#LabVIEW

Explore tagged Tumblr posts

Text

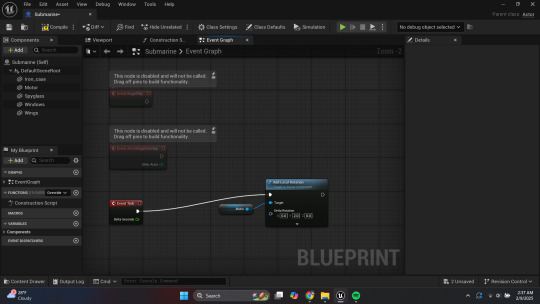

Function blocks are fun. You just connect the blocks correctly and make a reaction speed game.

It's making a scoreboard that's hard. Also making the scoreboard reactive.

But hardest of all is the documentation. Especially if you do it after the project is done and you have to go back and how the program you made works.

0 notes

Text

Telemetry Record & Replay System from Digilogic Systems

Digilogic's Telemetry Record Replay System is a new generation high-performance COTS solution based on the PXIe platform.

Our model is capable of recording live Telemetry data at various stages for a period of 2 to 4 hours without user intervention. Also, it is designed to support multiple interface technologies and operation scenarios for Defiance and Aerospace sectors.

For more information (or) to request a quote, Contact us. Phone: Hyderabad: (+91) 40 4547 4601 Bengaluru: (+91) 80 4975 6034 Website: www.digilogicsystems.com Email: [email protected]

#telemetry#telemetryrecord#digilogicsystems#cots#pxi#rfsignal#dspl#InnovativeSolutions#automationtesting#defence#aerospace#makeinindia#technology#LABVIEW

0 notes

Video

youtube

Acceso rapido a las funciones de Labview

0 notes

Text

everywhere i go i see her (labview)

#i quit my high school robotics team because i hated labview so much btw#i am and forever will be labview hater no. 1#tay.txt

3 notes

·

View notes

Text

Writing fiction

“You did it! It works!” They cheered. Meanwhile, you’re terrified, you fudged the numbers. It shouldn’t have worked.

#also programming#had the opposite experience when I tried to make a cute message handler based on the LabVIEW example#queued message handler. not cute

11K notes

·

View notes

Text

A Signal Processing Company in Defense and Aerospace

#Scenario Simulation#Modelling & Simulation#Signal Processing company in Hyderabad#Radar & EW Sensor Testing#Digital Signal Processing#Ansys STK AGI#Telemetry Receivers Manufacturers in hyderabad#radar target echo simulator#Digital Telemtry Receiver#EW Emitter simulator#Target simulator radar in hyderabad#Radar signal generator in hyderabad#Electronic warfare#sar simulator Hyderabad (synthetic aperture radar )#RF environment simulation#ELINT#comint#sigint simulator#THREAT simulator in hyderabad#Aerospace Signal processing company#Best Signal processing company in Hyderabad#Radar signal processing companies in india#Defense Equipment manufacturing companies#Communication systems IP in hyderabad#CRTK Applications#Telemetry manufacturers from Hyderabad#Digital Telemetry Transmitter#Radar Toolkit for Labview

0 notes

Text

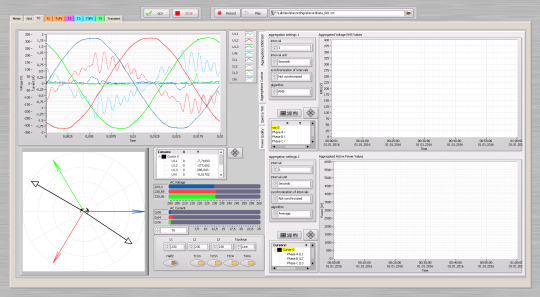

I realize I’m probably the odd one out here but my ideal UI is a cross between early web 2.0 and like. Analytical instrumentation software, like a LabVIEW program running a $200k potentiostat.

You may not like it, but that’s just because you’re weak. This is what high performance UI looks like:

168 notes

·

View notes

Text

slowly developing a fever while working on labview bullshit for 10 hours straight im going to have the most fucked up nightmares tonight

#this will give me a break from the excel stress nightmares#which are in turn a break from the c++ nightmares#i think. getting a phd may be quickly breaking me.

4 notes

·

View notes

Text

Tomorrow plans:

Sleep in as much as is reasonable

Do LabVIEW exam

Run E&M exam

Get home

Whip cream

Crepes

Go do drawing (commission + visual design for aa selfshipsona)

Do no homework even if brain tries insisting (relax time)

Call w parents (may or may not go well we will see)

Just generally take as much of a break as possible

5 notes

·

View notes

Text

The blog post is good. The image made me remember despair for a few heartbeats

0 notes

Text

Digilogic's Actuator Test Systems

Digilogic's Actuator Test System uses advanced equipment including a Frequency Response Analyzer, Universal Waveform Generator, Data Acquisition System, Servo Control Unit, and Load cell test setup.

The Actuator Test System is used to measure the performance of the Actuator using the Sine, Step, and Triangle waveform generated by the Universal Waveform Generator. Utilizing PXIe modules with LabVIEW software, the Actuator test system conducts comprehensive tests on Actuators. Data acquired from the testing process can be stored securely and analyzed to effectively meet the user's needs.

Digilogic's Actuator Test System, tailored for the demanding requirements of the defense and aerospace sectors, offers a comprehensive solution for testing actuators. The system employs an integrated approach, combining static and dynamic testing methodologies to rigorously evaluate the reliability and performance of actuators destined for mission-critical applications.

For more information about Digilogic's Actuator Test System, click the link below. https://bit.ly/3UuQSon

For any queries (or) to request a quote, Contact us. Phone: Hyderabad: (+91) 40 4547 4601 Bengaluru: (+91) 80 4975 6034 Website: www.digilogicsystems.com Email: [email protected]

Please stay connected with us on our other social media channels for the latest updates! YouTube: https://www.youtube.com/@digilogicsystems LinkedIn: https://www.linkedin.com/company/digilogicsystems/ Instagram: https://www.instagram.com/digilogic_systems/ Twitter: https://twitter.com/DigilogicSystem

#ActuatorTestSystem#DigilogicSystems#actuator#actuatortest#LabVIEW#PXI#digilogic#dataacquisitionsystem#testmeasurement#testingsolutions#testautomation#innovativesolutions#makeinindia

0 notes

Text

My scientific jokes are lost on all of you. Who will come make fun of LabVIEW with me and cry when we have to use it

6 notes

·

View notes

Text

Hey, I made a reflex game on LabVIEW (no that cool admittedly).

32K notes

·

View notes