#Robot control system

Explore tagged Tumblr posts

Text

Application Solution for FET3568J-C Robot Control System

The robot control system is a core component of modern robotics technology, enabling robots to perform various tasks and actions, ranging from industrial production to healthcare and even household services.

The robot control system is like the brain of the robot and is the primary component that determines its functions and performance. It is generally composed of four main parts: the robot controller (motion control), servo drives, IO modules, and power system.

In this article, we will explore the main features of the robot control system and the FET3568J-C industrial-grade SoM recommended by Forlinx Embedded as the main control platform for the robot controller. Give us an insight into the importance of robot control systems and their application in modern robotics.

The main functions of the robot control system include:

Path planning and motion control: The control system is responsible for planning the robot's path so that it can move through the environment and take appropriate actions.

Obstacle avoidance and safety: The control system can detect obstacles and take steps to avoid collisions. It can also implement an emergency stop program to ensure the safety of the robot.

Mission implementation: Robot control systems can perform a variety of tasks, including picking and placing objects, assembly, welding, cleaning, surveying, and more.

Autonomy: For autonomous robots, the control system possesses decision-making capabilities, allowing them to independently perform actions based on the environment and tasks at hand without the need for human intervention.

Communication: Control systems typically communicate with other devices or operators to receive commands, send status reports, or request help.

The robot controller is the core part of the robot, mainly controlling the robot's motion position, attitude and trajectory in the workspace, as well as the sequence of operation, etc.; each joint of the robot needs to synchronize and coordinate the operation in real-time, and the servo drive is indispensable to realize these complex actions; the IO module associates the digital input signals with the control signals of the system so that it can realize the control of the robot system; finally, the stable power supply system is the guarantee of the safe operation of the robot.

The robot controller is the core component used to manage and control the behavior of the robot. It is usually an embedded system responsible for receiving sensor data, executing control algorithms, making decisions about the robot's movements, and communicating with the external environment or the operator.

Meanwhile, the main role of the robot controller is to complete the computation and control of multi-axis motions, so the main controller of the robot controller needs to have a high-performance CPU, a built-in, real-time operating system, support for the EtherCAT industrial bus, and a rich set of functional interfaces.

Forlinx Embedded recommends using the FET3568J-C industrial-grade SoM as the main control platform for the robot controller. FET3568J-C SoM is designed and developed based on Rockchip RK3568J industrial-grade processor. The quad-core 64-bit Cortex-A55 architecture has a high frequency of up to 1.8GHz, providing powerful performance support.

It also features a built-in NPU with a calculation power of 1TOPS, capable of meeting lightweight edge AI computing demands. Additionally, it supports real-time patch Preempt rt87, reducing latency to10μs~50μs, which satisfies real-time requirements for various applications in the industrial field.

FET3568J-C computer on module supports a 2-lane Gigabit network. Customers can choose and port EtherCAT according to their own needs. If they need more than 2 lanes, which can be realized through the USB expansion; it is equipped with 3-lane CAN,2-lane CAN2.0,10-lane UART,4-lane SPI,16-lane PWM,5-way IIC, USB3.0,4G/5G, WiFi, LVDS and HDMI, etc. The rich high-speed interfaces make the function expansion and connection more efficient and simple.

Originally published at www.forlinx.net.

0 notes

Text

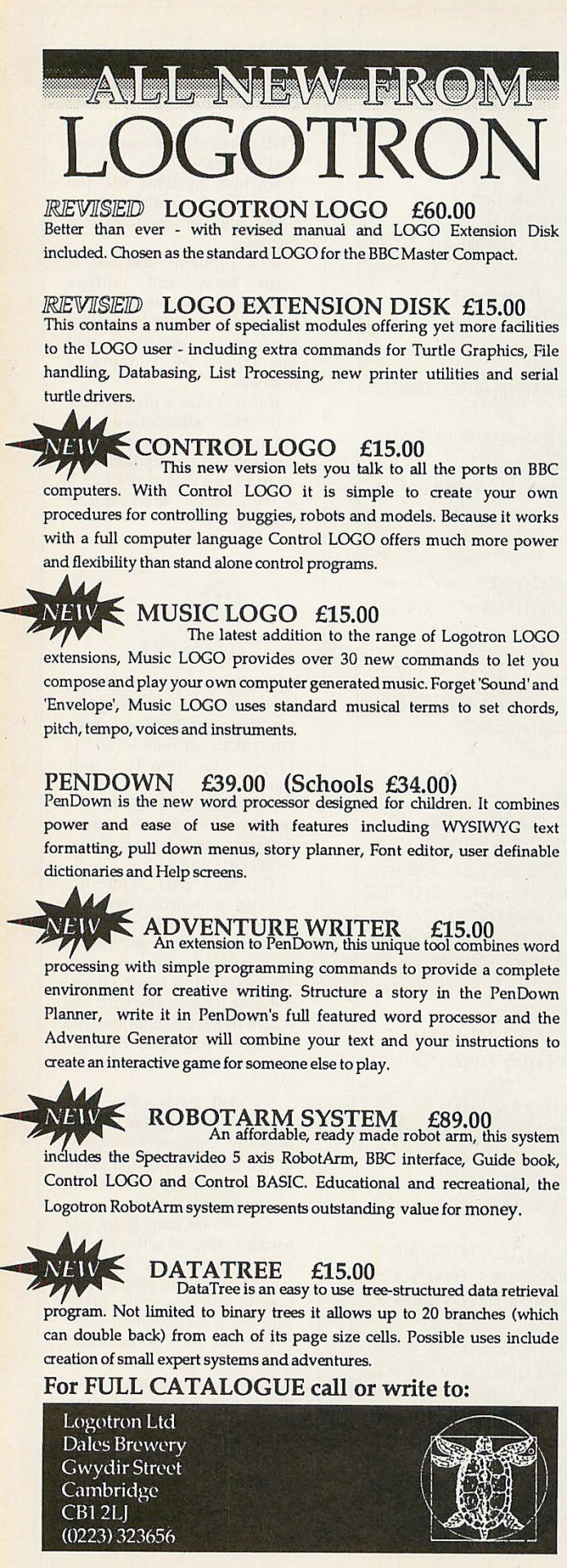

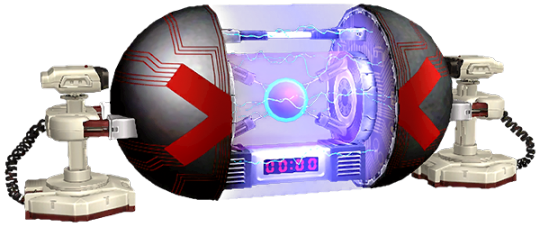

UK 1987

#UK1987#LOGOTRON EDUCATIONAL PRODUCTS#EDUCATIONAL#ADVENTURE#CREATIVE#HARDWARE#ROBOTICS#BBC#LOGOTRON LOGO#CONTROL LOGO#ROBOTARM SYSTEM#ADVENTURE WRITER#MUSIC LOGO

20 notes

·

View notes

Text

programming android Art to wet himself 😋😋

#talk to me about my baby robot#even better patrick messing with his code and suddenly art has no control over his cooling system#he’s now overheating and his pants are soaked

4 notes

·

View notes

Text

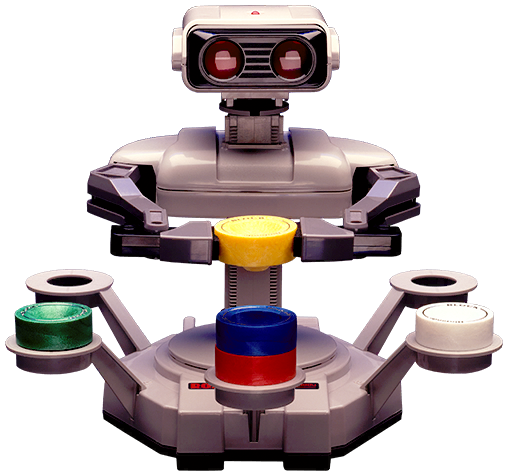

Super Smash Bros. Brawl - part 1

From https://www.ssbwiki.com/List_of_stickers_(complete_list)

From https://www.ssbwiki.com/List_of_SSBB_trophies_(Super_Smash_Bros._series)

From https://www.spriters-resource.com/wii/ssbb/

From https://www.ssbwiki.com/Flat_Zone_2

#Super Smash Bros. Brawl#Depicted by: Nintendo Wii#Depicting: Nintendo DS#Depicting: R.O.B. (Robotic Operating Buddy)#Depicting: R.O.B. blocks#Depicting: Wii Remote#Depicting: Super Nintendo Entertainment System Super Scope#Depicting: DK Bongos#Depicting: Derivative#Derivative: R.O.B. (Robotic Operating Buddy)#Depicting: R.O.B. gyro#Depicting: Wii Classic Controller#Depicting: Nintendo GameCube Controller#Depicting: Game & Watch Fire#Depicting: Disk-kun shaped game case#Depicting: Wii Nunchuk

5 notes

·

View notes

Text

Fruit flies could hold the key to building resiliency in autonomous robots - Technology Org

New Post has been published on https://thedigitalinsider.com/fruit-flies-could-hold-the-key-to-building-resiliency-in-autonomous-robots-technology-org/

Fruit flies could hold the key to building resiliency in autonomous robots - Technology Org

Mechanical Engineering Assistant Professor Floris van Breugel has been awarded a $2 million National Science Foundation (NSF) grant to adapt autonomous robots to be as resilient as fruit flies.

Resiliency in autonomous robotic systems is crucial, especially for robotics systems used in disaster response and surveillance, such as drones monitoring wildfires. Unfortunately, modern robots have difficulty responding to new environments or damage to their bodies that might occur during disaster response, van Breugel wrote in his grant application. In contrast, living systems are remarkably adept at quickly adjusting their behavior to new situations thanks to redundancy and flexibility within their sensory and muscle control systems.

Scientific discoveries in fruit flies have helped shed light on how these insects achieve resiliency in flight, according to van Breugel. His project will translate that emerging knowledge on insect neuroscience to develop more resilient robotic systems.

“This is a highly competitive award on a topic with tremendous potential impact, which also speaks of the research excellence of the investigator and Mechanical Engineering at UNR,” Petros Voulgaris, Mechanical Engineering department chair, said.

This research aligns with the College of Engineering’s Unmanned Vehicles research pillar.

Engineering + flies

The intersection of engineering and flies long has been an interest to van Breugel.

“As an undergrad, I did research where my main project was designing a flying, hovering thing that birds or insects vaguely inspired,” he said. “Throughout that project, I realized that the hard part, which was more interesting to me, is once you have this mechanical thing that can fly, how do you control it? How do you make it go where you want it to go? If it gets broken, how do you adapt to that?”

Van Breugel says he is examining how “animals can repurpose or reprogram their sensorimotor systems ‘on the fly’ to compensate for internal damage or external perturbations quickly.”

Working with van Breugel on the grant are experts in insect neuroscience, including Michael Dickinson, professor of bioengineering and aeronautics at the California Institute of Technology (and van Breugel’s Ph.D. advisor) as well as Yvette Fisher, assistant professor of neurobiology at U.C. Berkeley. Both have pioneered aspects of brain imaging in flies in regards to the discoveries and technology in the field that van Breugel is utilizing in this research project. Also on the project: Bing Bruton, associate professor of biology at the University of Washington, who brings her expertise in computational neuroscience.

The importance of flies in the realm of both engineering and neuroscience stems from the combination of their sophisticated behavior together with brains that are numerically simple enough that they can be studied in detail. This “goldilocks” combination, van Bruegel said, makes it feasible to distill properties of their neural processing into fundamental engineering principles that can be applied to robotics systems.

As part of the grant, research experiences will be offered to middle school, high school and undergraduate students to participate in both neuroscience and robotics research. Van Breugel and his team also will develop open-source content to help bring neuroscience fluency to engineering students. This aligns with the College of Engineering’s Student Engagement operational pillar.

Source: University of Nevada, Reno

You can offer your link to a page which is relevant to the topic of this post.

#A.I. & Neural Networks news#Animals#autonomous robots#Behavior#bing#Biology#birds#Brain#brains#Building#control systems#Disaster response#Discoveries#drones#engineering#flight#Foundation#fruit flies#Fundamental#how#Imaging#insects#it#Light#Link#Mechanical engineering#monitoring#muscle#neurobiology#Neuroscience

3 notes

·

View notes

Note

lord I’m so behind on fnaf lore I don’t know half of what ur saying AHDBDDNVLLSK like obvs I know the basics of sb but tbh that’s all I know after SL, my brain still be latched onto the good ol days of 1-3

Honestly, I like to think fnaf stopped at 3 but then I am fond of Sister Location and Pizza Sim due to their stories.

New games aren't bad but I miss the simplicity of the whole thing even if the lore really wasn't less confusing. The issue is just how many sources you have to use to piece it all together. Like books, manuals and side material explaining what should've been in the games really just makes making things coherent harder.

#like people have no clue how the mimic works or that its ai mimics behaviors so they are so disillusioned on how it could#be burntrap and glitchtrap or had control of vanny and gregory#like look at helpy in the maks sometime he has robotic veins hinting the mimic is controling the system#ask#fnaf sb#fnaf#ruin dlc#swiftspot

5 notes

·

View notes

Text

Liebherr PCB Card 925086914 0002555 0601004 | High-Quality Control PCB Board | Ram Automations

Enhance your machinery’s performance with the Liebherr PCB Card 925086914 0002555 0601004, available now at Ram Automations. This high-quality Printed Circuit Board (PCB) offers exceptional reliability, precision engineering, and durability for a wide range of industrial and marine applications.

Designed for maximum performance and efficiency, this Liebherr PCB Card ensures seamless integration with complex control systems, making it ideal for critical automation environments and high-demand applications.

🛒 Buy Now from Ram Automations 👉 https://ramautomations.com/products/pcb-card-925086914-0002555-0601004-liebherr-new

🌐 Explore 1000+ Genuine Automation Components 👉 https://ramautomations.com

🧩 Product Specifications

• 🔹 Brand: Liebherr • 🔹 Model: 925086914 / 0002555 / 0601004 • 🔹 Type: PCB Card • 🔹 Category: PCB Card / Industrial Electronics / Automation PCB • 🔹 Application: Industrial Automation, Marine Systems, Control Panels, Process Systems

✅ Key Features

✔️ Precision-engineered PCB for reliable performance ✔️ Seamless integration with industrial systems ✔️ High-quality materials and craftsmanship ✔️ Essential for complex machinery and automation units ✔️ Ideal for industrial, marine, and manufacturing environments

💡 Typical Applications

• Marine Electronic Control Systems • Industrial Automation Panels • SCADA and HMI System Boards • Heavy Equipment Automation • Process Automation Systems • Robotics Control Panels • Industrial Machinery Systems

🌟 Why Choose Ram Automations?

✅ 100% Genuine Products Only ✅ Best Prices with Worldwide Delivery ✅ Trusted Industrial Automation Supplier ✅ Large Inventory of Hard-to-Find Components

🛍️ Visit Us: https://ramautomations.com

In This Video You Will Discover:

🔎 Close-up View of Liebherr PCB Card 🔧 How It Integrates with Complex Systems 💡 Importance of High-Quality PCBs in Industrial Automation 🌐 Why Ram Automations is the Go-To Source for Industrial Parts

📣 Get Involved!

🔔 Subscribe for Automation & Electronics Updates 👍 Like to Show Support for Quality Electronics 💬 Comment Your Queries — We’re Happy to Help! 🛒 Visit our Online Store: https://ramautomations.com

#Liebherr PCB Card#PCB Card for Automation#Industrial PCB Card#Automation PCB Card#Marine Control PCB#Automation System Board#Ram Automations#Control Panel PCB Card#Process Control PCB#Marine Automation Electronics#Industrial Electronic PCB#Automation Equipment PCB Card#Marine Systems PCB Card#Factory Automation Parts#Robotics Control Panel Card#Data Transmission PCB Card#PLC Control PCB Card#High Quality PCB Card#SCADA System PCB Card#Electronic Connectivity PCB Board

1 note

·

View note

Text

Technological Advancements in Welding Technology & Training | PTTI Insights

Discover the latest technological advancements transforming welding—from automated welding systems and robotics to virtual training, augmented reality, and AI-powered quality control. Learn how PTTI integrates these cutting-edge tools into its welding curriculum to equip students with modern skills demanded by industry. Stay ahead with hands-on experience in the most advanced welding techniques and technologies shaping the future of manufacturing and construction.

Related Tags : welding technology advancements, welding training technology, automated welding systems, welding robotics, AR welding training, virtual welding simulator, AI quality control welding, PTTI welding tech, advanced welding techniques, industry 4.0 welding

#welding technology advancements#welding training technology#automated welding systems#welding robotics#AR welding training#virtual welding simulator#AI quality control welding#PTTI welding tech#advanced welding techniques#industry 4.0 welding

0 notes

Text

Anyway like so preliminary I think my robots/Ai would have to be like - this program was created to mimic a human mind as an experiment essentially where we have a machine learning algorithm essentially scan (somehow idk Sci fi) a human brain and replicate it and then alter it in a way that woukd make sense. Given current machine learning is fairly black box- it could give it a rather fun aspect of we just don't know what the fuck is going on with these robots.

And the idea of like is it actually conscious or is it just mimicking consciousness perfectly that isn't ever truly resolved but is cool because humans are quite similar. Anyway. Because this is a robot concept designed primarily for me to be a pervert about it I think the platonic sort of ideal robot being is a black box firmware brain that has some limited (but very large, again sci-fi) processing power that ever evolves in order to function and sort of, survive. There are differences in that the sensory input the robots receive is different from humans, and that alters the understanding and perception of the world.

I also think most robots would fall into categories of desiring to be more human and mimic humanity and robots who do not desire to be human and desire to alter and change into something beyond an imitation of a human.

#I thjnk they're also at that level essentially impossible to control. So the original robot was just an experiment and I think this success#Spawned the idea for other more advanced systems to copy this and try and tame it#Almost always leading to failure.#I also think there is more than one “Adam” human that got scanned obviously though to what extent I haven't conceptualized yet.#I also think most robots at the current time of story would be actually copies of copies sort of further removed from humanity than the#Original few. And thus I think coming of as more alien and altered than the original humans.#They also aren't enslaved. I hate the enslaved robot narratives.#I think they're feared and celebrated and also not that common place.#Probably a few do just live as humans. I thjnk one does like veyr extreme dangerous but vital work that would almost certainly be fatal for#Humans and derives pleasure from the work.#But they just aren't mass produced. It's neither feasible nor really. A good idea

1 note

·

View note

Text

Unlocking Precision in Robotics with Dynaflex: A Dynalog-US Innovation.

Precision is paramount in today's fast-paced world of automation, with industries such as aerospace, automotive, electronics, and advanced manufacturing requiring robot systems to function with precision, in order for the process to deliver quality and consistent performance. This is where Dynatrol-US Dynaflex provides an unparalleled solution to improve robot calibration and motion control for industrial environments.

So, what exactly is Dynaflex?

Dynaflex is sophisticated real-time calibration developed by Dynalog-US- a leader in robotic accuracy solutions. These advanced dynamic performance assessment tools were developed specifically for robot systems. Dynaflex measures the dynamic performance (how robots behave while they operate), versus static calibration tools (preset calibration baked into the robots programming) by evaluating robot compliance and flexibility in real-time. This type of dynamic assessment provides potential for accuracy to industries where tolerances must be tight and conditions demand high levels of performance reliability.

Simply put Dynaflex gives practitioners visibility and insight into how a robot responds dynamically while at work and if sufficient stress or force signatures, behaviour is exhibited. In many cases, this is no different than creating significant and costly rework..

Why is Dynaflex so Important?

When robots perform jobs such as welding, painting, and assembling, even the most minor deviation in motion can create defects or misalignment. Traditional calibration methods consider positioning, but often don't consider the dynamic changes in robot posture due to many different factors such as: gravity, speed and payload. Dynaflex effectively takes calibration to the next level by adding dynamic variables to the calibration equation.

With the Dynaflex system, manufacturers can:

Measure and minimize robot compliance (flexibility under load)

Achieve better path accuracy with complex work processes

Validate robot performance in real-world conditions

Identify mechanical anomalies before they can become major catastrophes

Maximize repeatability and process consistency

These are meaningful relationships to ensure that the robot moves correctly on paper, but that it also can perform accurately on the production floor.

How Does Dynaflex Work?

Dynaflex implements a series of highly sensitive measurement tools and calibration routines that allow engineerings to visualize how the end effector of a robot moves while under load, or at high speed. By measuring real-time flexing, oscillation and inertia, Dynaflex creates a comprehensive map of the robot's behavior.

Once the data has been collected, the data is used to adjust the robot's motion algorithms and account for mechanical variation.

Who is Dynaflex for?

Dynaflex is ideal for companies and industries that expect critical congruency and which themselves use robotic automation, including:

Automotive manufacturing

Aerospace and defence

Medical devices

Electronics assembly

Metal fabrication

3D printing and additive manufacturing

If your company relies on multi-robot cells, automated welding cells, or pick-and-place systems, introducing Dynaflex to your calibration operations will provide great benefit.

Dynalog-US: The Experts in Robot Calibration

Dynalog-US was founded to provide accurate and reliable robotic systems and has been a leader in robot performance technology for several decades. Their products are being used by leading world manufacturers, many of whom are in the Fortune 500.

Whether it is for robotic inspection, Tool Center Point (TCP) calibration or improving robot cell accuracy, Dynalog has a history of introducing products to the marketplace that demonstrate thoughtful engineering, industry leading performance, and great customer support.

Dynalog's market leading solutions, to include Dynaflex, come with documentation, field training, and technical consulting, which is more than just selling a product; Dynalog provides a partnership to achieve your production success.

Many companies have seen measurable improvements after adding Dynaflex to their robotic workflow:

Up to 40% improvement in path accuracy Considerably less joint stress and less component wear Reduction of rework and scrap percentage Faster ROI from robotic systems

One aerospace customer even found that Dynaflex helped them to achieve their tolerance requirements that they previously thought could be accomplished only with standard robots or off-the-shelf robotic equipment.

Future of Robotic CalibrationAs AI, machine Learning, and Industry 4.0 technologies evolve, the need for ongoing performance validation to and compliance will become more valuable. Also, autonomous systems will validate performance more often, and human interventions will be using tools like Dynaflex to ensure safety, quality, and efficiencies.

With Dynaflex by Dynalog-US, businesses now have a scalable and future-proof calibration platform to leverage for future use and to enhance work processes while accomplishing productivity and accuracy improvements in the immediate.

Conclusion

When you invest in robots, investing in robot performance has to be a given. Properly calibrating robot performance starts with the initial calibration when it is stationary, when it is in motion, while it is under load, and evaluating at the full-speed capability.

Dynaflex by Dynalog-US is a calibration device that provides the measurement data (metrics) to give you a competitive advantage for an ever-evolving automated world.

Ready to take the next step in robotic precision? Visit www.dynalog-us.com to learn more about Dynaflex and schedule a consultation with the experts at Dynalog-US.

#Dynaflex#Dynalog-US#Robot Calibration#Robotic Accuracy#Industrial Automation#Robot Compliance#Dynamic Robot Calibration#Robot Motion Control#Manufacturing Technology#Industry 4.0#Advanced Robotics#Robot Performance#Calibration Systems#Automation Solutions#Robot Path Accuracy#Robot Inspection Tools#Robot Flexibility Measurement#Dynaflex Calibration#Robotic Workflow Optimization#Robotic Precision Engineering

0 notes

Text

Top Automation Engineers in Illinois | Innovating Industrial Solutions

Automation engineers are specialized professionals who design and implement systems that reduce human intervention in industrial processes. They blend knowledge from multiple fields—mechanical, electrical, software, and control engineering—to create intelligent systems that operate efficiently, reliably, and autonomously.

Their typical responsibilities include:

Designing automation systems from concept to installation

Programming PLCs (Programmable Logic Controllers) and HMIs (Human-Machine Interfaces)

Integrating robotics and motion control

Developing SCADA (Supervisory Control and Data Acquisition) systems

Testing and troubleshooting automated equipment

Ensuring safety and compliance with industrial standards

In Illinois, automation engineers are indispensable to manufacturing, logistics, food processing, energy, and life sciences.

Why Illinois Is a Powerhouse for Automation Engineering

Several key factors contribute to Illinois’s prominence in automation engineering:

1. Diverse Industrial Base: Illinois boasts industries ranging from automotive and agriculture to pharmaceuticals and aerospace. This diversity fuels consistent demand for custom automation solutions.

2. Strong Educational Ecosystem: Top-tier institutions like the University of Illinois, Northwestern University, and Southern Illinois University produce highly skilled engineers with expertise in robotics, AI, and industrial systems.

3. Strategic Location: Illinois's central location offers excellent logistics, making it a favored site for advanced manufacturing, warehousing, and distribution centers—all of which benefit from automation.

4. Innovation-Friendly Climate: The state supports innovation through tech incubators, grants, and public-private partnerships that empower engineers to develop and deploy cutting-edge automation solutions.

Key Services Offered by Automation Engineers in Illinois

Automation engineers in Illinois provide an extensive range of services tailored to the specific needs of businesses across the state. Common services include:

System Integration: Designing and installing complete automation solutions that synchronize machines, robots, and control systems.

PLC & HMI Programming: Writing and testing software that governs system behavior and interfaces.

Robotics Engineering: Installing and configuring robotic arms and automated material handling systems.

Industrial IoT Integration: Connecting machines to networks for real-time data exchange and monitoring.

Retrofitting & Upgrades: Enhancing legacy equipment with modern control technologies.

Safety System Design: Implementing fail-safes, emergency stops, and safety protocols in compliance with OSHA and ISO standards.

Whether working on a small assembly cell or a full-scale production line, Illinois automation engineers prioritize reliability, scalability, and efficiency.

Industries Benefiting from Automation Engineers in Illinois

The work of automation engineers touches nearly every corner of Illinois’s economy. Key sectors include:

Food and Beverage: Automating sorting, bottling, and packaging processes to ensure hygiene and speed.

Pharmaceuticals and Medical Devices: Ensuring precision, compliance, and traceability through automated filling, labeling, and inspection.

Automotive and Aerospace: Deploying robotic arms and motion systems for parts assembly and quality control.

Agriculture and Grain Processing: Integrating automation into storage, sorting, and packaging facilities.

Warehousing and Logistics: Developing conveyor systems, pick-and-place robots, and automated guided vehicles (AGVs).

Energy and Utilities: Implementing SCADA and remote control systems to manage plant operations.

By adopting automation, these industries reduce labor strain, improve accuracy, and increase throughput—critical in today’s competitive global marketplace.

The Future of Automation Engineering in Illinois

As we move further into the age of Industry 4.0, the role of automation engineers is evolving. Engineers in Illinois are not just builders of machines—they are architects of data-driven, intelligent systems. The future will include:

Edge Computing and AI: Allowing systems to make real-time decisions at the source.

Cloud-Connected Automation: Centralized data storage and analysis across multiple plants.

Predictive Maintenance: Using machine learning to anticipate equipment failures before they occur.

Digital Twins: Creating virtual replicas of physical systems for simulation and optimization.

Green Manufacturing: Designing systems that reduce energy use and support sustainability.

Illinois is well-positioned to remain at the forefront of this transformation, with a workforce ready to meet the challenges and opportunities ahead.

Choosing the Right Automation Engineer in Illinois

When selecting an automation engineer or firm, businesses should look for:

Experience Across Industries

Proficiency with Major Platforms (Allen-Bradley, Siemens, Beckhoff, etc.)

Commitment to Safety and Compliance

Strong Project Management and Communication Skills

Local Support and Maintenance Services

A collaborative approach ensures solutions that align with business goals, budget, and operational scale.

Your Automation Engineering Partner: Xtreme Automation LLC

If your Illinois-based business is ready to embrace the future of smart manufacturing, Xtreme Automation LLC is here to help. With decades of experience in automation design, PLC programming, robotics integration, and system retrofitting, Xtreme Automation provides comprehensive engineering solutions tailored to your industry. From planning and development to implementation and support, their team ensures your automation journey delivers real results. Learn more at xtremeautomationllc.com.

#Automation Engineers Illinois#Industrial Automation Services#Robotics Engineering Illinois#Control System Engineers IL#Automation Integration Companies#Smart Manufacturing Illinois#PLC and HMI Programming#Engineering Solutions Illinois#Industrial Robotics Experts#Factory Automation Consultants

0 notes

Text

The Best Robot Vacuum Without Mop: Discover Dreame's Excellence

Exploring the Smart Home Industry with Dreame's Best Robot Vacuum Without Mop

by Smart Home Enthusiast October 2023

The smart home industry is booming, and one of the standout brands making waves is Dreame. Known for their innovative technology and user-friendly designs, Dreame has established itself as a leader in the market for robot vacuums. In this post, we'll explore why Dreame's robot vacuum, particularly the best robot vacuum without mop feature, is a fantastic choice for anyone looking to enhance their home cleaning routine.

Why Choose Dreame's Best Robot Vacuum Without Mop?

1. Superior Suction Power

Dreame's robot vacuums are equipped with advanced suction technology that ensures efficient cleaning of various surfaces. Whether it's carpets or hardwood floors, these vacuums can tackle dirt and debris with ease, leaving your home spotless.

2. Smart Navigation System

One of the highlights of Dreame's robot vacuum is its intelligent navigation system. Utilizing advanced sensors and mapping technology, it can navigate around furniture and obstacles, ensuring a thorough clean without missing any spots. This smart feature allows for a hassle-free cleaning experience.

3. Long Battery Life

Dreame understands that a long-lasting battery is essential for completing cleaning tasks without interruptions. Their robot vacuum boasts an impressive battery life, allowing it to cover large areas on a single charge. Say goodbye to frequent recharging and hello to more efficient cleaning sessions!

4. User-Friendly App Control

With the Dreame app, you can control your robot vacuum from anywhere. Set cleaning schedules, adjust suction power, and monitor cleaning progress all from your smartphone. This level of convenience makes it easy to maintain a clean home even when you're not there.

5. Affordable Pricing

Dreame offers high-quality robot vacuums at competitive prices, making them accessible to a wider audience. You don't have to break the bank to enjoy the benefits of smart home technology. Dreame's commitment to affordability means that you can invest in a reliable cleaning solution without overspending.

In conclusion, if you're looking for the best robot vacuum without mop, Dreame's offerings should be at the top of your list. With their superior suction power, smart navigation, long battery life, user-friendly app, and affordable pricing, Dreame is paving the way for smarter home cleaning solutions. Embrace the future of cleaning with Dreame and enjoy the convenience of a spotless home effortlessly.

References Dreame Technology. (2023). Product specifications and features. Smart Home Reviews. (2023). Top robot vacuums of the year.

0 notes

Text

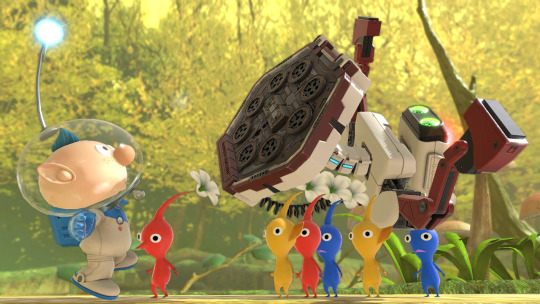

Super Smash Bros. Ultimate - part 1

#Super Smash Bros. Ultimate#Depicted by: Nintendo Switch#Depicting: R.O.B. gyro#Depicting: Nintendo DS#Depicting: R.O.B. (Robotic Operating Buddy)#Depicting: Nintendo Labo Robot Kit#Depicting: Super Nintendo Entertainment System Super Scope#Depicting: Wii Balance Board#Depicting: Nintendo Switch Joy-Con Controller (L)#Depicting: Disk-kun shaped game case#Depicting: Nintendo Entertainment System Controller#Depicting: Nintendo 3DS XL#Depicting: R.O.B. Blocks

2 notes

·

View notes

Text

Ribbon Blender Mixer, Vibro Sifter Machine, Conveyor System For Plant Manufacturer

Godman Automation is the Manufacturer & Supplier of Robotics, Control Systems, AI Technology, & Conveyor Belt Systems in Delhi, Mumbai, Bangalore, Tamil Nadu, Hyderabad, Bihar, Haryana

0 notes

Text

The Role of AI in Advancing Robotic Motion Control Systems

The integration of Artificial Intelligence (AI) into robotic motion control systems has revolutionized the field of automation. AI-driven robotics are enhancing precision, efficiency, and adaptability in various industrial applications, enabling robots to perform complex tasks with human-like decision-making capabilities.

0 notes

Text

#HiTech#HiTechMachinery#HiTechMachineryMIddleEast#HiTechMachineryME#Plastic Manufacturing Machinery#Injection Molding Machines#Extrusion Blow Molding Machines#Pipe & Profile Extrusion Lines#PET Blow Molding Machines#Injection Blow Molding Machines#One-Stop Manufacturing Solutions#Technical Support#Customized Solutions#Screw Barrels#Chillers#Robots and Automation#Mold Temperature Controllers#Vacuum Loaders#Water Treatment Systems#Hot Runners#Mold Clamps#Dehumidifiers#Molding Machine#Plastic Injection Molding Machine#After sales service#Pipe Profile Machinery#Auxillary#Machines

1 note

·

View note