#Rapid Prototyping Solutions

Explore tagged Tumblr posts

Text

Rapid Prototyping Solutions by XLC Precision

XLC Precision offers cutting-edge rapid prototyping solutions to bring your ideas to life faster. Our advanced technology ensures high accuracy, quick turnaround, and cost-effective results. From concept to creation, trust XLC Precision for reliable prototypes that support innovation, testing, and streamlined product development.

Visit:- https://www.xlcprecision.com/cnc-machining/

0 notes

Text

Maintenance Tips for Your CNC Turning Machine by MechPlus China

As a leading CNC turning machine manufacturing, MechPlus China understands the importance of proper maintenance to ensure precision and efficiency. Regular upkeep not only extends the machine's lifespan but also maximizes productivity and quality. Here are essential maintenance tips from MechPlus China to keep your CNC turning machine running smoothly and efficiently.

Keeping your CNC turning machine in top condition is crucial for optimal performance. Regular maintenance not only extends the machine's lifespan but also ensures precision and efficiency in your operations. Here are essential maintenance tips to keep your CNC turning machine running smoothly.

Daily Inspection and Cleaning

Start each day with a thorough inspection of your CNC turning machine. Check for any signs of wear and tear, and ensure all components are in good working order. Clean the machine daily to remove any debris, chips, and coolant residue. This prevents buildup that can affect performance and accuracy.

Lubrication

Proper lubrication is vital for the smooth operation of your CNC turning machine. Lubricate all moving parts as recommended by the manufacturer. This includes the spindle, guideways, and ball screws. Regular lubrication reduces friction, prevents wear, and extends the machine’s life.

Coolant Maintenance

Maintaining the coolant system is essential for the longevity of your CNC machine. Regularly check the coolant level and concentration. Replace or refill the coolant as needed. Also, clean the coolant tank and filters to avoid contamination that can damage the machine and workpieces.

Alignment and Calibration

Ensure that your CNC turning machine is properly aligned and calibrated. Misalignment can lead to inaccuracies in your machining processes. Regularly check and adjust the machine’s alignment and calibration according to the manufacturer’s guidelines. This ensures precision in your operations.

Check Electrical Components

Inspect the electrical components of your CNC turning machine regularly. Look for any loose connections, worn-out wires, or faulty switches. Address any electrical issues immediately to prevent machine downtime and potential safety hazards.

Monitor Machine Vibration

Excessive vibration can lead to poor machining quality and damage to your CNC turning machine. Monitor the machine for any unusual vibrations or noises during operation. Identify and address the source of the vibration to maintain optimal performance.

Regular Software Updates

Keep your CNC machine’s software up to date. Manufacturers often release updates that improve functionality and fix bugs. Regularly updating the software ensures your machine operates efficiently and takes advantage of the latest technological advancements.

Tool Maintenance

Regularly inspect and maintain the cutting tools used in your CNC turning machine. Sharp and well-maintained tools are crucial for high-quality machining. Replace worn or damaged tools promptly to ensure precise and efficient operation.

Preventive Maintenance Schedule

Implement a preventive maintenance schedule for your quick response machining tool. Follow the manufacturer’s recommended maintenance intervals for all components. Regular preventive maintenance helps identify potential issues before they become major problems, reducing downtime and repair costs.

Training and Safety

Ensure that all operators are properly trained in the maintenance and operation of the CNC turning machine. Regular training updates and adherence to safety protocols are crucial for preventing accidents and ensuring smooth operations.

Document Maintenance Activities

Keep detailed records of all maintenance activities performed on your CNC turning machine. Documenting maintenance helps track the machine’s condition over time and provides valuable information for troubleshooting and repairs with all types of customized machining parts.

In conclusion, regular maintenance of your CNC turning machine is essential for its longevity and performance. By following these tips, you can ensure your machine operates efficiently, reducing downtime and improving the quality of your machining processes. Implement these maintenance practices to keep your CNC turning machine in optimal condition.

#Prototyping solutions#SLA Rapid Prototyping manufacturing#SLS Rapid machining manufacturing#5 Axis CNC machining manufacturing#3D metal printing manufacturing

2 notes

·

View notes

Text

Top providers for 3D printing Services in Malaysia.

Projet Technology : This company provides 3D printing services catering to individuals, industrial, and educational institutions. While they are one of the leading 3D printing service providers in Malaysia, they also provide their services to hobbyists nationwide. They offer prototyping, production, and customization services using a range of materials. Projet is Malaysia’s reliable, one-stop 3D printing service provider. WEBSITE : http://projet.my

Why Choose Projet.my for Rapid Prototyping and 3D Printing in Malaysia?

Cutting-Edge Technology: At Projet.my, we leverage cutting-edge 3D printing technology to deliver unparalleled precision and quality in every prototype. Our state-of-the-art machinery ensures that your designs are brought to life with utmost accuracy, allowing for seamless iterations and improvements.

Custom Solutions:

No two projects are alike, which is why we offer tailor-made solutions to suit your specific needs. Whether you require intricate prototypes for product testing or high-volume production runs, our team at Projet.my is equipped to handle it all with finesse.

Speedy Turnaround:

Time is of the essence in the world of product development. With Projet.my, you can expect swift turnaround times without compromising on quality. Our streamlined processes and efficient workflows ensure that your prototypes are delivered promptly, giving you the edge in today’s competitive market.

Rapid Prototyping & 3D Printing Service Malaysia | Projet.my

Cost-Effective Solutions: We understand the importance of cost-effectiveness in every project. That’s why we offer competitive pricing options without compromising on the quality of our services. With Projet.my, you can achieve cost-effective solutions that meet your budgetary requirements without sacrificing on excellence.

Expert Guidance:

Navigating the world of rapid prototyping and 3D printing can be daunting, but fear not — our team of experts at Projet.my is here to guide you every step of the way. From initial concept to final production, we provide comprehensive support and expertise to ensure your project’s success.

Rapid Prototyping:

From concept to prototype, we specialize in rapid prototyping services that help you iterate quickly and efficiently. Whether you’re testing new designs or refining existing ones, our rapid prototyping solutions are designed to accelerate your product development process.

3D Printing:

Our advanced 3D printing capabilities allow for unparalleled precision and detail in every print. Whether you need functional prototypes or intricate models, our 3D printing services deliver exceptional results that exceed expectations.

Customization:

We understand that every project is unique, which is why we offer customizable solutions to meet your specific requirements. Whether you need bespoke materials, finishes, or design modifications, our team at Projet.my is dedicated to bringing your vision to life with precision and care.

#3d printing#3dprintingservice#additivemanufacturing#malaysia#penang#3d scanning services#3d printing service#rapid prototyping#fabrication#solution

2 notes

·

View notes

Text

Innovative Solutions in 3D Printing: QSY's Rapid Prototyping Services

The 3D printing industry is experiencing a remarkable transformation, and one brand leading the charge is QSY. As a trusted provider of rapid prototyping services, QSY is dedicated to delivering innovative solutions that meet the diverse needs of its clients.

QSY specializes in turning ideas into reality by offering high-quality 3D printing services that streamline the prototyping process. Their state-of-the-art technology allows for precise and efficient production, making it easier for businesses to test and refine their designs. Whether you're in the automotive, aerospace, or consumer goods sector, QSY's expertise can help accelerate your product development cycle.

What sets QSY apart is their commitment to customer satisfaction. They work closely with clients to understand their specific requirements and provide tailored solutions that enhance creativity and functionality. With a focus on quality and efficiency, QSY ensures that every project is completed on time and within budget.

In a world where time-to-market is crucial, QSY's rapid prototyping services empower companies to innovate faster, reduce costs, and bring their products to market with confidence. If you're looking for a reliable partner in the 3D printing space, QSY is the provider you can trust to elevate your projects and drive success.

0 notes

Text

Innovating Healthcare with Medical Product Design in UK

Revolutionizing healthcare starts with Medical Product Design in UK! From life-saving diagnostic tools to smart wearables, UK design consultancies are crafting cutting-edge medical devices that transform lives. These experts blend creativity, engineering, and strict ISO 13485 standards to ensure safety and innovation. Using 3D printing and AI simulations, they prototype fast, creating user-friendly, sustainable products for hospitals and homes. Whether it’s a startup’s first device or a global brand’s next breakthrough, Medical Product Design in UK delivers precision and impact. Know any cool UK-designed medical tech? Share your faves below! 🩺 #HealthTech #UKInnovation

#Medical Product Design in UK#health tech#product design#UK innovation#medical devices#rapid prototyping#sustainable design#3D printing#AI simulations#healthcare solutions

0 notes

Text

CNC Machining for Rapid Prototyping | Fast & Accurate Prototypes

Transform your product ideas into real-world solutions with Rapid Prototyping CNC Machining services from Impel Concepts. Their precision and speed help bring your vision to life with accuracy and efficiency. Whether you’re developing a concept or refining a part, Impel Concepts delivers quality every step of the way. Trust them for fast turnarounds and professional-grade prototypes tailored to your specifications.

#rapid prototyping cnc machining#cnc production machining#FEA Analysis#Concept Rendering#cnc machining solutions#Prototype development

1 note

·

View note

Text

A company making wooden wind turbine blades has successfully tested a 50-meter-long prototype that’s set to debut soon in the Indian and European markets.

Last year, the German firm Voodin successfully demonstrated that their laminated-veneer timber blades could be fabricated, adapted, and installed at a lower cost than existing blades, while maintaining performance.

Now, Voodin has announced a partnership with the Indian wind company Senvion to supply its 4.2-megawatt turbines with these wooden blades for another trial run.

Wind power has accumulated more than a few demerit points for several shortfalls in the overall industry of this fossil-fuel alternative.

Some of these, such as the impact on bird life, are justified, but none more so than the fact that the turbine blades are impossible or nearly impossible to recycle, and that they need to be changed every 25 years.

Wind turbine blades are made from a mixture of glass and carbon fiber heated together with sticky epoxy resin, and these materials can’t be separated once combined, which means they go into landfills or are incinerated when they become too battered to safely operate.

GNN has reported that folks will occasionally find second-life value in these giant panels, for example in Denmark where they are turned into bike shelters. In another instance, they’re being used as pedestrian bridges.

But there are way more wind turbine blades being made every year than pedestrian bridges and bike shelters, making the overall environmental impact of wind power not all green.

“At the end of their lifecycle, most blades are buried in the ground or incinerated. This means that—at this pace—we will end up with 50 million tonnes of blade material waste by 2050,” Voodin Blade Technology’s CEO. Mr. Siekmann said recently. “With our solution, we want to help green energy truly become as green as possible.”

The last 15 years have seen rapid growth in another industry called mass timber. This state-of-the-art manufacturing technique sees panels of lumber heat-pressed, cross-laminated, and glued into a finished product that’s being used to make skyscrapers, airports, and more.

At the end of the day though, mass timber products are still wood, and can be recycled in a variety of ways.

“The blades are not only an innovative technological advancement but a significant leap toward sustainable wind production,” said Siekmann, adding that this isn’t a case of pay more to waste less; the blades cost around 20% less than carbon fiber.

Additionally, the added flexibility of wooden blades should allow for taller towers and longer blades, potentially boosting the output of turbine by accessing higher wind speeds.

Now partnered with Voodin, Senvion will begin feasibility analysis in the next few months, before official testing begins around 2027.

#good news#wind turbines#wind power#environmentalism#science#environment#fossil fuel alternatives#mass timber#recycling

11K notes

·

View notes

Text

Mastering Rapid Prototyping for eLearning Development from Concept to Launch

Using rapid prototyping, that is driven by design thinking, L&D can give a concrete form to a rough idea, get stakeholder buy-in, improve the quality of instruction before large-scale implementation, and ultimately optimize learning outcomes and ROI.

The Case for Learning Fast in L&D

Delivering training that aligns with organizational goals and addresses actual learner needs is a pressing challenge for L&D today. As the training needs of a diverse, multi-generational, and hybrid workforce evolve, mastering rapid prototyping for eLearning development is the critical need of the hour.

Rapid prototyping allows L&D teams to visualize, experiment, and test different ideas in a concrete form using simple tools such as PowerPoint, Storyline, or even pen and paper. By identifying and correcting any misalignments early in the initial stages, commonly known as the “fail fast” approach, they can mitigate the risk of launching ineffective programs at scale. Further, by aligning training with learner needs or engagement strategies before committing extensive resources, L&D can save significant time and investments.

Prototyping enables L&D to improve stakeholder participation by providing a clear, firsthand explanation of how the solution will likely work and how design elements contribute to the overall effectiveness of the product. Furthermore, prototyping supports continuous testing, feedback, and refinement, ensuring a final design that is both highly functional and learner-centered.

Early validation through prototyping can benefit some common course design assumptions such as presuming that the course aligns with learners’ current knowledge and needs, the learners would prefer a specific format without actually testing the preferred mode of delivery, the pace of the training is appropriate, without testing whether it’s too fast, too slow, or too challenging, or that the chosen digital tools or platforms will work seamlessly for all users without testing for technical issues or accessibility concerns.

The Different Phases of Rapid Prototyping Process in eLearning

There are different stages of the rapid prototyping process in eLearning that are intentionally structured as low-cost phases, enabling quick pivoting without investing heavily in each step.

Usually, the prototyping process begins with the Ideation phase. Here L&D teams brainstorm and explore a wide range of ideas, focusing only on conceptualizing different possibilities. Moving into the Design phase, L&D uses simple tools to create mockups and more refined versions of the idea. In the next stage of Testing, L&D presents the eLearning prototype to the stakeholders to spot flaws, seek feedback, and identify areas for improvement. At this stage the prototype is still a rough version, therefore testing costs still remain low. In the Feedback phase, L&D gathers insights from real users and adjusts the design for better alignment with user expectations. Finally, in the Iteration phase, L&D refines the eLearning prototype based on the overall feedback to move closer to the final product with minimal cost and effort.

Benefits of Prototyping in eLearning Content Development

The iterative process of prototyping helps optimize learning outcomes before large-scale implementation to improve ROI. Some benefits of prototyping in eLearning content development include:

Creative Exploration: Encourages out-of-the-box thinking, allowing designers to freely explore innovative content ideas in a low-risk environment and identify the most effective ones to engage learners.

Early Problem Detection: Helps quickly identify potential design flaws and make adjustments before investing significant resources in a full-scale rollout, preventing costly and time-consuming fixes later.

Iterative Design: Supports continual refinement and improvement of the learning program through multiple cycles of testing, feedback, and user input.

Resource Efficiency: Streamlines the development process, making it more resource efficient by preventing time and money investment in ideas that won’t work.

Stakeholder Engagement: Involves key stakeholders early in the process for feedback and buy-in, creating a more collaborative and effective learning solution.

Expectation Setting: Establishes clear expectations by providing stakeholders with a preview of the course early on to see the direction and design in a tangible form and validate assumptions about the content, structure, and delivery methods before the full rollout.

Design Flexibility: Allows making quick adjustments without the need for major revisions. Being low-cost and incomplete, prototyping provides the freedom to explore changes without significant time or resource investment.

How to Develop eLearning Prototypes for Learning Programs

Following a stepwise procedure to develop eLearning prototypes ensures minimum errors and efficient resource allocation. A systematic approach to developing eLearning prototypes includes:

Defining Goals and Objectives: Establish a clear purpose for the eLearning prototype to ensure alignment with the overall learning strategy. Focus on core questions and the specific needs of learners to design relevant content and learning experiences.

Choosing the Fidelity Level: Select an appropriate fidelity level based on project stage and audience to ensure the eLearning prototype is developed with the appropriate detail and functionality for its intended purpose. Early-stage prototypes may have low fidelity, such as storyboards for early ideation, that focus on basic concepts. Whereas the later stages may require higher fidelity, such as using authoring tools and apps, for more realistic simulations.

Creating the Prototype: Create the eLearning prototype using selected tools and incorporating essential content, features, and interactions that reflect the key learning objectives. Focus on elements that directly impact the learner’s experience to develop a functional but not fully polished prototype.

Test and Gather Feedback: Test the eLearning prototype by sharing it with stakeholders and a sample of learners. Gather feedback using open-ended questions to encourage detailed responses on its clarity, usability, and engagement.

Iterate and Refine: Use the feedback gathered in the step above to identify areas of improvement and refinement of the design. Undertake multiple rounds of testing and adjustments for continuous improvement and optimization of the learning experience and to reach closer to the final, polished version.

Document and Share: Document and share the feedback and iterations throughout the prototyping process to maintain transparency and keep all stakeholders informed. Use this documentation as a valuable reference for future improvements, tracking progress, and to ensure consistency in design decisions.

Validating with Learners: Conduct usability or A/B testing to validate the eLearning prototype with learners and confirm the effectiveness of the design decisions. Use this final testing phase to ensure that the content, interactions, and structure resonate with the target audience and meet learning objectives.

Implementation and Launch: Use the refined eLearning prototype to transition it into the final learning product, ensuring that all elements are polished and ready for launch. Continue monitoring learner feedback even after implementation to assess the program’s effectiveness, identify areas for further improvements, and maintain the program’s relevance over time.

How AI will Further Enhance Rapid eLearning Prototyping

Driven by the power of AI, L&D stands at the cusp of a significant transformation. AI is not only speeding up the design and development process, but also enhancing rapid eLearning prototyping by automating content generation, personalization, and testing. AI-driven analytics provide real-time feedback for continuous optimization and quicker iterations of prototypes. And, with Generative AI becoming more embedded in L&D tools, the speed and scale of rapid eLearning prototyping is becoming transformative. Here’s a quick snapshot of how AI is accelerating the rapid eLearning prototyping:

Quick Content Creation: AI automates eLearning content generation, including text, multimedia, and learning modules, enabling L&D to prototype faster, possibly in a fraction of the time spent earlier.

Predictive Insights: AI-driven predictive analytics analyzes patterns in user behavior and content interaction to assess learner engagement potential, enabling L&D to identify the elements that are most likely to resonate with learners and optimize prototypes early.

Smart Feedback Interpretation: AI analyzes learner responses in real time, detecting emotional cues and preferences to provide valuable insights for refining prototypes, thereby facilitating data-driven adjustments for improved learner experience and effectiveness of the eLearning prototype.

Seamless Iteration: AI-driven automation streamlines the revision process. By quickly implementing changes based on feedback, it allows L&D to make adjustments efficiently and frees up time for designers to focus on strategic improvements.

Conclusion

Rapid prototyping for eLearning development is an important strategic tool for delivering effective eLearning programs and optimizing ROI. By facilitating testing of emerging designs and refining ideas before expensive implementation, it allows L&D teams to explore creative ideas, identify potential flaws early, and make quick adjustments, for greater resource efficiency.

With a systematic approach of defining goals, selecting fidelity levels, and gathering feedback, eLearning prototypes establish clear expectations and ensure alignment with learner needs. Furthermore, through iterative design that is based on real-time feedback from stakeholders and learners, eLearning prototypes support continuous refinement of training content and ensure a more engaging and effective learning experience.

The growing adoption of AI and generative AI in L&D will further enhance rapid prototyping by automating content creation, providing predictive insights, and enabling smarter feedback analysis. This combination of eLearning prototypes and AI-driven tools will significantly accelerate the development process, making it more flexible and focusing on creating impactful learning solutions that help drive ROI.

0 notes

Text

Nr.337, The German 4x4 Horch 1A personnel car.

The Horch 1A (or: Horch 108) was a German off-road passenger car from the interwar period and World War II. The first prototypes of this car were built in the mid-1930s, and serial production started in 1938 and lasted until 1941.

The length of the vehicle was 4.85 m, with a height of 2.04 m and a width of 2 meters. The curb weight was up to 3,600 kilograms. The drive was provided by a single, 8-cylinder Auto-Union engine with a capacity of 3.8 liters and power up to 81 HP. With time, however, the Ford engine (produced in Germany) with a capacity of 78 HP was used.

The Horch 1A was developed for the needs of the German armed forces, which, along with its rapid growth after 1933, aimed at obtaining a universal, light and possibly reliable passenger-off-road vehicle. The Horch plant met these needs by developing the vehicle presented below.

The vehicle uses such solutions as, for example, all-wheel drive, independent suspension of each wheel or the possibility of turning all wheels. Anyway, the last solution turned out to be highly unsuccessful in the course of operation.

It is worth noting that already in the course of World War II, the design of the car was simplified, which was manifested by, for example, the abandonment of the recesses in the fuselage for spare wheels. Horch 1A served in the German armed forces on virtually all fronts until 1945.

24 notes

·

View notes

Text

3D Printing in Architecture

3D printing, once a novelty in the tech world, has now firmly established itself as a game-changer in various industries, including architecture. The ability to create intricate models, prototypes, and even full-scale structures has opened up new possibilities for architects, engineers, and builders. In this blog post, we'll explore how 3D printing is revolutionizing architecture, from design concepts to construction practices.

Design Innovation

One of the most significant impacts of 3D printing in architecture is the freedom it provides in design. Traditional methods often limit architects to certain shapes and structures due to material and construction constraints. However, with 3D printing, these limitations are lifted. Architects can now experiment with complex geometries and organic forms that were previously impossible or too costly to achieve. This has led to a surge in innovative designs, pushing the boundaries of what architecture can be.

Prototyping and Modeling

Before the advent of 3D printing, creating detailed architectural models was a time-consuming and expensive process. With 3D printing, architects can quickly produce accurate scale models of their designs, allowing for better visualization and refinement. This rapid prototyping capability enables architects to identify potential issues early in the design process, saving time and resources in the long run. Additionally, clients can better understand the architect's vision through tangible models, leading to more effective communication and collaboration.

Sustainability and Efficiency

3D printing also offers significant benefits in terms of sustainability and construction efficiency. Traditional construction methods often generate a considerable amount of waste due to material overuse and mistakes. In contrast, 3D printing uses only the necessary amount of material, significantly reducing waste. Additionally, many 3D printing materials can be recycled or are made from sustainable resources, making this technology more environmentally friendly.

Moreover, 3D printing can streamline the construction process. Structures can be printed on-site, reducing the need for transportation and minimizing the carbon footprint associated with moving materials and equipment. This method also allows for faster construction times, which is particularly beneficial for large-scale projects or emergency housing needs.

Cost-Effective Construction

The cost of building with traditional methods can be prohibitive, especially for complex or custom designs. 3D printing offers a more cost-effective alternative by reducing labor costs and material waste. The precision of 3D printing ensures that only the exact amount of material needed is used, which not only lowers costs but also increases the structural integrity of the building. For developing countries or regions with limited resources, 3D printing presents a viable solution for affordable housing and infrastructure.

Challenges and Future Prospects

While 3D printing in architecture holds great promise, it is not without challenges. The technology is still relatively new, and large-scale 3D printing for buildings requires further development. Issues such as material limitations, regulatory hurdles, and the need for skilled operators must be addressed. However, ongoing research and innovation in the field are likely to overcome these challenges in the coming years.

#architectdesign#design#interior design#home interior#interiordoor#interior decorating#architecture#interiorstyling#interiors#home#3D#3d printing

34 notes

·

View notes

Text

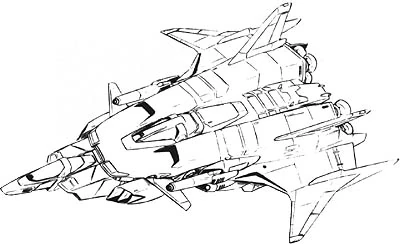

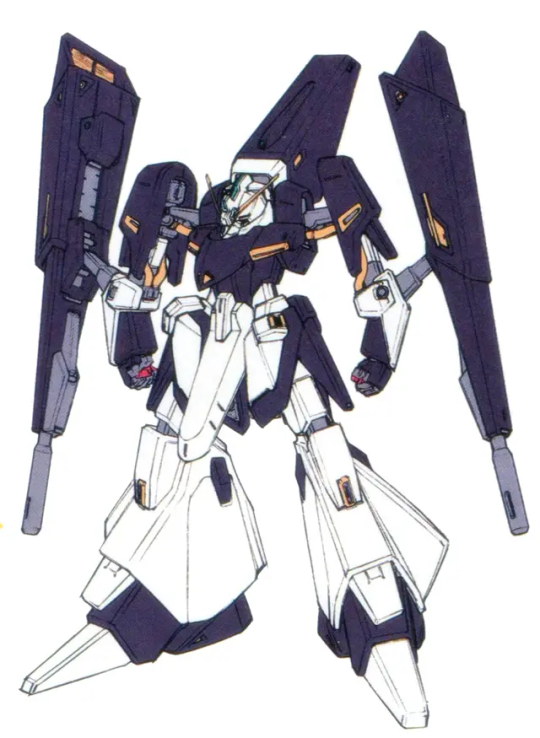

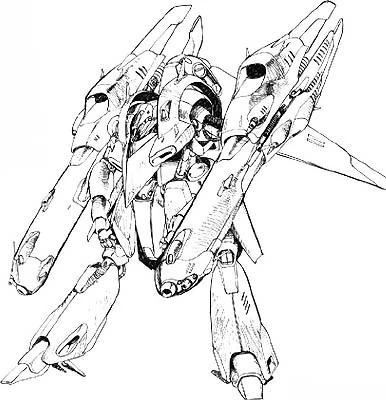

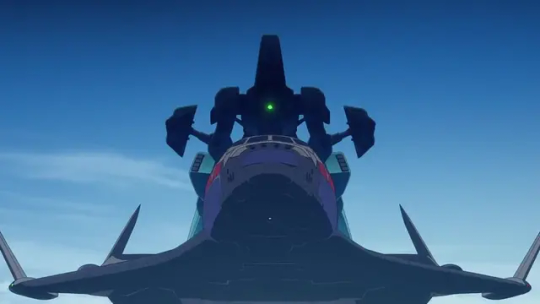

The ORX-005 Gaplant

With more incursions on Earth itself by Zeon remnant factions and other militant groups, the Federation sought a solution to the issue of MS mobility under gravity. While any mobile suit could make use of a sub-flight unit - such as the Dodai or Base Jabber - they were generally unreliable in combat situations, with rapid maneuvering potentially causing riders to lose balance.

Federation engineers began doing what they do best, and eventually produced the RX-78E Gundam GT-FOUR to serve as a proof of concept.

The machine - while plagued with issues - proved the viability of variable mobile suits, and was considered a success. With this success, the team was given the green light to continue development of variable machines.

The ORX-003 Domingo was one such machine, and would serve as the basis for development going forward. The Domingo stood at an impressive 25 meters in order to accommodate its transformation mechanism. It boasted an impressive mobile suit to mobile armor transformation time of under five seconds, but needed almost a full ten seconds to transform back.

The ORX-005 Gaplant saw its first deployment in UC 0085 as a joint project between the Augusta and Oakland research labs, incorporating lessons learned from the Domingo.

While the issue of unassisted flight was unimportant in space, the Gaplant was developed with space use in mind. Its MA mode was able to make use of the Active Mass Balance Auto-Control (AMBAC) system almost as efficiently as the MS mode, affording it extreme maneuverability.

However, this maneuverability came at a steep cost, and most pilots were unable to handle the intense g-force exerted on them in combat maneuvers. The Gaplant could only be handled by so-called Cyber-Newtypes, thanks to their enhanced bodies.

The Gaplant saw use during the Gryps conflict, where it was fielded by the Titans. At least two standard units are known to have existed at the time - piloted by Rosamia Badam and Yazan Gable respectively, with an unknown number of modified and/ or experimental units.

The Gaplant was also extensively experimented with by the Titans Test Team, resulting in a number of unconventional units, with some eventually falling into the hands of Zeon remnant groups. Recovered Gaplant prototypes were even modified and fielded by groups such as Karaba and the AEUG.

In UC 105, a group of hijackers used a Gaplant to approach and board Haunzen flight 356.

Known sightings of the Gaplant later on are rare. Notably, in U.C. 203, the wreckage of a Gaplant inspires Afranche Char to fight the Federation when it washes up on the shore of his home island.

The ORX-005 Gaplant was originally designed by Kazumi Fujita for the 1985 anime Moblie Suit Zeta Gundam.

This post was a request! Requests are always welcome!

27 notes

·

View notes

Text

CNC development history and processing principles

CNC machine tools are also called Computerized Numerical Control (CNC for short). They are mechatronics products that use digital information to control machine tools. They record the relative position between the tool and the workpiece, the start and stop of the machine tool, the spindle speed change, the workpiece loosening and clamping, the tool selection, the start and stop of the cooling pump and other operations and sequence actions on the control medium with digital codes, and then send the digital information to the CNC device or computer, which will decode and calculate, issue instructions to control the machine tool servo system or other actuators, so that the machine tool can process the required workpiece.

1. The evolution of CNC technology: from mechanical gears to digital codes

The Beginning of Mechanical Control (late 19th century - 1940s)

The prototype of CNC technology can be traced back to the invention of mechanical automatic machine tools in the 19th century. In 1887, the cam-controlled lathe invented by American engineer Herman realized "programmed" processing for the first time by rotating cams to drive tool movement. Although this mechanical programming method is inefficient, it provides a key idea for subsequent CNC technology. During World War II, the surge in demand for military equipment accelerated the innovation of processing technology, but the processing capacity of traditional machine tools for complex parts had reached a bottleneck.

The electronic revolution (1950s-1970s)

After World War II, manufacturing industries mostly relied on manual operations. After workers understood the drawings, they manually operated machine tools to process parts. This way of producing products was costly, inefficient, and the quality was not guaranteed. In 1952, John Parsons' team at the Massachusetts Institute of Technology (MIT) developed the world's first CNC milling machine, which input instructions through punched paper tape, marking the official birth of CNC technology. The core breakthrough of this stage was "digital signals replacing mechanical transmission" - servo motors replaced gears and connecting rods, and code instructions replaced manual adjustments. In the 1960s, the popularity of integrated circuits reduced the size and cost of CNC systems. Japanese companies such as Fanuc launched commercial CNC equipment, and the automotive and aviation industries took the lead in introducing CNC production lines.

Integration of computer technology (1980s-2000s)

With the maturity of microprocessor and graphical interface technology, CNC entered the PC control era. In 1982, Siemens of Germany launched the first microprocessor-based CNC system Sinumerik 800, whose programming efficiency was 100 times higher than that of paper tape. The integration of CAD (computer-aided design) and CAM (computer-aided manufacturing) software allows engineers to directly convert 3D models into machining codes, and the machining accuracy of complex surfaces reaches the micron level. During this period, equipment such as five-axis linkage machining centers came into being, promoting the rapid development of mold manufacturing and medical device industries.

Intelligence and networking (21st century to present)

The Internet of Things and artificial intelligence technologies have given CNC machine tools new vitality. Modern CNC systems use sensors to monitor parameters such as cutting force and temperature in real time, and use machine learning to optimize processing paths. For example, the iSMART Factory solution of Japan's Mazak Company achieves intelligent scheduling of hundreds of machine tools through cloud collaboration. In 2023, the global CNC machine tool market size has exceeded US$80 billion, and China has become the largest manufacturing country with a production share of 31%.

2. CNC machining principles: How code drives steel

The essence of CNC technology is to convert the physical machining process into a control closed loop of digital signals. Its operation logic can be divided into three stages:

Geometric Modeling and Programming

After building a 3D model using CAD software such as UG and SolidWorks, CAM software “deconstructs” the model: automatically calculating parameters such as tool path, feed rate, spindle speed, and generating G code (such as G01 X100 Y200 F500 for linear interpolation to coordinates (100,200) and feed rate 500mm/min). Modern software can even simulate the material removal process and predict machining errors.

Numerical control system analysis and implementation

The "brain" of CNC machine tools - the numerical control system (such as Fanuc 30i, Siemens 840D) converts G codes into electrical pulse signals. Taking a three-axis milling machine as an example, the servo motors of the X/Y/Z axes receive pulse commands and convert rotary motion into linear displacement through ball screws, with a positioning accuracy of up to ±0.002mm. The closed-loop control system uses a grating ruler to feedback position errors in real time, forming a dynamic correction mechanism.

Multi-physics collaborative control

During the machining process, the machine tool needs to coordinate multiple parameters synchronously: the spindle motor drives the tool to rotate at a high speed of 20,000 rpm, the cooling system sprays atomized cutting fluid to reduce the temperature, and the tool changing robot completes the tool change within 0.5 seconds. For example, when machining titanium alloy blades, the system needs to dynamically adjust the cutting depth according to the hardness of the material to avoid tool chipping.

3. The future of CNC technology: cross-dimensional breakthroughs and industrial transformation

Currently, CNC technology is facing three major trends:

Combined: Turning and milling machine tools can complete turning, milling, grinding and other processes on one device, reducing clamping time by 90%;

Additive-subtractive integration: Germany's DMG MORI's LASERTEC series machine tools combine 3D printing and CNC finishing to directly manufacture aerospace engine combustion chambers;

Digital Twin: By using a virtual machine tool to simulate the actual machining process, China's Shenyang Machine Tool's i5 system has increased debugging efficiency by 70%.

From the meshing of mechanical gears to the flow of digital signals, CNC technology has rewritten the underlying logic of the manufacturing industry in 70 years. It is not only an upgrade of machine tools, but also a leap in the ability of humans to transform abstract thinking into physical entities. In the new track of intelligent manufacturing, CNC technology will continue to break through the limits of materials, precision and efficiency, and write a new chapter for industrial civilization.

#prototype machining#cnc machining#precision machining#prototyping#rapid prototyping#machining parts

2 notes

·

View notes

Text

THE NEXT ZELDA

Things I Think The Devs Are Thinking About

This is the 2nd in a series of posts ruminating on the future of the series. This is Speculation- Not Inevitable Reality!

Part 2: ZELDA DUNGEON MAKER

They’ve been flirting with this idea for a while. EOW itself started as an attempt to scratch this itch, but was quickly swapped to its summoning gimmick. Something tells me this fixation isn’t gone yet.

The past 3 games are all about extreme functionality and toolsets given to players. They have explored weapon and tool creation, object manipulation, engineering gizmos/contraptions/transportation/automotons, sensors and timers and switches and traps and environmental blocks, monster spawning, chemistry play, status effects, and even modular room building for players. All of which has been baked in with a lot of physics.

Honestly, if you look at in it’s entirety… wouldn’t you say we have most of the pieces needed to make an interesting dungeon that can be expressed through some kind of building gameplay? Not saying they can just copy paste this stuff but, the devs have the experience and code under their belt to put all that in one experience tangibly.

Imagine all of the powers and equipment and tools from the past three games unified under one hood, and you’re walking/floating around building all the stuff. wouldn’t you say you could build a dungeon with all of that if it was optimized to do so and ran on a system with some *beef*?

And they have nearly a decade of deeply explored rapid & explosive prototyping with puzzles and traversal courses, modular dungeon systems, flexible puzzle solutions, and repetitive asset reutilization from a game dev angle because of the Wild Era Games. The shrines really highlight their efficiency and process here- and they literally use the player toolset to assist in making shrine Puzzles in TOTK as well. They have the experience to teach players how to make good dungeon design based on their knowledge and established modular systems and ensure it’s accessible. And while the shrines are far from perfect…. They illustrate that puzzle solutions can be satisfying even if intended solutions sometimes are missed-which is great for aspiring dungeon makers who might not be big brain rube-goldbergian designers. In many ways, they’ve been play testing ALL that with the shrines, no?

This is not to mention they remain consistently and vehemently oriented towards player freedom and agency. That seems to be something they want for the foreseeable future. Love it or hate it, Aonuma has his eyes and heart on this broadly speaking and envisions future titles to exploring player agency.

And, they are 100% aware of the dungeon critique & know people are deeply opinionated about what they want in dungeon design…soooo why not give them the power to make their own dungeons or play in other’s works? In the same way that they were absolutely shocked at what people created in TOTK, there’s a lot that they could learn from players, and there is a lot of incredible and boundless gameplay that could be made. This could be an incredible mutually beneficial exchange.

Let’s not forget the impact of Speedrunners and youtubers absolutely busting up everything BOTW’s world. A lot of what we got in TOTK was informed by people using glitches to do insane things on social media. All the devs did was iterate on and make accessible much of what was done and gave tools to go farther. A LOT of items and tools were informed by them. Bless those streamers. TOTK has an explosive engineering and glitch community aimed at cracking the game wide open, and its because of that enablement.

And here’s another thing that I think could be interesting under this hood-

Music. We already have examples of playing instruments and making music in MULTIPLE zelda games. What if you could make your own soundtracks ala oot/mm or mariopaint/animal crossing? Imagine you go pick up instruments and play and record them for your dungeon.

The thing I think they haven’t addressed, is that they need to figure out if there is a story to be had or if this is something that doesnt need one. If its a spinoff or literally just Mario Maker: Zelda Edition, it’s less pressing, but maybe less interesting to them.

Spinoff or not, multiplayer or not, imagine these:

-you are Ganon and this is Dungeon Keeper 3. You must build layers and contraptions to stop link & Zelda and claim power! This could be a great downfall timeline game.

-you are Link/Zelda trying to excavate ruins of temples, dungeons, fossils of old biomes, towns, etc, fitting them together, finding the right assemblage(or close enough to it) and going through time to solve and experience mysteries of the past

-you are a sage, trying to teach young link and or zelda the necessary skills to face ganon. Make puzzles and challenges that level up our heroes and prepare them for dungeons and the fight against ganon.

But maybe they aren’t ready for this yet and have yet another toolkit to make and explore. I think if this doesn’t happen we should be paying attention to what the core powers are in the next game.

And something that tilts away from this is… there are some pretty miffed fans who are yearning for some extremely restrictive challenge and are yearning for structured, clear play. EOW is in part, an attempt to address this… and it kinda does point towards a hopeful future for structured-zelda nerds.

This one seems less likely to be implemented in the Next Zelda than the Duo Protagonist concept… but it feels like it’s there. Silently. Maybe existing only as a motivator to explore new mechanics as devs.

Time will tell!

#the next zelda#game design#switch 2#tears of the kingdom#legend of zelda#breath of the wild#echoes of wisdom#speculation#game analysis#game development#part 2#zelda analysis

4 notes

·

View notes

Text

Binary Circuit - Open AI’s O3 Breakthrough Shows Technology is Accelerating Again

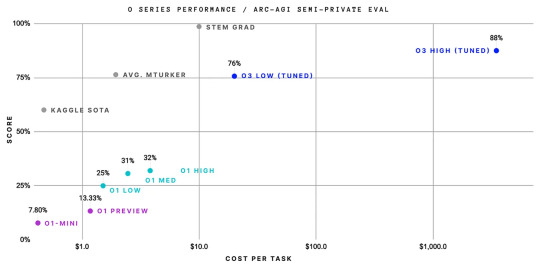

OpenAI model o3 outperforms humans in math and programming with its reasoning. It scored an impressive 88% on the advanced reasoning ARC-AGI benchmark. A big improvement from 5% earlier this year and 32% in September. Codeforces placed O3 175th, meaning it can outperform all humans in coding.

Image Source: ARC Price via X.com

Why Does It Matter? Most notable is the shorter development cycle. O3 launched months after O1, while previous AI models required 18-24 months.

Unlike conventional models that take months of training, o3 enhances inference performance. This means discoveries might happen in weeks, not years. This rapid technology advancement will require organizations to reassess innovation timeframes.

Impact on Businesses Many complex subjects can be developed faster after the o3 breakthrough.

Scientific Research: Accelerate protein folding, particle physics, and cosmic research

Engineering: Quick prototyping and problem-solving

Math: Access to previously inaccessible theoretical domains

Software Development: Enterprise-grade code automation

An Enterprise Competitive Playbook: Implement AI reasoning tools in R&D pipelines quickly. In the coming years, organizations will have to restructure tech teams around AI, and AI-first R&D will become mainstream.

Feel free to visit our website to learn more about Binary Circuit/Green Light LLC and explore our innovative solutions:

🌐 www.greenlightllc.us

2 notes

·

View notes

Text

Building the World's First True Reverse Video Search Engine

While it may not be widely known, no true video search engine currently exists. Services that claim to offer "reverse video search" are, in fact, merely searching via static images or individual frames, and they are transparent about these limitations.

The reason for this is simple: searching entire videos is a highly complex and resource-intensive task. The technical challenges and costs associated with processing full-length videos have made it prohibitive—until now.

At Comexp Research Lab, we have developed a new approach, based on the Theory of Active Perception (TAPe), that allows us to tackle these challenges with a fraction of the usual computational resources.

Leveraging TAPe, we’ve created an innovative solution capable of handling complex information processing problems in a more efficient manner. This breakthrough has enabled us to develop a new video search engine—essentially Google for videos—which we’ve named TAPe Reverse Video Search (RVS). In this article, we detail the journey toward building this pioneering technology and outline the progress we’ve made to date.

A Tangible Milestone: Creating the First True Reverse Video Search Engine

At Comexp Research Lab, our work has focused on developing services based on our proprietary video-by-video search technology, which mimics the efficiency of human perception. The TAPe model represents a significant departure from traditional search methods by utilizing a perceptual approach rooted in group theory.

In our discussions with peers, investors, and the general public, we typically delve into the Theory of Active Perception (TAPe) and present demonstrations that are conceptually straightforward. Yet, the feedback is often the same: “This is fascinating, but can you show us something more concrete?”

This year, we reached that milestone. We’ve launched a prototype of our video-by-video search engine. Although still in its early stages, the engine indexes videos much like how Google began by indexing text-based websites. In Google’s case, as the volume of indexed sites grew, so did its ability to deliver rapid, relevant search results. The same principle applies to video search, albeit with far greater challenges.

Indexing video content requires substantially more computational resources than indexing text. Even with modern technologies, the process remains slow, costly, and inefficient. For this reason, no major company—Google included—currently offers a fully realized video search engine that searches entire videos. This is where TAPe provides a significant advantage.

Revolutionizing Video Search with TAPe

Our search engine, powered by TAPe, enables users to search a vast archive of indexed video content to locate specific videos. The process begins by comparing the user’s video query against the indexed database and delivering the most relevant matches.

The Theory of Active Perception (TAPe) is a set of novel methods we’ve developed that fundamentally changes how information is processed. This approach allows us to achieve results that are orders of magnitude more efficient than conventional methods—using thousands of times less computational power, less time, and fewer resources overall.

Given the rapidly increasing volume of video content, we began by indexing feature films, documentaries, and TV series. As of now, our system has indexed 80,000 movies. This forms the foundation of our search engine, similar to how textual search engines require comprehensive indexing to be effective.

Additionally, we’ve expanded our capabilities to include television search. Our system tracks broadcasts from major global TV channels, allowing users to discover when and where specific video content, such as TV episodes, has aired. Our next major goal is to index YouTube content, which will significantly enhance the power of TAPe RVS.

Introducing ComexpBot: A Practical Application of TAPe Video Search

To facilitate the use of TAPe RVS and explore potential applications, we’ve developed a Telegram-based bot called ComexpBot. This tool allows users to search for films, TV series, and broadcasts by submitting video fragments instead of traditional text or image queries.

For example, a user might upload a brief clip or GIF, and the bot will quickly identify the corresponding film or series if it exists in our database. The bot returns detailed information, such as the title of the content, links to related websites (like IMDB), and even available trailers.

One of the most striking features of the bot is its ability to recognize videos from small, low-resolution snippets—sometimes as small as 260 pixels. This showcases the efficiency of TAPe’s video sequence processing, which significantly reduces the computational overhead compared to traditional frame-by-frame analysis.

The Underlying Technology: How TAPe Works

Unlike traditional computer vision techniques that rely heavily on convolutional neural networks (CNNs) and deep learning, TAPe employs a unique methodology. Rather than focusing on individual frames, TAPe processes sequences of frames—typically around 5 seconds of video—at once. This approach is counterintuitive but far more efficient than analyzing frames individually, especially considering that a 5-second video segment can consist of 120 to 300 frames.

Importantly, TAPe does not require pre-trained models, as most computer vision systems do. Instead, it learns in real time during the recognition process, much like human perception. This real-time learning enables TAPe to bypass many of the computationally expensive steps involved in traditional video processing. As a result, TAPe can extract the minimal number of features necessary to identify video content, leading to a significantly more efficient search process.

By creating a lightweight “cast” of each video—known as a tape-index—TAPe captures the essential characteristics of the content, which allows for fast and accurate searches. This method drastically reduces storage requirements and computational complexity.

Looking Forward: The Future of TAPe and Video Search

TAPe’s potential extends far beyond its current application in video search. While we are focusing on video recognition and analytics, the underlying technology has broader implications for fields such as artificial intelligence, machine learning algorithms, CPU and GPU development, autopilot systems, and real-time video analytics.

We are also planning to offer the TAPe Video Search API, which will enable researchers and enterprises to analyze vast amounts of video content more efficiently. Additionally, we are developing an extension of the TAPe API for website developers, making it accessible to a wider audience.

One of our most ambitious goals is to index YouTube content, beginning with the platform’s most popular videos. Although this represents only a small fraction of the total content on YouTube, it still amounts to a staggering 2,500 years' worth of video footage. We are confident that TAPe’s efficiency will allow us to tackle this challenge within a reasonable timeframe.

As the use of video content continues to grow exponentially, the demand for efficient, large-scale video search solutions will only increase. TAPe’s revolutionary approach positions it to play a key role in meeting this demand, providing a sustainable and scalable solution for video search in the digital age.

#machine learning#machinelearning#video#computer vision#science#neuroscience#youtube#video search#search engine optimization

2 notes

·

View notes

Text

Elevating Precision Manufacturing: The Role of Mekalite’s CNC Machining Service

In today’s competitive manufacturing landscape, precision, efficiency, and adaptability are key to staying ahead. CNC machining has emerged as a vital technology, enabling manufacturers to produce complex and high-precision parts consistently. At Mekalite, we are redefining excellence in CNC machining services by combining advanced technology, a skilled workforce, and a commitment to quality.

https://mekalite.com/

What is CNC Machining?

CNC (Computer Numerical Control) machining is a process that uses computerized controls to operate machinery and tools with high accuracy. This enables the production of intricate parts from a variety of materials, including metals and plastics, while maintaining tight tolerances. CNC machining is critical in industries such as aerospace, automotive, medical devices, and electronics.

Why Choose Mekalite for CNC Machining?

Mekalite sets itself apart by offering a comprehensive approach to CNC machining, ensuring every project is handled with precision and care.

Advanced Machinery and Capabilities Our cutting-edge, multi-axis CNC machines allow us to handle even the most complex designs with precision and consistency. Whether you need rapid prototyping, low-volume manufacturing, or full-scale production, Mekalite’s technology enables us to meet your unique needs.

Customized Solutions We understand that every project is different. Mekalite works closely with each client to understand their specific requirements, delivering tailored solutions that align with their design and functionality goals.

Strict Quality Assurance At Mekalite, quality is our top priority. Our rigorous quality control protocols cover every step of the production process, from material selection to final inspection. This commitment ensures every part meets the industry’s highest standards.

Industries Served by Mekalite

Mekalite’s CNC machining services support a diverse range of industries, including:

Aerospace: High-precision components for engines, structural parts, and aircraft interiors.

Automotive: Custom engine parts, suspension components, and detailed bodywork.

Medical: Surgical instruments, implants, and diagnostic equipment requiring tight tolerances.

Electronics: Housing frames, connectors, and precision parts for delicate devices.

Benefits of Partnering with Mekalite

Choosing Mekalite as your CNC machining service provider offers numerous advantages:

High Precision and Accuracy Our state-of-the-art CNC machines, combined with skilled operators, enable us to achieve exceptional accuracy and repeatability across all projects.

Wide Range of Materials Mekalite’s expertise spans across various materials, from metals like stainless steel and aluminum to specialized plastics. This flexibility allows for innovative product designs and customized applications.

Cost Efficiency and Scalability With automated processes and minimal manual intervention, CNC machining reduces labor costs while enhancing efficiency. Whether you need a single prototype or a large production run, Mekalite’s scalable services can adapt to your requirements.

Timely Deliveries Time is crucial in manufacturing. Our efficient workflows and commitment to meeting deadlines ensure that your projects are completed on schedule, every time.

Looking Ahead: Mekalite’s Commitment to Innovation

Mekalite is committed to staying ahead of industry trends and technological advancements. By continually investing in the latest CNC machinery and refining our processes, we aim to provide even more innovative and reliable solutions to our clients. Our vision is to be a trusted partner in helping businesses achieve new levels of success through precision manufacturing.

Conclusion

CNC machining is revolutionizing the manufacturing industry, and Mekalite is at the forefront of this transformation. Our combination of cutting-edge technology, tailored solutions, and a dedication to quality makes us a preferred partner for businesses across various sectors.

If you’re looking for a reliable CNC machining service provider that delivers precision and value, Mekalite is here to help. Contact us today to discuss your next project!

https://mekalite.com/

2 notes

·

View notes