#Iron Works

Explore tagged Tumblr posts

Text

Old Majestic Glass And Iron Entranceway, Bucharest, Romania

8K notes

·

View notes

Text

Thomas: Beyond! Lost Test Archive (2022)

So, I might as well share this. Back in 2022, I wrote a script for a hypothetical first issue of Thomas Beyond, and illustrated a couple of pages to get a feel for the art style I wanted. Sketches were done in Toon Boon Harmony and Inked/colored in Photoshop. Unfortunately, I wasn’t very satisfied with what I had made, and decided to rework the script and delete the pages I had already done. Looking back I really regret doing that, but I have a couple of archived screenshots (albeit VERY cropped) that I sent to some friends for their advice.

The Issue was titled “Mystery of the Mail”.

One night, Percy is tasked with his usual run with the mail train, retrieving Sodor’s outward-going mail for an express post train bound for the mainland. However, after dropping his mail vans off in their designated siding at the big station, he is shocked to find out they had vanished in the middle of the night, and the train had to depart the Island of Sodor without collecting them. While most initially assume it was yet another instance of Percy’s clumsiness, tensions grow even higher after Sir Topham Hatt reveals one of the mail vans contained a special delivery of stock meant for a bank. With the police beginning to thoroughly investigate the North Western Railway, and all of staff questioned, it becomes evident to all that the NWR fell victim to a train robbery. Percy is shunned by most of the other engines for being so careless, with some even suspecting he and his crew were somehow involved in the heist despite pleading their innocence. Percy is utterly distraught, and becomes a disgrace. Not one for wanting to see his best friend’s reputation sink further down, Thomas (with the help of his driver, Bob) vows to solve the mystery of the mail and clear Percy’s name.

Thomas and Bob’s mishaps and hijinks in detective work end up distracting them from their usual jobs on Thomas’ branch line. Sir Topham Hatt reprimands Thomas for his immaturity, and Bob for knowing better than to give into Thomas’ shenanigans. The next day, the two are tasked with assisting the Sodor Ironworks in dumping their molten slag (this is where the conversation in the first image occurs). During their stay there, Thomas and Bob discover that the Ironworks orchestrated the heist, having sent Iron Bert out to retrieve the cars. Bert’s crew stuck off the main line as much as possible to avoid drawing any attention from the signal boxes. Upon retrieving the vans, Bert flew the express headlamps to disguise himself as the post train in the dark. Edward comes forward and swears he heard 2 trains pass by his yard at night, adding an extra layer of truth to the story. The police grow suspicious and obtain a warrant to search the Ironworks’ premises. Sure enough, tucked away in a shed, the vans are recovered, with several crowbars pathetically still pried upon the completely-locked doors.

Percy’s name is finally cleared-up, and he is welcomed back by everyone. As for the Ironworks? Well, the manager was VERY conveniently not present the day the mail vans were found… or the day after… and the next one after that. Many suspect that he ether successfully fled the country, or those whom he had “connections” with caught-on that his mission had failed, and were the ones to “hold him accountable” rather than the law. Just one more layer to this mystery that may NEVER be solved.

I have issues with this plot. Everyone is so quick to dogpile on Percy, including Sir Topham Hatt. Also, while I do remember that Bob does butt-heads with Thomas a lot of the time in small dialogue bits, I feel like he DOES give into Thomas’ whole detective bit wayyy too easily. I characterize him as being a lot more level-headed and dry in order to bounce off of Thomas’ impulsivity and eccentricity. Also, bleh. Of COURSE the Ironworks are the bad guys! Who could’ve guessed that it WASN'T them after the moment they became apart of this? Also, I pulled the whole “The Ironworks may or may not have ties to the criminal underworld” way too early. I like that idea, it’s funny and provides a genuinely good force for our heroes to combat against, but idk. It came and went wayyy too quickly. I’m much prouder of the narrative I have going on now for Sudric Storm, I feel it’s a better introduction to the Thomas series in the form of a comic, and provides a much more enriching story for these characters to play around in.

Welp, that was a blast from the past. Hope you enjoyed! (Also, 14 hours? Thomas… that’s… literally nothing. That’s a pretty average amount of time for being awake on a given day, what??? Amateur.)

#thomas#thomas and friends#thomas the tank engine#fan comic#railway series#thomas comic#thomas the train#trains#ttte thomas#ttte#ttte fanart#ttte fanfic#percy the small engine#Ironworks#iron works#iron bert#edward the blue engine#sir topham hatt

52 notes

·

View notes

Text

Ka - Descendants of Cain (Iron Works, 2020) Genre: Abstract Hip Hop Artwork: Gustave Doré

#Ka#brownsvilleka#descendants of cain#iron works#2020#hip hop#abstract#abstract hip hop#gustave dore#bw

7 notes

·

View notes

Text

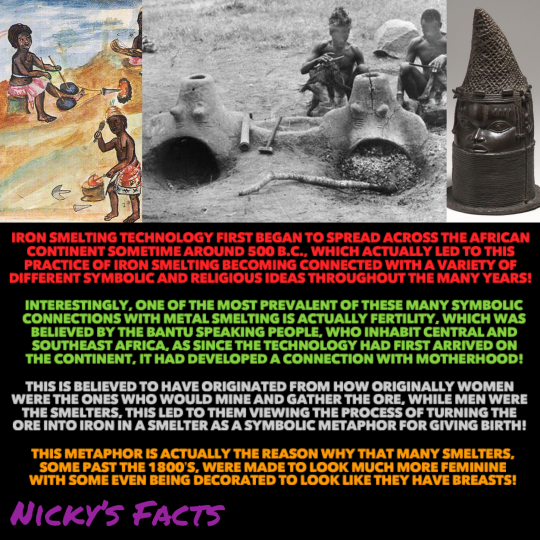

The feminine urge to mine and smelt iron ore!🪨

🔥🛠🔥

#history#iron#smelting#fertility#bantu#african history#ancient#femininty#motherhood#africa#technology#womens history#symbolism#black femininity#african culture#iron works#ancient history#girl power#mining#african women#traditional femininity#iron ore#precolonial africa#nickys facts

11 notes

·

View notes

Text

Firescreen, c1923

Designed by Edgar Brandt, French, 1880-1960

Polished cast iron

In the Modernism Collection of the Minneapolis Institute of Art, Minneapolis, Minnesota, USA

76 notes

·

View notes

Text

#mine 🖤

#mypix#morrigancrowphantompics#nature#antique#historic#landmark#water wheel#mill#forge#iron works#17th century#landscape#b & w photography

5 notes

·

View notes

Text

3 notes

·

View notes

Text

Y’all. I cannot with my horse.

18 notes

·

View notes

Text

Bonnybridge Foundry and Columbian Stove Works, Bonnybridge. Smith & Wellstood Ltd.

Aerial view of Smith & Wellstood Ltd.'s premises at Bonnybridge, including the Bonnybridge Foundry (upper r.) and Columbian Stove Works (lower l. centre). Illustration from a 1934 brochure on their "Esse Heat Storage Cooker".

The Foundry was erected to supply the Singer Sewing Machine Company. In 1890 Singers opened their own foundry and Bonnybridge was bought over subsequently by Smith and Wellstood who also owned the Columbian Stove Works.

It was some size, and incororated a number of businesses including;

Messrs. David Gillies & Sons

Rollo Industries

Messrs. E. Dyer (Engineering) Ltd.

Smith, Wellstood and Ure & Co.

Campbell Ferguson & Co., later became

George Mitchell & Sons Ltd.

Woodlea Foundry

Broomside Foundry Co. (1922) Ltd

Messrs. Lane & Girvan

Chattan Stove Works (Bonnyside Road)

Messrs. E. & R. Moffat

Dempster, Moore &Co. (Machinery) Ltd., Glasgow

Banknock Foundry

Broomridge Foundry

By the mid 1990s the site was cleared and today little remains of the old foundry buildings.

15 notes

·

View notes

Text

Preventing Defects and Imperfections in Welded Joints

Welding is a critical process used across industries to join metals in the construction of buildings, bridges, automobiles, aircraft, pipelines and many other structures. However, welding is not a perfect process and various types of defects can occur, both internally and externally in the welded metal. These welding defects are imperfections that deviate from acceptable tolerances, weakening the joint and potentially leading to catastrophic failures. Understanding the common types of welding defects, their causes, and preventive measures is crucial for ensuring the integrity and reliability of welded structures. In this article, we will explore the major categories of welding defects, delve into specific defect types, examine their causes, and discuss strategies for preventing their occurrence.

Types of Welding Defects

Welding defects can be broadly classified into two main categories:

External defects: Discontinuities that are visible on the surface of the weld metal

Internal defects: Imperfections that occur within the weld metal and are not readily visible

External Welding Defects

Some of the most common external welding defects include:

Cracks: Fractures that form in the weld metal or heat-affected zone due to thermal stresses, hydrogen embrittlement, or solidification shrinkage

Undercut: A groove-like defect along the edges of the weld bead, reducing the cross-sectional area and weakening the joint

Overlap: Excessive weld metal that flows onto the base material without proper fusion

Spatter: Small droplets of molten metal that solidify on the base material or surrounding area, affecting aesthetics and requiring additional cleaning

Internal Welding Defects

Internal welding defects are not readily visible and often require advanced inspection techniques to detect. Some common internal defects are:

Porosity: Gas bubbles or cavities that form within the weld bead due to trapped gas during solidification

Slag inclusion: Retention of solid materials, metallic or non-metallic, within the weld metal

Lack of fusion: Insufficient bonding between the base material and weld metal or between successive weld beads

Incomplete penetration: The weld does not fully extend through the thickness of the base material, leaving a gap or void

Causes of Welding Defects

Several factors can contribute to the formation of welding defects:

Poor welding technique: Incorrect welding parameters, improper electrode angle, or inadequate travel speed

Incorrect welding parameters: Unsuitable voltage, current, or wire feed speed settings

Contamination: Presence of impurities such as oil, grease, rust, or moisture on the base metal or filler material

Inadequate shielding gas coverage: Insufficient or improper shielding gas flow, leading to atmospheric contamination

Improper joint preparation: Incorrect joint design, poor fit-up, or inadequate cleaning of the joint surfaces

Preventing Welding Defects

To minimize the occurrence of welding defects and ensure high-quality welds, several preventive measures can be implemented:

Proper Welding Technique

Maintain the correct electrode angle and travel speed

Adjust welding parameters based on the material thickness and joint configuration

Ensure proper weld bead placement and overlap

Material Preparation

Thoroughly clean the base metal and filler material to remove contaminants

Ensure proper joint preparation, including beveling and fit-up

Preheat the base metal when required to reduce thermal stresses

Shielding Gas Management

Use the appropriate shielding gas composition and flow rate for the specific welding process and material

Regularly check and maintain the gas delivery system to prevent leaks or contamination

Ensure adequate gas coverage, especially in windy or drafty environments

Equipment Maintenance and Calibration

Regularly inspect and maintain welding equipment to ensure proper functioning

Calibrate welding machines and monitoring devices to maintain accurate settings

Replace worn or damaged components, such as contact tips and gas nozzles

Welder Training and Qualification

Provide comprehensive training to welders on proper techniques, parameter selection, and defect prevention

Ensure welders are qualified and certified according to relevant standards and codes

Encourage continuous learning and skill development through ongoing training and education

Implementing Quality Control Measures

Establish and follow welding procedures and specifications

Conduct visual inspections and non-destructive testing (NDT) to detect and evaluate defects

Implement corrective actions and process improvements based on defect analysis and root cause identification

Detecting and Correcting Welding Defects

Despite preventive measures, welding defects may still occur. Early detection and appropriate corrective actions are essential to maintain the integrity of welded structures. Some common methods for detecting and correcting welding defects include:

Visual Inspection

Examine the weld surface for visible defects such as cracks, undercut, overlap, or spatter

Use magnifying lenses or borescopes for closer inspection of hard-to-reach areas

Document and evaluate the severity of defects based on acceptance criteria

Non-Destructive Testing (NDT)

Employ NDT techniques such as radiographic testing (RT), ultrasonic testing (UT), magnetic particle testing (MT), or dye penetrant testing (PT) to detect internal defects

Interpret NDT results and determine the acceptability of defects based on applicable standards and specifications

Perform additional testing or sectioning for further evaluation if necessary

Corrective Actions

Remove defects by grinding, chipping, or gouging, ensuring complete removal of the defective material

Re-weld the affected area using proper techniques and parameters

Perform post-weld heat treatment (PWHT) when required to relieve residual stresses and improve mechanical properties

Re-inspect the repaired area to confirm the effectiveness of the corrective action

Advancements in Welding Technology

Welding technology continues to evolve, with advancements aimed at improving weld quality, productivity, and safety. Some notable developments include:

Automated welding processes: Robotic welding systems and computer-controlled welding machines enhance precision, consistency, and efficiency, reducing human error and variability.

Advanced welding consumables: New filler materials with improved mechanical properties, corrosion resistance, and weldability enable welding of challenging materials and in demanding environments.

Real-time monitoring and control systems: Sensors, data acquisition systems, and machine learning algorithms enable real-time monitoring of welding parameters, defect detection, and process optimization, leading to improved weld quality and reduced rework.

Conclusion

Preventing defects and imperfections in welded joints is crucial for ensuring the structural integrity, safety, and reliability of welded components across various industries. By understanding the common types of welding defects, their causes, and implementing effective preventive measures, welding professionals can significantly reduce the occurrence of defects and achieve high-quality welds.

3 notes

·

View notes

Text

#on this day in history#history#comedy#lunch atop a skyscraper#skyscraper#beautiful photos#black and white#lunch break#iron works#famous photographers#photography

2 notes

·

View notes

Photo

"Iron Worker in Construction" by Peter James Salter on INPRNT

#illustration#artist#peter james salter#inprnt#artists on tumblr#painting#tumblr milestone#concept art#construction#iron flame#iron works#illustrative art#illustrations#illustrator

2 notes

·

View notes

Text

At the staff meeting trying to convince our ironworking coworker that we need an iron furnace in the museum basement (so that we can be like Mandalorians)

#museums#museum life#museum curator#historical society#history#star wars#the mandalorian#iron works#staff meeting#i know you can have iron furnaces in a basement i promise#east coast#baby yoda#ironworking#curatorial#art history

6 notes

·

View notes

Text

What Materials Are Frequently Utilized In Iron Work Services, And Also Just How Do They Contribute To The Total Toughness?

In the wide realm of building and also construction, iron job solutions command a substantial location as a result of their necessity in developing resilient structures. The integral stamina, convenience, and also longevity of iron make it an optimal product for numerous applications varying from constructing frameworks to crafting complex decorative aspects.

However, the total long life as well as efficiency of iron-based frameworks are not exclusively contingent on the natural buildings of this metal; they are equally affected by the type of materials utilized combined with iron as well as the particular treatments applied during the construction procedure.

The extensive use alloys-- compounds made by incorporating two or even more metallic elements-- is a testimony to this reality. Alloys boost the physical buildings of pure metals, making them preferable for particular applications.

For instance, adding carbon to pure iron results in steel-- an alloy known for its increased strength and resistance versus wear and tear. Similarly, surface treatments like galvanizing can considerably improve corrosion resistance, consequently expanding the lifespan of iron frameworks.

This article aims to clarify these typically made use of materials in iron job services while elucidating exactly how they add towards boosting general sturdiness.

Checking out the Function of Alloys and Treatments in Enhancing Long Life of Structures

The unification of alloys and treatments in iron work services becomes a perfect symbol of strength as well as long life, dramatically boosting the sturdiness as well as life expectancy of frameworks.

Alloys are a fusion of 2 or more metallic elements, which when combined, existing superior homes contrasted to individual parts. Significantly, steel - an alloy predominantly made up of iron and also carbon - is renowned for its high tensile strength as well as malleability. It has become a staple in building due to these top qualities combined with its resistance to environmental results such as rusting. Other prominent selections consist of cast iron, identified by its terrific solidity as well as put on resistance, making it excellent for applications where toughness is paramount.

Moreover, various treatments have been created to additionally improve these intrinsic characteristics of alloys made use of in the field. Hot-dip galvanizing involves finish iron or steel with zinc, giving cathodic defense that prevents deterioration successfully. Similarly, powder layer uses added protection versus weathering whilst at the same time supplying a visually pleasing finish. The procedure entails using powdered paint electrostatically onto steel surface areas after that treated under warm to develop a difficult shell-like layer over the product's surface area.

These treatment approaches not only add in the direction of enhancing general architectural integrity but additionally supply considerable financial benefits by minimizing maintenance expenses and also expanding service life cycles.

#iron works#iron works near me#ironworkers#ornamental iron works#ironwork#wrought iron#metalwork#iron fabrication#iron designs#iron gates#iron fences#iron railings#iron sculptures#custom ironwork#architectural ironwork#decorative ironwork#ironworking tools

4 notes

·

View notes

Text

Blue 💙🩵

#illustration#art#blue art#iron gate#iron fence#iron works#decorative arts#border art#art frame#chandelier#sketchbook#sketch#drawing#abstract art

3 notes

·

View notes

Text

Multi_media Artist | Karlequin Arts

#karlequin.com#activity coloring books#stickers#commisions#iron works#animation#sculpture#stage props#death masks#non ai#stage prosthetics & make-up#🏴☠️

0 notes