#Robotic End-Effector

Note

howdy! I'm also a robot enthusiast and I'm trying to get better at designing robot characters. I absolutely adore all of your robot designs, especially the sweet salt cosmonauts! do you have any advice for designing robots?

Ohh thank you~!! ✨✨

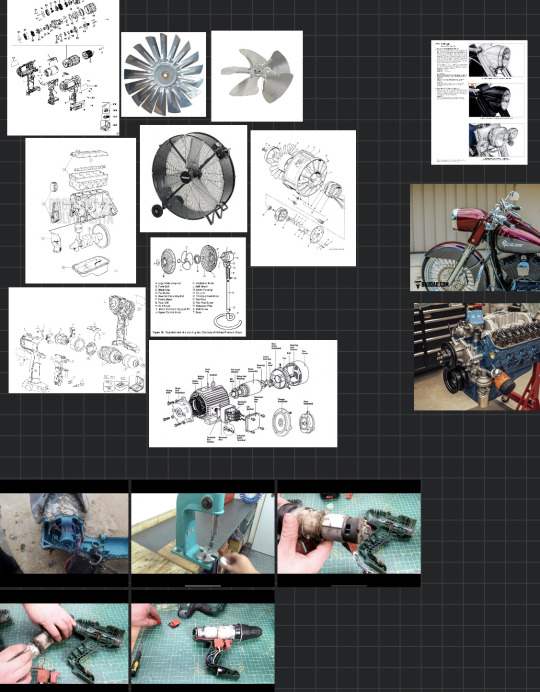

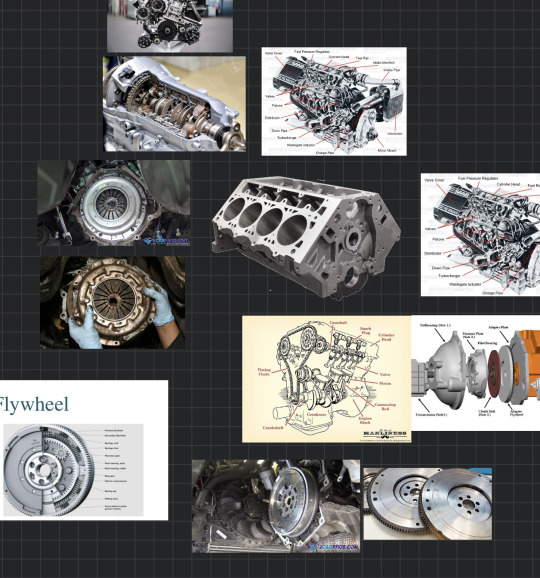

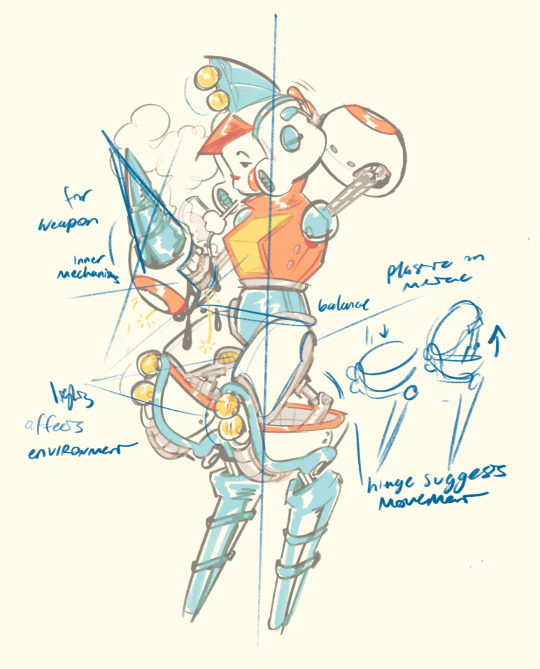

The biggest advice I can give is to study the functionality! That’s the most interesting part of robots to me, and influences all my designs. You definitely don’t have to understand the mechanics completely, but getting an idea of the basics, and knowing what the function and purpose of the robot is, and what parts help to carry out that function, is always a good starting place!

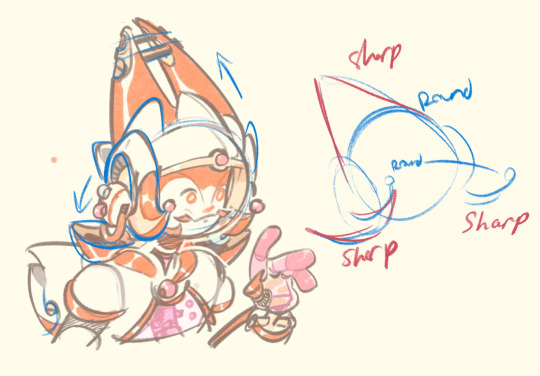

Here’s an example of how I was mostly focused on the saw mechanics of the shoulder, because that’s what was important to the story, and made the rest mostly aesthetic driven.

Whereas with Thylo, I had an idea of how I wanted his legs to look, and built the mechanics around that, to serve the aesthetic, but it also plays into his motion, and how he stands, and his balance.

For Snap, both her new and older designs are more personality driven, and wanted to keep her more ‘human’ elements more round and approachable, and her mechanical parts sharper, to sell that they’re weaponry, and that she’s both kind and a fighter. But even her sharp aspects are never perfectly straight, keeping it fun and light-hearted.

Her’s is also a transforming design, and every little piece serves that function, especially the head area, and I consider how the panels will fall or open, or attach. Again, it doesn’t have to be mechanically accurate, but if you’ve got a solid idea of how the physics work for the character, it really sells the design!

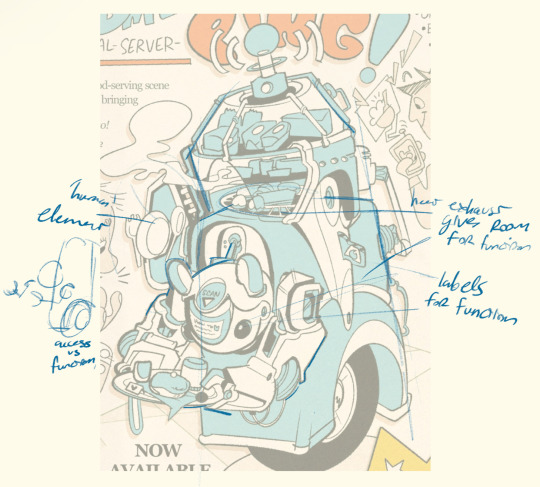

Even for less humanish designs, you can give a clear idea of the robot’s function through decals, or how it affects the environment/other characters.

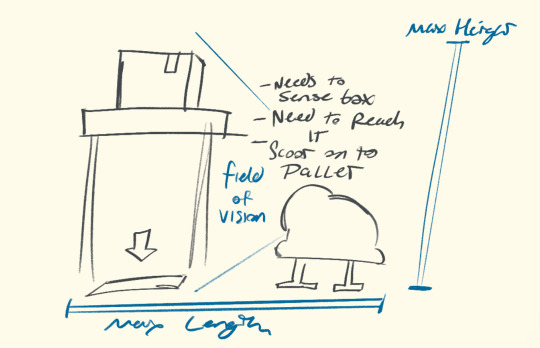

Here’s a little example: let’s say I wanna make a robot whose purpose is to lift boxes on top-shelves, and bring them down to a pallet. It would need a way to see the box, a way to reach it, and to push it onto the pallet.

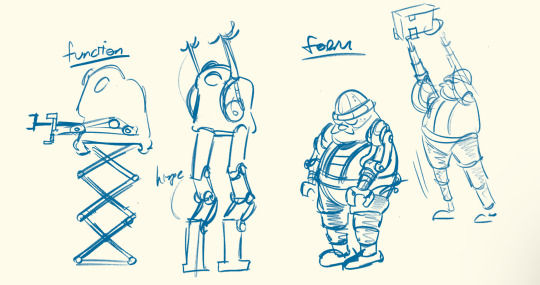

So, I’ll play with the idea of his functionality first. I could go with some sort of scissor lift, or hydraulic system, but I settle on mostly a telescoping mechanism, and build a little warehouse, or dock worker aesthetic around him.

In short, I’d say just study mechanism that interest you, play with their shapes, their motion, figure out the purpose or character of your robot, and how they function, and what ways you can best convey that through their design! Hope this helps! ✨

#sorry if that’s too rambly or incoherent I could go on for days about robots so I tried to keep it short#I didn’t even get into the degrees of freedom or end effectors lol#I guess it’s similar to drawing clothing in that it doesn’t have to be practical or realistic so long as it makes sense for the character#or the story or environment#but thanks so much for asking and hope this helps at least a little! ✨⭐️#asks#Thylo#Snap

83 notes

·

View notes

Text

Analyzing the Market Dynamics of Robot End Effector Market

The global robot end effector market size is expected to grow from USD 2.3 billion in 2023 to USD 4.3 billion by 2028, registering a CAGR of 13.5%.

Growing demand for modular end effectors, increasing adoption of cobots, penetration of automation in SMEs, and increasing adoption in the warehousing, pharmaceutical, and food industry are the main drivers for the growth of the robot end effector market.

The robot end-effector market will grow significantly due to its various applications in several industries, such as automotive, electrical & electronics, food & beverage, and pharmaceutical. Various key players in the market adopt different strategies such as acquisitions, product launches, collaborations, and partnerships to grow in the robot end effector market.

Download PDF Brochure:

https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=251736819

Driver: Increasing demand for modular end effectors by various industries.

Due to the fast-changing nature of industries, the demand for modular end effectors is increasing. This scenario is observed in the consumer goods industry, specifically packaging, where the shape, size, surface, or weight of the packaging is constantly changing. This shortens the life cycle of an end effector to 1 to 2 years and thereby increases the cost of replacement for the company. Modular end effectors have the capability to accommodate and handle a large variety of objects as required. A modular vacuum bar from Schmalz (Germany) can perfectly seal and lift objects regardless of their size; Zimmer Group (Germany) and Schunk (Germany) introduced a modular gripping system – MATCH with an unlimited range of uses from production and assembly to warehouse logistics, shipping, and even laboratory automation. This modularity ensures that the grippers do not have to be changed from time to time, thereby reducing the cost of redesigning and downtime associated with its change and replacement.

Restraint: High cost of deployment, especially for SMEs.

Small and medium-sized enterprises (SMEs) differ from large-scale industries such as automotive or electronics manufacturing in various ways. SMEs typically have a low threshold for capital expenditure, a low-risk appetite, and limited time to generate returns on their investment. Additionally, their applications are often specific and on a case-by-case basis. For instance, Saint-Gobain, a glass manufacturing company in France, required automation of its glass polishing process that was previously carried out manually. Robotiq successfully automated the process by programming its torque sensor to replicate the hand movements and pressure applied by a human. Unlike large industries, many SMEs have not built their infrastructure around deploying robots, and must often integrate them into their existing floor space at a later stage.

Opportunity: Advancement in robotics has surged the demand for soft grippers.

Advances in soft robotics, coupled with the increasing need to handle delicate items, have enabled rapid progress in soft grippers. Unlike traditional grippers that are made of rigid materials, these end effectors are fabricated from soft and flexible components. Earlier, most end effectors were able to only manipulate objects of fixed size and shape. However, industry requirements are slowly shifting toward the use of components that can grasp and manipulate a large variety of objects. Due to the material softness of the gripper arms, they can be used for sensitive applications such as in the food & beverage or glass manufacturing industries that can handle objects without damaging them. Fruits or vegetables have varying sizes, making soft grippers ideal due to their consistent clamping force irrespective of slight differences in size and shape. Soft grippers are mainly adopted by the food & beverage industry, one of the fastest-growing clients for soft grippers. Hence, the high penetration rate of automation in the food & beverage industry is expected to stimulate the adoption of soft grippers in the next 4 to 5 years.

Challenge: Interoperability and integration issues related to end effectors with existing facilities.

Interoperability is a very important function in any factory or manufacturing unit. There must exist a modular framework for both hardware and software to connect and coordinate various end effector systems. The focus is not only on the software side, which is used for programming, diagnosing, and monitoring but also the interchangeability of hardware between the end effector and robot arm. There have been cases in the robot end effector industry where a client has bought a robot arm and an end effector separately that were not fully compatible with each other, and the setup was a huge challenge from the onset.

0 notes

Text

The Essential Guide to Robotic Grippers: From End Effectors to Automation

Introduction:

The rise of automation has revolutionized countless industries, and robotic grippers play a fundamental role in this transformation. These ingenious mechanisms, also known as end effectors, act as the “hands” of robotic arms, enabling them to grasp, manipulate, and transport objects with precision.

This comprehensive guide delves deep into the world of robotic grippers. We’ll…

View On WordPress

#automation#Dexterous Grippers#End Effectors#Gripper Design#Machine Tending#Robotic Arms#Robotic Grippers

0 notes

Text

Robot End Effector Market Size, Share, Growth Analysis 2024 - 2030

0 notes

Text

youtube

youtube

youtube

youtube

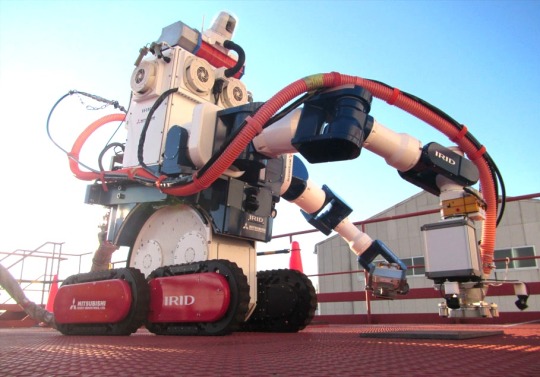

MEISTeR II (Maintenance Equipment Integrated System of Telecontrol Robot II), Mitsubishi Heavy Industries, Tokyo, Japan (2015). After the accident at Fukushima Daiichi Nuclear Power Plant in 2011, the interior of the reactor building is highly radioactive, and cannot be accessed by human workers. Remote controlled robots like MEISTeR II can carry out decontamination tasks using a range of specialised end-effectors. It can climb stairs, and it has a new "narrow space mode" that enables it to fold itself up into a compact form with a relatively tiny 85cm diameter footprint to navigate tight stairway landings. It even comes with its own decontamination train (second photo) for those stubborn radiological hazards.

59 notes

·

View notes

Text

"Late-Afternoon Meeting" (Reagan Ridley x Gender Neutral Reader One-shot)

Sequel ->

The straps of your mini backpack crumpled under your strong grip, and the robotic tentacle-like arm system you had within it struggled to stay inside it's tiny prison with your growing nervousness. You took a huff of air, which immediately went to waste when you screamed as someone suddenly grabbed your shoulder.

"Oh! Sorry- I'm really sorry, haha. Didn't think you'd react like that..." Brett, who's been your co-worker for the past few months, said with a regretful frown. He made a sad attempt at finger-gunning you before dropping one of his hands and rubbing his neck at the grimace worn on your face.

You sighed at his pitiful expression, before speaking up. "It's- It's fine Brett. I'm just kind of nervous right now." As you said this, your eyes cautiously wondered towards the double-doors in front of you.

"Oh, is this about the whole 'Reagan wants you in her lab later' thing? Cause if that's with this is about then I really don't think you need to worry!" He then proceeded to whisper not so discreetly into his hand, "Not that much at least."

You made a deadpan face at his unhelpful words, turning your head towards the entrance to Reagan's lab once more. You weren't scared of her, really! It's just that the way she always seemed to be glaring at you, not to mention always trying to one-up up you as if your lives were a constant competition, didn't exactly make you comfortable.

As if he could feel the anxiety pouring out of you, which he probably could, Brett gave you a reassuring pat on the shoulder. "Hey, don't worry too much! I mean, legally - Reagan isn't allowed to kill you." He said with a carefree smile, as if that'd make you feel any better. Instead you gave him a nasty side eye, watching as he scrambled to correct himself.

"I mean- Reagan's a nice person! Once you get to know her, which can take a while - but she's a nice person either way! You've got this broham!" He gave you an unconvincing thumbs up before running off in an awfully panicked manner for someone who considered Reagan to be 'harmless'. You couldn't blame him though, you feel bad for whoever will have to clean up your remains.

Taking one more deep breath - which this time didn't go to waste - you carefully opened Reagan's lab doors. And with a nonchalant 'come in' from Reagon herself, you stepped into the lion's den.

You could feel the way the air shifted as she stared up at you from one of her many desks, and when she put down the wire she was inserting to a coordinate frame of a robot, your breath hitched. "Right on time, although I thought you'd be a little earlier, this works out either or." She picked up a peculiar piece of metal as she made her way towards your form.

Reagan wiped one of her hands on her lab coat, avoiding eye contact like she always did, only this time her face was a little red. You raised a brow at her abnormal behavior, eyeing the steel piece in her hand, watching as she brought it closer to your face.

"Okay so, we both know that we match each other in our level of robotics, but-" she let out an almost aggressive sigh, "I was thinking about your technique and I found it to be, how do I say this? Interesting- I guess?" She briefly met your eyes, her glare harsher than it usually was.

"Look, what I'm trying to say is- I may have - kind of - replicated your style of robotics and created a prototype of some sort." She said the last bit in a fast paced fit of embarrassment, though your eyes could only focus on the piece of equipment in front of you.

It was just the end effector of an arm, but it seemed to sparkle with magic as you brought it closer to your eyes. "Wow, you made this, Reagan? It really does look similar to mine." You whispered in amazement.

"Pshh- I could make way better," She let her gaze fall onto your own, despite the fact that yours was still locked in on her creation. "But it is fun to experiment every once and a while." She let a gentle smile adorn her face.

"Are you going to make more? If you are, I could give you some blueprints so that you can really replicate my style?" Your eyes practically formed stars with your newfound excitement. Jumping in place, eagerly awaiting Reagan's answer while keeping the end effector safe in your hands.

Reagan held back a laugh at your animated demeanor, shaking her head almost fondly. "Maybe some other time, but uh- I actually wanted to ask you something." She patted her hands against her sides awkwardly, trying and failing to find the right words to express herself.

"I wanted to- I wanted us to- I don't know, do something? Together? Like an activity of some sort?" She hated the words that came out of her mouth, but anything was better than nothing, so she tried not to dawdle on her grievances.

You stared at her in confusion. Reagan? THE Reagan wanted to spend some time away from work to spend some time with YOU? Was this another run-in with her 'dating-robot-self'? You quickly did a once-over of her, seeing no shine on her skin, meaning this was definitely your Reagan.

"Uh, like a date?" Reagan's eyes widened and she instantly went to defend herself as if you had insulted her entire bloodline. Although, in reality she probably wouldn't care that much.

"NO! No- no of course not! Haha, I mean no way, you-" She lightly punched your arm. "-silly goose!"

The two of you stood in awkward silence, with Reagan's arm still extended from hitting you.

"Okay, yeah it's kind of a date, but- it's more like hanging out, y'know? Like those people with super close acquaintances do?"

You narrowed your eyes at her, "You mean friends?" She sighed.

"Yeah."

A warm smile made its way into your face, and you let out a laugh. "Man, if you wanted to hang out you didn't have to make everything feel so ominous!" You carefully set the steel end effector on one of Reagan's many desks, before making your way to her lab doors.

"What? What was ominous about it?" She stared up at you in confusion, a smile on her face nonetheless.

"You know- the whole 'always glaring at me thing' and the 'always trying to one-up me as if we're mortal enemies or something'! That wasn't exactly inviting." You let out an near sad laugh.

Reagan's smile faltered as the two if you continued to walk, entering the lift that would take you to the fake building entrance for Cognito Inc.

"Glaring at you? I don't think I was. I mean, admittedly I do stare at you a lot, but I'm not glaring!" Your cheeks warmed as she spoke, thinking about the implications of her words.

"And I'm not trying to one-up you! I'm just- trying to impress you, I guess. I've never actually met someone similar to me that I like." She let out a laugh, staring towards the ground as you focused on just her.

"You like me?"

Her eyes widened to the size of saucers, turning her head towards you so quickly you thought it'd spin right off. She opened her mouth, probably to defend herself again, but she seemed to realize something as she closed it instead.

"I guess I do, yeah?" She laughed again, this time a laugh filled with a warmth that matched her rosy cheeks. And as the Cognito Inc. doors closed behind you both, you realized it was a face you had never seen Reagan make.

"Well, I think I like you too." Reagan looked back at you, at first in shock, which then shifted to befuddled relief.

"That's... good? I'm not sure how to respond to something like that." You only took your eyes off her when you saw your bus pulling up.

"Well, maybe you should get used to it, I'll see you on our date, Reagan. Bye!" You frantically waved at her as you ran towards your bus. Watching as she slowly raised her hand to wave back, moving it back and forth in a state near of awe.

Watching as you hopped into your ride, Reagan let out a breath of shock. Out of all the ways this day could've ended, this had to be the best outcome. But as she thought about it more, she realized she didn't even have your number.

She laughed, punching the air violently as she made her way to her car. Oh well, she'd just ask Gigi for it.

#inside job#inside job x reader#reagan ridley#reagan ridley x reader#brett hand#gigi thompson#reader insert#gender neutral reader#x reader#one shot

463 notes

·

View notes

Text

Cancelled Missions: Testing Shuttle Manipulator Arms During Earth-Orbital Apollo Missions (1971-1972)

In this drawing by NASA engineer Caldwell Johnson, twin human-like Space Shuttle robot arms with human-like hands deploy from the Apollo Command and Service Module (CSM) Scientific Instrument Module (SIM) Bay to grip the derelict Skylab space station.

"Caldwell Johnson, co-holder with Maxime Faget of the Mercury space capsule patent, was chief of the Spacecraft Design Division at the NASA Manned Spacecraft Center (MSC) in Houston, Texas, when he proposed that astronauts test prototype Space Shuttle manipulator arms and end effectors during Apollo Command and Service Module (CSM) missions in Earth orbit. In a February 1971 memorandum to Faget, NASA MSC's director of Engineering and Development, Johnson described the manipulator test mission as a worthwhile alternative to the Earth survey, space rescue, and joint U.S./Soviet CSM missions then under study.

At the time Johnson proposed the Shuttle manipulator arm test, three of the original 10 planned Apollo lunar landing missions had been cancelled, the second Skylab space station (Skylab B) appeared increasingly unlikely to reach orbit, and the Space Shuttle had not yet been formally approved. NASA managers foresaw that the Apollo and Skylab mission cancellations would leave them with surplus Apollo spacecraft and Saturn rockets after the last mission to Skylab A. They sought low-cost Earth-orbital missions that would put the surplus hardware to good use and fill the multi-year gap in U.S. piloted missions expected to occur in the mid-to-late 1970s.

Johnson envisioned Shuttle manipulators capable of bending and gripping much as do human arms and hands, thus enabling them to hold onto virtually anything. He suggested that a pair of prototype arms be mounted in a CSM Scientific Instrument Module (SIM) Bay, and that the CSM "pretend to be a Shuttle" during rendezvous operations with the derelict Skylab space station.

The CSM's three-man crew could, he told Faget, use the manipulators to grip and move Skylab. They might also use them to demonstrate a space rescue, capture an 'errant satellite,' or remove film from SIM Bay cameras and pass it to the astronauts through a special airlock installed in place of the docking unit in the CSM's nose.

Faget enthusiastically received Johnson's proposal (he penned 'Yes! This is great' on his copy of the February 1971 memo). The proposal generated less enthusiasm elsewhere, however.

Undaunted, Johnson proposed in May 1972 that Shuttle manipulator hardware replace Earth resources instruments that had been dropped for lack of funds from the planned U.S.-Soviet Apollo-Soyuz Test Project (ASTP) mission. President Richard Nixon had called on NASA to develop the Space Shuttle just four months before (January 1972). Johnson asked Faget for permission to perform 'a brief technical and programmatic feasibility study' of the concept, and Faget gave him permission to prepare a presentation for Aaron Cohen, manager of the newly created Space Shuttle Program Office at MSC.

In his June 1972 presentation to Cohen, Johnson declared that '[c]argo handling by manipulators is a key element of the Shuttle concept.' He noted that CSM-111, the spacecraft tagged for the ASTP mission, would have no SIM Bay in its drum-shaped Service Module (SM), and suggested that a single 28-foot-long Shuttle manipulator arm could be mounted near the Service Propulsion System (SPS) main engine in place of the lunar Apollo S-band high-gain antenna, which would not be required during Earth-orbital missions.

During ascent to orbit, the manipulator would ride folded beneath the CSM near the ASTP Docking Module (DM) within the streamlined Spacecraft Launch Adapter. During SPS burns, the astronauts would stabilize the manipulator so that acceleration would not damage it by commanding it to grip a handle installed on the SM near the base of the CSM's conical Command Module (CM).

Johnson had by this time mostly dropped the concept of an all-purpose human hand-like 'end effector' for the manipulator; he informed Cohen that the end effector design was 'undetermined.' The Shuttle manipulator demonstration would take place after CSM-111 had undocked from the Soviet Soyuz spacecraft and moved away to perform independent maneuvers and experiments.

The astronauts in the CSM would first use a TV camera mounted on the arm's wrist to inspect the CSM and DM, then would use the end effector to manipulate 'some device' on the DM. They would then command the end effector to grip a handle on the DM, undock the DM from the CSM, and use the manipulator to redock the DM to the CSM. Finally, they would undock the DM and repeatedly capture it with the manipulator.

Caldwell Johnson's depiction of a prototype Shuttle manipulator arm with a hand-like end effector. The manipulator grasps the Docking Module meant to link U.S. Apollo and Soviet Soyuz spacecraft in Earth orbit during the Apollo-Soyuz Test Project (ASTP) mission.

Johnson estimated that new hardware for the ASTP Shuttle manipulator demonstration would add 168 pounds (76.2 kilograms) to the CM and 553 pounds (250.8 kilograms) to the SM. He expected that concept studies and pre-design would be completed in January 1973. Detail design would commence in October 1972 and be completed by 1 July 1973, at which time CSM-111 would undergo modification for the manipulator demonstration.

Johnson envisioned that MSC would build two manipulators in house. The first, for testing and training, would be completed in January 1974. The flight unit would be completed in May 1974, tested and checked out by August 1974, and launched into orbit attached to CSM-111 in July 1975. Johnson optimistically placed the cost of the manipulator arm demonstration at just $25 million.

CSM-111, the last Apollo spacecraft to fly, reached Earth orbit on schedule on 15 July 1975. By then, Caldwell Johnson had retired from NASA. CSM-111 carried no manipulator arm; the tests Johnson had proposed had been judged to be unnecessary.

That same month, the U.S. space agency, short on funds, invited Canada to develop and build the Shuttle manipulator arm. The Remote Manipulator System — also called the Canadarm — first reached orbit on board the Space Shuttle Columbia during STS-2, the second flight of the Shuttle program, on 12 November 1981."

source

#Apollo–Soyuz#Apollo Soyuz Test Project#ASTP#Apollo CSM Block II#CSM-111#Rocket#NASA#Apollo Program#Apollo Applications Program#Canadarm#Shuttle Manipulator Arms#Skylab Orbital Workshop#Skylab OWS#Skylab#Skylab I#Skylab 1#SL-1#Space Station#Apollo Telescope Mount#ATM#Cancelled#Cancelled Mission#my post

42 notes

·

View notes

Text

Universal Robots price in USA

Collaborative robots, or cobots, are a field in which Universal Robots (UR) is a pioneer in automated systems development. Thanks to their flexible, safe, and affordable automation solutions, these machines are redefining entire sectors. Considering Universal Robots' value proposition and price is crucial if you're considering making an investment in the USA.

Why Choose Universal Robots?

Flexibility

Ease of Use

Safety

Cost-Effective

Understanding the Price of Universal Robots in the USA

UR3e: $25,000 - $30,000

UR5e:$35,000 - $40,000

UR10e:$45,000 - $55,000

UR16e:$60,000 - $65,000

Factors Affecting the Price

End Effectors and Accessories

Software

Training and Support

Integration Costs

Return on Investment (ROI)

Increased Productivity

Reduced Labor Costs

Improved Quality

Scalability

Cobots from Universal Robots can be used for a variety of industrial applications, ranging from heavy lifting to small, precision operations. These cooperative robots provide a flexible, affordable option for companies trying to increase output, efficiency, and safety, with prices in the USA ranging from $25,000 to $65,000.

To know more click here:- Fortune Robotics

0 notes

Text

Palletizer Machines

A palletizer machine is a vital piece of equipment used in various industries for stacking products onto pallets in a systematic and efficient manner. By automating the process of arranging goods, palletizer machines improve productivity and reduce the need for manual labor, making them essential for large-scale production environments.

Types of Palletizer Machines

Palletizer machines come in different types, each suited to specific industries and product types. The common types include:

1. Conventional Palletizers

Conventional palletizers are designed to handle uniform products, such as boxes, cartons, and bags. They utilize mechanical arms or robotic technology to stack items in precise patterns.

2. Robotic Palletizers

Robotic palletizers are more flexible and can handle a wide variety of product shapes and sizes. These systems use robotic arms with end effectors to pick and place products on pallets in a pre-determined layout.

3. Inline Palletizers

Inline palletizers are designed for high-speed operations, usually found in industries where large volumes of uniform items need to be stacked quickly. These machines streamline the process by aligning products in a straight line for easy palletizing.

Key Features and Components

Palletizer machines consist of several key components, all working together to ensure efficient and accurate palletizing. The main components include:

1. Infeed Conveyor

This is where the products first enter the machine. The infeed conveyor guides the items to the palletizing area, ensuring they are correctly positioned.

2. Pallet Dispenser

The pallet dispenser automatically places an empty pallet in the palletizing zone. This ensures the system can operate continuously without manual intervention.

3. Layer Forming Area

In this section, the products are arranged into layers according to a preset pattern before being transferred to the pallet. The pattern can be adjusted based on the size and shape of the products.

4. Palletizing Robot or Mechanical Arm

The robotic arm or mechanical system is responsible for picking up the layers of products and placing them onto the pallet with precision. This component is the core of the palletizer machine.

5. Safety Systems

Modern palletizer machines come equipped with safety systems, such as sensors and emergency stop mechanisms, to ensure worker safety and prevent accidents during operation.

Benefits of Using a Palletizer Machine

Automating the vertical cartoner offers several advantages, making palletizer machines an attractive option for industries looking to optimize their production lines. Key benefits include:

1. Increased Efficiency

Palletizer machines significantly speed up the stacking process, allowing companies to handle larger volumes of products in less time.

2. Reduced Labor Costs

By eliminating the need for manual labor in the palletizing process, businesses can save on workforce expenses and reduce the risk of work-related injuries.

3. Improved Accuracy and Consistency

Palletizer machines ensure that products are stacked uniformly, reducing the risk of product damage and improving load stability during transportation.

4. Flexibility and Scalability

Robotic palletizers, in particular, offer the flexibility to handle various product types, making them ideal for businesses with diverse packaging needs.

Industries That Use Palletizer Machines

Palletizer machines are used in a wide range of industries, including:

Food and Beverage Industry: For stacking cartons, boxes, and bottles.

Pharmaceutical Industry: For handling delicate packages like medicine bottles and cartons.

Chemical Industry: For palletizing bags of chemicals and large drums.

Consumer Goods Industry: For arranging products like paper towels, toiletries, and packaged goods.

Conclusion

Palletizer machines are essential tools for modern manufacturing and distribution. Their ability to automate and streamline the palletizing process boosts productivity, reduces operational costs, and enhances safety. With technological advancements, the flexibility and functionality of palletizer machines continue to evolve, making them indispensable in various industries.

0 notes

Text

Robot End Effector Market is Register to Grow at a CAGR of 13.5% during 2023-2028

The global robot end effector market is expected to grow from USD 2.3 billion in 2023 to USD 4.3 billion by 2028, registering a CAGR of 13.5%. Increasing demand for modular end effectors and the growing adoption of collaborative robots due to the fast-changing nature of industries are among a few major factors driving the growth of the robot end effector market.

Key players operating in the robot end effector market include Schunk (Germany), Schmalz (Germany), Zimmer Group (Germany), Tünkers (Germany), and Destaco (US) are the top five players in the robot end effector market.

Download PDF Brochure:

https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=251736819

Grippers is expected to register a higher CAGR during the forecast period.

The market for grippers is largely driven by their handling application in a wide range of workpieces considering their various shapes and size. The increasing application of soft grippers and vacuum grippers in different varieties of handling and assembly applications across several industries would present several growth opportunities to players operating in the gripper segment.

Collaborative industrial robots to record the highest CAGR during the forecast period.

Robot end effector market for collaborative industrial robots is to grow at the highest CAGR during the forecast period. This is due to the adoption of collaborative robots, especially for small and medium-sized companies, to easily adapt to different tasks and enable a faster return on investment (ROI). These robots are witnessing widespread adoption in small and medium-sized enterprises and large-scale, traditional industries such as automotive. With the growing adoption of cobots in many new use cases, such as remote monitoring and remote manufacturing are being enabled, this factor is expected to propel the growth of the end effector market for collaborative industrial robots.

China is expected to account for the largest market share in Asia Pacific market from 2023 to 2028.

China accounted for the largest share of the robot end effector market in Asia Pacific in 2022 and is expected to remain the largest market throughout the forecast period. As many Asian countries are highly populated, and the geriatric population is becoming a concern for the future, the aging population, especially in China, is prompting companies toward automation and industrial robots to reduce costs. With the rise in industrial robots for automation, the demand for their associated end effectors is also expected to increase.

0 notes

Text

Assembly Lines have played an important role in the manufacturing industry ever since they were introduced by Henry Ford in the early 1900s. Evolution from manual to robotic assembly lines has benefited manufacturing not only in terms of precision and efficiency but also in terms of productivity and profitability.

Collaborative robots (Cobots) play a major role in assembly lines, alongside humans, especially in tasks involving small parts in hard-to-reach areas such as screwdriving, polishing, buffing, gluing, and pick-and-place. Besides, Cobots can be moved across assembly lines to perform diverse applications with precision.

We provide a wide range of solutions for industry in industrial automation and robotics as well as cobot's and end-effectors.

0 notes

Text

The Components Of Manipulators

Manipulators, often referred to as robotic arms or industrial robots, are versatile tools used in various industries for tasks that require precision, strength, or repetitive motion. They are designed to perform operations that are either dangerous, tedious, or beyond human capabilities. The functionality of a manipulator is determined by its parts, which work in unison to achieve the desired tasks.

The base of a manipulator is the foundation upon which the entire structure rests. It is typically mounted on a stable surface or integrated into a larger system. The base provides support and ensures that the manipulator remains stationary during operation. It is designed to withstand the weight and movement of the manipulator without compromising stability.

The arm is the primary component of a manipulator, responsible for the movement and positioning of the end effector. It is composed of multiple segments, each capable of rotating or extending to reach various points in space. The arm's design is crucial for the manipulator's range of motion and dexterity. It is often made of lightweight yet strong materials to small inertia and improve responsiveness.

Joints are the pivot points that allow the arm segments to move. They can be rotary, allowing for circular motion, or linear, enabling straight-line movement. The joints are equipped with actuators, such as motors or hydraulic systems, that provide the force necessary for movement. The precision and control of the joints are critical to the manipulator's ability to perform accurate and repeatable tasks.

The end effector is the terminal component of the manipulator, designed to interact with the environment. It can take various forms, such as grippers, suction cups, or specialized tools, depending on the task at hand. The end effector is typically attached to the arm via a quick-release mechanism, allowing for easy replacement or customization.

0 notes

Text

Exploring the Versatility of KHK Stock Gears Across Different Industries

Introduction

KHK Stock Gears, known for their precision and reliability, are essential components in various industrial applications. Their versatility makes them suitable for a wide range of industries, each with unique demands and challenges. As the authorized distributor of KHK Stock Gears, Seimitsu Factory Automation is proud to support these industries with high-quality gears that meet the highest standards of performance and durability.

Automotive/Automobile Industry

In the automotive industry, KHK gears play a crucial role in several key applications. They are integral to power transmission systems, ensuring smooth and efficient operation. Steering mechanisms also rely on these precision gears for accurate control. Furthermore, with the rise of electric vehicles, KHK gears are essential components in various EV systems. Successful implementations of KHK gears in the automotive sector demonstrate their reliability and efficiency in enhancing vehicle performance.

Robotics

Precision is paramount in robotics, and KHK gears are designed to meet this need. They are widely used in joint actuation, providing the necessary movement and control for robotic arms. End-effector mechanisms, which perform tasks such as gripping and manipulating objects, also benefit from the precision of KHK gears. Additionally, autonomous navigation systems in robots depend on these gears for reliable operation. Examples of KHK gears enhancing robotic performance can be seen in advanced manufacturing robots and automated guided vehicles (AGVs).

Aerospace Industry

The aerospace industry demands gears that can withstand high stress and extreme conditions. KHK gears are used in critical applications such as landing gear systems, flight control mechanisms, and satellite deployment systems. Their reliability and durability ensure safe and efficient operation in these high-stress environments. The use of KHK gears in aerospace demonstrates their ability to perform under the most demanding conditions, contributing to the overall safety and success of aerospace missions.

Medical Equipment

Precision and reliability are crucial in medical equipment, and KHK gears excel in these areas. Surgical robots, which require precise movements and control, utilize these gears to perform delicate procedures. Diagnostic machines, such as MRI and CT scanners, rely on KHK gears for accurate and reliable operation. Prosthetic devices also benefit from the precision and durability of these gears, enhancing the quality of life for users. KHK gears contribute to significant advancements in medical technology, ensuring better patient outcomes and improved healthcare services.

Industrial Automation / Machine Tooling

In the realm of industrial automation, KHK gears enhance efficiency in manufacturing and assembly lines. They are used in conveyors and material handling systems to ensure smooth and reliable movement of goods. Packaging machinery also relies on these gears for precise and consistent operation. CNC machines, which require accurate and repeatable movements, benefit from the precision of KHK gears. Real-world examples of improved productivity with KHK gears include faster production cycles, reduced downtime, and enhanced product quality.

Renewable Energy Sector

KHK gears play a vital role in renewable energy applications, such as wind and solar power generation. In wind turbines, gearboxes equipped with KHK gears ensure efficient power transmission, converting wind energy into electrical power. Tracking systems for solar panels, which follow the sun’s movement to maximize energy capture, also rely on these gears for accurate positioning. The use of KHK gears in renewable energy contributes to sustainable and efficient energy solutions, supporting the global transition to cleaner energy sources.

Seimitsu Factory Automation, as the authorized distributor of KHK gears, provides expertise and support across various industries. Our team offers technical support and customization services to meet the specific needs of each application. We have a track record of successful partnerships with different sectors, delivering high-quality gears that enhance operational efficiency and reliability. Our commitment to quality and innovation ensures that our customers receive the best solutions for their gear requirements.

Conclusion

The versatility and benefits of KHK Stock Gears are evident across a wide range of industries. From automotive to robotics, aerospace to medical equipment, industrial automation to renewable energy, KHK gears provide precision, reliability, and efficiency. Seimitsu Factory Automation is dedicated to supporting these industries with top-quality gears and exceptional service, reinforcing our commitment to innovation and excellence.

Explore the diverse applications of KHK Stock Gears and discover how they can enhance your operations. Contact Seimitsu Factory Automation for more information on our product offerings and technical support. Visit our website for product catalogs and technical resources, or reach out to our sales and support teams for personalized assistance. Let us help you find the perfect gear solutions for your industrial needs.

0 notes

Text

Armatron 2364 (Super Armatron, Armatron II, ROBO I) by Tomy, Japan (1984). Made by Tomy and distributed by Radio Shack, the Armatron resembles an industrial robot arm. It’s entirely electro-mechanical in construction, and while not programmable, it can be manipulated directly via two joysticks. The robot has a single electric motor and moving the joysticks engages different sets of gears to control the arm movement. The arm has six degrees of freedom: wrist rotation and vertical wrist flexing, horizontal elbow bending, shoulder rotation and elevation, and the the two-fingered end-effector can be opened and closed. Later models differ only in colour and the decals provided.

98 notes

·

View notes