#Water for injection

Explore tagged Tumblr posts

Text

Avoid Delays in Installing Your Water Purification Plant: A Complete Guide

Installing a water purification plant is a critical step for industries requiring high-purity water for their operations. Whether for pharmaceuticals, food and beverage, or specialty chemicals, ensuring timely installation is essential to avoid operational disruptions, increased costs, and compliance risks. However, delays are common due to factors like poor planning, supply chain issues, and unforeseen site conditions. Understanding these challenges and implementing proactive strategies can help keep your project on track. Let’s dive into the key causes of delays and how to prevent them.

Identifying the Causes of Delays

Delays in setting up a water purification plant often stem from a few recurring issues. Recognizing these early can help avoid costly setbacks:

1. Inadequate Project Planning

One of the primary causes of delays is insufficient planning. Without a detailed project roadmap, unforeseen hurdles can arise, such as infrastructure mismatches, unexpected equipment needs, or workflow inefficiencies. A proper plan ensures every step — from design to commissioning — is carefully mapped out.

2. Supply Chain Disruptions

Water purification systems require specialized components like RO membranes, EDI units, and control panels. Delays in sourcing these materials can hold up the entire installation. Partnering with reliable suppliers who can ensure timely delivery is crucial.

3. Regulatory and Compliance Bottlenecks

Industries such as pharmaceuticals must comply with strict water quality standards. Delays in securing necessary permits and approvals can push back installation timelines significantly. Early engagement with regulatory bodies helps prevent this.

4. Workforce and Skill Shortages

A lack of skilled personnel can result in inefficient installation processes. Additionally, poor communication between teams can slow progress, causing unnecessary delays. Ensuring that experienced technicians are involved from day one can prevent such issues.

5. Unanticipated Site Conditions

Every installation site is unique, and unforeseen conditions such as inadequate space, insufficient utilities, or unexpected infrastructure challenges can delay progress. Conducting a comprehensive site survey beforehand minimizes surprises.

Strategies to Ensure Timely Installation

Now that we know the common pitfalls, let’s explore effective strategies to dodge delays and ensure the timely installation of your water purification plant:

1. Meticulous Project Planning

A successful installation begins with a comprehensive plan. Define the project scope, set clear timelines, assign responsibilities, and establish contingency plans for potential disruptions. Regular project reviews help keep everything on track.

2. Partner with Reliable Suppliers

Choosing the right suppliers can make or break your installation timeline. Look for partners with a proven track record in delivering high-quality components like reverse osmosis membranes, EDI systems, and control panels on time. A reliable supplier can also offer technical support during installation.

3. Early Regulatory Compliance

Engage with regulatory bodies at the earliest stages of your project. Understanding industry-specific guidelines and securing the necessary permits in advance can prevent last-minute holdups. Staying updated with compliance standards ensures smooth approval processes.

4. Invest in Skilled Workforce

A trained workforce is key to swift installation. Invest in training programs and ensure your team is well-versed in handling specialized equipment. Clear communication between project managers, technicians, and external contractors keeps the workflow smooth and efficient.

5. Thorough Site Preparation

Conduct a detailed site assessment to identify potential hurdles before installation begins. Address infrastructure challenges, ensure the availability of utilities, and prepare the site to accommodate the plant and its components without disruptions.

The AMC Advantage: Preventing Delays Beyond Installation

While timely installation is crucial, maintaining peak performance over time is equally important. This is where an Annual Maintenance Contract (AMC) becomes a game-changer. AMC offers a structured plan for regular maintenance, ensuring long-term operational efficiency and minimizing the risk of unexpected breakdowns. Key benefits include:

Proactive Maintenance: Regular inspections prevent minor issues from escalating, reducing downtime.

Operational Efficiency: Timely servicing optimizes performance, ensuring water quality remains uncompromised.

Cost Control: Predictable maintenance costs prevent unexpected repair expenses, helping you manage budgets effectively.

Expert Support: Access to specialized technicians ensures quick resolutions and reduces dependency on in-house teams for complex issues.

Opting for AMC keeps your water purification system running smoothly and extends its lifespan, making it a wise investment for any industry relying on high-purity water.

Conclusion: Secure Your Success with the Right Partner

Avoiding delays in installing your water purification plant is achievable with the right approach. By prioritizing comprehensive project planning, partnering with reliable suppliers, securing early regulatory approvals, investing in skilled personnel, and preparing the site in advance, industries can ensure smooth and timely installations.

Beyond installation, maintaining performance is essential — and that’s where a trusted partner makes all the difference. Swjal Process Pvt. Ltd. stands out as a leading High-Purity Water Systems manufacturer in India, offering end-to-end solutions from installation to long-term maintenance. Partner with Swjal for reliable, efficient, and timely water purification solutions.

Would you like to add a client success story, highlight Swjal’s AMC offerings, or include a call to action? Let me know, and I’ll refine the article accordingly!

#water treatment system#manufacturer#biotech industry#water for injection#water treatment plant#swjalprocess#india

0 notes

Text

Baxter Water For Injection 1000ml - Joya Medical Supplies | Australia

Buy Baxter water for injection 1000ml from Joya Medical Supplies. Baxter sterilised water for injections is employed as a vehicle for medicinal products when water is a suitable solvent for dissolving or diluting injectable therapeutic substances for parenteral administration.

#Baxter Water For Injection 1000ml#Baxter Water For Injection#Water For Injection#Water For Injection 1000ml

0 notes

Text

https://joyamedicalsupplies.com.au/product/baxter-water-for-injection-1000ml/

Buy Baxter water for injection 1000ml from Joya Medical Supplies. Baxter sterilised water for injections is employed as a vehicle for medicinal products when water is a suitable solvent for dissolving or diluting injectable therapeutic substances for parenteral administration.

#Baxter Water For Injection 1000ml#Baxter Water For Injection#Water For Injection 1000ml#Water For Injection

0 notes

Text

How to Achieve Compliance with USP and EP Standards for WFI

Achieving compliance with United States Pharmacopeia (USP) and European Pharmacopoeia (EP) standards for Water for Injection (WFI) is a critical requirement for pharmaceutical and biotech companies. These standards provide guidelines for WFI purity, safety, and production methods, ensuring that the water used in injectable products meets the highest quality requirements. This article outlines the necessary steps to achieve compliance with these stringent regulations.

Understanding USP and EP Standards for WFI

USP and EP standards set forth rigorous requirements for the purity of Water for Injection, addressing contaminants such as endotoxins, bacteria, and organic impurities. The USP guidelines, primarily used in the United States, and EP guidelines, widely accepted in Europe, specify that WFI must be free from endotoxins, meet microbial limits, and achieve high purity levels. Both standards define acceptable production methods, including distillation and membrane-based technologies, to ensure reliable WFI production.

Key Steps for Achieving Compliance

Selecting the Right Production Method: The USP and EP permit only certain methods for WFI production. While distillation has traditionally been the preferred method, advancements in reverse osmosis (RO) and electrodeionization (EDI) are now accepted under EP guidelines. The chosen method must consistently produce water that meets all purity requirements, so selecting the appropriate technology is essential.

Conducting Regular Monitoring and Testing: Continuous monitoring of the WFI system is crucial to ensure compliance. Parameters such as conductivity, microbial counts, and endotoxin levels must be regularly tested. Installing automated monitoring systems provides real-time data and immediate alerts for any deviations, ensuring that corrective actions can be taken promptly.

Implementing Robust Sanitization Procedures: Sanitization procedures must be in place to prevent microbial contamination within the WFI system. Hot water or steam sterilization is often used to maintain a sterile environment. These procedures are essential for ensuring that the WFI meets microbial limits and remains compliant with USP and EP standards.

Documentation and Validation: Documentation of all procedures, tests, and maintenance activities is vital for demonstrating compliance during audits. Validation activities such as Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) should be documented to prove that the system operates as required.

Conclusion

Achieving compliance with USP and EP standards for Water for Injection requires a comprehensive approach that includes choosing the right production method, conducting routine monitoring, and maintaining detailed documentation. By following these guidelines, pharmaceutical and biotech companies can ensure the quality and safety of their WFI systems, meeting regulatory expectations and protecting patient safety.

Buy Water for Injection System from SWJAL PROCESS PVT. LTD., your trusted partner for USP- and EP-compliant WFI solutions.

0 notes

Text

youtube

EXCLUSIVE INTERIEW HYDERABAD PHARMA PRO & PACK | Industrial Revolution

Freture Techno Pvt. Ltd. and Swjal Process Pvt. Ltd. director Kailas Waghmare gives an exclusive interview at Pharma Pro & Pack, discussing the latest technologies and innovations transforming industrial manufacturing and production. In this insightful conversation, he highlights how Freture Techno is delivering cutting-edge solutions like lined valves and automation products to industries such as Pharma, Oil & Gas, and Chemical Processing. These advancements are making manufacturing processes more efficient, automated, and sustainable. To Know More: Pharma Pro& Pack https://pharmapropack.com/ Sjwal Process https://www.swjal.com/ Freture Techno https://www.freture.com/ Waghmare also touches on the synergy between Freture Techno and Swjal Process Pvt. Ltd., showing how both companies are driving innovation in their respective fields – from purified water systems to precision industrial valves. Get an in-depth understanding of the impact these technologies are having on the industry, and what the future holds for automated and sustainable manufacturing solutions.

#pharmapro&packHyderabad2024#industrial valves#manufacturers#freture techno#Pure Water System#water for injection#ROEDI water treatment#SWJAL PROCESS PVT LTD#pharmacutical industry#Youtube

0 notes

Text

The eye contact yeah.. butterflies

#mine#avatar explore page#avatar edits#avatar for you#new avatar blog#avatar the way of water#avatar 2009#new avatar writer#new writer#avatar gifs#Jake gifs#neytiri gifs#jeytiri#live laugh jeytiri#jeytiri edits#neytiri te tskaha mo'at'ite#jake sully edit#the tension here was crazy#I need it injected into my veins#jake x neytiri#babies#do not repost any of my gifs and use them please!#avatar fyp#avatar blog#avatar community#avatar Jake#avatar Neytiri#avatar#I miss them#my edits

217 notes

·

View notes

Text

instead of injecting roger waters with muscle relaxers in 1977 they should have injected him with estrogen <3

#lena.txt#me when i’m normal#roger waters#pink floyd#animals 1977#comfortably numb#finally speaking my truth#my last reblog just reminded me that estrogen could have saved my wife#i don’t think estrogen is a cure for hepatitis but tbf neither are muscle relaxers lmao#i feel like estrogen would have been safer to inject him with than the muscle relaxers ngl bc ik those were dangerous#i mean to him at least who knows if it was the muscle relaxers or if it was just him 🤷🏻♀️

26 notes

·

View notes

Text

I think my original post went to the void

but I need everyone to know i LOVE hoffrigg/shockshipping, after coffinshipping they're my favourite pairing in the fandom

I don't like the fighting between the two ships though, I think Hoffman has two hands and can hold them both

#hoffrigg#shockshipping#coffinshipping#hoffstrahm#i am polyam i will inject polyamory into all of my favourite fandoms#no more ship wars#one day i would love to write a long fic of hoffriggstrahm where rigg and strahm survive and work together to take down hoffman#but also have to deal with their own feelings and conflict over liking a serial killer#injecting hoffriggstrahm into the water source

40 notes

·

View notes

Text

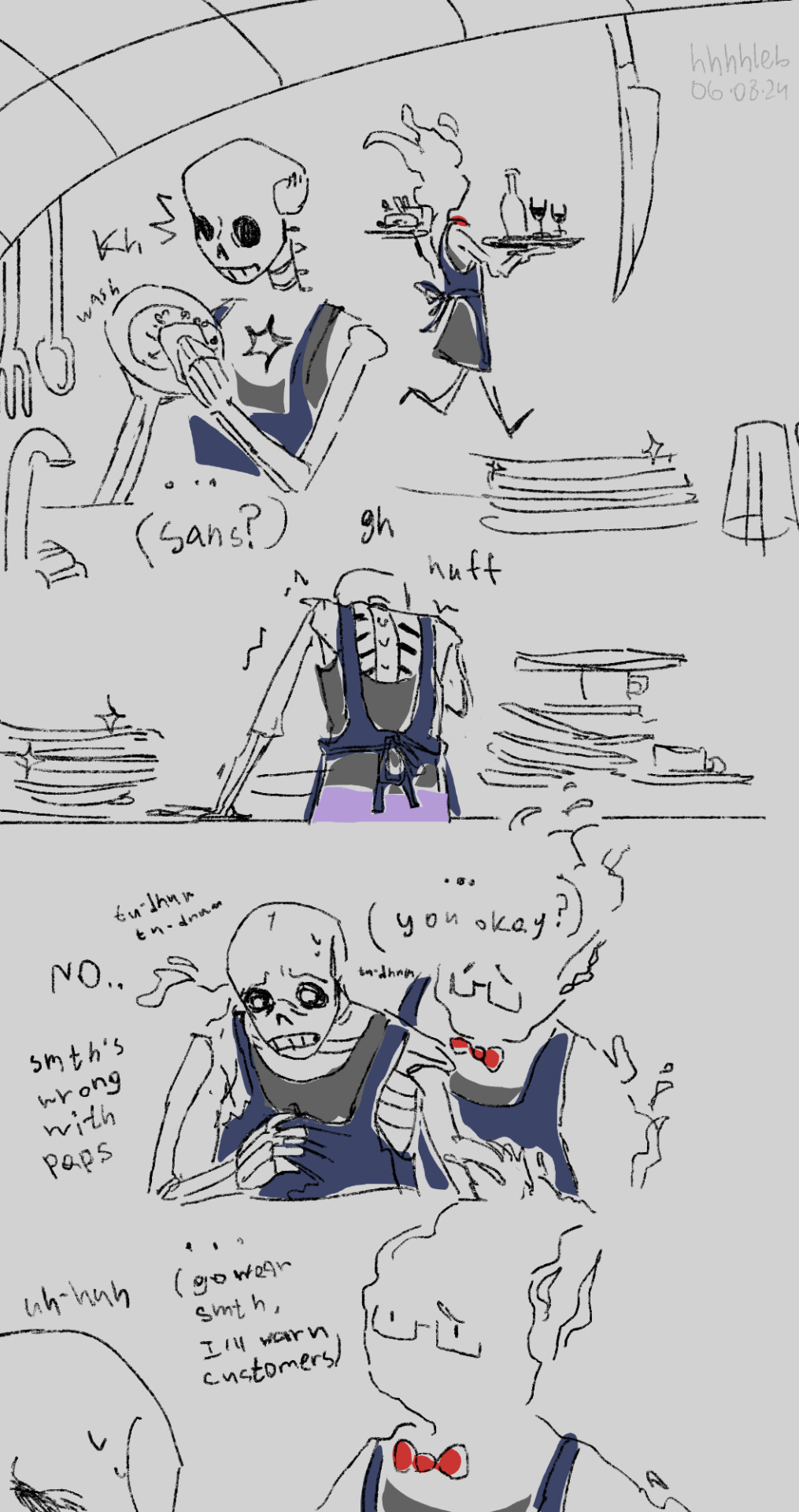

based on this concept they got soul bond and sans can feel when smth wrong with papyrus

good thing that sans didn't see the actual injury.. grillby knew that would greatly upset sans, so that's why he pushed him away. it also could have trigger some really bad memories for Sans..so grillby did good job x2 (more thoughts in tags)

#grillby in dress because why not#my art my rules#undertale#underlust#utmv#underlust sans#underlust papyrus#underlust grillby#lust sans#comics#sans actually knows what kind of responsobility he has - papy was told to sit in the library and do some puzzles#but he's a kid so he ran away it's not really sans' fault there#because of the lust injection grillby has higher tolerance for snow and water(the Heat is stronger)#so sans didn't want to kill him by pushing a living fire into icy water#he just really doesn't like being pushed(it reminds him of something he doesn't remeber but still has very bad feelings about)#lust sans in this interpretaion gives me strong fiona gallagher vibes....#papy here is 5 and sans like 19#and grillby's like 20 or 21#so sans is pretty emotional(alone raising a child since you were 15 does it to person) all this stress of working on multiple jobs and#and having no one to share this burden with#in this comics they just collegs with grillby#they eventually will become friends(and khm husbands in future) but now lust's trust issues are pretty bad#but Grillby doesn't rush him#They build their connection at a slow pace#the bar they work in belongs to someone (possibly a relative of Grillby) who will give it to Grillby in the future#and he will make a strip club there or smth#Papy does his best to be brave and strong bro#so sans doesn’t have to worry too much..(papy knows about sans’ weak soul.. papy’s pretty mature for his age)#sansby#if you squint

47 notes

·

View notes

Text

#i affirm#NOW THIS IS THE STUFF#injects straight zikki content into my veins#this is the ultimate OTP always#zikki#rikki chadwick#zane bennett#h2o just add water

77 notes

·

View notes

Text

Water Treatment Plant Required in Pharmaceutical and Biotech Industry

Importance of Water Treatment in Pharmaceutical and Biotech Industries

Water is a critical component in pharmaceutical and biotech industries, where high purity is essential for manufacturing, formulation, and cleaning processes. Contaminants such as dissolved solids, bacteria, and organic matter must be eliminated to comply with stringent industry standards. Water treatment plants ensure the production of high-purity water, maintaining product integrity and regulatory compliance.

Key Purification Technologies for Pharmaceutical and Biotech Industries

Advanced purification technologies are required to meet the industry's stringent demands. Reverse Osmosis (RO) is commonly used for removing dissolved impurities, while Electrodeionization (EDI) ensures ultra-pure deionized water. Ultrafiltration (UF) plays a crucial role in bacterial and endotoxin removal, while Water for Injection (WFI) systems provide pyrogen-free water for injectable formulations. The integration of these technologies guarantees consistent high-quality water.

Regulatory Compliance and Industry Standards

Regulatory bodies such as the US FDA, WHO, and cGMP enforce strict guidelines for pharmaceutical-grade water. Compliance with these standards is necessary to prevent contamination and ensure patient safety. Water treatment plants must meet validation protocols, including periodic monitoring and documentation, to demonstrate adherence to quality requirements.

Challenges in Pharmaceutical Water Treatment

Several challenges arise in pharmaceutical and biotech water treatment, including microbial contamination, scaling, and system validation. Maintaining water purity across storage and distribution systems requires continuous monitoring and automated control solutions. Failure to address these challenges can lead to compromised drug formulations and regulatory non-compliance.

Benefits of Advanced Water Treatment Systems

High-efficiency water treatment plants offer several benefits, including:

Enhanced Product Quality – Ensuring the purity of raw materials and formulations.

Regulatory Compliance – Meeting global pharmaceutical standards.

Cost Efficiency – Reducing maintenance and operational costs.

Sustainability – Minimizing wastewater generation and energy consumption.

Conclusion

Investing in a reliable water treatment plant is essential for pharmaceutical and biotech companies to maintain high-quality standards and regulatory compliance. Advanced purification technologies such as RO-EDI sytem, and WFI system ensure the highest level of water purity. A well-maintained water treatment system enhances efficiency, minimizes risks, and supports the production of safe and effective pharmaceutical products.

#RO-EDY#WFI System#Water for injection#high purity water solution#swjal process#manufacturer#mumbai#india

0 notes

Note

Do you ship lawbin?

I don't exactly ship them but I don't hate the ship either.. Just neutral, I guess? It's such a harmless ship but massively hated for no reason lmao.

I discovered it was a thing only after Sawyer7mage talked about them in a chapter review (good reviewer btw! some sarcasms he made here reminded me that he's a professional therapist pfff) Initially I didn't like the idea but some valid points have been raised in favor of the ship by him and others. Law/Robin don't have a lot going together so far, but public opinion can be easily swayed if Oda lets them interact more. Given the recent developments in late Wano, the chance is quite high.

Only problem is that these two seem to be drawn towards the type of people that are opposite of each other. Robin had flirted with larger and older men who aren't "conventionally attractive", and Law's buddies are all silly little fellows with little pride who like to pamper him all the time. But fanarts like this by @/takara_op did a great job convincing me that they'd be pretty fun to follow as a duo 👍🏼

Oda's depiction of Law and love and his character dynamic with women is an entirely different topic and I have a year old draft meta on this,,,,maybe I should post it some day 🫠 doesn't have much Lawbin in it though

#some wsj authors strict with no romance rule had gradually leaned towards subtle romance - often influenced by the people they work with#tpn author kaiu shirai for example made two characters interact in a sub-arc simply because his editor liked the two characters as a couple#a broody boy and a pretty girl btw#the editor had fanned the no romance policy himself while simultaneously fanboying over this specific ship#the same editor - suguru sugita - was oda's editor during dressrosa arc LOL#back to op - opla showrunner matt owens seems very supportive of Lawbin#then there's op film stampede director who definitely seemed interested#the chance of oda having lawbin thoughts injected by others from his surrounding wouldn't be surprising#he's been drawing a lot of romance subplot since dressrosa. almost in every arc in fact 🤔#I'm welcoming of the possibilities but rn I find their dynamic tad bit flat to really delve into#I'm more interested to talk about monet -> law but that's from my monet loving side#and no one in the fandom seems interested about their dynamic :(#but I digress#one piece#trafalgar law#trafalgar d. water law#nico robin#lawbin#law x Robin#asks#mine

38 notes

·

View notes

Text

https://joyamedicalsupplies.com.au/product/water-for-injection-10ml/

B.Braun sterile water for injection 10ml ampoule is a clear, odourless liquid. Buy Water For Injection 10ml in Australia from Joya Medical Supplies. Order today!

0 notes

Text

pink roblox avatar squishy being tortured for some reason F2U with source

#gifset#stimblr#stim#visual stim#squishy#roblox noob#pink#water drops#soap suds#injection#bubbles#squishing#jiggly#satisfying#gif#hands#needles#syringe#fast gif

11 notes

·

View notes

Text

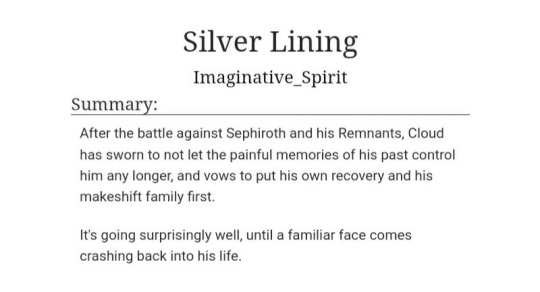

this fanfic.

#sefikura#sephiroth#cloud strife#advent children#fanfic#i revisit it every few months or so and AGGGGHHG#I LOVE IT SO MUCH#THANK YOU IMAGINATIVE SPIRIT WHOMEVER YOU MAY BE#The fucking angst. give me that shit#THE CHARACTER PORTRAYALS ARE SO GOOD DON'T TALK TK ME#if i could eat this fic i would#gonna inject this shit into my veins#gonna chug it like i haven't had anythjng to drink in 5 years#gonna breathe it in like it's my oxygen#my drug#AHHHHHGGGGG IT'S SO GOOD#starts bawling#i love them so much#they're perfect your honor#sefikura being the best ship in the universe sorry i don't make the rules#oh god oh fuck#my eyes are watering#my love for this fic#mwah mwah mwah mwahhhh it makes me so insane#i'm infatuated.

57 notes

·

View notes