#PROFINET

Text

BLIIoT Industrial Protocol PCB Board Customization

Industrial Protocol support: Modbus RTU, Modbus TCP, Profinet, EtherCAT, Ethernet/IP, PLC protocol, MQTT, OPC UA, etc.,

Communication support: Serial port, Ethernet port, 4G, WiFi, etc.,

For more customization needs, Please contact us.

0 notes

Text

The Difference Between Profibus and Profinet

Profibus and Profinet are two industrial communication protocols commonly used in the field of automation and process control.

Profibus (Process Field Bus) is a fieldbus protocol used for communication between automation devices, such as sensors, actuators, and controllers, in industrial automation systems. It was developed and standardized by the German Institute of Electrical and Electronics Engineers (IEC) in the late 1980s. Profibus is widely used in various industries, including manufacturing, automotive, and power plants.

Profibus supports different variants, including Profibus DP (Decentralized Periphery) and Profibus PA (Process Automation). Profibus DP is commonly used for communication between programmable logic controllers (PLCs) and field devices, while Profibus PA is used specifically for process automation applications.

Profinet (Process Field Network) is an Industrial Ethernet-based communication protocol introduced as an extension of Profibus. Unlike Profibus, which uses serial communication, Profinet uses Ethernet as the underlying communication medium. Profinet enables real-time communication between different automation devices and supports high data rates, making it suitable for demanding industrial applications.

Profinet provides flexibility and scalability, allowing seamless integration between various automation systems. It supports both cyclic and acyclic communication, enabling real-time control and configuration of devices on the network. Profinet also provides improved diagnostics and allows for remote device parameterization.

Both Profibus and Profinet are widely used in industrial automation systems, with their specific applications and advantages. Profibus is mainly used in legacy systems, while Profinet is preferred for new installations due to its compatibility with Industrial Ethernet standards and higher performance capabilities.

0 notes

Text

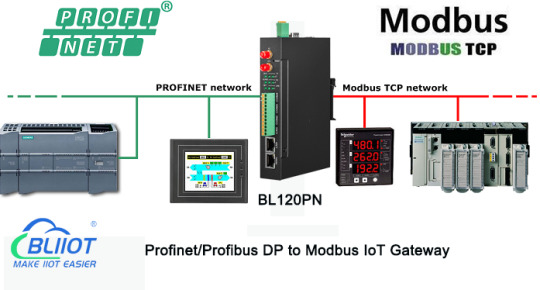

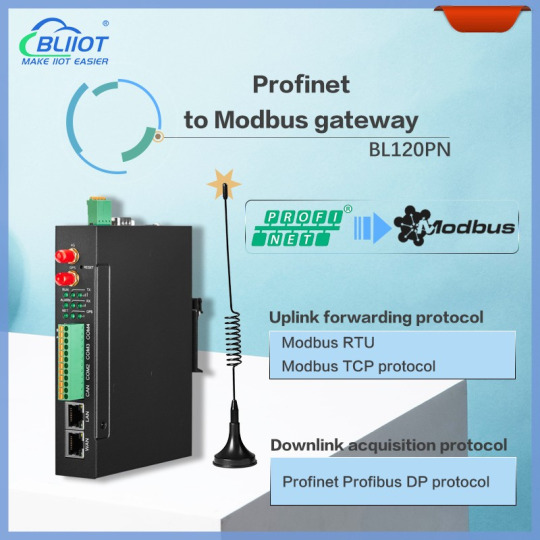

Siemens S7 Profinet/Profibus DP to Modbus IoT Gateway BL120PN

Introduction

BL120PN is a Profinet, Profibus D to Modbus gateway.

BL120PN downlink acquisition supports: Profinet, Profibus D.

BL120PN uplink supports: Modbus RTU, Modbus TCP protocols.

Features

BL120PN uses an embedded ARM MCU, a product developed based on Linux OS system, and has a high degree of stability. Provides 1RS232/RS485 optional serial port input, 2 power inputs, 1 power output, 2 Ethernet ports (WAN port and LAN port) and 2 USB interfaces, Supporting SIM cards and SD cards

BL120PN integrates a humanized configuration interface based on BLIIOT technology, as well as remote configuration, remote firmware upgrade and other functions. Users only need to make simple settings.

BL120PN adopts a fastening structure, redundant power supply design, and standard DIN35 rail installation.

How does BL120PN implement Profinet to Modbus protocol?

1. BL120PN collects data from the Profinet network through the Profinet protocol.

2. BL120PN maps data points in the Profinet network to registers in the Modbus network according to the preset mapping rules.

3. BL120PN sends the data in the register in the Modbus network to the Modbus RTU or Modbus TCP protocol device.

4. After receiving the data, the Modbus device parses and processes it according to the Modbus protocol, and performs corresponding control operations.

Application

BL120PN is widely used in the field of industrial automation, providing a reliable solution for communication between Profinet and Profibus D devices and Modbus devices. It can be used in scenarios such as equipment integration, network expansion, data monitoring and control, and automation system integration.

More information view: https://www.bliiot.com/

0 notes

Link

1.1 Product Features

This gateway is a Modbus-RTU/ASCII or non-standard protocol to ProfiNet protocol converter. It can realize the conversion of Modbus-RTU/ASCII or non-standard protocol to ProfiNet protocol. Any device with RS485/RS232/RS422 interface that supports Modbus-RTU/ASCII or non-standard protocols can use this product to interconnect with the industrial bus ProfiNet. Such as: PLC, DCS, distributed IO, frequency converter, scanner gun, motor starting protection device, intelligent high and low voltage electrical appliances, electricity measurement device, intelligent field measurement equipment and instruments, etc.

0 notes

Text

Siemens HMI: Enhance Your Manufacturing Processes and Industrial Operation

Introduction:

When it comes to industrial automation, Siemens HMI (Human Machine Interface) systems lead the way with powerful solutions that change controls and monitoring in manufacturing settings. Siemens HMI can help industries improve productivity, efficiency, and understanding of their operations: this includes having touchscreens that feel natural when you use them or any other kind of input such as keyboard or mouse while communicating through wires like Ethernet cable or wireless Bluetooth technology.

Key Features and Benefits:

Siemens HMI solutions are developed for the diverse needs of industrial manufacturing processes:

Intuitive Touch Screen Interfaces: Siemens HMI systems have user-friendly touchscreen displays that simplify the interaction of the operator, hence allowing them to move around quickly and visualize data in real time. As a result of easy monitoring, controlling production processes becomes easier for the operators, thereby improving their decision making while minimizing their response time.

Advanced Connectivity: Various automation components can be interconnected by Siemens HMI; Siemens PLCs and SCADA systems being some examples. In this manner, it becomes possible to monitor and control the entire factory from one control point. Moreover, this connection enables sharing information between machines, doing maintenance without intervention and service life prognostics, which improves Equipment Efficiency Overall.

Customizable Applications: Siemens HMI solutions offer applications and interfaces that are suitable for a given industry. Whatever processes companies deal with, they can employ Siemens HMI through such adaptations as development of process screens and introducing role-based access controls that correspond with the way this company operates as well as safety regulations in place.

Enhanced Productivity and Efficiency: Siemens HMI systems improve productivity by minimizing downtime, shortening setup times, and enhancing process reliability through centralizing control and offering real-time insights. Issues can be handled proactively by operators in addition to optimizing production schedules as well as maximizing resource utilization.

Use Cases:

Various industries use Siemens HMI for different applications:

Manufacturing: Streamline the production process and monitor quality constantly.

Food and Beverage: Managing packaging and processing operations that are complicated.

Pharmaceuticals: Watching over important values and making sure that rules are followed.

Automative: Supervising assembly lines and making manufacturing operations more efficient.

To Summarize:

Siemens HMI is a central part of industrial automation. With it, companies can move towards digital transformation and find efficiencies in operations. No matter if they want to strengthen control, bring in more productivity or guarantee they adhere to industry norms, Siemens HMI outperforms all others by offering exceptional performance and reliability. Discover how Siemens HMI changes industrial operations making them more efficient and competitive at the same time.

For more Information visit here

#Siemens HMI#Siemens SIMATIC HMI#Siemens SIMATIC Panel Touch#SIMATIC Mobile Panel#HMI Profinet#HMI SIMATIC#Human Machine Interface Siemens

0 notes

Text

A Human-Machine Interface: What Is It and How Does It Operate?

Human-Machine Interfaces from best Weidmuller power supplies create a usable interface that helps a person establish a communication system with a device. We can explain this more straightforwardly by saying it is simply an input/output device. The information is input here. The person operating the machine inputs it into the machine. The machine outputs the commands based on the data fed into it. On the other hand, the machine may also input the information from its sensors or hardware, which is then outputted on the HMI for the machine operator to decipher and ultimately make out.

Next, combined with programmable logic controllers or PLC, machine sensors record and put forward the information as inputted and received. HMIs are often utilised in industrial settings because of the particular input/output relationship they carry with them. In this sector, an HMI is very frequently used to decipher, see, and control the following information:

Production Time

Production Trends

Visual Data

Temperature Control

Human-Machine Interface and Its Benefits

Human Machine Interfaces, or HMI, from us as one of the best cable assemblies in India, has become part and parcel of machine designs in the industrial sector primarily because of the number of benefits it offers its users. First, the increased visibility of these interfaces makes data centralisation easy to read and ensures that vital notifications or production changes are never missed. This interface's enhanced efficiency results in accurate, real-time data generation that is particularly useful in such a high-paced environment. Here are some other benefits of Human Machine Interface and they are:

Reduction in Cost

Improved Usability

Improved Management of Time

Areas of Application of HMI

We find the maximum utilisation of Human Machine Interface from Hengstler counters supplies in the industrial settings as this sector needs to communicate with and control the machines accurately. This sector requires this kind of control so that industrial processing can be maintained at the optimal level, proper control over the final finished product can be maintained, and the overall safety of the process can be taken care of. To be specific, the industries that use HMIs include:

Manufacturing

Recycling and Waste Management

Oil and Gas

Energy and Power

Food and Beverage

We Give a New Meaning to the Word “Efficiency”

We, SR Indus Electro System, one of the best Weidmuller Distributors in India, are the single source provider equipped with the latest Human-machine Interface technology. It is capable of meeting complex processes of machines and systems. Weidmuller HMI provides efficient integration to your automation systems. They are optimised to meet specific human-machine interfaces. Through our UV66-BAS-4-RES-W easy multi-touch panels, it becomes easier to monitor and control the machines and systems. Moreover, the u-view multi-touch panels from Weidmuller offer perfect image quality and are fit for use in the industrial environment devoid of any restrictions. Additionally, we provide profinet encoders.

Our HMI is very efficient performance-wise, as its image quality is unparalleled. Besides the image quality, its powerful processors make working with u-view multi-touch panels smooth and enjoyable. The compatibility rate of u-view multi-touch panels allows them to be used in various applications. This becomes possible because we use world-class web technology based on HTML5. Hengstler encoders presents robust motor feedback encoders tailored for demanding applications, compatible with both brushless servo and stepper motors. Leveraging Acuro drive technology, dynamic servo drives transition into a fully digital realm for the first time. Even under harsh operating conditions, such as those encountered within motor housings, reliability remains uncompromised. Proudly brought to you by Sr Indus Electro Systems.

#hengstler encoders#weidmuller power supplies#cable assemblies#harting han connectors#electronic components supplier#profinet encoders

0 notes

Text

Ethernet cable vs network cable - what are the differences?

When setting up a network, whether it's for your home or office, one of the key components you'll need is cables to connect your devices. Two common types of cables used in networking are Ethernet cables and network cables. While these terms are often used interchangeably, there are differences between them. Here, we will explore the distinctions between Ethernet cables and network cables, and provide insights into choosing the best option for your networking needs.

1. Ethernet Cables:

Ethernet cables are a specific type of network cable that is commonly used to connect devices within a local area network (LAN). These cables typically have an RJ45 connector at each end, which is designed to plug into Ethernet ports on computers, routers, switches, and other network devices. Ethernet cables are used to transmit data using the Ethernet protocol, which defines standards for communication and data transfer within a network.

2. Network Cables:

Network cables, on the other hand, refer to a broader category of cables used for networking purposes. While Ethernet cables are a type of network cable, not all network cables are Ethernet cables. Network cables encompass a variety of cable types and standards, including Ethernet, coaxial, and fiber optic cables. These cables may be used for different networking technologies and applications, such as connecting devices to the internet, linking network switches, or connecting devices to a server.

3. Differences Between Ethernet Cables and Network Cables:

The main differences between Ethernet cables and network cables lie in their specific applications and standards:

- Ethernet cables adhere to the Ethernet standard, which specifies protocols and hardware requirements for Ethernet networking. These cables are typically used for local area networks (LANs) and follow standards such as Cat5e, Cat6, and Cat6a for data transmission.

- Network cables encompass a broader range of cable types and standards, including Ethernet, coaxial, and fiber optic cables. While Ethernet cables are a subset of network cables, other types of network cables may be used for different networking technologies and applications.

4. Choosing the Best Option:

When selecting cables for your networking setup, consider the following factors:

- Speed and Bandwidth: Ethernet cables support different speeds and bandwidths, with newer standards offering higher performance. Choose a cable that meets your network's speed requirements, such as Cat6 or Cat6a for gigabit or 10-gigabit Ethernet.

- Distance: Consider the distance between network devices when choosing cables, as different cable types have limitations on maximum transmission distances.

- Application: Determine the specific application and requirements of your network, such as data transfer speed, reliability, and environmental factors, to select the most appropriate cable type.

- Compatibility: Ensure that the cables you choose are compatible with your network devices, including computers, routers, switches, and other equipment.

Ethernet cables and network cables are essential components of networking infrastructure, enabling data transmission and connectivity within local and wide area networks. While Ethernet cables are a specific type of network cable used for Ethernet networking, network cables encompass a broader range of cable types and standards. Understanding the differences between Ethernet cables and network cables can help you make informed decisions when setting up your network and choosing the best cables for your needs. Whether you're buying Ethernet cables online or selecting network cables for your networking project, consider factors such as speed, distance, application, and compatibility to ensure optimal performance and reliability in your network setup.

#Etherline Cat 6A#Ethernet Cable Accessories#Ethernet Cable Cat#Ethernet Cable Connector#Ethernet Cable Price#Ethernet Cable Wire#Ethernet Cables#Ethernet Cat 7#Ethernet LAN Cable#Ethernet Power Cable#Profinet Cables#Profinet Cat 5#Profinet Wire#Rj45 Ethernet Cable#Cable LAN Cat 6#LAN Cat 5E#LAN Cat 6A#Industrial Ethernet Cable#Rj45 Cable

0 notes

Text

Integration of Smart Pushbutton Switches and Remote Control Technology: Driving Smart Manufacturing in Industry 4.0

With the rapid development of Industry 4.0 and the Internet of Things (IoT), traditional pushbutton switches are evolving towards intelligence. Smart pushbutton switches not only perform basic switching functions but also incorporate advanced technologies such as remote monitoring, automated control, and data communication. These smart pushbutton switches play a critical role in factory automation and smart manufacturing systems, meeting the growing demand for remote control while ensuring compatibility with industrial communication protocols (e.g., Modbus, Profinet), laying the foundation for comprehensive integration in Industry 4.0.

1. Integration Technology of Smart Pushbutton Switches

Smart pushbutton switches are a combination of traditional mechanical buttons and modern electronic technology. In addition to providing physical actuation, they integrate sensors, microprocessors, and communication modules to enable real-time monitoring, data collection, and remote control.

1.1 Internal Integration of Circuits and Sensor Technology Smart pushbutton switches feature built-in microcontrollers (MCUs) and sensors that allow real-time sensing of switch states and transmit data to cloud platforms or local management systems. For example, buttons can integrate pressure sensors, temperature sensors, or vibration sensors to monitor the operational status and environmental conditions of equipment.

Application Example: During an industrial manufacturing process, a pushbutton switch with an integrated temperature sensor can monitor equipment's temperature changes in real time. If the temperature exceeds a set threshold, the switch automatically sends an alert and controls the equipment to stop, preventing damage caused by overheating.

1.2 Data Collection and Communication Module Integration Smart pushbutton switches can also integrate wireless communication modules (e.g., Wi-Fi, Zigbee, or LoRa) to send collected data to remote servers. These switches are not limited to local operation but can be tracked in real-time through remote monitoring platforms, leveraging big data analysis to optimize production processes.

2. Remote Monitoring and Control of Smart Pushbutton Switches

In smart manufacturing environments, remote monitoring and control functions significantly enhance factory management efficiency. Traditional pushbutton switches require manual on-site operation, whereas smart pushbutton switches can achieve remote control via network connectivity, supporting automated management and reducing manual intervention.

2.1 Implementation of Remote Control Through wireless communication technology, smart pushbutton switches can connect with central control systems or mobile devices, enabling operators to remotely control switches through computers or smartphone applications. Smart switches can integrate with factory automation systems (e.g., SCADA systems) to provide real-time remote control and status monitoring of production equipment.

Application Example: In a large factory, smart pushbutton switches are used to remotely control the start and stop of machines. When a fault is detected on a production line, the factory manager can remotely shut down the related equipment from the control center or mobile app, minimizing production accidents and downtime.

2.2 Real-Time Data Feedback and Alarm Functions Smart pushbutton switches are capable not only of remote control but also real-time data feedback and alarm functions. When the switch detects an abnormal condition (e.g., overload, temperature anomaly, or circuit fault), the system immediately sends an alert to notify the management. Through the remote monitoring system, operators can quickly identify and resolve the issue, minimizing the impact of equipment failures.

Application Example: A manufacturing company’s smart pushbutton switch system monitors the electrical current of equipment in real time. If the current exceeds a safe range, the smart switch immediately cuts off the power and sends an alert, preventing potential overheating or burning of equipment.

3. Compatibility Design of Pushbutton Switches with Industrial Communication Protocols

In industrial automation, pushbutton switches play a crucial role as input devices. They must be compatible with various industrial communication protocols to seamlessly integrate into existing industrial control systems, such as PLC (Programmable Logic Controller) networks and Distributed Control Systems (DCS). Modbus, Profinet, and similar protocols are the core standards for industrial communication, and smart pushbutton switches need to be designed for seamless integration with these protocols.

3.1 Modbus Protocol Compatibility Design Modbus is a widely used protocol for communication between industrial devices, typically facilitating data transmission between PLCs and controllers. Smart pushbutton switches with built-in communication modules compatible with Modbus protocol can directly exchange data with PLCs. This allows the switches to perform not only simple switching operations but also bidirectional communication with device management systems, enabling remote status monitoring and parameter adjustments.

Application Example: In a factory, a smart pushbutton switch is connected to a PLC via Modbus, allowing real-time feedback of the switch status. Factory managers can adjust the switch's response parameters through the control system to optimize its sensitivity and operation.

3.2 Profinet Protocol Compatibility Design Profinet is an industrial Ethernet-based standard used for efficient real-time communication, especially in scenarios requiring high response speeds. By supporting the Profinet protocol, smart pushbutton switches can integrate seamlessly with fieldbus and control networks, providing fast and reliable responses.

Application Example: In an automated production line, smart pushbutton switches connect to the robotic control system via Profinet, enabling real-time control and feedback of multiple devices on the production line. Through the Profinet network, switch state changes can be transmitted to the control center within milliseconds, ensuring quick responses during the production process.

4. Application Prospects of Smart Pushbutton Switches in Industry 4.0

The integration and remote control technologies of smart pushbutton switches lay a solid foundation for Industry 4.0’s smart manufacturing. By integrating sensors and communication technology, pushbutton switches can play a more intelligent role in factory automation control.

4.1 Data-Driven Intelligent Decision-Making Smart pushbutton switches are not just operational interfaces but also sources of valuable data for smart manufacturing. These data can be used for production forecasting, equipment maintenance, and energy efficiency optimization. For example, data collected by smart pushbutton switches allow companies to analyze the status of equipment, predict potential failures, and conduct maintenance in advance, reducing unplanned downtime.

Application Example: A factory monitors real-time data from pushbutton switches to accurately predict maintenance times for production line equipment, preventing interruptions caused by equipment failure and improving overall operational efficiency.

4.2 Integration with Cloud Computing and Big Data Combining smart pushbutton switches with cloud computing and big data platforms enables broader remote management and optimization. Through cloud platforms, operators can not only monitor equipment status remotely but also use data analytics to identify potential issues and improvement opportunities.

Application Example: In a globalized production network, smart pushbutton switches connected to a cloud platform allow for remote management across different regions. Factory managers can monitor equipment operation in real-time across various facilities and make adjustments remotely.

5. Future Development Trends of Smart Pushbutton Switches

As IoT and smart manufacturing continue to spread, smart pushbutton switches will become even more intelligent and multifunctional. The following are key trends in the future development of smart pushbutton switches:

5.1 Application of Artificial Intelligence (AI) Technology By introducing AI algorithms into smart pushbutton switches, devices will be able to learn and optimize their operations autonomously. For example, smart switches may adjust their sensitivity based on usage habits or automatically modify control strategies by analyzing environmental data.

5.2 Introduction of Edge Computing Technology Future smart pushbutton switches will leverage edge computing technology to process more data locally, reducing reliance on remote servers. This will enhance system response speed and improve the autonomous decision-making capabilities of pushbutton switches.

Conclusion

The integration and remote control technologies of smart pushbutton switches are revolutionizing industrial manufacturing. Through compatibility with industrial communication protocols, smart pushbutton switches can seamlessly integrate into industrial automation systems, enabling real-time control and remote monitoring. In the future, with the introduction of artificial intelligence and edge computing technologies, smart pushbutton switches will play an even more crucial role in Industry 4.0, driving manufacturing towards greater intelligence and automation.

en.dghongju.com

0 notes

Text

6SL3210-5FE13-5UF0 AC Servo V90 3P 3.5kW

6SL3210-5FE13-5UF0 AC Servo V90 3P 3.5kW SKU:

6SL3210-5FE13-5UF0 Thông số kỹ thuật:

SINAMICS V90, with PROFINET Input voltage:

380-480 V 3 A -15%/+10% 13.8 A 45-66 Hz Output voltage:

0 – Input 11.0 A 0-330 Hz Motor:

3.5 kW Degree of protection:

IP20 Size C, 140x260x240 (WxHxD) 👉 Xem thêm:

0 notes

Text

Profinet: Advancing Ethernet-Based Fieldbus Solutions

In the world of industrial automation, seamless communication between devices and systems is crucial for ensuring efficiency, precision, and real-time control. As factories and production lines become more complex, there is an increasing demand for advanced communication protocols that can handle high data throughput with minimal latency. This is where Profinet comes in—an Ethernet-based fieldbus solution that is revolutionizing industrial automation.

Profinet, short for Process Field Network, is a communication protocol built on standard Ethernet technology, allowing for high-speed, real-time data transfer between industrial devices. It offers flexibility, reliability, and scalability, making it an essential tool for modern automation systems. Companies like Kingstar.com are leveraging this powerful technology to optimize performance in industrial applications, ensuring that machines and processes are synchronized and operate efficiently.

Why Profinet is Leading the Future of Industrial Communication

Profinet is more than just an upgrade to traditional fieldbus systems like Profibus; it’s a game-changer. Built on Ethernet, the global standard for IT networks, Profinet bridges the gap between office-based IT infrastructure and factory-floor automation, creating a fully integrated and responsive environment.

Key Benefits of Profinet

Real-Time Communication: One of the most significant advantages of Profinet is its support for real-time communication. With Profinet, devices can exchange data with extremely low latency, ensuring precise synchronization of tasks across the production line. Profinet is available in three communication classes: standard, real-time (RT), and isochronous real-time (IRT), the latter of which supports the most demanding real-time applications like motion control.

Scalability and Flexibility: Profinet can support a range of applications, from small automation systems to large, complex industrial networks. Its flexibility allows businesses to start with a basic setup and scale up as needed, seamlessly adding devices and expanding the system without significant overhauls. Kingstar.com uses Profinet to implement scalable, high-performance solutions that cater to various industries, enabling manufacturers to optimize their processes.

Integration with Other Networks: One of Profinet’s strengths lies in its ability to integrate with other industrial communication standards. It can work in tandem with Profibus, Modbus, and other fieldbus systems, making it ideal for plants that are transitioning to newer technologies or combining older equipment with modern automation solutions. This compatibility ensures that Kingstar.com solutions provide customers with the flexibility needed for diverse industrial environments.

High Reliability and Redundancy: Profinet offers built-in redundancy features that enhance the reliability of network communication. In industries like automotive, energy, and pharmaceuticals, where downtime can lead to significant losses, Profinet ensures that data continues to flow even in the event of network issues. It achieves this by providing alternative communication paths, ensuring seamless operation and reduced downtime—a key advantage that Kingstar.com capitalizes on to deliver robust automation systems.

Safety and Security Features: Profinet integrates functional safety protocols, such as PROFIsafe, to ensure the safe transmission of critical control data. This feature is essential for industries that require strict safety standards, such as chemical plants, oil and gas facilities, and automotive production lines. Profinet also incorporates advanced security measures to protect the network from cyber threats, making it a trusted solution for Kingstar.com and other companies operating in mission-critical environments.

0 notes

Text

Siemens 6AG2677-2DB42-2GB0 SIPLUS ET 200SP

Siemens 6AG2677-2DB42-2GB0 SIPLUS ET 200SP CPU 1515SP PC2 rail based on 6ES7677-2DB42-0GB0 with conformal coating, -40??+60 ??C, OT2 with ST1/2 (+70 ??C f??r 10 minutes), 8 GB RAM, 30 GB CFast with Windows 10 IoT Enterprise 64-bit and S7-1500 SoftwareController CPU 1505SP preinstalled, interfaces: 1x slot CFast, 1x slot SD/MMC, 1x connection for ET 200SP BusAdapter PROFINET, 1x 10/100/1000 Mbps…

0 notes

Text

BLIIoT Industrial High-Speed Bus Protocol Distributed I/O System BL21X series

Support Industrial Bus protocol PROFINET, EtherCAT, Ethernet/IP etc., The IO Coupler comes with 2*RJ45 and 1*RS485, Data can be quickly collected at the local coupler without polling through the IO backplane, improving the collection speed.

Adopting a pluggable terminal block structure, it is easy to maintain and install quickly, reducing costs.

0 notes

Text

LAN/RS485/RS232 PLC/DDC Modbus TCP RTU to Profinet Gateway for Process Automation Industries

The BL122 protocol converter is an industrial Ethernet gateway with Ethernet ports and RS-232/485 serial ports. Beilai BL122 protocol converter is used for converting Modbus RTU, Modbus TCP to PROFINET communications.

BL122 Modbus to PROFINET protocol conversion gateway enables seamless integration of Modbus devices into a PROFINET network. This gateway supports Modbus RTU, Modbus TCP converts data for communication with PROFINET devices.

It facilitates real-time data transfer, configuration flexibility, and industrial-grade reliability. Ideal for industrial automation, the gateway enhances system flexibility and scalability, ensuring efficient data exchange and communication across diverse protocols and devices.

0 notes

Text

SMART FLOW CONTROL

Smart flow control là thiết bị thông minh có nhiều chức năng dành cho công nghệ tên tiến. Đây là bộ điều khiển lưu lượng thông minh tích hợp các cảm biến truyền động và chức năng điều khiển một thiết bị duy nhất.

Kết hợp với van điều khiển, lưu lượng kế, cảm biến áp suất và nhiệt độ với khả năng tính toán tiên tiên. Thiết bị này cũng tích hợp nhiều công nghệ như HART®, PROFINET, Ethernet và Wifi để tích hợp liền mạch vào tất cả các hệ thống tự động hóa.

Tính năng nổi bật của Smart flow control

Sản phẩm được thiết kế với nhiều ứng dụng khác nhau như:

Kết hợp các cảm biến, bộ truyền động và bộ điều khiển giúp đo lưu lượng chính xác nhất.

Đo lường và xử lý các thông số cảm biến.

Tối ưu hoá liên tục thông qua các chức năng nhà máy.

Giám sát quy trình liên tục ngay cả khi cảm biến bị hỏng.

Xem thêm: STAUFF Pressure Filters

Ứng dụng trong công nghiệp

Thiết bị không chỉ duy trì hoạt động ổn định mà còn tăng cường độ tin cậy và an toàn của hệ thống. Dưới đây là ứng dụng của thiết bị này:

Kiểm soát dòng chảy

Điều khiển đầu vào cho bể chứa

Được ứng dụng trong kỹ thuật điều khiển và đo lường (ICE) trong nhiều ngành công nghiệp như hoá chất và hoá dầu, sản xuất điện,...

Công Ty TNHH TESFA rất vinh dự là một trong những đại lý ủy quyền hàng đầu của hãng KROHNE – Hân hạnh đồng hành cùng quý khách!

1 note

·

View note

Text

6AV2124-1GC01-0AX0 HMI KP700 Comfort

6AV2124-1GC01-0AX0 HMI KP700 Comfort

SKU: 6AV2124-1GC01-0AX0

Thông số kỹ thuật: SIMATIC HMI KP700 Comfort, Comfort Panel, key operation, 7″ widescreen TFT display, 16 million colors, PROFINET interface, MPI/PROFIBUS DP interface, 12 MB configuration memory, Windows CE 6.0, configurable from WinCC Comfort V11

Tình trạng: Hàng có sẵn, mới 100%

Chứng từ COCQ, tờ khai hải quan, có xuất hóa đơn VAT

Hãng sản xuất: Siemens

Giảm thêm 5% khi mua sản phẩm cùng danh mục có giá cao hơn

👉 Xem thêm: https://thanhthienphu.vn/6av2124-1gc01-0ax0/

#đạilýsiemens, #thanhthienphu, #thanh_thien_phu, #dai_ly_siemens_viet_nam, #thiếtbịđiênsiemens, #thietbidiensiemens, #đạilýsiemenstạiviệtnam, #thanhthiênphú, #dailysiemens

0 notes

Text

How SIMATIC HMI Comfort Panels Improve Process Control and Monitoring

Control systems are an integral part of any industry nowadays. They need to be dependable, efficient and more user-oriented if they are to ensure smooth running of operations. SIMATIC HMI Comfort panels from the SIMATIC HMI range of products by Siemens are specifically designed with operator control and monitoring functionalities in mind and hence are a requisite for any state of the art automation system. The new technology tailored to the panels seeks to respond to the modern industry who do not feel comfortable with anything less than professional efficiency, functionality and comfort.

Key Features of SIMATIC HMI Comfort Panels

High-Resolution Displays: The SIMATIC HMI Comfort Panels are fitted with high-definition widescreen displays ranging from 4 to 22 inches in size guaranteeing effective data visualization and user friendliness. The brilliant displays provide enhanced clarity, even in difficult lighting conditions, so operators can supervise the process and make decisions easily.

Multitouch Functionality: To enhance the ease of use of the panels, they are endowed with multitouch capability which may allow users to easily zoom, scroll, and swipe through the data as they would do with modern day smartphones and tablets. This complicates less navigation and ensures that even complex data is accessed and handled within no time.

Robust Design for Industrial Environments: This means that panels are designed to cope with extreme conditions within an industrial environment, such as dust, liquid and vibration. This is why by virtue of the IP65 rating provided to them, they can be used even in tough working conditions like factories, manufacturing units and even outside such installations.

Efficient Connectivity and Communication: The SIMATIC HMI Comfort Panels utilize several communication protocols, such as PROFINET, Ethernet, and PROFIBUS, thus increasing their flexibility to different industrial networks. This guarantees that there will be no hitches in communication within the automation system allowing effective data transfer and plays a major role in enhancing the processes.

Advanced Data Logging and Archiving: Operators are provided with a built-in data logging and archiving function which enables them to save, access, and evaluate old data right on the panel. This functionality helps companies in monitoring performance at different times, recognizing trends, and making changes based on what is observed in the present and in the past.

Integrated Energy Management: In contemporary industries, energy efficiency is of utmost importance. SIMATIC HMI Comfort Panels are equipped with energy management capabilities enabling the personnel to observe the energy utilized and fine-tune the proceedings in a manner that lessens waste and enhances productivity.

Advantages of Using SIMATIC HMI Comfort Panels

Enhanced Productivity: The Comfort Panels, with their smart touch screen technology, enhanced graphical features and user-friendliness, minimizes the chances of operator errors and helps in organizing processes more effectively resulting in better productivity.

Scalability: Available in different sizes and features, the Comfort Panels cover a range of industries from small operations to large manufacturing systems.

Seamless Integration: The panels harmoniously attach to Siemens’ SIMATIC S7-1200 and S7-1500 controllers as well as to other systems. Thus, their use is very flexible, which is essential in any complicated automation task.

Security: SIMATIC HMI Comfort Panels come equipped with high-end security features like the provision of user desires and a layered access control system to make sure that any sensitive information is kept safe and can only be accessed by the intended people.

Applications of SIMATIC HMI Comfort Panels

Manufacturing and Production: They are utilized in the manufacturing industry for production line monitoring, management, performance tracking, and machine operation management. Their sturdy configuration renders them suitable for use in highly dusty and vibrating conditions.

Process Automation: Control panels are important in the account of process automation. They provide users with the interface necessary for monitoring and controlling the processes of products for the likes of food and drinks, pharmaceuticals and chemicals ensuring quality of products.

Energy and Utilities: The energy and utility industries have also embraced the use of comfort panels given the need to monitor the energy consumption, manage the power distribution, and control the equipment used so as to achieve efficiency.

Transportation and Logistics: Within transport and logistics sector, these panels enable the control over the operation of conveyor systems, sorting machines and automated guided vehicles (AGVs), thereby increasing efficiency and minimizing downtime in warehouses and distribution centers.

Conclusion

Siemens' SIMATIC HMI Comfort Panels are the latest in operator handling and monitoring control technology. These panels feature high resolution screens, better connectivity, multitouch capability and sturdy construction thus they can meet the industry's demands of precision, efficiency and dependability in automation systems. It does not matter whether you are engaged in manufacturing, process automation or energy management, the SIMATIC HMI Comfort Panels will increase your operational capacity availing yourself of your solutions to streamline processes and raise production levels.

To get SIMATIC HMI Comfort Panels, get in touch with Naksh Technology for expert guidance and the best solutions for your needs. Investing in SIMATIC HMI Comfort Panels will assure businesses of successful operation over the long term because of enhanced productivity, reduced expenses, better decision making all thanks to Siemens’ cutting-edge automation technology.

#simatic hmi comfort panels#siemens hmi comfort panels#hmi comfort siemens#simatic hmi tp700 comfort#tp1200 comfort

0 notes