#EtherCat servo drive and controller

Explore tagged Tumblr posts

Text

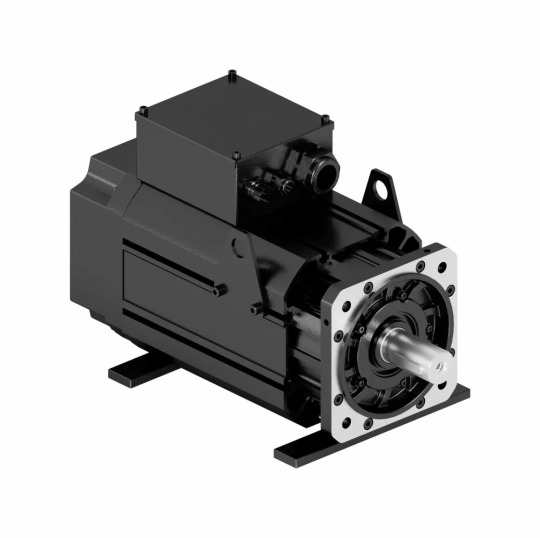

Small Servo Motors and Drives: Big Performance in a Compact Package

When you think of high-precision motion systems, it's easy to imagine large, complex machines operating in sprawling factories. But what about applications where space is limited, yet the demand for performance remains sky-high? This is where small servo motors and drives come into play—offering the same precision and control as their larger counterparts, in a much smaller footprint.

At their core, small servo systems provide closed-loop motion control using a servo motor and a dedicated drive. The combination ensures that position, speed, and torque are tightly managed, which is essential in applications like robotics, medical equipment, lab automation, and compact assembly lines.

1. Miniature Size, Maximum Accuracy

Don’t let their size fool you—small servo motors are engineered to deliver incredible accuracy. With high-resolution encoders and fast feedback loops, these motors can achieve micron-level precision. For industries where detail matters—like electronics, 3D printing, or optical manufacturing—this is a critical advantage.

2. Space-Saving, Cost-Saving

One of the biggest advantages of small servo motors and drives is their ability to save valuable space. Compact control cabinets, lightweight end-of-arm tools, and portable machines benefit greatly from these scaled-down systems.

But space isn’t the only thing saved—costs come down too. Smaller systems typically consume less power, generate less heat, and require fewer support components, making them more efficient both operationally and financially.

3. Highly Responsive for Delicate Tasks

In precision operations such as dosing, cutting, or delicate part manipulation, speed without control is useless. THM Huade’s small servo motors and drives are built for fast, intelligent response to changing loads or commands. Whether you’re operating a miniature conveyor belt or a robotic gripper, every movement is smooth and predictable.

4. Plug-and-Play Integration

Small servo drives from THM Huade come with user-friendly interfaces and are compatible with popular industrial control systems like EtherCAT and Modbus. The drives support both position and torque modes and offer configuration flexibility, so you can adapt them easily to a wide variety of compact machinery.

5. Built for Versatility

These small systems might be designed for tight spaces, but their capabilities are expansive. From lab automation to packaging equipment, and from laser cutters to textile machines—small servo motors and drives prove themselves in virtually any application where precision and footprint matter.

Why Choose THM Huade?

At THM Huade, we understand the challenges of fitting high-performance automation into limited space. Our small servo motors and drives are designed with engineers and integrators in mind—offering powerful functionality, long-term reliability, and seamless integration with your existing systems.

Backed by technical support and decades of industry experience, our solutions are built to help you scale precision, not just machinery.

💡 Interested in upgrading your compact motion system with intelligent servo technology? Visit THM Huade to discover small servo motors and drives that deliver big results in tight spaces.

#SmallServoMotors#ServoDrives#THMHuade#PrecisionAutomation#CompactMachinery#MiniServoSystems#SmartManufacturing#MotionControlTech#IndustrialAutomation#HighPrecisionDrives

0 notes

Text

Unlock Precision and Speed with Expert Laser Cutting Machine Manufacturers

Boundless Innovation in Each Cut with the Best Laser Cutting Machine Manufacturers.

Discover our dual-pallet laser cutting machines, engineered for high-speed production and reduced downtime. As reliable Laser Cutting Machine Manufacturers, we ensure that our machines come with simultaneous load/unload features to streamline workflow without sacrificing top cut quality. Optimized nesting software provides precision, burr-free cuts up to 50mm thickness, with no warping or tapering.

Key Performance Features of your most trusted Laser Cutting Machine Manufacturers.

As premier Laser Cutting Machine Manufacturers, we provide high-performance systems for efficiency, accuracy and flexibility. Our machines include a double pallet system, enabling quick job changing with simultaneous loading and unloading to increase throughput.

With micron-grade precision, they are ideal for fine detailing and precise contour cutting. Higher cutting speeds utilizing high-speed fibre lasers and motion control units allow greater productivity for various applications. The capacity to cut multi-materials is assured to deliver clean and precise cuts in mild steel, stainless steel, aluminium, copper and others.

A streamlined, user-friendly interface constantly improved by software updates and user input guarantees usability. Heavy-duty construction delivers vibration-free stability, even in continuous working situations and power-saving fibre lasers reduce long-term operating expenses.

Integrated safety solutions, such as emergency stop functionality and safety enclosures, guarantee safe operation. Available in configurations with different laser powers and table sizes, our equipment fulfils unique workflow needs.

Cut quality is sustained at high velocities with Fly Cut technology and our end-to-end support features technical support, web-based troubleshooting and predictive maintenance software.

Technical Specifications of the best Laser Cutting Machine Manufacturers at a Glance.

The Winarc two-pallet fibre laser sheet cutting machine is designed to deal with an extensive series of sheet sizes with a work length from 3000 mm to 8000 mm and a width from 1500 mm to 3000 mm. It has an axis speed up to 120 meters per minute, yet at the same time achieves a delicate positional accuracy of ±0.03 mm, which is ideal for bulk precision processing.

Driven by Ethercat networking, it provides real-time responsiveness for precise and efficient functioning. The machine accommodates laser powers ranging from 2 kw to 20 kw, with the flexibility to cut materials of different thicknesses. It is also fully integrated with CypNest, Radan and SigmaNest CAD-CAM software to enable precise nesting, seamless programming and optimum material utilization.

Winmaster dual-pallet laser cutting machines are equipped with globally recognized components to ensure maximum durability, accuracy and productivity in demanding industrial environments.

Fibre Laser Source

Brands: Raycus, IPG, Max, Trumpf

These best-in-class sources provide superior beam quality, low maintenance and reliable performance across metals.

CNC Control System

Brands: Cypcut, Eckelmann

User-friendly interfaces paired with high-speed processing allow for responsive and precise control.

Linear Guides & Bearings

Brands: Hiwin, CPC

Engineered for precision motion and long-lasting stability, ensuring high accuracy with every cut.

Servo Motors & Drives

Brand: Yaskawa

Renowned for fast acceleration and pinpoint control, boosting both speed and reliability.

Cooling Unit

Brands: Hanli, Hexacool, S&A

Ensures thermal stability, safeguards core components and extends service life.

Laser Cutting Head

Brands: Precited, Ray tools, WSX, Bochu

Designed for clean, efficient cutting with adaptive focusing and edge sharpness across material types.

0 notes

Text

How Advanced Servo Drives Improve Motion Control in Automation?

In the rapidly evolving world of industrial automation, Advanced Servo Drives play a crucial role in enhancing motion control, efficiency, and precision. These sophisticated drives offer seamless integration with robotic and automated systems, ensuring that machines perform with high accuracy and minimal downtime. As industries continue to push the boundaries of automation, companies like Oracle Robotics are pioneering innovative solutions to improve manufacturing processes through advanced motion control technology.

Understanding Advanced Servo Drives

Servo drives are essential components in motion control systems, responsible for regulating the torque, speed, and position of motors in automated machinery. Unlike traditional motor control systems, Advanced Servo Drives provide superior feedback mechanisms, allowing for precise adjustments based on real-time conditions. This level of control is critical in industries that require high-speed and high-precision operations, such as robotics, aerospace, automotive manufacturing, and electronics production.

Key Benefits of Advanced Servo Drives in Automation

1. Enhanced Precision and Accuracy

One of the most significant advantages of Advanced Servo Drives is their ability to deliver exceptional precision. By utilizing high-resolution encoders and sophisticated control algorithms, these drives can achieve extremely accurate positioning and motion control. This is particularly beneficial in applications such as CNC machining, robotic arms, and pick-and-place operations, where even minor deviations can lead to quality issues.

2. Higher Efficiency and Energy Savings

Energy efficiency is a top priority for modern industries aiming to reduce operational costs and minimize environmental impact. Advanced servo systems optimize energy consumption by dynamically adjusting motor output based on demand. Regenerative braking and energy recovery features further contribute to reducing power usage, making automation systems more sustainable and cost-effective.

3. Seamless Integration with Automation Systems

The latest Advanced Servo Drives are designed for easy integration with a variety of industrial automation platforms. They support multiple communication protocols such as EtherCAT, Modbus, and CANopen, ensuring compatibility with different control systems. This flexibility enables manufacturers to create highly customized and interconnected automation solutions tailored to their specific needs.

4. Increased Speed and Responsiveness

High-speed manufacturing processes demand fast and reliable motion control. Servo drives with advanced feedback and control mechanisms allow for rapid response times, reducing cycle times and increasing overall production output. Whether in conveyor systems, robotic automation, or material handling, these drives enhance operational speed without compromising accuracy.

5. Improved Reliability and Reduced Downtime

Downtime can be costly in any manufacturing setup. Advanced servo technology incorporates predictive maintenance capabilities, monitoring system health in real time to detect potential issues before they lead to failures. With self-diagnostic features and automated fault recovery, companies can prevent unexpected breakdowns and ensure continuous operation.

6. Adaptive Control and AI Integration

The future of Advanced Servo Drives lies in artificial intelligence (AI) and machine learning. Modern servo systems are incorporating AI-driven algorithms that can analyze performance data and adapt to changing conditions. This adaptive control improves efficiency, reduces wear and tear on components, and allows for real-time optimization of motion control processes.

Applications of Advanced Servo Drives in Industrial Automation

1. Robotics and Automated Assembly

In robotic automation, precise motion control is essential for tasks such as welding, assembly, and material handling. Servo drives enable robotic arms to move with high accuracy, improving consistency and reducing errors in production lines.

2. CNC Machining and Manufacturing

CNC machines rely on servo-driven motion control for precision cutting, drilling, and milling. With the help of Advanced Servo Drives, these machines achieve greater accuracy and smoother motion, leading to improved product quality and reduced material waste.

3. Packaging and Material Handling

From conveyor belt systems to automated packaging machinery, servo drives play a vital role in ensuring smooth and efficient movement of materials. Their ability to adjust speed and torque in real-time ensures seamless operation, reducing bottlenecks and increasing throughput.

4. Textile and Printing Industries

In textile manufacturing and high-speed printing applications, servo-driven motion control ensures precise fabric handling, accurate ink deposition, and synchronization of moving components. This results in consistent product quality and minimal defects.

The Future of Motion Control with Advanced Servo Drives

As industries continue to embrace automation, the demand for Advanced Servo Drives will only grow. Innovations in AI, IoT connectivity, and cloud-based monitoring will further enhance the capabilities of servo-driven systems, making them smarter and more efficient. Companies like Oracle Robotics are at the forefront of this technological revolution, providing cutting-edge motion control solutions that redefine the future of automation.

With continuous advancements in servo technology, manufacturers can expect even greater levels of precision, reliability, and energy efficiency. By integrating these sophisticated drives into their automation strategies, businesses can stay ahead of the competition, optimize production, and drive industrial progress into the future.

Conclusion

Advanced Servo Drives are transforming industrial automation by providing unparalleled precision, speed, and efficiency. From robotics to CNC machining and packaging, these drives enhance motion control across various applications, improving productivity and reducing operational costs. As the industry moves towards smarter automation, embracing advanced servo technology will be key to achieving next-level manufacturing excellence. With leaders like Oracle Robotics driving innovation, the future of motion control is brighter than ever.

0 notes

Text

How to Select the Right Servo Drive for Your Application: A Comprehensive Guide

Servo drives are crucial components in modern automation systems, providing precise control of electric motors in various industrial applications. Selecting the right servo drive for your specific needs can significantly impact your system's efficiency, accuracy, and overall performance. With numerous options on the market, it's essential to understand the key factors involved in choosing the best servo drive for your application. In this guide, we'll walk you through the critical considerations and steps to help you make an informed decision.

1. Understand Your Application Requirements

The first step in selecting the right servo drive is to thoroughly understand your application’s specific requirements. Servo drives are used in a wide range of applications, from robotics and CNC machines to packaging equipment and automated conveyor systems. Each application has unique demands in terms of speed, torque, and precision.

Speed requirements: Determine the required speed range of your motor. Applications like conveyor systems may require constant speed, while robotics and CNC machines often need dynamic speed control for precise positioning.

Torque requirements: Torque is the force that the motor produces. Some applications, such as heavy-duty industrial machinery, require high torque, while others, like small assembly line robots, may need lower torque. Make sure the servo drive can handle the maximum torque required by your motor.

Precision and accuracy: For applications that require precise positioning or tight control over motor movements, such as pick-and-place machines or medical devices, you’ll need a servo drive that offers high resolution and accuracy.

By understanding these core requirements, you can narrow down your servo drive options to those that meet the specific needs of your application.

2. Match the Servo Drive to the Motor

Once you’ve identified your application’s needs, the next step is to ensure that the servo drive is compatible with your motor. Servo drives are designed to work with specific types of motors, such as brushed or brushless DC motors, stepper motors, or AC motors. Matching the drive to the motor is crucial for optimal performance.

Motor type: Verify that the servo drive you’re considering is compatible with the motor you plan to use. For instance, if you’re using a brushless DC motor, you’ll need a drive that supports this type of motor.

Power ratings: Check the voltage and current ratings of both the motor and the servo drive. The servo drive must provide enough power to drive the motor effectively. Using a drive with insufficient power can lead to underperformance, while overpowered drives may result in inefficiency and unnecessary costs.

Feedback mechanism: Many servo systems rely on feedback mechanisms, such as encoders or resolvers, to ensure accurate positioning and control. Ensure that your servo drive is compatible with the feedback devices used in your system, as this will directly impact the precision of motor control.

3. Consider Control Options and Communication Protocols

Servo drives offer various control options and communication protocols that allow them to integrate seamlessly into different automation systems. Depending on your application’s complexity and requirements, you may need advanced control features or specific communication interfaces.

Control modes: Servo drives typically offer different control modes, such as torque control, velocity control, and position control. Choose a drive that provides the control mode that best suits your application’s needs. For example, CNC machines often require precise position control, while conveyor systems might prioritize velocity control.

Communication protocols: Modern servo drives support a variety of communication protocols, including EtherCAT, CANopen, Modbus, and others. Ensure that the drive you select is compatible with your existing automation system’s communication infrastructure. If you’re integrating the drive into an advanced control system, selecting a drive with flexible communication options can simplify system integration and future scalability.

4. Evaluate Environmental Conditions

Environmental conditions can significantly impact the performance and longevity of your servo drive. Consider the following factors when selecting a servo drive for your application:

Temperature range: Some servo drives are designed to operate in extreme temperature conditions, while others are better suited for standard industrial environments. Make sure to choose a drive that can withstand the temperature range of your operating environment.

Ingress protection (IP) rating: The IP rating indicates the drive’s resistance to dust and moisture. For applications in harsh or outdoor environments, selecting a drive with a higher IP rating (e.g., IP65 or higher) can help protect the drive from damage caused by exposure to water or dust.

Vibration and shock: In applications with high levels of vibration or shock, such as automotive manufacturing or heavy machinery, choose a servo drive that is built to withstand these conditions. Drives designed for rugged environments often feature reinforced components and housings to ensure durability.

5. Plan for Scalability and Future Needs

When selecting a servo drive, it's essential to consider not only your current application but also future needs. Investing in a drive that can scale with your operations or accommodate potential upgrades can save you time and money down the line.

Expandability: If you anticipate needing additional axes of control or increased system complexity in the future, choose a servo drive that can be easily expanded or integrated into a more advanced system.

Software and firmware updates: Some servo drives offer upgradable firmware or software, allowing you to add new features or improve performance over time. Drives with strong manufacturer support and regular updates can provide greater longevity and adaptability.

Conclusion

Choosing the right servo drive for your application involves careful consideration of your specific requirements, motor compatibility, control options, environmental factors, and future scalability. By following this comprehensive guide, you can ensure that you select a servo drive that enhances the performance, efficiency, and reliability of your automation system. Whether you’re working with robotics, CNC machinery, or any other precision-driven application, the right servo drive can make all the difference in achieving your operational goals.

0 notes

Text

Beckhoff AX5206 Digital Compact Servo Drives

Beckhoff AX5206 Digital Compact Servo Drives 2-channel. The AX5000 two-channel servo drives offer optimal function, flexibility and cost-effectiveness. The components required for operation, such as power supply unit, EMC filter and DC link capacitors, are already integrated. The control loop, which has a cascaded structure, supports fast and highly dynamic positioning tasks. EtherCAT as a…

View On WordPress

0 notes

Text

Application Solution for FET3568J-C Robot Control System

The robot control system is a core component of modern robotics technology, enabling robots to perform various tasks and actions, ranging from industrial production to healthcare and even household services.

The robot control system is like the brain of the robot and is the primary component that determines its functions and performance. It is generally composed of four main parts: the robot controller (motion control), servo drives, IO modules, and power system.

In this article, we will explore the main features of the robot control system and the FET3568J-C industrial-grade SoM recommended by Forlinx Embedded as the main control platform for the robot controller. Give us an insight into the importance of robot control systems and their application in modern robotics.

The main functions of the robot control system include:

Path planning and motion control: The control system is responsible for planning the robot's path so that it can move through the environment and take appropriate actions.

Obstacle avoidance and safety: The control system can detect obstacles and take steps to avoid collisions. It can also implement an emergency stop program to ensure the safety of the robot.

Mission implementation: Robot control systems can perform a variety of tasks, including picking and placing objects, assembly, welding, cleaning, surveying, and more.

Autonomy: For autonomous robots, the control system possesses decision-making capabilities, allowing them to independently perform actions based on the environment and tasks at hand without the need for human intervention.

Communication: Control systems typically communicate with other devices or operators to receive commands, send status reports, or request help.

The robot controller is the core part of the robot, mainly controlling the robot's motion position, attitude and trajectory in the workspace, as well as the sequence of operation, etc.; each joint of the robot needs to synchronize and coordinate the operation in real-time, and the servo drive is indispensable to realize these complex actions; the IO module associates the digital input signals with the control signals of the system so that it can realize the control of the robot system; finally, the stable power supply system is the guarantee of the safe operation of the robot.

The robot controller is the core component used to manage and control the behavior of the robot. It is usually an embedded system responsible for receiving sensor data, executing control algorithms, making decisions about the robot's movements, and communicating with the external environment or the operator.

Meanwhile, the main role of the robot controller is to complete the computation and control of multi-axis motions, so the main controller of the robot controller needs to have a high-performance CPU, a built-in, real-time operating system, support for the EtherCAT industrial bus, and a rich set of functional interfaces.

Forlinx Embedded recommends using the FET3568J-C industrial-grade SoM as the main control platform for the robot controller. FET3568J-C SoM is designed and developed based on Rockchip RK3568J industrial-grade processor. The quad-core 64-bit Cortex-A55 architecture has a high frequency of up to 1.8GHz, providing powerful performance support.

It also features a built-in NPU with a calculation power of 1TOPS, capable of meeting lightweight edge AI computing demands. Additionally, it supports real-time patch Preempt rt87, reducing latency to10μs~50μs, which satisfies real-time requirements for various applications in the industrial field.

FET3568J-C computer on module supports a 2-lane Gigabit network. Customers can choose and port EtherCAT according to their own needs. If they need more than 2 lanes, which can be realized through the USB expansion; it is equipped with 3-lane CAN,2-lane CAN2.0,10-lane UART,4-lane SPI,16-lane PWM,5-way IIC, USB3.0,4G/5G, WiFi, LVDS and HDMI, etc. The rich high-speed interfaces make the function expansion and connection more efficient and simple.

Originally published at www.forlinx.net.

0 notes

Video

youtube

Variable Frequency Drives Explained - Darwin Motion VFD Basics

Variable Frequency Drives Explained - Darwin Motion VFD Basics

A variable frequency drive (VFD) is a type of motor controller that changes the frequency and voltage of an electric motor's power source. The VFD may also control the ramp-up and ramp-down of the motor during startup and shutdown.

Check out our drives:

Micro Drive- Matrix 900 DR Matrix 350 / Solar Drive DR Matrix 500 DR Matrix 680 DR Matrix 880

VFD Servo Drive High Frequency Drives Profinet Comunication Drives EtherCAT Communication Drives

Call/WhatsApp: +91 8956113099 , +61432112288 E-mail: [email protected]

#youtube#VFD ACDRIVE VARIABLEFREQUENCYDRIVE SERVODRIVE SOLARDRIVE SOLARVFD vsd inverter converter darwinmotion microdrive regenerativedrive highfrequ

0 notes

Link

EtherCAT Automation & Technology has been specially optimized to enable low-cost design, in case you add an EtherCAT interface to a sensor, I/O device, or embedded controller it should not significantly increase the device costs.

0 notes

Text

Manufacturing mangos and Melbourne Airport with Beckhoff

According to Gary Brown, electrical engineer at AIE Global, there is no “one size fits all” solution when it comes to Industry 4.0 concepts. From their headquarters in Lake Wendouree, Brown’s team has been using advanced methodology to promote Australian innovation through process control and automation systems since 1985. According to Brown, AIE Global was established by a group of engineers with the specific aim of supporting turnkey automation projects. For ten years, they have utilised Beckhoff Automation solutions such as PLCs with remote I/O, robotics, and machine vision technology. “The more I investigated the Beckhoff product range, the more I liked what they offered,” he said. “EtherCAT I/O has allowed us to considerably reduce installation costs without any latency issues, and their CPU performance has meant that running out of memory is a thing of the past.” In 2010, the business won its first project using Beckhoff HMI based PLC for the operation of a multi-axis window manufacturing machine. Since then, it has been involved across a number of large-scale industrial projects requiring tailored engineering support. At Melbourne Airport, AIE Global was contracted for the design and installation of a PLC and SCADA automation system for an eight-megawatt trigeneration plant. Using seven Beckhoff CX2020 CPU Modules, alongside TwinCAT software, this infrastructure was responsible for providing general-use hot water via four natural gas driven generators. The PLCs were used in the automation of each genset, plant control, and hot water reticulation. According to Brown, having local EtherCAT-distriubuted I/O for each generator reduced the amount of electrical wiring running into the central control room, and allowed for a smaller cabinet size. This allowed for substantial cost savings, without negative impacts on performance. Additionally, AIE Global specialises in the development of servo drives for machine automation, also implementing Beckhoff PLC control. These are used by multiple manufacturing sites, specifically on pipe bending applications. “One large Victorian manufacturer required an upgrade for a multi-axis servo machine used for pipe bending,” said Brown. “The Beckhoff C6015 was used to replace an old Windows XP-based controller; rach pipe bend profile now has its own spreadsheet recipe file which is created externally and loaded using a USB stick.” Brown stated that contributing to Australian innovation is a key pillar of AIE Global’s approach, and in 2019 their engineers supported the design and implementation of a world-first mango auto harvester, developed by the Institute of Future Farming Systems (a division of CQ University). Part of a fully integrated system, it employs advanced sensor technology to identify and pick fruit, relying on Beckhoff C6015 Ultra-Compact Industrial PC and Automation Device Specification (ADS) protocol for communication and vision processing. “Looking back on the projects we have done, I can’t help but be impressed by the performance of Beckhoff’s product range,” Brown said. “EtherCAT is fast, with unlimited expansion capability, and the IEC 61131 programming environment significantly maximises productivity. Their large selection of library extensions also offer additional functionality, and can be added any time without needing CPU upgrades.” He added that the Windows platform allows the use of TwinCAT and has proven to be useful for the handling of recipe files, allowing them to be readily edited by the customer post-installation. “Many other PLC brands hide their functionality in an endeavour to make them easier to use. That leaves the engineer frustrated when they don’t work, and the technical support is inadequate. Beckhoff ensures a high level of functionality, reliability, and cost efficiency, with excellent backup support from the Australian sales office.” Beckhoff Customer Video – AIE Global Source link Originally published at Melbourne News Vine

0 notes

Text

Why the World Is Turning to Small Servo Motors for Big Industrial Challenges

You’ve probably never looked twice at a small servo motor. It’s compact, quiet, and almost too unassuming to be a game-changer. But if you’re working in robotics, automation, or fluid power systems, that little motor might just be your secret weapon.

In this post, you’re going to explore how small servo motors are transforming industries—from precision manufacturing to energy-efficient hydraulics—and why your next system upgrade might be a lot more compact than you imagined. Whether you're designing a robotic arm or looking for smarter ways to power a hydraulic motor pump, this read will equip you with real insights and modern thinking.

Let’s dive in.

1. The Big Potential in a Small Servo Motor

Imagine needing precise control in a small space—like a robotic gripper, a micro CNC machine, or a medical automation device. That’s where the small servo motor thrives. These motors offer:

Compact size

High torque-to-weight ratio

Precise control over motion, speed, and position

What’s fascinating is how industries that once relied on bulky systems are now turning to miniaturized alternatives. This isn’t just about saving space—it’s about smarter control and energy savings.

If you’ve dealt with complex motion systems before, you know the headaches that come from bulky motors that lack finesse. With a small servo motor, those problems shrink, quite literally.

2. The Rise of Compact Power: How It’s Reshaping Automation

Let’s say you’re developing a lightweight industrial robot or building a portable device that requires high accuracy. Large motors just won’t cut it.

That’s why the demand for small servo motors has spiked in areas like:

Electronics assembly

Medical robotics

Portable packaging systems

Drones and inspection bots

Even in the hydraulic world—traditionally dominated by size and force—you’re now seeing a shift. Smart engineers are integrating small servo motors with small hydraulic pumps to get the best of both worlds: precision and power.

In companies like THM Huade, engineers often explore such hybrid solutions—melding servo control with hydraulics to meet modern demands without compromising on reliability.

3. Integrating Small Servo Motors with Small Hydraulic Pumps

Now, here’s where things get interesting.

You’ve got a small servo motor on one hand, and a small hydraulic pump on the other. Together, they create a system that is:

Energy-efficient (thanks to variable-speed control)

Space-saving (essential for mobile equipment)

Exceptionally responsive (ideal for dynamic load changes)

This is particularly valuable in applications like:

Injection molding machines

Servo-hydraulic presses

Construction machinery

AGVs (Automated Guided Vehicles)

When you combine electronic precision with hydraulic muscle, you're no longer choosing between finesse and force—you get both. This approach is at the heart of innovation at forward-thinking motion companies like THM Huade.

4. What Makes These Setups So Valuable?

Let’s walk through the benefits from your perspective as a system designer, plant operator, or maintenance engineer.

✅ Size Matters (In a Good Way)

A small servo motor can fit into tight spaces. When integrated with compact hydraulic components, you reduce machine footprints—perfect for OEMs targeting mobile or modular designs.

✅ Reduced Energy Waste

Older hydraulic systems often run continuously. With servo-driven pumps, you only power what you need. The result? Lower energy bills and reduced system heat.

✅ Precise Feedback Loops

Need to hold a load mid-cycle or change directions quickly? Servo control offers real-time feedback—critical in applications like testing systems or forming machines.

✅ Simplified System Architecture

Modern industrial servo drives support multi-protocol control (EtherCAT, CANopen, etc.), which makes integration with PLCs and IoT platforms smoother.

This is especially true in THM Huade’s servo-hydraulic system designs, where precision, modularity, and performance converge.

5. Looking Ahead: What the Future Holds

The trend is clear—systems are getting smarter, smaller, and more connected. You’ll see more machines built with embedded intelligence, real-time diagnostics, and plug-and-play modules.

In that context, small servo motors aren’t just filling a niche—they’re setting the stage for the next wave of industrial automation. Paired with compact hydraulic systems and sophisticated industrial servo drives, the applications are endless.

From flexible manufacturing lines to autonomous maintenance systems, the drive toward smarter machines is gaining momentum. Companies like THM Huade are responding by designing systems that are adaptable, efficient, and intelligent at every scale.

Conclusion:

You started this read wondering what role a small servo motor could play in your big-picture system. Now you know—it could be the very component that simplifies your design, cuts your energy usage, and enhances your performance.

And when paired with modern hydraulic motor pumps or industrial servo drives, the possibilities are even broader. These compact solutions are no longer just for lightweight robots or medical tools—they're reshaping the future of industrial control and motion systems across the board.

If you're in the research or design phase of your next industrial project, take a closer look at the power of small servo motors and servo-hydraulic systems. Explore how compact control could be the smartest move you make this year.

#SmallServoMotor#IndustrialAutomation#SmartHydraulics#ServoDriveTechnology#MotionControl#CompactPower#ServoHydraulicSystem#HydraulicInnovation#FutureOfIndustry#THMHuade

0 notes

Text

Precision Linear Stages Have Been Ready For Delivery to Germany

Precision Linear Stages, or precision motorized linear stages, high precision motorized linear stages, Have Been Ready For Delivery to Germany. You are welcome to visit our download centre to check E-catalogues or watch our video centre to check more projects. https://youtube.com/shorts/zIdeQaMjhes?feature=share Guide rail embedded module (Precision Linear Stages), the new product has been improved on the existing basis in terms of design structure, sliding seat rigidity, sealing and dust prevention. It can be adapted to the mainstream servo and stepping motors in the market. There are more upgradeable models with built-in drive control integration, which meet the more needs of different customers. Guide rail embedded module Rigid lifting of sliding seat: The body and the sliding seat are integrated to improve the poor rigidity of the original sliding seat. Optimized torque characteristics and stronger rigidity: The torque characteristics are greatly enhanced, the load displacement is reduced, and the rigidity is stronger. Installation dimensions are compatible: It can adapt to the general installation dimensions at home and abroad. The installation size of aluminum base and slide can be customized. Full tightness and dust prevention of steel belt: High flexibility steel belt structure, durable. The fully enclosed structure reduces the entry of foreign matters and prevents the internal grease from being thrown out. It can be used in the bad environment of the clean room. Time saving and convenient assembly: The slide cover and coupling cover are designed without screws, which is convenient for disassembly and assembly. The screws can be fixed from top to bottom or from bottom to top without removing the steel belt. The installation datum bearing is added on the side of the body. There is a locating pin hole at the bottom of the body. Suitable for mainstream motor: Suitable for mainstream servo and stepping motor. The motor can be directly connected, installed on the left side, right side and bottom side. External photoelectric sensor. Customers can choose the motor brand according to their own needs. External oiling design: The whole series can be externally oiled, and the screw rod and guide rail can be lubricated at the same time without removing the cover. Embedded guide rail structure: The base and slide of the module are made of aluminum extruded profiles. After the embedded guide rail is grinded, the straightness and rigidity are greatly improved. Drive control integrated module The drive control integrated module, based on the advantages of the guide rail embedded module, integrates the guide rail embedded module, servo motor and drive controller. Small size, high integration and simple wiring simplify the electrical design of customers and meet their more space needs. Low voltage servo drive control integrated system: Support low voltage dc24~48v range. There is no need to configure additional drives and controllers for the drive control integrated device, and you can choose the built-in or external drive control integrated device. It supports EtherCAT, can bus and RS-485 communication. Support external pulse signal, i/o signal 5 in 3 out. Incremental encoder and absolute encoder can be selected. The absolute encoder has a built-in battery, and the origin can be maintained after power failure. Intelligent motion control software: PLC ladder diagram programming and motion control functions can flexibly realize various motion modes without external signals. It has the choice of position mode, speed mode and torque mode. Online real-time monitoring of pulse signals, i/o signals and status information of drive control body machine. Read the full article

0 notes

Text

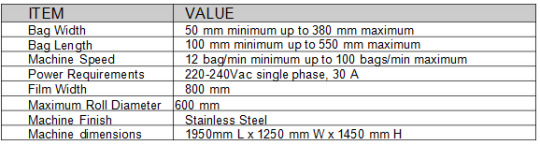

SPECIFICATION EXAMPLE:

A typical specification of a vertical form fill and seal machine can be as it is shown in the table below:

c. The necessities and requirements for the motion control. The machine consist basically in three axes driven by servomotors: The feeder. The side sealer The filler (considering an Auger-Type) The unwinder, if it exists, is usually one inverter with an embedded PID. The PID is executed in the inv erter and the setpoint is set from Motion controller (although it tend to be a fixed value). In moderns systems, inverter are controlled in similar way to servos using a common motion bus. The movements of the machine are basically point-to-point sequential movements, that is, every axis makes an independent movement but one movement in one axis cannot start until the previous movement in the sequence has not finished. The next diagram shows the sequence of a complete cycle:

The feeder needs a point to point position control with the possibility of a printed mark correction and the possibility to have an external encoder for the real positioning. The horizontal sealer is just a point-to-point positioner with two absolute positions. The Auger filler needs a point-to-point incremental positioner. The incremental position needs to be adjustable. d. The Omron solution with TJ2-MC04 General overview of the solution. This is the proposed Omron solution for the vertical form fill and seal machines.

The proposed solution is based on the TJ2-MC64 motion controller with the TJ2-ECT04 EtherCAT Master. The filler, feeder and sealer will be driven by G5 servodrives with EtherCAT interface and the unwinder will be a MX2 Inverter, also with EtherCAT option board. For this document we will assume that the embedded digital inputs and outputs in the TJ2-MC04 are sufficient for the machine. If more inputs or outputs are necessary, those can be added to the EtherCAT network by using the Omron slice IO’s and the EtherCAT interface (GRT1-ECT). How Omron solution match the machine requirements. The solution based in TJ2-MC64 match perfectly the machine requirements. Regarding the performance, the TJ2-MC64 can execute the necessary movements and supports registration correction (executed in the servodrive) and external encoder connection (also connected directly to the servodrive). The TJ2-MC64 controls the servomotors using the high performance EtherCAT motion bus. EtherCAT sends cyclicaly and deterministically the position reference to the servodrives. The system dramatically reduces the wiring of the machine because the connections to the servodrives is done by using cheap and widely available standard Ethernet cables (Category 5 or higher). That reduces cost of cables and installation manpower compared with the traditional pulse or analogue solutions. In addition, EtherCAT adds additional performance as you can access to all drive features from a single connection point, including read/write parameters, tuning, trace, diagnostics, etc. The inverter also is connected to the same EtherCAT network and is handled in the same way than a servodrive (in speed control in this case), this simplifies also the wiring and the engineering hours.

If more I/O’s are needed, they also can be connected to the EtherCAT network. For this we will use the Slice IO’s and the EtherCAT coupler: GRT1-ECT. The ACCURAX G5 servodrives with embedded EtherCAT interface(R88D-KNxxxx-ECT) controls the servomotor. The position loop is performed in the servodrive so, it is quick and independent on the number of axes. Besides, it has registration input and connection for the external encoder for the slip compensation. All this without additional boards.

ACCURAX G5 is the servo with the highest bandwidth (faster dynamic response) in the market (at January 2011). The servodrives also have embedded Safety (STO) to match the safety regulations in a simple way. Up to 8 servodrives can be connected to a single safety relay. The MX2 Inverter, with the EtherCAT interface module has an embedded PID that is used to control the unwinder so, the motion controller simply gives the PID reference and the sequence commands (run, stop, reset, …) via EtherCAT. The user interface typically is an NS touch screen HMI that provides a friendly graphic and intuitive environment to the machine operator. Besides we can make all the necessary machine adjustments, have a complete diagnostics and make all the operations from this single point. The HMI is connected to the TJ2-MC64 via Ethernet (FINS protocol) or via serial (Hostlink protocol).

0 notes

Text

Servo Motors and Drives Market Research Report

Servo Motors and Drives Market:

Growth opportunities in the servo motors and drives market look promising over the next six years. This is mainly due to the growing advancement and adoption of automation across industries, increasing adoption of energy-efficient international standards, and integrating motion control components in motors and drives.

Request for a FREE Sample Report on Servo Motors and Drives Market:

Servo Motors and Drives Market Dynamics (including market size, share, trends, forecast, growth, forecast, and industry analysis)

Key Drivers

The increasing innovation and acquisition of automation across industries, incorporation of motion control components in drivers and motors, ease to use, and the surging adoption of energy-efficient international standards coupled with the complementary regulations imposed on energy efficiency are the key drivers stimulating the growth of the global servo motors and drivers' market. The ongoing technological developments and execution of government policies like Minimum Energy Performance Standards (MEPS) across several countries and the augmented need for energy-efficient motor systems further fuel market growth.

The altering focus to sustain a high precision level, reduce labor cost and production wastage, expand the number of industries, and improve production output will raise the deployment of servo motors and drivers among industries and further accelerate market growth. Furthermore, industrial revolution 4.0 strengthened capabilities and encoder for adjustable speed drivers, creating enormous growth opportunities. However, the risk and uncertainty coupled with insufficient skilled professionals may curb the market growth.

Industry Segment Drivers

Based on the industry, the packaging segment is anticipated to expand at a higher CAGR during the forecast period. Expanding demand and using the accurate, faster machine and automated drives the adoption of servo motors and drives. Various applications in the packing industry, which include hybrid and electric injection molding machines, among others, are performed using servo motors and drivers.

Regional Drivers

Based on the regional coverage, Asia-pacific is predicted to witness a faster CAGR over the forecast period because of the escalating industrial activities and the rising demand for quick and accurate motors & drives for better productivity. The increasing demand for the low energy production process cost, integrated with the intensifying requirement of a software system, is bolstering the growth of the market. Furthermore, the growing production of machine tools and other sectors, including semiconductor and electronics related to automobiles or smartphones like electronics assembly, customized robot, and semiconductor machinery, for many applications are some other factors contributing to the market growth.

Servo Motors and Drives Market’s Leading Manufacturers:

· Kollmorgen Corporation

· Bosch Rexroth AG

· Emerson Electric Co.

· KINCO Automation Pvt. Ltd

· Schneider Electric SE

· Siemens AG

· Yaskawa Electric Corporation

· Adtech (SHENZHEN) Technology Co. Ltd

· FANUC Corporation

· Delta Electronics, Inc.

· Rockwell Automation Inc.

· ABB Group

· Mitsubishi Electric Corporation

Servo Motors and Drives Market Segmentation:

Segmentation by Offering:

· Hardware

o Sensors

o Controller Modules

o Encoders

o Electronic Amplifiers

o Other Components

· Software & Services

Segmentation by Type:

· Servo Motors

o AC Servo Motors

o DC Servo Motors

· Servo Drives

o AC Servo Drives

o DC Servo Drives

o Adjustable Speed Drives

Segmentation by Voltage Range:

· Low-Voltage Servo Motors and Drives (Up to 690v)

· Medium-Voltage Servo Motors and Drives (Above 690v)

Segmentation by Material of Construction:

· Stainless Steel Servo Motors and Drives

· Non-Stainless-Steel Servo Motors and Drives

Segmentation by Communication Protocol:

· Fieldbus

o Profibus

o Modbus

o CC-Link

o Devicenet

o Canopen

o Interbus

o Others

· Industrial Ethernet

o Profinet

o Ethernet/IP

o EtherCAT

o Powerlink

o Sercos III

o CC-Link IE

· Wireless

o WLAN

o Bluetooth

o WiMAX

o Wireless Hart

o Zigbee

o Others

Segmentation by Industry:

· Automotive & Transportation Industry

· Semiconductors & Electronics Industry

· Food Processing Industry

· Textile Industry

· Petrochemicals Industry

· Pharmaceutical & Healthcare Industry

· Packaging Industry

· Printing & Paper Industry

· Other Industries

Segmentation by Region:

· North America

o United States of America

o Canada

· Asia Pacific

o China

o Japan

o India

o Rest of APAC

· Europe

o United Kingdom

o Germany

o France

o Spain

o Rest of Europe

· RoW

o Brazil

o South Africa

o Saudi Arabia

o UAE

o Rest of the world (remaining countries of the LAMEA region)

About GMI Research

GMI Research is a market research and consulting company that offers business insights and market research reports for large and small & medium enterprises. Our detailed reports help the clients to make strategic business policies and achieve sustainable growth in the particular market domain. The company's large team of seasoned analysts and industry experts with experience from different regions such as Asia-Pacific, Europe, North America, among others, provides a one-stop solution for the client. Our market research report has in-depth analysis, which includes refined forecasts, a bird's eye view of the competitive landscape, key factors influencing the market growth, and various other market insights to aid companies in making strategic decisions. Featured in the 'Top 20 Most Promising Market Research Consultants' list of Silicon India Magazine in 2018, we at GMI Research are always looking forward to helping our clients to stay ahead of the curve.

Media Contact Company Name: GMI RESEARCH Contact Person: Sarah Nash Email: [email protected] Phone: Europe – +353 1 442 8820; US – +1 860 881 2270 Address: Dublin, Ireland Website: www.gmiresearch.com

0 notes

Text

Servo Motors and Drives Market Key Players, Industry Demand, Overview and Supply Chain Analysis, Forecast to 2027

The market mainly elaborates the definitions, classifications, market overview, and the industry chain analysis. The report also covers market size, share, trends, and growth analysis on the basis of different parameters. It profoundly displays the current market investigation situation and the upcoming situation in the coming years.

Key Drivers of the Servo Motors and Drives Market:

The significant drivers propelling the growth of the global servo motors and drives market are the increasing advancement and adoption of automation across industries, ease of use, and integration of motion control components in motors and drives, rising adoption of energy-efficient international standard, followed by the favorable regulations on energy efficiency. The technological innovation and implementation of government policies such as Minimum Energy Performance Standards (MEPS), in several countries, raised demand for energy-efficient motor systems, is further surging the growth of the global servo motors and drives market.

To know more about this market, request a sample @ https://www.gmiresearch.com/report/servo-motors-and-drives-market/sample-request

The increasing number of industries, changing focus towards maintaining a high precision level, reducing labor cost, and production wastage, along with improving production output will rise the deployment of the servo motors and drives across industries, which will further energize the growth of the servo motors and drives market size. In addition to this, industrial revolution 4.0, improved encoder and capabilities for adjustable speed drives create opportunities for the global servo motors and drives market. Furthermore, uncertainty and risk related to servo motors and drives, followed by a lack of skilled professionals, are hindering the growth of the market.

Top list of key players in the Servo Motors and Drives Market:

Yaskawa Electric Corporation

Mitsubishi Electric Corporation

Siemens AG

ABB Group

Schneider Electric SE

Rockwell Automation Inc.

KINCO Automation Pvt. Ltd

Delta Electronics, Inc.

Emerson Electric Co.

FANUC Corporation

Bosch Rexroth AG

Adtech (SHENZHEN) Technology Co. Ltd

Kollmorgen Corporation

Segmentation of the Servo Motors and Drives Market:

The report covers all the regions and countries of the world, which shows a regional development status, including the market size, volume, and value, as well as price data. Besides, the report also covers various segment data of the market.

Breakup by Offering:

Hardware

Software & Services

Sensors

Controller Modules

Encoders

Electronic Amplifiers

Other Components

Breakup by Type:

Servo Motors

Servo Drives

AC Servo Motors

DC Brushless Motors

AC Servo Drives

DC Servo Drives

Adjustable Speed Drives

Breakup by Voltage Range:

Low-Voltage Servo Motors and Drives (Up to 690v)

Medium-Voltage Servo Motors and Drives (Above 690v)

Breakup by Material of Construction (MOC):

Stainless Steel Servo Motors and Drives

Non-Stainless-Steel Servo Motors and Drives

Breakup by Communication Protocol:

Fieldbus

Profibus

Industrial Ethernet

Wireless

Modbus

CC-Link

Devicenet

Canopen

Interbus

Others

Profinet

Ethernet/IP

Ethercat

Modbustcp/IP

Powerlink

Sercos III

CC-Link IE

WLAN

Bluetooth

WiMAX

Wireless Hart

Zigbee

Others Industrial

Breakup by Industry:

Automotive & Transportation Industry

Semiconductors & Electronics Industry

Food Processing Industry

Textile Industry

Petrochemicals Industry

Pharmaceutical & Healthcare Industry

Packaging Industry

Printing & Paper Industry

Other Industries

Breakup by Region:

North America

Asia Pacific

Europe

RoW

United States of America

Canada

China

Japan

India

Rest of APAC

United Kingdom

Germany

France

Spain

Rest of Europe

Brazil

South Africa

Saudi Arabia

UAE

Rest of the world (remaining countries of the LAMEA region)

Request for Customization @ https://www.gmiresearch.com/report/servo-motors-and-drives-market/request-for-customization

About GMI Research:

GMI Research is a market research and consulting firm which provides bespoke industry & market research to help businesses in making the toughest business decision. We know the significance of accurate data; that’s why our analyst use a tailored methodology to study every market in detail because one size doesn’t fit all. We not only cover the traditional well-established market but also focuses on the niche market and markets in the emerging economies, where getting data and information is a challenge. This factor makes us a pioneer in the emerging market research space. Our syndicate reports cover multiple industries across various regions and countries.

Our in-depth market reports help propel your business with all the data, strategic inputs, and competitive intelligence to move ahead even in the most uncertain times. Featured in the ‘Top 20 Most Promising Market Research Consultants’ list of Silicon India Magazine in 2018, we at GMI Research look forward to help businesses stay ahead of the curve.

Contact GMI Research

Company Name: GMI RESEARCH EUROPE OFFICE: Level 1, The Chase Carmanhall Road, Sandyford Industrial Estate, Dublin D18 Y3X2, Ireland Email: [email protected] Website: https://www.gmiresearch.com

0 notes

Text

Servo Motors and Drives Market Forecast Report 2020 – 2027 – Top Key Players Analysis

The market mainly elaborates the definitions, classifications, market overview, and the industry chain analysis. The report also covers market size, share, trends, and growth analysis on the basis of different parameters. It profoundly displays the current market investigation situation and the upcoming situation in the coming years.

Key Drivers of the Servo Motors and Drives Market:

The significant drivers propelling the growth of the global servo motors and drives market are the increasing advancement and adoption of automation across industries, ease of use, and integration of motion control components in motors and drives, rising adoption of energy-efficient international standard, followed by the favorable regulations on energy efficiency. The technological innovation and implementation of government policies such as Minimum Energy Performance Standards (MEPS), in several countries, raised demand for energy-efficient motor systems, is further surging the growth of the global servo motors and drives market.

The increasing number of industries, changing focus towards maintaining a high precision level, reducing labor cost, and production wastage, along with improving production output will rise the deployment of the servo motors and drives across industries, which will further energize the growth of the servo motors and drives market size. In addition to this, industrial revolution 4.0, improved encoder and capabilities for adjustable speed drives create opportunities for the global servo motors and drives market. Furthermore, uncertainty and risk related to servo motors and drives, followed by a lack of skilled professionals, are hindering the growth of the market.

Top list of key players in the Servo Motors and Drives Market:

· Yaskawa Electric Corporation

· Mitsubishi Electric Corporation

· Siemens AG

· ABB Group

· Schneider Electric SE

· Rockwell Automation Inc.

· KINCO Automation Pvt. Ltd

· Delta Electronics, Inc.

· Emerson Electric Co.

· FANUC Corporation

· Bosch Rexroth AG

· Adtech (SHENZHEN) Technology Co. Ltd

· Kollmorgen Corporation

Segmentation of the Servo Motors and Drives Market:

The report covers all the regions and countries of the world, which shows a regional development status, including the market size, volume, and value, as well as price data. Besides, the report also covers various segment data of the market.

Breakup by Offering:

· Hardware

o Sensors

o Controller Modules

o Encoders

o Electronic Amplifiers

o Other Components

· Software & Services

Breakup by Type:

· Servo Motors

o AC Servo Motors

o DC Brushless Motors

· Servo Drives

o AC Servo Drives

o DC Servo Drives

o Adjustable Speed Drives

Breakup by Voltage Range:

· Low-Voltage Servo Motors and Drives (Up to 690v)

· Medium-Voltage Servo Motors and Drives (Above 690v)

Breakup by Material of Construction (MOC):

· Stainless Steel Servo Motors and Drives

· Non-Stainless-Steel Servo Motors and Drives

Breakup by Communication Protocol:

· Fieldbus

o Profibus

§ Modbus

§ CC-Link

§ Devicenet

§ Canopen

§ Interbus

§ Others

· Industrial Ethernet

o Profinet

o Ethernet/IP

o Ethercat

o Modbustcp/IP

o Powerlink

o Sercos III

o CC-Link IE

· Wireless

o WLAN

o Bluetooth

o WiMAX

o Wireless Hart

o Zigbee

o Others Industrial

Breakup by Industry:

· Automotive & Transportation Industry

o Semiconductors & Electronics Industry

o Food Processing Industry

o Textile Industry

o Petrochemicals Industry

o Pharmaceutical & Healthcare Industry

o Packaging Industry

o Printing & Paper Industry

o Other Industries

Breakup by Region:

· North America

o United States of America

o Canada

· Asia Pacific

o China

o Japan

o India

o Rest of APAC

· Europe

o United Kingdom

o Germany

o France

o Spain

o Rest of Europe

· RoW

o Brazil

o South Africa

o Saudi Arabia

o UAE

o Rest of the world (remaining countries of the LAMEA region)

About GMI Research:

GMI Research is a market research and consulting firm which provides bespoke industry & market research to help businesses in making the toughest business decision. We know the significance of accurate data; that’s why our analyst use a tailored methodology to study every market in detail because one size doesn’t fit all. We not only cover the traditional well-established market but also focuses on the niche market and markets in the emerging economies, where getting data and information is a challenge. This factor makes us a pioneer in the emerging market research space. Our syndicate reports cover multiple industries across various regions and countries.

Our in-depth market reports help propel your business with all the data, strategic inputs, and competitive intelligence to move ahead even in the most uncertain times. Featured in the ‘

Top 20 Most Promising Market Research Consultants’

list of Silicon India Magazine in 2018, we at GMI Research look forward to help businesses stay ahead of the curve.

0 notes

Text

Beckhoff powers flexible process control

According to Gary Brown, electrical engineer at AIE Global, there is no “one size fits all” solution when it comes to Industry 4.0 concepts. From their headquarters in Lake Wendouree, Brown’s team has been using advanced methodology to promote Australian innovation through process control and automation systems since 1985. According to Brown, AIE Global was established by a group of engineers with the specific aim of supporting turnkey automation projects. For ten years, they have utilised Beckhoff Automation solutions such as PLCs with remote I/O, robotics, and machine vision technology. “The more I investigated the Beckhoff product range, the more I liked what they offered,” he said. “EtherCAT I/O has allowed us to considerably reduce installation costs without any latency issues, and their CPU performance has meant that running out of memory is a thing of the past.” In 2010, the business won its first project using Beckhoff HMI based PLC for the operation of a multi-axis window manufacturing machine. Since then, it has been involved across a number of large-scale industrial projects requiring tailored engineering support. At Melbourne Airport, AIE Global was contracted for the design and installation of a PLC and SCADA automation system for an eight-megawatt trigeneration plant. Using seven Beckhoff CX2020 CPU Modules, alongside TwinCAT software, this infrastructure was responsible for providing general-use hot water via four natural gas driven generators. The PLCs were used in the automation of each genset, plant control, and hot water reticulation. According to Brown, having local EtherCAT-distriubuted I/O for each generator reduced the amount of electrical wiring running into the central control room, and allowed for a smaller cabinet size. This allowed for substantial cost savings, without negative impacts on performance. Additionally, AIE Global specialises in the development of servo drives for machine automation, also implementing Beckhoff PLC control. These are used by multiple manufacturing sites, specifically on pipe bending applications. “One large Victorian manufacturer required an upgrade for a multi-axis servo machine used for pipe bending,” said Brown. “The Beckhoff C6015 was used to replace an old Windows XP-based controller; rach pipe bend profile now has its own spreadsheet recipe file which is created externally and loaded using a USB stick.” Brown stated that contributing to Australian innovation is a key pillar of AIE Global’s approach, and in 2019 their engineers supported the design and implementation of a world-first mango auto harvester, developed by the Institute of Future Farming Systems (a division of CQ University). Part of a fully integrated system, it employs advanced sensor technology to identify and pick fruit, relying on Beckhoff C6015 Ultra-Compact Industrial PC and Automation Device Specification (ADS) protocol for communication and vision processing. “Looking back on the projects we have done, I can’t help but be impressed by the performance of Beckhoff’s product range,” Brown said. “EtherCAT is fast, with unlimited expansion capability, and the IEC 61131 programming environment significantly maximises productivity. Their large selection of library extensions also offer additional functionality, and can be added any time without needing CPU upgrades.” He added that the Windows platform allows the use of TwinCAT and has proven to be useful for the handling of recipe files, allowing them to be readily edited by the customer post-installation. “Many other PLC brands hide their functionality in an endeavour to make them easier to use. That leaves the engineer frustrated when they don’t work, and the technical support is inadequate. Beckhoff ensures a high level of functionality, reliability, and cost efficiency, with excellent backup support from the Australian sales office.” Beckhoff Customer Video – AIE Global Source link Originally published at Melbourne News Vine

0 notes