#IEC 61131-3 programming standard

Explore tagged Tumblr posts

Text

NX-ERA PLCs assist Control, Supervision and Monitoring of Water Treatment Plants to Enhance Efficiency (WTP and STP)

In our increasingly resource-conscious world, the efficient management of water, both in industrial and municipal settings, has moved from being a desirable practice to an absolute necessity. From ensuring the purity of drinking water that nourishes communities to effectively treating industrial wastewater generated by manufacturing processes, the challenges are complex and require sophisticated solutions. Enter the transformative power of industrial automation, where pioneering companies like Messung are at the forefront, developing cutting-edge Programmable Logic Controllers (PLCs) designed to revolutionize water monitoring and control systems for efficient industrial wastewater treatment.

A number of vital processes are involved in the complex movement of water from its natural origins to our homes and businesses and back again. The inability to provide real-time data, guarantee accurate chemical dosage, and maintain constant system reliability under a variety of operating situations are common drawbacks of traditional monitoring and control techniques. This is the exact point at which automation's intelligence and effectiveness, powered by reliable plc control systems, become essential. Through the use of advanced control techniques, automation guarantees constant water quality that satisfies stringent requirements, optimizes the use of precious resources, reduces waste production, and eventually helps to make water management more economically and environmentally responsible.

In this blog, we will explore how industrial automation through PLCs contributes towards efficiency in the process of water treatment.

The Imperative of Advanced Water Monitoring and Control

There are several complexities in the water distribution and treatment landscape. Among the many difficulties faced by operators is the requirement for constant, real-time monitoring of vital parameters such as flow rates, pressure levels, pH values, turbidity, and the presence of different contaminants. Maintaining the overall system reliability of pumps, valves, and other critical equipment is important for continuous operation while ensuring precise and timely chemical dosing is critical for efficient treatment.

The necessity for effective control methods is further increased by the more stringent environmental standards. There is tremendous demand for industries to use efficient industrial wastewater treatment systems that adhere to strict discharge regulations. To protect the public's health, municipal water treatment facilities also have to meet strict quality criteria. In this situation, integrating advanced automation technologies becomes essential to maintaining compliance and operational excellence, not merely a benefit. In order to maintain constant water quality and effective resource use, automation is becoming a necessity rather than a pipe dream.

NX-ERA PLC Series: The Nexus of Industrial Automation and the Cornerstone of Intelligent Water Management

An important advancement in automation technology for the water treatment industry is represented by our feature rich PLC series the NX-ERA. These PLCs designed with an extensive understanding of the specific demands of the sector, provide a strong and adaptable framework for controlling intricate water distribution and treatment procedures. From small-scale pumping stations to massive water and sewage water treatment plants, the NX-ERA series' built-in adaptability and scalability enable smooth adaptation to a broad range of system sizes and complexities. In order to minimize interruption and maximize investment protection, their strong compatibility with a wide range of industry standards guarantees smooth integration with current sensors, actuators, communication networks, and other essential infrastructure components.

Delving into the advanced features of plc within the NX-ERA series reveals a suite of capabilities designed for optimal water management.

High-speed Processing Power: Enables rapid and precise control of time-sensitive processes.

Advanced Communication Interfaces: Facilitate seamless data exchange with other control systems and enterprise-level platforms.

Remote I/O capabilities: Extend the reach of control and monitoring to geographically dispersed assets, providing operators with a comprehensive overview of their entire water network.

Integration with SCADA systems: Provides a centralized platform for visualization, data logging, alarm management, and advanced control strategies, empowering operators with the information and tools they need for effective decision-making.

NX-ERA PLC’s Advantage for Enhanced Automation in Water Treatment

Selecting NX-ERA PLC for water management applications translates into a multitude of tangible benefits:

Unwavering Reliability: NX-ERA PLC series is designed to withstand the harsh conditions of industrial settings, and have a high Mean Time Between Failures (MTBF) and a low Mean Time to Repair (MTTR). This ensures that vital water systems operate continuously and dependably, reducing downtime and increasing operational efficiency.

Unmatched Adaptability: NX-ERA PLC facilitates system updates and expansions by supporting a broad range of communication protocols, including industry-standard choices like Ethernet, Modbus, and Profibus. They also provide unmatched flexibility in interfacing with a variety of field devices and current control systems.

Intuitive User-Friendly Programming: Programmers can work in a familiar and intuitive environment as they comply with the IEC 61131-3 programming standard. The software's readily apparent interface speeds up timelines for projects and lowers engineering costs by making it easier to create, commission, and maintain control programs.

Enhanced System Diagnostics: The NX-ERA series' advanced diagnostic features give operators real-time information about the health of the system and possible problems, allowing for proactive maintenance and lowering the possibility of unplanned failures.

Robust Redundancy Architecture: NX-ERA PLCs offer comprehensive redundancy across critical system layers, including IO, CPU, Profibus, and Ethernet control networks. This multi-level redundancy ensures uninterrupted operations even in the event of hardware or communication failures, making them ideal for mission-critical water treatment applications where system uptime is paramount.

Diverse Applications Across the Water Treatment and Distribution Spectrum

NX-ERA PLC series finds versatile applications across the entire spectrum of water management:

Optimizing Water Treatment Plants: NX-ERA PLC automates vital procedures in water treatment plants, including backwashing, coagulation and flocculation, sedimentation, filtration, disinfection (including accurate chemical dosing), and raw water intake control. High-quality drinking water that adheres to stringent regulatory criteria is produced by ongoing turbidity monitoring and management.

Increasing Pumping Station Efficiency: NX-ERA PLC uses advanced control algorithms to regulate water flow rates and preserve ideal pressure in distribution networks. By optimizing pump operation depending on current demand and system conditions, this intelligent control results in significant energy savings.

Intelligent Reservoir Management: NX-ERA PLC offers real-time monitoring of vital data, including water levels, temperature, and water quality indicators, for reservoirs and storage facilities. This data enables proactive management of water resources, informed decision-making regarding water release, and early detection of potential issues.

Revolutionizing Wastewater Treatment Plants: The NX-ERA Premium PLCs are vital for controlling and monitoring sewage treatment processes. These include pumping, sedimentation, biological treatment, sludge handling, and discharge. The PLCs enhance efficiency by automating pumps, valves, and sensors. They reduce costs by saving energy and chemicals while ensuring compliance with environmental rules. With PLCs, industrial wastewater treatment becomes more precise and reliable.

Messung’s Role in Sustainable Wastewater Management

Protecting the environment and public health depends on efficient sewage treatment. To improve wastewater management, Messung offers reliable automation systems. Operators can precisely regulate sewage treatment processes with the NX-ERA PLC series, which guarantees higher pollutant removal, increased effluent quality, and less environmental impact.

It is essential to comprehend the water and sewage treatment processes, and the NX-ERA PLC Series offers the technology to maximize efficiency in both. Our cutting-edge automation systems enable sustainable, effective operations in both industrial and municipal corporations.

Conclusion

Advanced automation, like the NX-ERA PLC series, is essential for efficient and sustainable water management. With deep expertise in water industry challenges, we help build a greener future. With intelligent control, real-time monitoring, and seamless integration, we help organizations optimize treatment processes, reduce waste, and conserve water resources.

Ready to transform your water management with smart automation? Reach out to us today to explore how our cutting-edge controllers can boost efficiency, reliability, and sustainability in your operations.

#Programmable Logic Controllers (PLCs)#industrial wastewater treatment#water monitoring and control systems#plc control systems#process of water treatment#sewage water treatment plants#water management applications#IEC 61131-3 programming standard#water treatment plants#Premium PLCs#sewage treatment#water management

0 notes

Text

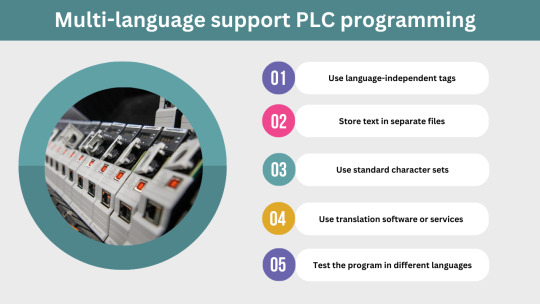

Multi-language support PLC Programming

Multiple languages in PLC (Programmable Logic Controller) programming can be crucial for various reasons, including internationalization, ease of collaboration across multinational teams, and compliance with local regulations.

IEC 61131-3 Languages

Language Selection

Internationalization and Localization

Comments and Documentation

Training and Support Materials

Standardization Across Projects

Testing and Validation

Collaboration Tools

Compliance with Regulations

Flexibility and Adaptability

🌐Website :- https://asteamtechno.com

👉Contact us :- +91 95372 40404

📧Email :- [email protected]

#trending#automation#tumblr trends#viral#viralpost#trendingnow#bestdeals#allen bradley#rockwell automation#plc#today on tumblr#artists on tumblr#poets on tumblr#plcprogramming#technology

3 notes

·

View notes

Text

Introduction to CODESYS PLC: A Comprehensive Overview

CODESYS (Controller Development System) is a leading software platform for industrial automation, widely used for programming and configuring Programmable Logic Controllers (PLCs). Developed by the German company 3S-Smart Software Solutions, CODESYS PLC is a versatile, hardware-independent development environment that supports a broad range of industrial applications, from factory automation to process control and motion control systems. This article explores the key features, benefits, programming capabilities, and applications of CODESYS PLC, highlighting its significance in modern industrial automation.

What is CODESYS?

CODESYS is an integrated development environment (IDE) that adheres to the international standard IEC 61131-3, which defines programming languages for PLCs. This standard ensures that CODESYS is compatible with a wide variety of hardware platforms from different manufacturers, making it a flexible and scalable solution. The platform supports all five IEC 61131-3 programming languages: Ladder Diagram (LD), Function Block Diagram (FBD), Structured Text (ST), Instruction List (IL), and Sequential Function Chart (SFC). Additionally, CODESYS extends support for object-oriented programming (OOP) with languages like Structured Text, enabling advanced programming techniques.

The CODESYS ecosystem includes not only the core IDE but also additional tools for visualization, simulation, debugging, and communication with field devices. It is used in industries such as manufacturing, energy, automotive, and building automation, offering a unified platform for developing complex automation solutions.

Key Features of CODESYS

IEC 61131-3 Compliance: CODESYS supports all standard PLC programming languages, allowing developers to choose the most suitable language for their application. This compliance ensures portability of code across different PLC hardware, reducing development time and costs.

Hardware Independence: CODESYS is compatible with over 1,000 devices from various manufacturers, including Siemens, Beckhoff, WAGO, and others. This flexibility allows engineers to write code once and deploy it on multiple platforms without significant modifications.

Integrated Visualization: CODESYS provides built-in tools for creating Human-Machine Interfaces (HMIs). Developers can design graphical user interfaces for operator panels, web-based visualizations, or mobile applications, all within the same environment.

Fieldbus and Communication Support: The platform supports a wide range of industrial communication protocols, such as Modbus, CANopen, EtherCAT, PROFINET, and OPC UA. This ensures seamless integration with sensors, actuators, and other devices in an automation system.

Simulation and Debugging: CODESYS includes a powerful simulation mode that allows developers to test their programs without physical hardware. The debugging tools enable real-time monitoring, breakpoints, and variable tracing, streamlining the development process.

Scalability and Modularity: From small embedded systems to large distributed control systems, CODESYS is highly scalable. Its modular architecture allows developers to add libraries, function blocks, and extensions as needed.

Safety and Security: CODESYS supports safety programming according to standards like IEC 61508 (SIL 2/3), making it suitable for safety-critical applications. It also includes features for secure communication and user authentication to protect against cyber threats.

Programming with CODESYS

CODESYS offers a flexible programming environment that caters to both novice and experienced developers. The five IEC 61131-3 languages provide diverse options:

Ladder Diagram (LD): Ideal for electrical engineers familiar with relay logic, LD resembles electrical circuit diagrams and is widely used for simple control tasks.

Function Block Diagram (FBD): A graphical language that uses blocks to represent functions, making it intuitive for designing complex systems.

Structured Text (ST): A high-level, text-based language similar to Pascal or C, suitable for algorithmic and mathematical operations.

Instruction List (IL): A low-level, assembly-like language for precise control, though less commonly used today.

Sequential Function Chart (SFC): Used for sequential control processes, SFC is ideal for applications requiring step-by-step execution, such as batch processing.

In addition to these, CODESYS supports object-oriented programming, allowing developers to create reusable code through classes, methods, and inheritance. This is particularly useful for large-scale projects where modularity and maintainability are critical.

Benefits of Using CODESYS

Cost Efficiency: By supporting multiple hardware platforms, CODESYS eliminates the need for proprietary software tied to specific vendors, reducing licensing and development costs.

Flexibility: Developers can work in their preferred programming language and deploy code on various devices, enhancing project flexibility.

Community and Ecosystem: CODESYS has a large user base and an active community, with extensive documentation, libraries, and third-party tools available through the CODESYS Store.

Rapid Development: The integrated environment, combined with simulation and debugging tools, accelerates development and testing cycles.

Global Adoption: CODESYS is used worldwide, ensuring that skills learned in the platform are transferable across industries and regions.

Applications of CODESYS PLC

CODESYS is employed in a wide range of industries, including:

Manufacturing: Controlling assembly lines, robotic systems, and CNC machines.

Energy: Managing renewable energy systems, such as wind turbines and solar plants, as well as traditional power distribution networks.

Building Automation: Integrating HVAC, lighting, and security systems for smart buildings.

Automotive: Controlling production lines and testing equipment in automotive manufacturing.

Process Control: Managing chemical plants, water treatment facilities, and food processing systems.

Getting Started with CODESYS

To begin using CODESYS, developers can download the free CODESYS Development System from the official website. The software is compatible with Windows and supports a variety of PLC hardware. Beginners can start with the extensive documentation and tutorials available online, while advanced users can explore the CODESYS Store for additional libraries and add-ons.

A typical workflow involves:

Installing the CODESYS IDE.

Selecting a target PLC and configuring the hardware.

Writing the program using one or more IEC 61131-3 languages.

Simulating the program to test functionality.

Deploying the code to the PLC and monitoring its performance.

Challenges and Considerations

While CODESYS is a powerful platform, there are some considerations:

Learning Curve: For beginners, mastering all five programming languages and the IDE’s features can take time.

Hardware Dependency: Although CODESYS is hardware-independent, specific PLCs may require proprietary drivers or configurations.

Licensing: While the core IDE is free, certain add-ons, libraries, or runtime licenses may incur costs, depending on the application.

Conclusion

CODESYS PLC by Servotechinc is a cornerstone of modern industrial automation, offering a robust, flexible, and scalable platform for PLC programming. Its adherence to IEC 61131-3, support for multiple programming languages, and extensive feature set make it a preferred choice for engineers worldwide. Whether you’re developing a small control system or a complex, distributed automation solution, CODESYS provides the tools to streamline development and ensure reliable performance. As industries continue to embrace digital transformation, CODESYS remains at the forefront, empowering automation professionals to build the systems of the future.

0 notes

Text

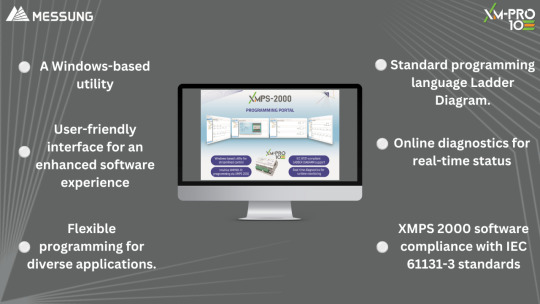

Introducing XMPS-2000: Messung's Advanced PLC Programming Software

Messung - Industrial Automation & Controls

Next generation Industrial Automation & Control Solutions for complex industrial processes, machines & production lines.

Messung Industrial Automation is proud to unveil the XMPS-2000 software, a powerful and intuitive Windows-based utility designed to enhance the programming experience for the XMPRO-10 PLC series. With a focus on user-friendly interfaces and robust functionalities, XMPS-2000 is set to redefine efficiency in industrial automation.

Key Features of XMPS-2000:

· User-Friendly Environment:

The software offers an intuitive interface, ensuring a seamless experience with various software tools.

· Programming Flexibility:

XMPS-2000 supports the standard Ladder programming language, making it compatible with a wide range of applications. The software complies with IEC 61131-3 Standards.

· Online Diagnostics:

Real-time diagnostics functionality allows users to monitor runtime status effectively.

Advanced Programming Capabilities:

· Hardware Configuration:

Facilitates CPU and I/O modules hardware configuration, simplifying system setup.

· Logic Blocks:

Enables the creation of subroutines that can be called within the main block, promoting organized and modular programming.

· Monitor Table:

Allows for user-defined tags, communication variables, and a watch window for real-time monitoring of discrete and analog I/Os.

· Online Monitoring:

Supports real-time monitoring of ladder programs and generates cross-references for efficient debugging.

· Force Value Functionality:

Permits value forcing during program testing, aiding in thorough validation processes.

· User Library:

Offers the creation of user-defined function blocks for customized tasks or specific applications, enhancing reusability.

System Configuration Management:

· Comprehensive Selection:

Allows selection of XMPRO CPU, local and remote I/O expansion modules, and displays total I/O count.

· Communication Parameterization:

Facilitates communication ports parameterization, supporting protocols like MODBUS TCP and RTU.

Hardware Selection Visualization:

· Detailed Display:

Provides visualization of hardware configurations for selected CPUs and I/O modules, with direct parameter configuration and viewing.

I/O Configuration:

· Assignment Flexibility:

Supports I/O assignment for onboard, expansion, and remote I/O modules, with mode selection for analog inputs and outputs.

· System-Generated Addresses:

Automatically generates I/O addresses, simplifying the configuration process.

Program Structure:

· Efficient Tools:

Features a toolbar with shortcuts to ladder elements and instructions, a project management window for file creation, and a program edit window in standard ladder format.

· Compiler and Monitoring:

Includes a compiler window for error display, an online monitor window for real-time project monitoring, and a watch window for user-selected variables.

The XMPS-2000 software exemplifies Messung's commitment to delivering innovative and efficient solutions in industrial automation. By integrating advanced features with a user-centric design, XMPS-2000 empowers engineers and technicians to achieve higher productivity and precision in their automation projects.

For more information and to experience the capabilities of XMPS-2000, contact Messung Industrial Automation.

0 notes

Text

What is the future of PLC in industrial automation?

Introduction.

The evolution of Programmable Logic Controllers (PLCs) has profoundly shaped the landscape of industrial automation. From their origins in relay logic systems to their integration with cutting-edge technologies, PLCs have been instrumental in revolutionizing how industries operate. This journey has seen significant milestones, including the birth of relay logic, the creation of the first true PLC by Dick Morley, and the adoption of industry standards. Today, PLCs continue to dominate manufacturing and extend their influence into energy management, building automation, and more. However, they face challenges in scalability, integration, and maintenance. Looking ahead, the future of PLCs holds promise, with emerging technologies like IoT, AI, and machine learning poised to enhance efficiency, sustainability, and adaptability, albeit accompanied by concerns regarding cybersecurity and workforce adaptation.

Past Innovations and Achievements.

The history of Programmable Logic Controllers (PLCs) is a story of important developments and how they've changed the way we make things. PLCs have been a big deal in the world of automation, making factories and other processes work better and faster. Milestones in PLC Technology. Milestones are important moments in the history of PLC technology when it made significant advancements, allowing for more automation. These key points in the evolution of PLCs include: 1. Birth of Relay Logic: PLCs started from relay logic, an old way of controlling machines using switches and wires. This old method from the early 1900s was the starting point for developing PLCs. 2. Introduction of the Modicon 084: In 1968, a big step forward happened with the creation of the Modicon 084 made by Dick Morley. This device is seen as the first real PLC and it changed the way control systems worked, shifting from relying on physical parts to using computer programs to control things. 3. Evolution of the PLC-3 and PLC-5: In the 1970s and 1980s, Allen-Bradley created the PLC-3 and PLC-5. These machines were better because they could do multiple tasks at once and store more information which made industries work better. 4. Adoption of the IEC 61131 Standard: The IEC 61131 standard made it easier for engineers to talk to PLCs by creating common languages like ladder logic and function block diagrams. This helped make things more consistent and compatible in the industry. Early Origins and Development To truly understand how PLC technology came to be it's important to know about its early stages which can be broken down into these phases: 1. Emergence of Relay-Based Control Systems: Before PLCs were invented industries used relay-based systems to control machines and processes. These systems worked but had limitations because they couldn't easily adapt or grow. 2. Dick Morley and the "Father of the PLC": Dick Morley, an American engineer is known as the "Father of the PLC." He became famous for inventing the Modicon 084 a device that replaced complicated relay systems. This all started with a bet made during a casual drink with friends. The bet was to create a controller that could do the job of those complex relays. And Morley succeeded changing the way industrial automation works. 3. Transition to Digital Logic: PLC technology changed how we control things. It went from using older less advanced methods to using computers with memory. This made it easier for engineers to make and change control programs. Advancements in Programmable Logic Controllers As technology got better, PLCs also improved a lot. Some important changes were made to make them more powerful and useful. These changes include: 1. Microprocessor Integration: Adding tiny but powerful chips to PLCs made them much better. They can now follow instructions and do difficult math stuff much faster. 2. Enhanced Communication Protocols: PLCs have changed to work better with modern technology. They can now talk to other machines using things like Ethernet/IP, Profibus and Modbus TCP/IP. This makes it easier to share information and check on things from far away. 3. Scalability and Modularity: Modern PLCs can be adjusted and changed to fit the needs of different industries like car factories or food processing. Real-World Applications The real value of any new technology is seen in how it's used in the real world. PLCs are now being used in many different situations changing how industries work. 1. Manufacturing and Assembly Lines: PLCs are like secret champions in factories. They manage tricky tasks like putting things together just right and making sure everything moves smoothly. They're in charge of robots and conveyor belts making sure everything is made perfectly. 2. Building Automation: In building automation PLCs control things like heating, cooling, lights and security making buildings use less energy and safer. 3. Energy Management: PLCs are important for managing energy, controlling how power is sent around, keeping an eye on how much energy is used and making smart grids work better. 4. Water Treatment and Wastewater Management: Water treatment plants use special computer systems to make sure our drinking water is clean and safe. These systems also help manage dirty water to keep our environment clean.

Current Landscape of PLC in Industrial Automation

In today's world of advanced automation Programmable Logic Controllers (PLCs) play a crucial role in coordinating and controlling various tasks in different industries. These devices are particularly important in manufacturing. They make things run smoothly, but there are some issues like expanding the system and keeping it in good shape. Let's take a closer look at what's happening in this field and the challenges it faces. The Dominance of PLC in Manufacturing PLCs are vital in manufacturing. They work seamlessly on assembly lines and production floors, making things run efficiently. They control various tasks from robots to conveyor belts to ensuring everything works smoothly. In the world of automation PLCs give manufacturers an advantage as they can control things in real-time and adjust to changing needs with accuracy. As manufacturing changes, the PLCs are still essential for keeping quality high, improving production and reducing mistakes. Key Industries Utilizing PLC PLCs are not just for factories other important industries use them too. These industries are: 1. Energy and Utilities: PLCs are like energy superheroes in the power world. They help control where electricity goes, keep an eye on how much is used and make sure smart grids work smoothly. They're like the protectors of energy efficiency. 2. Building Automation: In smart buildings, PLCs are like the brain that controls things to make the place comfy and safe. They manage the temperature, air, lights and security. 3. Food and Beverage: In cooking and making drinks, PLCs make sure everything is done just right. They help keep the taste and safety the same every time from following recipes to checking the quality of what's made. 4. Water Treatment and Wastewater Management: Water treatment and cleaning our used water wouldn't work well without PLCs. They are like silent helpers that make sure our water is safe and stays around for a long time. Challenges Faced by Traditional PLC Systems PLCs are known for making things work automatically and efficiently but old systems face problems in today's fast-changing technology world. 1. Scalability: Older PLCs can struggle to adapt to the changing needs of today's industries. Making them bigger or changing them to handle more work can be really hard. 2. Integration Issues: As industries rely more on data and connect different machines making them talk to each other can be tricky. Making sure that computers (PLCs) can talk to all kinds of equipment needs careful planning and doing things carefully. 3. Maintenance and Downtime Concerns: PLCs like complex machines those needed to be taken care of. But when we stop them for maintenance it can slow down work and make things less efficient. Hence, industries have to find a balance between keeping the system healthy and not causing too much disruption.

The Future of PLC in Industrial Automation

Industrial automation is changing, and the key to this change is the Programmable Logic Controller (PLC). In the future, PLCs will adapt to new technologies and global trends making it an exciting journey to see how they'll be used in industrial automation. Emerging Technologies and Trends In today's fast-paced digital era industrial automation systems are adopting new technologies and trends that will change how things work. Some important trends include: 1. Integration with IoT and Industry 4.0: When industrial machines (PLCs) join forces with the Internet of Things (IoT) and Industry 4.0. It lets them share information instantly watch them from afar and predict when they need repairs. As PLCs get more connected industries can take charge of their operations like never before. 2. AI and Machine Learning in PLC: Combining AI and Machine Learning with PLCs is like giving them a smart brain. These smart PLCs can adjust to changing situations, make processes work better and figure out when they need fixing. This teamwork between PLCs and AI is making automation even smarter and more advanced. Potential Benefits and Transformations In the future, PLCs (Programmable Logic Controllers) will bring lots of good changes to different industries. This will help them in many ways. 1. Enhanced Efficiency and Productivity: Advanced algorithms and predictive analytics in PLCs will make operations better, reduce downtime, and help us work faster. These PLCs can make quick decisions and adjust to changes, which will make things work really well. 2. Sustainability and Green Automation: As the world focuses more on being eco-friendly, Programmable Logic Controllers (PLCs) will be really important in making machines and systems more environmentally friendly. They'll use smart and efficient methods to save energy, control power usage and cut down on waste. This way the industrial automation will be in harmony with taking care of the environment. Addressing Challenges As PLCs get better, they need to deal with problems that come with new tech and ideas. Some of these problems are: 1. Cybersecurity and Data Protection: As we become more connected, the risk of cyberattacks goes up. It's crucial to protect important industrial systems and data. To do that, we need strong cybersecurity and data protection rules for the future. 2. Training and Workforce Adaptation: As technology gets better, people who work with machines need to learn new things. They will need training and education to learn how to use the new technology in machines called PLCs.

In conclusion

Programmable Logic Controllers (PLCs) have come a long way, revolutionizing industrial automation through significant milestones, from relay logic to advanced digital systems. They continue to dominate manufacturing and find applications in various industries, ensuring efficiency and reliability. However, they face challenges like scalability, integration issues, and maintenance concerns. The future of PLCs lies in their adaptation to emerging technologies such as IoT, AI, and Industry 4.0, promising enhanced efficiency and sustainability. Addressing cybersecurity and workforce adaptation will be crucial in this evolving landscape. PLCs are poised to play a pivotal role in the ever-changing world of industrial automation. Read the full article

0 notes

Photo

A Programmable Logic Controller (PLC) or programmable Controller is an industrial digital computer that evaluates all input states and makes custom-based programming decisions for controlling output devices. The main difference from most other computing devices is that PLCs are intended for and therefore tolerant of more environmental factors, less complexity, cost efficient and robust

Unique content :

A Programmable Logic Controller (PLC) or programmable Controller is an industrial digital computer that evaluates all input states and makes programming decisions for controlling output devices based on custom-based programming. The main distinction between PLCs and most other computing devices is that PLCs are designed for, and thus tolerant of, more environmental factors. They are also less complex, cost efficient, and robust.

Please Visit: https://ieng.tech/plc-programmable-logic-controller/

The PLCs ranges are from compact to Large programmable automation Controllers (PAC’s) with outstanding reliability and performance. Its expansion possibilities through locally and remotely over Profibus, Profinet and Fiber Optics.

The Programmable Logic Controller programming are complying to IEC 61131-3 standards.

We are providing the complete solutions for all sectors with a Master-slave communication or Master to Master communication according to customer demands.

2 notes

·

View notes

Text

Messung Automation Solutions for Water and Waste Water Projects

industrial automation & control systems suppliers

The Rising Demand

By year 2050, the global demand for water will rise by 55%. The 2015 report by United Nations World Water Development projects this rise across the various sectors.

India’s economy also critically depends on use and management of water for agriculture, industry and domestic consumption. Recognizing this dependence, the Ministry of Water Resources plans to invest significant funds into management of water and wastewater sector.

Some of the aims of good water resources management are:

· Improvement of water quality

· Improving energy efficiency while managing and treating water

· Minimizing leakage and wastage

· Conservation of resources

· Reducing downtime and operating costs

Use of dedicated Industrial Automation & Control Systems effectively meets the above objectives, at a cost-effective price point.

Infrastructure for Water Treatment

To supply quality water in the desired quantities, a typical city may have more than 20 to 30 Water Treatment Plants (WTP’s). At the discharge end, for treating used and polluted water, the city may have an equal number of Waste Water Treatment Plants (WWTP’s).

For optimum efficiency and speed of response, a Centralized Control and Monitoring Station supervises all the equipment and processes of plants from a single location. This Station accepts numerous inputs from all the plants to deliver real-time corrective responses to the changing parameter and conditions. As an upgrade, tech-savvy Municipal authorities now demand a cloud-based solution for supervision of all the water treatment facilities.

High-technology automation solutions conforming to industry standard protocols are essential to implement the future needs of the water treatment plants.

Challenges of Water Supply System

Designing and operating of water supply systems calls for a multi-criteria approach. In every case, water treatment system must reliably produce quality water at the lowest possible costs.

The criteria for water treatment process are:

· Flow of raw and treated water along with dosing of treatment chemicals

· Monitoring of water pressure at upstream and downstream locations and at critical points

· Monitoring levels in rivers, wells and reservoirs

· Disposal of sludge

· Monitoring of temperature for motors, bearings and valves

· Dosing of Fluorine, Chlorine and Calcium

· Monitoring turbidity and water quality

Water Treatment domain consists of several critical processes that can benefit from high technology automation for delivering consistent results.

Water Treatment Automation Solutions from Messung

Messung are the pioneers of Indian automation domain. A leading industrial automation & control systems supplier with over 3 decades of domain expertise, tens of thousands of Messung Programmable Logic Controllers (PLC) and allied products meet the automation challenges of Indian industries, under actual local site conditions.

With a view to the future, Messung now offers NX-ERA, the complete industrial automation solution for monitoring and controlling the entire water management process.

Messung’s NX-ERA PLC Systems can automate a variety of Water Treatment applications.

These include:

· Water Treatment Plant

· Reverse Osmosis Plant

· De-mineralized Water Plant

· Sewage Treatment Plant

· Effluent Treatment Plant

· Pumping Stations

· Reservoir Controls

Features of Messung NX-ERA

· One vendor – many solutions

· Easy to set-up, maintain, operate

· Compatible with all industry standard protocols

· Highly reliable system with high Mean Time Between Failures (MTBF) and low Mean Time to Repair (MTTR), with redundancy

· Local and remote access, with control to private mesh

· Local Human-Machine Interfaces (HMI’s) and Central Supervisory System

· Uses Open Protocols and Networks

· Power efficient with a small footprint

· Adds Distributed Control System (DCS) functionality through multiprocessing capability

· Can operate large numbers of remote Input/Output (I/O) points and backplane racks for implementing distributed architecture with redundancy

· Supports large screen displays and database server

· Interfaces with Supervisory Control and Data Acquisition (SCADA) systems

· Modular and expandable

Programming through the IEC 61131-3 compliant MasterTool IEC XE software.

·Easy to learn with rich graphics and intuitive textual language

·Function Block Diagram (FBD) that enables segmentation of block system to simplify maintenance and simultaneous execution of different tasks

·Multiple languages available within these blocks for versatility across the globe

Conclusion

Messung’s NX-ERA process automation and control solutions optimize complex control for water treatment and distribution systems. These solutions help implement highly efficient WTP designs that help treat and conserve water, an increasingly scarce resource.

The water-scarce future mandates a high degree of precision and reliability of water treatment plants. Messung’s process control and automation solutions effectively meet the monitoring and control requirements of water treatment with increased plant safety and availability.

Contact Messung for process automation & control solutions in India as well as smart factory automation & control solutions with Scada and power system automation, and machine automation & control solutions with cutting-edge Servo & Motion controls.

#industrial automation & control systems suppliers#industrial automation & control solutions in India#process automation & control solutions in India#process automation & control solutions in#factory automation & control solutions#smart factory automation & control solution in India#plc automation control panel

1 note

·

View note

Text

Programmable Logic Controllers By Dag H. Hanssen (ebook)

Programmable Logic Controllers By Dag H. Hanssen (ebook)

Widely used across industrial and manufacturing automation, Programmable Logic Controllers (PLCs) perform a broad range of electromechanical tasks with multiple input and output arrangements, designed specifically to cope in severe environmental conditions such as automotive and chemical plants. Programmable Logic Controllers: A Practical Approach using CoDeSys is a hands-on guide to rapidly gain proficiency in the development and operation of PLCs based on the IEC 61131-3 standard. CoDeSys, which is widely used in industrial design automation projects, the author takes a highly practical approach to PLC design using real-world examples. The design tool, CoDeSys, also features a built in simulator/soft PLC enabling the reader to undertake exercises and test the examples.

Introduces to programming techniques using IEC 61131-3 guidelines in the five PLC-recognised programming languages. Focuses on a methodical approach to programming, based on Boolean algebra, flowcharts, sequence diagrams and state-diagrams. Contains a useful methodology to solve problems, develop a structured code and document the programming code. Covers I/O like typical sensors, signals, signal formats, noise and cabling. Features Power Point slides covering all topics, example programs and solutions to end-of-chapter exercises via companion website. No prior knowledge of programming PLCs is assumed making this text ideally suited to electronics engineering students pursuing a career in electronic design automation. Experienced PLC users in all fields of manufacturing will discover new possibilities and gain useful tips for more efficient and structured programming.

These conventional panels are built up depending on the logic to be implemented after the mill builder provides the overall operational method which is elaborated further by the electrical supplier as per the actual implementation. While the functionality of the mill interlock panel is similar in the PLC panels, the concept defining the number of inputs and outputs came into the use with the implementation with PLC-s. As compared to the central relay and interlock panels or mill interlock panels , the modern day PLC based interlock panels are able to handle much more of functionalities as explained under III . Since the PLC-s themselves are micro- processor or controller based they have the same working architecture like the standard computer architecture with the following elements.

The inputs and the outputs form the bulk of the hardware depending on the plant requirement and capacity. While the PLC CPU, instruction sets, software, memory, communication and other capabilities . Apart from the functionalities , the PLC type is primarily decided based on the number and the type of inputs and outputs. The defining of the inputs and the outputs got into the use with the use of PLC-s for the control and interlock functions. This is because in the PLC panels the status of the inputs or outputs ( called input and output images ) or intermediate flags can be used any number of times as these are soft signals when implementing the logic.

The advantage of this method is that even at the beginning of a project ( even during the cost estimation stage ) one can estimate the number of inputs and outputs and decide the type of the PLC. https://instrumentationtools.com/ need not even be fully clear about the logic or the total functionalities to estimate the PLC-s. An example for selecting the number of inputs and outputs is given in one of the following sections . The types of industrial inputs and outputs are discussed first . They are the commonly used input devices They have basically two parts - operating buttons (actuators) and the contact units.

Normally 2 N/O and / or 2 N/C contact blocks are common when used with the conventional relay based control panels. With PLC based system, the input block need only be 1 N/O or 1 N/C. This input along with their complement can be used any number of times in the PLC ladder diagrams . The operator buttons are of different types; i. The buttons are normally with different colours, like the indication lamps to be described under the outputs. Green is normally used for ‘on’ functions and ‘Red’ is used for ‘off’ function; other colors like yellow, black etc are used for other functions like start, stop, jog, thread etc. functions.

Sometimes the mushroom headed red coloured off (emergency) PB actuators get mechanically latched when pressed; They need to be turned in one direction to release the same. They are selected for certain locking type control functions like enable / disable or forward / reverse selection type respectively. Some times the PB actuator unit has a transparent head(with appropriate coloured lens) with in built indication lamp, apart from the contact blocks. These are normally used to sense the reaching of the required physical limit by a machinery or a motion control system. The limit switch operates on physical contact and closes a switch provided with N/O and N/C contacts.

Here the rotary limit switch arrangement is coupled to the motor or the actual load shaft driving an operation. The coupling is through an appropriate gear box so that for number of revolution on the equipment shaft side, the limit switch shaft rotates once. On the limit switch shaft are number of cams and the cam actuation positions are set at the required appropriate angles. These cam settings are adjustable programmable. With this arrangement the individual cams operate the associated limit switches. The operation of these limit switches can be associated with the reaching of appropriate limits in a linear travel; eg.

Position vi. Stop ; top position for tipping the material into furnace. However they require external power supplies. 1. They also function as limit switches but without physical contact. 2. There are two types - called inductive proximity switches or capacitive proximity switches which operate due to changes in the magnetic field or the capacitance value under the proximity of the part or item being sensed. These switches also require external power supply and the outputs are normally open collector transistor type to which an external relay can be connected or can be a direct input to PLC input card.

3. These proximity sensors can also be used to measure the speed of a motor or drive by non-contact method. Of the above mentioned inputs, many of them are on/off type (either potential free contacts or open collector type) and are called as digital inputs and some of them are providing analog inputs for continuous controls. There are also other soft inputs like the keyboard inputs etc. but they do not form hard wired inputs. The above mentioned devices are input devices for a relay and PLC control system. There are also number of output devices which get connected to a relay or PLC based control system. The functioning of contactors are similar to relays; Additionally contactors have 3 or 4 power N/O contacts (normally) which is used to switch on the power.

The contactor coils are energized through PLC output or another relays contact and through the coil power supply (110VAC, 220VAC, 415VAC etc). DC supplied coils are also present some times. The contactors are normally used to switch 3 phase AC power to say a motor or a power modulator or such an application and they are extensively used. Contactors are normally available in various sizes (size 0 to size 16 - corresponding to 16 A to 630 A and more). Most of the contactors are for AC power switching. There are also DC power switching contactors available. They require special arc- chutes for lengthening the arc.

Hence these DC contactors are more expensive and need to be carefully selected. All contactors have auxiliary contacts for inter locking and relaying functions. 2 N/C contacts are provided for these auxiliary functions. Apart from the selection of contactors to match with output load current and voltage, they need to be selected, also considering the numbers of operating cycles per hour. Like a relay and contactor, the solenoid is an electro-mechanical device. In this the electrical energy is used to magnetically cause a mechanical movement. The solenoid; like the contactor has a frame, plunger and the coil. The coil is energized by AC or DC voltage.

Upon the application of the voltage to the coil, the corresponding plunger is pulled back through a spring in case the coil voltage is interrupted. The AC solenoid draws a large in-rush current on energizing, when the plunger is fully out. The current drops to minimum value when the plunger is fully in. Due to this, it is important to ensure that the solenoid is fully energized i.e. the plunger is fully in. Otherwise the solenoid coil will take more than rated current continuously resulting in the burn-out of the coil. As against this, DC solenoid takes a constant coil current; but AC solenoid has superior initial pull.

For many industrial applications, 24V DC solenoids are normally preferred. While the contactor as output devices are selected based on the load current and voltage requirement, the solenoids are normally selected to handle appropriate pressure, force or weigh to be lifted etc. Accordingly the solenoid size varies. 1. Single solenoid (with one motion) with one coil. When it is energized it moves against the spring and when de-energized comes back to original position. 2. Single solenoid (with one motion) but with two coils. This is similar to above but with latching feature. One coil is for switching on and another is for switching off.

3. Double solenoid (with two motions, say up / down) and with two coils. When one coil is energized, the motion is upwards and downwards when the other coil is energized. It goes to neutral position when both the coils are not energized. 4. As it can be understood the number of coils to be energized decide the number of outputs per solenoid to be considered by the PLC. Normally the above solenoids are on/off devices; some times it is required to provide a motion which is proportional to the supply current amplitude. There are also continuously adjustable devices - e.g screw down in a rolling mill, measuring gauge adjustment for a cut length etc which are controlled through a proportional control system based on electrical motors or hydraulic valves .

1 note

·

View note

Text

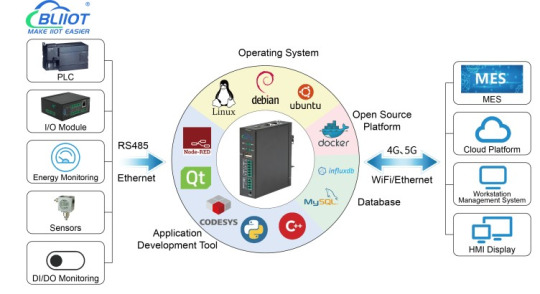

Transforming Industrial Automation with BLIIoT ARM Embedded Edge Gateway Computer EdgeCOM and Codesys

1. What is codesys

CODESYS is a general-purpose, IEC 61131-3-based development environment designed to provide reliable and flexible automation control systems. CODESYS supports multiple programming languages and hardware platforms, including Embedded ARM industrial computers. The core functions of CODESYS include PLC programming, HMI design and real-time monitoring.

2. Why use CODESYS?

Because it can improve the development efficiency and reliability of industrial automation control systems. CODESYS can provide a standardized programming language and framework, making porting and reuse between different hardware platforms easier. In addition, CODESYS also provides powerful debugging and testing tools to help developers complete software development more quickly and reliably.

3. So what is an BLIIoT Embedded ARM Edge Computer EdgeCOM BL300?

Embedded ARM industrial computer is a special computer, which is usually used in industrial automation control system. Compared with traditional desktop computers, embedded ARM industrial computers are smaller and more energy-efficient, and can undertake certain control tasks.

The BLIIoT EdgeCOM Compact ARM Embedded Computer BL300 series is designed for the harsh industrial environment. It adopts industrial grade NXP MCU inside, provides RS485, RS232, CAN, HDMI, USB, RJ45, DI, DO and Mini-PCIe for 4G, 5G, WiFi, etc.

The EdgeCOM Compact ARM Embedded Computer compatible with Linux, Ubantu, Debian OS, Node-red, Python, C++, QT, and MySQL, InfuxDB, SQLite database, Also compatible with IgnitionEdge, Codesys Edge Gateway, etc.

4. Embedded ARM industrial Edge computer supports codesys what can be achieved and the benefits

When the Embedded ARM industrial Edge computer supports CODESYS, it provides a more reliable and efficient solution for the development and operation of industrial automation control systems.

Support multiple communication protocols: Embedded ARM industrial Edge computer supports CODESYS, which can realize multiple communication protocols, such as Modbus, OPC UA, CANopen, etc., to facilitate data exchange and control between industrial equipment.

High performance and low power consumption: Embedded ARM industrial Edge computer uses ARM architecture, which can realize high-performance computing and low power consumption, suitable for long-term operation in industrial automation control systems.

Multi-tasking ability: Embedded ARM industrial Edge computer supports CODESYS to realize multi-tasking processing ability, run different tasks through multiple threads at the same time, and improve the response speed and efficiency of the system.

Hardware and software integration: Embedded ARM industrial Edge computer supports CODESYS, which can realize hardware and software integration, and package the hardware and software of the control system into a whole, which is convenient for installation and maintenance.

Highly customizable: Embedded ARM industrial Edge computer supports CODESYS to achieve high customization, and can flexibly select control algorithms, communication protocols, input and output methods, etc. according to different application scenarios to meet different control needs.

In short, using CODESYS for embedded ARM industrial Edge computers can improve the reliability, stability and efficiency of industrial automation control systems, help enterprises improve production efficiency and reduce operating costs.

More information about BLIIoT Industrial ARM Embedded Edge gateway Computer: https://www.bliiot.com/edge-computing-gateway-p00359p1.html

0 notes

Text

Rapidclick github

#RAPIDCLICK GITHUB FULL#

#RAPIDCLICK GITHUB SOFTWARE#

Set tags (I/O points), equipment (modules, devices, PLCs. Tool and language for data acquisition, process supervision, industrial automation, storing, reports generation and applications development. Naven is a port of the Apache Maven tool and concept to. Designed by real estate agents for real estate agents.

#RAPIDCLICK GITHUB SOFTWARE#

When a new job is available, SubAssistant automatically sends a text message or email with the job details.īPO Automation Software from the BPO Automation Group.Īutomate the broker price opinion (BPO) process. SubAssistant is an online service substitute teachers use to automatically and continuously check the online SubFinder®, SmartFindExpress® or Aesop® systems. Use RapidClick to save your hand from getting tired whenever you have to do a lot of clicking. RapidClick automatically clicks your mouse up to 20 times per second. It includes integrated compilers, fieldbus configuration, an integrated visualization editor, an optional motion control extension. Hundreds of devices of more than 250 automation manufacturers can be programmed with that tool. The pioneering engineering framework optimizes all planning, machine and process procedures and offers a standardized and integrated operating concept.It seamlessly integrates controllers, distributed I/O, HMI, drives, motion control and motor management into a single engineering.ĬoDeSys - the IEC 61131-3 programming system.CoDeSys is the market leading hardware independent programming system for PLCs and industrial controllers.

#RAPIDCLICK GITHUB FULL#

TIA Portal is the key to unlocking the full potential of Totally Integrated Automation (TIA). This greatly reduces the complexity of the configuration and allows automation systems to be programmed or configured. Programming is done in one of two graphical programming languages - FBD (Function Block Diagram) or LAD (Ladder Diagram).Simulation and online monitoring is available.Suitable for use in small automation applications such as lighting, heating, ventilation, gate control etc.ĬX-One software allows users to build, configure and program a host of devices such as PLCs, HMIs and motion-control systems and networks using just one software package with one installation and license number. LOGO! Soft Comfort is software for programming simple Siemens LOGO! PLCs.

1 note

·

View note

Text

Introducing XMPS-2000: Messung's Advanced PLC Programming Software

Messung Industrial Automation is proud to unveil the XMPS-2000 software, a powerful and intuitive Windows-based utility designed to enhance the programming experience for the XMPRO-10 PLC series. With a focus on user-friendly interfaces and robust functionalities, XMPS-2000 is set to redefine efficiency in industrial automation.

Key Features of XMPS-2000:

User-Friendly Environment: The software offers an intuitive interface, ensuring a seamless experience with various software tools.

Programming Flexibility: XMPS-2000 supports the standard Ladder programming language, making it compatible with a wide range of applications. The software complies with IEC 61131-3 Standards.

Online Diagnostics: Real-time diagnostics functionality allows users to monitor runtime status effectively.

Advanced Programming Capabilities:

Hardware Configuration: Facilitates CPU and I/O modules hardware configuration, simplifying system setup.

Logic Blocks: Enables the creation of subroutines that can be called within the main block, promoting organized and modular programming.

Monitor Table: Allows for user-defined tags, communication variables, and a watch window for real-time monitoring of discrete and analog I/Os.

Online Monitoring: Supports real-time monitoring of ladder programs and generates cross-references for efficient debugging.

Force Value Functionality: Permits value forcing during program testing, aiding in thorough validation processes.

User Library: Offers the creation of user-defined function blocks for customized tasks or specific applications, enhancing reusability.

System Configuration Management:

Comprehensive Selection: Allows selection of XMPRO CPU, local and remote I/O expansion modules, and displays total I/O count.

Communication Parameterization: Facilitates communication ports parameterization, supporting protocols like MODBUS TCP and RTU.

Hardware Selection Visualization:

I/O Configuration:

Assignment Flexibility: Supports I/O assignment for onboard, expansion, and remote I/O modules, with mode selection for analog inputs and outputs.

System-Generated Addresses: Automatically generates I/O addresses, simplifying the configuration process.

Program Structure:

Efficient Tools: Features a toolbar with shortcuts to ladder elements and instructions, a project management window for file creation, and a program edit window in standard ladder format.

Compiler and Monitoring: Includes a compiler window for error display, an online monitor window for real-time project monitoring, and a watch window for user-selected variables.

The XMPS-2000 software exemplifies Messung's commitment to delivering innovative and efficient solutions in industrial automation. By integrating advanced features with a user-centric design, XMPS-2000 empowers engineers and technicians to achieve higher productivity and precision in their automation projects.

For more information and to experience the capabilities of XMPS-2000, contact Messung Industrial Automation.

#XMPS-2000 software#Messung Industrial Automation#industrial automation#I/O modules#IEC 61131-3 Standards#XMPRO-10 PLC series#plc#programmable logic controller#plc controller#plc automation#plc controller supplier in india#plc controller manufacturer in india

0 notes

Text

Introduction to CODESYS PLC: A Comprehensive Overview

CODESYS (Controller Development System) is a leading software platform for industrial automation, widely used for programming and configuring Programmable Logic Controllers (PLCs). Developed by the German company 3S-Smart Software Solutions, CODESYS PLC is a versatile, hardware-independent development environment that supports a broad range of industrial applications, from factory automation to process control and motion control systems. This article explores the key features, benefits, programming capabilities, and applications of CODESYS PLC, highlighting its significance in modern industrial automation.

What is CODESYS?

CODESYS is an integrated development environment (IDE) that adheres to the international standard IEC 61131-3, which defines programming languages for PLCs. This standard ensures that CODESYS is compatible with a wide variety of hardware platforms from different manufacturers, making it a flexible and scalable solution. The platform supports all five IEC 61131-3 programming languages: Ladder Diagram (LD), Function Block Diagram (FBD), Structured Text (ST), Instruction List (IL), and Sequential Function Chart (SFC). Additionally, CODESYS extends support for object-oriented programming (OOP) with languages like Structured Text, enabling advanced programming techniques.

The CODESYS ecosystem includes not only the core IDE but also additional tools for visualization, simulation, debugging, and communication with field devices. It is used in industries such as manufacturing, energy, automotive, and building automation, offering a unified platform for developing complex automation solutions.

Key Features of CODESYS

IEC 61131-3 Compliance: CODESYS supports all standard PLC programming languages, allowing developers to choose the most suitable language for their application. This compliance ensures portability of code across different PLC hardware, reducing development time and costs.

Hardware Independence: CODESYS is compatible with over 1,000 devices from various manufacturers, including Siemens, Beckhoff, WAGO, and others. This flexibility allows engineers to write code once and deploy it on multiple platforms without significant modifications.

Integrated Visualization: CODESYS provides built-in tools for creating Human-Machine Interfaces (HMIs). Developers can design graphical user interfaces for operator panels, web-based visualizations, or mobile applications, all within the same environment.

Fieldbus and Communication Support: The platform supports a wide range of industrial communication protocols, such as Modbus, CANopen, EtherCAT, PROFINET, and OPC UA. This ensures seamless integration with sensors, actuators, and other devices in an automation system.

Simulation and Debugging: CODESYS includes a powerful simulation mode that allows developers to test their programs without physical hardware. The debugging tools enable real-time monitoring, breakpoints, and variable tracing, streamlining the development process.

Scalability and Modularity: From small embedded systems to large distributed control systems, CODESYS is highly scalable. Its modular architecture allows developers to add libraries, function blocks, and extensions as needed.

Safety and Security: CODESYS supports safety programming according to standards like IEC 61508 (SIL 2/3), making it suitable for safety-critical applications. It also includes features for secure communication and user authentication to protect against cyber threats.

Programming with CODESYS

CODESYS offers a flexible programming environment that caters to both novice and experienced developers. The five IEC 61131-3 languages provide diverse options:

Ladder Diagram (LD): Ideal for electrical engineers familiar with relay logic, LD resembles electrical circuit diagrams and is widely used for simple control tasks.

Function Block Diagram (FBD): A graphical language that uses blocks to represent functions, making it intuitive for designing complex systems.

Structured Text (ST): A high-level, text-based language similar to Pascal or C, suitable for algorithmic and mathematical operations.

Instruction List (IL): A low-level, assembly-like language for precise control, though less commonly used today.

Sequential Function Chart (SFC): Used for sequential control processes, SFC is ideal for applications requiring step-by-step execution, such as batch processing.

In addition to these, CODESYS supports object-oriented programming, allowing developers to create reusable code through classes, methods, and inheritance. This is particularly useful for large-scale projects where modularity and maintainability are critical.

Benefits of Using CODESYS

Cost Efficiency: By supporting multiple hardware platforms, CODESYS eliminates the need for proprietary software tied to specific vendors, reducing licensing and development costs.

Flexibility: Developers can work in their preferred programming language and deploy code on various devices, enhancing project flexibility.

Community and Ecosystem: CODESYS has a large user base and an active community, with extensive documentation, libraries, and third-party tools available through the CODESYS Store.

Rapid Development: The integrated environment, combined with simulation and debugging tools, accelerates development and testing cycles.

Global Adoption: CODESYS is used worldwide, ensuring that skills learned in the platform are transferable across industries and regions.

Applications of CODESYS PLC

CODESYS is employed in a wide range of industries, including:

Manufacturing: Controlling assembly lines, robotic systems, and CNC machines.

Energy: Managing renewable energy systems, such as wind turbines and solar plants, as well as traditional power distribution networks.

Building Automation: Integrating HVAC, lighting, and security systems for smart buildings.

Automotive: Controlling production lines and testing equipment in automotive manufacturing.

Process Control: Managing chemical plants, water treatment facilities, and food processing systems.

Getting Started with CODESYS

To begin using CODESYS, developers can download the free CODESYS Development System from the official website. The software is compatible with Windows and supports a variety of PLC hardware. Beginners can start with the extensive documentation and tutorials available online, while advanced users can explore the CODESYS Store for additional libraries and add-ons.

A typical workflow involves:

Installing the CODESYS IDE.

Selecting a target PLC and configuring the hardware.

Writing the program using one or more IEC 61131-3 languages.

Simulating the program to test functionality.

Deploying the code to the PLC and monitoring its performance.

Challenges and Considerations

While CODESYS is a powerful platform, there are some considerations:

Learning Curve: For beginners, mastering all five programming languages and the IDE’s features can take time.

Hardware Dependency: Although CODESYS is hardware-independent, specific PLCs may require proprietary drivers or configurations.

Licensing: While the core IDE is free, certain add-ons, libraries, or runtime licenses may incur costs, depending on the application.

Conclusion

CODESYS PLC by Servotechinc is a cornerstone of modern industrial automation, offering a robust, flexible, and scalable platform for PLC programming. Its adherence to IEC 61131-3, support for multiple programming languages, and extensive feature set make it a preferred choice for engineers worldwide. Whether you’re developing a small control system or a complex, distributed automation solution, CODESYS provides the tools to streamline development and ensure reliable performance. As industries continue to embrace digital transformation, CODESYS remains at the forefront, empowering automation professionals to build the systems of the future.

0 notes

Text

MESSUNG : FORTY YEARS OF INNOVATION AND GROWTH

Messung - an enterprising, diversified group - celebrates 40+ years in the industry. Working with zeal and diligence, Messung delivers the most innovative and cost-effective solutions for Indian industries. Messung works with OEMs and end-users to deliver the most effective solutions - best in category offerings that help set up world-class industrial automation solutions, building automation solutions, and home, office & hotel automation solutions; custom-built workplace technology systems for ESD, general and cleanroom applications; cutting-edge power distribution and control and energy management solutions.

Messung helps industries, institutions and OEMs enhance efficiency and optimise their processes and workplaces.

LEGACY OF INNOVATION

Messung was the result of one man’s passion and entrepreneurial zeal. In 1981, Messung’s founder, Mr. Farook Merchant quit his stable job with an electronics company in Pune to start developing prototypes of a programmable logic controller in a rented garage. India’s first indigenous PLC was launched within a couple of years. The PLC was based on a 1-bit processor that revolutionized industrial automation and replaced the traditional relay contactor logic.

Messung’s first PLC was installed at Kirloskar Oil Engines, Pune, in 1984. The PLC was displayed at several trade shows and industry exhibitions and attracted rave reviews and earned Messung numerous awards. It won the GS Parkhe award and the FIE Foundation Award for Best Product Design in 1986, and Mr. Farook Merchant received the National Award for Outstanding Entrepreneur in 1988. He also won the national award for excellence in Electronics from the (DOE) Department of Electronics in the year 1998.

Messung has a long list of innovations and initiatives that include:

- The first Rack type PLC based on an 8-bit microprocessor which achieved over 6000 installations. Some notable customers include Kalyani Steel, HAL’s MIG aircraft testing equipment and Telco’s heat treatment plant.

- The ‘small wonder’ Micro PLC made especially for smaller machines which had 25000 installations and won the Best Product Award at IMTEX.

- Human Machine Interfaces (HMIs) that transformed industrial operations and work as smart panels for easy access and programming of PLCs.

- A modular PLC designed for complex requirements that went on to win the FIE Award for Best Product Design.

- India’s first IEC 61131-3 standards-based PLC - a more powerful and compact version of the previous modular PLC.

- PLCs that target small scale applications in the automotive industry.

- Brand Labelling ofNX-ERAPLCs - designed as per IEC 61131programming standards.

- XM-PRO Seriesof Remote I/O Modules based on CANopen, Modbus and their own MESbus

BEYOND AUTOMATION

Messung’s innovative R&D extends beyond automation. Messung’s experience of the safety risks, health hazards, and challenges of the industrial workplace inspired them to find and deliver meaningful solutions. Under its Workplace Technology business in 2019, Messung introduced the AFM-PLUS range of world-class solutions for ESD, General and Cleanroom workplaces, which is now manufactured locally under the ‘Navonmesh - Make in India’ initiative.

ESD Workplace Systems: Messung is justifiably proud of its AFM-PLUS series of ESD worktables, ESD chairs & stools, ESD trolleys, cabinets, and related storage solutions. This series is manufactured at Messung’s own manufacturing facility under the ‘Navonmesh - Make in India’ Initiative and adheres to the latest global standards. The series offers increased ESD protection, comfort, and productivity in ESD workplaces such as R&D labs, manufacturing departments, calibration centres, assembly stations and training centres of the electronics industry.

General Workplace Systems: Messung offers a similar range of workplace furniture in non-ESD versions for general industrial workstations. The range’s world-class looks, specifications and affordable rates help it grow in popularity across industry verticals. Messung also offers customized solutions with its own design centre and manufacturing plant in Pune.

Cleanroom Workplace Systems: Messung also offers chairs and stools for industrial and biological cleanrooms which can be customized for specific requirements.

BEYOND FORTY!

Messung relentlessly delivers cutting edge solutions that empower enterprises with excellence - through changing times, advancing technologies, growing competition, and economic challenges.

From its modest start as India’s first PLC manufacturer, through 4 decades of developing cutting-edge technologies for industrial automation and control to the diversified conglomerate it is today, Messung has kept growing with zest, fluidity, and determination.

In the present day, the Messung Group spans three businesses: Automation & Controls, Electrical Engineering and Workplace Technology with each serving different industries.

Messung continues to innovate and grow, all while providing world-class products at cost-effective prices for customers and applications across industries.

The Group’s corporate office, business offices, R&D centre and manufacturing facilities are located in Pune, India. Messung’s solutions and products are sold across India and are supported by a strong service network.

For more information on the Messung Group, please visit www.messung.com

#industrial automation solutions#pioneer in industrial automation#first indigenous PLC#first indigenous PLC manufacturer#Remote I/Os#lab tables#ESD chairs#ESD workstations#PLC manufacturer#building automation solutions

0 notes

Photo

PLC -Programmable Logic Controller

A Programmable Logic Controller (PLC) or programmable Controller is an industrial digital computer that evaluates all input states and makes custom-based programming decisions for controlling output devices. The main difference from most other computing devices is that PLCs are intended for and therefore tolerant of more environmental factors, less complexity, cost efficient and robust

The PLCs ranges are from compact to Large programmable automation Controllers (PAC’s) with outstanding reliability and performance. Its expansion possibilities through locally and remotely over Profibus, Profinet and Fiber Optics.

The Programmable Logic Controller programming are complying to IEC 61131-3 standards.

We are providing the complete solutions for all sectors with a Master-slave communication or Master to Master communication according to customer demands.

We offer the following PLC brands

Allen Bradley

Siemens

ABB

FANUC

Mitsubishi

Omron

https://ieng.tech/plc-programmable-logic-controller/

0 notes

Text

BELT TESTING MACHINE WITH MESSUNG'S NX-ERA XPRESS PLC SERIES

The belt center distance measurement is standard practice to measure the center distance of the flat belt and V belt. The belts are tested at a particular load in LBF at this load; the objective of the system is to find out the exact center distance and belt override of the belts. Some constituents of the testing apparatus are:

⮚ Pulleys – to stretch the belt and insert it

⮚ Load Cell – to measure the load or belt tension

⮚ Transducer – to calculate the belt override

⮚ Servo system – to generate the desired load

⮚ Magnetic Linear Scale – to measure the distance

APPLICATIONS WHERE BELT TESTING MACHINE IS USED :

ENGINE MANUFACTURER INDUSTRY

This system is majorly used in the engine manufacturer industry. The belts are tested for their reliability and durability.

THE CUSTOMER:

Our customer specializes in the Manufacturing of Standard & Customized Measuring equipment. These equipments are designed as per Industry Standards. Integrated with the latest technologies, these equipments provide reliable & efficient testing operations.

THE SOLUTION:

Messung is among the best PLC automation companies in India. Our engineers studied the plant and its requirements and came up with a solution consisting of

● NX-ERA XPRESS XP325 PLC Controller

● 7 inch HMI Display Touch Screen

● Servo System (Fuji)

Programmable Logic Controllers (PLCs) have been used in various control systems in order to increase efficiency, reduce the initial investment and minimize the long-term maintenance costs.

The NX ERA EXPRESS based machine offers a cutting edge user experience (UX). The screen - a plc automation control panel - allows the user to set test parameters, view test values during and after the test, and record test memories for future references. It allows the user to have overall control over the entire test program with just a touch.

THE HEART OF THE SYSTEM: NX-ERA XPRESS