#Compression Testing Machine Manufacturer

Explore tagged Tumblr posts

Text

A Compression Testing machine is an important instrument in many sectors. It includes the construction industry and academics. There are various materials whose compressive strengths can be accurately determined with this equipment.

#Compression Testing Machine#Compression Testing Machine Price#Compression Testing Machine Manufacturer#Compression Testing Machine in India#Compression Testing Machine Supplier#CTM Machine

0 notes

Text

Computerized Compression Testing Machine

Computerized compression testing machine is a device used to measure the compressive strength and behavior of materials under a controlled load. It applies axial forces to a specimen in a downward direction and measures its response, allowing for the determination of various mechanical properties. Compression Testing Machines are used in various industries like construction, rubber, spring manufacturing and similar other industries where compressive strength of the material is to be tested. Our Compression Testing Machine is equipped with hydraulic loading, available in load capacity from 100kN to 1000kN. The loading is with the hydraulic system and the measurements are using the state of art digital control panel. Test results are displayed on the DRO which can be transferred to the computer for further analysis.

Compression Testing Machine

Compression Tester

Material Compression Testing

Industrial Compression Tester

Compression Strength Testing

Compression Test Equipment

Compression Testing Services

Universal Testing Machine

Compression Testing Standards

High-precision Compression Testing

#manufacture#manufacturer#metallurgical#industrial equipment#testing#tester#compression testing machine#strength tester#testing machine#strength testing machine#material compression tester#indutrial compreesion tester#compression tester#manufacturer in india#supplier in india#compression testing machine manufacturer#cimpression testing machine supplier

1 note

·

View note

Text

The Effective Lab India box compression tester is a necessary equipment to ensure the quality of packaging material, which is used to measure the strength of the material of the corrugate boxes during packing. This machine ensures that the packaging products or boxes can withstand the pressure during stacking and shipping without collapsing, bending or warping. This helps manufacturers maintain product safety during transportation or ensure the quality and strength of the product before it reaches the market.

#box compression strength tester#box compression tester#manufacturing#manufacturer#box compression test machine

0 notes

Text

Manhole Cover Compression Testing Machine

Reliable and Accurate Testing for Manhole Covers The Manhole Cover Compression Testing Machine is a specialized testing device designed to assess the structural integrity of manhole covers under extreme pressure. This testing machine plays a crucial role in ensuring that manhole covers meet the required safety standards and durability expectations. Whether used for quality control in…

#ASTM Manhole Cover Test#Civil Engineering Testing#Compression Resistance#Compression Strength Test#Compression Testing#Construction Equipment Testing#Custom Testing Solutions#EN 124 Testing#Hydraulic Load Testing#Hydraulic Testing Machine#Industrial Testing Machines#ISO Manhole Cover Standards#Jinan Wangtebei Instrument#Load Cell Testing#Load Testing#Manhole Cover Compliance#Manhole Cover Deformation Test#Manhole Cover Performance Test#Manhole Cover Quality Control#Manhole Cover Strength#Manhole Cover Testing Equipment#manhole cover testing machine#Pressure Test Machine#Testing Equipment for Infrastructure#Testing Machine Manufacturer

0 notes

Text

Premium White Hard PTFE Sheets for Demanding Industrial Applications

Aohong's white hard PTFE sheet stands as a benchmark in high-performance fluoropolymer solutions, delivering exceptional mechanical strength and chemical resistance. Manufactured from 100% virgin PTFE (polytetrafluoroethylene), these rigid fluoropolymer sheets maintain superior dimensional stability across extreme temperatures (-200°C to +260°C), outperforming conventional filled PTFE variants in purity and longevity.

Unmatched Material Properties

Our pure white PTFE sheets exhibit critical advantages:

0.02% deformation under 20MPa compressive load (ASTM D695)

28MPa tensile strength – 40% higher than recycled PTFE blends

60kV/mm dielectric strength (IEC 60243 at 200°C)

Zero moisture absorption – ideal for semiconductor cleanrooms

Microscopic analysis reveals a homogeneous crystalline structure with <0.1% void content, achieved through Aohong's proprietary isostatic pressing technology.

Precision Manufacturing Process

At our ISO 9001:2015-certified Suzhou facility, each sheet undergoes:

Ultra-fine resin filtration (99.99% purity)

Cold compaction at 65MPa for density uniformity

Controlled sintering (375±5°C for 20 hours)

Precision machining to ±0.03mm tolerances

This process yields FDA-compliant white PTFE sheets meeting:

USP Class VI biological safety standards

EU 10/2011 food contact regulations

RoHS 3 Directive compliance

Industrial Applications

Medical Devices

MRI component insulators

Autoclavable surgical tool handles

Food Processing

Non-stick conveyor liners

Dairy equipment gaskets

Semiconductor

Wafer carrier components

Plasma etch chamber liners

Chemical Processing

Hydrofluoric acid tank linings

Chlor-alkali cell seals

Quality Verification

Every production batch includes:

FTIR spectroscopy for molecular integrity checks

DSC analysis confirming 327±2°C melt point

X-ray diffraction testing crystallinity (15-20% range)

100% thickness gauging with laser micrometers

Recent third-party testing demonstrated 300% longer service life versus Chinese Q/YZB standards for PTFE sheets in sulfuric acid exposure.

Customization Options

Aohong provides tailored solutions:

Thicknesses from 0.5mm to 150mm

Anti-static versions (10⁶-10⁹ Ω/sq)

High-wear grades with 15% improved abrasion resistance

FDA white color-stable formulations

Pre-cut blanks for CNC machining

Why Aohong Excels

With 18 years of PTFE specialization, we offer:

12-month performance guarantee

Teflon™-equivalent properties at competitive pricing

Technical support from materials PhDs

Case Study: A Shanghai semiconductor fab reduced particle contamination by 92% after switching to our ultra-clean white PTFE sheets for wafer handling.

Advanced White PTFE Sheet Solutions for Critical Environments Contact Aohong today to request samples or discuss your application requirements. Our engineers combine deep material science expertise with practical experience from 1,200+ successful installations worldwide.

2 notes

·

View notes

Text

Ceramic Blasting Beads: A Key Technology for Enhancing Fatigue Resistance in Medical Device Metal Components

In the modern medical device industry, the reliability and durability of metal components directly impact patient safety and treatment efficacy. From implantable devices to surgical instruments, from diagnostic equipment to therapeutic devices, metal component fatigue failure remains a significant challenge for medical device manufacturers and quality control managers. Ceramic blasting beads, as an advanced surface treatment technology, are revolutionizing the fatigue resistance performance of medical device metal components. This article will explore in depth how ceramic blasting beads enhance the fatigue resistance of medical device metal components and the special value of this technology in the medical field.

Metal Fatigue Issues in Medical Devices

Severity of Fatigue Failure

In the medical device field, metal component fatigue failure can lead to catastrophic consequences:

Implant fractures may require emergency revision surgeries

Surgical instrument failures during use may endanger patients' lives

Diagnostic equipment malfunctions may lead to misdiagnosis or delayed treatment

Therapeutic device failures may interrupt treatment plans

FDA data indicates that approximately 25%-30% of medical device recall events are related to metal component fatigue failures, causing serious impacts on patient safety and healthcare institutions.

Unique Challenges Facing Medical Device Metal Components

Medical device metal components face unique challenges:

Biocompatibility requirements: Materials must be non-toxic, harmless, and not cause immune responses

Strict sterilization conditions: Must withstand high temperature, high pressure, radiation, and other sterilization methods

Complex physiological environments: Long-term exposure to corrosive body fluids

Cyclic loading conditions: Such as orthopedic implants bearing periodic physiological loads

Zero-tolerance requirements: Medical devices cannot allow any risk of failure

These challenges make medical device metal components face more severe fatigue issues than general industrial applications.

Technical Characteristics of Ceramic Blasting Beads and Advantages in Medical Applications

Ceramic blasting beads offer unique application advantages in the medical device field:

Good biocompatibility: Materials like zirconium oxide and aluminum oxide have passed ISO 10993 biocompatibility testing

No residual contamination: Will not leave particles on component surfaces that could cause infection

High surface cleanliness: Can thoroughly remove surface machining marks and contaminants

Controllable surface roughness: Can adjust surface topological structure according to different medical device requirements

Non-magnetic: Will not affect the use of magnetic-sensitive medical equipment such as MRI

Medical-grade ceramic blasting beads typically have the following technical parameters: Technical Parameter Typical Specification Significance in Medical Applications Sphericity >98% Ensures surface treatment uniformity Purity >99.9% Avoids chemical contamination Hardness Mohs 9 Suitable for treating hard materials such as titanium alloys Particle size range 20-150μm Can be used for precision medical devices Surface finish Ra 0.1-0.8μm Meets different interface contact requirements

Mechanisms by Which Ceramic Blasting Beads Enhance Medical Device Fatigue Resistance

1. Formation of Residual Compressive Stress Layer

When ceramic blasting beads impact the metal surface at high speed, they form a residual compressive stress layer on the surface. This mechanism is particularly important for medical devices because:

The compressive stress layer effectively prevents micro-crack initiation and propagation in fluid environments

It improves the resistance of medical-grade metals such as titanium alloys and stainless steel to corrosion fatigue

It is especially important for implants that bear alternating loads (such as orthopedic screws, bone plates, artificial joints)

Research shows that appropriate ceramic blasting treatment can form a compressive stress layer with a depth of 0.1-0.2mm on medical-grade titanium alloy surfaces, increasing fatigue life by 100%-200%.

2. Microstructure Optimization

In medical device applications, microstructure optimization has special significance:

Grain refinement improves the metal's yield strength, enhancing implant resistance to deformation

Increased dislocation density reduces stress concentration phenomena in physiological environments

Changed microstructure facilitates cell attachment and tissue integration (crucial for osseointegration)

Microstructure optimization can significantly improve the safety factor of medical devices, especially in the field of long-term implants.

3. Surface Topography Control

For medical devices, surface topography control has dual significance:

Mechanical aspect: Appropriate surface roughness reduces fatigue crack sources

Biological aspect: Optimized surface microstructure promotes cell attachment and biological integration

Different types of medical devices require different surface topographical structures: Medical Device Type Recommended Surface Roughness (Ra) Purpose Orthopedic implants 1.0-2.0μm Promote osseointegration Joint replacements 0.05-0.2μm Reduce friction and wear Cardiovascular stents 0.3-0.8μm Improve blood compatibility Dental implants 1.5-2.5μm Enhance tissue bonding Surgical instruments 0.1-0.4μm Improve corrosion resistance and cleanliness

4. Surface Bioactivity Regulation

Unique to medical applications, ceramic blasting can also regulate metal surface bioactivity:

Change surface energy and wettability, affecting protein adsorption and cell attachment

Adjust the chemical composition and structure of the surface oxide layer

Provide an ideal foundation for subsequent surface functionalization treatments (such as hydroxyapatite coating)

This bioactivity regulation both improves device biocompatibility and enhances metal fatigue resistance, forming a dual safeguard.

Ceramic Blasting Process Optimization in Medical Device Production

Medical devices have requirements for surface treatment far higher than general industrial applications, and ceramic blasting processes must be conducted under strictly controlled conditions:

Key Process Parameters

Process Parameter Medical-Grade Recommended Range Special Considerations Blasting pressure 0.3-0.5MPa Adjust according to device size and wall thickness Blasting distance 80-150mm Uniformity control Blasting time 20-90s Avoid excessive treatment causing precision loss Bead specification 20-150μm Determined by device precision and surface requirements Coverage requirement >98% Ensure no fatigue-weak zones

Special Process Control Points

Contamination-free process environment: Clean room grade blasting environment to prevent particle contamination

Batch quality control: 100% surface inspection to ensure zero defects

Parameter validation: Validate blasting parameters through fatigue testing

Sterilization compatibility: Ensure blasted surfaces can withstand subsequent sterilization processes

Traceability: Complete process recording, complying with medical device regulatory requirements

Medical Device Application Case Studies

Case 1: Titanium Alloy Spinal Fixation System

Challenge: Spinal fixators bear complex cyclic loads in the body, with fatigue failure being the main issue.

Solution: 45-75μm zirconium oxide ceramic blasting treatment of titanium alloy spinal screws and connecting rods.

Results:

Fatigue strength increased by 36%

Failure rate reduced from 2.3% to 0.4%

Patient revision surgery rate decreased by 75%

Product 5-year survival rate improved to 98.7%

Case 2: Stainless Steel Orthopedic Surgical Instruments

Challenge: Orthopedic surgical instruments require repeated use and sterilization, facing serious stress corrosion fatigue issues.

Solution: 50-100μm aluminum oxide ceramic blasting treatment, forming a uniform surface compressive stress layer.

Results:

Instrument service life extended 2.5 times

Sterilization cycle resistance improved by 40%

Surface corrosion resistance increased by 65%

Repair and replacement costs reduced by 58%

Case 3: Cobalt-Chrome Alloy Artificial Hip Joints

Challenge: Artificial hip joints require excellent fatigue strength and biocompatibility.

Solution: Two-stage ceramic blasting: coarse blasting (125μm) to form a compressive stress layer, fine blasting (45μm) to optimize surface topographical structure.

Results:

Fatigue strength improved by 43%

Friction coefficient reduced by 28%

Metal ion release decreased by 67%

Implant service life increased from 12 years to over 20 years

Case 4: Nitinol Cardiovascular Stents

Challenge: Cardiovascular stents work in a pulsating environment, requiring extremely high fatigue resistance and blood compatibility.

Solution: Ultra-fine (20-45μm) zirconium oxide blasting, optimizing surface morphology and oxide layer.

Results:

Stent fatigue life increased to over 400 million cycles

Thrombosis risk reduced by 32%

Restenosis rate decreased by 26%

Product safety incident reports reduced by 81%

Quality Control and Regulatory Compliance

For medical device manufacturers and quality control managers, ceramic blasting treatment is not just a technical means to improve product performance but also a key step in ensuring regulatory compliance:

FDA and NMPA Compliance Points

Process validation: Required according to FDA 21 CFR 820.75 and relevant NMPA regulations

Surface characteristic testing: Including ASTM F86 surface inspection and ISO 4287 surface roughness testing

Fatigue testing requirements: Compliance with standards such as ASTM F1801, ISO 14242

Biocompatibility assessment: Comprehensive biological evaluation according to ISO 10993-1

Risk management: Incorporating blasting treatment into ISO 14971 risk management system

Key Quality Control Testing Methods

Test Item Test Method Acceptance Criteria Surface roughness Surface profilometer Within design specifications ±10% Residual stress X-ray diffraction Surface compressive stress >200MPa Coverage Microscopic inspection >98% Surface defects Electron microscopy No cracks, peeling, or sharp edges Metal ion release ICP-MS Below ISO standard limits Accelerated fatigue testing According to ISO standards Achieves 5 times design life or more

Cost-Benefit Analysis: Medical Device Perspective

In the medical device field, the cost-benefit of ceramic blasting technology needs to be evaluated from multiple levels:

Direct Cost Benefits

Reduced product recall costs: Each medical device recall costs an average of $3-7 million; improving fatigue performance can significantly reduce recall risks

Decreased warranty claims: Fatigue-related failure claims reduced by 65%-80%

Extended product life: Implant service life extended by 50%-100%, reducing revision surgery rates

Enhanced market competitiveness: Product reliability becomes a key selling point, increasing brand value

Indirect Cost Benefits

Accelerated regulatory approval: Reliable fatigue data support speeds up registration and approval processes

Improved physician and patient satisfaction: Reduces medical disputes caused by device failures

Better insurance coverage: Higher reliability devices more easily obtain insurance coverage

Enhanced corporate reputation: Avoids negative publicity due to product fatigue failures

Return on investment analysis shows that in the high-end medical device field, investment in ceramic blasting technology typically pays back within 18-24 months, with long-term ROI exceeding 300%.

Frequently Asked Questions (FAQs)

Does ceramic blasting treatment affect the sterilization efficacy of medical devices?

No. On the contrary, appropriate ceramic blasting treatment can improve the surface microstructure, reducing microbial attachment points and enhancing sterilization effectiveness. Research shows that optimized ceramic blasting treatment can improve the Sterility Assurance Level (SAL) of medical device surfaces.

Do different types of medical-grade metals require different ceramic blasting materials?

Yes, different metals require different blasting materials and parameters:

Titanium alloys: Zirconium oxide beads recommended (matching hardness, avoiding embedding)

Stainless steel: Can use aluminum oxide or zirconium oxide beads

Cobalt-chrome alloys: Zirconium oxide beads recommended (reducing surface contamination)

Nitinol: Must use ultra-fine zirconium oxide beads (avoiding damage to superelastic properties)

What post-processing steps are required after ceramic blasting treatment?

Medical devices typically require the following post-processing steps:

Ultrasonic cleaning (removing all residual particles)

Passivation treatment (forming a stable oxide layer)

Electrochemical polishing (for certain applications)

Surface functionalization (if special biological characteristics are needed)

Sterilization packaging (preventing contamination)

How does ceramic blasting affect the service life of medical devices?

By increasing fatigue strength and reducing corrosion sensitivity, ceramic blasting can significantly extend medical device service life:

Implantable devices: Life extended by 50%-100%

Surgical instruments: Usage cycle count increased by 150%-200%

Diagnostic equipment: Metal component failure interval extended 3-5 times

How is the consistency and reliability of the ceramic blasting process validated?

The medical device industry uses the following methods to validate process consistency:

Process Validation Studies (PVS)

Statistical Process Control (SPC)

Failure Mode and Effects Analysis (FMEA)

Accelerated Life Testing (ALT)

Real-time stability monitoring and data trend analysis

Future Development Trends

Ceramic blasting technology in the medical device field is developing in the following directions:

Biofunctionalized blasting materials: Ceramic beads containing antibacterial elements or bioactive factors

Gradient blasting technology: Achieving different surface characteristics in different areas of the same component

Intelligent monitoring blasting systems: Real-time quality control based on machine vision and AI

Personalized parameter optimization: Adjusting implant surface characteristics according to specific patient needs

Hybrid processes combined with 3D printing: Providing optimal surface treatment for complex geometries

Conclusion

Ceramic blasting bead technology provides significant improvements in fatigue resistance for medical device metal components, which has special significance in the medical field. Through forming residual compressive stress layers, optimizing microstructures, controlling surface topography, and regulating bioactivity, ceramic blasting technology not only improves the safety and reliability of medical devices but also extends service life, reduces patient risk, and decreases healthcare costs.

For medical device manufacturers and quality control managers, understanding and correctly applying ceramic blasting technology is a key strategy for improving product quality, ensuring regulatory compliance, and enhancing market competitiveness. As medical devices develop toward smaller size, more functionality, and greater personalization, ceramic blasting technology will continue to play an irreplaceable role, providing more reliable safeguards for patient safety and treatment efficacy.

2 notes

·

View notes

Text

Precision-machined zirconia ceramic parts

The high strength and high toughness of zirconia ceramic blocks enable these blocks to maintain their block shape and performance stability under high pressure and high friction conditions, thereby ensuring the operational stability and long life of the equipment. The characteristics and application areas of zirconia ceramic blocks are as follows:

Precision-machined small holes and snap-in

The block design contains multiple precision-machined small holes and snap-in positions to ensure precise fixing and positioning in electrical equipment.

High strength

The high porosity (Vickers hardness of 11.5 GPa) and high strength (compressive strength of 2000 MPa) of zirconia ceramics ensure that the shape and performance are maintained under high-pressure and high-friction conditions, enhancing the stability of the equipment.

Sufficient electrical insulation

Provides excellent electrical insulation performance in high-voltage environments to prevent electrical failures and ensure safe operation.

High temperature resistance

Good high temperature resistance (thermal shock stability coefficient 250℃) enables the block to be used in high temperature working environment without damage.

Application field

Electrical equipment

Used in electrical components such as electric thermal protectors and terminal blocks to provide stable electrical insulation and high temperature performance.

Precision machinery

Used for fixing and positioning in precision instruments and equipment to ensure accurate assembly and stable operation of mechanical parts.

High-temperature industrial applications

Suitable for any industrial environment that requires high temperature resistance and electrical insulation, such as furnace temperature control systems and high temperature test equipment.

General industry

Abrasion resistance and wear resistance, also used in various applications that require long-term stability and industry.

Edgetech specializes in manufacturing a range of high-performance ceramic components, encompassing zirconia, Alumina, silicon carbide,

Silicon nitride, aluminum nitride, etc. Renowned for their exceptional thermal stability, electrical insulation properties, high-temperature resilience, and wear resistance, these ceramic parts play a pivotal role in numerous vital industries, including aerospace, electronics, machinery, military, automotive, and beyond.

0 notes

Text

material testing machine supplier

Reliable supplier of high-quality material testing machines, offering a wide range of equipment for tensile, compression, hardness, impact, and fatigue testing. Our machines are designed for precision, durability, and compliance with international standards, serving industries like construction, automotive, aerospace, and manufacturing. We provide expert support, installation, and calibration services for optimal performance.

1 note

·

View note

Text

A device known as a compression testing machine called CTM in short. It is used to determine a material’s compressive strength. The CTM was created In order to ensure that the sample would be compressed until it broke. A cylinder with a piston within that raises and lowers to transfer the load to the sample is a crucial component of the apparatus.

#Ctm Machines#Compression Testing Machines#Compression Testing Machine#Universal Testing Machine#Universal Testing Machines#Universal Testing Machine Manufacturer

0 notes

Text

Digital Compression Testing Machine-D SERIES

Digital compression testing machines are widely used in various industries where accurate measurement of compressive strength and material behavior is essential. They are commonly employed in construction, manufacturing, civil engineering, and research laboratories for quality control, material testing, and product development purposes. Digital compression testing machine is an advanced version of a computerized compression testing machine. It incorporates digital technology to provide improved control, accuracy, and data acquisition capabilities specifically for compression testing applications. The term “digital” refers to the use of digital displays, sensors, and electronic control systems in the machine.

#manufacture#industrial equipment#manufacturer#metallurgical#metallographicequipments#compression testing#compression tester#compression testing machine#compression tester machine#digital compression testing machine#digital compression tester machine

1 note

·

View note

Text

In the era of packaging it is important to ensure that packaging boxes can withstand compression forces. A box compression tester is a special test machine used to evaluate the compressive strength of cartons, corrugated boxes and other packaging materials. It uses controlled pressure on a box until it is deformed or failed, and provides data with its maximum load -bearing capacity. Box Compression Test is necessary to ensure packaging quality & durability, reduce number of product damage and maintain product safety. By investing in a box compression tester, the industry can optimise its packaging solutions and follow global standards.

#manufacturer#manufacturing#box compression test formula#box compression tester#box compression strength tester#box compression test machine

0 notes

Text

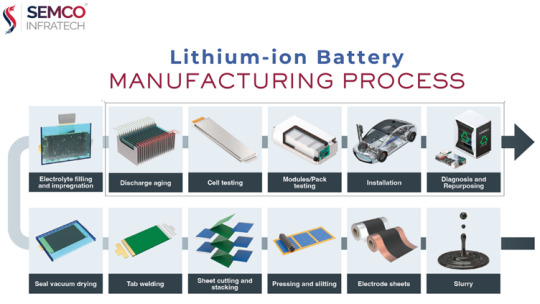

Step-by-Step Guide to Lithium Battery Pack Assembly and Cell Making Equipment

The rise of electric vehicles, renewable energy systems, and portable electronics has significantly increased the demand for lithium-ion batteries. But behind these powerful energy sources lies a highly intricate and controlled manufacturing process.

From raw materials to finished products, battery making machines and advanced battery making equipment are essential in ensuring efficiency, precision, and safety at every stage.

Understanding the Fundamentals

Before diving into the production process, it's crucial to understand the core components of a lithium-ion battery:

Positive Electrode: Made from materials such as lithium cobalt oxide (LCO), lithium nickel manganese cobalt oxide (NMC), or lithium iron phosphate (LFP).

Negative Electrode: Typically composed of graphite.

Separator: A porous membrane that separates the electrodes while allowing lithium ions to flow.

Electrolyte: A gel or liquid that enables ion movement between electrodes.

Current Collectors: Usually, aluminium for the positive electrode and copper for the negative, these provide a conductive path for electrons.

The battery works through the reversible movement of lithium ions between electrodes. During charging, lithium ions migrate to the negative electrode; during discharge, they return to the positive side—producing electrical energy.

The Lithium-Ion Battery Assembly Process: A Multi-Stage Journey

The lithium-ion battery assembly process can be categorized into three key stages:

1. Front-End: Electrode Manufacturing

This initial phase focuses on producing high-performance electrodes, a critical step in the battery cell making machine workflow.

Slurry Preparation: Active materials (e.g., LCO or graphite) are mixed with binders like PVDF and conductive agents to form a uniform slurry.

Coating: The slurry is precisely applied to metal foils using high-precision battery-making equipment, ensuring uniform thickness.

Drying & Calendaring: Coated electrodes are dried to eliminate solvents and then compressed for better conductivity.

Slitting & Die Cutting: Electrodes are cut into specific dimensions to fit the battery cell, making machine specifications.

2. Middle-End: Cell Assembly

The second stage of the lithium-ion battery assembly process involves assembling the core components.

Winding/Stacking: Positive and negative electrodes are alternately layered with separators to form a cell stack.

Electrolyte Filling: The electrolyte is carefully injected into the cells to enable ion movement.

Sealing: The cells are sealed using heat or ultrasonic sealing to avoid leakage and ensure safety.

3. Back-End: Formation and Packaging

The final stage is about bringing the battery to life.

Formation: Cells undergo multiple charge-discharge cycles to stabilize their chemistry.

Testing & Sorting: Advanced battery making machines test each cell for voltage, capacity, and other parameters. Cells are then sorted accordingly.

Packaging: Assembled cells move into the lithium battery pack assembly stage, where they are configured into packs, enclosed, and prepared for shipment.

Key Challenges in Lithium Battery Manufacturing

Quality Control: Every step, from mixing to testing, demands extreme precision.

Safety: Mishandling materials or processes can result in thermal runaways or fire hazards.

Environmental Responsibility: Managing chemical waste and emissions is critical for sustainability.

Technological Advancements: The demand for higher capacity and faster charging batteries drives constant innovation in battery making equipment.

Conclusion

The lithium-ion battery assembly process is a sophisticated, multi-layered operation that relies heavily on precision, quality, and cutting-edge technology. With growing applications in EVs, consumer electronics, and energy storage, understanding this process—and the role of battery-making machines—is vital. As innovations continue to emerge, the evolution of lithium battery pack assembly will remain central to the future of sustainable energy solutions.

#battery making machine#battery making equipment#battery cell making machine#lithium ion battery assembly#lithium battery pack assembly#lithium ion battery assembly process#lithium ion battery manufacturing process

0 notes

Text

Shot Blasting Machines in Construction: Improving Concrete and Steel Structures

Construction projects require durable materials that can withstand the test of time. Shot blasting machines are widely used in the construction industry to clean, prepare, and strengthen materials like steel and concrete. This article discusses the importance of shot blasting in construction and how it contributes to the quality and durability of structures.

Why Shot Blasting is Essential in Construction

In construction, shot blasting is primarily used to prepare steel for welding and coating and to clean concrete surfaces. This ensures that materials are ready for further processing and treatment, improving both their strength and longevity.

Applications of Shot Blasting in Construction

Cleaning and Preparing Steel Surfaces

Shot blasting removes contaminants such as rust and dirt from steel surfaces, making them ready for coating, welding, or further processing.

Concrete Surface Profiling

Shot blasting is used to clean and profile concrete surfaces, ensuring that coatings and sealants adhere properly.

Surface Strengthening

The compressive stress created by shot blasting strengthens steel and concrete surfaces, making them more resistant to wear and corrosion.

Coating Preparation

Shot blasting improves the bonding of coatings to both concrete and steel, ensuring long-lasting protection from weathering and other environmental factors.

For construction companies seeking reliable shot blasting equipment, partnering with leading shot blasting machine manufacturers like Krishna Shot Blasting ensures you receive high-quality machines designed for both steel and concrete applications.

Final Thoughts

Shot blasting machines are indispensable tools in the construction industry, providing effective cleaning, surface profiling, and strengthening of steel and concrete materials. By selecting a reputable shot blasting machine manufacturer, construction companies can enhance the durability and quality of their projects.

0 notes

Text

Optimizing Engine Performance with Quality Detroit Diesel Parts and Cylinder Heads

When it comes to maintaining or upgrading your diesel engine, few names carry the weight and reliability of Detroit Diesel Parts. Known for their high-performance standards and durability, these parts are essential for ensuring long-term functionality and efficiency. Whether you're performing routine maintenance or replacing critical components, using authentic parts—especially the cylinder head—can make all the difference.

One of the most vital components in any diesel engine is the cylinder head. This crucial part sits atop the engine block and seals the cylinders, forming the combustion chamber. It controls air and fuel intake, exhaust gas expulsion, and houses important elements like valves, spark plugs, and fuel injectors. Choosing a high-quality cylinder head is fundamental not only to the engine’s power output but also to its overall lifespan. This is where the value of using reliable Detroit Diesel Parts becomes evident.

A faulty or worn-out cylinder head can lead to a host of engine problems, from reduced compression and overheating to complete engine failure. It's not just about fixing what's broken; it's about preventing potential issues before they compromise your engine. Mechanics and fleet managers alike recognize that investing in dependable diesel engine components is more cost-effective in the long run. This includes sourcing from reputable suppliers that prioritize quality and compatibility.

For those looking to purchase top-grade parts, shop.nadieselparts.com is a trusted destination. They offer a comprehensive range of Detroit Diesel Parts that cater to various models and needs. From fuel system components to exhaust systems and electronic controls, every product on the site is designed to meet or exceed OEM standards. Their inventory is particularly strong when it comes to core engine components such as the cylinder head, providing customers with durable, performance-tested options that match manufacturer specifications.

What sets this supplier apart is not only the variety of inventory but also the commitment to customer satisfaction. They understand that diesel engines are the backbone of many industries—from transportation and construction to agriculture and marine applications. Any downtime due to engine trouble can result in significant financial losses. That’s why sourcing dependable Detroit Diesel Parts from an experienced supplier like shop.nadieselparts.com becomes a strategic business decision.

Another reason engine builders and repair specialists prefer using a genuine cylinder head is due to the exacting tolerances and engineering precision required for diesel engines. Even a slight imperfection or mismatch can lead to subpar performance or catastrophic damage. That’s why it's critical to use parts that are specifically designed and tested for your engine’s make and model.

The benefits of choosing authentic parts go beyond just fit and function. There’s also the matter of warranty and technical support. When you buy from a verified supplier, you often receive product guarantees that protect your investment. Technical assistance is also more readily available when dealing with standardized, well-documented components. This gives you peace of mind that your equipment is in optimal condition and that help is available when needed.

In today’s competitive and demanding market, reliability isn’t just a bonus—it’s a necessity. Using top-quality diesel engine components, especially those from established brands like Detroit, is a proven way to keep your machines operating smoothly. A well-functioning cylinder head, paired with other premium parts, contributes to improved combustion, better fuel economy, and reduced emissions—key performance indicators in any industry.

In conclusion, whether you're performing routine service or a complete engine rebuild, investing in genuine Detroit Diesel Parts is a wise choice. And when it comes to sourcing critical components like the cylinder head, shop.nadieselparts.com offers the selection, quality, and expertise to help you get the job done right. Don’t settle for second-best when it comes to your engine’s health—choose parts that deliver performance, reliability, and long-term value.

For more info:-

Facebook

0 notes

Text

Top Reasons to Invest in a Box Compression Tester

Source of Info: https://www.perfectgroupindia.co.in/blog/top-reasons-to-invest-in-a-box-compression-tester

Introduction

A Box Compression Tester is a valuable tool for businesses searching to obtain perfect strength and quality of their packaging materials. This modern device allows manufacturers to improve product safety during storage and transportation by analyzing the compression protest of boxes. Finding this equipment reduces the possibility of damage and customer dissatisfaction while also improving packaging quality. Knowing the best reasons to buy a Compression tester will help you improve quality control, reduce expenses, maintain a competitive advantage in the market, regardless of your industry requirements, e-commerce, or manufacturing.

Improve Packaging Strength A Box Compression Tester allows you to check your boxes are strong enough to withstand the pressure they will experience. The boxes need to be solid in structure whether they are being transported over long distances or set up in a storage space. This tool gives accurate details about the maximum weight a box can support. Businesses can make sure they are using the proper materials to make accurate and strong boxes in this way.

Prevents Product Damage Customers become dissatisfied when products are damaged and boxes are crushed by unsuitable packaging. You will avoid these problems by using a Box Compression Tester to confirm the box's strength in advance. Products stay safe during shipping when the boxes are strong, and companies save money by reducing the chances of returns, supplies, and complaints.

Supports Compliance with Standards There are high packaging quality requirements for many industries. As an example, the e-commerce, food, and medicine sectors need to make sure that their boxes fulfill certain strength standards. Businesses can guarantee compliance and avoid damages or product by choosing a Box Compression Tester, which allows them to test their boxes according to these international standards.

Improves Customer Satisfaction Customers expect their items to arrive in perfect condition. Products are guaranteed to be secured and delivered undamaged in a strong, durable box. Businesses can increase customer satisfaction and brand trust by using a Box Compression Tester to improve the quality of their packaging.

Reduces Wastage Weak boxes often damage items, used to waste. Companies create strong, accurate boxes to avoid product loss by investing in a Box Compression Tester. The machine helps in detecting faulty batches during production, allowing you to get off of weak boxes before they are used and further reducing down on material waste.

Enhances Cost-Effectiveness By testing the strength of packaging boxes, you can make sure that the proper amount of material is being used neither too little or too much. A tester helps in creating the perfect balance, guaranteeing cost savings through the use of the right material and avoiding unimportant investments.

Boosts Brand Reputation Packaging is often a customer's first personal contact with your brand. A product that is average packaged can give the wrong impression, but a strong and durable package improves the reputation of your company. By purchasing a Box Compression Tester, you can make sure that your boxes are up to high standards and present your company as trustworthy and quality.

Enables Better Decision-Making A Box Compression Tester gives you accurate information about how strong your packaging is. Making informed choices regarding production methods, box design, and materials is made easier with the use of this information. For example, you can easily modify your design or material to meet the strength requirements if your boxes don't pass the compression test. This guarantees the best possible packaging performance while saving time and money.

Adapts to Various Box Types You can use a Box Compression Tester to test different packaging designs and sizes, whether you're making cardboard boxes, cartons, or something else. The tester is a smart investment for many different industries because of its portability, which allows it to be used with a wide range of product lines.

Minimizes Transportation Losses Boxes are exposed to strong external forces like shocks, vibrations, and stacking pressures while in transport. Products may be damaged if weak boxes break down. To make sure your boxes can withstand transportation difficulties, you can recreate such situations using a compression tester. By doing this, damage is reduced and products are delivered to clients in the condition they were meant to be in.

Simple to Use The user-friendly interfaces of modern testers make them simple to use. The machine produces results quickly, and the testing process is simple. Your team can use this device properly even with no experience, which will help you improve your packaging quality checks.

Supports Business Growth Investing in equipment that improves the quality of products is a step toward long-term achievement. In addition to improving your packaging, a Box Compression Tester helps your business expand overall. Delivering outstanding products in safe packaging gives you a competitive advantage, supports customer trust, and creates new growth.

Conclusion To guarantee the strength and quality of packaging, it is important to purchase a Box Compression Tester. This innovative testing instrument helps companies avoid damage during storage and transportation by giving accurate details about how durable boxes are. It helps with cost reduction, product safety, and packaging material optimization by choosing the load capacity. An important instrument for businesses searching for dependable, productive packaging solutions is a tester. Use this modern device to improve the quality of your packaging right now and protect your items like never before. You can choose a perfect group india to be accurate and meet the demands of modern packaging.

#industrial#equipments#perfectgroupindia#perfectinstruments#technology#droptester#business#boxcampressiontester

0 notes

Text

Tired of Cracks and Gaps Under Heavy Equipment? Here’s the Solution | ADT Industries Pvt. Ltd.

Industrial floors, loading bays, and machine foundations are constantly exposed to extreme loads and vibration. Over time, this stress leads to the development of cracks, gaps, and surface degradation—posing safety risks and compromising the integrity of the structure. If you're facing these issues, it's time to consider a professional-grade repair and protection solution. At ADT Industries Pvt. Ltd., we specialize in high-performance construction chemicals designed to withstand the toughest industrial conditions.

Understanding the Problem Heavy-duty environments such as warehouses, manufacturing plants, and equipment platforms demand durable flooring systems. Constant mechanical movement, dynamic loading, and thermal expansion contribute to cracks and voids, which can:

Damage expensive machinery

Cause uneven surfaces and trip hazards

Allow water, oil, or chemical seepage

Lead to costly downtime and repairs

The ADT Industries Solution At ADT Industries Pvt. Ltd., we offer a range of crack fillers, gap sealants, and high-strength repair mortars engineered specifically for industrial use. Our products are formulated to deliver:

Exceptional compressive strength

Resistance to oil, chemicals, and abrasion

Fast-setting properties for minimal downtime

Long-term structural integrity

Whether you need to fill expansion joints, repair cracks under machines, or level out uneven surfaces, our expert-recommended solutions ensure a smooth, safe, and durable finish.

Product Highlight – ADT Epoxy Crack Filler & Repair Mortar Our epoxy-based fillers and polymer-modified mortars are ideal for repairing deep cracks and gaps under heavy equipment. These products offer superior bonding with concrete, excellent load-bearing capacity, and resistance to industrial wear and tear.

Key Benefits:

Load-resistant and vibration-tolerant

No shrinkage or cracking after curing

Easy application and fast curing time

Ideal for high-traffic and high-load zones

Industries We Serve:

Engineering & Manufacturing Facilities

Warehousing & Logistics Hubs

Food & Beverage Plants

Power Plants & Substations

Heavy Equipment Foundations

Why ADT Industries Pvt. Ltd.? As one of India’s leading manufacturers and suppliers of construction and waterproofing chemicals, we pride ourselves on delivering solutions backed by technical expertise, product innovation, and consistent quality. Our materials are tested under rigorous conditions to ensure they perform reliably in even the most demanding environments.

Conclusion Cracks and gaps under heavy equipment are not just cosmetic—they're a sign of deeper structural stress. ADT Industries Pvt. Ltd. offers industry-grade products to restore and protect your facility's flooring and foundation. Trust us to help you maintain safety, performance, and longevity with solutions that work as hard as your equipment does.

Get in Touch To learn more or request a product consultation, contact our technical support team today. ADT Industries Pvt. Ltd. – Strength You Can Build On.

0 notes