and meet stricter environmental standards.

Conclusion Bag making machines may not often be in the spotlight, but they are indispensable in our everyday lives. From the paper sack at the bakery to the heavy-duty bags used in construction, these machines quietly power the global flow of goods. As technology advances and sustainability becomes non-negotiable, bag making machines will continue to evolve—offering smarter, cleaner, and more efficient solutions to meet the demands of a changing world.

0 notes