#Belt conveyors

Text

Conveyor Idlers: A Guide to Smoother Operations

Conveyor idlers play a critical role in the overall efficiency of material handling systems. By reducing friction between the belt and the support structure, these components help to maintain smooth belt movement, ensuring consistent material flow. High-quality conveyor idlers are designed to withstand harsh industrial conditions, from extreme temperatures to abrasive materials, ensuring minimal maintenance and extended service life. For More Information visit on:-https://methodsindia.com/

#Conveyor Idlers#Conveyor Pulleys#Pipe Conveyors#Structural Steel Fabrication#Conveyor Rollers#Pre-Engineered buildings#Belt Conveyors

0 notes

Text

Top 5 Benefits of Belt Conveyors for Material Handling in Industrial Settings

In the fast-paced world of industrial operations, efficient material handling is crucial to maintaining productivity and reducing operational costs. Among the various equipment options available, belt conveyors stand out as a versatile and reliable choice for many industries. In this blog, we’ll explore the top five benefits of using belt conveyors in industrial settings.

1. Efficiency in Material Handling

Belt conveyors are designed to move materials quickly and efficiently from one point to another. This capability is especially valuable in industries that require the continuous movement of bulk materials. Unlike manual labor or other handling methods, belt conveyors ensure a consistent flow of materials, minimizing delays and increasing overall productivity. Their ability to operate at various speeds and inclines makes them adaptable to different processes, ensuring that materials are delivered exactly where they’re needed, when they’re needed.

2. Cost-Effectiveness

Investing in belt conveyors can lead to significant cost savings over time. By automating the material handling process, companies can reduce labor costs, as fewer workers are needed to move materials manually. Additionally, the consistent and controlled movement of materials reduces the risk of damage, leading to lower costs associated with material loss or equipment wear and tear. Belt conveyors also have a long lifespan, requiring minimal maintenance when properly installed and maintained, further enhancing their cost-effectiveness.

3. Versatility

One of the most notable benefits of belt conveyors is their versatility. They can be customized to suit a wide range of applications, from transporting light materials like grains to handling heavy loads such as mining ores. Belt conveyors can also be configured to operate in various environments, including extreme temperatures, high humidity, or corrosive conditions. This adaptability makes them suitable for use in diverse industries such as agriculture, mining, manufacturing, and food processing.

4. Durability and Reliability

Belt conveyors are built to withstand harsh industrial conditions. They are constructed using high-quality materials that resist wear, corrosion, and abrasion, ensuring a long operational life even in demanding environments. The reliability of belt conveyors minimizes downtime, as they are less prone to breakdowns compared to other material handling systems. This durability ensures that operations can continue smoothly without frequent interruptions for repairs or maintenance.

5. Enhanced Safety

Safety is a top priority in any industrial setting, and belt conveyors contribute to a safer working environment. By automating the movement of materials, they reduce the need for manual lifting, which can lead to injuries such as strains or sprains. Belt conveyors can also be equipped with safety features such as emergency stop buttons, guards, and sensors to detect obstructions, further reducing the risk of accidents. The smooth and controlled movement of materials also prevents spills and accidents that could occur with less stable handling methods.

Conclusion

Belt conveyors offer numerous benefits for material handling in industrial settings, making them an invaluable asset for businesses looking to improve efficiency, reduce costs, and enhance safety. Their versatility, durability, and reliability make them suitable for a wide range of applications, ensuring that they can meet the unique needs of various industries. By investing in belt conveyors, companies can streamline their operations and maintain a competitive edge in the market.

0 notes

Text

Best conveyor supplier and manufacturer in faridabad, India

#conveyor manufacturer#conveyorbelt#conveyorsystems#conveyor rollers#conveyorsolutions#belt conveyors

0 notes

Text

As one of the representatives of made in China, the conveyor belt produced by Qingdao Baiqi Rubber Co., Ltd. has excellent performance characteristics. Widely received in the industry and mining, cement and other customer fields. The following are the main performance characteristics of Qingdao Baiqi conveyor belt:

1. Excellent wear resistance

The conveyor belt of Qingdao Baiqi adopts advanced rubber formula and manufacturing process, which makes it have extremely high wear resistance. This performance makes the conveyor belt perform well in the handling of high wear materials such as ore and coal, significantly extending the service life and reducing the frequency of replacement.

2. High strength and tensile properties

The conveyor belt skeleton material produced by the company is usually made of high-strength polyester canvas or nylon canvas, which not only gives the conveyor belt excellent tensile strength, but also improves its durability. Even under the conditions of high load and long distance transportation, the conveyor belt can still maintain stable performance and is not easy to break or deformation.

3. Excellent weather resistance

After special treatment, the conveyor belt of Qingdao Baiqi has excellent weather resistance and can work normally in a variety of harsh environments. Whether it is extreme high temperature or low temperature, the conveyor belt can maintain good elasticity and strength, and adapt to a variety of harsh working environments.

4. Chemical corrosion resistance

When handling materials containing acids, alkalis or other corrosive substances, the conveyor belts of Qingdao Becchi show excellent chemical resistance. This makes the conveyor belt widely used in the chemical industry, and can maintain a good use effect for a long time.

5. Low noise operation

The conveyor belt design also takes into account the noise problem, and its transmission system is optimized to make the conveyor belt less noisy during operation, especially suitable for applications with high noise requirements, such as food processing and pharmaceutical industries.

6. Diversified application areas

Qingdao Baiqi conveyor belt product line covers mining, metallurgy, power, coal, building materials, chemical, food and other industries. Whether it is high temperature environment, low temperature environment or special environment requiring oil resistance and corrosion resistance, Qingdao Baiqi can provide suitable conveyor belt solutions.

7. Customized services

Qingdao Bagchi also provides customized conveyor belt services, which can adjust the size, material and performance parameters of the conveyor belt according to the specific needs of customers, ensuring that the product can perfectly adapt to the specific working environment and application needs.

Qingdao Baiqi Rubber Co., Ltd. has become a leader in the conveyor belt industry with its high wear resistance, high strength, weather resistance, chemical resistance, low noise and a wide range of applications. The company continues to innovate to provide efficient and durable conveying solutions to customers around the world.

0 notes

Text

Our belt conveyors provide reliable material handling solutions. We design and manufacture conveyors to meet your specific needs. For #BeltConveyors, Visit: https://prime-mfg.com.au/belt-conveyor/

0 notes

Text

Streamlining Material Handling: Belt Conveyors by Delta Stark

Delta Stark presents a comprehensive range of belt conveyors designed to optimize material handling processes across various industries. With a focus on efficiency and reliability, our belt conveyors are engineered to seamlessly transport goods, ensuring smooth operations and enhanced productivity.

Belt conveyors offer a versatile solution for transporting bulk materials, packages, or components over long distances or between different levels within a facility. From manufacturing plants to distribution centers, our belt conveyor systems are tailored to meet the specific requirements of each application, delivering consistent performance and minimal downtime.

At Delta Stark, we prioritize durability and performance, using high-quality materials and robust construction methods to ensure the longevity and reliability of our belt conveyors. Whether you need to move heavy loads or delicate items, our conveyors are engineered to handle various payloads with precision and care.

Our team of experienced engineers works closely with clients to design and customize belt conveyor systems that seamlessly integrate into existing workflows while maximizing efficiency and throughput. We understand that every project is unique, which is why we offer flexible solutions tailored to your specific needs and budget.

With Delta Stark's belt conveyors, you can streamline your material handling processes, reduce manual labor, and optimize operational efficiency. Experience seamless transportation of goods with our reliable and durable belt conveyor systems, designed to meet the demands of modern industries. Trust Delta Stark for all your material handling needs and elevate your productivity to new heights.

0 notes

Text

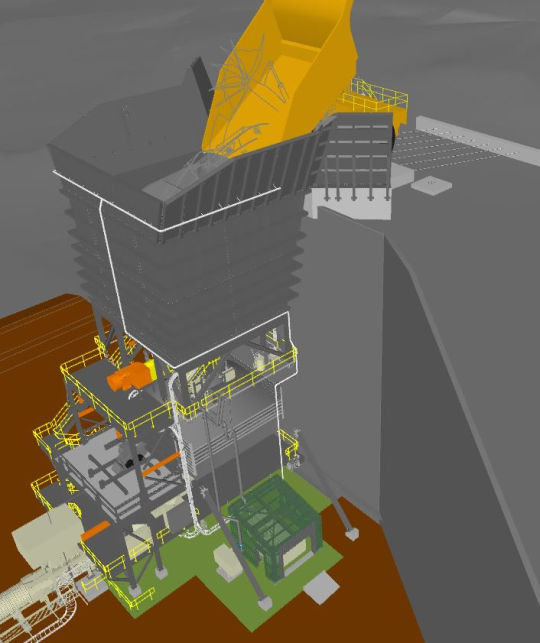

Little P.Eng. Engineering: Leading the Way in Bulk Material Transport Design across North America

In industries where massive volumes of materials are processed, the importance of efficient and safe bulk material transport cannot be overstated. Little P.Eng. Engineering stands as a beacon of excellence in this niche, offering top-tier structural and mechanical designs for a variety of equipment across Canada and the USA.

The Genesis of Bulk Material Transport

Bulk material transport is an integral cog in the machine of large-scale industries. Be it mining, manufacturing, or agriculture, the ability to move vast amounts of raw or processed materials efficiently ensures seamless operations and reduced downtimes. This task's complexity demands innovative solutions tailored to specific needs and geographic conditions.

Decoding Little P.Eng. Engineering's Portfolio

Apron Feeders:

Role: Essential in mining and heavy industry, they deliver a steady feed of materials to other machines.

Little P.Eng. Precision: Custom designs account for rugged conditions, ensuring robustness, minimal wear-tear, and efficient feeding speeds.

Belt Conveyors:

Role: The backbone of many industries, they transport materials over short to long distances.

Little P.Eng.'s Approach: Focus on load-bearing capacity, adaptive designs for different terrains, and durability in varied climatic conditions.

Belt Feeders:

Role: Controlled feeding of bulk materials, often used in coordination with other systems.

Little P.Eng.'s Vision: Precision-engineered for accurate delivery rates and volumes, ensuring no overloading or wastage.

Mobile Conveyor Bridges:

Role: Vital for large mining operations, they offer flexibility in transporting materials across significant distances.

Little P.Eng.'s Craft: Mobility and stability converge, ensuring these bridges can be relocated effortlessly without compromising safety.

Mobile Transfer Conveyors:

Role: As the name suggests, these conveyors are mobile and are often used in tandem with other stationary equipment.

Little P.Eng. Insight: Prioritizing easy maneuverability, these conveyors also spotlight on energy efficiency and fast material transfer.

Tube Conveyors:

Role: They provide enclosed transport, often used for grains, powders, or any material susceptible to external contamination or spillage.

Little P.Eng.'s Touch: Airtight sealing, efficient transport mechanism, and designs that reduce maintenance downtimes.

In-plant Conveyor Systems:

Role: Within factories or processing plants, they link various stages of production or processing.

Little P.Eng. Expertise: Modular designs that fit seamlessly into existing infrastructures, ensuring no workflow disruption.

Pipe Conveyor Systems:

Role: Offering enclosed transport, they are often used for materials like coal, ensuring no spillage or dust emissions.

Little P.Eng.'s Specialty: Enhanced curvature ability, ensuring a smaller footprint and efficient transport even in space-constrained areas.

Steel Belt Conveyors:

Role: Handling materials at high temperatures or those that might be abrasive or cut regular belts.

Little P.Eng. Mastery: Heat-resilient designs, ensuring prolonged lifespans even under intense conditions.

The North American Landscape: Challenges and Innovations

From the icy terrains of Northern Canada to the industrious heartlands of the USA, each region poses its unique challenges. Whether it's dealing with permafrost or ensuring equipment can withstand desert heat, Little P.Eng. Engineering's designs embody adaptability, ensuring machinery performs at its peak regardless of external conditions.

Moreover, with both countries emphasizing sustainable operations, the engineering firm ensures eco-friendly designs, minimizing energy consumption and environmental impact.

Conclusion

In an age where efficiency can dictate market standings, Little P.Eng. Engineering's contribution to the bulk material transport sector across Canada and the USA is undeniable. Through an intricate understanding of mechanics, topography, and industrial needs, the firm crafts solutions that don't just move materials but advance industries.

Read more:

Transforming the Landscape of Bulk Material Management through Structural and Mechanical Design

Tags:

Little P.Eng. Engineering

Structural design

Mechanical design

Mining equipment

Tailored equipment design

Bulk material transport

Modular design

Apron feeders

Belt conveyors

Belt feeders

Mobile conveyor bridges

Mobile transfer conveyors

Tube conveyor systems

In-plant conveyor systems

Pipe conveyor systems

Steel belt conveyors

North American industry

Sustainable operations

Material movement solutions

Efficient material transport

Custom machinery design

Industrial innovations

Canada industrial machinery

USA industrial machinery

Adaptability in design

Eco-friendly machinery

High-temperature material handling

Enclosed transport systems

Production workflow

Advanced material handling

Bulk Material Handling & Processing

Engineering Services

Structural Engineering Consultancy

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Little P.Eng. Engineering#Structural design#Mechanical design#Mining equipment#Tailored equipment design#Bulk material transport#Modular design#Apron feeders#Belt conveyors#Belt feeders#Mobile conveyor bridges#Mobile transfer conveyors#Tube conveyor systems#In-plant conveyor systems#Pipe conveyor systems#Steel belt conveyors#North American industry#Sustainable operations#Material movement solutions#Efficient material transport#Custom machinery design#Industrial innovations#Canada industrial machinery#USA industrial machinery#Adaptability in design#Eco-friendly machinery#High-temperature material handling#Enclosed transport systems#Production workflow#Advanced material handling

0 notes

Text

#industrial equipment#material handling#dust collectors#vibrating screens#belt conveyors#chain conveyors#coal handling plants#ash handling plants

0 notes

Text

7 Types Of Conveyor Belt Systems

In the modern day, a conveyor belt works by looping around two or more pulleys, with a continuous band allowing objects to be transported from one location to another. The belt constitutes a closed spiral around the pulleys to keep circling continually. The things being carried are placed on the top side of the belt as it moves. There are often walls along the sides of the belt to prevent objects…

View On WordPress

#Accumulating Conveyors#Belt Conveyors#Conveyor Belt Systems#Curved Conveyors#Incline Conveyors#Magnetic Conveyors#Roller Bed Conveyor Belts#Vertical Conveyors

0 notes

Text

raison d’etre + sushi = profit

#p5#persona 5#persona 5 royal#yusuke kitagawa#persona 5 yusuke#p5 akechi#akechi goro#goro akechi#kitagoro#akekita#my first p5 art i posted online!#for a p5 based art trade with my good friend uhenishi on twitter:3#IF UOU SEE THIS UHE HIIIII FROWS UP#SORRY IF THE DIALOGUE IS CHEESY OR MY CHARACTERIZATION IS OFF I TRIED MY BEST AND THIS IS MY PERSONAL INTERPRETATION OF THEM:3#they should have interacted more they haved a lot in common Tch… watever…..#of course they would have a deep talk at a sushi conveyor belt place. yusuke’s broke

7K notes

·

View notes

Text

13 years to realize if I did my first webcomic page like a meme it might've gone viral...

168 notes

·

View notes

Text

High-Quality Conveyor Idlers for Durable Performance

Let’s improve the material handling efficiency of your system with our top-of-the-line conveying idlers, made to be the most durable and functional. These idlers are constructed to sustain high capacities even in difficult environments, ensuring that they run smoothly and consistently in any situation. Trust our accuracy in production to obtain the decision of low maintenance costs and long-term operation thus keeping your business running smoothly.

#Conveyor Idlers#Conveyor Pulleys#Pipe Conveyors#Structural Steel Fabrication#Conveyor Rollers#Pre-Engineered buildings#Belt Conveyors

0 notes

Text

Belt Modules and Curve Conveyors are available at orionmis with a speed 2 m/s.Along with Customizable Lengths as per best dumps motor handle heavy loads

0 notes

Photo

Leaf beetle, Paropsisterna fastidiosa, Chrysomelidae

Found in Australia

Photos 1-5 (female laying eggs) by debtaylor142 and 6-7 by gibbergavin

#animals#curators on tumblr#insects#bugs#beetle#leaf beetle#Paropsisterna fastidiosa#eggs#one nice bug#your honor i love her!!!#lil egg conveyor belt

1K notes

·

View notes

Text

Dropped by Sushi Express (爭鮮), the conveyor belt sushi restaurant at Sun Plaza for a quick lunch. This black & gold plate of Grilled Beef Sushi scrolled pass and I just had to grab it. Topped with caramelized sweet onions, the thin beef is a tad dry but the portion is good nonetheless.

Baked Cheesy Mussels came next and was quickly gobbled down. :D Looking like a toppled tree, this Spicy Chicken Drumlet was crispy and juicy to the bite.

A jumbo Aburi Cheesy Salmon Sushi caught my eye. A long thin slice of salmon molded over sushi rice topped with cheese and torched. The salmon is melt in the mouth soft and the piece of canned peach gave it sweetness.

A braised Abalone Sushi came into sight, sitting like a gold ingot on top the molded rice. Taste wise, it doesn’t offer much of an impression, just chewiness. This plate of Mock Abalone Salad gives a much better value with a mild spicy and whole lots of texture.

Normally, the Anago Sushi will be presented length wise but here half of the saltwater eel is folded under the rice due to the smaller plate. Of course, I couldn’t leave without eating a slice of their Blueberry Cheesecake which had shrunk to a smaller size over the past few years.

#Sushi Express#爭鮮#Conveyor Belt Sushi#Sushi#寿司#Taiwanese#Japanese#Grilled Beef Sushi#Baked Cheesy Mussels#Spicy Chicken Drumlet#Salmon Sushi#Cheese#Aburi#Torched#Seared#Abalone Sushi#Mock Abalone Salad#Anago Sushi#Blueberry Cheesecake#Dessert#Food#Buffetlicious

64 notes

·

View notes

Text

What are Belt Conveyors? How Do they Work and How are they Used?

Efficient material handling is crucial for optimizing productivity and minimizing operational costs. Belt conveyors, belt conveyor systems, roller conveyors, and chain conveyors play pivotal roles in streamlining material flow within various industrial processes. These versatile systems provide a safe, reliable, and efficient means of transporting materials, contributing to enhanced production efficiency.

What are Belt Conveyors?

Belt conveyors consist of a continuous loop of material-carrying belts driven by pulleys. They are designed to transport bulk materials, such as grains, ores, or boxes, from one point to another. The belts operate on motorized pulleys, allowing smooth and controlled transportation.

Belt conveyors offer numerous advantages, including high efficiency, reliability, and low operating costs. They can cover a vast range of materials and can be customized to suit various applications. Moreover, belt conveyors are gentle on materials, reducing the risk of damage during transportation.

Types of Belt Conveyors

There are various types of belt conveyors, like trough belt conveyors, flat belt conveyors, and steep incline belt conveyors. Each type serves specific material handling needs, making them versatile solutions for diverse industries.

Efficiency of Roller Conveyors

Roller conveyors operate using a series of rollers placed along a frame. Materials move by the force of gravity or through manual pushing, making them ideal for certain industries, such as warehousing and distribution centers.

Roller conveyors provide efficient and cost-effective material transportation, reducing manual handling and the risk of strain injuries. They are especially useful for moving packages, crates, and pallets within a facility.

What are Chain Conveyors?

Chain conveyors utilize chains to move materials along the conveyor path. These conveyors are commonly used for heavy-duty applications or when materials cannot be moved efficiently by other means.

Advantages of Chain Conveyors

Chain conveyors are well-known for their strength and durability to handle heavy loads. They are highly reliable and can withstand harsh operating conditions, making them indispensable in industries dealing with bulk materials.

Integrating Conveyors for Optimal Material Handling

To achieve optimal material handling efficiency, integrating different types of conveyors is often necessary. By combining belt conveyors, roller conveyors, and chain conveyors strategically, a seamless material flow can be achieved.

Combining Different Conveyors for Synergy

Each conveyor type has its unique strengths, and combining them strategically can enhance the overall efficiency of the material handling system. The right combination depends on the nature of the materials and the operational requirements.

Streamlining Operations with Automation

Automation of conveyor systems can further optimize material handling processes. Automated conveyor systems can intelligently sort, route, and process materials, reducing human intervention and potential errors.

The Future of Conveying Technology

Innovations in Conveyor Systems

As industries continue to evolve, conveyor technology follows suit. Innovations like smart conveyor systems, energy-efficient designs, and IoT integration are paving the way for even greater material handling efficiency.

Sustainable Practices in Material Handling

With a growing focus on sustainability, conveyor systems are embracing eco-friendly solutions. Concepts such as regenerative braking and material recycling contribute to environmentally responsible material handling practices.

Safety Considerations in Conveyor Usage

Identifying Potential Hazards

While conveyors are efficient tools, they come with inherent risks. Identifying potential hazards, such as pinch points and entrapment areas, is crucial to ensure a safe working environment.

Implementing Safety Measures

Employing safety measures, such as installing emergency stop buttons, safety barriers, and proper training for operators, is vital in preventing accidents and injuries associated with conveyor usage.

Maintenance and Care for Longevity

Regular Inspection and Cleaning

To maintain conveyor performance and prolong its life, regular inspections and cleaning are essential. This helps mark and solve potential issues before they escalate into major problems.

Addressing Wear and Tear

Conveyor components experience wear and tear over time. Timely replacement of worn-out parts ensures smooth operation and prevents unexpected breakdowns.

Lubrication and Preventive Maintenance

Proper lubrication of conveyor components and adherence to a preventive maintenance schedule contribute significantly to the system's longevity and reliable performance.

Addressing Common Misconceptions

There is a common misconception that conveyors are energy-wasting solutions. In reality, well-designed and maintained conveyors are highly efficient and contribute to overall process optimization.

Some believe that conveyors generate excessive noise and negatively impact the environment. However, modern conveyor technologies employ noise reduction methods and eco-friendly materials, mitigating these concerns.

Conclusion

Belt conveyors, belt conveyor systems, roller conveyors, and chain conveyors revolutionize material handling, streamlining industrial operations with unparalleled efficiency. Embracing the right conveyor technology, combined with safety measures and regular maintenance, ensures a productive and safe working environment.

As conveyor technology continues to advance, businesses can look forward to even more innovative and sustainable solutions for their material handling needs. Delta Stark provides premium consultancy on belt conveyors and their uses. Contact us today if you are interested.

0 notes