#Remote I/O modules

Explore tagged Tumblr posts

Text

The industrial landscape is undergoing a metamorphosis, driven by the transformative power of the Internet of Things (IoT) and the dawn of Industry 4.0. At the heart of this revolution lies seamless communication between a myriad of machines and devices that populate the factory floor. This symphony of data exchange hinges on two crucial technologies: Remote Input/Output (I/O) modules and Industrial IoT (IIoT) Gateways. Let's delve into the intricate dance between these technologies and how they unlock the true potential of Industry 4.0.

Demystifying Remote I/O Modules

In today's era of smart work, remote I/O modules serve as extended hands for the factory's control system, enabling signal collection and control from sensors and actuators spread throughout the facility. Connected to a central controller via communication protocols like Modbus or Ethernet, these modules enable real-time monitoring and control, even for distant locations within the factory.

IIoT Gateways: The Vital Link

IIoT Gateways serve as the critical bridge between the bustling industrial world and the ever-evolving information age. IIoT Gateways are devices that serve as intermediaries between sensors, machines, and the cloud in Industrial Internet of Things (IIoT) systems. These gateways collect, process, and transmit data from connected devices to cloud-based platforms for analysis and action. IIoT Gateways play a crucial role in facilitating real-time monitoring, analysis, and control of industrial processes, leading to improved efficiency, productivity, and decision-making in manufacturing environments.

The Power of Integration

Visualise an expansive factory floor adorned with strategically placed sensors and actuators. Remote I/O modules, serving as the backbone, seamlessly collect data from these dispersed devices. The IIoT Gateway assumes the role of the central nervous system, consolidating data from multiple remote I/O modules and perfectly transmitting it to the "brain" – cloud-based analytics and control applications. This harmonious integration heralds a new era of possibilities for Industry 4.0

0 notes

Text

Importance of Using Industry 4.0 Sensors: Check Pros!

Industry 4.0 sensors have become fundamental instruments in many industries, particularly manufacturing, automotive, and logistics. In manufacturing, these technologies provide real-time monitoring of the manufacturing processes, early identify the potential risk of equipment failure, and reduce downtime.

Similarly, logistics companies take advantage of 4.0 sensors and remote I/O modules because these devices permit efficient inventory scheduling, route optimisation, and tracking of items in transit, leading to cost savings and higher customer satisfaction.

In the automobile industry, they enable predictive maintenance, maintain continuous operations and improve vehicle safety.

Pros and Cons of Using Advanced 4.0 Sensors and I/O Modules:

Well-established technical module suppliers deliver top-notch quality advanced human-automation technical solutions to increase productivity, process optimisation, predictive maintenance, proactive decision-making, and performance improvement.

Although, many businesses often think about initial implementation costs, and potential job displacement due to automation, as considered as a few cons of implementing advanced technology like I/O modules or 4.0 sensors.

Despite these difficulties, the overall benefits of employing such technology usually surpass the drawbacks, especially when implemented by lab-tested top-notch quality devices and properly handled by experts.

Well-established suppliers of these advanced human-machine interfaces, provide appropriate training for skill development to operate and optimise the devices along with solving any potential challenges associated with implementing these advanced technologies.

These technologies improve operations, maximise efficiency, and immediate updates on machine health to minimise downtime.

It also enables preventative maintenance processes and simplifies data-driven decision-making.

They allow businesses to respond quickly to changing market demands, increase product quality, and maintain a competitive edge in the industry.

These solutions enable smart businesses to make and carry out quality decisions with minimal human intervention.

They will have a better opportunity to begin integrating 4.0 sensor practices, procedures, and technology than practising traditional technology.

Therefore, businesses should contact only reliable services that can guide them to implement advanced technologies with certification in advanced technical training and control.

How to Find a Trusted Supplier of Advanced Technology Supplier?

It requires thorough research and study to find a reliable supplier of advanced technology like 4.0 sensors or I/O modules.

Identify reliable manufacturers with a demonstrated track record of creating high-quality HMIs.

Consider product reliability, customisation choices, interoperability with existing systems, and after-sales assistance.

Read client testimonials and case studies to determine satisfaction levels. Again, seek guidance from industry counterparts and engage with HMI technology experts.

Contact suppliers to get comprehensive technical support, regular updates, and warranties.

Finally, check and compare overall services, pricing, and customer service, and select the most dependable supplier for your business needs.

Source

0 notes

Text

Was the moon landing fake using CGI? No, this idea is impossible

(picture from the Apollo 11 moon landing Wikipedia Page)

There is an interesting theory that says the moon landing by the crew of Apollo 11 was filmed using Computer-generated imagery or in a studio on Earth.

I am not sure where these people get their ideas from as Computer-generated imagery (CGI) at the time was not that good. In fact, it was rubbish, and not that convincing, you can see examples of this in the picture and the article below, entitled The History of CGI in the Movies.,

Also, movie special effects in the 1960s were mostly done by models, animation, or other practical methods, not computers.

(Picture above from article "8 Bit Sprites to WebGL: How Computer Graphics Have Changed the World" a link to this article can be found in the reference section of this blog post)

They also did not film it in a movie set on Earth, as the lighting and movements of the Astronauts would be all wrong. It could have only been filmed on the moon.

As to the question, some moon landing deniers used in the past to justify their claims, which is

"How did they film the Astronauts coming out of the landing module or LM, as no Astronauts got out at this stage"

This issue can easily be solved by the fact that there was a remote camera mounted to the side of the landing module, or LM, which was moved into position and started filming before the astronauts got out.

(The weird ideas that moon consistency theorists have can be easily researched and easily debunked, probably even by a child moon landing fan as it is that easy and not hard to understand.)

This proves that consistency theory people do not know anything about the subject they are debunking and don't even have a basic understanding of history, science, or photography for, that matter.

Below is an interesting video by the MythBusters as they dismantle ideas, followed by moon landing deniers.

Also, check out photographer Dave McKeegan's video and his YouTube channel below, where he debunks moon landing theory claims, especially the claims that the pictures and videos of the moon landing were faked on Earth.

youtube

Dave McKeegan

References:

Apollo 11 - Wikipedia

Moon landing conspiracy theories - Wikipedia

Moon landing conspiracy theories debunked

The History of CGI in Movies

8-Bit Sprites to WebGL: How Computer Graphics Have Changed the World

Take note, consistency theory, people, maybe the meme below mocking you is correct, and the meme below shows 1980s CGI, not 1960s

Also, check out my history blog version

#moon landing#history#apollo 11#cgi#technology#Youtube#compuer graphics#special effects#space#science#moon

4 notes

·

View notes

Text

Interesting Papers for Week 23, 2023

On the role of feedback in image recognition under noise and adversarial attacks: A predictive coding perspective. Alamia, A., Mozafari, M., Choksi, B., & VanRullen, R. (2023). Neural Networks, 157, 280–287.

Human-level play in the game of Diplomacy by combining language models with strategic reasoning. Bakhtin, A., Brown, N., Dinan, E., Farina, G., Flaherty, C., Fried, D., … Zijlstra, M. (2022). Science, 378(6624), 1067–1074.

The case against probabilistic inference: a new deterministic theory of 3D visual processing. Domini, F. (2023). Philosophical Transactions of the Royal Society B: Biological Sciences, 378(1869).

Efficient stabilization of imprecise statistical inference through conditional belief updating. Drevet, J., Drugowitsch, J., & Wyart, V. (2022). Nature Human Behaviour, 6(12), 1691–1704.

Noradrenergic signaling mediates cortical early tagging and storage of remote memory. Fan, X., Song, J., Ma, C., Lv, Y., Wang, F., Ma, L., & Liu, X. (2022). Nature Communications, 13, 7623.

Place cells dynamically refine grid cell activities to reduce error accumulation during path integration in a continuous attractor model. Fernandez-Leon, J. A., Uysal, A. K., & Ji, D. (2022). Scientific Reports, 12, 21443.

Dopamine promotes head direction plasticity during orienting movements. Fisher, Y. E., Marquis, M., D’Alessandro, I., & Wilson, R. I. (2022). Nature, 612(7939), 316–322.

Dynamic control of decision and movement speed in the human basal ganglia. Herz, D. M., Bange, M., Gonzalez-Escamilla, G., Auer, M., Ashkan, K., Fischer, P., … Brown, P. (2022). Nature Communications, 13, 7530.

Deep brain stimulation creates informational lesion through membrane depolarization in mouse hippocampus. Lowet, E., Kondabolu, K., Zhou, S., Mount, R. A., Wang, Y., Ravasio, C. R., & Han, X. (2022). Nature Communications, 13, 7709.

Human hippocampal responses to network intracranial stimulation vary with theta phase. Lurie, S. M., Kragel, J. E., Schuele, S. U., & Voss, J. L. (2022). eLife, 11, e78395.

Dissociable behavioural signatures of co-existing impulsivity and apathy in decision-making. Petitet, P., Zhao, S., Drew, D., Manohar, S. G., & Husain, M. (2022). Scientific Reports, 12, 21476.

Oscillations support short latency co-firing of neurons during human episodic memory formation. Roux, F., Parish, G., Chelvarajah, R., Rollings, D. T., Sawlani, V., Hamer, H., … Hanslmayr, S. (2022). eLife, 11, e78109.

Decreased Modulation of Population Correlations in Auditory Cortex Is Associated with Decreased Auditory Detection Performance in Old Mice. Shilling-Scrivo, K., Mittelstadt, J., & Kanold, P. O. (2022). Journal of Neuroscience, 42(49), 9278–9292.

A perceptual glitch in serial perception generates temporal distortions. Sierra, F., Muralikrishnan, R., Poeppel, D., & Tavano, A. (2022). Scientific Reports, 12, 21065.

Behavioral and neural representation of expected reward and risk. Sun, S., Cai, C., & Yu, R. (2022). NeuroImage, 264, 119731.

Depolarization block in olfactory sensory neurons expands the dimensionality of odor encoding. Tadres, D., Wong, P. H., To, T., Moehlis, J., & Louis, M. (2022). Science Advances, 8(50).

Subjective time is predicted by local and early visual processing. Tonoyan, Y., Fornaciai, M., Parsons, B., & Bueti, D. (2022). NeuroImage, 264, 119707.

The encoding of touch by somatotopically aligned dorsal column subdivisions. Turecek, J., Lehnert, B. P., & Ginty, D. D. (2022). Nature, 612(7939), 310–315.

Free energy model of emotional valence in dual-process perceptions. Yanagisawa, H., Wu, X., Ueda, K., & Kato, T. (2023). Neural Networks, 157, 422–436.

Environment Symmetry Drives a Multidirectional Code in Rat Retrosplenial Cortex. Zhang, N., Grieves, R. M., & Jeffery, K. J. (2022). Journal of Neuroscience, 42(49), 9227–9241.

#science#Neuroscience#computational neuroscience#Brain science#research#cognition#neurons#neurobiology#cognitive science#neural networks#neural computation#psychophysics#scientific publications

39 notes

·

View notes

Text

How Advanced Components Like the 1769-L24ER-QBFC1B and Industrial Ethernet Switches Are Shaping Smarter Automation

Industrial automation continues to evolve, with modern facilities prioritizing real-time communication, precise control, and seamless device integration. From intelligent controllers to advanced networking gear, the foundation of smart manufacturing relies heavily on dependable hardware. Among the standout tools enabling this transformation are the 1769-L24ER-QBFC1B, the compact yet powerful Allen Bradley controller series, versatile Industrial Ethernet Switches, and legacy-supporting adapters like the 1784-U2DHP.

Why Controllers Like the 1769-L24ER-QBFC1B Matter

Tight control over machine processes starts with the right logic controller. The 1769-L24ER-QBFC1B, part of Allen Bradley's CompactLogix line, is built for integrated motion and control applications. Offering embedded digital, analog, and high-speed counter I/O, this controller is particularly effective in systems where space is limited, but versatility cannot be compromised.

Its dual Ethernet ports support device-level ring topologies, adding fault tolerance and reducing downtime—a critical factor in high-output environments.

The Role of a Modern Allen Bradley Controller in Scalable Systems

Modern automation isn’t just about basic on/off control; it's about data-driven decisions, predictive maintenance, and remote diagnostics. The Allen Bradley controller family—such as the 5069-L320ERMS3—brings high-speed processing, built-in safety, and seamless integration with Studio 5000 software, supporting everything from packaging lines to advanced robotics. These controllers enable synchronized motion, streamlined programming, and scalable deployment.

Reliable Communication Starts with Industrial Ethernet Switches

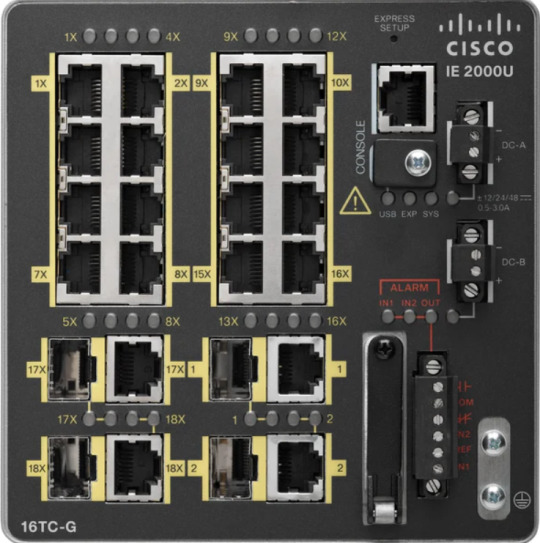

Data flow across industrial networks must be both fast and secure. That’s where an Industrial Ethernet Switch like the Cisco IE-2000-16TC-G-E comes into play. Engineered for harsh environments, this switch features robust build quality and supports advanced switching protocols like QoS and VLANs—ensuring smooth traffic management even in network-heavy setups.

In automation systems where devices like HMIs, PLCs, and I/O modules constantly communicate, an industrial-grade switch ensures that data isn’t just fast—it’s also reliable and isolated from disruptions.

Bridging the Gap with 1784-U2DHP

While modern systems lean on Ethernet-based protocols, many plants still operate legacy systems that use older communication methods like Data Highway Plus (DH+). The 1784-U2DHP adapter serves as a bridge, allowing USB-equipped laptops to interface with DH+ networks. It provides essential diagnostic and programming access to older equipment, extending the lifecycle of valuable assets and supporting a phased modernization strategy.

Final Thoughts

Industrial control systems today demand more than just speed—they need resilience, flexibility, and smart connectivity. From an intuitive Allen Bradley controller like the 1769-L24ER-QBFC1B to rugged Industrial Ethernet Switches and legacy support tools like the 1784-U2DHP, these technologies together form the backbone of intelligent automation systems.

0 notes

Text

IOy Series with SNMP Support — PLC+I/O+Protocol Gateway

Smart, modular I/O modules designed for efficient remote monitoring and management. With built-in edge intelligence and flexible I/O options, IOy enables seamless SNMP integration for networked industrial systems, improving visibility. Simplify industrial monitoring, from edge to core. 📈

0 notes

Text

Allen Bradley Micro820 Controller

The Allen-Bradley Micro820 is a small PLC that maintains functionality while being especially tailored for situations with limited space. In addition to embedded analog and digital I/O, built-in Ethernet, a microSD slot, and compatibility for extension I/O modules, it comes in 20-point I/O variants. The Micro820 allows developers to design intelligent control systems without the need for large, costly hardware because to its compact size and wide range of functions.

Integrated I/O and Communication

Expansion Capability

microSD Card Slot

Real-Time Clock

Connected Components Workbench (CCW) Software

Remote Access Support

1 note

·

View note

Text

In today's industrial setup , efficiency reigns supreme. Businesses are constantly seeking ways to streamline processes, boost productivity, and gain a competitive edge. Here’s how Remote I/O modules are changing the perspective. These intelligent devices act as the crucial link between your central control system and the vast network of sensors and actuators spread across your factory floor. But Remote I/Os are no longer just simple data collectors. The latest advancements are revolutionising the way the operations used to be optimised , and let’s take a look at how Instrutel, a frontrunner in industrial automation solutions, is being part of this change.

Remote I/O Modules: The Backbone of Industrial Automation

Remote I/O modules serve as distributed workstations for your central control system. Imagine them as miniature control centres strategically placed near sensors and actuators throughout your facility. These modules collect data from sensors (inputs) like temperature, pressure, or flow rates, and send control signals (outputs) to actuators like motors, valves, and pumps. This eliminates the need for complex, sprawling wiring systems, simplifying plant layout and maintenance.

The Future Technology and Trends in Remote I/Os

The future of Remote I/O modules is brimming with exciting possibilities, driven by advancements in various technological domains. Here's a closer look at some key trends shaping the landscape:

1. Edge Computing and Analytics:

● Traditional Remote I/O modules primarily focus on data collection and transmission. However, the future lies in edge computing. This empowers Remote I/O modules to process and analyse data locally, closer to the source. Imagine modules performing basic anomaly detection or predictive maintenance calculations, enabling faster response times and proactive decision-making.

0 notes

Text

SIMATIC S7 1200: The Smart Choice for Industrial Automation

It is well known that automation generally plays a very important role in the improvement of efficiency, precision, and productivity within various industrial sectors. SIMATIC S7-1200 from Siemens is considered the best known and widely used versatile automation controller. This S7-1200 is a compact yet powerful PLC for small and medium-sized automation projects, providing flexibility, scalability, and durable performance.

What is SIMATIC S7-1200?

The SIMATIC S7-1200 is a programmable logic controller (PLC) developed by Siemens. It is within the large industrial automation portfolio that Siemens has to offer. The S7-1200 has been built to meet the requirements of modern industries with its intuitive engineering environment, advanced communication capabilities, and increased processing power. With applications from process automation to machine control and data acquisition, the S7-1200 can be easily integrated into systems.

Core features of the SIMATIC S7-1200

Compact and Modular: The S7-1200 PLC is designed to fit into very small spaces; this makes it perfect for small control cabinets. It is therefore modular, so that one can add additional modules to it in case these are needed.

Integrated PROFINET Communication: Makes it possible to attach to any industrial network and communicate easily with any other device over PROFINET. It could allow remote access along with cloud connectivity especially for Industry 4.0 applications.

Efficient Programming with TIA Portal: The TIA Portal by Siemens stands for Totally Integrated Automation that allows easy programming and configuration. Simple diagnostics, monitoring, and troubleshooting interface are available through TIA portal.

High-Speed Processing and Reliability: Execution of control logic would be very fast because of the robust processor that S7-1200 has. The equipment is to be adapted for usage under long-term operation in the industry, so it will work reliably even in harsh conditions.

Flexible I/O Variants: It is equipped with internal digital and analog I/O and has add-on options as well. It can act as a support to a vast array of sensors and actuators making it flexible depending on what the application is.

Applications for SIMATIC S7-1200

Wide industrial uses of the SIMATIC S7-1200 PLC:

1. Manufacturing and Production Lines:

Assembly line, conveyor system, and robot application automation.

Monitoring and control of production processes lead to improved efficiency.

2. Packaging and Material Handling:

Optimizing the packaging systems for food, pharmaceuticals, and consumer goods.

Control of automated warehouse and material handling systems.

3. Water and Wastewater Management:

Management of pumps, valves, and treatment processes for water supply and waste management efficiently.

4. HVAC and Building Automation:

Control of heating, ventilation, and air-conditioning for energy savings.

Add Security in Building Automation and Lighting Management.

5. Renewable Energy and Applications of Smart Grids:

Control of solar and wind systems.

Grid integration and real-time monitoring.

Reasons to Choose SIMATIC S7-1200 for Your Automation Needs.

The S7-1200 PLC has an optimum performance-to-price ratio for its domain, providing an adequate solution for medium to low-scale automation. Easy system integration increases productivity and allows future expansions. Robust security features maintain data integrity and protection against illegitimate access.

Conclusion

The SIMATIC S7-1200 is an excellent choice when it comes to reliable and advanced PLCs for industrial automation. It provides all the features needed for a training course in programming, communication, and modern automated industrial systems.

Naksh Technology Solutions LLP supplies Siemens PLCs, HMIs, and drives with quality automation solutions. Call us today to find out how the S7-1200 PLC can enhance your industrial processes and ramp up efficiency levels!

0 notes

Text

Introducing XMPS-2000: Messung's Advanced PLC Programming Software

Messung - Industrial Automation & Controls

Next generation Industrial Automation & Control Solutions for complex industrial processes, machines & production lines.

Messung Industrial Automation is proud to unveil the XMPS-2000 software, a powerful and intuitive Windows-based utility designed to enhance the programming experience for the XMPRO-10 PLC series. With a focus on user-friendly interfaces and robust functionalities, XMPS-2000 is set to redefine efficiency in industrial automation.

Key Features of XMPS-2000:

· User-Friendly Environment:

The software offers an intuitive interface, ensuring a seamless experience with various software tools.

· Programming Flexibility:

XMPS-2000 supports the standard Ladder programming language, making it compatible with a wide range of applications. The software complies with IEC 61131-3 Standards.

· Online Diagnostics:

Real-time diagnostics functionality allows users to monitor runtime status effectively.

Advanced Programming Capabilities:

· Hardware Configuration:

Facilitates CPU and I/O modules hardware configuration, simplifying system setup.

· Logic Blocks:

Enables the creation of subroutines that can be called within the main block, promoting organized and modular programming.

· Monitor Table:

Allows for user-defined tags, communication variables, and a watch window for real-time monitoring of discrete and analog I/Os.

· Online Monitoring:

Supports real-time monitoring of ladder programs and generates cross-references for efficient debugging.

· Force Value Functionality:

Permits value forcing during program testing, aiding in thorough validation processes.

· User Library:

Offers the creation of user-defined function blocks for customized tasks or specific applications, enhancing reusability.

System Configuration Management:

· Comprehensive Selection:

Allows selection of XMPRO CPU, local and remote I/O expansion modules, and displays total I/O count.

· Communication Parameterization:

Facilitates communication ports parameterization, supporting protocols like MODBUS TCP and RTU.

Hardware Selection Visualization:

· Detailed Display:

Provides visualization of hardware configurations for selected CPUs and I/O modules, with direct parameter configuration and viewing.

I/O Configuration:

· Assignment Flexibility:

Supports I/O assignment for onboard, expansion, and remote I/O modules, with mode selection for analog inputs and outputs.

· System-Generated Addresses:

Automatically generates I/O addresses, simplifying the configuration process.

Program Structure:

· Efficient Tools:

Features a toolbar with shortcuts to ladder elements and instructions, a project management window for file creation, and a program edit window in standard ladder format.

· Compiler and Monitoring:

Includes a compiler window for error display, an online monitor window for real-time project monitoring, and a watch window for user-selected variables.

The XMPS-2000 software exemplifies Messung's commitment to delivering innovative and efficient solutions in industrial automation. By integrating advanced features with a user-centric design, XMPS-2000 empowers engineers and technicians to achieve higher productivity and precision in their automation projects.

For more information and to experience the capabilities of XMPS-2000, contact Messung Industrial Automation.

0 notes

Text

ARMxy SBC BL310 ARM Embedded Computer in Industrial Boiler Monitoring and control

Case Details

Boiler monitoring requires real-time acquisition of parameters such as temperature, pressure, and flow, execution of control logic, and data transmission to the cloud for analysis. The BL310 series, powered by the NXP i.MX6ULL Cortex-A7 processor (up to 800MHz), combined with rich I/O interfaces, flexible communication modules, and industrial-grade design, perfectly meets the complex requirements of boiler monitoring.

Industrial Environment Adaptability

Wide Temperature Range: Operates reliably from -40°C to 85°C, suitable for high- or low-temperature boiler room environments.

Electromagnetic Compatibility: Passes GB/T 9254 Class A and CISPR 32 Class A tests, ensuring resistance to electromagnetic interference and stable operation in industrial settings.

Protection and Installation: IP30 protection rating, aluminum alloy + stainless steel casing, and DIN35 rail mounting, ideal for space-constrained control cabinets.

1.2 Data Acquisition and Control

Versatile I/O Interfaces: Supports RS485, RS232, CAN, DI/DO, relays, AI/AO, RTD, and thermocouple signals through X-series and Y-series I/O boards, meeting the needs for temperature, pressure, and flow data acquisition in boilers.

Precise Control: Supports PWM output and pulse counting for valve control and flow monitoring.

Flexible Expansion: Built-in Mini PCIe interface supports WiFi/4G modules for wireless data transmission.

1.3 Communication and Cloud Integration

Industrial Protocol Support: Equipped with BLIoTLink software, supporting protocols like Modbus, BACnet, IEC104, MQTT, and OPC UA, enabling seamless integration with PLCs, SCADA systems, or cloud platforms (e.g., AWS IoT Core, Thingsboard).

Remote Management: BLRAT remote access tool facilitates device maintenance, reducing on-site operational costs.

Rapid Development: Integrated Node-Red enables quick development of IoT applications, simplifying data visualization and logic control.

Typical Application Scenarios in Boiler Monitoring

The BL310 can implement the following core functions in boiler monitoring:

Temperature Monitoring: Uses Y51/Y53 (PT100/PT1000) or Y58 (thermocouple) boards to measure boiler water and flue gas temperatures.

Pressure Monitoring: Acquires pressure sensor data via Y31/Y33 (4-20mA or 0-10V).

Flow Monitoring: Monitors fuel or water flow using Y95/Y96 (pulse counting).

Status Control and Alarms: Implements switching control and alarm outputs via Y01/Y02 (DI/DO) or Y24 (relay) boards.

Remote Monitoring: Transmits data to cloud platforms via 4G/WiFi modules and MQTT protocol for real-time boiler status monitoring.

Data Analysis: Leverages cloud platforms for historical data storage, trend analysis, and energy optimization.

Recommended Configuration

To meet boiler monitoring requirements, the following BL310 configuration is recommended:

Model: BL310L-SOM314-X4-Y51-Y24

Host: BL310L (with 4G module for remote monitoring).

SOM Module: SOM314 (512MB DDR3L, 8GB eMMC, -40~85°C, suitable for high storage and wide temperature needs).

X Board: X4 (2x RS485 + 2x CAN, for connecting to PLCs or other devices).

Y Board 1: Y51 (2-channel 3-wire PT100 for precise temperature monitoring).

Y Board 2: Y24 (4-channel relay output for controlling alarms or valves).

Software Configuration:

Pre-installed BLIoTLink and BLRAT, supporting Modbus-to-MQTT conversion and integration with Thingsboard or AWS IoT Core.

Node-Red for developing data dashboards to display real-time temperature, pressure, and other parameters.

Implementation Suggestions

4.1 Hardware Installation

Install the BL310 in the boiler control cabinet using DIN35 rail mounting, ensuring proper grounding via the 1-pin GND terminal.

Use a 24VDC power supply (supports 9-36V wide voltage range) with reverse polarity and overcurrent protection for enhanced safety.

Configure WiFi/4G antennas as needed to ensure stable signal transmission.

4.2 Software Development

Use Node-Red to quickly develop data acquisition, alarm logic, and visualization dashboards.

Configure BLIoTLink to collect Modbus RTU/TCP data and transmit it to the cloud via MQTT.

Set up BLRAT for remote access, enabling maintenance personnel to monitor device status in real time.

4.3 Testing and Validation

Conduct high/low-temperature and electromagnetic compatibility tests before deployment to ensure reliability in boiler room environments.

Refer to technical support’s Node-Red and BLIoTLink development examples for rapid function validation.

Test 4G/WiFi connection stability to ensure uninterrupted data transmission.

Precautions

I/O Board Selection: Note that Y63 (4x RS485/RS232) occupies two Y slots, preventing the addition of a second Y board.

Storage Needs: For large historical data storage, choose SOM314 (8GB eMMC) over SOM310 (256MB Nand).

Network Security: Configure MQTT authentication and encryption to prevent data breaches.

Custom Development: For special requirements (e.g., vibration monitoring), contact Beilai Technology for customization (see Technical Support section).

Conclusion

The BL310 ARM embedded computer, with its high-performance processor, versatile I/O interfaces, industrial-grade reliability, and flexible software ecosystem, provides an efficient and intelligent solution for boiler monitoring. By enabling real-time data acquisition, remote monitoring, and cloud platform integration, the BL310 significantly enhances the automation and operational efficiency of boiler systems, contributing to the advancement of industrial IoT and smart manufacturing. Whether for new boiler monitoring systems or upgrades to existing setups, the BL310 is a reliable and trusted choice.

0 notes

Text

0 notes

Text

ARMxy RK3588 Industrial Controller Modbus RTU to Modbus TCP for Protocol Bridging

BL450 Series ARM Embedded Computer is an industrial-grade ARM controller with flexible I/O configuration, based on the Rockchip RK3588J/RK3588 processor, featuring a quad-core ARM Cortex-A76 + quad-core ARM Cortex-A55 + triple-core ARM Cortex-M0 architecture, witha clock speed of up to 2.0G/2.4GHz. It is equipped with 32GB/64GB/128GB eMMC and 4GB/8GB/16GB LPDDR4X RAM and ROM configurations. Supporting a rich set of I/O interfaces, it also integrates a 6TOPS NPU, enabling deep learning capabilities. The BL450 series iswidely used in industrial control, edge computing, AIoT, artificial intelligence, communication management, AGV robots, machine vision inspection, robotics, industrial IoT gateways, energy storage systems, automation control, and transportation infrastructure.

BL450 Series ARM Embedded Computer offers 1 to 3 optional RJ-45 network ports, including two 10/100/1000M ports and one 10/100M adaptive port, along with 2×USB 3.1, one optional HDMI 2.1, and optional X-series and Y-series I/O boards for communication, PWM output, pulse counting, and other data acquisition and control functions. It supports 8K@30fps H.264 video encoding and 8K@60fps H.265 video decoding. Built-in Mini PCIe interface allows support for Bluetooth, WiFi, 4G, and 5G communication modules.

BL450 Series supports multiple operating systems, including Linux-5.10.209, Linux-RT-5.10.209, Ubuntu 20.04, Debian 11, and Android 13. It is also compatible with Docker containers, Node-Red, and Qt-5.15.10 for graphical development. The BLIoTLink industrial protocol conversion software enables fast industrial data acquisition and conversion, facilitating seamless integration with mainstream IoT cloud platforms and industrial SCADA software. Additionally, the BLRAT remote access tool provides remote access and maintenance, while Node-Red allows for rapid IoT application development.

Designed with professional electrical performance and high/low-temperature testing, the BL450 series operates reliably under harsh electromagnetic interference and extreme temperatures ranging from -40°C to 85°C. With DIN35 rail mounting, it is suitable for various industrial applications.

0 notes

Text

Rockwell Micrologix Series

MicroLogix PLCs are compact, cost-effective, and are commonly used in small to medium-sized industrial automation applications.

Models in the Series:

MicroLogix 1000: Compact, entry-level PLC with limited I/O capabilities.

MicroLogix 1100: Features built-in Ethernet communication and online editing.

MicroLogix 1200: Offers enhanced I/O capabilities and modular expandability.

MicroLogix 1400: Adds advanced networking, built-in Ethernet/IP, and expanded memory.

MicroLogix 1500: Modular, expandable with higher processing power.

Programming:

Uses RSLogix 500 or Connected Components Workbench (CCW) software.

Ladder logic programming language is primarily used.

Communication:

Supports protocols like Ethernet/IP, DF1, Modbus RTU, and DH485 depending on the model.

Some models include integrated Ethernet ports for remote monitoring and control.

I/O Options:

Digital and analog I/O available.

Expandable I/O modules (available for some models like MicroLogix 1200, 1400, and 1500).

Applications:

Suitable for small-scale automation tasks such as material handling, packaging, HVAC control, and machine automation.

Next Blog on Micrologix Expansion IO's

1 note

·

View note