#Factory automation standards

Explore tagged Tumblr posts

Text

...

#personal#my husband negged me about stern and now im like kinda determined to get a 750+ on the GMAT and try to get in#he didn't mean it as a neg lol...... but it's his bitter school that he wanted for undergrad and didn't get into#and he was like ''hey u prb wont get in... my hs grades were better than urs even tho my sats were lower''#but BRUH >.< we were cheating scandal year so that doesn't couuuuunt#and it's undergrad not grad he's talking about#(my bitter school was cooper union it was the only b-arch 5 year architecture school i applied to that didn't accept me#which is probably good because i wouldn't have been able to swap into digital design there and would have been stuck in archi and i was#MISERABLE in archi lol i also make more than my friends in archi and work less than them :D )#BUT THIS MEANS I NEED TO BRUSH UP ON STANDARDIZED TEST MATH ;A;#the only math i've done since college is like....javascript and that does nawt count#i use jsx to automate little pictures..... put little pictures together for kids clothing....and yell at factories#no math at work other than minimal coding............. my brain is slow at test math now#(i have to practice my stupid sat level math a bit anyways soon cuz imma get dragged into doing test prep for my cousins soon :/)#the only things that seem like they'll make me more money in my career are if i go further into operations and automation#or if i go FAR more creative... and business operations seems far far more stable#(also i much prefer being thrown ''here's a fun math game automate this part of our design process away'' than...#''pls make 10 versions of a tee shirt in 5 days that need to pass thru legal thx'')

0 notes

Text

SECS/GEM on Canon MPA 600 Super Aligner Through the EIGEMBox

In the dynamic world of semiconductor manufacturing, ensuring that legacy equipment can keep up with modern communication standards is essential for maintaining productivity and efficiency. The Canon MPA 600 Super Aligner, a widely used piece of equipment in semiconductor fabs, often lacks the native SECS/GEM capabilities required for seamless integration into contemporary manufacturing systems. Enter EIGEMBox, a patented, plug-and-play solution that brings SECS/GEM compliance to legacy equipment without the need for extensive hardware or software installations.

In this blog, we will explore the benefits of using EIGEMBox to enable SECS/GEM on the Canon MPA 600 Super Aligner and how this can revolutionize your manufacturing process.

What is SECS/GEM?

SECS/GEM (SEMI Equipment Communications Standard/Generic Equipment Model) is a set of protocols developed by SEMI (Semiconductor Equipment and Materials International) to standardize communication between semiconductor manufacturing equipment and host systems. These protocols are critical for enabling automation, real-time data collection, and equipment control, which are essential for the efficiency and productivity of modern semiconductor fabs.

The Importance of SECS/GEM Compliance SECS/GEM compliance offers several significant benefits for semiconductor manufacturing: Automation: SECS/GEM protocols enable the automation of equipment operations, reducing the need for manual intervention and minimizing the risk of human error. This leads to higher throughput and more consistent production quality.

Data Collection and Analysis: SECS/GEM allows for real-time data collection from equipment, which can be analyzed to monitor performance, optimize processes, and predict maintenance needs. This data-driven approach helps in making informed decisions that improve overall efficiency.

Equipment Control: With SECS/GEM, equipment can be controlled remotely by the host system, allowing for better coordination and scheduling of manufacturing tasks. This ensures optimal utilization of resources and reduces downtime.

Interoperability: SECS/GEM provides a standardized communication framework, ensuring that equipment from different vendors can work together seamlessly. This interoperability is crucial for maintaining a cohesive and efficient manufacturing environment.

Challenges with Legacy Equipment

While SECS/GEM offers numerous advantages, many legacy equipment like the Canon MPA 600 Super Aligner lack native SECS/GEM capabilities. Upgrading these machines to meet modern standards can be a complex and costly process, often requiring significant hardware and software modifications. This is where EIGEMBox comes into play.

Introducing EIGEMBox

EIGEMBox is an innovative, patented solution designed to bring SECS/GEM capabilities to legacy equipment without the need for additional hardware or software installations. This plug-and-play device makes it easy to upgrade older machines, ensuring they can communicate effectively with modern control systems and integrate seamlessly into automated manufacturing environments.

Key Features of EIGEMBox

Plug-and-Play Convenience: EIGEMBox is designed for easy installation and operation. Simply connect the device to your legacy equipment, and it starts working immediately, without the need for extensive configuration or setup.

No Hardware or Software Installation Required: Unlike traditional SECS/GEM integration solutions that often require complex hardware and software installations, EIGEMBox eliminates these hassles. This makes it a cost-effective and time-saving solution for upgrading your equipment.

Patented Technology: EIGEMBox utilizes patented technology to ensure reliable and efficient communication between your legacy equipment and modern control systems. This guarantees seamless integration and improved operational efficiency.

Enhanced Data Exchange: With EIGEMBox, your legacy equipment can exchange data in real-time with control systems, enabling better monitoring, analysis, and optimization of manufacturing processes.

Benefits of Using EIGEMBox with Canon MPA 600 Super Aligner

Upgrading the Canon MPA 600 Super Aligner with EIGEMBox offers several significant benefits:

Extended Equipment Life: By enabling SECS/GEM compliance, EIGEMBox extends the operational life of the Canon MPA 600 Super Aligner, allowing you to maximize your investment in this equipment.

Improved Efficiency: Enhanced communication and control capabilities lead to better coordination of manufacturing tasks, increased throughput, and reduced downtime. This results in the overall improved efficiency of your manufacturing process.

Cost Savings: EIGEMBox eliminates the need for costly hardware and software upgrades, providing a more affordable solution for integrating SECS/GEM protocols into your manufacturing processes.

Seamless Integration: EIGEMBox ensures that your Canon MPA 600 Super Aligner can communicate effectively with modern control systems, enabling a smoother and more efficient manufacturing operation.

Case Study: Successful Integration of EIGEMBox with Canon MPA 600 Super Aligner

One of our clients, a leading semiconductor manufacturer, faced challenges in integrating SECS/GEM protocols into their Canon MPA 600 Super Aligner. After implementing EIGEMBox, they experienced a significant improvement in production efficiency. The plug-and-play nature of EIGEMBox allowed for a quick and hassle-free integration process, resulting in a 20% increase in equipment utilization and a 15% reduction in downtime. The client was able to extend the life of their existing equipment while achieving substantial cost savings. How to Get Started with EIGEMBox Ready to revolutionize your semiconductor manufacturing processes with EIGEMBox? Here’s how you can get started:

Contact Us: Reach out to our team for a consultation. We’ll assess your current equipment and provide tailored recommendations for integrating EIGEMBox into your manufacturing environment.

Easy Installation: Once you’ve decided to move forward, our team will guide you through the simple installation process. No need for extensive configuration or setup – just plug it in and start reaping the benefits.

Ongoing Support: Our commitment to your success doesn’t end with installation. We offer comprehensive support to ensure that your EIGEMBox operates seamlessly and delivers the desired improvements in efficiency and productivity.

Contact Us Today! Don’t let outdated equipment hold back your semiconductor manufacturing operations. With EIGEMBox, you can achieve modern communication and control capabilities without the need for costly hardware or software installations. Contact us today to learn more about how EIGEMBox can transform your Canon MPA 600 Super Aligner and drive your manufacturing processes forward.

#SECS/GEM integration#Canon MPA 600 Super Aligner#EIGEMBox#semiconductor manufacturing#legacy equipment upgrade#plug-and-play SECS/GEM#SECS/GEM compliance#semiconductor automation#factory automation#SECS/GEM protocol#SECS/GEM communication#equipment control systems#real-time data collection#manufacturing process optimization#cost-effective SECS/GEM solution#improve production efficiency#legacy equipment SECS/GEM#EIGEMBox installation#semiconductor industry standards#SECS/GEM host simulation#reduce equipment downtime

0 notes

Text

Humans are weird: Hubris before the fall

( Please come see me on my new patreon and support me for early access to stories and personal story requests :D https://www.patreon.com/NiqhtLord Every bit helps)

A decade ago there was a powerful world by the name of Oma that was the crown jewel of the Omak Domain. Rich with natural resources and rare metals, it was able to establish a powerful trade network that generated billions of credits monthly leading to the people of Oma to grow fat with decadence. This led to a rapid degradation of their societal values to such an extent that they believed that they and only they were truly worthy of running galactic trade and began pressuring their neighboring governments to relinquish trade control of their domains to them.

When they finally approached the humans they sent forth a trade delegation to their parliament. This delegation did not present a sympathetic view of their stewardship, nor a presentation outlining the benefits of their management skills in intergalactic trade. No; this delegation strode into the terran parliament and denounced human trade standards as inferior and unworthy implementation between galactic powers.

No strangers to prideful boasting, the humans naturally took great offense to the grand standing of the delegation and cast them out without even hearing their full proposal. In response, the Oma began sanctioning the terran domain; isolating its trade routes and starving it off much needed resources.

For months the human diplomats tried to reach out to the Oma to find a political solution, but each attempt was met with the repeated message “Submit”.

As time passed and riots began to break out across human worlds from the lack of materials, the terran government finally had enough and dispatched a war fleet to Oma. The fleet was comprised of nearly three fifths of their entire naval power and was spear headed by the latest Herald class battleship “Saladin” with the equally famous Admiral Timmins in command.

Being comprised of mainly trade ships; the Omak Domain navy was primarily built around fast moving frigates, destroyers, and smaller patrol craft capable of catching pirates that preyed upon their shipping lanes. They were little more than a speed bump to the well-disciplined prowess of terran armada and was swept aside easily as the human ships made for orbit directly above Oma. Yet even with this encroaching ring of steel the Oma public did not panic.

Unlike their navy, the Omak Domain’s ground forces were substantially better in comparison. They had fought many ground wars to secure trade outposts, mining operations, and subjugation camps and were thusly made up of a hardened collective of veteran soldiers and automated war machines that were capable to five terran soldiers. So when the human fleet finally did position itself in orbit above Oma, the Omak military was confident they would repel any invasion attempts made by the humans; even going so far as to openly mock Admiral Timmins in a direct communique that not one human soldier would live to set foot on their world.

To their surprise Admiral Timmins agreed to those terms and began the battle.

From the launch bays of every terran ship came hundreds of heavily armed fighters, bombers, drones, and reconnaissance craft that swarmed through Oma’s atmosphere. Not a single lander or ground soldier was deployed as the Admiral coordinated a planet wide devastating air campaign of destruction.

The Omak air force was overwhelmed in a matter of hours by the constant waves of enemy aircraft and found itself further crippled as their launch sites were surgically struck from orbit by human warships. When the last of the Omak air power was expended the human air power had complete control over the skies of the planet.

Civilian targets such as cities and towns were ignored; but the precious foundries, factories, and mining complexes that had given the Omak people such wealth were reduced to little more than burnt pieces of metal and ash. The Omak rulers watched as their life blood of commerce was taken from them one continent at a time and sent countless messages to the human fleet for peace. Their reply was always a single word that none of the Omak would agree to.

“Submit.”

By a month’s end the world of Oma was little more than a smoldering crater. Gleaming cities now stood as silent watchers over miles of burnt landscapes and wasted industrial complexes. The people who had only known wealth and power were now left to wander the ruins of their former trade empire as the human fleet still held orbit over the world. Fragments of the Omak Domain attempted to bypass the human fleet to deliver supplies but each attempt was met with the humans either seizing the ship and the valuable cargo or destroying it just as it was about to land.

It didn’t take long for the previously subjugated peoples that had relinquished control to the Omak to begin rising up once more and regaining their sovereignty. Some the newly freed powers sent their own delegations to the human fleet and kneeled before Admiral Timmins; thanking the humans for bringing their oppressors low. Each time the Admiral would thank the aliens and invite them to the viewing decks so they could look down at the burnt world that had once held them so firmly under its thumb.

In a way it was both a gesture of friendship and a warning to all those that would come after; that the realms of man would never take kindly to the hubris of fools.

#humans are space oddities#humans are space orcs#humans are insane#humans are weird#scifi#story#writing#original writing#niqhtlord01#ai generated art#bing image creator

99 notes

·

View notes

Text

The Difference Between Low, Medium, and High Voltage Switchgear

Switchgear plays a critical role in the generation, transmission, and distribution of electrical power. It ensures safe and efficient operation by controlling, protecting, and isolating electrical circuits and equipment. But not all switchgear is created equal — low, medium, and high voltage switchgear are designed for different voltage levels and applications.

Understanding the differences between these types is crucial for electrical engineers, electricians, project managers, and anyone involved in power systems. In this article, we break down what sets them apart in terms of voltage range, components, applications, design, and safety considerations.

What is Switchgear?

Before diving into the differences, let’s clarify what switchgear is.

Switchgear refers to the combination of electrical disconnect switches, fuses, or circuit breakers used to control, protect, and isolate electrical equipment. It is essential for de-energizing equipment for maintenance and for clearing faults in the power system.

Classification by Voltage Level

Low Voltage Switchgear (LV)

Voltage Range:

Up to 1,000V AC (typically 400V/690V in 3-phase systems)

Key Components:

Miniature Circuit Breakers (MCBs)

Molded Case Circuit Breakers (MCCBs)

Residual Current Devices (RCDs)

Contactors and relays

Busbars, metering, control panels

Applications:

Residential and commercial buildings

Data centers and office spaces

Light industrial automation

Control panels and motor control centers (MCCs)

Characteristics:

Compact and easy to install

High frequency of operation

Relatively simple maintenance

Often enclosed in modular panels

Standards:

IEC 61439

NEC (National Electrical Code)

Medium Voltage Switchgear (MV)

Voltage Range:

1kV to 36kV (sometimes up to 72.5kV)

Key Components:

Vacuum circuit breakers (VCBs)

SF₆ (sulfur hexafluoride) insulated switchgear

Current and voltage transformers (CTs, VTs)

Protective relays

Grounding switches

Applications:

Electrical substations

Large factories and industrial plants

Railways and airports

Renewable energy farms (wind/solar)

Characteristics:

Higher insulation and safety requirements

More robust protection systems

Often installed indoors or in compact outdoor enclosures

May use gas-insulated or air-insulated designs

Standards:

IEC 62271–200

IEEE C37 series

High Voltage Switchgear (HV)

Voltage Range:

Above 36kV (commonly 66kV, 132kV, 220kV, up to 765kV)

Key Components:

SF₆ circuit breakers

Air blast or oil circuit breakers (older systems)

Gas-insulated switchgear (GIS)

Disconnectors and earthing switches

High-end protection relays and SCADA integration

Applications:

National and regional power transmission networks

Power generation plants

Interconnecting large substations

Critical infrastructure (e.g., large data centers, airports)

Characteristics:

Complex installation and high-cost infrastructure

Requires rigorous safety procedures and specialized training

Often installed outdoors or in GIS (Gas Insulated Switchgear) format

Includes extensive monitoring and automation

Standards:

IEC 62271–100 (HV circuit breakers)

IEEE C37.06

ANSI C37 series

Safety Considerations

Always follow local electrical codes, use personal protective equipment (PPE), and conduct routine maintenance regardless of switchgear type.

Conclusion

Choosing the right switchgear type is critical for ensuring safe and efficient power distribution. Whether you’re designing a residential panel or a high-voltage substation, knowing the difference between low, medium, and high voltage switchgear helps you make informed decisions about equipment, safety, and performance.

Mastering this knowledge isn’t just good practice — it’s essential for anyone serious about a career in the electrical field.

10 notes

·

View notes

Text

companies bragging about/threatening replacing their entire workforce with AI while whining that no one want to work anymore would be comical if it wasn't deeply infuriating.

like, we have the massive workforce we have bc that workforce was designed to fill factories and plants that needed a bunch of people on duty to manufacture things. then manufacturers automated that process and dropped a bunch of people. then they exported their work to the east where they didn't have to *checks notes* follow safety standards and pay people enough to live. and that massive workforce just kinda... found something else to do, or didn't, but that hole was never really patched. (the tech boom arguably opened up new industries and thus new jobs, but it's not like former assembly line workers got hired to code in assembly.)

fast forward to now, and almost a whole generation of people were told to get college degrees if they wanted good jobs and security, only to be shut out of those jobs bc now you need 10 years of experience and a personal recommendation from the boss' uncle, if there are even jobs/positions still available for that degree. and the generation that bellowed "go to college or you'll work at mcdonald's" turned around and started mocking the people who stand behind cash registers with a degree hung up on their apartment wall for expecting what they were told to expect.

companies cut slack, make 1 person do the job of 5 so they only have to shell out 1 paycheck, and fire anyone who even thinks about unionization while daring to act like they're a "family" when they really mean they expect you to dedicate your life to them. companies pay out the lowest wages they're legally allowed to and scoff at people who (rightfully) call them out on it bc "you shouldn't just be in it for the money, you should do this bc you love it!" when passion doesn't pay the rent. companies fire a department and replace them with an AI that does a worse job, but it's faster and cheaper so the investors love it. companies make applicants jump through hoops to get hired (if they're even actually hiring) and think that anyone who doesn't play their games just isn't committed enough. companies complain that no one wants to work anymore bc no one wants to work for them.

of course people want to work. they have bills to pay and groceries aren't free yet. you just don't want to pay them.

you're the employer. start employing. you make jobs. make them.

because like it or not, you can't last without workers, and workers can absolutely last without you.

#it speaks#rant#anti capitalism#no one wants to work anymore#like it's called the labor market for a reason#if you're not offering#no one's taking#don't complain you have no purchases when you've closed your stall and barricaded it#i made a fake linkedin account for trolling a while back and the mindset is just so stupidly toxic#having standards looks bad on your resume huh? i guess you should get your own then#it's like they straight up don't understand that people need money to live in a capitalist system. yeah dude people wanna get paid#they're creating the perfect conditions for people to give up on working and then complaining that people are. giving up on work

12 notes

·

View notes

Text

From Design to Deployment: How Switchgear Systems Are Built

In the modern world of electrical engineering, switchgear systems play a critical role in ensuring the safe distribution and control of electrical power. From substations and factories to commercial buildings and critical infrastructure, switchgear is the silent guardian that protects equipment, ensures safety, and minimizes power failures.

But have you ever wondered what goes on behind the scenes, from the idea to the actual installation? Let’s dive into the full journey — from design to deployment — of how a switchgear system is built.

Step 1: Requirement Analysis and Load Study

Every switchgear project begins with requirement analysis. This includes:

Understanding the electrical load requirements

Calculating voltage levels, short-circuit ratings, and operating current

Identifying environmental conditions: indoor, outdoor, temperature, humidity

Reviewing applicable industry standards like IEC, ANSI, or DEWA regulations (especially in UAE)

This stage helps engineers determine whether the project needs low voltage (LV), medium voltage (MV), or high voltage (HV) switchgear.

Step 2: Conceptual Design & Engineering

Once the requirements are clear, the conceptual design begins.

Selection of switchgear type (air insulated, gas insulated, metal-enclosed, metal-clad, etc.)

Deciding on protection devices: MCCBs, ACBs, relays, CTs, VTs, and fuses

Creating single-line diagrams (SLDs) and layout drawings

Choosing the busbar material (copper or aluminum), insulation type, and earthing arrangements

Software like AutoCAD, EPLAN, and ETAP are commonly used for precise engineering drawings and simulations.

Step 3: Manufacturing & Fabrication

This is where the physical structure comes to life.

Sheet metal is cut, punched, and bent to form the panel enclosures

Powder coating or galvanizing is done for corrosion protection

Assembly of circuit breakers, contactors, protection relays, meters, etc.

Internal wiring is installed according to the schematic

Every switchgear panel is built with precision and must undergo quality control checks at each stage.

Step 4: Factory Testing (FAT)

Before deployment, every switchgear unit undergoes Factory Acceptance Testing (FAT) to ensure it meets technical and safety standards.

Typical FAT includes:

High-voltage insulation testing

Continuity and phase sequence testing

Functionality check of all protection relays and interlocks

Mechanical operations of breakers and switches

Thermal imaging to detect hotspots

Only after passing FAT, the switchgear is cleared for shipping.

Step 5: Transportation & Site Installation

Transportation must be handled with care to avoid damage to components. At the site:

Panels are unloaded and moved to their final location

Cabling and bus duct connections are established

Earthing systems are connected

Environmental sealing is done if installed outdoors or in dusty environments

Step 6: Commissioning & Site Acceptance Testing (SAT)

This final stage ensures the switchgear is ready for live operation.

Final checks and Site Acceptance Tests (SAT) are performed

System integration is tested with other components like transformers, UPS, and generators

Load tests and trial runs are conducted

Commissioning report is generated, and documentation is handed over to the client

Conclusion

From idea to execution, the journey of building a switchgear system is highly technical, safety-driven, and precision-based. Whether you’re in power generation, industrial automation, or commercial construction, understanding this process ensures you choose the right system for your needs.

7 notes

·

View notes

Text

On the Skidelsky/Fuller post I reblogged, I absolutely welcome automation given the following criteria:

1. The output is identical or, holistically, more positive than human labor output

2. This automation occurs within an economic system in which GDP growth (or similarly fraught metrics) is not the primary objective

3. The automation aids the sustainability of nature and humanity

The USA's agriculture industry is a wonderful example of modern automation failing all three of these criteria. Throughout the entire industrial revolution, agriculture has trended away from being a society-wide confederation of family/community-scale, labor-intensive smallholdings to our current reality of a small number of monolithic industrial farms that are maintained by astoundingly few people who operate increasingly complex and expensive equipment.

Our massive-scale industrial farms are fantastic at what they were designed for; they grow as much of a staple crop as possible without regard to human or environmental health, doing so using minimal labor. Fundamentally, it is an extractive industry. Fossil fuels are extracted to power the machinery, processing, and logistics systems. Nutrients are extracted from the soil to the point that crop growth can only be sustained with heavy amounts of industrial fertilizer input. Entire ecosystems are sacrificed when forests are cleared to be exploited and repeatedly battered with pesticides. This is all primarily to produce soybeans, feed corn, and cotton to then process into products like factory farm livestock feed-slurry, corn syrup, junk food, and sweatshop garments. Secondarily, it is to produce flavorless, nutrition-void produce that can be sold year-round. Consistency is the goal, although one may find that nature itself is curiously inconsistent.

This case study of automation's failings can be traced back to a few major factors:

1. Old-style agriculture work is disagreeable to the USA's perverted fascination for infinite GDP growth; each farm laborer that can be replaced by a machine is a potential worker that could move into a city (or suburb) and put in the same amount of hours at a higher-dollar job. It's just opportunity cost, and this is more-or-less what Skidelsky and Fuller find offensive about our current labor zeitgeist; instead of the now-jobless laborers being free to pursue their interests, they are instead shoehorned into some shitty desk job that produces a relatively greater amount of money to be leeched by executives and shareholders -- this is "more productive" to our economy on the basis of GDP growth and thus must be prioritized over agricultural labor.

2. Industrial approaches to large-scale agriculture are inherently reductive to an extreme extent. Nature is far more complex than Liebig or any other enlightenment thinker ever imagined. Industrialization is great at making cars or computer chips or Gucci jackets or whatever, as these are things that can be standardized with relative ease. Nature cannot be tamed and standardized in a similar way; ecosystems, particularly soil ecosystems, can vary massively even in small areas of the same climate type. Our agriculture systems cope with this simply by ignoring such factors and reducing crop growth to a formula. In X region, plant Y variety of Z crop on A date and apply a regimen of B-type fertilizer and C-type pesticide on D date etc etc. This is the most egregious reduction of something in all of history.

Liebig's reduction of agriculture to the NPK model, just three elements, is good for achieving the singular goal of making your plant of choice come out of the ground, but it ignores all the nuance of soil, climate, and evolution. The other factors don't matter. Modern lab-designed fertilizers often feature a plethora of additional micronutrients, but the goal is still to produce a healthy crop, not healthy soil. Soil itself is an organism, it is something that must be nurtured to be healthy; industrial pesticide/fertilizer regimens are to the soil as feed slurry/antibiotic regimens are to factory farm animals.

Natural processes are, itself, the greatest form of automation for agriculture. Plants and animals that are native to a region have evolved to grow there regardless of human intervention. It is our disruption of these processes that forces agriculture to be labor/resource-intensive. This isn't to say that everyone must immediately abandon all non-native foods and adopt a primarily undomesticated Ötzi diet, but instead, it's worth considering that the complexity of modern technology is not even close to being at parity with the complexity of nature; nature has a several billion year head start. There is no way to flawlessly "tame" it with technological solutions, but a comfortable middle ground can certainly be found.

If sustainable, climate-friendly food production is the primary objective of agriculture, this is far more easily achieved by small, ecology-considerate farms than massive, largely automated industrial farms. A healthy soil ecosystem will aid in growth, flavor, nutrition, and, (quite importantly) carbon sequestration. Broadforking, shoveling, and wheelbarrow-pushing is absolutely more labor intensive than sitting back in a huge John Deere tractor with GPS-based autopiloting features, but the extra labor can turn a woefully extractive process into one that is instead highly regenerative.

20 notes

·

View notes

Text

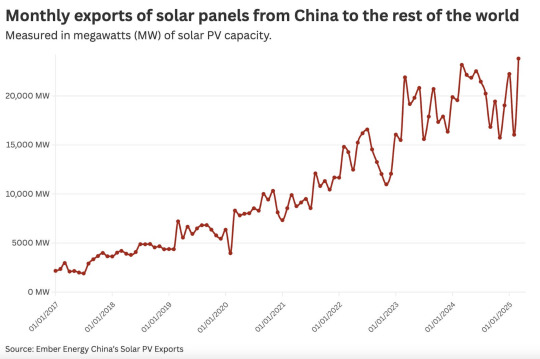

Excerpt from Sustainability by Numbers:

When it comes to clean energy technologies, China is crushing it.

It dominates the supply chain of the main energy minerals. It’s not only rolling out solar power rapidly at home, it’s also exporting huge amounts of solar panels elsewhere. Take a look at the chart [above], which shows solar PV exports from China to the rest of the world. Increasingly, these panels are going to low-to-middle income countries who are hungry for energy, and will go after whatever’s cheap: that’s Chinese solar.

It produces three-quarters of the world’s batteries. Its largest EV carmaker, BYD, is producing high-quality electric cars for as little as $10,000, and is growing rapidly in many markets across the world. BYD is now targetting the domestic battery market. CATL, the world’s largest battery manufacturer, is pushing the limits of battery technologies, with claims that it can add 300 miles of charge in just 5 minutes (I have some doubts about battery degradation, but I’d obviously love this to be true). The list goes on.

European and American manufacturers are being left in the dirt. One response has been protectionist policies: slapping on tariffs and implementing import quotas. A few newsletters ago, I argued that these were not good interventions if the goal was to increase the number of energy jobs in European and American markets. That’s because most clean energy jobs are in deployment and maintenance rather than manufacturing, and since higher costs slow down the rollout of renewables, increasing prices reduces the total number of people working in clean energy (even if the number working in manufacturing increases).

It produces three-quarters of the world’s batteries. Its largest EV carmaker, BYD, is producing high-quality electric cars for as little as $10,000, and is growing rapidly in many markets across the world. BYD is now targetting the domestic battery market. CATL, the world’s largest battery manufacturer, is pushing the limits of battery technologies, with claims that it can add 300 miles of charge in just 5 minutes (I have some doubts about battery degradation, but I’d obviously love this to be true). The list goes on.

China mainly dominates these markets because it has produced a long-term industrial strategy for these technologies and has honed an optimised, modern supply chain as a result.

The notion that China’s manufacturing output is purely the result of some centralised, governmental program is misguided; it has developed an incredibly competitive market with companies fighting for any edge to cut prices and beat competitors. The solar and battery industries are pretty brutal to be in, with slim margins.

Since China also refines a lot of the minerals and smaller components, its supply chains can become incredibly integrated, which also makes them more optimised.

The second big chunk is labour costs. Now, it’s undeniable that wages in the US are higher than they are in China. But this is not necessarily because Chinese salaries are abysmally low. Yes, they are low by American or European standards, but wages for factory roles are often higher than they are in the US’s southern neighbour, Mexico.

The biggest factor in labour costs is automation. The US uses six times as many workers per GWh (I initially found these numbers pretty shocking and hard to believe), so it’s not surprising that labour costs much more. China has invested heavily in automation, meaning many processes run with very little human input.

This is something else to keep in mind when considering the case for “bringing manufacturing jobs home.” There’s certainly scope for this, but it is at odds with the fact that low costs often rely on automation, not human labour. Especially with the growth of artificial intelligence, some manufacturing jobs could be increasingly vulnerable.

3 notes

·

View notes

Text

I am once again recommending Master of Orion (1993).

It's thirty years old, it originally came on floppy discs, and it's really good. The interface is crisp. The ship design system is neat. The technology research system is not your standard tech tree. It has helpful hotkeys like "Indicate next world that has enemy fleet inbound". It has antifeatures like "not doing a Cinematic Camera Pan for several seconds". It has detail while avoiding micromanagement by giving you mostly high-level control, and automatic reassignment of overflow when something like factory construction fills up.

I say it again because of discourse from a mutual's post.

hello gamer. you claim to want "shorter games with worse graphics that are made by people who are paid more to do less". in front of you is itch dot io, which has a "pay what you want" feature,

that… feels like an unfair take?

I don't want the claim as stated, I strongly suspect it's something said because it's catchy more than it's accurate, and I want to dissect its relation to things I do want, like MOO1.

shorter games

No, I want games with less padding.

I want fewer cinematic camera pans, and fewer cutscenes, and less of the dev team showing off their fancy tech demo, and fewer animations in the interface because the interface should have sub-second response time, and less loading time because the game should be smaller, and less grinding unless you're an idle game in which case it should be automated, and I want more automation and macros for things that are a waste of my attention as well as my time. Give me autoresolve for battles with weak enemies. Give me minions that can be sent to do things for me. Give me "repeat until" orders. Give me a dialogue meta-option that says "I've played this before, give me the TL;DR". Give me speed-up and skip buttons.

itch.io games have some of these, but also have less gameplay.

worse graphics

I'm close to agreeing with this, but IMO it's less about the graphics themselves and more about the 50GB graphics package and rendering engine that contemporary games like to include for little to no gameplay improvement, and then that enables lazy devs to think "another 3GB isn't a problem when we're already past 50GB" and the game bloats to 150GB as each dev includes a whole-ass library for one function, and then there's 10GB updates to download repeatedly.

I don't know if this is literally what happened behind the scenes, but a recent game like Baldur's Gate 3 did hit 150GB. Which also brings me to,

people who are paid more

I want developer studios to fire the movie team and redistribute their salary to the rest of the devs, with movie team describing the Thing that 'graphics department' has grown into.

A game like Age of Mythology doing in-engine cutscenes was cool when the engine was primarily a game engine and hands had eight polygons; these days it seems like AAA games also want to be movies and that means turning the game engine into a movie-maker, and hiring an entire movie team to render the 3D model of each character's armpit hair and the physics of how it moves in the wind when the character raises his arm.

Since budget is limited, that movie team comes at the expense of every other aspect of the game, like gameplay, writing, bugtesting, et cetera, and it still won't be as good a movie as an actual movie.

do less

See above. Less padding, less cinema.

20 notes

·

View notes

Text

𝑻𝒉𝒆 𝑪𝒍𝒆𝒎𝒆𝒏𝒕𝒊𝒏𝒆 𝒑𝒕. 𝟐: 𝒅𝒆𝒔𝒊𝒈𝒏 𝒂𝒏𝒅 𝒔𝒚𝒔𝒕𝒆𝒎𝒔

𝒔𝒄𝒊-𝒇𝒊 𝒅𝒓

𝒔𝒉𝒊𝒑 𝒄𝒍𝒂𝒔𝒔 𝒂𝒏𝒅 𝒄𝒐𝒏𝒇𝒊𝒈𝒖𝒓𝒂𝒕𝒊𝒐𝒏

Class: Modified mid-class freighter (original designation untraceable)

Dimensions: Compact and fast—built more for speed and evasion than cargo bulk

Original Use: Unknown. Judging by the design mix, she may have once been a light cargo hauler, but at this point, almost nothing about her is stock.

𝒉𝒖𝒍𝒍 𝒂𝒏𝒅 𝒂𝒓𝒎𝒐𝒓

Plating: Mismatched but reinforced. Some hull panels are standard titanium composite, others are salvaged from military vessels. I once found a piece stamped with a defense contractor logo. Soren played dumb.

Damage Markers: Scars from asteroid grazes, plasma burns, and at least one railgun strike that tore through the starboard side before being patched with a piece of what appears to be an old satellite dish.

Stealth Coating: A stolen stealth coating on one side (only one side), giving her a bizarre half-gloss appearance when flying in certain light.

𝒑𝒓𝒐𝒑𝒖𝒍𝒔𝒊𝒐𝒏 𝒂𝒏𝒅 𝒎𝒂𝒏𝒆𝒖𝒗𝒆𝒓𝒂𝒃𝒊𝒍𝒊𝒕𝒚

Here’s where things get... illegal.

Engine Type: Tri-core fusion drive (overclocked illegally)

Thrusters: Multi-angle vectoring thrusters scavenged from a racing skiff

Hyperspace Drive: Installed after-market. Very not standard. Definitely not licensed. Burns through fuel like sin, but gets the job done.

Maneuverability: Shockingly agile for her size. She’s not built to win dogfights—she’s built to not get hit.

Speed: Capable of outpacing most patrol cruisers and nearly anything in her class. Soren once escaped a blockade by flipping her vertical, killing main thrust, and gliding between two gunships with only manual microthrusters. Clemmy didn’t love that. But she did it.

Max Velocity: Classified (by Soren) as “if she shakes apart, you pushed her too far.”

Signature Trick: Emergency micro-bursts for fast stops or rapid angular shifts—great for dodging, terrible for unsecured passengers.

𝒐𝒇𝒇𝒆𝒏𝒔𝒊𝒗𝒆 𝒔𝒚𝒔𝒕𝒆𝒎𝒔

While not technically a warship, Clemmy has teeth—and Soren is not shy about using them.

Primary Weapons:

Retractable twin plasma cannons mounted under the nose (illegally modified for rapid cycling)

Hidden turret along the dorsal fin with full 360° tracking (camouflaged beneath sensor shielding)

Secondary Systems:

Ion net disruptor (used for disabling ships mid-chase)

Forward grappling harpoon (officially for salvage… unofficially for “creative boarding solutions”)

Mod Notes: All weapons have been internally rewired for faster charge times and energy efficiency. Soren insists it’s “completely safe.” The ship disagrees. The floor near the control relay is still scorched.

𝒅𝒆𝒇𝒆𝒏𝒔𝒊𝒗𝒆 𝒔𝒚𝒔𝒕𝒆𝒎𝒔

Shielding: Layered energy-dispersal field adapted from outdated military specs. It’s finicky, but when tuned right, it can absorb an entire volley without so much as a flicker.

Hull Reinforcement: Polyceramic inner shell under the patchwork hull. Not factory standard. Probably military surplus. Possibly stolen.

Cloaking:

Partial stealth mode: One side only. Meant for short bursts, ambushes, or dodging sensor sweeps. Jax once described it as “trying to hide behind your own arm.”

Signature Dampeners: Basic-grade dampeners, good enough to fool low-level scans or confuse weapons locks for a few seconds.

Countermeasures:

Chaff and flare deployment for missile evasion

ECM scrambler array that definitely violates at least five galactic communication laws

Reinforcement Field: Short-range gravitic pulse projector, used to knock boarding parties off balance or repel magnetic tethers.

𝒏𝒂𝒗𝒊𝒈𝒂𝒕𝒊𝒐𝒏 𝒂𝒏𝒅 𝒑𝒊𝒍𝒐𝒕𝒊𝒏𝒈

Primary Navigation System: Jury-rigged hybrid between an outdated freighter nav-core and a racing AI module. The interface is messy, but the calculations are blindingly fast—when they don’t crash mid-jump.

Manual Controls: Everything important is mapped to tactile controls. Soren doesn’t trust full automation. If the nav AI glitches mid-dive, he wants to feel the override.

Autopilot: Exists. Technically. Mostly used as a glorified parking brake or when Soren needs to sleep for 20 minutes in a safe orbit.

Charting Software: Half-legal, half-pirated. Capable of plotting hyperspace routes through narrow, high-risk corridors that most ships avoid.

Backup Systems: A wall-mounted hardcopy star chart in the cockpit. Just in case. Zia thinks this is hilarious. Soren calls it “responsible.”

𝒅𝒐𝒄𝒌𝒊𝒏𝒈 𝒄𝒂𝒑𝒂𝒄𝒊𝒕𝒚 𝒂𝒏𝒅 𝒂𝒄𝒄𝒆𝒔𝒔

Docking Clamps: Can attach to standard civilian ports, refueling stations, and most illicit trade hubs. May need to be “persuaded” into alignment.

Shuttle Bay: None. She’s too compact for internal hangars. Instead, she has one reinforced top-hatch cradle rigged for small detachable pods—used rarely, and only when absolutely necessary.

Airlocks:

Main Port: Standard-sized, sealed, and usually a bit stubborn when opening.

Secondary Hatch: Hidden behind a supply wall in the engine bay. Used for stealth entries and exits.

𝒓𝒆𝒑𝒂𝒊𝒓 𝒂𝒏𝒅 𝒎𝒂𝒊𝒏𝒕𝒆𝒏𝒂𝒏𝒄𝒆 𝒏𝒆𝒆𝒅𝒔

Routine Repairs: Constant. Something is always groaning, leaking, sparking, or “just about to give out but not yet.”

Spare Parts: Stored in crates scattered across the ship—engine parts in the pantry, coolant lines under the bench seat, wiring spools in my hydroponics pod (which I do not appreciate).

Self-Diagnostics: Unreliable. The system either reports “everything is fine” (it’s not), or starts shrieking about seven simultaneous reactor leaks (there are none). Soren usually ignores it and just listens to the hum of the engine to diagnose problems.

Repairs in Flight: Doable. Often necessary. Soren has made mid-warp hull welds while dangling from a tether. Zia once had to climb into the bulkhead to manually restart a fried fuse bank after a flare surge.

Critical Weakness: The fuel converter. If anything’s going to go first, it’s that. It’s been patched, rewired, and coaxed with offerings—but one day, it’s going to die loudly.

𝒔𝒚𝒔𝒕𝒆𝒎 𝒊𝒏𝒕𝒆𝒈𝒓𝒂𝒕𝒊𝒐𝒏

Power Grid: Custom-wired. Inconsistent. If too many systems are running at once (say, stealth mode, shields, and weapons), things start flickering. Choosing what gets power is sometimes a strategic decision—or a desperate one.

AI Integration: No full AI. Just a scattered handful of voice-assist systems, diagnostic subroutines, and a navigation core that occasionally asks Soren if he’s “sure about that” when he plots something stupid.

Voice Recognition: Primarily responds to Soren’s voice, but Zia has jury-rigged access to certain commands—especially life support, lighting, and doors.

𝒅𝒐𝒄𝒌𝒊𝒏𝒈/𝒃𝒐𝒂𝒓𝒅𝒊𝒏𝒈 𝒇𝒆𝒂𝒕𝒖𝒓𝒆𝒔

Hard-dock only. No fancy mag-coupling or remote landers.

Zero-G Transfer Capability: Yes, with magnetic grip points and a manually sealed transition tunnel.

Boarding Defense: Reinforcement field, sealed bulkheads, and at least three blasters stashed near the doors “just in case.”

𝒔𝒚𝒔𝒕𝒆𝒎 𝒏𝒐𝒕𝒆𝒔

Most systems are custom-built, hotwired, or frankensteined together. Only Soren knows how everything works—and even he sometimes has to hit things to make them run.

Diagnostics require manual calibration. The ship’s internal sensors are either hyper-sensitive or utterly dead.

Flight path records? Wiped. Regularly. On principle.

𝒊𝒏 𝒔𝒉𝒐𝒓𝒕:

Clementine might look like a rustbucket. But she’s got the firepower of a private gunship, the speed of a racer, and the evasive instincts of a hunted animal. She doesn’t win fights with brute force—she wins them by being faster, smarter, and just illegal enough to stay one step ahead of the galaxy’s worst.

𝒆𝒙𝒕𝒓𝒂

Ok, I'm gonna be honest here, my friend who's really into sci-fi had to help me write most of this, because as I've said before, I know like nothing about it. So all the fancy technical stuff in here was all him.

@aprilshiftz @lalalian

#reality shifting#shiftblr#desired reality#shifters#scripting#original dr rambles#reality shifter#dr scrapbook#original dr scrapbook

6 notes

·

View notes

Text

It used to be that when BMW would refit a factory to build a new car, the only way the automaker could check if the chassis would fit through the production line was to fly a team out and physically push the body through the process, making note of any snags.

Now, process engineers can simply run a simulation, sending a 3D model of the car through a near-identical digital twin of the factory. Any mistakes are spotted before the production line is built, saving time and money.

Such is the power of the industrial metaverse. Forget sending your avatar to virtual meetings with remote colleagues or poker nights with distant friends, as Mark Zuckerberg envisioned in 2021 when he changed Facebook’s name to Meta; the metaverse idea has found its killer app in manufacturing.

While the consumer version of the metaverse has stumbled, the industrial metaverse is expected to be worth $100 billion globally by 2030, according to a World Economic Forum report. In this context, the concept of the metaverse refers to a convergence of technologies including simulations, sensors, augmented reality, and 3D standards. Varvn Aryacetas, Deloitte’s AI strategy and innovation practice leader for the UK, prefers to describe it as spatial computing. “It’s about bridging the physical world with the digital world,” he says. This can include training in virtual reality, digital product design, and virtual simulations of physical spaces such as factories.

In 2022, Nvidia—the games graphics company that now powers AI with its GPUs—unveiled Omniverse, a set of tools for building simulations, running digital twins, and powering automation. It acts as a platform for the industrial metaverse. “This is a general technology—it can be used for all kinds of things,” says Rev Lebaredian, vice president of Omniverse and simulation technology at Nvidia. “I mean, representing the real world inside a computer simulation is just very useful for a lot of things—but it’s absolutely essential for building any system that has autonomy in it.”

Home improvement chain Lowe’s uses the platform to test new layouts in digital twins before building them in its physical stores. Zaha Hadid Architects creates virtual models of its projects for remote collaboration. Amazon simulates warehouses to train virtual robots before letting real ones join the floor. And BMW has built virtual models for all its sites, including its newest factory in Debrecen, Hungary, which was planned and tested virtually before construction.

To simulate its entire manufacturing process, BMW filled its virtual factories with 3D models of its cars, equipment, and even people. It created these elements in an open-source file format originated by Pixar called Universal Scene Description (OpenUSD), with Omniverse providing the technical foundation for the virtual models and BMW creating its own software layers on top, explains Matthias Mayr, virtual factory specialist at BMW.

“If you imagine a factory that would take half an hour to walk from one side to the other side, you can imagine it’s also quite a large model,” Mayr says. Hence turning to a gaming company for the technology—they know how to render scenes you can run through. Early versions of the virtual factory even had gaming-style WASD keyboard navigation, but this was dropped in favor of a click-based interface akin to exploring Google Street View in a browser, so anyone could easily find their way.

BMW also uses Omniverse for collaboration on car design and customization visualizations for customers, but a key benefit is being able to model production lines. New cars mean a new assembly process, but refitting a factory is a daunting process. Previously, key information was held in silos—production crews understood details of the assembly process, external suppliers had specs of new parts or machinery, architects had detailed building plans—and costs would pile up for every delay or mistake. “The later you find a problem, the worse it is,” says Lebaredian.

Now, problems are worked out virtually, with a central location for standardized data to be held. There’s still a critical human element: Mapping a facility requires sending a laser scanner strapped to a person running through a factory to capture point cloud data about how everything is arranged. Design engineers also need to create a 3D model of every stage of a car as it’s assembled. This level of detail allows BMW to virtually test the assembly process, complete with simulations of robotics, machines, and even human workers, as BMW has data tracking how long it takes employees to assemble a part.

The main idea is to avoid errors—does that machine even fit there?—but the system also enables optimization, such as moving a rack of components closer to a particular station to save steps for human assemblers. “You can optimize first and gain a lot of efficiency in the first production, and in the construction phase, you have fewer mistakes,” Mayr says. “It’s less error prone.”

Omniverse being a Nvidia platform, AI is naturally next. BMW is already layering in generative AI to help with navigation of its virtual models—they’re so massive that finding a particular point in the digital factory can still require asking a human expert for directions. But the aim is to use AI to optimize production lines too. “Because you have the whole data available, not just for one plant, it will be able to make good suggestions,” says Mayr—lessons learned in one factory could more easily be applied to others.

And then there’s robotics and other autonomous systems. Here, Omniverse can offer a digital space for testing before deploying in the real world, but it can also generate synthetic training data by running simulations, just as driverless car systems are trained with virtual video footage generated by AI. “Real-world experience isn’t going to come mostly from the real world—it comes from simulation,” says Lebaredian.

Aryacetas predicts that the biggest impact from the industrial metaverse will be embodied or physical AI—in other words, robots. “Robots aren’t fully there yet, but they’re rapidly training up to understand the physical world around them—and that’s being done because of these underlying spatial computing technologies,” he says.

The future of the metaverse isn’t avatars in a virtual world; it’s digital twins teaching industrial robots how to step out into the physical one.

2 notes

·

View notes

Text

Asset Located

(Reverse 1999 ocs)

It wasn't often her family contacted her, rather it wasn't often she would respond to their constant needs for updates and messages about their standing with the Foundation - the influx of letters, pager messages and whatnot filling her already stacked mailbox sitting abandoned in the corner of her office. It was a true wonder she choose to open the latest one that had, against all odds peeked her interest.

She waded through an ashen cacophony of charred wood and deteriorated stone, iron rusted and melting in certain places. If this factory had seen better days no evidence of it could be seen. Much of the building had collapsed in on itself during the fire, poor infrastructure and lack of proper safety protocols ensured anything of value that was in the factory was destroyed in the chaos ... all but one.

The letter denoted something of interest to the family that had been lost decades ago, and with the 'convenience' of the Storm dragging London to the 1930s Foundation personnel were able to find traces of the 'asset' in this factory. Further reading into the letter described how the 'asset' had been situated in this factory for some time, judging from interviews and sightings of workers and local residents: she was only messaged to seek out the 'asset' when the building suddenly caught on fire, engulfing the building with flame. The family hoped to salvage the 'asset' in whatever state it was currently in, hoping to retrieve it before the Foundation got their hands on it first. However, something strange was noted about this fire: no causalities whatsoever were recorded, all accounted for workers somehow had been miraculously saved in the inferno by someone; flames diverted or a hand pulling them to safety just before the ceiling collapsed.

She noted going through the wreckage it would have been near impossible for a zero causality rate with the previously mentioned lack of proper equipment and safety regulations, noting the frequency of accident in Laplace and her Department with its more (somewhat) advanced standards. Everyone in the building was found and relatively unharmed, whatever aided in their escape likely was trapped in the building's wreckage, hence her visit .

...

For an hour her search yielded nothing: outdated machinery, ash and broken parts of the building as far as the eye could register. Her family was finally insane, she figured as she began to leave the area. Finally succumbing to rumours and speculations to salvage some semblance of dignity and status by digging through the mud like rats. Wasting her previous vacation days on a whim and bordeom ... Until she noticed a shift in certain fallen bricks.

So someone was still unaccounted for, she promptly rushed over to the individual, choosing not to immediately locate the fellow Foundation personnel that accompanied her to the place. They would take ages to respond, and time (literally and figuratively) never acted in their favour, so she began to gently lift away the debris ... to reveal not someone, but something.

Stepping back, Juni realised she had located the 'asset'. And the 'asset' looked back.

...

Proportionally, it was human-like: an automation likely from the Steam Age like Madam Lucy; limbs casted in dull slivers and gold shifted and tweaked as it was freed from the debris. Its orb shaped head, with a peculiarly large smile had finally faced her; dim flickering lights serving as eyes registering her presence. From the unatural tweaking, Juni speculated the fire or the debris had damaged some of its components and rendered it unable to get up, instead pathetically tweaking and twisting in an attempt to stand. Juni approached it, and proceeded to grab its head and inspect it, the automaton seemed to twist even more in protest, but was unable to do anything to halt Juni's inspection. The tweaking quickly stopped after a few seconds.

There ... the 'asset' still contained the primary element noted in the letter, her unexpected trip yielded results at last. It glimmered dimly within the mess of wires, tubing and frame of the automaton's head: further inspection of the automaton showed it was largely intact, a few nicks and bumps in certain parts but largely whole. Its inability to move at the current moment was likely the result of over-arcanum exertion, putting it into a forced rest state of sorts. It would be quite easy to take the automaton to her family, earn some good graces with them and finally stop their constant pestering ... however further regarding the machine Juni considered another option: taking it for herself. She could easily take to the Foundation and register it as her assistant, fix it and maybe finally have enough help in her understaffed department. And as a bonus would further piss off her family.

Satisfied with her conclusion, Juni located the golden object attached to its head, remembering how the letter described the process of activating the arcane array and promptly shut off the automaton. The tweaking ceased as its eyes dimmed out. She stood up, inspecting the automaton again: she probably will need to call Foundation personnel to carry the thing, her left arm was already shaking in pain despite the short inspection.

The trip wasn't a total loss at all.

#reverse 1999#r1999#r1999 oc#reverse 1999 original characters#Containment Trio#forgor remembered#The Wayward Automaton#hi heres me finally posting my oc lore#idk if i need more tags?#forgor writes

4 notes

·

View notes

Text

Getting Started with Industrial Robotics Programming

Industrial robotics is a field where software engineering meets automation to drive manufacturing, assembly, and inspection processes. With the rise of Industry 4.0, the demand for skilled robotics programmers is rapidly increasing. This post introduces you to the fundamentals of industrial robotics programming and how you can get started in this exciting tech space.

What is Industrial Robotics Programming?

Industrial robotics programming involves creating software instructions for robots to perform tasks such as welding, picking and placing objects, painting, or quality inspection. These robots are typically used in factories and warehouses, and are often programmed using proprietary or standard languages tailored for automation tasks.

Popular Robotics Programming Languages

RAPID – Used for ABB robots.

KRL (KUKA Robot Language) – For KUKA industrial robots.

URScript – Used by Universal Robots.

Fanuc KAREL / Teach Pendant Programming

ROS (Robot Operating System) – Widely used open-source middleware for robotics.

Python and C++ – Common languages for simulation and integration with sensors and AI.

Key Components in Robotics Programming

Motion Control: Programming the path, speed, and precision of robot arms.

Sensor Integration: Use of cameras, force sensors, and proximity detectors for adaptive control.

PLC Communication: Integrating robots with Programmable Logic Controllers for factory automation.

Safety Protocols: Programming emergency stops, limit switches, and safe zones.

Human-Machine Interface (HMI): Designing interfaces for operators to control and monitor robots.

Sample URScript Code (Universal Robots)

# Move to position movej([1.0, -1.57, 1.57, -1.57, -1.57, 0.0], a=1.4, v=1.05) # Gripper control (example function call) set_digital_out(8, True) # Close gripper sleep(1) set_digital_out(8, False) # Open gripper

Software Tools You Can Use

RoboDK – Offline programming and simulation.

ROS + Gazebo – Open-source tools for simulation and robotic control.

ABB RobotStudio

Fanuc ROBOGUIDE

Siemens TIA Portal – For integration with industrial control systems.

Steps to Start Your Journey

Learn the basics of industrial robotics and automation.

Familiarize yourself with at least one brand of industrial robot (ABB, KUKA, UR, Fanuc).

Get comfortable with control systems and communication protocols (EtherCAT, PROFINET).

Practice with simulations before handling real robots.

Study safety standards (ISO 10218, ANSI/RIA R15.06).

Real-World Applications

Automated welding in car manufacturing.

High-speed pick and place in packaging.

Precision assembly of electronics.

Material handling and palletizing in warehouses.

Conclusion

Industrial robotics programming is a specialized yet rewarding field that bridges software with real-world mechanics. Whether you’re interested in working with physical robots or developing smart systems for factories, gaining skills in robotics programming can open up incredible career paths in manufacturing, automation, and AI-driven industries.

2 notes

·

View notes

Text

About socoje.com

SOCOJE is a factory direct sales company integrating production and sales that was re-established in order to expand production and scale. socoje was established in 2023. Its address is Room 1, 8th Floor, Building 513, Mingdu Garden South District Phase 1, Zhuodaoquan Village, Hongshan Township, Hongshan District, Wuhan City, Hubei Province,China. Its production bases are located in Dongguan and Ningbo . We are committed to designing, developing and manufacturing high-quality and innovative products to meet our customers' needs. As a leading Factory direct sales company, we possess advanced production facilities, technologies, and an experienced team. Our goal is to maintain a leading position in the market of intelligent mechanical equipment and accessories by providing reliable, durable, and competitive products. Our product range covers a variety of intelligent mechanical equipment and accessories, including but not limited to automation equipment, robots, control systems, metal machining category, plastic machining category, wood machining category, laser category, various tools, and components. We prioritize product quality and performance, ensuring that each product meets customer requirements and provides exceptional performance and reliability. As a Factory direct sales company, we have established long-term and stable partnerships with global collaborators. We work closely with suppliers, partners, and customers, actively listening to their feedback and needs. We believe that collaboration is key to achieving mutual success, and we strive to develop and succeed together with our partners. We always adhere to the principle of putting quality first. Through strict quality control processes and testing procedures, we ensure that each product meets high standards. We also prioritize environmental sustainability and take measures to reduce the environmental impact of our production processes. On socoje.com, you can learn about our product line, technical capabilities, and manufacturing processes. We welcome potential customers, partners, and suppliers to reach out to us to explore collaboration opportunities. If you have any questions or requirements regarding our products or services, our team is dedicated to providing support and assistance. Thank you for your interest and support in socoje! We look forward to working with you to create a better future for the intelligent mechanical equipment and accessories industry!

2 notes

·

View notes

Text

The Need for Digitization in Manufacturing : Stay Competitive With Low-Code

Industry 4.0 is transforming manufacturing with smart factories, automation, and digital integration. Technologies like the Internet of Things (IoT), artificial intelligence (AI), and low-code applications are enabling manufacturers to streamline processes and develop customized solutions quickly. Low-code platforms empower manufacturers to adapt to global demands, driving efficiency and innovation.

Previously, cross-border transactions in manufacturing faced delays due to bureaucracy, complex payment mechanisms, and inconsistent regulations. These challenges led to inefficiency and increased costs. However, Industry 4.0 technologies, such as digital payments, smart contracts, and logistics tracking, have simplified international transactions, improving procurement processes.

Low-code applications are key in this transformation, enabling rapid development of secure solutions for payments, customs clearance, and regulatory compliance. These platforms reduce complexity, enhance transparency, and ensure cost-effective, secure global supply chains. This shift aligns with the demands of a connected global economy, enhancing productivity and competitiveness.

The Need for Digitization in Manufacturing

Digitization has become crucial for manufacturing to stay competitive, with new technologies and the need for automation driving the sector’s transformation. Key features include ERP systems for centralized management of inventory, finances, and operations; digital supply chain tools for visibility and disruption prediction; real-time data for performance monitoring; sustainability tracking; and IoT/RFID for better tracking, accuracy, and reduced waste.

Low-code applications play a pivotal role in digitization by enabling rapid development of tailored solutions for inventory management, supply chain optimization, and performance analytics. These platforms streamline processes, reduce manual work, and enhance agility, helping manufacturers implement digital transformations quickly and cost-effectively.

Upgrading Manufacturing Capabilities in the Era of Industry 4.0 with Low-code Solutions

Low-code applications are becoming essential for digital transformation in manufacturing, addressing operational challenges while managing increased production demands and a shortage of skilled staff. These platforms enable manufacturers to quickly develop tailored applications without needing specialized coding expertise, fostering faster, more flexible operations. By streamlining processes and aligning with modern consumer demands, low-code technology helps bridge the skills gap, empowering manufacturers to stay competitive and seize new opportunities in a rapidly evolving market.

Low-code Technology Benefits for Modern Industries

As digital transformation becomes increasingly crucial for manufacturing, many enterprises in the sector face challenges with outdated processes, legacy system limitations, customization challenges, and inadequate resources. Low-code applications offer a compelling solution, enabling manufacturers to streamline operations by eliminating paper-based processes and automating workflows across functions such as Production, Sales, Logistics, Finance, Procurement, Quality Assurance, Human Resources, Supply Chain, and IT Operations. Additionally, low-code platforms enhance compliance and safety standards through built-in automated tools.

These platforms deliver impressive results, including over 70% improvement in productivity and close to 95% improvement in output quality in specific scenarios. This is particularly evident in automating complex processes like order fulfillment—from receiving customer orders to delivering finished products and managing invoicing with customers. Use cases also include automating inventory management, enhancing predictive maintenance with real-time data, and optimizing supply chain operations. Low-code solutions make it easier for manufacturers to implement changes quickly, boosting agility and reducing time-to-market while improving overall operational efficiency.

Conclusion

Low-code platforms are driving digital transformation in manufacturing, addressing sector-specific challenges in industries like automotive, aviation, and oil & gas. With Industry 4.0 and smart manufacturing, iLeap’s low-code platform helps integrate IoT, advanced analytics, and end-to-end automation, leading to optimized workflows and real-time decision-making. By adopting agile development, manufacturers can quickly adapt to new technologies and market demands, making iLeap the ideal partner for digital transformation. Unlock the potential of Industry 4.0 with iLeap and turn challenges into growth opportunities.

3 notes

·

View notes

Text

A non-exhaustive list of Minecraft mods I really like

Create

The gold standard of modern modded Minecraft shenanigans, with it's smooth animations, and crazy moving contraptions, and focus on automation/factories, and trains (if you're into that).

Thaumcraft

Easily one of the best magic systems I've seen in Minecraft, with research and potentially world ending threats. Also, the basis for the spectacular mod pack Blightfall, were all the weird corruption stuff is recontextualized as an alien taint already spread across the planet.

Equivalent Exchange

If Cookie Clicker was a Minecraft mod, it would be this. Converting any item into any other item thru a points system, with really powerful items to mold and shape your world to how you want.

Dimensional Doors

Pocket dimensions for your building, and pocket dungeons for your exploring. Really cool if you're more into building interior spaces without having to plan how it will look on the outside.

Not Enough Items

Basically a requirement in every mod pack because of the recipe list. It would be a crime not to mention it.

It's really a shame I could never put a mod pack with all of these in it together since they're pretty much restricted to different versions of the game.

#minecraft#modded minecraft#factory game#magic system#blightfall#thaumcraft#equivalent exchange#dimensional doors#minecraft create mod

31 notes

·

View notes