#PLC Programming

Explore tagged Tumblr posts

Text

Siemens Quick Tips: Time-Saving Fill Handle

Siemens Quick Tips: Automating Engineering Tasks for Maximum Efficiency Siemens is at the forefront of automation, engineering, and digital transformation, offering innovative solutions that enhance efficiency, productivity, and connectivity. To help engineers, technicians, and system integrators make the most of Siemens technologies, we have compiled a collection of Siemens Quick Tips – a…

2 notes

·

View notes

Video

youtube

SCADA Applications in Water Treatment #scada #tech #shorts #industrial #...

Asteam Techno Solutions Pvt. Ltd. is AVEVA (Formerly Wonderware) Registered System Integrator providing sale/service/support and execute the HMI/SCADA, Historian/MES Solutions to End-user & OEM/System Integrator community for their diverse needs Asteam Techno Solutions Pvt. Ltd. is a leading and preferred solution provider for all kind of Industrial Automation requirements in the field of Process and Power Automation. Established in 2017, Asteam Techno Solutions is an ISO 9001: 2015 certified company, having its Design, Manufacturing & Repair facility located in Surat, Gujarat, India and provides total integration under one roof.

#youtube#scada#scadaprogramming#plc#plc programming#plc automation#industry#industrial#automation#youtumblr#tumblr

2 notes

·

View notes

Text

Is Your Industrial System Running at Peak Efficiency?

Don't let outdated electrical and instrumentation systems hold you back! iPAC Automation delivers top-tier E&I services designed to optimize your operations. We provide:

Precision Engineering: Ensuring accuracy and reliability.

Seamless Integration: Minimizing downtime and maximizing productivity.

Expert Solutions: Tailored to your specific industry needs.

From design to commissioning, we've got you covered. Get the E&I edge you need to stay ahead.

Ready to transform your industrial processes? Click the link in our bio to learn more and request a consultation!

#IndustrialAutomation#ElectricalEngineering#Instrumentation#EandIServices#AutomationSolutions#Industry40#iPACAutomation#USAIndustry#EngineeringServices#TechInnovation#plc programming#plc services#automation

0 notes

Text

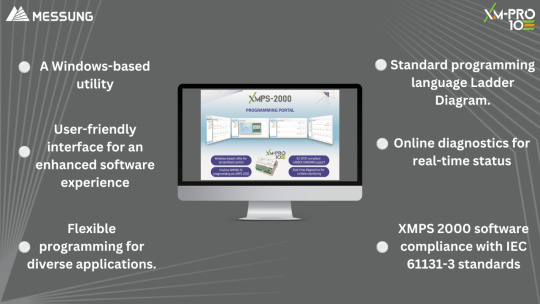

Introducing XMPS-2000: Messung's Advanced PLC Programming Software

Messung Industrial Automation is proud to unveil the XMPS-2000 software, a powerful and intuitive Windows-based utility designed to enhance the programming experience for the XMPRO-10 PLC series.

0 notes

Text

PLC Programming In Pune

Perfecto Robotics provides PLC Programming In Pune. With our expertise and dedication, we offer Our clients comprehensive PLC programming solutions. PLC programming are used to reduce human decision-making efforts to gain higher efficiency.

What is PLC Programming?

Firstly, at Perfecto Robotics, we prioritize understanding your requirements. We begin by conducting thorough consultations to grasp the intricacies of your requirements. This initial step ensures that we align our services precisely with your expectations.

PLCs are commonly used in manufacturing plants, assembly lines, and other industrial settings. PLCs are also used to automate tasks previously performed by electromechanical relays, timers, and other traditional control devices. They offer flexibility, reliability, and ease of programming, making them essential components in modern industrial automation systems.

PLC Programming Data:

A (PLC) Programmable logic controller is able to pull a large amount of data items. The data items are together with the sensor data. PLC can monitor inputs and outputs to and from a machine.

Data Collection For PLC Programming Controlled Machines:

A PLC can generate huge amounts of data to control the machine. However, Programmable logic controllers are limited in data storage and usually only accessible for the engineers.

Bidirectional PLC-to-PC communications:

Bidirectional PLC-to-PC communications enable data exchange between a Programmable Logic Controller (PLC) and a personal computer(PC) in both directions.

With the best PLC Programming In Pune, Perfecto Robotics stands out as your trusted partner. With our expertise, dedication, and commitment to excellence, we ensure superior solutions that drive your success. Contact us today to discuss your requirements for the Perfecto Robotics difference firsthand.

0 notes

Text

Elevate your automation game with CalCon & KNEO Automation!

🔹 PLC, HMI, SCADA Software Development: Unlock the full potential of your industrial processes with our cutting-edge software solutions. 🔹 Empower your team with seamless control, real-time monitoring, and data-driven insights. 🔹 Maximize efficiency, reduce downtime, and enhance productivity with our expertly crafted PLC programs. 🔹 Seamlessly integrate HMI and SCADA systems for intuitive and user-friendly control interfaces. 🔹 Stay ahead of the competition with our advanced robotics integration and virtual commissioning solutions

For more details https://bit.ly/4eR6rQn

Transform Industrial Automation with CalCon & KNEO: PLC, HMI, SCADA Solutions & More!

0 notes

Text

Importance of PLC Programming in Industrial Automation

In the industrial automation world, PLC Programming plays an important role. It helps in maintaining the complex interactions between machinery, sensors, actuators and human operators. Also, it ensures precise control, monitoring and optimization of manufacturing processes. Read More: https://margorautomation.com/blog/importance-of-plc-programming-in-industrial-automation/

0 notes

Text

How Industrial Automation Companies Enhance Production Efficiency?

The quest for production efficiency has never been more pressing in today's rapidly evolving industrial landscape. As industries face increasing global competition, rising labour costs, and ever-changing consumer demands, the role of industrial automation companies has become crucial.

These companies provide innovative solutions that streamline operations, reduce costs, and improve product quality. In this blog, we will explore how industrial automation companies enhance production efficiency and the technologies they employ to achieve these results.

Understanding Industrial Automation

Industrial automation involves using control systems - such as computers, robots, and machinery - to manage and monitor production processes with minimal human intervention. The benefits of automation extend across multiple sectors, including manufacturing, transportation, and utilities.

By employing automation, companies can increase productivity, improve product quality, and ensure consistency while significantly reducing human error.

Key Components of Industrial Automation

Industrial automation companies leverage various technologies to facilitate automation. These include:

Robotics: Robotic systems can perform repetitive tasks with high precision and speed, thus significantly reducing cycle times in production.

Control Systems: These systems manage machinery and processes, ensuring optimal performance and efficiency throughout the production line.

Sensors and Actuators: These components gather data and execute actions based on real-time feedback, optimising operations and improving decision-making.

Through these technologies, industrial automation companies design and implement solutions that enhance productivity and efficiency across various industries.

Enhancing Production Efficiency

1. Streamlining Processes

One primary way industrial automation companies enhance production efficiency is by streamlining processes. Traditional manufacturing methods often involve multiple steps that can be time-consuming and prone to human error.

Automation integrates these processes into a single, cohesive system, simplifying operations. For instance, an automated assembly line can handle everything from material handling to product assembly.

This integration reduces the need for manual labour, decreases lead times, and results in faster production cycles. Additionally, automated guided vehicles (AGVs) help transport materials within the facility, further enhancing workflow efficiency.

2. Reducing Operational Costs

Cost reduction is another significant benefit of automation. By minimising human intervention, companies can lower labour costs and decrease the likelihood of costly errors.

Industrial automation companies implement systems optimising resource usage, ensuring materials are utilised efficiently, and minimising waste.

Moreover, automated systems can operate continuously without breaks, leading to higher output levels. This continuous operation reduces production costs per unit, positively impacting the company’s bottom line.

For example, companies using automated palletising systems can achieve higher throughput without additional labor costs.

3. Improving Quality Control

Quality control is a critical aspect of manufacturing, and industrial automation companies enhance production efficiency by integrating sophisticated quality control measures directly into automated processes.

Automated systems can be equipped with sensors that detect defects in real-time, allowing for immediate corrective action. This immediate feedback ensures that only products meeting quality standards proceed through production.

Maintaining consistent quality can improve customer satisfaction and reduce return rates. For instance, a food processing plant using automated quality inspection systems can quickly identify contaminated products, ensuring that only safe items reach consumers.

4. Enhancing Flexibility and Scalability

Flexibility is essential in a dynamic market. Consumer demands can shift rapidly, and companies must adapt quickly to remain competitive.

Industrial automation companies provide solutions that enhance flexibility and scalability, allowing manufacturers to quickly reconfigure their production lines to accommodate new products or changes in demand.

For example, modular automation systems can be easily adjusted or expanded as needed. This adaptability helps companies respond swiftly to market fluctuations, minimising downtime and ensuring production meets customer requirements.

In industries such as consumer electronics, where product life cycles are short, the ability to rapidly adjust production capabilities is invaluable.

5. Utilising Data Analytics

Data analytics plays a vital role in optimising production efficiency. Industrial automation companies leverage advanced data analytics tools to collect and analyse data from automated systems. This data provides valuable insights into operational performance, enabling companies to identify areas for improvement.

Manufacturers can make informed decisions regarding equipment maintenance, production schedules, and resource allocation by analysing trends and patterns. For example, predictive maintenance techniques allow companies to anticipate equipment failures before they occur, reducing downtime and associated costs.

By integrating data analytics into their operations, companies can make proactive adjustments that enhance overall efficiency.

6. Enhancing Worker Safety

Automation improves efficiency and enhances worker safety. Many industrial processes involve hazardous conditions, exposing workers to potential dangers. By implementing automated systems, industrial automation companies can minimise the risk of accidents and injuries.

For instance, robots can be deployed in unsafe environments for human workers, performing tasks that would otherwise pose risks. This shift protects employees and improves overall productivity, as workers can focus on higher-value tasks that require human expertise.

In industries like manufacturing and warehousing, implementing automation significantly reduces the likelihood of workplace accidents.

7. Sustainability and Environmental Impact

Sustainability is increasingly becoming a priority for companies, and automation can significantly achieve environmentally friendly practices. Industrial automation companies help manufacturers reduce their environmental footprint by optimising energy usage and minimising waste.

For example, automated systems can monitor energy consumption in real-time, allowing companies to adjust operations to reduce energy waste. Additionally, by implementing smart manufacturing practices, companies can recycle materials more effectively and reduce overall waste, contributing to a more sustainable production model.

Case Studies: Success Stories in Industrial Automation

1. Automotive Manufacturing

The automotive industry is a prime example of industrial automation companies enhancing production efficiency. Companies like Ford and Toyota have successfully integrated robotics and automation into their production lines, significantly improving speed and quality.

Ford's use of automation in its assembly plants has allowed the company to achieve higher production rates while maintaining strict quality standards. By employing advanced robotics for tasks such as welding and painting, Ford has minimised manual labour while ensuring consistency and precision.

2. Food and Beverage Industry

In the food and beverage sector, automation enhances efficiency while ensuring safety and compliance with regulations. Industrial automation companies provide solutions that automate packaging, bottling, and quality control processes.

Coca-Cola, a notable example, has implemented automated systems to streamline its bottling operations. These systems allow for faster production while maintaining strict quality standards. This automation enables the company to respond quickly to changes in consumer demand, ensuring product availability when and where it is needed.

Future Trends in Industrial Automation

As technology continues to advance, the future of industrial automation looks promising. Emerging trends such as artificial intelligence (AI), machine learning, and the Internet of Things (IoT) are expected to further enhance industrial automation companies' capabilities.

1. Artificial Intelligence and Machine Learning

AI and machine learning technologies enable automated systems to learn from data and improve their performance over time. This capability can enhance predictive maintenance, quality control, and operational efficiency.

Companies can optimise their operations by integrating AI into automation processes based on real-time insights.

2. IoT Integration

The Internet of Things connects machines and devices, enabling seamless communication and data exchange. Industrial automation companies are increasingly adopting IoT technologies to enhance their monitoring and control capabilities.

This integration allows for real-time tracking of production processes, enabling companies to make data-driven decisions that improve efficiency.

Conclusion

Industrial automation companies play a vital role in enhancing production efficiency across various sectors. These companies are at the forefront of transforming the industrial landscape by streamlining processes, reducing costs, improving quality control, and enhancing worker safety.

As industries continue to face new challenges, the importance of automation will only grow. Businesses that partner with Plc Programming can gain a competitive edge, ensuring they remain relevant in a fast-paced market.

In a world where efficiency is paramount, embracing automation is not just a strategy for keeping up with competition; it is a fundamental shift in redefining what is possible in production efficiency.

Whether you are a manufacturer looking to boost operational capabilities or simply interested in the advancements in automation technology, industrial automation companies are clearly in charge of shaping the industry's future.

#Industrial Automation Companies#Plc Commissioning#Plc Programming#Industrial Automation#Industrial Control System

0 notes

Text

Need Help with Your PLC Programming? We’ve Got You Covered!

Industry Professionals, Attention!

Are you facing challenges with your PLC programming? At IPAC Automation, we understand the complexities of industrial automation and the critical role PLCs play in your operations. That’s why we offer comprehensive PLC Programming Services to ensure your systems run smoothly and efficiently.

What We Can Do for You:

New PLC System Programming: Our experienced engineers will design and program your PLC system from scratch, tailored to your specific needs and equipment.

PLC System Modifications: Need to adapt your existing PLC program? We can modify and optimize your current code for improved functionality.

Troubleshooting & Debugging: Experiencing PLC issues? We’ll diagnose the problem and provide effective solutions to get your system back up and running.

Ongoing Support: We offer ongoing maintenance and support plans to ensure your PLC system remains optimized and up-to-date.

Benefits of Choosing IPAC Automation:

Experienced & Certified Engineers: Our team holds industry certifications and possesses extensive experience with various PLC brands and applications.

Efficient Project Management: We follow a structured approach, ensuring timely project completion and clear communication throughout the process.

Cost-Effective Solutions: We offer competitive rates and deliver results that optimize your production and minimize downtime.

Ready to Streamline Your Industrial Automation?

Visit our PLC Programming Services page at IPAC Automation PLC Programming to learn more about our expertise and how we can help you achieve your automation goals.

Let’s discuss your project! Feel free to comment below or send us a message to discuss your specific PLC programming needs.

.

.

.

#PLC #PLCProgramming #IndustrialAutomation #Automation #Engineering #Manufacturing

#plc programming#PLC Services#industrial equipment#industrial automation#manufacturing services#manufacturer#manufacturing

1 note

·

View note

Text

PLC Programming

Discover expert PLC programming services with Alpha Team Control. Our skilled professionals provide customized PLC programming solutions to optimize your industrial automation processes. From design and implementation to maintenance, we ensure your PLC systems run smoothly and efficiently. Enhance your operational efficiency with our reliable and innovative PLC programming services. Explore our expertise and commitment to excellence. Partner with Alpha Team Control for superior PLC programming solutions. Contact us today at 1800 257 428.

1 note

·

View note

Text

Making the Switch from DCS to PLC Systems with the Help of Expert PLC Programming

In today's industrial landscape, maximizing efficiency and optimizing operations are crucial for success. Many facilities still rely on Distributed Control Systems (DCS) for automation. While DCS have served their purpose well, advancements in Programmable Logic Controllers (PLCs) offer a compelling reason to consider an upgrade.

Here at iPAC Automation, we understand the complexities of transitioning from a DCS to a PLC system. Our expert PLC programming services can ensure a smooth and successful migration, unlocking the numerous benefits PLCs offer.

Why Upgrade from DCS to PLC Systems?

Several factors make PLCs an attractive alternative to DCS, particularly for modern industrial applications:

Cost-Effectiveness: PLCs generally have lower upfront and ongoing maintenance costs compared to DCS. Their modular design allows for easier troubleshooting and replacement of individual components.

Scalability: PLCs excel at handling smaller, more focused processes. Their modularity allows for easier expansion or modification as your needs evolve.

Flexibility: PLCs offer greater programming flexibility. iPAC's PLC programming services can tailor control logic to your specific requirements, ensuring optimal performance for your unique application.

Ease of Use: Modern PLCs boast user-friendly interfaces and readily available programming tools. This simplifies troubleshooting, maintenance, and even future modifications.

Benefits of iPAC Automation's PLC Programming Services

Upgrading to a PLC system can be a complex undertaking. iPAC Automation streamlines the process with our comprehensive PLC programming services:

Expert Analysis and Planning: We begin by thoroughly analyzing your existing DCS system and understanding your operational goals. This allows for a customized migration plan that minimizes downtime and disruption.

Seamless Code Conversion: Our skilled PLC programmers efficiently convert your DCS control logic into robust and optimized PLC code. We prioritize code clarity and maintainability for future modifications.

Hardware Integration: iPAC's team seamlessly integrates your existing field instruments with the new PLC system. We ensure proper communication protocols and data exchange for reliable operation.

Detailed Testing and Commissioning: Rigorous testing and commissioning ensure the upgraded PLC system functions flawlessly, meeting all safety and performance standards. We provide comprehensive documentation for future reference and support.

Ongoing Support: iPAC Automation doesn't stop at implementation. We offer ongoing support to ensure your PLC system continues to operate at peak efficiency. This includes troubleshooting, maintenance guidance, and even future programming modifications.

A Smooth Transition with iPAC Automation

Upgrading from a DCS to a PLC system can be a significant step towards a more efficient and cost-effective operation. With iPAC Automation's expert PLC programming services, you can navigate this transition with confidence. Our experience, expertise, and commitment to excellence ensure a smooth migration that unlocks the full potential of your PLC system.

Contact iPAC Automation today to discuss your specific needs and learn how our PLC programming services can help you achieve your automation goals.

1 note

·

View note

Text

Siemens Quick Tips: Target 1500S™ for Simulink®

Siemens Quick Tips: Automating Engineering Tasks for Maximum Efficiency Siemens is at the forefront of automation, engineering, and digital transformation, offering innovative solutions that enhance efficiency, productivity, and connectivity. To help engineers, technicians, and system integrators make the most of Siemens technologies, we have compiled a collection of Siemens Quick Tips – a…

0 notes

Text

1 note

·

View note

Text

Engineering Training In Pune

Welcome to Perfecto Robotics Institute, your perfect destination for Engineering Training In Pune. Our organization prides itself on offering advanced courses designed to equip you with essential technical skills.

At Perfecto Robotics Institute, we are dedicated to providing exceptional training programs for individuals of all skill levels. Whether you are a beginner looking to build a solid foundation to grow your career. We provide step-by-step guides in robotics as well as automation fields. In the Institute we take practical exercises for students to better understand as well as for incrementing their knowledge.

Lesson Highlights:

Moreover, Our educational program is carefully designed to cover a wide range of engineering disciplines. Students benefit from hands-on training using state-of-the-art equipment, ensuring the application of practical knowledge in real-world situations.

Why should you choose us?:

Additionally,

our expert professors are industry-experienced.

We provide outstanding practical experience to the students.

Individual guidance.

We support you foster collaboration.

Rich learning environment.

From basic principles to advanced techniques.

Career Opportunities:

With Perfecto Robotics Institute we provide successful completion of our training programs. our courses are designed to meet your specific needs. We provide career opportunities in automotive, robotics, etc.

Offered Courses:

Basic Industrial Automation

Advanced Industrial Automation

Basic Industrial Robotics

Advanced Industrial Robotics

In conclusion, Perfecto Robotics Institute stands out as an indication of excellence in Engineering Training in Pune. Whether you aspire to enhance your skills or embark on a new career path in engineering, we are committed to helping you achieve your professional training experience.

Ready to take the next step toward a successful career in engineering? Contact Perfecto Robotics Institute today to learn Engineering Training In Pune for more about our courses, enrollment procedures, and how we can support your educational journey.

0 notes

Text

Industrial PLC Programming

Introduction to Industrial PLC Programming

Industrial Programmable Logic Controllers (PLCs) play a pivotal role in automating processes across various industries. These programmable devices execute specific tasks in response to inputs and produce outputs, thereby controlling machinery and processes in manufacturing plants, factories, and other industrial settings.

Importance of PLC Programming in Industrial Automation

PLC programming is essential for streamlining operations, improving efficiency, and ensuring precision in industrial processes. By programming PLCs, engineers can automate repetitive tasks, monitor equipment performance, and implement complex control algorithms to optimize production.

Components of Industrial PLC Systems

Industrial PLC systems comprise hardware and software components. The hardware includes the PLC itself, along with input and output modules, sensors, actuators, and communication interfaces. The software encompasses programming tools, such as ladder logic editors, function block editors, and other programming languages.

PLC Hardware

The hardware components of a PLC system provide the physical interface between the control system and the machinery it controls. These components include the CPU (Central Processing Unit), memory modules, digital and analog input/output modules, power supply units, and communication modules.

PLC Software

PLC software enables engineers to develop and deploy control logic for industrial processes. Common programming languages used in PLC programming include ladder logic, function block diagrams, structured text, sequential function charts, and instruction lists.

Basic Concepts of PLC Programming

Understanding fundamental concepts is crucial for mastering PLC programming.

Input and Output (I/O) Modules

I/O modules serve as the interface between the PLC and external devices such as sensors, switches, actuators, and motors. Inputs receive signals from sensors or switches, while outputs send signals to actuators or motors to control their operation.

Ladder Logic Programming

Ladder logic is a graphical programming language commonly used in PLC programming. It represents logic functions and control sequences using rungs and contacts resembling electrical relay circuits.

Function Block Diagram (FBD)

Function block diagrams provide a visual representation of control logic using interconnected function blocks. Each block represents a specific function or operation, facilitating modular programming and code reuse.

Advanced PLC Programming Techniques

Beyond basic programming concepts, advanced techniques offer greater flexibility and scalability in PLC programming.

Sequential Function Chart (SFC)

SFC programming allows engineers to design complex control sequences using state-based logic. It breaks down processes into discrete steps or states, transitioning between them based on predefined conditions.

Structured Text (ST)

Structured text is a high-level programming language resembling Pascal or C, suitable for implementing complex algorithms and mathematical calculations in PLC programs.

Instruction List (IL)

Instruction list programming involves writing PLC programs using mnemonic codes corresponding to specific instructions executed by the PLC processor. It offers a low-level approach to programming and is commonly used for performance-critical applications.

Industrial Applications of PLC Programming

PLC programming finds extensive use in various industrial applications, including:

Manufacturing Automation: PLCs control assembly lines, robotic arms, conveyors, and other machinery in manufacturing plants to optimize production processes.

Process Control: PLCs regulate parameters such as temperature, pressure, flow rate, and level in industrial processes such as chemical manufacturing, water treatment, and HVAC systems.

Robotics: PLCs coordinate the motion and operation of industrial robots for tasks such as material handling, welding, painting, and assembly.

Challenges and Considerations in Industrial PLC Programming

While PLC programming offers numerous benefits, engineers must address several challenges and considerations:

Safety Concerns

Ensuring the safety of personnel and equipment is paramount in industrial automation. Engineers must implement appropriate safety measures and fail-safe mechanisms in PLC programs to prevent accidents and hazardous situations.

Maintenance and Troubleshooting

Regular maintenance and timely troubleshooting are essential for ensuring the reliability and efficiency of PLC systems. Engineers must possess strong troubleshooting skills and diagnostic capabilities to identify and rectify faults promptly.

Cybersecurity Risks

As industrial systems become increasingly interconnected and digitized, cybersecurity threats pose a significant concern. Protecting PLCs from unauthorized access, malware, and cyberattacks requires robust security measures and adherence to industry standards and best practices.

Future Trends in Industrial PLC Programming

The future of PLC programming is shaped by emerging technologies and trends that offer new opportunities and challenges:

Internet of Things (IoT) Integration

Integrating PLCs with IoT platforms enables real-time monitoring, remote access, and data analytics, enhancing operational efficiency and predictive maintenance capabilities.

Machine Learning and Artificial Intelligence

Applying machine learning algorithms and AI techniques to PLC programming enables adaptive control, anomaly detection, and predictive optimization, paving the way for autonomous industrial systems.

Conclusion

Industrial PLC programming plays a vital role in driving automation, efficiency, and innovation across diverse industries. By mastering PLC programming techniques and embracing emerging technologies, engineers can unlock new possibilities and propel industrial automation into the future. If you want to read more blogs related these type of topics so visit here👉PujaControls

#plc#automation#technology#software development#industrial automation#labviewsoftware#system integration#labview#plc automation#plc programming

1 note

·

View note