#Tube conveyor systems

Text

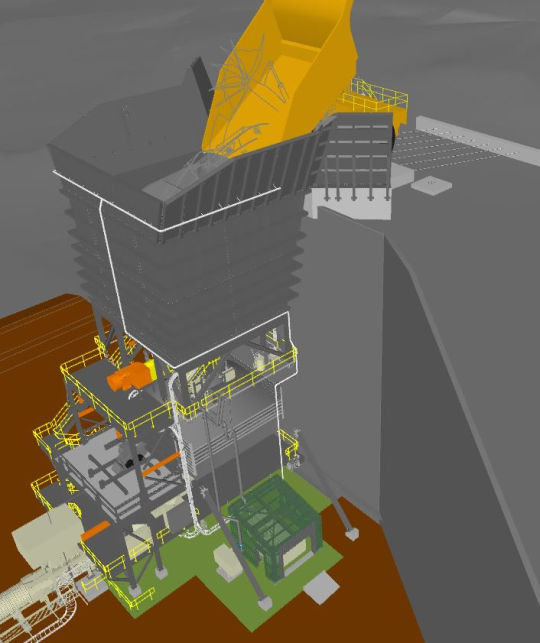

Little P.Eng. Engineering: Leading the Way in Bulk Material Transport Design across North America

In industries where massive volumes of materials are processed, the importance of efficient and safe bulk material transport cannot be overstated. Little P.Eng. Engineering stands as a beacon of excellence in this niche, offering top-tier structural and mechanical designs for a variety of equipment across Canada and the USA.

The Genesis of Bulk Material Transport

Bulk material transport is an integral cog in the machine of large-scale industries. Be it mining, manufacturing, or agriculture, the ability to move vast amounts of raw or processed materials efficiently ensures seamless operations and reduced downtimes. This task's complexity demands innovative solutions tailored to specific needs and geographic conditions.

Decoding Little P.Eng. Engineering's Portfolio

Apron Feeders:

Role: Essential in mining and heavy industry, they deliver a steady feed of materials to other machines.

Little P.Eng. Precision: Custom designs account for rugged conditions, ensuring robustness, minimal wear-tear, and efficient feeding speeds.

Belt Conveyors:

Role: The backbone of many industries, they transport materials over short to long distances.

Little P.Eng.'s Approach: Focus on load-bearing capacity, adaptive designs for different terrains, and durability in varied climatic conditions.

Belt Feeders:

Role: Controlled feeding of bulk materials, often used in coordination with other systems.

Little P.Eng.'s Vision: Precision-engineered for accurate delivery rates and volumes, ensuring no overloading or wastage.

Mobile Conveyor Bridges:

Role: Vital for large mining operations, they offer flexibility in transporting materials across significant distances.

Little P.Eng.'s Craft: Mobility and stability converge, ensuring these bridges can be relocated effortlessly without compromising safety.

Mobile Transfer Conveyors:

Role: As the name suggests, these conveyors are mobile and are often used in tandem with other stationary equipment.

Little P.Eng. Insight: Prioritizing easy maneuverability, these conveyors also spotlight on energy efficiency and fast material transfer.

Tube Conveyors:

Role: They provide enclosed transport, often used for grains, powders, or any material susceptible to external contamination or spillage.

Little P.Eng.'s Touch: Airtight sealing, efficient transport mechanism, and designs that reduce maintenance downtimes.

In-plant Conveyor Systems:

Role: Within factories or processing plants, they link various stages of production or processing.

Little P.Eng. Expertise: Modular designs that fit seamlessly into existing infrastructures, ensuring no workflow disruption.

Pipe Conveyor Systems:

Role: Offering enclosed transport, they are often used for materials like coal, ensuring no spillage or dust emissions.

Little P.Eng.'s Specialty: Enhanced curvature ability, ensuring a smaller footprint and efficient transport even in space-constrained areas.

Steel Belt Conveyors:

Role: Handling materials at high temperatures or those that might be abrasive or cut regular belts.

Little P.Eng. Mastery: Heat-resilient designs, ensuring prolonged lifespans even under intense conditions.

The North American Landscape: Challenges and Innovations

From the icy terrains of Northern Canada to the industrious heartlands of the USA, each region poses its unique challenges. Whether it's dealing with permafrost or ensuring equipment can withstand desert heat, Little P.Eng. Engineering's designs embody adaptability, ensuring machinery performs at its peak regardless of external conditions.

Moreover, with both countries emphasizing sustainable operations, the engineering firm ensures eco-friendly designs, minimizing energy consumption and environmental impact.

Conclusion

In an age where efficiency can dictate market standings, Little P.Eng. Engineering's contribution to the bulk material transport sector across Canada and the USA is undeniable. Through an intricate understanding of mechanics, topography, and industrial needs, the firm crafts solutions that don't just move materials but advance industries.

Read more:

Transforming the Landscape of Bulk Material Management through Structural and Mechanical Design

Tags:

Little P.Eng. Engineering

Structural design

Mechanical design

Mining equipment

Tailored equipment design

Bulk material transport

Modular design

Apron feeders

Belt conveyors

Belt feeders

Mobile conveyor bridges

Mobile transfer conveyors

Tube conveyor systems

In-plant conveyor systems

Pipe conveyor systems

Steel belt conveyors

North American industry

Sustainable operations

Material movement solutions

Efficient material transport

Custom machinery design

Industrial innovations

Canada industrial machinery

USA industrial machinery

Adaptability in design

Eco-friendly machinery

High-temperature material handling

Enclosed transport systems

Production workflow

Advanced material handling

Bulk Material Handling & Processing

Engineering Services

Structural Engineering Consultancy

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Little P.Eng. Engineering#Structural design#Mechanical design#Mining equipment#Tailored equipment design#Bulk material transport#Modular design#Apron feeders#Belt conveyors#Belt feeders#Mobile conveyor bridges#Mobile transfer conveyors#Tube conveyor systems#In-plant conveyor systems#Pipe conveyor systems#Steel belt conveyors#North American industry#Sustainable operations#Material movement solutions#Efficient material transport#Custom machinery design#Industrial innovations#Canada industrial machinery#USA industrial machinery#Adaptability in design#Eco-friendly machinery#High-temperature material handling#Enclosed transport systems#Production workflow#Advanced material handling

0 notes

Text

Formula

Part 3

[Part 1][Part 2]

Back to the present from Part 1! The full effect of the formula on the man is becoming clearer.

—————

That had been a year ago now and the man moaned as his bed finally completed pushing him into a sitting position. He suckled hard on his liquid tube and the drool quickly pooled from behind the hose and cascaded down his chins, his desires triggered by the sounds of the conveyor belts and the pumping of his belly cord.

The AI sensed his arousal before he even fully felt it and the hose attached to his dick began sucking furiously. He came hard just as the hands brought delicious morsels to his mouth. Only then did he release his tube and munch greedily.

His arms had been useless for a year and he had lost the ability to significantly move his head months ago. He no longer expended any energy besides what he needed to move his mouth and that had caused his body to explode with fat. His days were spent being fed by mechanical arms then advanced machines at night. The man’s every whim answered with insane efficiency.

He was an immense monument to unfettered gluttony. His body spread out in every direction and the slightest quiver would set off long undulations of his flesh. Arms so laden with adipose that they were now immoveable, not even his fingers and hands could escape the excess calories. The fat from his wrists encased the majority of his hands, only the tips of his fat fingers peeked out from the rolls. His arms sat comfortably on the fat that entombed him. His numerous chins led to two massive breasts that spread out over the thick roll that was the start of his incredible belly. It was his proudest creation. So huge that even when sitting up, it was still in his vision, slowly becoming the only thing he could see despite the height of the television monitors above him. His thighs, though partly buried under his belly ages ago, had become useless the moment he decided to never get up again. They were piled with fat and his feet were in the same predicament as his hands: buried under the rolls of his ankles; toes barely visible.

His ass had grown exponentially, the fat accumulating and raising his skeleton higher. His body’s position on the bed made it that the best way to even get close enough to his head was from behind, but even then a person would have to stretch their arms to reach due to the intense neck rolls and back fat pushing him forward.

He could feel how much surface area his belly took up, though he couldn’t possibly see it himself. If he closed his eyes and concentrated, he swore he could feel every millimeter his fat was slowly covering as he added more and more calories to his body. His bed had been changed out not all that long ago, but he couldn’t really tell time anymore as his life had descended into one of pure fattening bliss. However, he knew it would have to be upgraded any day now, his massive body barely capable of being raised by the intricate pulley system. It was an inevitability he would soon be incapable of being lifted by anything other than construction machinery—barley. Soon, his flesh would fall over the sides of the bed, something he absolutely hated the feel of, that damnable gravity, and his employees would be left with the task of figuring out what to do with him. A part of him loved knowing so much of his business went to keeping him alive and joyful; cooking and feeding him. Departments designed for the sole purpose of achieving the endless goal of his growth.

Even though the edge of his stomach was so far away, he could still feel the wonderful new, soft flesh joining the rest of his belly’s constant jiggling. He let out a mumble between gobbles and mechanical arms whirled down to apply lotion to the end of his stomach, their metal fingers moving across the deep stretch marks. The happy snorts he made triggered more arms to descend down and start massaging the rest of his momentous belly, the lotion being applied and gently smeared all across his quivering flesh.

The jostling had caused his belly to begin sloshing once more, the food in his stomach moving to and fro, and he released a loud burp through the food still being stuffed down his gullet. It caused him to spit up once more, but he didn’t even stop his eating. Instead, he waited for the mechanical arms to clean it up and bring it back to his lips while he chewed the offerings from the other arms, lapping it up in between bites.

He suddenly felt movement to the right of him on his cascading flesh. The man released a delightful moan as he realized what it was. His sweet baby brother must finally be awake! His scanned excitement caused the hands to move faster to feed him, thinking he simply wanted more food, but his disapproving snorts encouraged them to slow back down. However, he didn’t cease his consumption as he waited to see his baby’s face.

It was taking longer than usual. The vibrations shifted to that of a struggle and he became worried. Through his gobbles, he was able to give a command to help his brother and he saw multiple metallic arms descend out of the corner of his eye, just barely visible past his full, fat cheeks. He felt what amounted to a ‘pop’, like a suction cup finally released. Only slightly audible above the sounds of pumping and the workings of his digestion was a deep breath and coughs.

“Bro-,” he swallowed quickly, “-ther?” It was difficult to talk when your mouth was constantly being filled. Another annoyance.

The movement on his body changed to that of climbing and finally his brother’s beautiful face crested his massive right moob and the man smiled. It dropped once he took in his brother’s disheveled state. His gorgeous brown hair, peppered with highlights of blonde, inherited from their mother, was a mess, eyes still wide from fear, and sweat dripping from his brow.

“What?” He chewed a few more bites. “Hap—,” a quick swallow, “—pend?”

His brother stared at him for a moment then shook his head. “I…I fell asleep on you like normal, but, I…” The young man looked behind and down then back at his brother. “Fell in?”

The man curled an eyebrow and the little brother continued. “I guess I somehow fell into one of your deep rolls. I woke up and was trapped! I…I couldn’t get out.”

The fat man’s eyes widened and for the first time in a long while, he wished he could still move his arms and his hands so he could rub his little brother’s back to comfort him. Instead, the slight movement he subconsciously made in response to his brother’s fear caused his whole body to move like a wave. He watched as his brother grabbed onto his moob to steady himself and not tumble down his cliffs of fat.

Then his baby brother frowned. He hated when he frowned. There should be no need. His little brother had everything he could ever want! Of course, he had to admit he had become overly clingy in the last year. As the only person the man ever got to see anymore, he had become obsessed with having his little brother with him as often as possible. He would complain the moment his brother would return from his short trips away from their home. The complaints were difficult to articulate through his constant eating, but it was always so upsetting. He had given his brother everything! He would give him the entire world if it had a sticker price! The man had already written a will(that he hoped would never have to be used due to the formula, but wrote one regardless) that gave his brother his entire company, assets, EVERYTHING! The least he could do was stay by his older brother’s side. His father in all but name.

Yes, his greed and gluttony had extended to everything else in his life. Not even his little brother was spared. He even hated it when his brother had to leave the room to use the restroom or fetch a book to busy himself. Every second he wasn't with him was agony, one possibly worse than the feeling of hunger. (He tried to forget the shocked look on his brother’s face when he suggested he too have tubes attached so he no longer had to leave him.)

”I’m.” More swallowing and chewing. “Sorry, my,” a gulp, “sweet-,” more eating, “-brother.”

His little brother’s frown didn’t shift. He looked around at the expanse of his older brother then back at his face.

“I…I need to talk to you…” He whispered. The man blinked a few times, a slight anxiety rising in the back of his head, but nodded as he chewed.

“Without you eating. Stop for now so you can talk to me.”

The man moaned sadly, but was able to communicate to the computer to stop feeding him. He looked towards his little brother expectantly and pushed down the tantrum his mind was having over the loss of food.

“I know that…your health isn’t a factor. The formula has been upgraded many times and can continue to be, but.”

The man found himself forcing his brain to pay attention, to not think about how much he wanted to continue eating. He kept his eyes locked with his brother’s.

“I’m still worried, big brother. My worry has been growing,” his brother paused and looked over his older brother’s mass at the word, “because this…this isn’t healthy. Maybe no longer physically, but definitely, um, mentally.”

Mentally. Mentally. He tried to focus on his brother’s last word as to not have his mind wander to the increasing problem of his lack of constant eating. He was salivating, heavily, and could feel the drool pooling in his mouth, flowing past his lips and down his chins in waves. His stomach was starting to make sounds, angry sounds.

He had to keep paying attention. He had to keep from eating. It was what his precious brother wanted and he had to give it to him.

The mechanical arms descended and began rubbing the flesh of his belly.

His little brother must have heard the discontent of his stomach since he absently patted it as he continued. “You haven’t been yourself lately! Yo-you even suggested I should be all hooked up and stuff, like you are! That’s…that’s insane! I love you so, so, so very much! I, I, I blame myself! I wanted you to finally have something of your own to enjoy after so many years of you taking care of me! Sacrificing for me! But this?! Brother, I almost suffocated in your rolls! Sleeping on you like you prefer! Big brother?”

The younger brother had finally noticed the pained expression on his older brother’s face. It was excruciating! The intense sharp pains emanating from his belly couldn’t be ignored anymore, but he stubbornly kept himself from commanding the arms to return to their loyal feeding. He had to do this for his baby brother! It was like his stomach was dying without the steady flow of food down his gullet. Even for a few minutes! The slobber now pulled in the cleavage of his huge breasts. His mouth never completely shut anymore anyway unless he was chewing, the weight of his chins pulled down his lower jaw, and his fat cheeks kept his lips pursed. A mechanical hand brought the vacuum hose down to suck the pooling liquid away while multiple hands busied themselves wiping up the remaining drool. It was all for naught. His salivating wasn’t decreasing, but only intensifying.

“My precious, I’m so…” It was still difficult to speak even without the food being crammed past his lips. The fat that pressed down on his larynx didn’t help and had caused his voice to become even deeper than it once was. “So sorry. But it’s too late. You…you know that. I’m trying, though…right now…I’m trying.” His voice hitched at the end, tears welling up in his eyes. But he was ashamed. Ashamed because the tears weren’t entirely for his brother’s honest words, but also, and possibly moreso, for his poor, poor stomach. Its roars of discontent now echoed in his room. A desperate moan escaped from him, but he still used all of what was left of his self-control to keep from calling for the arms.

“You…you can’t even stop eating for a few minutes to talk to me, can you?” His brother asked sadly, his own tears falling down his precious cheeks.

The older brother shut his eyes in pain for a minute, but answered, “No, no, I can. I’m trying!” His last word was filled with desperation and heartache. He could do this. He can finish this conversation without meat and cake and all else he fancied being pushed down his throat. He had to!

“I’m just so worried, big brother! All you think about is food and how you can get more. You are massive, brother! I…I didn’t even know a person could get this big! Jesus, you’re over three tons now! Mentally, I don’t know where your head is anymore. I even heard some of the scientists talking about how you’ve ordered a larger gastronomy tube! Why?! Yo-you know how invasive changing out your current one is! For godsakes, your fat has fused to it!”

A freight train of hunger hit him at breakneck speed. He released a deep yell at the pain.

“Brother?”

Then it happened. An alarm went off and a multitude of machine arms dropped down. The conveyor belt laden with food started up again as the hands quickly picked up plates and started to feed him. No! He tried to shut his mouth the best he could, his attempts to turn his head away all in vain; a mechanical hand gripped his first chin and began making the movements of chewing for him.

He truly cried now as he looked over at his little brother, the younger man’s eyes full of terror and acceptance.

His brother had left after mentioning he was going to talk to the head scientist, the last glance towards his big brother full of confusion and worry.

For the short time his little brother was gone, the man was in a constant tug of war between his hate of himself for upsetting his brother and the anger his stomach was communicating to him. Even after the hands started feeding him again, rage filled pain would shoot through him when he chewed. Something had irrevocably changed with his body and he felt guilty over the fact his mind and stomach were irritated with his brother. If he had just let him continue eating during their conversation then this wouldn’t be happening! If he could, he would have shook his head to dissipate such thoughts. His little brother had come to him honestly and with worried love. He shouldn’t be mad at him about it, but empathetic! Although he was sorry, he still couldn't shake the anger at his feasting being interrupted, especially since his belly was encouraging the bother.

Now, it seemed his stomach truly never wanted it to happen again and it was dawning on him that even the time it took to chew was too long for his body to handle.

After what felt like days, but had to be at most an hour, and his growing irritation that his brother dared to leave his side, the little one returned with the lead scientist in tow.

“It happened while I was talking to him. He stopped eating and it had to have been only minutes before everything changed! Like he was in excruciating pain!” The massively obese man wanted to correct him and state how it wasn’t ‘like’ excruciating pain, but exactly that! There was no way he was stopping eating to say even one word.

“The arms! The arms came down and started stuffing food into his mouth without him asking for it! I could tell he was fighting it, but they just made him chew! I figured you would know what’s happening. What did you and the others come up with?” His little brother’s words were filled with desperation.

The lead scientist looked over the quivering mass, the stretch marked skin glistening with sweat, and shook his head. “I was afraid of this. We all were. But he pays us better than any employer could ever do for scientists, so we did as asked. We always do.” He placed his hand on the man’s stomach and both he and the little brother could tell, even as slight as it was, the fat creeping past the hand. Growing right before their eyes.

“The formula changes his body on a molecular level so he can live out this fantasy of endless food. But it has gotten away from him. From us. It has changed his body so that he can’t even stop filling his stomach for a moment. His body has evolved, something that would normally take generations upon generations completed for one person in a matter of years. It would be a celebrated scientific achievement if it wasn’t so…” he petered off.

”So, terrifying?” The little brother finished. The scientist nodded.

“Honestly, this is dark science. This is the kind of thing we should morally never try to do, but the money! After what we’ve done to him, the only thing left is to continue to do as he says, or at least, what his body wants. Even without the NDA’s and his hush money to keep the formula from anyone, so he could have it all to himself…I don’t think anyone working on it would ever reveal it to the public. Look what it has done to him!”

The younger brother swallowed hard in barely restrained horror. His big brother was at the point of no return. No amount of begging was going to change the fact that his beloved brother’s body could no longer handle any interruption in food.

Alarms sounded from the multiple computer monitors located near the fat man’s head causing the scientist to run around his boss’s huge body to check the read outs. The little brother followed, his hand sliding across his older brother’s flesh as he walked.

As he rounded the widest part of his brother’s body, he could finally make out pained moans echoing down from where his big brother’s head should be, though he could only barely see the tuft of dark brown hair past his swollen neck rolls.

He found the scientist furiously typing away at a keyboard. Different percentages and charts flickered across the screens until they stopped on a simplistic image representing his big brother’s stomach.

“Dammit!”

“What, um, what’s wrong?” The little brother queried, apprehension clear in his words.

“I was worried about this! Whenever he stops to chew in between the robotic feeding, it’s causing him sharp pain in his stomach. His body can’t even wait for him to take bites!

The little brother’s eyes widened and he came up behind his brother and lovingly massaged a massive back roll

“What…what has to be done?” He whispered, the head scientist barely hearing him over the sound of pumping liquid and non-stop noises of digestion.

“The direct feeding tube that is inserted down his throat at night, well, will have to be permanent.” The scientist sighed and hit a few more buttons which heralded the familiar sound of the mechanical arm bringing down the feeding tube.

“Wait!”

The scientist pressed a key, stopping the machine, and turned to his boss’s younger brother.

”Please. Let me tell him first.”

———

One last chapter to go.

#bhm weight gain#male feedee#ssbhm#weight gain#bhm wg#fat bhm#fat blob#ffa bhm#ssbhm belly#ssbhm feedee#weight gain fiction#extreme weight gain#ssbhm fiction#my writing

16 notes

·

View notes

Text

Part I

Today was a Day unlike any other. Today was the Day Vic could finally rid himself of his Human Imperfections. Free of Bones, free of Muscles, free of a limited analogue biological Existence. Finally he would fuse with Exa forever.

But the Lab would not open for another few Hours. He had some Time to kill, so why not start this unusual Day like any other: with Breakfast.

The Oatmilk and the Maize Kernels rotated for a few Minutes in the Microwave, eventually they started Popping. Warm Milk and Cereal, the only Breakfast that could satisfy someone as picky as him.

Taste, the Thought of that amused Vic, as a Porygon it would not have Tastebuds in the usual Sense, instead there would be Nutrition Sensors that would detect the Value of each Bite and then send a Report to it's seccondary Input Stream... that would feel so much better than throwing chewed up wet biological Matter down your Throat right next to your Airtube where you hope that the small Meatflap that seperates the two Tubes doesn't act up and makes you almost suffocate from a small Droplet of Water.

He still had Time after finishing his Meal. Enough Time to look at himself in the Mirror one last Time. He looked like he usually did, round Face, short blue Hair, almost unnoticeable Stubble. Not enough to get a full Beard, but also not so little that he could get away without shaving. Should he shave one last Time? Did that even matter at this Point, it was just another Reminder of how little Control he had over his Body. Every Cell and every Follicle doing whatever it was made to do, with no Way to change or reprogram it. At least his Hair Color was somewhat variable, blue suited him, it looked somewhat artificial. Was that the Reason why he dyed his Hair that Way? He could not remember, it just felt right.

After getting dressed, in his usual Clothes(which he would not need anymore), and his Labcoat, which he never forget to wear when having Lab Duty, because 'Labcoats are cool'. It was finally Time to leave his Dorm.

The Halls were as wide as ever, with a Conveyor Belt on each Side for Accessibility. But Vic liked walking, at least a Bit more than standing and waiting. But soon enough he wouldn't do either, he could just fly anywhere. And for longer Distances he would just need a Port of the Network, and go instantly anywhere on the Planet.

Lost in Thought he almost ran into one of the Guys from Engineering, Vic would be able to remember his Name, if remembering Names wasn't one of his biggest Weaknesses. (another Thing that being a Porygon could fix) The Guy had blonde Hair and was currently typing up a storm on his two Wrist Computers, criss-cross.

Vic was trying to remember his Name, but all his Mind could come up with were "Chromaton, Chromedome, Chromillion, Chromard and Chromateur." none of which sounded like real Names to him.

"Victor, good to see you, i wanted to commend you on your impeccable job of creating an operating system for my newest invention." Chromos(?) said with his usual calm and collected Tone of Voice.

"well, i wouldn't call it impeccable. i was thinking about my own project while working on it, i made a few mistakes. like, if i was you i would wait with the testing phase until i got it's personality matrix to connect with it's mainframe properly." Vic rebutted, despite being somewhat scared of the Guy.

"But Victor, we are both researchers you should be able to see the value in praxis before theory. It passed all of the tests with flying neutrals. why don't you see for yourself."

The Researcher procured a Pokéball and threw it onto the Floor. A small artificial Pokémon materialized in front of Vic, it just barely reached his Knees, but only if you included those stylized Loudspeakers on the Side of it's Head. It activated it's typical Idle Mode, just scanning the Area without a greater Purpose.

Chromatorium(?) exuded an Aura of Superiority. "You can see that this little prototype is totally harmless right?"

"well not exactly. just because it hasn't harmed anyone yet won't mean it will be safe in the future. i'll make you an offer, deactivate it for now, and i'll look over the code one more time. like in the afternoon, after i'm done with my research?" Vic argued, trying to be diplomatic.

"I will consider it, i'll put V-22 on hold, and as long as temporarily fusing with a Z-Version doesn't mess up your brain you can debug it."

Vic wanted to say something, especially after that last Comment, but all he could muster was a pathetic "ok... later..." Vic hated it when he didn't know how to counter an Insult. he was so much better at this online.

Chromatasio(?) and his little Gremlin left the Scene by sidestepping onto the Conveyor Belt and riding to what Vic hopes is the Engineering Workshop where Chromoze(?) would hopefully put the Project on hold.

Vic decided that running was no longer worth it and he stepped on the other Conveyor. slowly riding into the Direction of the Computer Lab.

9 notes

·

View notes

Text

And yet there IS snow! It just requires a chiller plant, coils under the slop to keep the snow machine snow cold enough, but the skating rink, alas, was liquid. Maybe that gets put in use later in the year when school is out.

It’s $35 US for two hours. You get an inner tube to ride, and there’s a neat conveyor belt system that takes you up to the top.

There is a small roller coaster up the mountain and to the right. It looks pretty wild, but nobody was riding. $18 for one trip around.

I don’t know the price to play in the snow piles, but if those are still there this Summer…

I would hate to see their electric bill.

This is not at Sky Valley, GA, but rather over the state line in North Carolina.

12 notes

·

View notes

Text

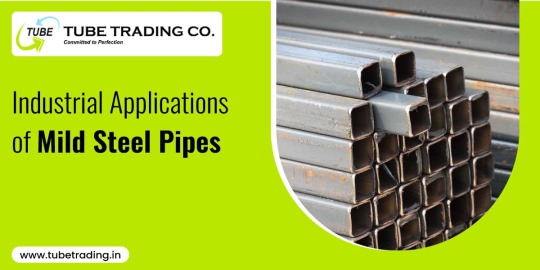

Industrial Applications of Mild Steel Pipes

Mild Steel (MS) pipes are widely used in industrial applications due to their exceptional strength, durability, and affordability. As a reliable MS Pipe dealer in Gujarat, Tube Trading Co., understands the importance of these versatile pipes in a range of sectors. In this article, we will explore the industrial applications of MS pipes and highlight their significance as a Square pipe distributor in Vadodara.

Construction Industry:

The construction industry heavily relies on the utilization of mild steel pipes for various applications. These pipes are commonly employed in plumbing systems, water distribution networks, and sewage lines. The corrosion resistance and durability of MS pipes make them particularly suitable for underground installations. Moreover, they are extensively used for structural purposes in the construction of frameworks for buildings, bridges, and other infrastructure projects. The square-shaped MS pipes supplied by Tube Trading Co. - an excellent Square pipe distributor in Vadodara, make them highly suitable for creating sturdy supports, columns, and frames, enhancing the overall strength and stability of structures.

Oil and Gas Industry:

The oil and gas industry heavily relies on mild steel pipes for efficient resource transportation. These pipes are crucial for conveying petroleum products, natural gas, and various chemicals. The strength, reliability, and cost-effectiveness of MS pipes make them an excellent choice for pipelines in the industry. They possess the ability to withstand high-pressure applications, making them suitable for both onshore and offshore operations. The most trusted and noteworthy MS Pipe dealer in Gujarat - Tube Trading Co. caters to the demand for quality pipes in the oil and gas sector, ensuring the seamless flow of resources and contributing to the industry's overall productivity.

Automotive Manufacturing:

MS pipes are widely used in the automotive sector for manufacturing exhaust systems and chassis components. The excellent weldability of MS pipes allows for easy fabrication, enabling the production of customized exhaust systems that meet specific performance requirements. Additionally, the durability and strength of MS pipes make them suitable for creating sturdy chassis components, ensuring the safety and structural integrity of vehicles.

Agriculture and Irrigation:

Mild steel pipes are an integral part of irrigation systems in the agriculture sector. These pipes are used to transport water from sources such as wells, rivers, or reservoirs to fields for crop irrigation. MS pipes are durable and resistant to harsh environmental conditions, making them suitable for both above-ground and underground installations. They are also utilized in the construction of fencing structures, greenhouses, and enclosures for livestock. Square pipes, distributed by Tube Trading Co. - a reliable MS Pipe dealer in Gujarat, are commonly employed to create robust support frames for agricultural structures, ensuring their stability and longevity.

Manufacturing and Engineering:

Mild steel pipes are widely utilized in the manufacturing sector for diverse purposes. They play a crucial role in the fabrication of machinery, equipment, and conveyor systems. MS pipes are employed as conduits for the efficient transport of fluids, gases, and other materials within manufacturing plants. Due to their strength and ductility, these pipes are reliable for conveying compressed air, hydraulic fluids, and various chemicals. Furthermore, in the automotive industry, MS pipes find extensive usage in the production of exhaust systems, roll cages, and chassis components, thanks to their durability and affordability.

Infrastructure Development:

MS pipes play a significant role in infrastructure development projects. They are used for the construction of bridges, flyovers, and elevated highways, providing structural support and facilitating the transportation of people and goods. MS pipes are also employed in the installation of underground utility networks, including water supply, sewage, and gas pipelines.

Choosing the right-sized mild steel pipes for your project:

Choosing the right-sized mild steel pipes for your project is crucial to ensure proper functionality, structural integrity, and cost-effectiveness. Let’s explore some key factors to consider while choosing the right-sized MS pipes:

Flow Requirements: Determine the flow rate or volume of fluids or gases that will pass through the pipe. Calculate the required pipe diameter based on the desired flow velocity and pressure drop. This will help you choose a pipe size that can handle the anticipated flow without causing excessive pressure loss.

Load-Bearing Capacity: Assess the load-bearing requirements of your project. Consider the weight or load that the pipe will need to support, whether it's structural loads, machinery, or equipment. Larger-diameter pipes with thicker walls generally have a higher load-bearing capacity, providing greater strength and stability.

Material Compatibility: Ensure that the chosen mild steel pipe is compatible with the fluids or gases that will be conveyed. Consider factors such as corrosion resistance, chemical compatibility, and temperature limitations. Mild steel pipes are generally suitable for a wide range of applications, but if you anticipate exposure to corrosive environments, you may need to consider additional protective coatings or alternative materials.

Installation Considerations: Evaluate the available space and installation requirements. Consider factors such as the pipe's length, flexibility, and ease of joining. Determine whether you need straight lengths or require bends, fittings, or connectors to navigate through the project site. Ensure that the chosen pipe size can be accommodated within the available space without hindering the overall functionality of the system.

Standards and Regulations: Comply with industry standards and regulations governing pipe sizing for specific applications. Different industries and regions may have specific guidelines regarding pipe size selection. Familiarize yourself with relevant codes and standards to ensure compliance and to guarantee the safety and efficiency of your project.

Cost Considerations: Evaluate the cost implications associated with different pipe sizes. Larger-diameter pipes with thicker walls tend to be more expensive than smaller ones. Consider the balance between cost and performance to ensure that you select a pipe size that meets your project requirements while optimizing your budget.

Consultation and Expert Advice: If you are uncertain about the appropriate pipe size for your project, it is advisable to consult with experienced engineers, contractors, or MS pipe dealers. They can provide valuable insights and help you make an informed decision based on the specific needs and constraints of your project.

Final Thoughts:

Mild steel (MS) pipes have become indispensable in numerous industrial applications due to their versatility, reliability, and cost-effectiveness. In Gujarat, a state experiencing rapid industrial growth, Square pipe distributors in Vadodara serve as crucial suppliers, fulfilling the demand for quality pipes, including square pipes. The construction industry benefits from mild steel pipes for plumbing and structural applications, while the manufacturing sector relies on them for machinery fabrication. In agriculture, these pipes find extensive usage in irrigation systems and the construction of agricultural structures. Furthermore, the oil and gas industry heavily depends on MS pipes for efficient resource transportation. The widespread utilization of mild steel pipes underscores their importance in driving industrial development and infrastructure growth.

#distributor#Jindal pipes#steel industry#steel companies#industrial#seamless pipes#piping material#plumbing industry#construction structure#manufacturer#construction sites

7 notes

·

View notes

Text

Pneumatic Conveyor System Manufacturers

Pneumatic Conveyor System Manufacturers

Join the success journey of Essar Air Systems, a leading name in the pneumatic conveyor system manufacturing industry. Since our founding in 2007, we have been dedicated to meeting market demands while establishing ourselves as a trusted provider of high-performance air pollution control solutions. Our product range includes:

Pulse Jet Bag Filters

Centrifugal Fans

Fume Extraction Systems

Cyclone Separators

Tube Axial Flow Fans

Venturi Scrubbers

Quality and reliability are at the core of everything we do. Our robust production system ensures that every pneumatic conveyor we manufacture meets the highest standards. We recognize that each industry has unique needs, which is why we offer customized solutions tailored to our clients.

As an ISO 9001:2008 certified company, we are committed to maintaining a quality management system that enhances our global reputation. We take pride in being one of the most sought-after manufacturers in the field and remain grateful for the trust our customers place in us.

Our mission is clear: to work toward a cleaner, greener future for all.

Other Recommended Products:

Explore our offerings in Screw Conveyors, manufactured with the same commitment to quality and innovation in Hyderabad.

0 notes

Text

0 notes

Text

What is Industrial Relays ? ( Part - 2 )

Types of Relays

Electromechanical Relays (EMRs)

Solid-State Relays (SSRs)

Time-Delay Relays

Thermal Relays

Reed Relays

Electromechanical Relays (EMRs)

General-Purpose Relays: They used for general switching applications with different coil and contact configurations.

Power Relays: They designed to handle high-current loads, typically used in industrial applications.

Reed Relays: They contain a pair of magnetic reeds. They open and close the circuit in response to a magnetic field. They are known for their fast switching speed.

2. Solid-State Relays (SSRs)

Zero-Crossing SSRs: They switch on when the AC load voltage crosses zero, reducing electrical noise and surge currents.

Random Turn-On SSRs: They can turn on at any point in the AC cycle, allowing more precise control in certain applications.

Hybrid SSRs: Combine mechanical contacts and solid-state elements to enhance performance and reliability.

3. Time-Delay Relays

On-Delay Relays: Activate the circuit after a set time once the input is applied.

Off-Delay Relays: Keep the circuit active for a set time after the input is removed.

Interval Relays: Switch on for a preset interval, regardless of the input duration.

4. Thermal Relays

Overload Relays: They protect motors and circuits from overcurrent. They do this by sensing heat from excessive current flow.

Bimetallic Relays: They use a bimetal strip that bends with heat to break or make a circuit, commonly used in motor protection.

5. Reed Relays

Utilize reed switches enclosed in a glass tube and activated by an electromagnetic coil, used in low-current and high-speed switching applications.

Basic Application of Relays

Automotive Systems:

Relays control headlights, horns, fuel pumps, and other vehicle parts. They let low-power switches operate high-power circuits.

2. Industrial Automation:

In industrial machinery, relays control motors and conveyor belts. They enable precise control and automation of complex tasks.

3. Home Appliances:

Relays are in appliances like washing machines and microwaves. They control functions like heating, motors, and timing.

4. Safety Systems:

Relays are used in fire alarms and emergency systems. They ensure critical systems work during emergencies.

5. Telecommunications:

Relays route signals and control information flow in telecom networks. They ensure efficient data transmission.

6. Power Systems:

In power distribution, protection relays check and protect electrical circuits. They guard against overloads, short circuits, and other faults. This ensures a reliable power supply.

Importance Of Relays

Relays are important. They control large devices with small, safe signals. They keep parts of a circuit separate. This protects sensitive components from high voltage or current. Relays also make it easy to automate tasks. They let machines work without direct human control. They can switch many devices on or off. They help keep systems safe by turning things off in case of a problem. They also amplify weak signals to control bigger loads. , relays are essential for managing and protecting electrical systems efficiently.

To Know More Visit : https://vashiisl.com/collections/relays

Summary

In summary, relays are like important part in the electrical world, connecting simple controls to powerful systems. From their early use in telegraphs to their key role in today’s technology, relays are essential for managing complex tasks, ensuring safety, and enabling remote control. As technology evolves, relays remain crucial, showing that even basic components can drive innovation and efficiency in our connected lives.

1 note

·

View note

Text

The Basics of Honey Filling Machines: A Beginner’s Guide

Honey, with its natural sweetness and versatility, is a staple in kitchens around the world. As the demand for honey grows, efficient and precise packaging becomes increasingly important. Enter the honey filling machine—an essential tool for honey producers that streamlines the packaging process. If you’re new to the world of honey production or considering investing in a filling machine, this guide will walk you through the basics.

A honey filling machine is a specialized piece of equipment designed to fill jars, bottles, or containers with honey in an efficient and consistent manner. Unlike manual filling, which can be time-consuming and prone to errors, a honey filling machine automates the process, ensuring uniform quantities and reducing labor costs.

The operation of a honey filling machine begins with the preparation of the honey. The honey is first prepared and heated to a suitable temperature to ensure it flows easily. This step is crucial because honey can be quite viscous, and heating helps in maintaining a consistent flow rate.

Once prepared, the filling mechanism comes into play. Honey filling machines typically use one of several mechanisms to dispense honey. Piston filling systems use a piston to draw and dispense a precise volume of honey. Gravity filling systems rely on gravity to fill containers from a tank or hopper positioned above. Peristaltic filling systems use rotating rollers to push honey through a tube and into the container.

Containers are then positioned under the filling nozzles, either manually or using a conveyor system. The machine dispenses honey into the containers based on the chosen mechanism, and this process can be adjusted for different volumes and container sizes. After filling, containers often pass through a capping station where lids are applied and sealed.

There are several reasons to use a honey filling machine. Efficiency is a significant advantage, as automated filling machines can process hundreds or even thousands of containers per hour, significantly increasing production speed compared to manual methods. Consistency is another key benefit, as machines ensure each container receives a uniform amount of honey, which is vital for maintaining product quality and meeting customer expectations.

Using a honey filling machine also reduces labor costs by automating the filling process, thereby decreasing the need for manual labor. Additionally, modern honey filling machines are designed with hygiene in mind. They are easy to clean and often come with features to minimize contamination.

When choosing a honey filling machine, consider several key features. Capacity is an important factor; determine the machine’s capacity in terms of the number of containers it can fill per hour and choose one that matches your production needs. Adjustability is also crucial; look for machines that can easily adjust for different container sizes and filling volumes.

Ease of cleaning is another important consideration; opt for machines that are easy to disassemble and clean to ensure proper hygiene. Accuracy is essential as well; ensure the machine offers precise filling to avoid wastage and ensure product consistency. Finally, choose machines made from high-quality, food-grade materials to maintain honey purity and safety.

There are different types of honey filling machines to suit various needs. Manual filling machines are ideal for small-scale operations and require manual effort to fill each container. They are cost-effective but labor-intensive. Semi-automatic filling machines offer automation for some parts of the filling process but still require manual intervention for tasks such as container placement and capping. Fully automatic filling machines are designed for large-scale production and handle the entire filling process, including container handling and capping, with minimal human intervention.

To ensure your honey filling machine operates smoothly, regular maintenance is essential. This includes routine cleaning to prevent honey buildup and contamination, regular inspection for wear and tear on moving parts, and periodic calibration to ensure accurate filling.

Investing in a honey filling machine can significantly enhance the efficiency and consistency of your honey production process. By understanding the basics—how the machine works, its benefits, and key features—you can make an informed decision that will support your business’s growth and success. Whether you’re a small artisan producer or a large commercial operation, there’s a honey filling machine suited to your needs. Exploring different models and consulting with suppliers can help you find the best fit for your honey production goals. Happy filling!

Source: https://autopackmachinespvtltd.wordpress.com/2024/08/31/the-basics-of-honey-filling-machines-a-beginners-guide/

0 notes

Text

Vial Liquid Line

Vial Liquid line that includes a washing, sterilizing, liquid filling, cap sealing, and labeling machine is used to fill injectable vials. This is known as an injectable liquid filling line. Every machine was oriented to function as a single, cohesive system. We have both Automatic and Semi-Automatic Vial Liquid Lines in our inventory. Automatic lines, also known as fully automatic vial liquid lines, have conveyors on each machine that are connected to one another for uninterrupted automatic operations.

Automatic Vial Liquid Line

Washing, sterilizing, filling stoppering, and labeling machines make up automatic vial lines. Every machine is connected to function as a single, cohesive system. Automation is used in operations to remove human intervention. These lines are also known as Production Scale Vial Filling Lines or High-Speed Vial Production Lines. The equipment in this kind of filling line is listed below:

Vial Washing Machine

The AI-VRW Automatic Rotary Vial Washing Machine is made to wash glass vials without letting non-contact machine parts come into touch with the vials. A gripper system on the Automatic Rotary Vial Washing Machine model grips the vial from the neck and inverts it while the washing process is underway. Once the washing process is complete, the vial is released on the outfeed star wheel arrangement in a vertical position, ensuring a positive wash of the vials. With the use of spare components, our machine model can clean glass vials and containers ranging in capacity from 2 to 100 milliliters. A specifically constructed Gripper holds the glass vial from its neck, inverts it, and moves it further on a rotary moving system for the washing process. The glass vial feeds through a turn table to the infeed Star Wheel.

Sterilization Tunnel

In order to sterilize and dehydrogenate cleaned empty pharmaceutical glassware used in parenteral product packaging, this type of continuous sterilizer is a fully automated system that specifically uses forced convection of filtered air through a high efficiency particulate air filter.

Vial Liquid Filling Machine

Glass vials that are injectable can be filled with an injectable liquid filling machine, such as an automatic vial liquid filling machine. Turntable, stainless steel stat conveyor belt, and special eccentric pre-, filling, and post-gassing comprise the basic unit. 316L stainless steel syringes that are incredibly accurate and efficient, non-toxic synthetic rubber tubing, and a compact, easily accessible panel.

Vial Cap Sealing Machine

The PP/Flip-ff cap sealing onto round glass vials is appropriate for the Automatic Vial Cap Sealing Machine. The machine for capping vials is specifically made of stainless steel and has a mild steel frame with stainless steel cladding and enclosures. The Vial Capping Machine has a vibratory bowl feeder that allows the cap to be continuously fed for online operation on any liquid or powder filling line. Machine adaptable to different Vial sizes and, with the use of spare parts, to Plain/Flip-Off Caps. The Capping Machine is a useful tool for the pharmaceutical industry because it may operate automatically online and has fewer production requirements.

Vial Inspection Machine

Glass vials that can be injected are appropriate for inspection using an automatic vial inspection machine. The four tracks that make up the Vial Inspection Machine are made of nylon-6 roller chain, and they can be purchased with a spinning assembly that includes 24V DC wiring and AC drive rejection units. Additionally, the ability to modify speed was made possible with a variable AC frequency drive. All of the machine’s contact parts are composed of authorized engineered polymers and stainless steel, in compliance with cGMP regulations.

Vial Sticker Labeling Machine

One of the easiest vertical vial sticker labeler devices to use is the Automatic Vial Sticker Labeling Machine. This apparatus has a cutting-edge Micro Processor Control label dispensing mechanism with a product and label detection system. The Vial Labeler can be used to label spherical objects such as vials. Depending on the vial and label size, it may label up to 100 vials in a minute. An optional unique label sensing system allows an electronic and mechanical system specifically developed to put transparent (No Look) labels on vials at a very fast speed.

Semi-Automatic Vial Liquid Line

Machines for washing, sterilizing, filling stoppers, sealing caps, inspecting, and labeling make up a semi-automated vial liquid line. These devices operate on their own and are integrated with one another. These lines are also known as small-scale vial liquid lines or low-cost vial production lines. The equipment in this kind of filling line is listed below:

Semi-Automatic Vial Washing Machine

A reliable, ampoule and vial washing machine that complies with cGMP standards is the semi-automatic vial washer, also known as the vial jet washer. It is small, adaptable, and semi-automatic. With the use of appropriate replacement components, the Multijet Vial Washing Machine’s stainless steel architecture allows it to wash glass vial sizes ranging from 2 to 100 milliliters and ampoule sizes from 1 to 20 milliliters. FDA-approved materials or stainless steel 316L are used to make all contact parts.

Dry Heat Sterilizer

Bottles, vials, and ampoules that have been cleaned can be sterilized using an ampoule sterilizer or dry heat sterilizer. It is constructed from MS heavy angles with an exterior wall composed of stainless steel 304 and an inner wall made of stainless steel 316. Our double door DHS is manufactured in compliance with cGMP requirements that are authorized in injectable pharmaceutical factories that uphold a class 100 environment. For cGMP compliance, all contact parts are constructed from FDA-approved materials or stainless steel 316L.

Vial Liquid Filling Machine

Glass vials that are injectable can be filled with an injectable liquid filling machine, such as an automatic vial liquid filling machine. Turntable, stainless steel stat conveyor belt, and special eccentric pre-, filling, and post-gassing comprise the basic unit. 316L stainless steel syringes that are incredibly accurate and efficient, non-toxic synthetic rubber tubing, and a compact, easily accessible panel.

Vial Cap Sealing Machine

The PP/Flip-ff cap sealing onto round glass vials is appropriate for the Automatic Vial Cap Sealing Machine. The machine for capping vials is specifically made of stainless steel and has a mild steel frame with stainless steel cladding and enclosures. The Vial Capping Machine has a vibratory bowl feeder that allows the cap to be continuously fed for online operation on any liquid or powder filling line. Machine adaptable to different Vial sizes and, with the use of spare parts, to Plain/Flip-Off Caps. The Capping Machine is a useful tool for the pharmaceutical industry because it may operate automatically online and has fewer production requirements.

Vial Inspection Machine

Glass vials that can be injected are appropriate for inspection using an automatic vial inspection machine. The four tracks that make up the Vial Inspection Machine are made of nylon-6 roller chain, and they can be purchased with a spinning assembly that includes 24V DC wiring and AC drive rejection units. Additionally, the ability to modify speed was made possible with a variable AC frequency drive. All of the machine’s contact parts are composed of authorized engineered polymers and stainless steel, in compliance with cGMP regulations.

Vial Sticker Labeling Machine

One of the easiest vertical vial sticker labeler devices to use is the AutomaticVial Sticker Labeling Machine. This apparatus has a cutting-edge Micro Processor Control label dispensing mechanism with a product and label detection system. The Vial Labeler can be used to label spherical objects such as vials. Depending on the vial and label size, it may label up to 100 vials in a minute. An optional unique label sensing system allows an electronic and mechanical system specifically developed to put transparent (No Look) labels on vials at a very fast speed.

#injectable liquid filling line#fully automatic vial liquid lines#Vial Washing Machine#Sterilization Tunnel#Vial Liquid Filling Machine#Vial Cap Sealing Machine#Vial Inspection Machine#Vial Sticker Labeling Machine#Semi-Automatic Vial Liquid Line#Dry Heat Sterilizer

0 notes

Text

What is planetary Gear Motors?

Planetary Geared Motors efficiently handles the speed and optimises the torque. They can be used in wide industrial applications ranging from steel plants to material handling equipments.

Components of Planetary Geared Motors

Motor speed reducers can be categorised in the following ways depending on how they are internally configured:

Planetary Speed Reducers

Stages of planetary gear motors are grouped, and each one has the following layout:

Sun Gear (Central Gear)

The sun gear in a planetary gearbox rotates the neighbouring planetary gears, which are mounted on a carrier to prevent slippage while in use. The planetary gears rotate the ring gear while the sun gear is powered. The sun gear is the main gear. It rotates on a bigger axis and is greater in size.

Multiple Planet Gears

The epicyclic gear typically consists of two gears, one of which meshes with the sun gear and the other with the planetary ring gear. These are used to lower speed. They are utilised to boost torque and slow down motors. Planetary gears' primary and essential job is to adjust the rotational speed or torque between the input and output shafts while transmitting torque.

Planet Carrier

The planet gear is held by the planet carrier, which rotates in the opposite direction of the planet gear. Typically, it offers support to allow two gears to roll without slippage by connecting their centres. A planet carrier that meshes with the sun can carry up to three gears.

Ring Gear (Outer Gear)

Numerous planet gears that are utilised to drive the outer ring, shaft, or spindle share the load from the sun gear. The ring gear provides a reverse direction by rotating in the same direction as the sun gear.

Advantages Of Planetary Gear Motors

Increased Repeatability

Its faster radial and axial loads are more dependable and robust, reducing gear misalignment. Additionally, flawless repeatability is provided by consistent transmission and reduced vibrations under various loads.

Perfect Accuracy

The movement's accuracy and dependability are improved by the rotation's maximum angular stability.

Efficient Durability

Because there is greater surface contact, the noise intensity is lower. Jumping is almost negligible, and rolling is much smoother. Owing to its torsional rigidity and improved rolling, it is more durable. Your bearings assist in minimising the losses that would result from the shaft rubbing against the box directly, improving this characteristic. As a result, the gear operates more smoothly and with more efficiency.

High Degrees of Effectiveness

Planetary reducers are more effective and minimise losses during operation due to their internal design and architecture. In actuality, these driving systems are the most efficient ones available today.

Improved Torque Transmission

The mechanism can transmit and endure more torque when there are more teeth in connection. Things also performs it in a more consistent way.

Maximum Adaptability

Its gearbox, which is cylindrical and can be mounted practically anywhere, houses the mechanism.

Disadvantages of Planetary Gear Motors

A planetary gear system will generally cost more than a traditional gearbox.

Planetary gear design and production are challenging and highly complex.

It would be difficult to figure out a planetary gear system's efficiency

It is challenging because the gear system demands exact gearing.

Some planetary gearing configurations operate noisier than others.

The driving component and the driven component must coincide to avoid any additional gearing.

Applications of Planetary Gear Motors

It is utilised in packing equipment for industrially reproducible goods.

They are utilised in cutter head drives, coil tubing injectors, and pumps.

It can be used in drives like wheel drives, track drives, conveyor drives, slew drives, hoist drives, and winch drives, among others.

These gears are frequently employed in robotics to increase torque.

It is utilised in printing presses to lower the rollers' speed.

Regulations For Planetary Gearboxes

When a manufacturer lists the operating time of your gears or the maximum torque they can withstand, keep in mind that each manufacturer establishes its own standards. Nevertheless, these parameters are governed by a few rules.

ISO 6636 for gears.

DIN ISO 281: Contains all the guidelines necessary to calculate bearings correctly.

ISO 9409: Part II discusses how the output shafts of these geared motors are designed in accordance with various requirements.

#planetarygearmotors#planetarygearmotorsmanufacture#planetarygearmotorssuppliers#kavitsuransmissions#kavitsu

0 notes

Text

How Does a Potato Planter Work?

1. Seed Potato Distribution

At the heart of a potato planter is the mechanism that handles seed potato distribution. In most planters, there’s a hopper or a seed box that holds the seed potatoes. The seeds are fed from the hopper through a series of tubes or conveyors. Depending on the design, the distribution system may use a belt, chain, or rotating discs to deliver the potatoes to the planting area.

2. Placement Mechanism

Once the seed potatoes are distributed, they need to be placed in the soil at the correct depth and spacing. This is where the planting mechanism comes into play.

Manual Planters: For smaller operations, manual planters often use a wheel or lever system to create furrows in the soil. The operator places the seed potatoes into these furrows manually, and the machine then covers them with soil.

Mechanical Planters: Larger, mechanized planters have more advanced systems. They might use rotating discs or plow-like blades to open furrows, followed by a mechanism that drops the seed potatoes into the furrows. Some models also feature adjustable settings to control the depth and spacing of the planting.

3. Soil Coverage

After the seed potatoes are placed in the furrows, the next step is to cover them with soil. This is usually done by a set of covering blades or discs that follow behind the planting mechanism. These blades push soil over the seed potatoes and compact it to ensure good seed-to-soil contact. Proper coverage is essential to protect the seed potatoes and promote healthy sprout development.

What is a Potato Planter?

A potato planter is an agricultural machine specifically designed to plant seed potatoes in the soil. These machines automate the process of placing seed potatoes in rows at a uniform depth and spacing, which is crucial for optimal growth and yield. Potato planters come in various designs, ranging from simple manual devices to complex mechanized systems, and are used by both small-scale farmers and large agricultural operations.

Types of Potato Planters

Potato planters come in various types, each suited to different scales of operation and planting conditions:

Single-row Planters: Ideal for small gardens or hobby farms, single-row planters are simple and often manually operated. They are perfect for precision planting in smaller plots.

Multi-row Planters: These are designed for larger-scale farming and can plant several rows of potatoes simultaneously. They are often towed behind a tractor and can handle more significant quantities of seed potatoes.

Precision Planters: These sophisticated machines offer precise control over planting depth, spacing, and even seed size. They are usually used in commercial farming to maximize yield and efficiency.

Advantages of Using a Potato Planter

Efficiency: Potato planters save time and labor compared to manual planting, making large-scale operations much more manageable.

Consistency: These machines ensure uniform planting depth and spacing, which contributes to more even growth and higher yields.

Reduced Soil Disturbance: Modern planters are designed to minimize soil disruption, which helps in maintaining soil structure and health.

Cost-Effective: Although the initial investment in a potato planter can be significant, the increase in efficiency and yield can offset the cost over time.

Conclusion

Potato planters are a vital tool for modern agriculture, transforming the way potatoes are planted and making the process more efficient and less labor-intensive. Whether you’re managing a small garden or a large farm, understanding how these machines work can help you choose the right planter for your needs and optimize your potato planting strategy. With the right equipment, growing potatoes can be a smooth and rewarding experience, leading to bountiful harvests and delicious results.

For more information, please contact us!

Website :- www.veermechanical.com

Contact No. :- +91–8630287830, +91–9358434496

Email :- [email protected], [email protected]

#Potato Planter#Potato Planter manufacturer#Potato Planter supplier#Potato Planter manufacturer in India#Isher engineering works#veer mechanical

1 note

·

View note

Text

How do tube laser cutting machines integrate with other manufacturing processes?

Tube laser cutting machines can integrate with other manufacturing processes in several ways:

Computer-Integrated Manufacturing (CIM): Tube laser cutting machines are often part of a CIM system, where the cutting process is seamlessly integrated with other computer-controlled manufacturing operations like bending, welding, and assembly. Tube laser cutting machine manufacturers This allows for efficient data transfer, process optimization, and overall workflow automation.

CAD/CAM Integration: Tube laser cutting machines can directly receive design files from CAD (Computer-Aided Design) software and then use CAM (Computer-Aided Manufacturing) software to generate the cutting program. This streamlines the design-to-fabrication process.

Material Handling Integration: Tube laser cutting machines can be integrated with automated material handling systems, such as conveyors, robots, or automated storage and retrieval systems. This allows for the efficient movement of raw materials and cut parts between different manufacturing stages.

Quality Control Integration: The cutting data and process parameters from the tube laser cutting machine can be connected to quality control systems, enabling real-time monitoring, measurement, and statistical process control.

Enterprise Resource Planning (ERP) Integration: Tube laser cutting machines can be linked to ERP systems, which provide a centralized platform for managing various business functions, such as inventory, production planning, and order tracking.

Maintenance and Diagnostics: Some tube laser cutting machines are equipped with remote monitoring and diagnostic capabilities, allowing for proactive maintenance and optimization of the cutting process.

By integrating tube laser cutting machines with other manufacturing processes, companies can achieve increased efficiency, reduced lead times, improved quality, and better overall control over their production operations.

0 notes

Text

The Comprehensive Guide to Conveyors: Moving the World Forward

In today’s fast-paced industrial landscape, conveyors are the unsung heroes behind the seamless movement of goods, materials, and products. From manufacturing plants to distribution centres, these mechanical systems play a pivotal role in ensuring efficiency and productivity.

In this comprehensive guide, let’s delve into the world of conveyor transfer, exploring its types, applications, benefits, and future trends. Whether you're a business owner, an engineer, or simply curious about the backbone of modern logistics, this blog will provide you with valuable insights into the fascinating realm of conveyors.

What Are Conveyors?

Conveyors are mechanical devices designed to transport materials or products from one location to another. They are commonly used in various industries, including manufacturing, mining, agriculture, and logistics. The primary function of a conveyor is to move items quickly and efficiently, reducing manual labour and increasing productivity. Conveyors can be simple, such as a roller conveyor, or complex, like a robotic arm integrated with a conveyor belt.

Types of Conveyors

Belt Conveyors

Belt conveyors are the most common type of conveyor system. They consist of a continuous belt made of rubber, fabric, or metal, which moves over rollers or a flat surface. Belt conveyors are ideal for transporting a wide range of materials, from lightweight items to heavy loads. They are widely used in industries like manufacturing, mining, and food processing.

Applications:

Assembly lines

Material handling in warehouses

Food processing

Advantages:

Versatile and adaptable

Can transport items over long distances

Low maintenance

Roller Conveyors

Roller conveyors use a series of rollers, mounted on a frame, to move items. They can be powered or gravity-fed, depending on the application. Roller conveyors are ideal for transporting heavy or bulky items, such as pallets or large packages.

Applications:

Pallet handling

Sorting and packaging lines

Automotive assembly

Advantages:

Durable and robust

Suitable for heavy loads

Easy to install and modify

Chain Conveyors

Chain conveyors use chains to move items along a production line. They are commonly used in industries where products need to be transported through different processing stages, such as in automotive manufacturing or steel mills. Chain conveyors are ideal for handling heavy materials and can be designed to move products horizontally, vertically, or at an incline.

Applications:

Automotive assembly

Steel and metal processing

Heavy-duty material handling

Advantages:

Can handle high loads

Flexible design options

Suitable for harsh environments

Screw Conveyors

Screw conveyor transfer consists of a helical screw blade that rotates within a tube, moving materials along the length of the conveyor. They are commonly used in industries such as agriculture, food processing, and waste management. Screw conveyors are ideal for transporting granular or powdery materials, such as grains, flour, and cement.

Applications:

Grain handling

Waste disposal

Food processing

Advantages:

Efficient for bulk materials

Can transport materials at an incline

Low maintenance

Benefits of Conveyors

Increased Efficiency

Conveyors streamline the transportation of materials, reducing the need for manual labor and increasing overall efficiency. This results in faster production times and lower operational costs.

Improved Safety

By automating the movement of materials, conveyors reduce the risk of workplace injuries caused by manual lifting and handling. They create a safer working environment by minimising human interaction with potentially hazardous materials.

Cost-Effective

Conveyors offer a cost-effective solution for material handling, reducing the need for manual labor and increasing productivity. They also help lower transportation costs by efficiently moving goods within a facility.

Versatility

Conveyors can be customised to meet the specific needs of different industries and applications. They can handle a wide range of materials, from small items to heavy loads, and can be designed to fit within various layouts and production processes.

Future Trends in Conveyor Technology

As technology continues to evolve, so do conveyor systems. Here are some of the emerging trends that are shaping the future of conveyors:

Automation and Integration

The integration of automation and robotics into conveyor systems is becoming increasingly common. Automated conveyors can be programmed to perform specific tasks, such as sorting, packaging, and assembly, reducing the need for manual intervention and increasing efficiency.

Smart Conveyors

Smart conveyors are equipped with sensors and IoT technology, allowing them to collect and analyse data in real-time. This enables predictive maintenance, reducing downtime and improving overall system performance.

Energy Efficiency

Energy-efficient conveyors are designed to reduce power consumption and minimise environmental impact. They use advanced technologies, such as energy-efficient motors and regenerative braking, to optimise energy usage.

Modular Design

Modular conveyors offer flexibility and scalability, allowing businesses to easily expand or modify their conveyor systems as needed. This makes them an ideal solution for industries with changing production requirements.

Final Words

Conveyors are an integral part of modern industrial operations, providing a reliable and efficient means of transporting materials and products. From belt conveyors in manufacturing plants to screw conveyors in agriculture, these systems play a crucial role in enhancing productivity and safety.

As technology continues to advance, conveyor transfer are becoming smarter and more versatile, paving the way for even greater efficiencies in the future. Whether you’re looking to improve your current operations or explore new material handling solutions, understanding the capabilities and benefits of conveyors is essential for success in today’s fast-paced industrial world.

Source From : The Comprehensive Guide to Conveyors: Moving the World Forward

0 notes

Text

How to find square pipe dealers in Vadodara?

What are square pipes?

Square pipes are a type of structural steel tubing with a square cross-section. They are typically made from hot-rolled or cold-rolled steel and are used for a variety of construction and engineering purposes. Some common uses for square pipes include framing, fencing, handrails, and support structures.

Square pipes manufactured by an excellent supplier of Square pipe beam in Vadodara, Tube Trading Co., are generally stronger and more rigid than round pipes, making them well-suited for use in construction and engineering applications where strength and stability are important. They are also relatively easy to cut and weld, which makes them a popular choice for many types of projects.

Square pipes are typically measured by their width, which is the distance across the flat sides of the square cross-section. The thickness of the pipe walls is also an important consideration, as it determines the strength and rigidity of the pipe. Square pipes are available in a range of sizes and thicknesses to suit different applications.

How to find the best square pipe dealer in Vadodara?

There are several ways you can find the best square pipe dealer in Vadodara:

- Search online directories or business listings:

There are several online directories and business listings that can help you find square pipe dealers in Vadodara. You can try searching for "square pipe dealers in Vadodara" or "steel supply companies in Vadodara" to find a list of businesses that may be able to help you.

● Contact local steel supply companies or construction material suppliers:

If you know of any local steel supply companies or construction material suppliers in Vadodara, they may be able to point you in the direction of square pipe dealers in the area.

● Ask for referrals from other professionals:

If you know other professionals in the construction or engineering fields in Vadodara, they may be able to provide you with recommendations for reputable square pipe dealers in the area.

● Connect with professional companies or industrial associations:

There may be industry associations or professional organizations in Vadodara that can provide you with information about square pipe dealers in the area. You can try contacting these organizations to ask for recommendations or to find out if they have a list of recommended suppliers.

● Check with local hardware stores or building supply stores:

Local hardware stores or building supply stores may carry square pipes or be able to order them for you. They may also be able to provide you with information about where to find square pipe dealers in the area.

Applications of Square pipes:

Some common applications for square pipes include:

- Framing:

Square pipes are often used as framing members in construction, such as for building walls, floors, and roofs.

- Fencing: