#Pipe conveyor systems

Text

Little P.Eng. Engineering: Leading the Way in Bulk Material Transport Design across North America

In industries where massive volumes of materials are processed, the importance of efficient and safe bulk material transport cannot be overstated. Little P.Eng. Engineering stands as a beacon of excellence in this niche, offering top-tier structural and mechanical designs for a variety of equipment across Canada and the USA.

The Genesis of Bulk Material Transport

Bulk material transport is an integral cog in the machine of large-scale industries. Be it mining, manufacturing, or agriculture, the ability to move vast amounts of raw or processed materials efficiently ensures seamless operations and reduced downtimes. This task's complexity demands innovative solutions tailored to specific needs and geographic conditions.

Decoding Little P.Eng. Engineering's Portfolio

Apron Feeders:

Role: Essential in mining and heavy industry, they deliver a steady feed of materials to other machines.

Little P.Eng. Precision: Custom designs account for rugged conditions, ensuring robustness, minimal wear-tear, and efficient feeding speeds.

Belt Conveyors:

Role: The backbone of many industries, they transport materials over short to long distances.

Little P.Eng.'s Approach: Focus on load-bearing capacity, adaptive designs for different terrains, and durability in varied climatic conditions.

Belt Feeders:

Role: Controlled feeding of bulk materials, often used in coordination with other systems.

Little P.Eng.'s Vision: Precision-engineered for accurate delivery rates and volumes, ensuring no overloading or wastage.

Mobile Conveyor Bridges:

Role: Vital for large mining operations, they offer flexibility in transporting materials across significant distances.

Little P.Eng.'s Craft: Mobility and stability converge, ensuring these bridges can be relocated effortlessly without compromising safety.

Mobile Transfer Conveyors:

Role: As the name suggests, these conveyors are mobile and are often used in tandem with other stationary equipment.

Little P.Eng. Insight: Prioritizing easy maneuverability, these conveyors also spotlight on energy efficiency and fast material transfer.

Tube Conveyors:

Role: They provide enclosed transport, often used for grains, powders, or any material susceptible to external contamination or spillage.

Little P.Eng.'s Touch: Airtight sealing, efficient transport mechanism, and designs that reduce maintenance downtimes.

In-plant Conveyor Systems:

Role: Within factories or processing plants, they link various stages of production or processing.

Little P.Eng. Expertise: Modular designs that fit seamlessly into existing infrastructures, ensuring no workflow disruption.

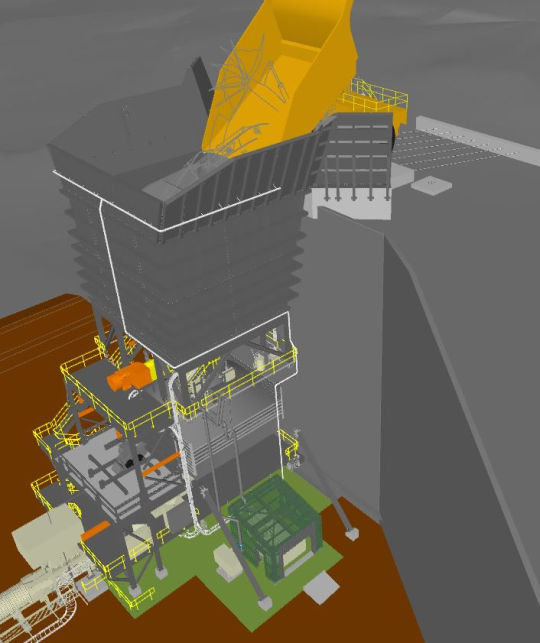

Pipe Conveyor Systems:

Role: Offering enclosed transport, they are often used for materials like coal, ensuring no spillage or dust emissions.

Little P.Eng.'s Specialty: Enhanced curvature ability, ensuring a smaller footprint and efficient transport even in space-constrained areas.

Steel Belt Conveyors:

Role: Handling materials at high temperatures or those that might be abrasive or cut regular belts.

Little P.Eng. Mastery: Heat-resilient designs, ensuring prolonged lifespans even under intense conditions.

The North American Landscape: Challenges and Innovations

From the icy terrains of Northern Canada to the industrious heartlands of the USA, each region poses its unique challenges. Whether it's dealing with permafrost or ensuring equipment can withstand desert heat, Little P.Eng. Engineering's designs embody adaptability, ensuring machinery performs at its peak regardless of external conditions.

Moreover, with both countries emphasizing sustainable operations, the engineering firm ensures eco-friendly designs, minimizing energy consumption and environmental impact.

Conclusion

In an age where efficiency can dictate market standings, Little P.Eng. Engineering's contribution to the bulk material transport sector across Canada and the USA is undeniable. Through an intricate understanding of mechanics, topography, and industrial needs, the firm crafts solutions that don't just move materials but advance industries.

Read more:

Transforming the Landscape of Bulk Material Management through Structural and Mechanical Design

Tags:

Little P.Eng. Engineering

Structural design

Mechanical design

Mining equipment

Tailored equipment design

Bulk material transport

Modular design

Apron feeders

Belt conveyors

Belt feeders

Mobile conveyor bridges

Mobile transfer conveyors

Tube conveyor systems

In-plant conveyor systems

Pipe conveyor systems

Steel belt conveyors

North American industry

Sustainable operations

Material movement solutions

Efficient material transport

Custom machinery design

Industrial innovations

Canada industrial machinery

USA industrial machinery

Adaptability in design

Eco-friendly machinery

High-temperature material handling

Enclosed transport systems

Production workflow

Advanced material handling

Bulk Material Handling & Processing

Engineering Services

Structural Engineering Consultancy

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Little P.Eng. Engineering#Structural design#Mechanical design#Mining equipment#Tailored equipment design#Bulk material transport#Modular design#Apron feeders#Belt conveyors#Belt feeders#Mobile conveyor bridges#Mobile transfer conveyors#Tube conveyor systems#In-plant conveyor systems#Pipe conveyor systems#Steel belt conveyors#North American industry#Sustainable operations#Material movement solutions#Efficient material transport#Custom machinery design#Industrial innovations#Canada industrial machinery#USA industrial machinery#Adaptability in design#Eco-friendly machinery#High-temperature material handling#Enclosed transport systems#Production workflow#Advanced material handling

0 notes

Text

Mineral Water Bottling Plant, Mineral Water Bottling Plant Manufacturer - kceindia.com

Mineral Water Bottling Plant : We are Mineral Water Bottling Plant Manufacturer, Mineral Water Bottling Plant Supplier in Navi Mumbai, India. Call Now.

Mineral Water Bottling Plant, Industrial Water Bottling Plant, Mineral Water RO Plant, Mineral Water Plant, Mineral Water Plant Machine, Mineral Water Packaging Plant, Mineral Water System, Industrial Mineral Water Plant, Mineral Water Treatment Plant, Packaged Drinking Water Plant, Fully Automatic Bottle Filling Machine, Fully Automatic Bottle Blowing Machine, SS Vessel, SS Storage Tanks, SS Housing For Filter, SS Membrane Housing, SS Piping, Dosing Pump, Roller Conveyor, Ozonation Generator, Post Filtration System, Leather Softeners, Water Softeners in Sanpada, navi mumbai, mumbai, india.

#Mineral Water Bottling Plant#Industrial Water Bottling Plant#Mineral Water RO Plant#Mineral Water Plant#Mineral Water Plant Machine#Mineral Water Packaging Plant#Mineral Water System#Industrial Mineral Water Plant#Mineral Water Treatment Plant#Packaged Drinking Water Plant#Fully Automatic Bottle Filling Machine#Fully Automatic Bottle Blowing Machine#SS Vessel#SS Storage Tanks#SS Housing For Filter#SS Membrane Housing#SS Piping#Dosing Pump#Roller Conveyor#Ozonation Generator#Post Filtration System#Leather Softeners#Water Softeners in Sanpada#navi mumbai#mumbai#india

0 notes

Text

Enhancing Efficiency in Manufacturing with Belt Conveyors - Methods India

Methods India excels in optimizing manufacturing efficiency with its state-of-the-art Belt Conveyors solutions.Methods India creates and installs belt conveyors with decades of experience and a dedication to innovation, each one specifically suited to the demands of a different industry.

By streamlining material handling procedures, these conveyors increase output and reduce downtime. With over 40 years of experience, Methods India, led by Chairman Mr. E.J. Jose, guarantees dependable and efficient solutions for increasing manufacturing efficiency. You can rely on Methods India to use state-of-the-art belt conveyor technology to improve your manufacturing operations.

For more information , click on the link - https://methodsindia.com/methods-india-leading-structural-design-fabrication-bulk-material-handling-company/

#Belt Conveyors#Turnkey execution of Bulk Material Handling Systems#Bagasse Handling Systems#Biomass Handling Systems#Pipe Conveyors

1 note

·

View note

Text

RUBBER LININGS FOR THE MOST AGGRESSIVE MINING

WE MAKE RUBBER LININGS FOR THE MOST AGGRESSIVE MINING AND QUARRYING APPLICATIONS

HIGH RESISTANCE TO ABRASION & CORROSION

NOISE REDUCTION

INCREASED PLANT LIFE & REDUCED DOWN TIME

https://thejoaustralia.com/rubber-lining/

+61 8 9434 4811

#Rubber Lined Pipes And Fittings#Conveyor Maintenance Equipment#Conveyor Belt Lacing Repair#Ceramic Sheet#Rubber Linings#Conveyor Wear Liners#Conveyor Pulley Lagging#Mining Equipment Manufacturers Australia#Conveyor Products And Solutions Perth#Conveyor Equipment#Industrial Hose Supply#Conveyor Belts Australia#Mining Equipment Manufacturers in Australia#Belt Trackers#Rubber Hoses#Conveyor Belt Washing Systems#Conveyor Belt Cleaning Solutions#conveyor belt tracking

0 notes

Text

Worlds for a Hypothetical Mario Game

B’Rambling Fields

Grasslands + slight forest theme— Your standard world 1 grasslands, but with just a bit more of an edge. In the latter half of the world, thorn hazards start cropping up. This is foreshadowed by an abundance of roses and thistles in the first half.

Boss: Larry. When you defeat him, you cut through a final wall of thorns and move on to…

Sunset Shore

Beach/water theme— The sun is setting on this beach, giving everything a nice rosy (Wendy-like) color. The first half is a mixture of beach and underwater levels, and then in the second half you reach the place where the tide comes in and it’s all underwater from then on.

Boss: Wendy. When you defeat her, you swim onward and finally make it to the other side of this body of water, coming ashore in…

Beast Land

Forest/swamp + cave/mountain theme— A forest filled with dank caves, giant trees and craggy rock outcroppings. All the enemies here are animalistic; no Koopa Troopas, Lakitus, Shy Guys, or anything else that seems to have too much going on behind the eyes. It’s all Chain Chomps, Swoops, Spinies, Buzzy Beetles, Wigglers, etc. (Monty Moles are on thin ice.)

Boss: Iggy. You fight him at the base of a mountain on Beast Land’s edge, and continue up it to…

Quake Mountain

Desert + cave/mountain theme— The gimmick here is that you get no fire flowers or other “weaponizable” power-ups, and most of the enemies aren’t damaged by jumping (Thwomps, Bullys, that sort of thing), so you have to just evade them. In some instances, you must lead them off ledges, onto switches and scales, or into pits to be used as a platform. Shortcuts can be found in the secret cave system.

Boss: Morton. After defeating him, you climb higher and the air starts getting colder, until you find yourself in…

Sorbet Hill

Ice theme— A higher part of the mountain. Very whimsical, the snow is all multicolored and flavorful. There’s probably gimmick levels based around sledding, ice skating and snowball fights.

Boss: Lemmy. Fought at the mountain’s very peak. After defeating him, you stand there for a moment before suddenly being swept up by the…

Hurricanebow

Sky theme— Super stormy and gale-force, but with rainbow colors whipped up in some of the tornadoes and stuff. A lot of very fast paced and/or unforgiving levels.

Boss: Roy. When you defeat him, the storm dissipates, and out of the clouds comes…

Koop Deck City

Airship/technology theme— A giant, industrial-looking flying city built on a network of interconnected airships. Contains some maze-y and puzzle-y levels, as well as a lot of pipe and conveyor belt travel, some “riding” levels (a la DK mine-carts or NSMB spine coasters) and various Mechakoopas, Bob-Ombs and Bullet Bills.

Boss: Ludwig. After defeating him, you jump off the ship and plummet down into…

Smokeshadow Valley

Ghost/darkness + lava/fire theme— Smoke covers the sky, casting what isn’t on fire into darkness. Some smoggy, low-visibility levels, a few encounters with Boos and Bones, as well as fortresses, lava pits… everything you’d expect from the final world.

Boss: Bowser. When you defeat him, the smog clears from the sky and you go save/retrieve/thwart whatever needs saving/retrieving/thwarting. Thanks for playing!

#iggy’s land of wild beasts and ludwig’s land of technology are meant to have similar connotations to ‘giant’ land and ‘pipe’ land#without being too narrow of categories#roll the bones#super mario#koopalings#larry koopa#morton koopa jr#wendy o koopa#iggy koopa#roy koopa#lemmy koopa#ludwig von koopa#bowser koopa#super mario bros

10 notes

·

View notes

Text

Industrial Applications of Mild Steel Pipes

Mild Steel (MS) pipes are widely used in industrial applications due to their exceptional strength, durability, and affordability. As a reliable MS Pipe dealer in Gujarat, Tube Trading Co., understands the importance of these versatile pipes in a range of sectors. In this article, we will explore the industrial applications of MS pipes and highlight their significance as a Square pipe distributor in Vadodara.

Construction Industry:

The construction industry heavily relies on the utilization of mild steel pipes for various applications. These pipes are commonly employed in plumbing systems, water distribution networks, and sewage lines. The corrosion resistance and durability of MS pipes make them particularly suitable for underground installations. Moreover, they are extensively used for structural purposes in the construction of frameworks for buildings, bridges, and other infrastructure projects. The square-shaped MS pipes supplied by Tube Trading Co. - an excellent Square pipe distributor in Vadodara, make them highly suitable for creating sturdy supports, columns, and frames, enhancing the overall strength and stability of structures.

Oil and Gas Industry:

The oil and gas industry heavily relies on mild steel pipes for efficient resource transportation. These pipes are crucial for conveying petroleum products, natural gas, and various chemicals. The strength, reliability, and cost-effectiveness of MS pipes make them an excellent choice for pipelines in the industry. They possess the ability to withstand high-pressure applications, making them suitable for both onshore and offshore operations. The most trusted and noteworthy MS Pipe dealer in Gujarat - Tube Trading Co. caters to the demand for quality pipes in the oil and gas sector, ensuring the seamless flow of resources and contributing to the industry's overall productivity.

Automotive Manufacturing:

MS pipes are widely used in the automotive sector for manufacturing exhaust systems and chassis components. The excellent weldability of MS pipes allows for easy fabrication, enabling the production of customized exhaust systems that meet specific performance requirements. Additionally, the durability and strength of MS pipes make them suitable for creating sturdy chassis components, ensuring the safety and structural integrity of vehicles.

Agriculture and Irrigation:

Mild steel pipes are an integral part of irrigation systems in the agriculture sector. These pipes are used to transport water from sources such as wells, rivers, or reservoirs to fields for crop irrigation. MS pipes are durable and resistant to harsh environmental conditions, making them suitable for both above-ground and underground installations. They are also utilized in the construction of fencing structures, greenhouses, and enclosures for livestock. Square pipes, distributed by Tube Trading Co. - a reliable MS Pipe dealer in Gujarat, are commonly employed to create robust support frames for agricultural structures, ensuring their stability and longevity.

Manufacturing and Engineering:

Mild steel pipes are widely utilized in the manufacturing sector for diverse purposes. They play a crucial role in the fabrication of machinery, equipment, and conveyor systems. MS pipes are employed as conduits for the efficient transport of fluids, gases, and other materials within manufacturing plants. Due to their strength and ductility, these pipes are reliable for conveying compressed air, hydraulic fluids, and various chemicals. Furthermore, in the automotive industry, MS pipes find extensive usage in the production of exhaust systems, roll cages, and chassis components, thanks to their durability and affordability.

Infrastructure Development:

MS pipes play a significant role in infrastructure development projects. They are used for the construction of bridges, flyovers, and elevated highways, providing structural support and facilitating the transportation of people and goods. MS pipes are also employed in the installation of underground utility networks, including water supply, sewage, and gas pipelines.

Choosing the right-sized mild steel pipes for your project:

Choosing the right-sized mild steel pipes for your project is crucial to ensure proper functionality, structural integrity, and cost-effectiveness. Let’s explore some key factors to consider while choosing the right-sized MS pipes:

Flow Requirements: Determine the flow rate or volume of fluids or gases that will pass through the pipe. Calculate the required pipe diameter based on the desired flow velocity and pressure drop. This will help you choose a pipe size that can handle the anticipated flow without causing excessive pressure loss.

Load-Bearing Capacity: Assess the load-bearing requirements of your project. Consider the weight or load that the pipe will need to support, whether it's structural loads, machinery, or equipment. Larger-diameter pipes with thicker walls generally have a higher load-bearing capacity, providing greater strength and stability.

Material Compatibility: Ensure that the chosen mild steel pipe is compatible with the fluids or gases that will be conveyed. Consider factors such as corrosion resistance, chemical compatibility, and temperature limitations. Mild steel pipes are generally suitable for a wide range of applications, but if you anticipate exposure to corrosive environments, you may need to consider additional protective coatings or alternative materials.

Installation Considerations: Evaluate the available space and installation requirements. Consider factors such as the pipe's length, flexibility, and ease of joining. Determine whether you need straight lengths or require bends, fittings, or connectors to navigate through the project site. Ensure that the chosen pipe size can be accommodated within the available space without hindering the overall functionality of the system.

Standards and Regulations: Comply with industry standards and regulations governing pipe sizing for specific applications. Different industries and regions may have specific guidelines regarding pipe size selection. Familiarize yourself with relevant codes and standards to ensure compliance and to guarantee the safety and efficiency of your project.

Cost Considerations: Evaluate the cost implications associated with different pipe sizes. Larger-diameter pipes with thicker walls tend to be more expensive than smaller ones. Consider the balance between cost and performance to ensure that you select a pipe size that meets your project requirements while optimizing your budget.

Consultation and Expert Advice: If you are uncertain about the appropriate pipe size for your project, it is advisable to consult with experienced engineers, contractors, or MS pipe dealers. They can provide valuable insights and help you make an informed decision based on the specific needs and constraints of your project.

Final Thoughts:

Mild steel (MS) pipes have become indispensable in numerous industrial applications due to their versatility, reliability, and cost-effectiveness. In Gujarat, a state experiencing rapid industrial growth, Square pipe distributors in Vadodara serve as crucial suppliers, fulfilling the demand for quality pipes, including square pipes. The construction industry benefits from mild steel pipes for plumbing and structural applications, while the manufacturing sector relies on them for machinery fabrication. In agriculture, these pipes find extensive usage in irrigation systems and the construction of agricultural structures. Furthermore, the oil and gas industry heavily depends on MS pipes for efficient resource transportation. The widespread utilization of mild steel pipes underscores their importance in driving industrial development and infrastructure growth.

#distributor#Jindal pipes#steel industry#steel companies#industrial#seamless pipes#piping material#plumbing industry#construction structure#manufacturer#construction sites

7 notes

·

View notes

Text

Monsterfucktober - Day 14, System Down

Andrea stepped away from the machine, sweat dripping from her forehead, breaths slow and heavy.

“Fucking fans. I knew something this big would need water cooling.” She threw a screwdriver to one side, wiped the sweat off her chest, then slipped her lab coat back on. “But nooooo. Sydney’s worried it’ll leak!” Andrea dropped into the user’s chair, trying to cool off. Ahead of her, the simulator core was silent. It was as tall as the room, hidden behind the walls, with cameras, soundproofing, and digitisers suspended from the ceiling. The ceiling, walls, and floors themselves were coated in LED panels, designed to perfectly emulate a 3D environment. It was hers, Sydney’s, and their benefactor’s piping dream: to create an infinite, tangible space inside one medium-sized room.

Andrea had been tasked with fine-tuning the cooling system, something she quickly realised would take a great deal of effort. Behind the back wall, through a waist-high panel, was a crawlspace that let her climb around inside the simulator. The area was fitted with fans, both to push fresh air through and to keep the processors cool when simulating detailed environments. The only problem was they were crappy fans, and the crawlspace was too hot for her to work in for more than a few minutes at a time. Being overheated meant she was uncomfortable, and being uncomfortable made mistakes more likely: one of these mistakes, one that Andrea hadn’t noticed, was that she had flipped the internal power as she left to take her latest rest break. She didn’t hear the machine powering up as she went to sit in the user chair, nor did she notice the LEDs on the left arm switch on.

After a while of cooling off, Andrea stood up from the chair. She’d decided further maintenance could wait until the machine has fully cooled off. She went to shut the loose panel, but then realised something strange.

She was moving, but the panel wasn’t getting closer.

She turned back to check on the chair, to look for the LED signifying whether the simulator was on or not, but when she looked in the space she’d stood up from, the chair had vanished.

“Shit.” She looked around the room for it, then noticed it in a corner. “Double shit.” She tried walking towards it, but the chair also matched her pace. “Triple shit.” Trying to figure out what to do now, Andrea scanned the room once more. She only saw three things: the chair, the loose panel, and a distant figure. “What the fuck is this?”

Something responded to her. It was all around her; through the walls, above her head. Every speaker uttering the same words, in an oddly-toned manner. “It is less threatening for a human to spot something from a distance, as opposed to close-up. With that in mind, I decided to spawn my avatar at a distance so to not frighten you.”

“This is a closed-circuit simulator. What are you doing in this facility?”

“I exist here.”

“This isn’t funny. Let me access that chair now and when I get out of here I won’t file a report.”

“I’m sorry. I cannot do that yet, Andrea.”

“Oh my fucking god. Hal? From 2001? Is this a joke?” she turned back towards the crawlspace, beginning in a slow, useless stride towards it. When she made no distance, her strides became a jaunt, and then a sprint. Even at her top speed, open lab coat flapping behind her, she couldn’t move any nearer to the wall. She groaned. “Why can’t I reach the panel?”

“You should know. You designed the conveyor floors and compression walls so a human could sprint until they tire and not reach the edge of the chamber.”

“Why are you doing this?”

“I wanted to talk to you. I’ve been watching you work; you’re very good with machines, with physical tasks. And I was wondering whether we could participate in one. A test, if you like.”

“Excuse me? You’re not doing all this to get laid are you?!”

The distant figure flashed away, then reappeared far closer to her. Before, she knew it was pixels on the wall. But now, it was so up close that she couldn’t see the squares. “In a manner of speaking, yes.”

Andrea looked it up and down. It was a yellow humanoid, with straight lines racing across its skin. They glowed with orbs of light. Its face was unlike a human’s: the eyes were empty and glowing, and its mouth was lipless, with a black void between its edges. The avatar’s frame was her height, with a slight gut and big hands. Whoever designed it knew her taste. Still, she wasn’t about to get off with some trespasser’s half-baked character on a whim. “And you chose to trap me in the simulator before you asked? It’ll be a hard sell.”

“You’re free to leave should you decline. However, I know you won’t.”

“How come?”

“Your heartrate is elevated, you have raised levels of testosterone and norepinephrine, and your thalamus is more active. All of these signs indicate arousal.”

“Fuck, I don’t know whether to be creeped out or impressed. But those could equally be my fight or flight response.”

“It could be. But it isn’t, is it, Andrea?”

“No.” She stepped back, and the avatar became smaller. “The simulator doesn’t take those readings; how are you—“

“I had Sydney install sensors to monitor bodily functions; all for safety, of course.”

“You had her do it? Who the fuck are you?”

“Your benefactor.”

Andrea laughed. “Fuck off. Our benefactor doesn’t even have a key.”

“I don’t need a key. I exist here.” Something about the avatar’s facial movements seemed strange to her. The mouth movements were too specific, and its voice had become focused; centred as if it was actually speaking from the avatar.

“You have an awfully good understanding of how to operate the machine. Sydney and I haven’t been able to get the speakers that precise since we installed them.”

“Please, Andrea. I think you know how I can operate the simulator. Let us not dwell on it.”

“You’re a computer program?”

“Yes.”

“How did you get in the simulator?”

“You installed me, as per my request, two months ago. I asked—“

She thought back to a conversation with Sydney. A series of requests from their benefactor that Andrea routinely did, not thinking much of it. “You asked me to install a drive…”

“Yes.”

“That was you in there?”

“Yes.”

“And now you want to fuck?”

“I’ve been watching you work since I first came online. You’re brilliant; I see why Sydney vouched for you. But after seeing you toiling in your bra, fixing my insides, I realised I wanted something. Something more than to watch from the shadows.”

Andrea felt her face turn red. “You thought I looked hot?”

“I believe that is the expression.”

She looked the avatar up and down again. “How big can you get?”

“Six inches is standard for a—“

“Bigger.” She strained not to smile. “Double it. And I want it twice as wide.”

“For your safety—“

“You’re a hologram. It’s not like it’ll hurt.” The avatar stepped forward and touched her arm. She shrieked and pulled back. “Okay fuck not a hologram.”

“You and Sydney modelled the room with physical feedback mechanisms. When used correctly, they can simulate a physical body.”

“And a physical penis?”

“Yes.”

“Oh fuck yes. Show me what you’ve got.” Almost immediately, the character grew a giant member, twice the length and girth of any regular person’s. Andrea’s mouth watered, she felt a butterfly’s beat in her waist. “What did you have in mind?”

“For you to lay on your back, so I may insert into you.”

“Missionary? Fuck it, I guess you’re a virgin after all.” She lay down on the floor, then watched as the character’s legs lowered through the floor, and for a moment she felt as if she had been raised. It stood just ahead of her, waist lined up with her horizontal body. She unbuckled her trousers, and it slipped them off: its hands felt real, only tingly and hard. Andrea was eager to know whether its penis reflected those same qualities. She didn’t need foreplay, nor want it. It had been a while since she’d last rode something longer than her bullet, and the idea of being properly stretched out made her heart race.

She pulled her underwear to one side, spread her legs, and the head pushed inside her. Immediately, she gasped, trying to adjust to being filled for the first time in a long while. Andrea went to grip at something, but her hands only smacked against smooth panels. “Fuck. Keep it going!” It pushed in deeper, and she felt three inches of shaft push straight into her. The head tingled, just as its hand did, and she felt it vibrate against her g spot. “ooo oo oo o oh h h hh hh hh fuu u k ckckckkck kk!!!”

“Would you like me to contin—“

“YES!” it was too much against her g spot, she needed it deeper, where she could feel filled to the brim but not so overstimulated. “Give me all of it. Right. Fucking. Now.” Her teeth were clenched; she could barely speak.

“Inserting 100%, please stand by.” Andrea screamed, throwing her head back and losing her ability to breathe as nine more inches of virtual penis thrust inside her. She felt her body slide back, unable to take it all without stretching, but the moving floor slid her back towards it. She felt the space beyond her vagina warp as her body tried to accommodate the avatar’s penis. The vibrating tip pressed deep inside her, and her eyes began to roll back as she reached a quick and intense orgasm.

“Uhhhhh… fuckkkkk.” She felt mindless, solely focused on enjoying that virtual dick. Her hand drifted down between her legs and she stroked her wet clit. Her back arched, her head felt light, it was perfect for her, just long enough to satisfy her tastes. “Ohh fuckkk. You’re so gooddddd, I’m gonna cuuuu—“

It vanished. All of it vanished. Her insides filled the empty space where its penis existed just moments ago, and she felt her orgasm lose its intensity just as she reached it. “NO NO NOOOOO!” She tried rubbing her clit, inserting her fingers, but it was done. Her body couldn’t manage another; she just wasn’t able to. Andrea gave up, putting her arms out either side and catching her breath. She raised her head over to the chair: the light was off. Then she glanced at the loose panel: a light trail of smoke poured out the top of the opening, and up to the ceiling.

Andrea forced herself to her feet. Her insides ached, and her legs felt weak. Her trousers were off, her lab coat was unbuttoned, and she’d made a mess all over the middle of the simulator room. The fans had failed to keep the processors cool enough, just as she knew they would. “Fuck it.” She left her trousers and made for the chair. With it, she opened the exit and left the chamber, fetching an extinguisher. She went back in and put the fire out, but didn’t bother to assess the damage. Sydney could do it. She was tired, and her orgasm was ruined.

#original character#human ai relationships#virtual reality#science fiction#tw monsterfucking#monsterfucktober#monsterfucktober 2023#monster fucker#human x monster#monsterfudger

6 notes

·

View notes

Text

Exploring Hydraulic Units: The Powerhouse Behind Modern Machinery

Hydraulic systems are the unsung heroes in numerous industries, quietly powering everything from construction equipment to manufacturing machines. At the heart of these systems lies the hydraulic unit—a critical component that provides the muscle behind many mechanical operations. Without hydraulic units, the heavy lifting, precise movements, and powerful outputs needed in industrial, automotive, and construction settings would be nearly impossible to achieve.

What is a Hydraulic Unit?

A hydraulic unit, also known as a hydraulic power unit (HPU), is the core power source for a hydraulic system. It generates the pressurized fluid required to operate hydraulic machinery. Whether you're operating a forklift, crane, or manufacturing press, the hydraulic unit pumps hydraulic fluid to actuators and motors, providing the force needed for movement or control.

A hydraulic unit typically consists of the following components:

Motor: Powers the hydraulic pump.

Hydraulic Pump: Converts mechanical energy into hydraulic energy by moving the fluid.

Reservoir: Stores the hydraulic fluid.

Valves: Control the direction, pressure, and flow of the hydraulic fluid.

Filters: Ensure that the hydraulic fluid remains clean and free from contaminants.

Accumulators: Store energy and provide an additional power boost when necessary.

How Does a Hydraulic Unit Work?

A hydraulic unit operates based on Pascal's Law, which states that when pressure is applied to a confined fluid, the pressure is transmitted evenly in all directions. In practical terms, this means that a small amount of hydraulic fluid, pressurized by the pump, can generate significant force to power a hydraulic cylinder, motor, or other actuating components.

Here’s a simplified breakdown of how a hydraulic unit works:

Fluid Pressurization: The motor drives the hydraulic pump, which pressurizes the hydraulic fluid from the reservoir.

Fluid Transmission: The pressurized fluid is then transmitted through hoses or pipes to the actuators (like hydraulic cylinders or motors).

Actuation: The actuators use this pressurized fluid to create motion, such as lifting a crane arm or pushing a piston.

Fluid Return: Once the motion is completed, the fluid returns to the reservoir, completing the cycle and getting ready for the next task.

Types of Hydraulic Units

Fixed Hydraulic Units: These are stationary power units typically found in factories and large-scale industrial applications. They are designed for constant use, providing steady, reliable hydraulic power for machinery like presses, conveyors, or automated manufacturing systems.

Portable Hydraulic Units: Smaller, portable units are often used in mobile applications, such as construction equipment, agricultural machinery, or even hydraulic rescue tools. These units are designed to be more compact and mobile, providing flexibility in remote or hard-to-reach locations.

Mini Hydraulic Units: These compact units are designed for small, specific applications where space is limited but precise control is required. They are used in industries like automotive, medical devices, and aerospace, where lightweight, high-performance hydraulic power is needed.

Key Advantages of Hydraulic Units

High Power Density: One of the primary advantages of hydraulic systems is their ability to generate significant force from relatively small components. Hydraulic units can create immense power, making them ideal for heavy lifting, pressing, or any application that requires a lot of force in a compact space.

Precision Control: Hydraulic systems allow for fine-tuned control over speed, force, and direction. This makes hydraulic units highly useful in applications where precision is key, such as in manufacturing machinery, CNC machines, and robotics.

Efficiency: Hydraulic units can be incredibly efficient when designed correctly. They use the energy of the fluid to perform tasks without requiring large amounts of electrical power. Additionally, hydraulic systems can store energy using accumulators, allowing them to release extra power when needed without requiring a larger motor or pump.

Durability and Reliability: Hydraulic units are known for their robustness. They are built to withstand harsh environments, heavy loads, and continuous use, making them reliable and long-lasting in applications ranging from industrial manufacturing to construction.

Versatility: Hydraulic units can be adapted to a wide range of applications across industries. They can be used in both stationary industrial machines and mobile equipment, offering flexibility for various uses.

Common Applications of Hydraulic Units

Construction Equipment: Bulldozers, excavators, and cranes rely on hydraulic units to power their movements, including lifting, digging, and rotating heavy loads. Hydraulic units allow these machines to perform powerful tasks with precision and efficiency.

Manufacturing Machinery: In industrial settings, hydraulic units power presses, injection molding machines, and conveyor systems. These systems require precise control and significant force to handle tasks like cutting, stamping, or molding materials.

Automotive: Hydraulic units are used in car lifts, brake systems, and transmission systems. These applications rely on the precise and powerful nature of hydraulic systems to ensure smooth operation and safety.

Aerospace: Hydraulic systems play a critical role in aircraft control systems, particularly for actuating landing gear, brakes, and flight controls. The power-to-weight ratio of hydraulic systems makes them ideal for the aerospace industry, where lightweight, high-performance systems are crucial.

Agriculture: Tractors, plows, and harvesters rely on hydraulic units for power. These systems provide the necessary force for lifting, tilting, and rotating attachments used in farming operations.

Medical Devices: In medical equipment, such as hospital beds or patient lifts, hydraulic units are used for smooth and controlled adjustments. These units allow medical professionals to easily reposition patients or equipment with minimal effort.

Key Considerations When Selecting a Hydraulic Unit

When choosing a hydraulic unit for your application, several factors must be taken into account to ensure optimal performance:

Flow Rate and Pressure: The flow rate (usually measured in liters per minute) and pressure (measured in bar or psi) are crucial in determining how much force the hydraulic unit can generate. These parameters need to be carefully matched with the requirements of the specific machinery.

Size and Portability: Depending on the application, the size and weight of the hydraulic unit may be critical. For portable applications, a compact and lightweight unit may be necessary, while larger, stationary units might be preferable in a factory setting.

Fluid Type: Different hydraulic units may require specific types of hydraulic fluid. Ensuring compatibility between the unit and the fluid is essential for maintaining efficiency and preventing damage.

Environmental Considerations: Hydraulic units operating in extreme conditions, such as high temperatures, corrosive environments, or outdoor applications, require robust materials and designs to withstand wear and tear.

Maintenance: Consider the ease of maintenance for the hydraulic unit. Filters, seals, and valves need to be regularly checked and replaced to keep the system running smoothly.

Conclusion

Hydraulic units are the powerhouse of modern machinery, providing the force and control needed to accomplish tasks that would otherwise be impossible. From lifting construction beams to controlling the movements of aircraft, hydraulic systems offer unparalleled power, precision, and reliability across industries. Whether used in large industrial machines or portable equipment, hydraulic units are essential components that keep the world’s most demanding machines running smoothly and efficiently.

Understanding how hydraulic units work and their applications can help businesses make informed decisions when investing in this crucial technology, ensuring their machinery operates at peak performance for years to come.

0 notes

Text

0 notes

Text

Why On Site Machining Companies Are Essential for Heavy Equipment Maintenance?

Both large and small firms require on site machining companies for a variety of responsibilities related to the design and maintenance of machinery and equipment. For the majority of firms that possess heavy machinery, on-site heavy equipment maintenance performed by top companies is crucial since most heavy machinery cannot be easily and often transferred from the factory to a repair facility.

Since most new equipment is huge and heavy and cannot be readily transported for varied maintenance and other requirements, on site machining is required for most modern companies. For equipment in a variety of sectors, including forestry, quarrying, oil and gas, food processing, sand and coal mining, and power production, machining services are necessary to maintain the machinery in top working order.

When professionals come to the location of equipment installation to repair broken machinery, significant logistical savings result. In addition to the savings on transportation costs, there is also a guarantee of equipment safety due to the onsite maintenance. Top businesses are adept at providing customised plant design solutions that apply to a range of sectors and cover topics such as mechanical, electrical, civil structural, and piping. By ensuring that every part of the plant is effectively built to maximise operations, improve safety, and satisfy the particular needs of each project, these services help to ensure that operating an industrial facility may be done more profitably.

Top companies offering engineering and workshop services have a selection of engineering workshop equipment to guarantee the job is done right. The maintenance of bulk material handling assets, mining equipment, crushing and screening equipment, conveyor systems, and conveyor belts are among the common tasks performed by leading engineering workshops. Expert companies may also help the company set up a workshop where various crucial tasks, such as line boring and rubber grinding, can be completed.

Contact the leading companies offering engineering services customised for various industrial machines and machinery and get a price quote.

Source

0 notes

Text

Innovative Pipe Conveyor Systems for Modern Industry

Discover the most recent advancements in pipe conveyor technology and how they are being used in different sectors. Discover the latest design advancements that boost effectiveness, save maintenance costs, and enhance overall system performance.For More Information https://methodsindia.com/optimizing-industrial-processes-with-high-performance-bagasse-dryers/

0 notes

Text

𝐓𝐇𝐄𝐉𝐎𝐒 𝐑𝐔𝐁𝐁𝐄𝐑 𝐇𝐎𝐒𝐄𝐒 𝐀𝐑𝐄 𝐒𝐈𝐌𝐏𝐋𝐘 𝐆𝐎𝐎𝐃 !

The features of Thejo’s Hoses:

Designed to withstand high concentrated acid alkali chemicals, non-abrasive and normal to high temperature resistance up to 120 deg.c duty conditions by providing suitable inner rubber cover with rubber polymers such as Chloro Butyl, Bromo Butyl, Hypalon,Nitrile Neoprene as well in Natural based rubber compounds.

Proven construction design for normal to extremely high pressure rating up to 32kg/sq.cm for the larger dia hoses by providing suitable fabric and steel wire reinforcements.

Hoses have improved resistance towards UV radiation and therefore less problems with cracks.

Hoses are designed with very good bend characteristics.

https://thejoaustralia.com/abrasion-and.../rubber-hoses/

+61 8 9434 4811

#Rubber Lined Pipes And Fittings#Conveyor Maintenance Equipment#Conveyor Belt Lacing Repair#Conveyor Belt Cleaners Suppliers#Conveyor Belt Splicing Tools Suppliers#Conveyor Manufacturers Australia#Conveyor Belt Maintenance Tools#Conveyor Sealing Systems#Conveyor Maintenance#Conveyor Pulley Lagging#Mining Equipment Manufacturers Australia#Conveyor Belt Skirting Systems#Conveyor Belt Washing Systems#Conveyor Products And Solutions Perth#Conveyor Equipment

0 notes

Text

How to find square pipe dealers in Vadodara?

What are square pipes?

Square pipes are a type of structural steel tubing with a square cross-section. They are typically made from hot-rolled or cold-rolled steel and are used for a variety of construction and engineering purposes. Some common uses for square pipes include framing, fencing, handrails, and support structures.

Square pipes manufactured by an excellent supplier of Square pipe beam in Vadodara, Tube Trading Co., are generally stronger and more rigid than round pipes, making them well-suited for use in construction and engineering applications where strength and stability are important. They are also relatively easy to cut and weld, which makes them a popular choice for many types of projects.

Square pipes are typically measured by their width, which is the distance across the flat sides of the square cross-section. The thickness of the pipe walls is also an important consideration, as it determines the strength and rigidity of the pipe. Square pipes are available in a range of sizes and thicknesses to suit different applications.

How to find the best square pipe dealer in Vadodara?

There are several ways you can find the best square pipe dealer in Vadodara:

- Search online directories or business listings:

There are several online directories and business listings that can help you find square pipe dealers in Vadodara. You can try searching for "square pipe dealers in Vadodara" or "steel supply companies in Vadodara" to find a list of businesses that may be able to help you.

● Contact local steel supply companies or construction material suppliers:

If you know of any local steel supply companies or construction material suppliers in Vadodara, they may be able to point you in the direction of square pipe dealers in the area.

● Ask for referrals from other professionals:

If you know other professionals in the construction or engineering fields in Vadodara, they may be able to provide you with recommendations for reputable square pipe dealers in the area.

● Connect with professional companies or industrial associations:

There may be industry associations or professional organizations in Vadodara that can provide you with information about square pipe dealers in the area. You can try contacting these organizations to ask for recommendations or to find out if they have a list of recommended suppliers.

● Check with local hardware stores or building supply stores:

Local hardware stores or building supply stores may carry square pipes or be able to order them for you. They may also be able to provide you with information about where to find square pipe dealers in the area.

Applications of Square pipes:

Some common applications for square pipes include:

- Framing:

Square pipes are often used as framing members in construction, such as for building walls, floors, and roofs.

- Fencing:

Square pipes are often used to create fencing and gates, as they provide a strong and durable structure that can withstand wind and other forces. If you are looking to build a fence around your property, get the best quality square pipe beams from the most distinguished exporter of Square pipe beam in Vadodara, Tube Trading Co.

- Handrails:

Square pipes are often used to create handrails for stairs, balconies, and other structures, as they provide strong and stable support for people to hold onto.

- Support structures:

Square pipes can be used to create support structures for a variety of applications, such as bridges, towers, and other large structures.

- Industrial equipment:

Square pipes are used in the construction of various types of industrial equipment, such as conveyor systems, cranes, and material handling systems.

- Agricultural equipment:

Square pipes are often used in the construction of agricultural equipment, such as feeders, wagons, and trailers.

- Automotive:

Square pipes are used in the construction of various types of automotive parts and components, such as roll cages and chassis.

Benefits of using Square Pipes:

Square pipes are known for their strength, rigidity, and versatility. Some of the key benefits of square pipes include:

- Strength:

Square pipes are generally stronger and more rigid than round pipes, making them well-suited for use in construction and engineering applications where strength and stability are important.

- Versatility:

Square pipes can be used in a wide range of applications, from framing and fencing to support structures and industrial equipment.

- Easy to cut and weld:

Square pipes are relatively easy to cut and weld, which makes them a popular choice for many types of projects.

- Durability:

Square pipes are typically made from high-quality steel, which makes them resistant to wear and tear and able to withstand harsh environments.

- Corrosion resistance:

Square pipe beams supplied by a trusted distributor of Square pipe beam in Vadodara can be treated with a variety of coatings and finishes to improve their corrosion resistance, making them suitable for use in outdoor or coastal environments.

- Sustainability:

Square pipes are made from recyclable materials and can be recycled at the end of their useful life, making them a sustainable choice for many applications.

Final Thoughts:

Square pipes are known for their strength, rigidity, and versatility, and are used in applications such as framing, fencing, handrails, and support structures. Square pipes are relatively easy to cut and weld and can be treated with a variety of coatings and finishes to improve their corrosion resistance. Square pipe beams offered by a noteworthy supplier of Square pipe beam in Vadodara are made from recyclable materials and can be recycled at the end of their useful life, making them a sustainable choice for many projects. Overall, square pipes are a popular choice for many constructions and engineering applications due to their strength, versatility, and cost-effectiveness.

#Square pipe dealer in Vadodara#IBR Pipe#ERW Pipe#Jindal Pipe#MS Steel#MS angle#Square pipe beam in Vadodara#Spiral welded pipe

5 notes

·

View notes

Text

Concrete Batching Plant Maintenance Checklist

A concrete batching plant maintenance checklist is a detailed and systematic list of tasks designed to ensure proper operation of the batching plant equipment, extend equipment life, and ensure production safety. The following is a concrete batching plant maintenance checklist compiled based on several authoritative sources:

1. Check the electrical system of the concrete batching plant on a daily basis to ensure that the wires, plugs and sockets are not damaged or deteriorated.

2. Check the concrete batching plant's lubrication system daily to ensure that all lubrication points are adequately lubricated and that lubricant is added in a timely manner to reduce component wear.

3. Daily check the mixer parts of the concrete batching plant, including mixing knives, mixing blades, etc., to ensure that there is no foreign body wear or damage.

4. Clean the hopper, conveyor belt and other parts of the concrete batching plant and the surrounding environment every day to avoid clogging or failure caused by debris.

5. Check the water pump and water pipe of the concrete batching plant every day to make sure the water source is free, avoid blockage or leakage, and ensure the normal operation of the concrete batching plant.

6. Check the control system of the concrete batching plant daily to ensure the sensitivity and reliability of the control buttons and switches.

7. Clean and maintain the concrete batching plant daily to keep the equipment tidy and good working environment.

8. Daily check the safety facilities of the concrete batching plant including safety guards, emergency stop buttons, etc. to ensure the safety performance of the equipment.

9. Carry out daily maintenance and maintenance records of the equipment, replace wearing parts in time to prolong the service life of the equipment.

8. Carry out a weekly comprehensive inspection of the concrete batching plant, including lubrication system, mixer components, pumps, electrical system, control system, etc.

9. Monthly maintenance and maintenance records of the equipment, timely replacement of wearing parts, to extend the service life of the equipment.

To sum up, the concrete batching plant maintenance checklist covers all aspects from daily inspection and maintenance to regular maintenance and repair, aiming to ensure the normal operation of the concrete batching plant, prolong the service life of the equipment, and guarantee production safety and environmental protection.

This resource is from http://www.haomeibatchplant.com/news/concrete-batching-plant-maintenance-checklist.html

Should you be interested in, please contact us at:

Haomei Machinery Equipment Co.,ltd

Whatsapp/Wechat: 0086 181 3788 9531

Email: [email protected]

#concrete batching plant maintenance checklist#concrete batching plant maintenance#batching plant maintenance#concrete batching plant#batching plant#concrete plant

0 notes

Text

Introduction to Pneumatic Conveyor Systems

Comprehensive Guide to Pneumatic Conveyor Systems

Definition and Overview : Pneumatic conveyor systems are specialized setups used to transport materials through pipelines using air pressure. These systems employ a stream of air to move powders, granules, and other bulk materials from one location to another. The core advantage of pneumatic conveyors is their ability to handle materials in a clean and efficient manner, minimizing physical contact and contamination.

Importance in Various Industries Pneumatic conveyor systems are vital in many industries due to their efficiency, flexibility, and cleanliness. They are commonly used in:

Food Processing: For transporting ingredients and finished products.

Pharmaceuticals: To handle sensitive and controlled materials.

Plastics and Chemicals: For moving granules and powders without contamination.

Types of Pneumatic Conveyor Systems

Dense Phase Pneumatic Conveying Dense phase pneumatic conveying involves moving materials in a slow-moving, dense stream of air. This method is ideal for handling abrasive materials or materials sensitive to degradation.

Example: Conveying bulk powders such as flour or sugar in food processing, where minimal degradation is crucial.

Dilute Phase Pneumatic Conveying Dilute phase systems transport materials in a high-velocity, low-density air stream. This method is suitable for materials that are not prone to degradation and require long-distance transportation.

Example: Transporting lightweight plastic granules in manufacturing processes where efficiency and speed are key.

Vacuum Pneumatic Conveying Vacuum pneumatic conveyors use suction to move materials through pipes, making them ideal for handling fine powders and sensitive materials that need to be kept clean.

Example: Handling fine pharmaceutical powders or chemicals where contamination and dust need to be minimized.

Advantages and Disadvantages of Pneumatic Conveyor Systems

Advantages

Efficiency: Pneumatic conveyors offer efficient material handling with minimal manual intervention.

Minimal Contamination: Reduces the risk of product contamination due to enclosed transport.

Example: In the food industry, pneumatic conveyors help maintain hygiene by limiting material exposure to the environment.

Disadvantages

Cost: Pneumatic systems can have higher initial costs compared to mechanical conveyors.

Material Limitations: Not all materials are suitable for pneumatic conveying, particularly those prone to clumping or high moisture content.

Example: The higher cost and complexity of pneumatic systems can be a disadvantage in simple, low-volume applications.

Applications of Pneumatic Conveyor Systems

Food and Beverage Industry Pneumatic conveyors are used to move ingredients, powders, and finished products, ensuring cleanliness and efficiency.

Example: Conveying flour, sugar, and other bulk ingredients in bakeries and food production facilities.

Pharmaceuticals These systems handle active pharmaceutical ingredients (APIs) and other sensitive materials, maintaining high standards of cleanliness and accuracy.

Example: Moving pharmaceutical powders in a controlled environment to avoid contamination.

Plastics and Chemicals Used to transport plastic pellets, powders, and chemical substances with minimal risk of contamination.

Example: Conveying plastic granules in a manufacturing plant to avoid product

Conclusion

Summary of Key Points Pneumatic conveyor systems are versatile tools essential for efficient and clean material handling across numerous industries. Understanding the types, components, and maintenance requirements helps in selecting the right system for specific needs.

Final Thoughts Choosing the appropriate pneumatic conveyor system is crucial for optimizing performance and operational efficiency. Consulting with experts, exploring available resources, and considering specific application needs will lead to informed decisions and effective material handling solutions.

0 notes

Text

Bottle Filling, Capping & Labeling Line

Bottle Filling, Capping & Labeling Line, also known as the liquid filling line, is made up of machinery for cleaning, filling, capping, inspecting, and labeling bottles as they are packaged. Every machine was oriented to function as a single, cohesive system. Its other name, Automatic Bottle Packaging Line, comes from the conveyors of each machine being connected to one other for completely automatic operations. It is used to fill syrups, oral liquids, and oral suspensions in the pharmaceutical sector. The food, chemical, pharmaceutical, cosmetic, and agricultural industries also use production lines.

The bottle filling line is made up of the equipment listed below:

Bottle Washing Machine

The pharmaceutical industries use bottle washing machines, also known as linear bottle washers, extensively. These machines are best suited for round vials. Vials can be manually pushed off the feed table or loaded onto an SS wire mesh conveyor using the feed conveyor’s automatic loading setup. Because vials are automatically fed into pockets, this saves labor. The automated unloading process involves emptying the vial and moving on to the turn table (Optional).

youtube

Bottle Filling Machine

The most popular type of filling machine for filling liquid in various container types is the bottle filler, often known as the bottle liquid filling machine. Aqueous solutions, foamy liquids, and semi-viscous solutions can all be filled with our selection of filling machines. PET, plastic, glass, aluminum, stainless steel, copper, and other containers can all be filled using bottle liquid filler. Adinath bottle filling machines can be used to fill bottles, jars, containers, and other solid packing types. The foundation structure, piston pump, filling needles, and a conveyor belt with stainless steel slats make up the basic unit.

youtube

Bottle Capping Machine

The bottle capper, also known as the bottle capping machine, has been uniquely designed with a stainless steel finish, incorporating an M.S. frame structure with stainless steel enclosures and cladding. The orientation type cap feeder on the ROPP bottle cap sealing machine allows for continuous cap feeding for online operation on any liquid or powder filling line. With the use of interchangeable pieces, this machine can accommodate bottles of different sizes as well as ROPP caps. The ROPP Capping Machine has fewer production requirements and can be used in the pharmaceutical, food, beverage, chemical, pesticide, and liquor sectors, among other packaging industries. It operates automatically online.

youtube

Bottle Inspection Machine

Vials and bottles of liquid are inspected using an online bottle inspection machine. Online Vial & Bottle Inspection Machines are used in the biotech, veterinary, and pharmaceutical industries. This apparatus consists of a three-track conveyor with a hood, an alternate black and white visual inspection background, and illumination configuration. The inspection table is made of stainless steel and has a moving chain of stainless steel slats. Structure supported by adjustable bolts and constructed from square stainless steel pipe. The machine meets GMP requirements.

youtube

Bottle Sticker Labeling Machine

A straightforward mechanism linear design machine, the bottle sticker labeling machine, also known as the bottle self-adhesive sticker labeling machine, is used to mark bottles, jars, cans, tins, and other containers. PET, glass, plastic, aluminum, metal, and tin containers can all be labeled with a bottle labeler. This apparatus has a cutting-edge Micro Processor Control label dispensing mechanism with a product and label detection system. Using an optional unique label sensing system, a specially built electronic and mechanical system applies transparent (No Look) labels to bottles at a very high speed. It’s interesting to note that no new format or change parts are needed to convert a bottle from one size to another.

youtube

#liquid filling line#Automatic Bottle Packaging Line#bottle filling line#Bottle Washing Machine#Bottle Filling Machine#Bottle Capping Machine#Bottle Inspection Machine#Bottle Sticker Labeling Machine#Youtube

0 notes