#Thread Forming Machine Screw

Explore tagged Tumblr posts

Text

DD’s Yandere Poll Series: Surviving the Yan!Penacony Boys (based on this post)

Rules/warnings: Read the below scenario and pick your answer or comment your own reaction. Dark content ahead!

Incident #2 — The Wager

Aventurine knows your angry footsteps from a mile away as you shove your way through the Penaconian casino and straight to his table.

He has plenty of time to react, but he sits back in bemused silence as you slap his hand, sending aces and spades flying across the table and fluttering to the floor.

You are livid. Aventurine cannot help but chuckle at your adorable expressions as he begins to concoct a plan. After all, emotional betters tend to be reckless.

“Damn, and that was a good hand, too.”

You grit your teeth at his lackadaisical dismissal. “Screw your game. Are you going to tell me why there were IPC goons posted outside my apartment yet again this morning?”

He folds his hands and tilts his head innocently, a smirk painting his lips. “You assume I had something to do with that?”

“Don’t play dumb!” The rein on your temper is hanging on by a thread. You take a deep breath to reset yourself, then place both palms on the table to brace yourself. “What do you want?”

By this point, the others at the table have enough common sense to flee, leaving the two of you alone. The sounds of the slot machines and cheers of the casino-goers echo through the charged atmosphere between you.

“Darling, I think I’ve made that painstakingly obvious.” Before you can react, he grips one of your wrists and pulls you down so you are leaning across the table, face inches from his own. He runs a gloved finger along your cheek, licking his bottom lip. “Have you finally come to concede?”

You narrow your eyes but do not struggle—yet. “You fucking wish.”

“Such a filthy mouth,” he drawls, much to your chagrin. “If not to acquiesce to my desires, then what brings your lovely presence here? Care to take a seat?” He motions, of course, to his lap.

You inhale sharply and speak before you lose your courage, temper, or both. “I want to make a wager with you.”

His eyes widen ever so slightly; you’ve either surprised or excited him. Neither bode well for you.

“One game. We both know what we want from it.”

“Ah ah, I’ll need some clarification as to what I’m actually betting on,” Aventurine teases as he begins to reassemble the deck of cards, all while maintaining your eye contact.

Aeons, he’s actually going to make you spell it out. “I win, I get my out from you and the IPC. I get to leave Penacony and never look back. If I lose…” Your throat collapses for a moment before you spit out, “You win me.”

Aventurine releases you, leaning back in his chair. He grabs the newly formed deck of cards and begins shuffling. “I accept. But, since I have more to lose here—” You begin to protest, but he quickly tuts you into silence, “I will be the one choosing the game. Deal?” He extends his hand, golden rings glinting. You think you can hear the tick tick tick of his watch, counting down to your end.

You look over his expression, his body language, the smug smile. He’s hiding his ace, you can tell, but what choice do you have?

Slowly, you sink into the seat across from him.

“I’ll take that as a yes,” he laughs, reeling his hand in with an exaggerated pout. “In that case, we’ll be playing Maverick.”

Your accelerated heartbeat calms ever so slightly. That’s one game you’ve heard of. A game of pure luck rather than skill. You can work with that.

“The rules are simple.” He lays two cards, face down, in front of you. “Your goal is to guess a number that falls within these two cards. If you’re in the correct range? You walk out of this casino and never see me ever again.”

Your heart soars, but quickly falters when you spot the mischievous glint in his irises. “But, if you’re wrong and your number falls outside…” His thumb and index finger form the shape of a pistol, which he pretends to fire into your heart with a dramatic bang.

“Your heart is mine.”

No backing down.

He gestures between you and the cards, prompting you ahead. That smirk never falters.

Glancing between the two cards, you go with your gut. Defiantly holding his breathtaking blue and pink gaze, you speak aloud your favorite single digit number.

Aventurine hums and flips both cards simultaneously.

Two king of spades stare back at you mockingly.

“Looks like I win.”

#yandere honkai star rail#yandere hsr#yandere#yandere aventurine#yandere aventurine x reader#honkai star rail#hsr aventurine#aventurine#aventurine x reader#aventurine honkai star rail#yanderecore#yandere imagines#hsr drabbles#hsr headcanons

636 notes

·

View notes

Note

These thingies are so fun to read, could you make a list of things to do if your f/o is a robot??? Over half of mine are robotic in some way shape or form it's a heavy pattern lmao

~ @puzzlingrubberknife just using anon bc why not lolz

absolutely!

write them out a document or make a slideshow telling them parts of human culture you find interesting! if they aren't that familiar, maybe you could also explain slang to them.

you totally should read up on what sorts of parts and code that are needed to make robots.

to add to this, if your robot f/o uses an llm to speak to you (bc I'm sure there are fictional robots that use like... the power of magic to communicate idk) maybe look into some llm's you think they use!

if your s/i has the ability to "work on" or change robot parts and things, if your f/o is the type to enjoy something like that, make a list of "upgrades" you think would suit them (jetpack upgrade??? super crazy blasters??? machine gun ??????)

if your robot doesn't understand humor or sarcasm, teach them! (silly robot puns ?! one could say y'all are wire-crossed lovers)

imagine taking them out places, especially places they know nothing about. of course, if they're sensitive to water you'd want to avoid, like, water parks.

if your f/o has an endless stream of knowledge at their fingertips they can access, maybe you can make a list of things that they enjoy the most.

if they do not have something like that, you could teach them something you like doing! art, creative writing, playing music, cooking, things like that!

do they have a favorite lubricant for their screws? do they love or hate WD-40? if they don't, you could always look into different kinds of oils to try!

if they have a charger, imagine decorating it! assuming it wouldn't get too hot, you could make a little collage of stickers you could put on it (picsart as tons of stickers you can look up and make a collage out of)

(ik a default to this all the time) but making "mechanical" jewelry. bracelets with gear and screw and bolt charms, honestly you literally could drill little tiny holes into washers and make them into a bracelet (or braid thread around them)

if your robot can't eat normal food describe food to them you think they'd like! different sweets or dinner foods or breakfast foods

this one was also tough but it was fun to think about!

#i said in my brain “okay what if i f/oed kiibo...”#self shipping#self ship#selfship#selfshipper#self shipper#selfshipping#f/o#f/o community#fictoromantic#romantic f/o#yumeship#ficto community#fictoromantism#fictional other#fictosexual#self ship imagine#selfship community#f/o imagines#fun f/o lists

55 notes

·

View notes

Note

Pls make a blurb about Reader forcing Patrick to help build a house for calico critters made with real wood and anything and this big man with big hands is just sewing tiny curtains, it sounds tew cute 🥹

It's not you who forces him but your baby girl Eleanor who doesn't like any of the houses displayed on the website. She has this particular idea about a princess looking three storey house with flowers and hearts, having provided Patrick with multiple sketches and thorough instructions on where the furtniture must be located.

"She's gonna be the death of me, I swear. Are you sure we can't find anything like this online?" Patrick mutters in partial annoyance, that is present mainly to find his distress, because - apart from tennis - he's not used to working with his hands at all.

You have a hard time focusing, unable to tear your eyes away from the typical dad stance - feet apart, balled fists resting on his hips - a belt with all the necessary tools ha going loosely around Patrick's hips. Damn, he looks really hot.

You rub his exposed arm, glad for the summer heat that made Patrick wear one of his sleeveless tops, and you thank god that Eleanor has currently gone to the local swimming pool with Lily and the Donaldsons. At least you don't have to control your primal urges.

"Oh, don't be so fussy babe. You're gonna nail it," you coo, pressing a kiss to his cheek.

The sight is a mix of both arousing and comical. Patrick's muscles flex as he cuts the wood planks with a hand saw, the motion reminding you of multiple different things. He's grunting and mumbling under his breath - Why did I agree to this? Goddamn, this is ridiculous. - eyes rolling onto the back of his head when he sees that one piece is smaller than the remaining three.

"Are you having any issues, darling?" you mock with a laugh from where you're sitting in the garden chair, legs crossed comfortably, glancing up from your book. His reaction makes you giggle.

Patrick shoots you a glance, brows furrowed, and a drop of sweat rolls down his cheek. "You wanna try it yourself, sweetheart?"

This is the peak dad performance in your eyes, with you lounging under the sun while your gorgeous husband looks absolutely stunning, sweat covered, with little insults leaving his mouth. He manages to get all the essential pieces before putting them all together, drilling screws into the wood to form the main box shape, and finally putting in the planks make for the storeys.

When the outline is finally done and painted all white, Patrick lets it dry outside and moves into the living now, now fighting with your sewing machine. Unfortunately, the little windows must have curtains.

"This is fucking devil's work. How do you even use that?" he's sitting there like a school boy about to cry over his math homework, completely lost.

You lean over him, your arms on either side of his head as you take one of the pink fabric squares. Patrick's breath hirches completely as you begin explaining the basics. "It's easy, just work slowly. First, you took the thread - yup, here - then just place it there, under the needle."

Your husband has a fucking hard time focusing on the instructions, lips parting hungrily as the soft inside of your arm brushes over his cheek. He really can't resist, pressing a few kisses to your soft skin, for which he earns a gentle slap on the back of his head.

"Focus," you command, earning a sigh in response. He really just wanted to kiss you, to feel you. "Foot on the pedal - good - it begins moving when you step on it. Just let the fabric run through the whole way, and be careful about your fingers. C'mon, try it."

It takes Patrick a few tries - okay, a bit more than just a few - but eventually, he ends up with four squares that resemble curtains at least a bit. That is, unfortunately, all he can deliver. Being a good wife, you do the rest for him, sewing little beddings for the beds, a table cloth and the two remaining curtains.

The rest of the afternoon consists of Patrick painting messy details on the wooden walls and bringing some boxes from your old home down from the attic - thank god you kept all of your Barbie house equipment - and attempting to fit the pieces into the wooden house. He steals a few mint leaves from the garden and makes tiny makeshift house flowers with them, knowing he'd have to swap those every two or three days, but whatever makes his darling daughter happy, right?

And when Eleanor comes back home, her hair damp and a thin layer of sunburn on her freckled cheeks, she can't contain her excitement.

"Daddy!" she squeaks, throwing her short arms around your husband's neck. He picks her up, literally blushing when she peppers his fave with sloppy baby kisses.

"D'you like it, princess?" he asks with excitement shining in his own eyes. He'd be really fucking disappointed if she didn't.

And she nods eagerly, immediately squirming to hop down and examine the small house thoroughly. "It's so cute daddy, they're all gonna fit rhere! The bed's too big but that's okay. They can have a sleepover!"

Later that day, when Eleanor is playing in her room and moving the animal figures into their new accomodation, you take Patrick in your arms. He seems to be exhausted, even though this whole process can't come even close to what he experiences on court, but he's more than happy to snuggle in your arms.

"She really loves it," you whispers, gently threading fingers through his curly hair. Patrick hums in response, digging his face deeper into your chest. "I'm so lucky to have such a handy husband at home. All for me."

At that, Patrick perks up, lifting himself on his elbows to hover over you, mischief glowing in his eyes. "Yeah?

You nod, humming as you begin rubbing his arms, gently squeezing the muscles that flex as Patrick's holds his weight above you. God, you could bite into that flesh. "Yeah. And he's really fucking hot as well."

"Is he?" Patrick echoes, leaning closer to nudge your nose with his own, chuckling at your smugness. You're so pretty.

And you nod again, now wrapping your arms around his shoulders to bring him in for a kiss. His caloused palms move under your shoulders to scoop you into him, fully settling between your legs and pushing you into the mattress. You're so warm and soft for him, a perfect pillow to rest on, cheeky and smug when you compliment him. He supposes that's good enough of a reward for his hard work.

But unfortunately, a high pitched daddy! fills the house before he could move further, and all the appetite is lost when Eleanor asks for yet another home made house.

#challengers#patrick zweig#patrick zweig x reader#patrick zweig fluff#dad!patrick zweig#girl dad!patrick zweig#calico critters#ask

58 notes

·

View notes

Text

Here's a picture (that I forgot I had) of the underside of my sewing machine

This machine was meant to go into a sewing desk, although it does have some little feet to hold it off of a tabletop if it's not put into any kind of base, like the plastic base I have (the machine was in it when I thrifted it, attached with hinges like it would be in a sewing desk)

A lot of machines like this, which were made to go into a desk or other kind of frame, are open on the bottom like this, which makes them incredibly easy to clean and oil down there

But, that plate behind the bobbin area, held on with the screws? If your machine has something like that, leave it alone. That's where the spinning driveshaft motion, that comes from the side, gets turned 90° in different directions, to drive the back-and-forth movement of both the oscillating hook around the bobbin (which loops the thread to form the stitch) and to drive the small circular movement of the feed dogs (the things that move the fabric and control stitch length.) I have seen posts from Old Sewing Machine Repair People who wish they had never opened those parts up, because they are the most ridiculously complex sets of gears in the machines, and they are so well sealed and packed in grease that it turned out they didn't need to do anything in there, anyway. They were just really curious.

(Not saying that area should never be opened, just...it should never be opened without preparation)

10 notes

·

View notes

Text

An Introduction to the Lathe Machine: Basics Every Engineer Should Know

A lathe machine is one of the most versatile and essential tools in mechanical engineering workshops. Its primary function is to remove unwanted material from a workpiece to shape it into the desired form. Whether you're a beginner or revisiting your engineering fundamentals, here's everything you need to know about the lathe machine:

Key Components of a Lathe Machine

Bed: The sturdy base that supports the entire machine and ensures stability during operations.

Headstock: Houses the spindle, gears, and motor that drive the workpiece.

Tailstock: Positioned opposite the headstock, it supports longer workpieces and holds tools like drills.

Carriage: Used to move the cutting tool along the bed. It includes the saddle, cross-slide, compound rest, and tool post.

Lead Screw: Enables precise movement of the carriage during threading operations.

Types of Lathe Machines

Engine Lathe: The most common type, suitable for various operations like turning, facing, and threading.

Turret Lathe: Ideal for mass production with repetitive tasks.

CNC Lathe: Computer-controlled for high precision and automation.

Common Lathe Operations

Turning: Shaping the outer surface of a cylindrical workpiece.

Facing: Smoothing the end of a workpiece to make it flat.

Drilling: Creating holes with the help of a drill bit mounted on the tailstock.

Threading: Forming screw threads using special tools.

Knurling: Adding texture to improve grip on cylindrical surfaces.

Why Are Lathe Machines Important?

Lathe machines are indispensable for crafting intricate components with high precision. They're widely used in automotive, aerospace, and manufacturing industries, making them a cornerstone of mechanical engineering.

💡 Follow "TIC Learning Center" for more insightful mechanical engineering posts!

#mechanical#engineering#material#sciences#lathe#lathe machine#cnc lathe#the lathe of heaven#lather rinse repeat

5 notes

·

View notes

Text

Idly thinking about the brilliance of TNG's Lower Decks, so please do bear with me for a little while here... The show's seventh season often gets a not entirely unjustified rap as being a piece of filler while various parts of the writer's room were off shepherding the launch of Voyager and the transition to film with Generations, but here at last the season manages to attain the lofty heights of exactly what we expect from the "final season" of a show like this, in a fashion far more satisfying than simple continuity references or closure to running plot threads could ever be.

What I mean is that it demonstrates the inherent perks of the writer's room as a model of television production, something that has kind of been lost in the age of streaming and micro-writer's rooms. There isn't enough space for someone like, say, Brannon Braga with his weird exploration of body horror and/or temporal fuckery, or Ronald D. Moore with his cynical realpolitik.

Lower Decks very much hinges on René Echevarria's proven talents as one of the strongest writers in the TNG stable when it comes to intimate, character-driven pieces. The pitch came from outside the writer's room, but that hints at the real function of the room as a machine, whereby an abstract idea is subjected to a very particular finesse that helps bring out particular facets of a given script.

Ironically, Echevarria's own Star Trek career is another instructive proof-of-concept in this regard. His first script was The Offspring, but it was given an extensive do-over by Michael Piller and Melinda Snodgrass to better fit the aesthetics of the show. And here, his talents have developed far enough that he's effectively put on the other end of the process.

And it works. The script is beautifully constructed, with so many clever bits that invite the audience to become an active participant in the very procedure of watching Star Trek. The Alaska/Canada screw-up from Lavelle and Ben, the decision to cut away from the transport of Joret Dal and only show the hint of a Cardassian uniform, and of course the central set piece of the intercut poker games. (Here, for the visual triumphs, we should also commend director Gabrielle Beaumount.)

The episode derives its power from the audience's understanding that there were 165 episodes before this one, with their own rhythms and cadences. It disrupts it, but ultimately, in Worf's mutual connection with the lower decks personnel at the very end, collapses the narrative back into its familiar form. Of course, like all good narrative collapses, it comes at a cost, namely that of Ensign Sito.

It's brutal, and soul-crushing, to have spent so much time with this character only to have her swept away by the vicissitudes of fate, but it never feels cynical.

(In fact, one of the more bitterly memorable moments in watching the episode with my parents tonight - who had not seen the episode, or at least not recently - was my mother worriedly voicing her suspicions that Sito was not slated for a happy ending, and my father noting how bleak it would be for them to bring back this character to tell such a story. Crucially, he did not say this to disapprove, and I think it speaks volumes to how much Echevarria's script relies on the audience applying the televisual grammar of Star Trek to the episode.)

I'll admit I haven't seen any of the more modern Trek shows beyond Season 2 of Discovery - not out of conscious choice, mind you, I just have only so many hours of the day to watch Star Trek - but I can absolutely understand why this was the episode that got to pretty much single-handedly inspire the concept of an entire show, even if only in spirit.

For a show that can often feel rather formulaic - which isn't a problem, because the formula is a very, very good one that leads to some fantastic episodes - Lower Decks is proof that TNG wasn't *entirely* content to just coast by and rest on its laurels. It would have been justified to do so, but it still threw in the odd stylistic leap here and there.

And in so doing, it inadvertently prefigures more experimental modern television techniques - and contrasting against some of the more frustrating tendencies of the streaming era - all amidst a genuinely heartfelt and moving story. With all due respect to The Pegasus, Parallels and All Good Things, for me I think Lower Decks has now emerged as the champion of Season 7.

It's just that fantastic.

27 notes

·

View notes

Text

Got screwed by LaPoste again. Flatmate woke me up to pay €11: more than the cost of the item with postage: I'd already paid import taxes, it was tracked so they could have emailed me for the €3 custom fee, it had a CN22 that said both these things but it was folded inwards so their shoddy machines didn't scan it.

A few years ago this would have ruined half my day. But I've been doing whatever therapy technique it is to take your strong emotions and break it down into every single component and examine every facet until it's something you understand, can accept and form solutions

Here's a little peek at what comes out after lots of uncomfortable moments of digging down:

ANGER because this is ethically wrong and entirely avoidable:

If they'd bothered to open the CN22, i wouldn't have to pay. As is I was presented with losing the item and reorder (with wait time) or hand over the money. Their corner cutting on personnel led to this.

Customs fee was actually €3. The extra €8 is a handling fee for laposte. If your parcel has tracking, customs contact you by email and you pay online. I did it last week for the Japan parcel. I was not sent an email for this.

None of that €8 handling fee goes to the postie who has an extra five minutes to make up for. I wouldn't mind if it was a tip, we cash-tip regularly for difficult deliveries.

There's no receipt and most people pay in cash so an unscrupulous postie could ask for whatever whenever. Half of my spam is claims from various delivery companies claiming my parcels are held up and need money, they opened a terrible can of worms

Laposte is not great at what they do and have not operated as a public service for a long time now with massive inflation on the cost of sending stuff. A postcard stamp (in country!) will set you back $1.6

RESENTMENT because I was extremely strict about hobby money.

A €11 loss would have meant two yarn or partial reroots to make up for it. Possibly selling one of my personal collection. At least four hours of work.

Every single supply and unexpected expense like parcel loss or extra fees came from the hobby fund which would be in the red if it wasn't a current sales moment. (My first rotary tool was bought with hobby money even though it had non doll purposes for example.)

I knew at the time that it was unhealthy thinking but hadn't found an alternative or ways to mentally unblock.

IMPOTENCE:

recourse is nearly impossible the post office system is designed that way: no receipt and they can claim bad formatting of the CN22 masked the barcode. It's always something. They sent my australia parcel to austria, billed me, i opened a case and checked in every month and nothing.

poverty mindset: if you've ever felt the sting of removing an item from the conveyor belt to afford the total, you know that someone else's small change is something big and important and painful. Even once you have some money it doesn't go away: donating to others is easy, being cheated by a system is awful.

Solutions:

As much as possible, I don't use LaPoste and their extortionate prices for sending to France and the EU. My two posties get regular tips and cash gifts at Christmas but I don't use the post office unless I absolutely have to. Mondialrelay or Point to Point get my money whenever possible. That feels good and makes losses feel less bad.

I treat unexpected expenses like a lost parcel, disgruntled client or new fees as a tip to myself. I put in the work, did everything I could and something out of my control happened. The expense is marked down but cancelled out from my personal kitty. I have been inconvenienced: I'm not going to let it hurt or work it off.

Hobby supplies that are multipurpose are a third category. I was putting glues, chemicals, thread and needles under expenses when I use them for all sorts of repairs.

More importantly: the hobby money spreadsheet became a guideline not a business expenditure book.

Since about 2019 I've also been trying to integrate the idea of the joy of the hobby having its own cost and reward built in:

If i make no money back from a €30 gunky bundle of dolls, there was still €30 worth of enjoyment in fixing them up. The experience of practising even if it comes out all wrong is also valuable. And you often get a tutorial out of it 😁 (see my "mistakes I make so you don't have to" tag)

There was a time before handicap benefits where every cent counted but even then we all managed to make tough choices so we could save small amounts of 'cushion' money - We'd all learned to be so cautious that the cushions went mostly untouched until benefits hit and something unlocked despite still being under the poverty line: the cushion had gone from €30 (100 if we had a good series of months) to €300 emergency funds and no medical expenses were paid out of pocket (as opposed to upfront with a potential refund later) and that made all the difference.

But also a big change was the mindset:

Normal people's unwinding experiences often aren't free even if it's just eating your own snacks at a local bit of grass.

Really throwing out the idea that hobbies should be monetized (that part was hard to unlearn, not just because it was so prevalent but because of shame at not "having a job"- i know now that my full-time job is to keep this body alive and I get maybe 3 hours max to not be about surviving)

Even in poverty you deserve treats because those make priceless memories. Hobby time is valuable because it's what's makes us human not just productivity/survival machines.

-----------------------

Anyway I've also been trying to apply this to my rejection sensitive dysphoria, knowing I'm going to lose Lily soon, frustration with how slow core muscle rebuilding is taking, as well as the very real fear of alienating my sister by accident or just clashing needs (NGL I spiralled most of the day when we had the odd confrontation last week).

but I'd rather break down something less personal in public. ^^;

Here's hoping this little thing that would drive me batty from feeling powerless, which now doesn't sting as much helps someone

#saf#therapy by going ''WTF is wrong with you: give me an itemized list"#then taking that list and asking for more context more details more honesty#personal#tw: poverty mindset

3 notes

·

View notes

Text

Ah yes, the totally normal and not at all neurodivergent urge to repeat a satisfying action that is typically part of a larger set of actions to complete a specific task, but you just like how this one action makes your teeth itch pleasantly, so you just do that.

My favorites that my parents had me do to manage my stealthy little demon called autism growing up that I still revert to over fidget toys:

Unraveling knit or crocheted pieces that have mistakes in them.

Untangling... Basically anything. They purposely tangled balls of yarn by putting them in the washing machine so I could untangle them. I was also always in charge of tangled cables and undoing knots.

Shredding paper by hand. There is nothing that settles my (I forgot the word and my brain is supplying limbic system but I highly doubt that's it) quite like ripping paper into tiny pieces. They discovered this one when I first learned how to make recycled paper from a craft magazine my mom was subscribed to and spent hours shredding paper for the pulp without even actually doing the rest of the process.

Clay. I had so many modeling clay sets as a kid it was insane I would build a billion intricate things just because I liked building and later sculpting. If I didn't have a usable set you could find me on the edge of the pond building intricate fairy villages with mud, which was much messier, so they got me clay every chance they got.

Puzzles. I still enjoy them, I just now don't think they're very useful and also very ugly as a decor piece so I help people build em as a bonding activity but I don't own any.

Painting. Like yeah art and whatever but my favorite is actually just household maintenance. Window frames need a fresh coat? On it. Furniture needs a sanding and some varnish? Gimme! Ceilings looking stained? Hopping to it. New color on the walls? I can do it fast but I will be spending several hours on it just because it's so nice.

Tying and snipping ends on my mom's and later my own sewing projects. Literally my favorite part of sewing anything. Started out with me wanting to help my mom sew but I was 8, noticeably adhd and had just almost cut off half my pinky trying to cut an orange so tying threads it was and I never looked back.

Labeling things. My dad processes his own meat (it's more sustainable than veganism and buying commercially to raise your own small herds of livestock and subsist off it and you're also guaranteed that the slaughtering process is humane and nothing goes to waste) and bought a huge roll of 6000 blank label stickers. Labeling everything is my responsibility and I get irrationally angry if anyone else does it.

Hammering nails into things, turning screws into things, but surprisingly not boring or drilling those are icky. Chopping wood is a recent discovery but that one's fun too, and so is cutting pipes or tiles for home maintenance, as well as stripping the ends off cables to extend or mend a cable.

Glue gun, soldering iron and putty knife are all my best buds lemme use a tool to evenly apply a form of adhesive lemme lemme pleeeaase!

Obsessed with his mind

48K notes

·

View notes

Text

Types of Mandrel for Different Machining and Manufacturing: A Complete Guide

In the world of precision machining and manufacturing, mandrels play a silent but vital role. Whether you're working with metal, drilling operations, or even jewelry design, the mandrel is a go-to tool for holding, supporting, or shaping a workpiece during fabrication.

But what exactly is a mandrel, and why does it matter so much?

A mandrel, also referred to as an arbor, is a cylindrical or tapered rod used to secure workpieces or tooling components during machining. Instead of clamping directly to the machine’s chuck, the workpiece is mounted on the mandrel, which provides better balance, accuracy, and stability. This is especially crucial for items that are delicate or irregular in shape.

Why Use a Mandrel?

Mandrels allow for:

Improved workholding when a chuck or faceplate isn’t suitable

Higher precision in rotating the workpiece around its true center

Reduced deflection or misalignment during machining operations

Types of Mandrels You Should Know

There are many variations of mandrels, each designed for specific tasks:

1. Solid Mandrel: A plain, tapered cylindrical bar ideal for standard, symmetrical workpieces.

2. Step Mandrel: Features stepped diameters for holding parts with different hole sizes. Great for versatile operations.

3. Gang Mandrel: Used to hold multiple hollow workpieces at once—perfect for speeding up production.

4. Collar Mandrel: Has two fixed collars to grip large workpieces with diameters over 100 mm.

5. Screwed Mandrel: Includes a threaded end to securely hold parts with internal threads.

6. Cone Mandrel: Features a sliding cone to adjust for different workpiece diameters, useful for varying inner diameters.

7. Expanding Mandrel: Uses a tapered arbor and split bush design to expand and grip the inside of hollow parts tightly.

8. Ring Mandrel (Triblet): Popular in jewelry, this tapered tool is used to size, form, and shape rings accurately.

How Mandrels Improve Manufacturing

They help in forging and reshaping delicate pieces (especially in jewelry).

Ensure the workpiece rotates concentrically for precision.

Reduce errors and tool wear caused by unstable setups.

Support advanced operations like boring, grinding, or finishing.

From metal lathe operations to intricate ring making, mandrels are indispensable. Their role in securing workpieces and ensuring flawless rotation cannot be overstated. With so many types available, choosing the right mandrel for your application can significantly improve both quality and efficiency.

For a deep dive into specifications, design differences, and use cases, check out the full article here: Types of Mandrel for Machining and Manufacturing

#Mandrel#LatheTools#MachiningBasics#ManufacturingTech#PrecisionMachining#MachineShop#Metalworking#ToolTalk#CraftWithLathe#WorkshopGear#JewelryMaking#LatheMandrel#MachiningTools#SolidMandrel#EngineeringTips

0 notes

Text

Super Duplex Fasteners: Complete Guide for Buyers, Engineers & Industry Professionals

Introduction to Super Duplex Fasteners

In demanding industrial applications where high strength and superior corrosion resistance are required, Super Duplex Fasteners have emerged as a leading solution. These fasteners are made from super duplex stainless steel, which offers a unique combination of excellent mechanical properties and outstanding resistance to various forms of corrosion. Super Duplex Fasteners are extensively used in industries like oil & gas, chemical processing, marine engineering, offshore drilling, desalination plants, and petrochemical manufacturing due to their superior strength and corrosion resistance.

This blog provides a complete, in-depth understanding of Super Duplex Fasteners, including their types, chemical composition, mechanical properties, grades, advantages, applications, and why Ananka Fasteners is a trusted manufacturer and supplier.

What is Super Duplex Stainless Steel?

Super Duplex Fasteners are made from Super Duplex stainless steel, a category of stainless steels with a dual-phase microstructure comprising austenite and ferrite in roughly equal proportions. This dual-phase structure imparts superior strength and enhanced resistance to stress corrosion cracking, pitting, and crevice corrosion compared to standard stainless steels.

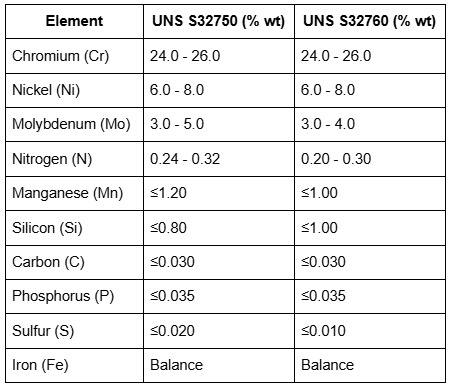

Common Grades of Super Duplex Stainless Steel:

UNS S32750 (1.4410) – SAF 2507

UNS S32760 (1.4501) – Zeron 100

UNS S32550

UNS S32900

These grades are especially popular for fasteners in critical service environments where both strength and corrosion resistance are required.

Key Characteristics of Super Duplex Stainless Steel:

Elevated levels of chromium (24–26%), molybdenum (3–5%), and nitrogen (0.2–0.3%) enhance its strength and corrosion resistance.

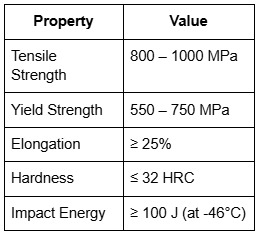

Excellent pitting and crevice corrosion resistance

Offers outstanding resistance to chloride-induced stress corrosion cracking (SCC)

Provides up to twice the yield strength of standard austenitic stainless steel fasteners, ensuring superior durability in harsh environments.

Outstanding fatigue and erosion resistance

Types of Super Duplex Fasteners

Bolts:

Hex Bolts

Heavy Hex Bolts

Socket Head Cap Screws

Stud Bolts

U-Bolts

Eye Bolts

Anchor Bolts

Carriage Bolts

Nuts:

Hex Nuts

Heavy Hex Nuts

Lock Nuts

Cap Nuts

Coupling Nuts

Screws:

Machine Screws

Self-Tapping Screws

Thread Cutting Screws

Set Screws

Washers:

Flat Washers

Spring Washers

Lock Washers

Belleville Washers

Custom Fasteners:

Forged or machined as per customer drawings or international standards.

Chemical Composition of Super Duplex Fasteners

Mechanical Properties of Super Duplex Fasteners

Key Standards & Specifications

Super Duplex Fasteners are produced in compliance with multiple international standards and specifications to ensure high quality, performance, and global industry acceptance.

ASTM A182 for forged fastener components

ASME B18.2.1, B18.2.2 for dimensional standards

Advantages of Super Duplex Fasteners

Outstanding Corrosion Resistance: Superior protection against pitting, crevice corrosion, and stress corrosion cracking, making Super Duplex Fasteners ideal for chloride-rich and harsh environments.

Superior Strength: Delivers up to twice the strength of conventional austenitic stainless steels such as 316L, ensuring long-term durability and performance.

Cost-Effective: Although initially more expensive, their longer lifespan reduces maintenance and replacement costs.

Excellent Fatigue Resistance: Ideal for dynamic load-bearing applications.

Superior Performance in Aggressive Environments: Withstand high pressures, temperatures, and corrosive chemicals.

Applications of Super Duplex Fasteners

Oil & Gas Industry: Subsea pipelines, manifolds, wellhead equipment, and offshore drilling platforms.

Chemical & Petrochemical Plants

Marine Industry: Shipbuilding, desalination plants, and seawater cooling systems.

Power Generation: Flue gas desulfurization units, turbines, and heat exchangers.

Pulp & Paper Industry: Digesters, bleaching equipment, and washers.

Why Choose Ananka Fasteners for Super Duplex Fasteners?

At Ananka Fasteners, we specialize in manufacturing and supplying high-quality Super Duplex Fasteners for global industries. Our key differentiators:

In-House Manufacturing: Advanced CNC machining, forging, and heat treatment facilities.

Stringent Quality Control: ISO certified processes with full traceability and certified test reports.

Global Export Capabilities: Fast and reliable delivery across the USA, Europe, Middle East, Africa, and Asia.

Custom Manufacturing: We produce special fasteners according to customer drawings, standards, and material specifications.

Conclusion

Super Duplex Fasteners are the optimal choice for industries facing extreme mechanical stresses and highly corrosive environments. Their superior strength, exceptional corrosion resistance, and long-term durability make them a highly cost-effective solution. Whether you're involved in oil & gas, marine, chemical, or power generation sectors, Super Duplex Fasteners will provide the reliable performance your projects demand.

At Ananka Fasteners, we are fully equipped to meet your needs with precision, quality, and timely delivery.

Frequently Asked Questions (FAQ)

Q1. What makes Super Duplex Fasteners superior to regular stainless steel fasteners?Super Duplex Fasteners offer twice the strength and significantly higher corrosion resistance, especially against chloride-induced stress corrosion cracking.

Q2. Can Super Duplex Fasteners be used in seawater applications?Yes, they are specifically designed for harsh chloride environments like seawater, making them ideal for marine and offshore use.

Q3. Are custom sizes and specifications available?Absolutely. We manufacture custom fasteners based on client specifications, drawings, and international standards.

Q4. Do you provide mill test certificates?Yes, all our fasteners come with full material test reports (MTRs) as per EN 10204 3.1 or 3.2.

#SuperDuplexFasteners#UNSS32750#FastenersManufacturer#OffshoreFasteners#CorrosionResistance#DuplexBolts#SuperDuplexNuts#AnankaFasteners#GlobalExporter#MarineFasteners#Duplexfasteners#Blog#Articles#Ananka#Buyers#B2B#Business#Manufacturing#manufacturer#supplier#fasteners#tumblr#tumblr blog

0 notes

Text

Securing Tomorrow: Fasteners and the Power of Connection - Caliber Enterprise

Fasteners: The Building Blocks of Industrial Strength

Fasteners are the core of every structure, machine, and component that demands reliability and stability. At Caliber Enterprise, we specialize in delivering high-performance fastening solutions designed for diverse industries and demanding environments. As one of the leading Fasteners Manufacturers in India, we take pride in our commitment to quality, precision, and on-time delivery, offering an unmatched range of industrial fasteners trusted by engineers and manufacturers worldwide.

Fasteners may be small in size, but their role in mechanical and structural integrity is enormous. These essential components are used across virtually every industry—construction, automotive, aerospace, energy, electronics, and more. Without fasteners, assembling parts into functioning systems would be nearly impossible. As industries continue to evolve, so does the demand for high-performance fasteners designed for strength, durability, and ease of use.

What Are Fasteners?

Fasteners are hardware devices used to mechanically join two or more objects. Unlike welding or adhesive bonding, fasteners typically allow for disassembly without damaging the components involved. They are used for both permanent and temporary connections depending on the application.

The most commonly used fasteners include:

Bolts – Threaded fasteners used with nuts to form a secure joint. Common in structural and automotive applications.

Nuts – Mated with bolts to clamp parts together.

Screws – Threaded fasteners that can create their own mating thread in materials like wood, metal, or plastic.

Washers – Used with bolts and nuts to distribute load and prevent surface damage or loosening.

Each fastener type is manufactured in a variety of sizes, thread types, materials, and coatings, enabling engineers and builders to choose the right product for specific needs.

Global Presence and Regional Excellence

India has emerged as a global hub for fastener production, offering cost-effective and high-quality solutions. Reputed Fasteners Supplier supplies products not only to local markets but also to demanding international industries such as oil & gas, construction, shipbuilding, and energy.

For clients in South India, Fasteners manufacturers in Chennai offer quick access to premium-grade products with custom dimensions and finishes. These manufacturers cater to regional infrastructure projects and OEMs requiring precise and consistent quality. Meanwhile, the presence of Fasteners manufacturers in Australia highlights the global reach of Indian suppliers, who export vast quantities of nuts, bolts, and screws to industrial markets across the southern hemisphere.

Sourcing Made Simple with Weight Charts and Product Guides

For engineers and procurement managers, calculating weights and selecting the right fasteners can be complex without the proper data. That’s where a nut bolt weight chart in kg pdf becomes essential. These charts help users estimate total shipment weight, understand load-bearing capacity, and ensure the correct fastener is chosen for the application. The availability of downloadable weight charts enhances transparency, simplified logistics, and improves decision-making across industries.

A leading Fasteners Supplier in India will typically offer detailed catalogs, technical specifications, and weight charts for various products like hex bolts, socket screws, flange nuts, and structural washers. Some even provide 3D CAD drawings, torque guides, and installation instructions to support engineers in design and assembly.

Conclusion:

Fasteners are really important parts, like screws, bolts, and nuts. They hold things together, from small phones to huge buildings. They make sure everything stays strong and safe.We help people find the best Fasteners Manufacturer in India. India makes great fasteners and sends them all over the world, even to places like Australia. They also give useful tools like nut bolt weight charts to help people choose the right fasteners. So, with good fasteners, we can build strong and safe things for the future.

0 notes

Text

Top-Notch CNC Turning Services in India for Precision Manufacturing

High-Precision CNC Turning Solutions Across India

CNC Turning Services in India are revolutionizing the manufacturing industry. With cutting-edge machinery and expert technicians, Indian manufacturers are delivering high-accuracy, cost-effective solutions to global clients.

Whether it’s stainless steel, aluminum, brass, or titanium, Indian CNC workshops handle complex geometries with ease. These services meet the needs of aerospace, automotive, medical, and electronics sectors.

Why Choose CNC Turning Services in India?

Cost-Effective Production India offers competitive pricing without compromising on quality. This makes it a global hub for outsourced machining services.

Advanced Technology Indian CNC units are equipped with modern lathes and automated controls. They ensure tight tolerances and smooth finishes every time.

Skilled Workforce Trained engineers and machinists deliver consistent results with every part. They focus on both precision and productivity.

Rapid Turnaround With efficient workflows, Indian CNC manufacturers reduce lead times. They are capable of quick production runs and urgent orders.

Industries Served by Indian CNC Turning Experts

Automotive Industry Precision parts like shafts, axles, bushings, and gear blanks are machined to exact tolerances.

Aerospace Sector CNC turning enables the production of complex components required in aviation and defense applications.

Medical Devices Implant-grade titanium parts and surgical instruments require absolute accuracy, which CNC turning delivers flawlessly.

Electronics and Telecommunications Small intricate components like connectors, sleeves, and pins are manufactured using high-speed CNC turning.

Materials Used in CNC Turning in India

Aluminum

Stainless Steel

Mild Steel

Brass

Copper

Titanium

Plastic (Nylon, PTFE, PEEK)

Each material is selected based on project requirements and is machined under controlled conditions for the best output.

Types of CNC Turning Operations Offered

Facing – Levels the surface for clean finishes.

Parting – Separates the piece from raw material.

Threading – For bolts, screws, and fasteners.

Drilling & Boring – Precise holes and internal cavity forming.

Grooving & Knurling – Functional and aesthetic detailing.

These processes can be performed on single-spindle or multi-axis CNC turning centers, depending on design complexity.

Benefits of Outsourcing CNC Turning Services to India

Lower Operational Costs You reduce in-house machinery investment and staffing overhead.

Scalable Production Whether it's a prototype or bulk batch, Indian workshops adjust accordingly.

ISO-Certified Quality Most facilities follow ISO 9001 and other relevant standards to ensure part reliability.

Global Export Capability Parts are packed, labeled, and shipped with proper documentation, making them export-ready.

Custom CNC Turning Services for Your Projects

Indian companies offer tailored machining solutions. CAD files, drawings, and specifications are carefully reviewed before production begins. They also provide first-article inspection reports and full traceability if needed.

Best Cities for CNC Turning Services in India

Pune

Bangalore

Coimbatore

Rajkot

Ludhiana

Ahmedabad

Chennai

These cities host top-tier CNC manufacturing hubs and deliver quality on time, every time.

How to Choose a Reliable CNC Turning Partner in India

Look for certifications and client reviews.

Ask about their quality control procedures.

Request samples or trial orders.

Confirm lead time and packaging standards.

Ensure they support international shipping.

Conclusion

India has become a global powerhouse for CNC Turning Services india. With precision, speed, and cost-effectiveness at the core, it’s the ideal destination for your machining needs. Partner with an Indian CNC expert today to elevate your manufacturing game.

1 note

·

View note

Text

Your Shoulders and Chest Are Holding You Back—Here’s Why and How to Fix It

You’re in the gym, ready to dominate chest day, but instead of feeling like a beast, your shoulders are whining, and your pecs look like they’re on strike.

Sound familiar? A heated debate in a popular fitness community recently blew up over this exact issue: lifters stuck with achy shoulders, lagging chest development, or both.

A while back, a heated discussion in a popular fitness community tackled this exact problem: lifters struggling with weak chests, achy shoulders, or both.

The discussion wasn’t just gym bro drama—it was a wake-up call about why so many people struggle with upper body training.

Today, we’re breaking down the biggest mistakes holding you back and sharing no-BS fixes to build a strong, pain-free chest and shoulders. Buckle up—this is gonna hit hard.

Ever hit the gym, ready to crush a chest workout, only to feel your shoulders screaming or your bench press stalling out? It’s like your upper body’s staging a mutiny.

The Upper Body Struggle Is Real

Nothing kills your gym vibe like a weak chest or cranky shoulders. You’re grinding through bench presses, but your pecs aren’t growing, or your shoulders feel like they’re about to pop.

In that fitness community thread, a seasoned lifter pointed out a brutal truth: Most people mess up their upper body training by ignoring balance, form, or recovery.

The result? Plateaus, pain, and a whole lot of frustration.

Think about it: If your shoulders hurt every time you press, or your chest feels flat despite endless reps, something’s off. Maybe you’re overdoing it, using bad technique, or neglecting key muscles.

A smart upper body plan focuses on compound lifts like bench presses and overhead presses, paired with accessories like rows and dips, to build strength without wrecking your joints. But too many lifters chase the pump with random routines, and their progress pays the price.

A 2020 study in the Journal of Strength and Conditioning Research found that balanced training programs—targeting both primary and supporting muscles—reduce injury risk and boost performance. So, if your upper body’s lagging, it’s time to get strategic.

⚡ “A weak chest or achy shoulders aren’t just bad luck—they’re a sign your training’s out of whack.” ⚡

The Upper Body Crisis Nobody Talks About

Let’s be honest: Nothing kills your gym mojo faster than shoulder pain or a chest that refuses to grow.

You’re grinding through bench presses, but your shoulders feel like they’re about to stage a walkout, and your pecs? Still waiting for their big debut.

The fitness community discussion laid it bare: Most lifters are sabotaging their upper body gains with bad habits—poor form, imbalanced training, or just plain overdoing it.

Why does this happen? Because upper body training is a balancing act. Your chest, shoulders, and triceps all have to play nice, but most people treat the bench press like it’s the only move that matters.

Spoiler: It’s not. A smart plan mixes compound lifts (like bench and overhead presses) with targeted accessories (think rows, flys, and face pulls) to keep everything in sync. Screw that up, and you’re begging for pain or plateaus.

A 2020 study in the Journal of Strength and Conditioning Research found that balanced training programs—hitting both primary and supporting muscles—slash injury risk and boost strength. So, if your upper body’s crying for help, it’s time to rethink your approach.

⚡ “Shoulder pain and a weak chest aren’t just bad days—they’re red flags your training’s broken.” ⚡

Conflict #1: Overloading Shoulders While Starving Your Chest

One big debate in the community discussion was about muscle imbalance.

Some lifters complained their shoulders were taking over during chest exercises, leaving their pecs underdeveloped.

The veteran lifter’s take? You’re probably benching wrong or skipping the right accessories.

Here’s the deal: The bench press is a chest exercise, but it leans hard on your shoulders and triceps too.

If your form’s off—say, flaring your elbows or shrugging your shoulders—your delts do all the work, and your pecs snooze.

Fix it by tucking your elbows slightly (think 45-degree angle) and keeping your shoulder blades pinched back.

Also, add chest-focused moves like dumbbell flys or pec-deck flys to isolate those pecs.

A friend of mine, let’s call her Sarah, struggled with a weak bench until she added 3 sets of flys after her presses. Six months later, her chest was popping, and her bench PR shot up 20 pounds.

Conflict #2: Your Bench Press Is a Shoulder Killer

One of the loudest gripes in the fitness community was about the bench press.

Lifters complained their shoulders were getting smoked while their chests stayed flat. The veteran lifter’s hot take? Your form’s probably garbage, and it’s letting your shoulders steal the show.

Here’s the deal: The bench press is a chest exercise, but it’s also a team effort—your shoulders and triceps are in on the action.

If you’re flaring your elbows out like you’re doing jazz hands or shrugging your shoulders up to your ears, you’re dumping the load on your delts.

The fix? Tuck your elbows slightly (aim for a 45-degree angle), pinch your shoulder blades together, and keep your feet planted for stability.

Also, throw in chest-specific moves like dumbbell flys or pec-deck flys to wake up those pecs.

A 2019 study in Sports Medicine showed that combining compound and isolation exercises boosts chest activation without overtaxing shoulders.

Yet, tons of lifters bench with zero focus, then wonder why their shoulders hate them.

Real talk: If your shoulders hurt more than your chest after benching, you’re not training—you’re torturing your joints.

💬 “Bad bench form turns your chest day into shoulder punishment. Fix your setup, or pay the price.” 💬

Conflict #3: You’re Ignoring Your Back (And It’s Screwing You)

Another big clash in the discussion was about balance—or the lack of it. Some lifters were so chest-obsessed they barely touched their back muscles.

The veteran’s response? Neglect your lats and traps, and you’re begging for weak presses and jacked-up shoulders.

Think about it: Your upper body’s like a seesaw. If you’re all chest and no back, you’re tipping over—literally. Weak lats and traps mess up your bench stability and pull your shoulders forward, setting you up for pain and lousy posture.

A solid plan includes pulling exercises like barbell rows, pull-ups, or face pulls at least as often as you push. For example, try matching every bench set with a row set to keep things even.

A 2021 study in Medicine & Science in Sports & Exercise found that balanced push-pull training reduces shoulder strain and improves pressing strength. But let’s be real—most gym bros skip back day because it’s not “sexy.” Newsflash: A strong back makes your chest look better and your shoulders feel better.

⚡ “No back, no gains. Skip pulling exercises, and your chest and shoulders will suffer.” ⚡

Conflict #4: Overtraining vs. Under-Recovering

The community thread got spicy when some lifters blamed their shoulder pain on “overtraining.” The veteran pushed back hard, saying it’s not about training too much—it’s about recovering too little. If your shoulders are fried, you’re probably not eating, sleeping, or resting enough.

Let’s get real: Are your shoulders trashed because you’re benching five days a week, or because you’re surviving on coffee and four hours of sleep? True overtraining is rare for most lifters—it’s usually under-recovery in disguise.

A smart upper body routine might hit chest and shoulders twice a week, with heavy days (3-5 reps) and lighter accessory days (8-12 reps). But if you’re not eating enough protein (aim for 0.8-1g per pound of body weight) or getting 7-9 hours of sleep, your body can’t rebuild.

A 2020 meta-analysis in Journal of Sports Sciences found that adequate recovery (nutrition, sleep, and rest days) is just as critical as training for strength gains. So, if your shoulders are screaming, check your lifestyle before you blame the barbell.

I know a guy, let’s call him Mike, who kept getting shoulder twinges from heavy benching. He was training hard but eating like a bird and sleeping five hours a night.

He upped his calories, prioritized sleep, and added a rest day—boom, pain gone, bench up 15 pounds in two months. Recovery isn’t sexy, but it’s the secret sauce.

💬 “Overtraining’s a myth for most. Under-eating and under-sleeping are the real shoulder killers.” 💬

Conflict #5: Mobility Myths vs. Actual Fixes

One last debate in the thread was about shoulder mobility. Some lifters thought endless stretching would fix their pain, while the veteran argued that mobility work alone won’t cut it—you need strength and stability too.

Here’s the truth: Tight shoulders can contribute to pain, but stretching like a yoga guru won’t magically save you. Strong, stable shoulders come from a mix of mobility drills (like arm circles or doorway stretches) and strength exercises (like face pulls or external rotations).

For example, try 2 sets of 15 face pulls twice a week to fire up your rear delts and rotator cuffs.

A 2018 study in Journal of Strength and Conditioning Research showed that combining mobility and stabilizing exercises reduces shoulder pain more than stretching alone.

Yet, so many lifters waste time foam-rolling their lives away instead of building bulletproof shoulders.

Hot take: Mobility’s overrated without strength. Train your shoulders to move well and hold strong.

⚡ “Stretching’s nice, but strong shoulders don’t come from yoga. Build stability to stay pain-free.” ⚡

Time to Fix Your Upper Body Game

That fitness community debate wasn’t just a bunch of lifters whining—it was a roadmap for anyone struggling with shoulder pain or a weak chest. The big takeaways? Fix your bench form to save your shoulders and grow your pecs. Balance pushing and pulling to keep your upper body in check.

Prioritize recovery—eat, sleep, repeat. And don’t fall for the mobility trap; build strength and stability instead. But here’s the kicker: None of this works if you’re half-assing it.

Consistency is the difference between a so-so chest and a set of pecs that stop traffic.

So, take a hard look at your upper body routine. Are you benching like a shoulder assassin? Skipping back day? Starving your recovery?

Start with a balanced plan—bench and rows twice a week, add flys and face pulls, and fuel your body right. Track your progress, listen to your shoulders, and don’t be afraid to dial it back if pain creeps in. The gym’s a marathon, not a sprint, and your upper body deserves better.

Got a shoulder horror story or a chest-building hack that works? Drop a comment and let’s keep this convo going. Your next big bench PR is out there—go grab it.

Gold Nuggets for Upper Body Domination

⚡ “Shoulder pain and a weak chest aren’t just bad days—they’re red flags your training’s broken.”

💬 “Bad bench form turns your chest day into shoulder punishment. Fix your setup, or pay the price.”

⚡ “No back, no gains. Skip pulling exercises, and your chest and shoulders will suffer.”

💬 “Overtraining’s a myth for most. Under-eating and under-sleeping are the real shoulder killers.”

⚡ “Stretching’s nice, but strong shoulders don’t come from yoga. Build stability to stay pain-free.”

0 notes

Text

Taps vs. Dies: Understanding the Key Differences in Threading Tools

Threading is a vital machining process widely used in industries like construction, automotive, plumbing, and manufacturing. At arhtrd, we understand the importance of clean, precise threading for ensuring structural integrity and component compatibility. Whether assembling machinery or repairing stripped threads, threading ensures bolts and fasteners fit securely by forming helical grooves on cylindrical surfaces.

Two of the most essential tools in the threading process are taps and dies. Though both are used to create threads, they serve very different functions. This comprehensive guide from arhtrd will explain threading, break down the differences between taps and dies, and help you choose the right tool for your application.

What Is Threading?

Threading is the process of cutting spiral grooves—called threads—on the inside or outside of a cylindrical object. These grooves allow fasteners such as screws and bolts to engage securely.

Internal Threading: Creates threads inside a drilled hole for bolts or screws to fit.

External Threading: Forms threads on the outside of a rod or pipe, allowing it to fit into a threaded hole.

At arhtrd, we emphasize the importance of accurate threading for strong joints, tight seals, and easy disassembly in applications across aerospace, manufacturing, plumbing, and more.

What Is a Tap?

A tap is a tool used to cut internal threads within a pre-drilled hole. This tool is essential for preparing a surface to receive a threaded fastener.

Types of Taps

Taper Tap: Features a gradual taper, making it easy to align and start the thread—perfect for beginners or initial threading steps.

Plug Tap: Designed with a medium taper and used for general-purpose internal threading.

Bottoming Tap: Has nearly no taper and is used to cut threads near the bottom of blind holes.

Common Uses of Taps

Creating threads for bolts, nuts, and internal components.

Repairing stripped or damaged internal threads.

Threading a variety of materials, including metal, plastic, and wood.

At arhtrd, we recommend using precision-ground taps for maximum accuracy and durability in both DIY and professional settings.

What Is a Die?

A die is used to cut external threads on rods, pipes, and bolts. Dies are crucial in forming male threads that fit securely into tapped holes.

Types of Dies

Round Dies: Commonly used for cutting or rethreading external threads.

Hex Dies: Feature a hexagonal shape and are compatible with standard wrenches for easy manual threading.

Adjustable Dies: Allow for minor thread size adjustments, making them ideal for custom fits.

Common Uses of Dies

Creating external threads on rods or pipes.

Repairing damaged bolt threads.

Producing specialty fasteners in mechanical, automotive, and plumbing applications.

arhtrd’s collection of high-performance dies ensures clean cuts, thread consistency, and long-lasting tool life.

Taps vs. Dies: What Sets Them Apart?

Understanding the core differences between these tools is essential for selecting the right one.

1. Functionality

Taps create internal threads for receiving screws or bolts.

Dies create external threads on cylindrical objects like rods or pipes.

Example: If you're attaching a bolt to a solid surface, use a tap to create internal threads. If you're making a bolt from a rod, use a die to cut external threads.

2. Thread Cutting Process

Tapping Process:

Drill a hole in the material.

Insert the tap and rotate to cut internal threads.

Carefully back off periodically to clear debris.

Die Threading Process:

Secure the rod or pipe.

Fit the die and turn it to form external threads.

Apply cutting oil to reduce friction and ensure a smooth finish.

Both processes are taught in threading guides on the arhtrd blog and product manuals.

3. Required Tools

Taps: Used with a tap wrench for torque and alignment.

Dies: Used with a die stock or wrench for balanced threading.

At arhtrd, we offer ergonomic tap wrenches and die stocks that ensure accuracy and reduce user fatigue.

4. Thread Repair Applications

Taps re-cut and restore worn or damaged internal threads.

Dies are used to repair damaged threads on bolts, rods, or pipes.

Thread repair is a key component of our maintenance kits available at arhtrd.com.

5. Speed and Efficiency

Taps may take longer as they require pre-drilled holes and careful alignment.

Dies can be faster since they cut threads directly onto the material.

Nonetheless, both require steady hands and the proper tools—available through arhtrd—to avoid thread misalignment or tool breakage.

Conclusion: Trust arhtrd for Precision Threading Tools

Taps and dies are essential tools for professionals and DIY enthusiasts alike. Taps are used to cut internal threads, while dies cut external threads. Knowing which tool to use—and how to use it—ensures strong, reliable, and properly aligned threaded connections.

At arhtrd, we pride ourselves on providing high-quality threading tools, detailed guides, and expert support. Whether you're restoring threads, assembling parts, or creating custom fasteners, you can count on arhtrd for the accuracy, efficiency, and durability your projects demand.

0 notes

Text

Cutting vs. Forming Taps: Lifecycle Costs and When to Use Each

Choosing the right tap for your threading job isn’t just about getting the job done. It’s about doing it right, efficiently, and cost-effectively over time. Two popular cutting and forming taps offer different advantages depending on your material, application, and production volume. Understanding their lifecycle costs and best-use scenarios can help you make smarter decisions in the shop.

What Are Cutting Taps?

Cutting taps remove material to create threads. As they turn into the hole, flutes on the tap carve away metal chips, forming internal threads to match a bolt or screw.

Cutting taps are versatile and work well in various applications, including pipe taps for threading cylindrical holes in plumbing or gas lines. They are especially ideal when thread standards must be tightly controlled.

What Are Forming Taps?

Forming taps (roll taps or fluteless taps) don’t cut material. Instead, they displace it. The tap pushes metal into the desired shape, creating strong, work-hardened threads without producing chips.

Since forming taps generate no chips, they are perfect for operations where chip clogging can cause tool breakage or poor finishes.

Comparing Lifecycle Costs

While cutting taps are often cheaper upfront, forming taps can offer better value over time. Here’s how they compare in terms of lifecycle costs:

Tool life:

Forming taps generally last longer than cutting taps, often 2 to 3 times longer.

Cutting taps wear faster, mainly when used on abrasive or hard materials.

Thread quality and strength:

Threads made with forming taps are usually stronger due to cold work hardening.

Cutting taps may create slightly rougher threads, especially near the end of their lifespan.

Coolant and lubrication:

Forming taps typically require better lubrication to reduce friction during thread forming.

Cutting taps need sound chip evacuation systems and cutting fluids to remove heat and debris.

Maintenance and downtime:

With longer tool life and fewer broken taps, forming taps reduce the need for frequent tool changes and machine stops.

Cutting taps may lead to more downtime, especially in high-volume settings.

Special Case: Pipe Taps

Pipe taps, which create threads for plumbing and gas fitting applications, are usually cutting taps. This is because they often need to cut precise, tapered threads in harder materials like cast iron or steel, and cutting taps provides better control and accuracy for these applications.

However, if the application allows it and the material is ductile, forming-style pipe taps may be used in specialized setups. That said, due to the precision and material constraints, cutting is still the norm for most pipe threading jobs.

Final Thoughts

The right tap depends on more than just the thread you need. It’s about material, production volume, and long-term costs. Cutting taps are a go-to for general use, especially with hard materials and precise specs. While forming taps offer a chip-free, longer-lasting solution for softer metals.

Taking the time to choose between cutting and forming taps can pay off not just in performance but also in reduced tool costs, better threads, and fewer headaches on the shop floor.

0 notes