#Easymethod

Explore tagged Tumblr posts

Text

How to use QR Codes in Your Business?

In today’s dynamic digital landscape, all kinds of businesses are looking for new creative ways to communicate with customers. This one tool quick response code has created an impact in the industry. QR codes are now used nearly everywhere: e-menus in hotels, virtual business cards, customer feedback, and boarding passes at the airport. Regardless of the growing popularity of this new technology, every business owner should consider several factors when utilizing this technology to ensure a positive customer experience. Qrtli is making it easy for the business to provide information quickly to consumers. Here are a few key points every business should keep in mind beforehand. 1. Marketing and promotions: By incorporating QR codes through a QR code generator into your print materials, you can offer exclusive discounts or special promotions directly to customers. Additionally, these codes can seamlessly direct customers to event registration pages, allowing for quick and easy sign-ups with just a scan. Furthermore, you can encourage customers to follow your social media profiles by linking them through a QR code, making it effortless for them to engage with your brand online. 2. Networking opportunities: Elevate your networking game by incorporating QR codes into your business cards. Out of many ways you can link the codes to your LinkedIn profile, portfolio, or website, and easily connect with potential customers or clients. Also adding the code to the email signature can help in the access of professional information. 3. Streamlined Transactions: Now we see every small to big business owners use QR codes for payment. The cashless transaction through QR codes has been successful over time. A lot of restaurants use it for digital menus, allowing diners to browse options without the need for physical menus. All these methods enhance convenience and safety. 4. Event management: Utilize voucher codes through a voucher generator to simplify event registrations by directing customers to sign-up pages with just a scan. This quick and convenient method enhances user experience, allowing attendees to register effortlessly and securely, ultimately increasing participation and streamlining your event management process. 5. Enhance Product Information: Incorporate QR codes into your product packaging to provide customers with easy access to detailed information, usage instructions, and how-to videos. This addition not only enriches the shopping experience but also empowers customers to make informed decisions about their purchases. By offering valuable resources at their fingertips, you can enhance satisfaction and build trust in your brand. 6. Drive Traffic to Your Website: Incorporate QR codes into your print advertisements to seamlessly direct potential customers to your website. This innovative approach not only enhances online visibility but also simplifies the process for interested viewers to learn more about your offerings. By providing a quick and convenient way to access your site, you can effectively drive traffic, increase engagement, and ultimately boost conversions, making your marketing efforts more impactful and accessible.

7. Resource sharing in education:

QR codes in education facilitate resource sharing and navigation by providing quick access to digital content. Teachers can place QR codes in classrooms or on assignments, linking to videos, articles, or interactive activities. This method enhances student engagement, promotes self-directed learning, and streamlines access to supplementary materials, making it easier for students to explore and understand complex subjects. QR codes offer businesses a unique opportunity to enhance customer engagement, streamline processes, and boost sales. By implementing QR codes creatively and strategically, companies can foster stronger connections with their audience, making it easier for customers to access information, promotions, and services. Whether used for marketing, payment processing, or resource sharing, QR codes help businesses stay ahead in today’s competitive marketplace. Embrace this dynamic tool to transform your operations and elevate customer experiences. Discover the potential of QR codes and unlock new opportunities for growth with qrtli, your partner in maximizing the benefits of this innovative technology.

#qrcode#dynamiccode#staticcode#qrtli#Scannow#Createnow#Marketing#Trending#viral#Eventmanagement#Easymethod#Securemethod

1 note

·

View note

Text

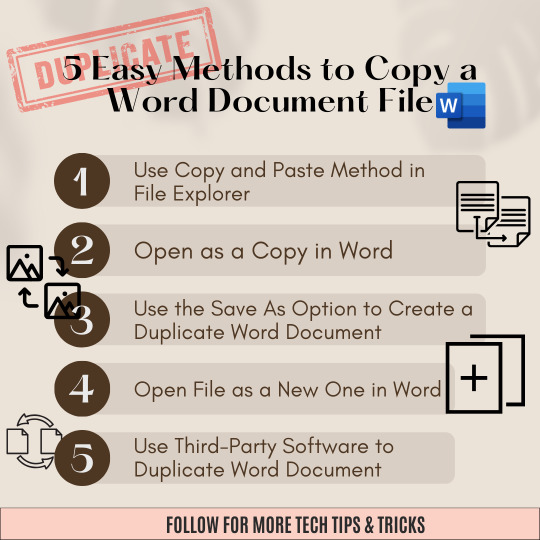

5 Easy Methods to Copy a Word Document File

👀🔎Looking to copy a Word document file without any hassle?📑

✅5⃣ Check out these 5 Easy Methods 📝🔄 - perfect for students, professionals, or anyone in need of a quick solution💡💻

👋Say goodbye to formatting issues🚫and hello to seamless copying♻️ 🙌📄

#wordtips#documentcopying#easymethods#productivitytips#workfromhome#officehacks#studentlife#lifeskills#howto#microsoftword#worddocuments#msword#copyandpaste#duplicate#duplication#backup#techtips#wordtutorial#newdocument#lifesaver#timesaver#youneedtoknowthis

0 notes

Text

Double Boiler Myths Exposed: Funny Chef's Easy Method

Double Boiler Myths Exposed: Funny Chef's Easy Method https://www.youtube.com/watch?v=ajUhupwoKiE ***Full video premiering 1/19/24!! Subscribe and hit the bell to be reminded!**** In this hilarious short video, Funny Chef debunks the myths surrounding the double boiler method. With his signature humor, he calms your fears and demonstrates the easy way to use this technique. Learn how to melt chocolate, heat sauces, and more without the risk of burning or clumping. Funny Chef's entertaining demonstration will leave you confident and ready to tackle any recipe that calls for a double boiler. Say goodbye to the confusion and embrace the simplicity with this informative and funny tutorial! #DoubleBoilerMythsExposed #FunnyChef #CalmsFears #Humor #EasyMethod #MeltChocolate #HeatSauces #RiskOfBurning #RiskOfClumping #EntertainingDemonstration #Confident #Informative #FunnyTutorial via Comedy Kitchen With Chef Cell https://www.youtube.com/channel/UCTEEUTpbWCowJm1b6FxC7IQ January 17, 2024 at 06:24PM

#chickenfried#glutenfree#wontons#lowcarbbread#ketobread#keto#loudbuffalo#deliciously#chickenfriedwontons

0 notes

Text

https://bit.ly/3Cw6jmj

2 Methods to lock and unlock PDF file easily

0 notes

Photo

Try this easiest way of getting your answers.. Blessed be all Love Zinia www.reikiflames.com #waterdivination #easymethod #watermagick #healer #whitewitch #reikiflames #ziniamorwall (at Pune,Mumbai,Maharashtra) https://www.instagram.com/p/CA27QeshNOp/?igshid=ti5w334pxrci

0 notes

Link

In this Video, I am explaining the very easy and fast multiplication short tricks of any 2 number in seconds. If you are preparing for any government exam like SSC, Bank PO, Clerk, Railway then without fast calculation you can't crack the exam.

Please watch full video to learn maths short tricks to do fast multiplication of any number.

0 notes

Text

Teaching children an easy way to draw different animals

A video blog by Pinki Kumar on teaching our children an easy way to draw different animals. Author Pinki Kumar Pinki is a special educator, play therapist and a mother of a neurodivergent kid. She has a YouTube channel Play and learn to teach different methods and strategies. These videos are a great resource for the parents to help their child learn various skills.

View On WordPress

0 notes

Video

youtube

How To Make $600 Per Day For FREE - Easy Method!!! 💰Worldwide Method - A...

#howtomake600perdayeasymethod#worldwidemethod#easymethod#makemoneyonlinefast#makemoneyonlinefast2020#sidehustles#affiliatemarketing#onlinejobs#easypaypalmoney#easypaypalmoney2020#makemoneyonline2020fast#sidehustleideas#digitaldave

0 notes

Video

Are you a student ??? or want to make some extra cash ??Watch this video.

0 notes

Video

⌛ Easy Method Easy Faluda #shorts #trending #viral #easymethod #srilanka...

0 notes

Text

Binding is oval in shape with a broad strong backbone ideally suited

Plastic Comb Binding is a versatile and easymethod of securing loose pages into attractive, professionally bounddocuments. Its open-flat/lay-flat capabilities allow the user to workon financial documents with ease; and the structure of the elementallows documents to be easily reopened and updated or copied, whileremaining reusable, making it unique from all other binding elements.The extensive customization capabilities on the backbone of the bindingelement assure recognition while on the reader's shelf. The economicalform of "advertising" also makes Plastic Comb Binding unique from allother binding elements available. GBC / Ibico's Plastic Comb Binding elements are made from rigidPolyvinyl Chloride (PVC) sheeting. The individual rings are spaced9/16" center-to-center,Wholesale Kitchen Wet Wipes and the elements are available in lengths up to28 rings. GBC / Ibico controls the manufacturer of comb binding elements from rawmaterial to the finished product.

Special processes and manufacturingtechniques are used to produce high quality PVC sheeting to meet rigidspecifications. Other ingredients are added to raw PVC resins toimprove the color, elasticity, impact strength, stress-crack resistanceand tensile strength. To manufacture comb binding supplies, the PVC resins and otheringredients are mixed in a "blender". From the blender, this compoundis fed into an extruder, which produces mother rolls of plastic. Thegauge tolerance of the extruded sheeting is controlled to withinone-thousandth of an inch. These mother rolls are slit to the variouswidths needed for each diameter. The slit rolls are fed into theblanking equipment which produces flat combs or blanks, and the blanksare automatically rolled by rolling machines The cover supplies for Comb binding range from economical sturdy grainpaper covers to boardroom quality Regency covers, as well as unlimitednon-standard stocks for custom covers.

Hardcases and Vinyl and Polycovers are also available for use with Plastic Comb Binding when ultraimage or extra-heavy durability is required. Comb binding supplies are available in two primary styles: round combswhich are sometimes referred to as wideback combs or cerlox and ovalcombs which are sometimes referred to as surelox. Round Combs or widback combs are the most popular comb binding element.They are particularly suited for use with two piece covers because thewide backbone extends the full length of the book and protects theedges of the pages. Imprinting on the backbone may be used foridentification of the contents, or for advertising of a company name orslogan. These combs are available in twelve diameters from 3/16" to1-1/8". Oval Combs or surelox elements provide the strength and dependabilitynecessary to successfully bind thick documents. This element has twounique locks, designed by GBC / Ibico, which prevent documents fromopening up.

Plastic Binding is oval in shape with a broad strongbackbone ideally suited for imprinting. Oval combs are available infour sizes including: 1-1/4", 1-1/2", 1-3/4" and 2" To lock oval plastic combs, grasp the comb binding element so that thebackbone is facing upward and the "T" shaped hole in the corner of thebackbone is facing you. Squeeze the backbone, compressing it into a "U"shape. Place the tip of the end ring into the outer side of the "T"shaped hole. Release the backbone of the element and the ring will lockinto place within the hole. Practice this procedure several times withan empty comb binding spine to get the hang of it. Simply reverse theprocedure to unlock.

0 notes

Text

They are particularly suited for use with two piece covers

Plastic Comb Binding is a versatile and easymethod of securing loose pages into attractive, professionally bounddocuments. Its open-flat/lay-flat capabilities allow the user to workon financial documents with ease; and the structure of the elementallows documents to be easily reopened and updated or copied, whileremaining reusable, making it unique from all other binding elements.The extensive customization capabilities on the backbone of the bindingelement assure recognition while on the reader's shelf. The economicalform of "advertising" also makes Plastic Comb Binding unique from allother binding elements available. GBC / Ibico's Plastic Comb Binding custom cnc machining elements are made from rigidPolyvinyl Chloride (PVC) sheeting. The individual rings are spaced9/16" center-to-center, and the elements are available in lengths up to28 rings. GBC / Ibico controls the manufacturer of comb binding elements from rawmaterial to the finished product. Special processes and manufacturingtechniques are used to produce high quality PVC sheeting to meet rigidspecifications.

Other ingredients are added to raw PVC resins toimprove the color, elasticity, impact strength, stress-crack resistanceand tensile strength. To manufacture comb binding supplies, the PVC resins and otheringredients are mixed in a "blender". From the blender, this compoundis fed into an extruder, which produces mother rolls of plastic. Thegauge tolerance of the extruded sheeting is controlled to withinone-thousandth of an inch. These mother rolls are slit to the variouswidths needed for each diameter. The slit rolls are fed into theblanking equipment which produces flat combs or blanks, and the blanksare automatically rolled by rolling machines The cover supplies for Comb binding range from economical sturdy grainpaper covers to boardroom quality Regency covers, as well as unlimitednon-standard stocks for custom covers. Hardcases and Vinyl and Polycovers are also available for use with Plastic Comb Binding when ultraimage or extra-heavy durability is required. Comb binding supplies are available in two primary styles: round combswhich are sometimes referred to as wideback combs or cerlox and ovalcombs which are sometimes referred to as surelox. Round Combs or widback combs are the most popular comb binding element.

They are particularly suited for use with two piece covers because thewide backbone extends the full length of the book and protects theedges of the pages. Imprinting on the backbone may be used foridentification of the contents, or for advertising of a company name orslogan. These combs are available in twelve diameters from 3/16" to1-1/8". Oval Combs or surelox elements provide the strength and dependabilitynecessary to successfully bind thick documents. This element has twounique locks, designed by GBC / Ibico, which prevent documents fromopening up. Plastic Binding is oval in shape with a broad strongbackbone ideally suited for imprinting. Oval combs are available infour sizes including: 1-1/4", 1-1/2", 1-3/4" and 2" To lock oval plastic combs, grasp the comb binding element so that thebackbone is facing upward and the "T" shaped hole in the corner of thebackbone is facing you. Squeeze the backbone, compressing it into a "U"shape. Place the tip of the end ring into the outer side of the "T"shaped hole. Release the backbone of the element and the ring will lockinto place within the hole. Practice this procedure several times withan empty comb binding spine to get the hang of it. Simply reverse theprocedure to unlock.

0 notes

Photo

Easymethod of forced labour and slavery? Childnapping, isolation and mental abuse. https://www.instagram.com/p/CfBI88BMleI/?igshid=NGJjMDIxMWI=

0 notes

Text

Safety and Automation of Collaborative Robot System in Work Environment- Juniper Publishers

Summary

A few factors are important for determining the effects of automation on the work environment, including the technological design and applications, approaches used for their presentation, and the automation goals of the organization’s management team. The application of robotics and automation to industrial processes provide optimization benefits relative to the work processes, however, the potential also exist for new situations to develop that may introduce system risks and human psychological risks to the employees. The main goal is to plan, design and implement robotic and automation programs that will be beneficial to the workforce, improving productivity, safety and quality.

The application and implementation of modern industrial automation and robotics systems may potentially pose a challenge and perhaps unpromising combination of requirements. It is logical to expect that control systems must generally interface with sensor or actuator signals, which is germane to other modern applications. For most modern industrial applications, such as programmable automation (PA), advanced control features (ACF), enterprise data integration (EDI), robotic cells interoperability (RCI) and network connectivity, there has been increasing demand for their use. The innovative edge in industrial robotics and automation involve accessible and user-friendly collaborative robot (cobots) solutions[1], that allow the human workforce and robots cells to share skills towards achieving same goal. The human workforce performance adds to this collaboration with the inherent cognitive skills and opportunities for flexibility, while the robotic systems bring high powered speed, accuracy, precision and repeatability. To efficiently optimize this collaborative set-up, there are a few challenges that should be addressed. All direct contacts between the workers and the operational robotic cells must be prevented to assure safe interaction and collaboration. Capitalizing on the benefits of human cognitive skills, it is crucial to correctly plan and design all spontaneous operator interfaces, with special considerations for safety critical systems, making it easy and safe for the operators to program and interact with the robotic cells.

Introduction

The global annual industrial robots supply is predicted to increase at the rate of 13% and it was estimated that 2.6 million industrial robots will be operational by 2019 [2], with highest demands in the automotive and electronic industries. Other small and medium scale companies are beginning to also employ the collaborative solutions of using both robots and human skills. Majority of the design and development efforts for human-friendly, safe and adaptable automation and robotic are from industrial manufacturing. To be at the competitive advantage in today’s marketplace, the manufacturing industry rely on automation and robotics to stay ahead. The concept of robots can be traced as far back as to the beginning of civilization. Aristotle conceptualized in 322 B.C., the emergence of an intelligent tool that “when ordered or even of its own accord, could do the work that befits it.” Fast forward to the 20 century, the 1960’s marked the emergence of industrial robots on assembly lines of America’s automobile manufacturing companies. Currently, there are several major advancements and technological breakthroughs that have integrated control systems and automation innovations, artificial intelligence (AI) methodologies and microprocessors, to optimize the functionality of robots, expanding to other fields such as medicine, agriculture, transportation etc. These technological advancements in the design of automated robots have not been able to completely eradicate the potential for risks for cobot and traditional robot (trabot), see Figure 1. A fault to a safety critical system of a robot can pose fatal or serious injuries to humans and may also result to the loss of capital investments in the machines [3].

Safety Critical Systems

A Safety Critical System (SCS) is a system that can potentially cause accidents directly or indirectly, once failed. These failures can potentially causefatalities, environmental damages and property/financial losses. The overall system must be safe which depends on proper operations of the robot and examples of SCS include; production industries (manufacturing controls, interlocking systems, maintenance and application of robotic cells), process industry (chemical process control, energy and power generation etc.), medicine (medical robotic cell controls, radiation therapy systems etc.). Identification systems, programmable logic controllers (PLC), industrial and power controls systems, sensor systems are examples of automation technologies currently widely used. The automation of SCS operationsinvolved embedded control systems which applies to both the hardware and software components including the devices, equipment, electrical and mechanical components. Whenever these software and hardware are employed for SCS control, there is a potential for these components to pose imminent hazards to operators or anyone in the zone of exposure of the systems. The automation is dependent on the software capabilities and the proper development and design of the software will produce efficient operation with capabilities of anticipating, detecting and eliminating potential hazards that may contribute to software errors of the SCS, hence protecting people, property and the environment.

The complexities, sophistication and requirements for robotic systems are addressed for the automation and robotics industry through the International Organization for Standardization (ISO) for robots and robot systems integration. ISO 10218-1:2006 - specifies the requirements and guidance for the assurance of safety in design and construction of the robot only (manipulator and controller) and not the overall robot system. The standard was updated in 2011 as Part 2 - or ISO 10218-2:2011, which includes the robot system/cell and application. It also covers the integration and installation of robot system or cell, which therefore means that it provides a more comprehensive set of requirements for robot safety. ISO TS 15066:2016 provides the technical specification of safety requirements for collaborative industrial robot systems in the work environment and it also provides supplementary requirements and guidance on collaborative industrial robot operations (does not apply to non-industrial robots) in the ISO 10218-1:2006 and ISO 10218-2:2011. ANSI/RIA R15.06-2012 is an adaptation of the 10218-2:2011.

Industry 4.0Initiative and Intuitive User Interfaces

In today’s high-speed high accuracy economy, manufacturing companies continue to drive for increased efficiency, production speed, quality and workforce safety, cobot can be significantly effective in protecting workers, at same time, increasing outputs and decreasing the operational costs and associated expenses. In manufacturing technologies, the contemporary trend in automation and data exchange which makes production system smarter is known as Industry 4.0 and it also involves the use of collaborative robotic solutions [4]. Industry 4.0 presents transparency which is crucial for efficient supply chain. The benefits of industry 4.0 are as follows;

a) Process efficiency: Automation, robotics and digitalization reduce redundancy and increase flexibility through optimization solutions.

b) Increased production and quality: The product quantity and quality can be enhanced throughintegrated automation, real-time monitoring and quick intervention for the correction of system errors.

c) Cost reduction and energy savings: Industry 4.0 increases overall process efficiency which in turn, yields direct energy and cost savings.

d) Less human intervention: With robots taking over repetitive manual jobs, humans can be used for more skillful tasks.

e) Competitive advantage: Industry 4.0is promising to become indispensable and companies that adopt this strategy stand to gain and become a leader in the industry.

f) Personalization: Products can be safely and quickly made based on thecustomer’sneeds and current trends.

The application of cobot for industrial processes is valuablesince the system can be trained through intuitive systems, usingprogramming by demonstration [5], augmented reality [6], walkthrough programming [7] etc. In contrast, traditional non-cobots usually require experts to program the robotic cell using the conventional programming methodologies. There are challenges involved with the use of robots for industrial processes, one of which is often associated with operator interactions with the robot, since it typically entails specialized knowledge. Equally, the availability of intuitive procedures of interactions with robots through proper programming is a significant enabler for continuousimplementation of automation and robotic technologies, which would also benefit small and medium sized companies. Easymethods of interactions with industrial robots in a timely fashion that also reducesoperator’s errors and preserves situational awareness, are required.

Optimizing Safety with Smarter Robots

Safety is crucial for products and system designs particularly at collaborative work areas, where robots operate alongside humans. The safety and reliability of robotic systems are integral to optimal solution developments for future practical challenges in robotic design for human situations [8]. The developmentand evolution of automation processes and robotics are crucial to the changing world. The first developed industrial robots were huge, hydraulically powered machines. The early robots lacked intelligence without the operator’s assistance, though they functioned withsubstantial strength. Industrial robots evolved into electrically powered standalone units, with enhancedperformance and accuracy in the 1980’s. The continuous improvements to microprocessors and innovations to automated control technologies have positioned robots as the center-piece tool for industrial revolution.

Human-Robot Collaboration (HrC)

The human-robots interaction is being transformed due to the advent of innovative software and SCS functionality [9]. Conventionally, people were protected from being hurt, injured or killed from the action of a moving robot, by using either of the hazard control methods that include elimination, substitution, warnings, engineering control (safe guards and barriers), administrative control (e.g. training) or protective equipment. Whenever an operator interfaces with the robot (for instance loading or unloading of materials), safety control systems (such as., light screen, safety mat, other presence sensing devices) would have to be in place guarantee that the robot is in a safety position and state. Basically, the robot’s motion is conditioned and eventually, the energy source is removed, and the robot then stops completely. The effect of which slows down production. Innovations in software-based SCS have produced safe-speed core technology that allows for the manipulation of the robot’s operational motion, so that humans can share the workspace together. In the same work area, robots could bring heavy slabs closer, while the skilled operator marks them, though this process would have to take place only if there are environmental sensors or presence sensing sensors in the work zone. Never technologies now also allow for Robot-to-Robot Synchronization(r2rS). This happens when one robot is programmed to coordinate the actions of multiple other robots. The combination of HrC and r2rS can significantly reduce down time, increase productivity and further enhances safety.

Conclusion and future directions of research

To address safety related issues for automation and robotics, it is important to consider optimizing performance relative to the limits of safety rather than classifying safety as a criterion that limits performance, therefore the use of performance-oriented solutions should be desired.

Furthermore, enhancing the effectiveness of HrC in actual industrial situations is the primerfor adaptive solutions for comprehensive robotics [10]. Animpendinggoal in the research and development community is to automate robots and equip them with suitable cognitive processing skills and collectiveindependent proficiencies, thereforereleasing or complimenting thecognitive efforts of human operators, particularly in intricate tasks and situations.

For More Open Access Journals Please Click on: Juniper Publishers

Fore More Articles Please Visit: Robotics & Automation Engineering Journal

0 notes

Video

instagram

How to open a bottle of wine with your shoe 😊 . . . #WineHacks #Wine #WineBottle #BottleOfWine #HowToOpenABottleOfWine #LifeHacks #EasyMethods #DIY #DoItYourself #WineTricks #Hacks #Tricks #Methods #WineBlogger #WineTales https://www.instagram.com/p/BtxzSu8Hp7Z/?utm_source=ig_tumblr_share&igshid=d15w3xwqak4g

#winehacks#wine#winebottle#bottleofwine#howtoopenabottleofwine#lifehacks#easymethods#diy#doityourself#winetricks#hacks#tricks#methods#wineblogger#winetales

0 notes