#Heat Shrink Cable Sleeves

Text

Essential Uses of Heat Shrink Cable Sleeves

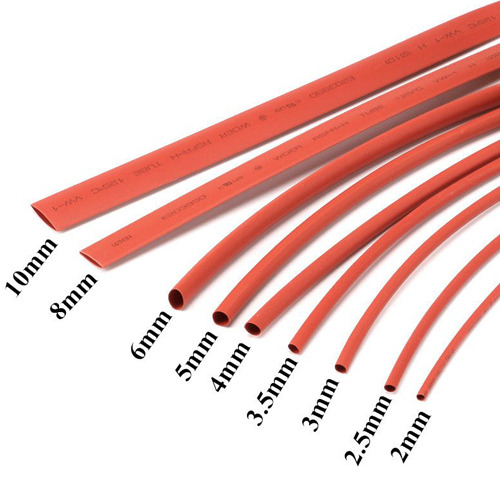

Heat shrink cable sleeves are essential components used in various industries for electrical insulation, cable protection, and wire bundling purposes. These sleeves are typically made from durable materials like polyolefin, PVC, or fluoropolymers, which shrink when exposed to heat, creating a tight seal around cables or wires. Here are some key aspects and applications of heat shrink cable sleeves:

Insulation and Protection: Heat shrink cable sleeves provide excellent electrical insulation, protecting cables and wires from environmental factors such as moisture, dust, heat, and abrasion. They help prevent short circuits, electrical shocks, and damage to the wiring system, ensuring reliable performance and safety.

Versatility: Available in various sizes, colors, and shrink ratios, heat shrink cable sleeves are versatile and can accommodate a wide range of cable diameters and applications. They can be used in automotive, aerospace, marine, telecommunications, and electronics industries, among others, for insulation, identification, and organization of cables and wires.

Easy Installation: Installing heat shrink cable sleeves is simple and requires only a heat source, such as a heat gun or oven. Once heated, the sleeve shrinks uniformly around the cable or wire, conforming to its shape and providing a snug fit. This makes it easy to cover complex cable configurations and irregular shapes effectively.

0 notes

Text

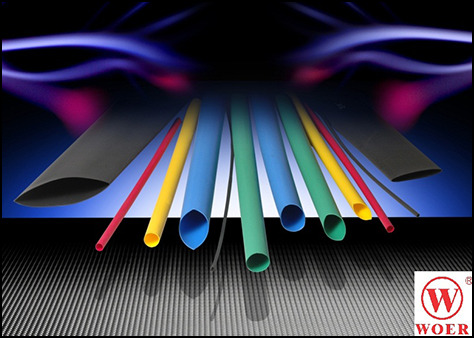

UPM Heat Shrink, Wire and Cable Sealing Insulation Protection Bundling Connectivity Identification

#upmheatshrink#heat shrink tubing#wire bundling#identification#marker sleeve#thin wall heat shrink#medium wall heat shrink#heavy wall shrink tubing#cable protection#sealing protection#heat shrink factory#heat shrink supplier

0 notes

Text

Get Better Connections with Yamuna Densons Copper Braids

We are one of the leading manufacturers and suppliers of copper braid. If you are looking for the best Copper Braid Manufacturers and Suppliers in India, So you have come to the right location. Please visit Yamuna Denson. Yamuna Denson Copper braid construction varies depending on the desired flexibility and application. A copper braid can be made with different wire diameters, with a smaller diameter resulting in greater flexibility. The degree of flexibility offered by various weaves, such as flat, round, and rope braids, can be selected by the particular needs of the application.

To know more information about our products, you can directly contact us at (91) 11 - 47025670.

#connector front & rear#cold shrink cable joints & terminations#conductor cover#heat shrinkable end caps#medium voltage cable jointing kit#low voltage cable jointing kit#bus bar connector#cable repair sleeve#shrinkable anti tracking#copper braid#Cable Repair Sleeve#Bus Bar Connector

0 notes

Text

Heat Shrink

A member of Gala Group of Industries with its establishments in the year 1979. entered into the business of Cable management products with specialization in the field of PVC and Heat Shrinkable range of products like Heat Shrink, Cable Joints, Cable Terminations, cable end sealing caps, Spreader caps, heat shrink end caps, heat shrink tubes, heat shrink sleeve, Cable Accessories, PVC Caps, Cable Splicing Kit, Branch Joint, heat shrinkable four way cable breakout, Heat Shrink Tape, Transition Joint, Electrical Insulating tubes, Strain relief Tubs, MV Cable Joints, Cable Splice, Bus bar Insulation Product, Low Voltage Splices, LV Cable Joint, etc.

0 notes

Text

Cable Ties Supplier in Ahmedabad | Control Panel Accessories Supplier in Ahmedabad - Samir Trading

Cable Ties Supplier in Ahmedabad | Control Panel Accessories Supplier in Ahmedabad - Samir Trading

About Samir Trading Corporation

Since 1982 in the Electrical Industry and in the Cable Tie industry since year 1986, with such a long experience we have the determination and the foresight to offer a wide range of high quality electrical products to Control panels manufacturers, Machine manufacturers, Electrical contractors, etc.

KSS is an ISO 9001 & ISO 14001 & OHSAS 18001 certificated company and has been approved by UL, CSA, VDE, DNV, GL, LLOYD, CE, ABS, IP68.

Customer Satisfaction with Best Quality at Reasonable Prices

OUR PRODUCTS

1.Cable Ties:

2. Control Panel Accessories:

3. Cooling Solution:

4.Copper lugs:

5.Heat Shrinkable sleeves:

6.Wiring accessories :

OUR BLOGS

1.KSS Cable Ties Supplier In Ahmedabad:

2.Locks & Hinges Suppliers In Ahmedabad:

3.Spirals Suppliers In Ahmedabad:

4.Printable Sleeves Suppliers In Ahmedabad:

5.Cable Tie Gun/Tool Suppliers In Ahmedabad:

6.Polyolefin Heat shrink Tubing Suppliers In Ahmedabad:

7.Cable Tie Mount Suppliers In Ahmedabad:

Quick Link

Home

About Us

Blogs

Contact Us

Products

Cable Ties

Heat Shrinkable Sleeves

Wiring Accessories

Control Panel Accessories

Cooling Solutions

Copper Lugs

Get in Touch

1451, Mamunayak Ni Pole, Nr. Jagat Agencies, Gandhi Road, Ahmedabad, Gujarat - 380001.

+91 97253 99929

+91 90168 13316

#Cable Ties Supplier in Ahmedabad#Wiring Accessories Supplier in Ahmedabad#Control Panel Accessories Supplier in Ahmedabad#Cooling Fan Supplier in Ahmedabad#Heat shrinkable sleeves Supplier in Ahmedabad#Copper Lugs suppliers In Ahmedabad.

0 notes

Text

Simplified Remedies: Professional Heat Shrink Cable Sleeve

One kind of plastic pipe that is used to shield and heat shrink cable sleeve, wiring, and other components is called heat shrink tubing. It is constructed from a number of components, including silicone, PVC, and polyolefin. Using a heat gun or another heat source, the pipe is heated until it shrinks and takes on the shape of the thing it is covering. This produces a tight, snug fit that enhances the object's insulating qualities and helps shield it from harm.

By Lowering Workplace Mishaps, Worker Security

Bar caps shield exposed reinforcing bars from harm, reducing the risk of accidents for building employees who may come into touch with them. Workers run the danger of impalement or severe injury from unintentional contact with projecting rebars if rebar covers are not used.

Construction sites are made safer by using caps to cover the uncovered ends of rebar. As a result, there is a decreased chance of worker injuries and workers' compensation claims due to a decrease in workplace accidents and occurrences. It is possible to make metals and alloys that are used in wire and cable applications resistant to corrosion, but corrosion prevention only comes from insulating the material.

Features of Insulation That Lessen Cable Stress

Heat shrink tubing helps to avoid excessive strain or stretch of wires and cables constrained to not enough room or length, even while it protects cabling and cabling from exposure to external conditions. The primary purpose of electrical wire and cable insulation is to guard against electrical shock.

On the other hand, energy loss and dissipation via the wiring is also stopped by the insulating properties of wires and cables. Cable insulators are made of non-conductive material and are intended to function as a barrier between themselves and anything that could come into touch with the cabling. Additionally, stronger resistance and improved information or energy transfer are offered by thicker insulation.

Any metal will eventually corrode because oxygen and metal combine to generate a new substance called oxide that degrades the metal's connections over time. Wires and cables are fully sealed and shielded from any external disturbance-induced corrosion via heat shrink tubing.

Source - https://heavyequipmentsuppliers.blogspot.com/2024/05/simplified-remedies-professional-heat.html

0 notes

Text

Bhagyadeep Cables: Leading the Way as a Premier Heat Shrink Sleeves Manufacturer in India

In the realm of electrical insulation and protection, heat shrink sleeves play a vital role in safeguarding wires, cables, and electronic components from environmental factors and mechanical damage. As industries demand reliable solutions for insulation and sealing, the need for high-quality heat shrink sleeves has soared. Among the manufacturers rising to meet this demand, Bhagyadeep Cables stands out as a premier provider, known for its excellence and innovation in producing heat shrink sleeves in India.

Precision Engineering and Innovation:

Bhagyadeep Cables embodies a legacy of precision engineering and innovation, reflected in its state-of-the-art manufacturing facilities and dedicated team of experts. Leveraging cutting-edge technology and advanced materials, they produce heat shrink sleeves of impeccable quality and performance. Whether it's designing sleeves for electrical insulation, cable bundling, or environmental protection, Bhagyadeep Cables combines expertise with innovation to deliver solutions that exceed industry standards.

Customized Solutions for Varied Applications:

Understanding that different industries and applications require tailored solutions, Bhagyadeep Cables offers a wide range of heat shrink sleeves customized to meet specific requirements. From standard sizes to bespoke designs, they work closely with clients to develop sleeves that offer optimal protection and performance. Whether it's for automotive wiring, aerospace applications, or industrial machinery, Bhagyadeep Cables provides heat shrink sleeves that ensure reliability and longevity in diverse environments.

Stringent Quality Control Measures:

Quality is paramount at Bhagyadeep Cables, and they adhere to stringent quality control measures to ensure the durability and reliability of their heat shrink sleeves. Each sleeve undergoes rigorous testing for shrink ratio, insulation resistance, and resistance to heat, moisture, and chemicals. By maintaining strict quality standards and certifications, Bhagyadeep Cables instills confidence in customers, assuring them of products that meet or exceed industry requirements.

Commitment to Customer Satisfaction:

Bhagyadeep Cables places a strong emphasis on customer satisfaction, striving to exceed expectations at every turn. Their customer-centric approach involves understanding the unique needs of each client and providing personalized solutions with unmatched quality and service. Whether it's offering technical assistance, expedited delivery, or ongoing support, Bhagyadeep Cables is dedicated to building lasting partnerships based on trust, reliability, and mutual success.

Sustainability and Environmental Responsibility:

As advocates for sustainability, Bhagyadeep Cables integrates eco-friendly materials and manufacturing processes into their operations. They prioritize the use of recyclable materials and energy-efficient production techniques, minimizing their environmental footprint while delivering high-quality products. By embracing sustainability, Bhagyadeep Cables not only contributes to environmental conservation but also sets an example for responsible manufacturing practices in the industry.

Driving Innovation and Industry Advancement:

Bhagyadeep Cables remains at the forefront of innovation in the heat shrink sleeve industry, continuously pushing the boundaries of what's possible. They invest in research and development initiatives to develop new materials, manufacturing techniques, and product designs that enhance performance and efficiency. By driving innovation and industry advancement, Bhagyadeep Cables sets new standards for heat shrink sleeves, powering progress across various sectors and applications.

In conclusion, Bhagyadeep Cables stands as a trusted partner and innovator in the realm of heat shrink sleeves manufacturing in India. Through precision engineering, customized solutions, stringent quality control, commitment to customer satisfaction, sustainability initiatives, and a drive for innovation, they continue to lead the industry forward, providing reliable solutions that safeguard and protect electrical components in diverse environments. As the demand for high-quality heat shrink sleeves grows, Bhagyadeep Cables remains dedicated to delivering excellence and driving progress for years to come.

0 notes

Text

Enhancing Power Distribution: Exploring Cable Jointing Kits and Switchgear Connections

In the realm of power distribution, efficiency, safety, and reliability are paramount. One crucial aspect that ensures seamless operation is the quality of cable jointing kits and switchgear connections. These components play a pivotal role in ensuring the uninterrupted flow of electricity, minimizing downtime, and safeguarding personnel and equipment against potential hazards.

Understanding Cable Jointing Kits

Cable jointing kits are indispensable components in electrical installations, facilitating the connection of power cables while ensuring electrical insulation and mechanical strength. These kits are designed to withstand various environmental conditions, including moisture, heat, and chemical exposure, thereby ensuring long-term reliability.

Types of Cable Jointing Kits

Heat Shrink Cable Jointing Kits: These kits utilize heat shrinkable materials to provide a secure and robust connection between cables. The heat shrink tubing, when heated, conforms to the shape of the cables, creating a tight seal that prevents moisture ingress and maintains insulation integrity.

Cold Shrink Cable Jointing Kits: Unlike heat shrink kits, cold shrink joints do not require heat for installation. Instead, they rely on pre-expanded rubber tubes that shrink to form a tight seal when the supporting core is removed. This method simplifies installation and reduces the risk of heat-related damage to cables.

Resin Cable Jointing Kits: Resin-based joints utilize epoxy or polyurethane compounds to encapsulate cable connections, providing excellent insulation and protection against environmental factors. These kits are particularly suitable for underground or submerged applications where moisture ingress is a concern.

Key Considerations for Cable Jointing Kits

Compatibility: Ensure that the chosen jointing kit is compatible with the cable types, sizes, and voltage ratings specified for the installation.

Environmental Suitability: Select kits that are rated for the environmental conditions present in the installation area, such as temperature fluctuations, moisture levels, and exposure to chemicals.

Ease of Installation: Consider the ease of installation, especially in confined spaces or challenging environments, to minimize downtime and labor costs.

Long-Term Reliability: Prioritize kits with a proven track record of reliability and durability to minimize the risk of future failures or maintenance issues.

Exploring Switchgear Connections

Switchgear forms the backbone of electrical distribution systems, allowing operators to control, protect, and isolate electrical circuits effectively. Properly installed and maintained switchgear connections are essential for ensuring the safety and reliability of power distribution networks.

Types of Switchgear Connections

Bolted Connections: Bolted connections are commonly used in medium to high voltage switchgear for their robustness and reliability. These connections involve tightening bolts to secure conductors or busbars, ensuring low resistance and high mechanical strength.

Crimped Connections: Crimping is a widely adopted method for connecting conductors in low voltage switchgear and control panels. This technique involves deforming a metal sleeve around the conductors using a crimping tool, creating a strong and durable connection.

Plug and Socket Connections: Plug and socket connections offer versatility and ease of maintenance, allowing for quick disconnection and reconnection of electrical components. These connections are often used in modular switchgear designs for their convenience and flexibility.

Best Practices for Switchgear Connections

Proper Torque Application: Ensure that bolts and connectors are tightened to the manufacturer's recommended torque specifications to prevent overheating, arcing, and mechanical failure.

Regular Inspections: Implement a routine inspection schedule to detect signs of corrosion, loose connections, or other issues that may compromise the integrity of switchgear connections.

Use of Insulating Materials: Apply insulating materials such as heat shrink sleeves or insulating tape to exposed conductors or connections to prevent accidental contact and electrical faults.

Adherence to Standards: Follow industry standards and guidelines for switchgear design, installation, and maintenance to ensure compliance with safety regulations and optimal performance.

Conclusion

In conclusion, cable jointing kits and switchgear connections are integral components of power distribution systems, contributing to their efficiency, reliability, and safety. By selecting the appropriate kits and implementing best practices for installation and maintenance, operators can ensure the seamless operation of electrical networks while mitigating the risk of downtime and hazards. Investing in high-quality components and adhering to industry standards is key to optimizing the performance and longevity of power distribution infrastructure.

0 notes

Text

Why Is Fire Stopping So Important?

A key component of passive fireproofing is fire stopping, sometimes called compartmentation. It describes the procedure of using fire-resistant material to seal gaps and cracks between walls and floors to prevent fire from spreading across different "compartments" of a building.

The significance of fire-stopping

Fire prevention is crucial to building safety. They must prevent fires from spreading through various building divisions. Smoke and flames can swiftly spread through a building without fire stops, destroying it and endangering its people. Fire stops assist emergency responders in putting out fires before they spread. Fire-fighting measures must be monitored and evaluated after installation. You may be liable for not complying with fire safety requirements if a fire occurs.

Use suitable fire-preventing materials and hire reputed companies offering fire-stopping services for advice.

How does it operate?

Use technologies like thermal bonds to seal large and small openings between building regions to stop or considerably delay fire spread. The walls of each area should be industry-approved fire-resistant, and fire-stopping devices prevent fire, smoke, and heat from spreading.

We'll review some fire-stopping items now:

Fire Collars

A fire-resistant fire collar covers pipes, ducts, cables, and other penetrations in walls and ceilings. A fire collar's material swells when heated, filling gaps and preventing fire and smoke from spreading. Due to its heat resistance, it will also shield the surrounding region. When inert, a fire collar allows pipes and similar to expand and shrink as they heat up and cool down. Different fire collars suit different uses and room styles.

Fire Sealants

These procedures seal holes between rooms that fire or smoke could pass through. They come in several kinds and based on the region you're sealing. Silicone, acrylic, and foam are ideal for diverse locations. Some buildings enable movement, whereas others don't. These protect wall, ceiling, and floor joints and partitions.

Fire Sleeves

Fire sleeves are tubes that fit around pipes, cables, and hoses that pass through walls or ceilings. They prevent fires so other portions of the building can operate. Some fire sleeves don't protect what they contain. When subjected to severe heat, the fire sleeve around a plastic pipe will grow and expand, squeezing it and impeding fire, smoke, and heat.

Fire Covers

Always install fire-resistant ceiling tiles and lighting. When removing a ceiling tile to install a light, you'll need a fire or luminaire cover to cover the back. This cover further protects the fire-resistant ceiling. Many different fire-stopping materials, including gypsum plaster, cement mortar, ceramic, glass fibers, and others, can be employed. Thus, you must hire builders who understand fire rules and can reduce fire spread in your structure. A fire stop survey by a qualified contractor is worth having for an older building built before the current fire rules.

Conclusion

Even with the finest fire stops, evacuate a building that catches fire quickly. Leave the building without collecting your belongings, but don't rush. The last thing you want is to fall downstairs. Leave via stairs, not the lift, and walk as far away from the building as possible; most companies establish a meeting spot and phone the fire department if the electricity goes out.

Check everyone out by doing a head count if you're a family or small business or using a sign-in book.

Be safe rather than be sorry!

Summary:

Fire stopping is a critical aspect of passive fireproofing, involving the use of fire-resistant materials to seal gaps and cracks in buildings. It prevents the spread of fire, smoke, and heat, ensuring the safety of occupants and allowing emergency responders to control fires more effectively. Hiring reputable companies and using suitable fire-preventing materials is essential to comply with fire safety requirements and protect against potential liability.

Resource Box:

Alpha Progress offers high-quality STI Firestopping Sprays for professional construction projects. These sprays provide effective fire protection and help ensure the safety of buildings and occupants.

0 notes

Text

"Mastering Precision and Protection: Unveiling the Wonders of PVC Heat Shrinkable Sleeves"

In the realm of industrial materials and insulation solutions, the significance of high-quality PVC Heat Shrinkable Sleeves cannot be overstated. These sleeves are instrumental in protecting wires, cables, and components against environmental factors, corrosion, and abrasion, thereby ensuring durability and reliability in various applications. Amidst the array of manufacturers, Dee Five Shrink Insulations Pvt Ltd stands tall as an unrivaled leader in producing PVC sleeves in bulk quantity.

Pioneering Innovation

At the heart of Dee Five Shrink Insulations Pvt Ltd lies a dedication to innovation. Their relentless pursuit of excellence is manifested in their cutting-edge manufacturing processes, where advanced technology converges with years of industry expertise. By incorporating the latest machinery and adhering to stringent quality standards, they consistently deliver PVC Heat Shrinkable Sleeves that exceed industry benchmarks.

Unparalleled Quality

Quality serves as the cornerstone of Dee Five Shrink Insulations Pvt Ltd's operations. Each sleeve undergoes rigorous testing at every stage of production to ensure adherence to international quality norms. From the sourcing of premium-grade raw materials to the final inspection, their commitment to quality control is unwavering. This meticulous approach guarantees that their PVC Heat Shrinkable Sleeves offer exceptional insulation, superior protection, and prolonged service life.

Customization and Bulk Production

One of the distinctive attributes of Dee Five Shrink Insulations Pvt Ltd is their capability to cater to bulk orders without compromising on customization. Understanding the diverse requirements of clients across industries, they offer a spectrum of sizes, colors, and specifications. Whether for electrical, automotive, or industrial applications, their ability to tailor-make sleeves while meeting large-scale demands sets them apart.

Reliability and Timely Delivery

In the competitive landscape of manufacturing, reliability, and timely delivery are non-negotiable. Dee Five Shrink Insulations Pvt Ltd excels in both aspects, fostering enduring relationships with clients through consistent product quality and adherence to delivery schedules. Their streamlined processes and efficient logistics ensure that bulk orders reach customers within stipulated timelines, facilitating seamless operations for their clients.

Customer-Centric Approach

Beyond the product, Dee Five Shrink Insulations Pvt Ltd thrives on a customer-centric philosophy. They prioritize understanding client needs, offering technical support, and providing after-sales service to ensure utmost satisfaction. Their commitment to forging long-term partnerships goes beyond mere transactions, establishing trust and reliability in every interaction.

Conclusion

Dee Five Shrink Insulations Pvt Ltd emerges as a beacon of excellence in the competitive landscape of PVC Heat Shrinkable Sleeve manufacturing. Their dedication to innovation, unwavering commitment to quality, capacity for customization, reliability in delivery, and customer-centric approach collectively position them as the foremost choice for businesses seeking superior insulation solutions in bulk quantity.

For enterprises seeking reliability, quality, and scalability, Dee Five Shrink Insulations Pvt Ltd stands as the epitome of excellence in PVC Heat Shrinkable Sleeve manufacturing.

0 notes

Text

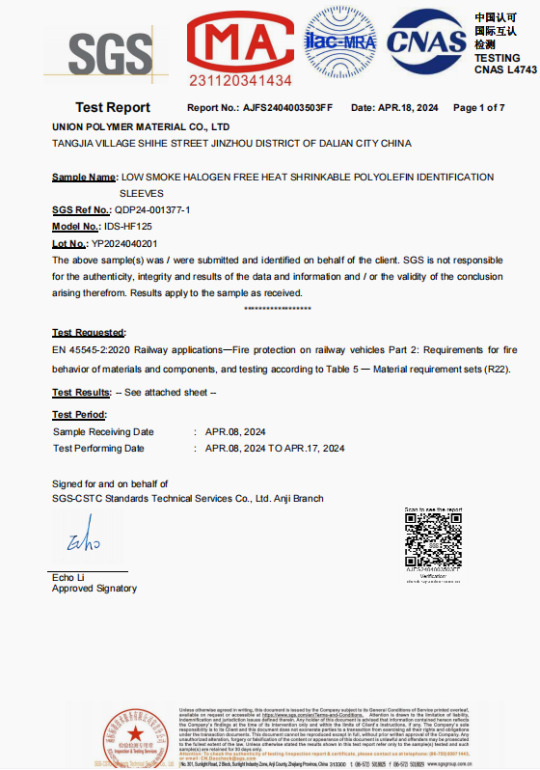

Heat Shrink Identification Marker Sleeve for railway vehicles, Comply with EN45545 .

#heat shrink tubing#shrink marker sleeve#identification sleeve#railway vehicles#upm heat shrink#cable marking#ladder format

0 notes

Text

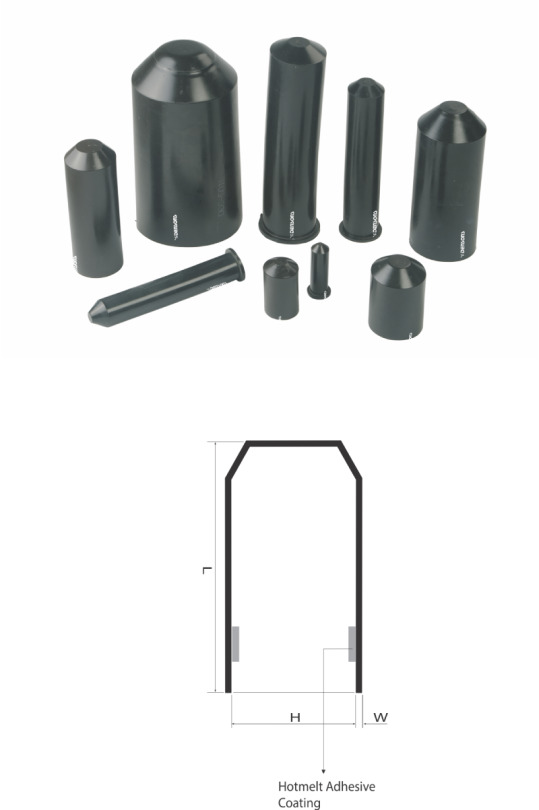

Protect Your Equipment with Yamuna Denson's Heat Shrinkable End Caps

Yamuna Denson Heat Shrinkable End Caps provide optimum waterproofing and environmental protection for underwater, underground, and outdoor applications. Our heat-shrink end caps are highly resistant to moisture, fungus, and weathering. We also offer electrical end caps with pre-coat sealants. The heat-shrink end caps are available in several sizes to accommodate varying cable diameters due to their large range-taking ability.

Contact Us Today.

#connector front & rear#cold shrink cable joints & terminations#conductor cover#heat shrinkable end caps#medium voltage cable jointing kit#low voltage cable jointing kit#bus bar connector#cable repair sleeve#shrinkable anti tracking#copper braid

0 notes

Text

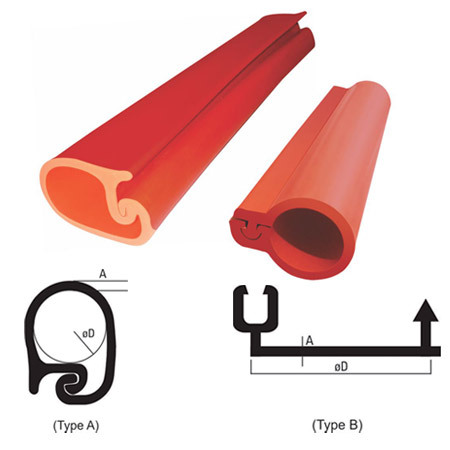

Angle Boot

Cable management products like cable end sealing caps,heat shrink end caps,heat shrinkable moulded shapes,heat shrinkable tubes,busbar insulation shrouds, heat shrinkable wrap around sleeve

0 notes

Text

Heat Shrink

A member of Gala Group of Industries with its establishments in the year 1979. entered into the business of Cable management products with specialization in the field of PVC and Heat Shrinkable range of products like Heat Shrink, Cable Joints, Cable Terminations, cable end sealing caps, Spreader caps, heat shrink end caps, heat shrink tubes, heat shrink sleeve, Cable Accessories, PVC Caps, Cable Splicing Kit, Branch Joint, heat shrinkable four way cable breakout, Heat Shrink Tape, Transition Joint, Electrical Insulating tubes, Strain relief Tubs, MV Cable Joints, Cable Splice, Bus bar Insulation Product, Low Voltage Splices, LV Cable Joint, etc.

0 notes

Text

Industrial Strength: Audio Visual Cable Management for Commercial Spaces

The increasing reliance on audio visual technology in commercial spaces like offices, retail stores, hotels, educational institutions etc has led to a growing need for efficient av rack cable management. A mess of cables snaking across floors and behind furniture can not only look unprofessional but also pose safety hazards. Proper cable management ensures workplace safety and reliability of AV systems over long run.

The Basics of AV Cable Management

Any cable management system for commercial spaces needs to be rugged and durable to withstand high traffic areas. It must be able to accommodate growing cable needs as technology and systems upgrade over time. Some basic elements involved in av rack cable management are:

Cable Trays and Raceways

Open cable trays allow hooking cables on surfaces above false ceilings or below raised floors. Enclosed raceways provide additional protection and are preferable for public areas with dust, moisture. Trays can be surface mounted, recessed or suspend from structure. Material choices include steel, aluminum or non-metallic.

Cable Ties and Wraps

Reusable cable ties of different sizes are essential for neat bundling of loose cables. Heat shrink tubing or sleeves provide abrasion protection during installation and movement. Velcro wraps allow adjustable grouping.

Cable conduits and Channels

Flexible or rigid metallic/non-metallic conduits safely route cables along walls or floors. Surface mounted wiremold channels elegantly conceal cables against baseboards or along skirting.

Patch Panels and Outlets

Neatly terminated connections at central patch panels in equipment rooms allow flexible reconfiguration of signals. Welcoming additions are surface mounted boxes, floor boxes or in-wall outlets for end points.

Junction Boxes

Pull boxes, disconnect boxes provide easy access for future cable additions/changes without dismantling entire runs. Covers keep intact when not in use.

Cable Management for Specific Areas

Different functional areas have customized cable management needs:

Lobbies and Reception

Welcoming first impressions require subtle, blended-in solutions. Under-carpet raceways, discreet skirting channels, small in-wall boxes serve purpose aesthetically.

Conference Rooms

Tight management is key around tables with multiple user devices. Tables with central grommets, floor pockets, high-density outlet boxes facilitate easy access.

Open-Plan Offices

Breakout spaces need versatile, movable screens. Modular tray systems, movable furniture channels create flexibility for regular shifts.

Cafeterias and Lounges

Ability to withstand moisture, impacts becomes important. Exposed conduits paired with durable enclosure back boxes hold up to wear-and-tear.

Techniques for Efficient Implementation

Proper planning and established techniques ensure long term, scalable av rack cable management:

Documentation

As-built drawings guide future upgrades/troubleshooting by depicting existing cabling plant layout, pathways, termination/patch points.

Labeling

Consistent identification of cables, outlets, termination points aids tracing circuits, troubleshooting fast.

Spooling

Looping generous lengths of slack cable into junction/pull boxes eases future pulls/repairs without dismantling.

Conduit Fill Calculations

Maximizing fill without cramming ensures smooth pulling of future cables through pathways.

Firestop Sealant

Maintaining compartmentalization at wall/floor penetrations safeguards wiring from fire, smoke spread in emergencies.

Testing

Post-installation certification verifies cabling, termination integrity before use, acts as baseline for future tests.

Future-Proofing AV Systems

Proactive considerations future-proof av rack cable management:

Cable Specifications

Selection of ‘Category’ rated cables supports higher bandwidths of tomorrow’s AV/IT systems on existing pathways.

Sizing of Infrastructure

Oversizing conduits, raceways, termination capacity to handle bandwidth intensive applications like 4k video, IoT.

Consolidation Points

Creation of intermediate cabling/equipment distribution hubs eases scalability across zones.

Power Distribution

Careful load calculations, ample circuits accommodate more devices/displays with PoE/PoE+.

Monitoring

Incorporation of network switches with LAN monitoring/alerts alerts early bottlenecks ahead of failures.

Outsourcing Installation

Engaging certified cabling installers secures high quality, standards compliance for longevity, ROI.

Conclusion

Implementing robust industrial strength av rack cable management ensures easy upgrading, reworking of commercial AV systems crucial for long term business operations. Done right, it delivers aesthetic, functional benefits with scalability to support technological evolutions to come. Neat, buried cabling gives clean feel while simplifying troubleshooting and future changes to networked infrastructure.

0 notes

Text

Immech – 300 pcs Colours Assorted Polyolefin Heat Shrink Tube, Insulated Wire Cable Sleeving Wrap, Multicolour, 8 Different Cut Size with Box

View On WordPress

0 notes