#Silicon component manufacturer

Text

Anti Vibration Mounts, Manufacturer, Mumbai, India

Find here to get more details of Anti Vibration Mounts, We are manufacturer, supplier, dealer and best service provider of Anti Vibration Mounts in Mumbai, India.

#Rubber Products#Moulded Rubber Parts#Extruded Rubber Parts#Sponge Moulded Parts#Metal Bonded Parts#Manufacturers Of Rubber Components#Manufacturers Of Moulded Rubber Parts#Manufacturers Of Extruded Rubber Parts#Rubber Moulded Parts#'O' Rings#Oilseal#U Seal#V Seal#Chevron Packing For Pumps#Hydraulics Seal#Mechanical Seal#Neoprenen Rubber#Nitrile Rubber#Epdm Rubber#Hypalon Rubber#FKM Rubber#Natural Rubber#Polymers#Flourinated Rubber#Silicone Rubber#Polyurethane Rubber#Ethylene Propylene Terpolymers#Synthetic Rubber#Chemical Resistance#O Rings

0 notes

Text

#custom rubber extrusion#rubber washer manufacturers#injection molding Winnipeg#silicone manufacturers California#molded rubber components

0 notes

Text

Silicon Photonics: The Marvel of Light-Speed Data Transformation

Silicon Photonics is an innovative integration of circuit design that seamlessly melds the realms of optics and electronics. At its core, this technology leverages silicon chips to transmit and process optical signals, thereby enabling high-speed data transmission and communication. What sets this technology apart is its ingenious fusion of micro-scale optical components within silicon chips, seamlessly uniting the transmission of optical signals with the processing of electronic signals.

Get the full article: Silicon Photonics

More electronics knowledge: Smbom's News

#electronics#integrated circuits#semiconductor#components#electronic#package#module#electronic devices#chips#manufacturing#silicon photonics#silicon photonics market

0 notes

Text

China is upping the critical minerals stakes by curbing exports of graphite, a key raw material in electric vehicle batteries.

The West can’t say it wasn’t warned.

When China announced restrictions on exports of gallium and germanium in July, former Vice Commerce Minister Wei Jianguo was quoted in the China Daily as saying it was “just the start” if the West continued to target China’s high-technology sector.

Restricting the flow of two metals used in the manufacture of silicon chips was “a well-thought-out heavy punch” in reaction to the U.S. Chips Act, Wei said.

The Biden administration has since tightened restrictions on the flow of advanced artificial intelligence chips to China, announcing on Friday a new raft of measures aimed at closing previous loopholes.

China is responding in kind, this time taking aim at the West’s electric vehicle (EV) ambitions.

There is much potential for further escalation in this unfolding critical minerals battle between China and the West.[...]

Graphite has slipped under the radar in the broader critical raw materials debate. China’s control of other battery inputs such as cobalt, nickel and lithium has grabbed the headlines.

Those are all used to make the battery cathode. It won’t work, however, without an anode, which is invariably made of graphite.

Indeed, graphite is the largest EV battery component by weight, typically accounting for between 50 and 100 kg.

China is the dominant player in the global supply of both natural graphite and synthetic graphite, which has been taking an increasing share of the market.

The country accounts for around two-thirds [!!] of all natural graphite production and, according to consultancy Benchmark Minerals, supplies around 98% [!!!!!] of the world’s synthetic graphite anodes.

23 Oct 23

33 notes

·

View notes

Text

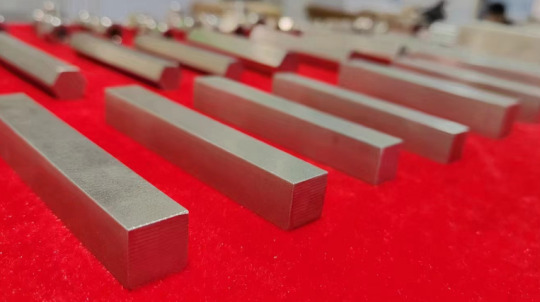

What are the materials used in weapons manufacturing?

Materials used in weapons manufacturing are chosen based on their mechanical properties, durability, and suitability for specific applications. The materials used in weapons manufacturing are:

1. Alloys, including steel, aluminum, titanium, nickel, and cooper.

2. Composites, including carbon fiber, glass fiber, and kevlar.

3. Ceramics, including alumina, silicon carbide, and boron carbide.

4. Polymers, including polyamide, polycarbonate, and polyethylene.

5. Specialized Coatings and Treatments, including ceramic coatings, teflon coatings, and phosphate coatings.

6. Explosives and Propellants, including RDX (Cyclotrimethylenetrinitramine), TNT (Trinitrotoluene), and composite propellants.

7. Electronic and Semiconductor Materials, including silicon, and gallium nitride (GaN).

Alloys

High-Strength Steel - Commonly used in the manufacturing of

Barrels: The main component of a firearm, responsible for propelling projectiles.

Receivers: The housing for the firearm's action, holding essential components.

Slides (pistols): The moving part that houses the barrel and holds ammunition.

Frames (pistols): The base of the handgun, supporting other components.

Bolts and carriers (rifles): Components involved in the firing cycle.

Springs: Essential for firearm operation, providing recoil and return forces.

Steels like 4140, 4340, and maraging steel are known for their toughness, high yield strength, and resistance to wear.............

#science#metals#alloys#materials#materials science#materials science and engineering#composites#ceramics#polymers#engineering#firearm

10 notes

·

View notes

Text

BABY, YOU MAKE ARMAGEDDON LOOK SO EASY ⸻ introducing yoon eunseok, d7.

wait till you hear about this next nominee: YOON EUNSEOK, born on the 8th of SEPTEMBER, 1993 and bears a striking resemblance to SONG KANG. they’re a FOURTH year BACHELOR OF BUSINESS ADMINISTRATION student and ACED EVERY COURSE WITHOUT AN ATTENDANCE COMPONENT — impressed yet? rumor has it they’re hoping to be the COO OF THE YOON GROUP, but personally, i think they should aim a little higher — something like the king’s club, for one. now, that suits them a little more, don’t you think? guess we’ll just have to see if they’ve got the talent for it in our upcoming recruitment round.

hello!! i'm shrimps, (25, she/they) like the fried rice, and i'm very excited to terrorize your lovely muses with my lil guy eunseokkie! i'm hoping to get around to my dms soon-ish (i'm kissing your foreheads, btw), but feel free to leave a like and i'll appear in your walls! if you'd rather plot on disco, just lmk.

BACKGROUND

pretentious nonsense full bio

tl;dr : guy who's a supporting character in his own story suffers a minor existential crisis in deciding between (a) wanting to do his own thing and (b) fulfilling the role he was quite literally created to play. unfortunately, he's made this everyone else's problem.

this is subject to change if needed to fit with e2, but i imagined the yoon family to run a silicon mining business that skyrocketed in no small part due to eunseok's father marrying into a family that manufactures semiconductors.

eunseok's father . . . now there's a real schemer. everything he did was designed to gain control of the family company, and eunseok was no exception. eunseok has grown up acutely aware of this, and is completely normal and unaffected as a result.

eunseok wasn't always a menace!! eunseok always had a predilection for mischief, but genuinely tried to be the perfect heir as a child — though he soon realized that nothing he did really mattered. if he did everything he was supposed to do, fine. that was the minimum expectation. if he acted out, the consequences would just be swept away like the trouble never happened. yoon eunseok had a very particular role to fulfill, you see, and something like proper parenting wasn't going to get in the way of eunseok's father's plan to take over the family company.

and so a monster was born.

2013 (+ 2016) : invited to the club to terrorize the other initiates. wish i was joking about this one. driven to succeed because (a) he plays to win and this is the sort of environment he thrives in, unfortunately, and (b) as a fuck you to the other initiates in his class. interestingly, the actual benefits of being in the king's club are at most a tertiary motivation to eunseok — i guess one of the weaknesses of never concocting your own schemes is that you aren't great at long-term planning. throws notorious parties. kinda notorious, period — there are rumors that he'll hook up with anyone tall and beautiful, regardless of gender (this is true); that he races mclarens on the weekends (this is false); and that he bribed (true), slept with (false), and physically threatened (technically false) his way to the top end of the class. endlessly ambitious and seemingly insatiable, you might be wondering: what's the point, if eunseok's whole deal is that he'll trot obediently back to daddy's side when the man calls?

well, i'm not saying that it's the painful crash at the end. but i'm not not saying that, either. i don't think eunseok really knows, himself.

2024 : the pawn is put in play; the dog is leashed. placed as an evp somewhere, then named coo upon his father's ascension to ceo/chairman/whatever. appears to have chilled out dramatically, but time will tell whether this is maturity, resignation, or mere suppression. :)))))))

PERSONALITY

entj. waffles between chaotic neutral and chaotic evil.

character inspo/parallels include roman roy, sylvain gautier, dorian gray, the cuntier end of taemin's solo discography (stream eternal out aug 19!!!!), the weeknd's trilogy album, nero, and lestat de lioncourt. also my uni roommate's various finance-bro exes. lmao.

all of this to say: think of the most annoying guy you know. think of a shark in the water. think of a poorly-trained bloodhound let off the leash. think of blood, generally — something slick and thrumming and visceral. if eunseok wants something, he will take it, because honestly? eight times out of ten, the taking is what he really wants, in the end.

weirdly intense but deeply unserious lol.

he's no master manipulator . . . moreso a cudgel lol. does very little plotting for how often he seems to be Making Moves(tm). how things never really come back to bite him should be studied in a lab, or maybe made into a hbs case study, but he's smarter than most people give him credit for, particularly in actual business management (unironically i think he would thrive as a logistics guy), but he cares little for mind games and saving face and also likes baiting fights for fun so. yeah.

thinks everyone playing nice is a hypocrite and a dummy! comes across as super arrogant but like in his mind . . . he's just being honest? like, yeah. he's rich. he wins a lot. by virtue of him winning, someone else, e.g., you, are a loser. life is short so why are we wasting time pretending otherwise?

ooough i wanna punch eunseok just reading this back. ironically i'd still absolutely go to the club with him because despite it all you know our boy is good fun. also you'll probably leave with an insane story. but i digress.

WANTED CONNECTIONS

these r. rough but! i'm really very open to brainstorming!!

a childhood friend — someone who witnessed eunseok's various metamorphoses and who is probably the only person, other than eunseok's father, who was unsurprised when eunseok fell in line after graduation. i'm flexible re: the exact contours of the relationship (ride or dies for life! drifted apart! bitter enemies), but i like the idea of someone knowing eunseok better than he knows himself.

2024 : if yr muse is involved with electronics: i present to u the (pending) heir of korea's largest semiconductor manufacturer. mwah ok.

2016 : love, hate, whatever — the point is that eunseok is used to evoking strong reactions. your muse, however, doesn't seem to care at all, nonreactive to flirtation and fury, and that really doesn't sit well with eunseok. tensions are high; maybe this volatility comes to a head.

2016 : alternately, maybe an initiate who has gotten the idea of gaining eunseok's approval into their head (get well soon!). get ready to have your time supremely wasted, buddy.

2016 : another envelope-pusher. yeah, the king's club parties, but you two party, making recklessness a game.

2016 (+2024, maybe!) : the person whose door eunseok finds himself stumbling to when the party's over. in the haze between intoxication and sobriety, you get to see a eunseok that even eunseok doesn't get to see — one that voices insecurities and worries. it's a weird sense of trust, and not even one necessarily tied to fondness (though it could be!). it could also be fun, i think, if they didn't keep in touch but for eunseok drunk-dialing your muse. that'll make the reunion exciting, eh!!

friends. enemies. flings. i don't necessarily know that eunseok's capable of holding down a relationship but i think it could be funny to see him try. in 2024 his family's probably trying to set him up with someone, so that could be something, maybe?

10 notes

·

View notes

Text

Anonymous: imagine being like,,, a sentient sex doll. a pretty one, not one of the goofy creepy ones. a pretty little doll no bigger than maybe 30cm tall, but your owner is this huge guy that loves dressing you and using you to de-stress by shoving his cock into your silicone-insert tummy. maybe he even gets too rough and splits it open, only to have new ones ready to install...

Ooh, this one is creative! Being a pretty little plaything for someone so much bigger than me… You probably had a sentience in mind reminiscent of being trapped in a doll’s body, but I like the idea that there’s an option for sentient, responsive dolls specifically so that they can be toyed with and played with more than a normal doll ever could. It would just be cute if they were fully advertised with their moans and whines, their begging, even their screaming and tears.

Maybe my owner shelled out for a sentient doll specifically so that he could make it whine and whimper. He knows that he’s a big guy, so he figured it’d be easy enough to dominate something as small and weak as me. He’s right, of course - sentience be damned, I was still made to be a doll, so I’m powerless to resist my owner. The first time he lays his cock atop my body to show off just how much he can stuff me full, I’m terrified, but unable to resist as he slowly, slowly fucks me open, breaking me in over a period of days to mold my silicone body to the right shape.

After that, he gets rougher. The bulge of his cock in my abdomen is uncomfortable, but not so uncomfortable that I can’t take it. I was designed to take it, after all. I was designed to take his cock at all times, however he wants me to take it. I have to obey him when he impales me and commands that I stroke his cock through my silicone skin. I have to. My sentience fights against my purpose, arguing for free will instead of my design, but the manufacturing process wins as I have dozens of toy orgasms around a cock too big for me.

A particularly stressful day puts him in a bad mood, and he takes longer to return home from work than usual. When he does, however, he slaps a box of replacement abdominal components on his desk and then dangles me in front of them. It takes me a second to realize that, if he has the parts, he’s probably going to need them. If I were human, I would be crying in earnest, but instead I sob in a quiet simulation of resignation as he positions his cock at my entrance.

He jerks me up and down roughly, faster than he’s ever used me before. The bulge in my middle is more prominent than ever, and I scream, sensing that something inside of me will break. Much like humans, I’m programmed to know when something is wrong. I don’t have a traditional pain response, but my diagnostics system treats things like they’re painful, in a way. I just know that he’s stretching me too thin, using me too rough, pushing me to my limits, and I sob, asking him to stop, begging him to slow down. If anything, that just makes him more aggressive.

With the rip of silicone, he finally bursts through my rubber belly, and I scream. He doesn’t stop, his cock thrusting through the open hole he’s made, and he just jerks me up and down even harder. He commands me to hug his cock, to wrap my arms around it, and I can only obey, making something tight for him to thrust into as I sob for breath that I don’t even need. He keeps using me until he reaches his breaking point, and only then does he pull out and jack off to completion, cumming into my toy body cavity.

After he’s recovered from breaking me, he finally gives me the mercy of replacing my damaged silicone insert. He’s not gentle about it, not at all, and makes sure that I know he’s keeping the damaged one around - just in case he wants to really treat me rough again.

He also reminds me, with a grin, that he has enough replacement components to repeat this fun little trick with almost any of my body parts.

#Originally posted October 14th 2022#asks#anonymous#my writing#nsft text#patreon.com/septimusmoonlight#recurring anon: 🩸🧵#size difference#pain#stretching#gore tw

15 notes

·

View notes

Text

Customized silicon chips for material characterization of printed electronics

How efficient are new materials? Does changing the properties lead to better conductivity? The Fraunhofer Institute for Photonic Microsystems IPMS develops and manufactures silicon substrates for this purpose. This enables the fundamental electrical characterization of materials such as a novel graphene emulsion. Customized designs enable the optimal measurement of semiconductors and conductors.

Organic semiconductors are key components in organic electronics and photovoltaics. They are used to make flexible electronic devices and printed solar cells. Typical for this class of materials are low temperature processes as well as large area deposition and patterning using various coating and printing techniques. The active semiconductor materials significantly determine the performance of the entire system.

Read more.

8 notes

·

View notes

Text

Key Design Considerations for Pantograph Support Insulators in High-Speed Rail Systems

In the realm of high-speed rail systems, every component plays a crucial role in ensuring safe and efficient operations. Among these components, pantograph support insulators stand out as critical elements that facilitate the seamless transmission of power from overhead lines to the train's electrical system. As a leading pantograph insulator manufacturer in India, Radiant Enterprises recognizes the importance of meticulous design considerations in crafting reliable and durable insulators. In this blog post, we'll explore the key design considerations essential for pantograph support insulators in 25 KV high-speed rail systems, shedding light on Radiant Enterprises' commitment to excellence in manufacturing.

Understanding Pantograph Support Insulators

Pantograph support insulators are integral components of the overhead electrification system in high-speed rail networks. These insulators provide electrical isolation and mechanical support for the pantograph, which is the apparatus mounted on the train's roof responsible for collecting electricity from the overhead wires (catenary). In 25 KV high-speed rail systems, where trains operate at exceptionally high speeds, the performance and reliability of pantograph support insulators are paramount.

Design Considerations for Pantograph Support Insulators

Material Selection: The choice of materials significantly influences the performance and longevity of pantograph support insulators. At Radiant Enterprises, we utilize high-quality, durable materials such as silicone rubber or composite polymers that exhibit excellent electrical insulation properties, mechanical strength, and resistance to environmental factors such as UV radiation, pollution, and temperature variations.

2. Electrical Insulation: Ensuring reliable electrical insulation is paramount to prevent electrical arcing and ensure the safe transmission of power. Our pantograph support insulators are engineered to withstand high voltage levels (25 KV) and exhibit low electrical conductivity to minimize power losses and mitigate the risk of electrical faults.

3. Mechanical Strength: Pantograph support insulators are subjected to mechanical stresses induced by the pantograph's movement and external forces such as wind loads and vibrations. Therefore, our insulators undergo rigorous mechanical testing to ensure they can withstand these forces without deformation or failure, ensuring uninterrupted operation and minimal maintenance requirements.

4. Corrosion Resistance: In outdoor environments exposed to moisture, pollution, and corrosive agents, corrosion resistance is essential to maintain the structural integrity of pantograph support insulators over their operational lifespan. Our insulators are engineered with corrosion-resistant materials and undergo surface treatments to enhance their resistance to rust and degradation, ensuring long-term reliability and performance.

5. Dimensional Accuracy: Precision engineering is critical to ensure proper fit and alignment of pantograph support insulators with the overhead wires and the train's pantograph. Our insulators are manufactured with tight tolerances and undergo strict quality control measures to guarantee dimensional accuracy and compatibility with the rail infrastructure, minimizing installation challenges and optimizing performance.

6. UV Stability: Exposure to ultraviolet (UV) radiation can degrade insulator materials over time, compromising their electrical and mechanical properties. Therefore, our pantograph support insulators are formulated with UV-stabilized materials that withstand prolonged exposure to sunlight without degradation, ensuring reliable performance and longevity in outdoor applications.

Radiant Enterprises: Your Trusted Pantograph Insulator Manufacturer in India

As a leading manufacturer of pantograph support insulators in India, Radiant Enterprises is committed to delivering superior quality products that meet the stringent requirements of high-speed rail systems. Our state-of-the-art manufacturing facilities, coupled with a team of experienced engineers and quality assurance experts, enable us to design and produce pantograph insulators that excel in performance, reliability, and durability.

Conclusion

In the dynamic world of high-speed rail systems, the reliability and performance of pantograph support insulators are critical for ensuring safe and efficient operations. By adhering to meticulous design considerations such as material selection, electrical insulation, mechanical strength, corrosion resistance, dimensional accuracy, and UV stability, manufacturers like Radiant Enterprises can deliver pantograph insulators that meet the demanding requirements of 25 KV high-speed rail systems. As a trusted pantograph insulator manufacturer in India, Radiant Enterprises is committed to providing innovative solutions that contribute to the advancement of railway electrification technology and the seamless operation of high-speed rail networks.

#Customised epoxy insulators manufacturer in India#Pantograph insulator manufacturer in India#25 KV pantograph support insulators manufacturers in India#25 KV roof busbar support insulator manufacturers in India#Solid third rail insulator#Customized Powerrail Epoxy Insulators#Epoxy Insulators#Epoxy insulator manufacturers in India

7 notes

·

View notes

Text

Excerpt from this New York Times story:

Less than a year ago, CubicPV, which manufactures components for solar panels, announced that it had secured more than $100 million in financing to build a $1.4 billion factory in the United States. The company planned to produce silicon wafers, a critical part of the technology that allows solar panels to turn sunlight into electrical energy.

The Massachusetts-based company called the investment a “direct result of the long-term industrial policy contained within the Inflation Reduction Act,” the 2022 law that directed billions of dollars to develop America’s domestic clean energy sectors. CubicPV was considering locations in Texas, where it would employ about 1,000 workers.

But a surge of cheap solar panels from China upended that project. In February, CubicPV canceled its plans to build the factory over concerns it would no longer be financially viable thanks to a flood of Chinese exports. As CubicPV was gearing up to make wafers in the United States, prices of those components were dropping by 70 percent.

The setback underscores the concerns rippling across the U.S. solar industry and within the Biden administration about whether President Biden’s industrial policy agenda can succeed. Top administration officials have begun warning that efforts to finance a domestic clean energy industry are being undermined by a surge of cheaper Chinese exports that are driving down prices and putting the United States at a competitive disadvantage.

The fate of the CubicPV factory is the type of outcome that Treasury Secretary Janet L. Yellen has warned is likely if China does not stop dumping heavily subsidized green energy products into global markets at rock bottom prices. She took that message to China last week, warning that its industrial strategy was warping supply chains and threatening American workers.

China appeared to dismiss those concerns. Following Ms. Yellen’s meeting with Chinese Premier Li Qiang, his office said, “The development of China’s new energy industry will make an important contribution to the worldwide green and low-carbon transition.”

Chinese overcapacity has been a central topic this week at the spring meetings of the International Monetary Fund and the World Bank. Ahead of talks with Chinese officials at the Treasury Department on Tuesday, Ms. Yellen said that China was not operating on a “level playing field” and warned that by producing more green energy products than the world can absorb, it was putting American firms and workers at risk.

4 notes

·

View notes

Text

Exporters of Stainless Steel 304 Pipes & Tubes: Global Supply

@manilaxmiindustrial : Manilaxmi Industrial

Explore the features, applications of Stainless Steel 304 Pipes & Tubes. This guide highlights their importance in various industries, emphasizing durability and corrosion resistance.

Stainless Steel 304 Pipes, Stainless Steel 304 Tubes, SS 304 Pipes, SS 304 Tubes, Stainless Steel, Pipes, Tubes, Industrial Materials

Stainless Steel 304 is one of the most widely used and versatile types of stainless steel in the industry. Known for its exceptional corrosion resistance, durability, and aesthetic appeal, Stainless Steel 304 Pipes and Tubes are vital components in a variety of applications, spanning across multiple industries.

What is Stainless Steel 304?

Stainless Steel 304 belongs to the austenitic family of stainless steel, which is composed of 18-20% chromium and 8-10.5% nickel, along with other elements such as carbon, manganese, and silicon.

The high chromium content provides excellent corrosion resistance, while the nickel enhances its strength and toughness.

This combination makes Stainless Steel 304 a popular choice for pipes and tubes, particularly in environments where corrosion resistance is a critical factor.

Applications of Stainless Steel 304 Pipes & Tubes

Stainless Steel 304 Pipes and Tubes are used in a wide array of industries due to their adaptability. Some of the most common applications include:

Food and Beverage Industry: The hygienic properties of Stainless Steel 304 make it ideal for food processing, storage, and transportation. It is resistant to corrosion from food products, cleaning agents, and the wide range of temperatures involved in food production.

Chemical and Petrochemical Industries: Stainless Steel 304 can withstand harsh chemicals, making it a preferred material for chemical processing equipment and pipelines. Its resistance to acidic and alkaline solutions ensures longevity in these demanding environments.

Construction Industry: Stainless Steel 304 Pipes and Tubes are frequently used in architectural structures, particularly in areas where aesthetics and durability are important. Its resistance to weathering and corrosion makes it a suitable material for both interior and exterior applications.

Automotive Industry: The durability and strength of Stainless Steel 304 make it an excellent choice for automotive exhaust systems, fuel lines, and other components that require resistance to high temperatures and corrosion.

Pharmaceutical Industry: In environments where cleanliness is paramount, Stainless Steel 304 shines. Its non-reactive properties and ease of cleaning make it ideal for the pharmaceutical industry, especially in the manufacturing of medicines and medical equipment.

#Manilaxmi Industrial#manufacturers#exporters#suppliers#industrial#innovation#pipeaccessories#manilaxmiindustrial

3 notes

·

View notes

Text

Understanding Hearing Aid Domes: A Comprehensive Guide

Hearing aid domes are integral components of behind-the-ear (BTE) and receiver-in-canal (RIC) hearing aids, significantly influencing both comfort and auditory experience. This article delves into the nature of hearing aid domes and provides insights on how to maintain them for optimal performance.

What is a Hearing Aid Dome?

A hearing aid dome is a small, bell-shaped silicone piece that attaches to the end of a hearing aid's tubing or speaker. It sits comfortably in the ear canal, serving as a medium to transmit sound. Domes come in various sizes and styles, such as open, closed, and power, to accommodate different hearing needs and ear canal shapes.

Types of Hearing Aid Domes

Open Domes: Characterized by multiple holes, they allow natural and amplified sound to mix, suitable for mild to moderate hearing loss.

Closed Domes: With fewer holes, they provide more sound isolation and are ideal for moderate to severe hearing loss.

Power Domes: Completely occlusive, they are designed for severe to profound hearing loss, offering maximum amplification and minimal feedback.

Benefits of Using Hearing Aid Domes

Comfort: Their soft silicone material makes them comfortable for extended wear.

Improved Sound Quality: Domes can enhance sound clarity and reduce feedback.

Versatility: Available in different types, they cater to a wide range of hearing impairments.

How to Care for Hearing Aid Domes

Proper maintenance of hearing aid domes is crucial for their longevity and performance. Here’s how to care for them:

Regular Cleaning: Wipe the dome daily with a soft, dry cloth. Avoid using water or cleaning agents unless specified by the manufacturer.

Inspect for Wax Build-up: Earwax can accumulate on the dome, affecting sound quality. Check regularly and clean with a gentle brush if necessary.

Replace When Necessary: Domes should be replaced every 2-6 months, or sooner if they become stiff, discolored, or damaged.

Handle with Care: When attaching or removing the dome, be gentle to avoid damaging the hearing aid speaker.

Consult Your Audiologist: Regular check-ups with your audiologist can ensure your domes and hearing aids are in optimal condition.

Troubleshooting Common Issues

Feedback or Whistling: This may indicate an ill-fitting dome. Consult your audiologist for a proper fit.

Muffled Sound: Often a result of wax build-up. Clean the dome and the hearing aid’s speaker if necessary.

Discomfort: If a dome causes discomfort, a different size or style may be needed.

FAQs

How often should I replace my hearing aid domes?

Typically, every 2-6 months, but this can vary based on usage and care.

Can I clean my hearing aid domes with water?

Generally, it’s not recommended unless specified by the manufacturer. Use a dry, soft cloth instead.

Are hearing aid domes one-size-fits-all?

No, they come in various sizes and styles to fit different ear canals and hearing needs.

Conclusion

Hearing aid domes are small yet significant components that enhance the hearing aid experience. Understanding their types, benefits, and the care required can help users get the most out of their hearing aids. Regular maintenance, along with professional guidance, ensures these devices continue to improve the quality of life for individuals with hearing impairments.

6 notes

·

View notes

Text

AI & Data Centers vs Water + Energy

We all know that AI has issues, including energy and water consumption. But these fields are still young and lots of research is looking into making them more efficient. Remember, most technologies tend to suck when they first come out.

Deploying high-performance, energy-efficient AI

"You give up that kind of amazing general purpose use like when you're using ChatGPT-4 and you can ask it everything from 17th century Italian poetry to quantum mechanics, if you narrow your range, these smaller models can give you equivalent or better kind of capability, but at a tiny fraction of the energy consumption," says Ball."...

"I think liquid cooling is probably one of the most important low hanging fruit opportunities... So if you move a data center to a fully liquid cooled solution, this is an opportunity of around 30% of energy consumption, which is sort of a wow number.... There's more upfront costs, but actually it saves money in the long run... One of the other benefits of liquid cooling is we get out of the business of evaporating water for cooling...

The other opportunity you mentioned was density and bringing higher and higher density of computing has been the trend for decades. That is effectively what Moore's Law has been pushing us forward... [i.e. chips rate of improvement is faster than their energy need growths. This means each year chips are capable of doing more calculations with less energy. - RCS] ... So the energy savings there is substantial, not just because those chips are very, very efficient, but because the amount of networking equipment and ancillary things around those systems is a lot less because you're using those resources more efficiently with those very high dense components"

New tools are available to help reduce the energy that AI models devour

"The trade-off for capping power is increasing task time — GPUs will take about 3 percent longer to complete a task, an increase Gadepally says is "barely noticeable" considering that models are often trained over days or even months... Side benefits have arisen, too. Since putting power constraints in place, the GPUs on LLSC supercomputers have been running about 30 degrees Fahrenheit cooler and at a more consistent temperature, reducing stress on the cooling system. Running the hardware cooler can potentially also increase reliability and service lifetime. They can now consider delaying the purchase of new hardware — reducing the center's "embodied carbon," or the emissions created through the manufacturing of equipment — until the efficiencies gained by using new hardware offset this aspect of the carbon footprint. They're also finding ways to cut down on cooling needs by strategically scheduling jobs to run at night and during the winter months."

AI just got 100-fold more energy efficient

Northwestern University engineers have developed a new nanoelectronic device that can perform accurate machine-learning classification tasks in the most energy-efficient manner yet. Using 100-fold less energy than current technologies...

“Today, most sensors collect data and then send it to the cloud, where the analysis occurs on energy-hungry servers before the results are finally sent back to the user,” said Northwestern’s Mark C. Hersam, the study’s senior author. “This approach is incredibly expensive, consumes significant energy and adds a time delay...

For current silicon-based technologies to categorize data from large sets like ECGs, it takes more than 100 transistors — each requiring its own energy to run. But Northwestern’s nanoelectronic device can perform the same machine-learning classification with just two devices. By reducing the number of devices, the researchers drastically reduced power consumption and developed a much smaller device that can be integrated into a standard wearable gadget."

Researchers develop state-of-the-art device to make artificial intelligence more energy efficient

""This work is the first experimental demonstration of CRAM, where the data can be processed entirely within the memory array without the need to leave the grid where a computer stores information,"...

According to the new paper's authors, a CRAM-based machine learning inference accelerator is estimated to achieve an improvement on the order of 1,000. Another example showed an energy savings of 2,500 and 1,700 times compared to traditional methods"

2 notes

·

View notes

Text

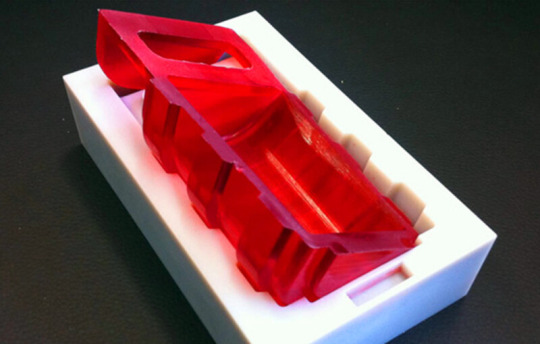

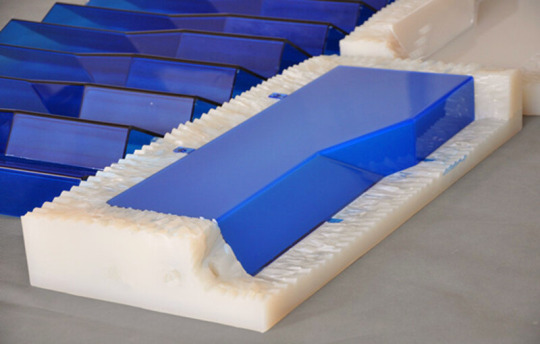

Working of Vacuum Casting and Its Multiple Uses

To make complicated components, a liquid substance is sucked into a silicone mold under vacuum. This method is known as vacuum casting. Rubber and plastic are examples of elastomers that are utilized as liquid materials in vacuum casting.

Since polyurethane resin, a kind of elastomer is employed as the casting medium, vacuum casting is also frequently referred to as polyurethane casting or urethane casting. When producing plastic components, vacuum casting is a more cost-effective method than injection molding because of its reduced manufacturing costs.

For batch manufacturing and other low-volume production tasks, vacuum casting is a great method of production. Vacuum casting is widely utilized in India's manufacturing of industrial electronics, FMCG, and consumer goods.

How do you work with vacuum casting?

Injection molding, in which cast material is poured into molds to create items, and vacuum casting services are very comparable processes. The kinds of molds used in injection molding and vacuum casting differ from one another.

Molds for injection molding might be formed of steel, aluminum, or other materials. Silicone molds are utilized in vacuum casting, nevertheless. This significantly lowers the mold-making cost because silicone is more affordable and has better durability.

Polyurethane is the most often utilized casting material in this procedure. The qualities of various polyurethanes vary, including good shock and temperature resistance, elasticity, flexibility, and structural stiffness. Thus, different polyurethanes may be employed depending on the kind of product being created.

Vacuum casting uses

Making complicated and sophisticated goods may be accomplished more cost-effectively and efficiently with vacuum casting as opposed to the conventional injection molding method.

Due to its efficient production process, vacuum casting finds widespread application in the fabrication of commercial items. The following are a few industries that employ vacuum casting:

Manufacturing of consumer goods

Vacuum casting is a more effective method of producing consumer goods including combs, hair brushes, makeup packaging, sunglasses, pens, and other stationery.

Industry of Food and Beverages

Vacuum casting is used to create food and beverage containers, bottles, cans, mugs, and glasses. Due to the process's great efficiency and ability to produce goods quickly, vacuum casting is widely utilized in various industries where rapid manufacture is essential.

Advanced industry

Excellent heat and shock resistance is a feature of polyurethanes. Therefore, the recommended production procedure for creating electrical device housings is vacuum casting by Vacuum Casting Manufacturer using polyurethanes.

Follow our Facebook and Twitter for more information about our product.

#vacuum casting#vacuum casting services#Explore vacuum casting#Vacuum Casting Services China#Vacuum Casting Manufacturer#Vacuum Casting supplier

2 notes

·

View notes

Text

Just an idea for part of a setting:

Union Transistor Company:

Initially founded before the supply chain collapsed as a for profit semiconductor company, after the supply chain collapsed, it reorganized into a cooperative, the entire thing was built to run off of geothermal, readily available in the Pacific Northwest where the main building was first built.

They supply semiconductor devices, mostly silicon, to traveling traders in exchange for food and materials such as things they may refine silicon from or dopant materials. They do have the requisite tools and knowledge to make gallium arsenic semiconductors, but they don’t have the materials to do so regularly, so if you need those you must come to them with the materials.

In addition to manufacturing new semiconductors, their main business is in reclamation, taking old computers and salvaging any functional components and recycling the rest using methods developed just before the great collapse.

They also send people out to find old records, patent office archives, engineering researchers and their notes, that type of thing, as well as tools needed to make such things, as such they have also taken the battery market with their Iron-sulfide rechargeable batteries, though, unlike semiconductors they share how to make these batteries because they don’t require access to highly specialized facilities to create and as such this knowledge doesn’t give an incentive to invade them.

The insane future-proofing of the place was the result of pre-collapse trillionaire George Markus thinking he would use this as his stronghold to rule from. He however made the foolish mistake of trusting his enforcement over some of the best scientific minds of the day to machine. In two weeks thirteen different groups had control over the security system, and George Markus had been shot by one of them with his own turrets. After another two weeks of constantly trying to lock eachother out of the system and failing, a truce was called and they decided that cooperation was the way forward, and that they had a duty to keep the place running if they hoped for things to be rebuilt at some point.

2 notes

·

View notes

Text

Is Monel similar to Inconel?

Many of our customers have such a question: Is Monel similar to Inconel? As a matter of fact, both Monel and Inconel are nickel-based alloys with exceptional corrosion resistance and high-temperature performance, but they differ significantly in composition, properties, and applications. In this article, let’s delve into the key aspects of these two alloys to understand their similarities and differences.

Is Monel similar to Inconel?

Composition:

Monel, also known as Monel alloy, is primarily a nickel-copper alloy, typically containing up to 67% nickel and 28% copper, with the remaining portion composed of iron, manganese, carbon, and silicon. This composition gives Monel its excellent corrosion resistance, particularly against acids and alkalies.

On the other hand, Inconel is a nickel-chromium alloy, with chromium content ranging from 15% to 25%, depending on the specific grade. Inconel alloys also contain significant amounts of other elements like iron, molybdenum, and titanium, which contribute to their high-temperature strength and oxidation resistance.

Properties:

Both Monel and Inconel exhibit excellent corrosion resistance, but the specific environments they thrive in differ. Monel’s corrosion resistance is particularly noteworthy in marine and chemical processing applications, where it can withstand the corrosive effects of saltwater and various acids.

Inconel, on the other hand, is renowned for its ability to maintain its mechanical properties at extremely high temperatures. It is often used in aerospace and power generation applications where materials must withstand extreme heat and pressure. Inconel’s chromium content also gives it superior resistance to oxidation and sulfidation at high temperatures.

When it comes to mechanical properties, Inconel generally offers higher strength and hardness compared to Monel. However, Monel has better formability and weldability, making it easier to shape and join into complex structures.

Applications:

The differences in composition and properties lead to distinct applications for Monel and Inconel. Monel is commonly used in the chemical processing, marine, and food processing industries due to its resistance to corrosion and ease of fabrication. Its ability to withstand the corrosive effects of saltwater makes it a popular choice for marine applications like shipbuilding and offshore drilling.

Inconel, on the other hand, finds its niche in high-temperature applications where strength and oxidation resistance are paramount. Aerospace, power generation, and petrochemical industries rely on Inconel alloys for components that must operate in extreme environments.

Conclusion:

While Monel and Inconel are both nickel-based alloys with exceptional corrosion resistance, they are not interchangeable. Each alloy has its unique composition, properties, and applications. Monel excels in corrosive environments and offers good formability and weldability, while Inconel is renowned for its high-temperature performance and oxidation resistance.

Thank you for reading our article and we hope it can help you to find the answer to the question: Is Monel similar to Inconel? If you are looking for Monel and Inconel suppliers and manufacturers online now, we would advise you to visit Huaxiao Alloy.

As a leading supplier of Monel and Inconel Alloys from Shanghai China, Huaxiao Alloy offers customers high-quality products such as Monel 400, Monel K500, Inconel 600, Inconel 601, Inconel 625, and Inconel 718 at a very competitive price.

2 notes

·

View notes