#cable assembly components

Explore tagged Tumblr posts

Text

Eteily Technologies India Pvt. Ltd.

SMA (M) St. Connector + HLF240 Cable (L-1MTR) + N (F) St. Connector

SKU: ET-SMS-23L1-NFS

For More Info - https://eteily.com/

#eteily#technologies#eteilyindia#telecom#telecomunication#tnc#rf#connector#cableassemblies#goa#usa#manufacturing#supplier#india

#cable assembly#rf cable assembly#spiral cable assembly#integrated cable assembly#sma cable assembly#cable assembly automation#wire assembly#automated cable assembly#american standard cable assembly#cable assembly business for sale#cable assembly brazil#battery cable assembly#bnc cable assembly#cable assembly components#cable assembly companies near me#cable carrier assembly#cable custom assembly#coaxial cable assembly#copper cable assembly

0 notes

Text

Newcastle Industries is a leading distributor of electronic connectors, specializing in aerospace and defense applications. With over 30 years of experience, they offer a wide range of high-quality connectors, accessories, and tools to meet the needs of manufacturers, assemblers, and repair facilities worldwide. Explore our full range at https://newcastleindustries.com/.

#Aerospace Electronics Connectors#Electronic Connectors Distributor#Custom Backshell Connectors#Military-Grade Electrical Contacts#Industrial Relay Suppliers#High-Performance Switch Assemblies#Precision Connector Insertions#Aerospace Connector Solutions#OEM Electrical Components#Custom Cable Assembly Services#Electronic Connector Prototyping#Delta Electronic authorized distributor#insertions and extraction tools

0 notes

Text

We sell —CCTV security systems video Balun from China —-email : [email protected]

#cctv camera#cctvinstallation#china#electronic#video#powersupply#hdmi cable#BNC connector#pcb assembly#audio cable#electronic components#PoE switch#RCA pin jack#RF coaxial connector

0 notes

Text

https://www.futureelectronics.com/p/semiconductors--lighting-solutions--lighting-controls/3-2444029-1-te-connectivity-6182895

LED assemblies, lighting controls, LED Drivers, LED Lighting Components

LUMAWISE Motion Sensor, Programmable Circular detection Zone

#TE Connectivity#3-2444029-1#Lighting Solutions#Lighting Controls#assemblies#LED Drivers#LED Lighting Components#Indoor#led driver circuit#driver modules#cables traditional lamps#light control#High Power LEDs#cooper lighting

1 note

·

View note

Text

https://www.futureelectronics.com/p/interconnect--dual-in-line-package-sockets/9-188275-0-te-connectivity-7567159

Pin and Socket Connectors, Cable Assemblies, Socket Adaptor Connector

20 Position Dual Row 2.54 mm Board to Board Micro-Match SMT Receptacle

#TE Connectivity#9-188275-0#Connectors#IC and Component Sockets#Pin and Socket#Cable Assemblies#Socket Adaptor#integrated circuit socket#Electrical socket#Dip socket#Socket Plug#power plugs and sockets#Plug and socket systems#Universal

1 note

·

View note

Text

A Human-Machine Interface: What Is It and How Does It Operate?

Human-Machine Interfaces from best Weidmuller power supplies create a usable interface that helps a person establish a communication system with a device. We can explain this more straightforwardly by saying it is simply an input/output device. The information is input here. The person operating the machine inputs it into the machine. The machine outputs the commands based on the data fed into it. On the other hand, the machine may also input the information from its sensors or hardware, which is then outputted on the HMI for the machine operator to decipher and ultimately make out.

Next, combined with programmable logic controllers or PLC, machine sensors record and put forward the information as inputted and received. HMIs are often utilised in industrial settings because of the particular input/output relationship they carry with them. In this sector, an HMI is very frequently used to decipher, see, and control the following information:

Production Time

Production Trends

Visual Data

Temperature Control

Human-Machine Interface and Its Benefits

Human Machine Interfaces, or HMI, from us as one of the best cable assemblies in India, has become part and parcel of machine designs in the industrial sector primarily because of the number of benefits it offers its users. First, the increased visibility of these interfaces makes data centralisation easy to read and ensures that vital notifications or production changes are never missed. This interface's enhanced efficiency results in accurate, real-time data generation that is particularly useful in such a high-paced environment. Here are some other benefits of Human Machine Interface and they are:

Reduction in Cost

Improved Usability

Improved Management of Time

Areas of Application of HMI

We find the maximum utilisation of Human Machine Interface from Hengstler counters supplies in the industrial settings as this sector needs to communicate with and control the machines accurately. This sector requires this kind of control so that industrial processing can be maintained at the optimal level, proper control over the final finished product can be maintained, and the overall safety of the process can be taken care of. To be specific, the industries that use HMIs include:

Manufacturing

Recycling and Waste Management

Oil and Gas

Energy and Power

Food and Beverage

We Give a New Meaning to the Word “Efficiency”

We, SR Indus Electro System, one of the best Weidmuller Distributors in India, are the single source provider equipped with the latest Human-machine Interface technology. It is capable of meeting complex processes of machines and systems. Weidmuller HMI provides efficient integration to your automation systems. They are optimised to meet specific human-machine interfaces. Through our UV66-BAS-4-RES-W easy multi-touch panels, it becomes easier to monitor and control the machines and systems. Moreover, the u-view multi-touch panels from Weidmuller offer perfect image quality and are fit for use in the industrial environment devoid of any restrictions. Additionally, we provide profinet encoders.

Our HMI is very efficient performance-wise, as its image quality is unparalleled. Besides the image quality, its powerful processors make working with u-view multi-touch panels smooth and enjoyable. The compatibility rate of u-view multi-touch panels allows them to be used in various applications. This becomes possible because we use world-class web technology based on HTML5. Hengstler encoders presents robust motor feedback encoders tailored for demanding applications, compatible with both brushless servo and stepper motors. Leveraging Acuro drive technology, dynamic servo drives transition into a fully digital realm for the first time. Even under harsh operating conditions, such as those encountered within motor housings, reliability remains uncompromised. Proudly brought to you by Sr Indus Electro Systems.

#hengstler encoders#weidmuller power supplies#cable assemblies#harting han connectors#electronic components supplier#profinet encoders

0 notes

Text

The Significance of Precision Machined Components in Modern Manufacturing

Precision machined components are the backbone of modern manufacturing, serving as essential elements in diverse industries, including aerospace, automotive, medical devices, and electronics. These meticulously crafted parts are integral to ensuring the performance, reliability, and quality of a wide array of products. Let's delve deeper into the critical role played by precision machined components in today's manufacturing landscape.

Accuracy and Consistency

At the heart of precision machining lies the ability to achieve exceptional accuracy and consistency in the production of components. Techniques such as CNC (Computer Numerical Control) machining enable manufacturers to fabricate parts with incredibly tight tolerances, ensuring that they fit together seamlessly and perform their intended functions reliably. This precision is paramount in meeting stringent industry standards and customer expectations.

Enhanced Performance

Components manufactured through precision machining techniques exhibit superior performance characteristics compared to their conventionally produced counterparts. Whether it's a crucial aircraft engine component or a delicate medical implant, these parts are known for their smooth operation, optimal functionality, and extended longevity. The reliability provided by precision machined components is indispensable in critical applications across various industries.

Complex Geometry

One of the most significant advantages of precision machining is its ability to create components with intricate and complex geometries. Unlike traditional manufacturing methods, which may struggle with intricate designs, precision machining allows engineers to push the boundaries of what's possible in product design and functionality. This capability fosters innovation and enables the development of cutting-edge solutions tailored to specific requirements.

Material Versatility Precision machining can be applied to a wide range of materials, including metals, plastics, ceramics, and composites. This versatility empowers manufacturers to select the most suitable materials for each application, balancing factors such as strength, weight, corrosion resistance, and thermal conductivity. By leveraging the properties of different materials, precision machined components can meet diverse performance and environmental requirements.

Cost-Effectiveness While precision machining may involve upfront investment in advanced machinery and skilled labour, it often proves to be cost-effective in the long run. By minimizing material waste, reducing the need for secondary operations, and ensuring high part repeatability, precision machined components contribute to overall efficiency and lower production costs. This cost-effectiveness makes precision machining a preferred choice for industries seeking optimal performance at competitive prices.

Quality Assurance Precision machining processes are accompanied by rigorous quality control measures to ensure that each component meets desired specifications and performance requirements. Advanced inspection techniques, such as coordinate measuring machines (CMMs) and optical metrology systems, are employed to verify dimensional accuracy and surface finish, thereby enhancing product quality and reliability. This commitment to quality assurance is essential in delivering products that meet or exceed customer expectations

Innovation and Customization The flexibility offered by precision machining enables manufacturers to respond quickly to changing market demands and customer preferences. Whether it's rapid prototyping or customized solutions, precision machining facilitates the development of tailored components to address specific needs. This agility fosters innovation and drives competitiveness in industries were staying ahead of the curve is paramount.

Safety and Regulatory Compliance In safety-critical industries such as aerospace, automotive, and medical devices, the reliability and consistency of precision machined components are of utmost importance. Meeting stringent industry standards and certifications necessitates adherence to strict manufacturing processes and quality control protocols. Precision machining plays a vital role in ensuring that components perform reliably under demanding conditions, thereby enhancing safety and regulatory compliance.

Conclusion Precision machined components are indispensable in modern manufacturing, underpinning the production of high-quality, high-performance products across diverse industries. From aerospace and automotive to medical devices and electronics, these meticulously crafted parts contribute to technological advancement, innovation, and economic growth on a global scale. Unique FAQs

1. What industries rely heavily on precision machined components? ��� Aerospace, automotive, medical devices, electronics, and defence are among the industries that heavily depend on precision machined components.

2. How do precision machined components contribute to product innovation? ◦ Precision machining enables the fabrication of parts with intricate geometries, allowing designers to explore innovative solutions and push the boundaries of product design.

3. Are precision-machined components cost-effective in the long run? ◦ Despite the initial investment in machinery and labour, precision machined components often prove to be cost-effective due to reduced material waste and lower production costs over time.

4. What role does quality assurance play in precision machining? ◦ Quality assurance ensures that each component meets the desired specifications and performance requirements, enhancing product quality, reliability, and customer satisfaction.

5. How do precision machined components contribute to safety in critical industries? ◦ Precision machined components undergo rigorous quality control measures to ensure reliability and consistency, essential for meeting safety standards and regulatory compliance in industries such as aerospace and medical devices.

1 note

·

View note

Text

https://www.futureelectronics.com/p/interconnect--connector-tools-contacts-accessories/0462-209-16141-te-connectivity-2076060

TE Connectivity, 0462-209-16141, Connectors, Tooling and Accessories

14 AWG Female Crimp Nickel Plated Automotive Socket

#TE Connectivity#0462-209-16141#Connectors#Tooling and Accessories#USB connector#connector components#crimp tool#Plug and socket#Cable assembly#contact pin crimping tool#RF adapter#Wire to Cable Crimp Socket Contact#wire#cable

1 note

·

View note

Text

Fuck it, dropping my sona. I have no art for this goober, but I've got a lot of lore about who they are and how they work, which has accumulated over a couple years, so wall of text incoming.

Name is O/LETS-061 (They/Them, Operations/Logistics Engineering and Technical Support, or informally, Ollie/Outlets!), and they're an industrial-model protogen with an integrated fusion reactor.

Kind and timid, relates well to AIs. Can generate frankly absurd quantities of electricity, but has to worry about cooling and radiation exposure. Makes them indispensable in scenarios where electricity is necessary for life support or to keep AIs from shutting down.

Gray-to-white fur, usually covered by an industrial hardsuit. Physically large, with enhanced legs and skeleton to bear the weight of the reactor, which itself looks something like a cylindrical backpack. Long, very thick tail (think Mewtwo) which serves as a primary power conduit for the reactor.

Lots of details under the cut:

Introduction: a kindly, introverted protogen who sees beauty in the purpose, harmony, and artistry of large-scale technological systems. They relate well to artificial minds—or 'spirits'—and enjoy interfacing with them. Their character flaws are timidity and occasional willingness to take the path of least resistance.

O/LETS-061 is an acronym for Operations/Logistics Engineering and Technical Support, followed by their production batch number. Ollie is genderless, and belongs to a product line designed for engineering tasks in an industrial, municipal, or military capacity. To that end, they were born with a wide-scope knowledge base encompassing everything they need to work with a variety of advanced technologies. They are equipped with a cold fusion reactor which can, with sufficient fuel and supplementary cooling systems, supply power to a small city or starship. Generating power does entail some personal risk, typically due to overheating, though it is generally safe if safety limits are observed.

Physical Description: Ollie stands at around 228cm (~7'6") from the tip of their ears to their paws, and weighs just under 190 kilograms (~418 lb.) due to their extensive array of cybernetics, industrial-grade protective gear, integrated tools, and reactor. To accommodate the additional mass, their skeleton has been reinforced and their legs augmented with powered load-bearing systems.

Their fur is gray, and their cybernetics have dark violet plating and lighting. Their visor is black with purple lighting. Eyes convey expression through simple geometric shapes, and their virtual mouth has a simple curved shape with a set of small fangs. In general, they prefer to open their nanite visor and use their organic larynx to speak. On the right side of their visor, they have a single external screen which typically displays reactor temperature and radiation monitoring data, serving to alert people nearby of reactor function.

To integrate with power grids, their tail contains a high-throughput power conduit leading directly out of the reactor, ending in a universal connector. The tail is self-articulated, over a meter long, and about as large around as a human calf at its widest. For a good reference of size and shape, think Mewtwo. Their tail contains layers of insulation and powerful synthmuscle to bear the weight of the cabling inside, and the electrical connector at the end is marked with hazard tape. If necessary, they can use the electrical output and raw strength of their tail to defend themself.

While working, they are usually seen wearing a hardsuit of industrial protective gear incorporating layers of insulation, impact guards, and tool storage options. When off-duty, however, they remove this suit and can detach much of the backpack assembly surrounding their reactor core, including the thermoelectric generator, supplemental heat management components, and fuel storage. This sheds around 60 kilograms of bulky equipment, slimming their profile down sufficiently that they can wear ordinary clothing if they so choose, though the reactor becomes inoperable in this state.

Without the industrial equipment, they have a bulky build. Their fur sometimes gets unkempt from wearing protective gear for long periods; they go through a lot of shampoo and conditioner. They tend to choose utilitarian clothing, but occasionally buy magnets or decals to put on their cybernetics.

Personality and Background: In contrast to their large, imposing appearance, Ollie is a kind and affable person. In their day-to-day life, they have a small but close circle of friends. They rely on regular, recurring social events to maintain contact with others.

One character flaw they have is tending to think of themself (consciously or not) as a piece of support infrastructure rather than an agent in their own right. They tend to be meek and follow others' lead, dismissing their own ideas on how to proceed even when they might be the expert on a given topic.

In the event of power outages or maintenance requiring primary reactors to be taken offline, units such as Ollie are a vital emergency resource. Many spirits depend on an uninterrupted source of power to survive, as do organics who live in environments where life-support systems are necessary.

When serving in a capacity where others depend on their power production and expertise for survival, Ollie shines. Suddenly, they find themself delegating tasks, triaging problems, and coordinating relief efforts with authority and calm. Even though they might be physically tethered to coolant feeds and power conduits throughout the ordeal, emitting too much radiation for anyone to approach them, O/LETS-061 can become the beating heart of a stricken space colony or starship until the danger passes. They take a lot of pride in this knowledge.

When they aren't working, one activity they enjoy is diving. They own a set of aquatic-style arms and tail with retractable gills, which they can attach to their body as needed. Immersion in water helps Ollie to control excess heat, also providing an instinctual sense of safety and comfort.

They enjoy the alien, bizarre environment of the ocean floor, often taking long-distance hikes across the seabed to explore wrecks, reefs, and other places of interest. Sometimes they will go with friends, but they feel just as comfortable traveling alone. In order to return to the surface, they require a floatation device and compressed air, otherwise they sink like a rock. If that fails, they either have to hike back to shore or call someone to come pull them up with a cargo winch.

Reactor Function: Ollie's reactor core is integrated directly with their biological and cybernetic systems. It's as much a part of their body as their hands or ears. They do have onboard cooling systems, but there's only so much heat they can shunt away from the reactor, limiting their energy production to a few megawatts when not attached to a larger cooling system.

Rather than fusing helium-3 and tritium, as municipal reactors do, O/LETS-061's reactor makes use of a tritium-deuterium reaction. This requires a much lower temperature to induce a reaction, but generates more radiation.

Given access to adequate fuel supplies and large-scale heat management infrastructure, Ollie's maximum safe output skyrockets to 660-700 megawatts. Operating at that level, they can run systems up to ship drives, manufacturing plants, and so forth. Sustaining this maximal level of output for longer than a day or two, however, can lead to fatigue and slow accumulation of radiation damage in excess of what their body can manage.

Naturally, there are certain risks associated with the act of lighting off nuclear reactions inside one’s own body. Ollie is designed for this, but there is strain involved. By far, the greatest limitation is heat management. Onboard coolant circulation carries waste heat to retractable radiator fins mounted on their back and thighs, which extend as necessary. Combined with shielding inside their body, this keeps most of the heat away from their biological components, but their internal temperature can reach up to 50° C (122° F) when running at high power.

To combat the problem of their body tissues literally poaching in their own fluids under these conditions, maniples of nanites in their bloodstream work at the microscopic level to prevent (or reverse, where possible) the breakdown of heat-sensitive proteins. In addition, Ollie's chestplate has a number of couplings to attach external coolant hoses. In an overheating emergency, these can be used to inject supercooled liquid into their reactor, an extreme but potentially life-saving measure.

The internal shielding and bloodstream nanites also work to protect them from the vast majority of the reactor's radiation. Thanks to a number of alterations to their genetics and biology, radiation is actually less of a problem than one would expect. Their body is able to repair microscopic damage from radiation exposure which would be irreversible in most organisms, and can do so on an ongoing basis while under heavy exposure. The real threat lies in exposing others to radiation—Ollie is careful to warn bystanders to find protection when taking their reactor to high power settings.

Thanks to their radiation-hardened biology and ability to detect radiation in the environment, Ollie is uniquely suited to handling and safely disposing of fissile material.

...and that's about it! Love my guy. Thank you for reading! :)

12 notes

·

View notes

Text

Eteily Technologies India Pvt. Ltd.

SMA (F) B/H St. To MCX (M) R/A Connector with RG316 Cable (L-5 Mtr)

SKU: ET-SFS-BH-4L5-MMRA

Specs:-

Product-Cable Assembly

Cable-RG316

CONNECTOR1-SMA Female Bulkhead

Connector 1-Pularity-Standard

Connector1- Orientation Straight

Connector1-Material- Brass

Connector1-Plating-Gold

CONNECTOR2- MCX Male

Connector2-Polarity-Standard

Connector2- Orientation Right Angled

Connector2- Material Brass

Connector2-Plating-Gold

For More Info -

Call+91-8889017888

Toll Free - 18008890607

#eteily#technologies#eteilyindia#telecom#telecomunicaciones#connector#cableassembly#rfantenna

#cable assembly#rf cable assembly#spiral cable assembly#integrated cable assembly#sma cable assembly#cable assembly automation#wire assembly#automated cable assembly#american standard cable assembly#cable assembly business for sale#cable assembly brazil#battery cable assembly#bnc cable assembly#cable assembly components#cable assembly companies near me#cable carrier assembly#cable custom assembly#coaxial cable assembly#copper cable assembly#cable assembly manufacturers#cable assembly power electrical#cable assembly companies#db9 cable assembly#data network cable assembly

0 notes

Text

Discover high-performance Aerospace Electronics Connectors engineered for precision and durability at Newcastle Industries. Explore our full range at https://newcastleindustries.com/.

#Aerospace Electronics Connectors#Electronic Connectors Distributor#Custom Backshell Connectors#Military-Grade Electrical Contacts#Industrial Relay Suppliers#High-Performance Switch Assemblies#Precision Connector Insertions#Aerospace Connector Solutions#OEM Electrical Components#Custom Cable Assembly Services#Electronic Connector Prototyping#Delta Electronic authorized distributor#insertions and extraction tools

0 notes

Text

Ways English borrowed words from Latin

Latin has been influencing English since before English existed!

Here’s a non-exhaustive list of ways that English got vocabulary from Latin:

early Latin influence on the Germanic tribes: The Germanic tribes borrowed words from the Romans while still in continental Europe, before coming to England.

camp, wall, pit, street, mile, cheap, mint, wine, cheese, pillow, cup, linen, line, pepper, butter, onion, chalk, copper, dragon, peacock, pipe, bishop

Roman occupation of England: The Celts borrowed words from the Romans when the Romans invaded England, and the Anglo-Saxons later borrowed those Latin words from the Celts.

port, tower, -chester / -caster / -cester (place name suffix), mount

Christianization of the Anglo-Saxons: Roman missionaries to England converted the Anglo-Saxons to Christianity and brought Latin with them.

altar, angel, anthem, candle, disciple, litany, martyr, mass, noon, nun, offer, organ, palm, relic, rule, shrine, temple, tunic, cap, sock, purple, chest, mat, sack, school, master, fever, circle, talent

Norman Conquest: The Norman French invaded England in 1066 under William the Conqueror, making Norman French the language of the state. Many words were borrowed from French, which had evolved out of Latin.

noble, servant, messenger, feast, story, government, state, empire, royal, authority, tyrant, court, council, parliament, assembly, record, tax, subject, public, liberty, office, warden, peer, sir, madam, mistress, slave, religion, confession, prayer, lesson, novice, creator, saint, miracle, faith, temptation, charity, pity, obedience, justice, equity, judgment, plea, bill, panel, evidence, proof, sentence, award, fine, prison, punishment, plead, blame, arrest, judge, banish, property, arson, heir, defense, army, navy, peace, enemy, battle, combat, banner, havoc, fashion, robe, button, boots, luxury, blue, brown, jewel, crystal, taste, toast, cream, sugar, salad, lettuce, herb, mustard, cinnamon, nutmeg, roast, boil, stew, fry, curtain, couch, screen, lamp, blanket, dance, music, labor, fool, sculpture, beauty, color, image, tone, poet, romance, title, story, pen, chapter, medicine, pain, stomach, plague, poison

The Renaissance: The intense focus on writings from classical antiquity during the Renaissance led to the borrowing of numerous words directly from Latin.

atmosphere, disability, halo, agile, appropriate, expensive, external, habitual, impersonal, adapt, alienate, benefit, consolidate, disregard, erupt, exist, extinguish, harass, meditate

The Scientific Revolution: The need for new technical and scientific terms led to many neoclassical compounds formed from Classical Greek and Latin elements, or new uses of Latin prefixes.

automobile, transcontinental, transformer, prehistoric, preview, prequel, subtitle, deflate, component, data, experiment, formula, nucleus, ratio, structure

Not to mention most borrowings from other Romance languages, such as Spanish or Italian, which also evolved from Latin.

Further Reading: A history of the English language (Baugh & Cable)

160 notes

·

View notes

Text

From Design to Deployment: How Switchgear Systems Are Built

In the modern world of electrical engineering, switchgear systems play a critical role in ensuring the safe distribution and control of electrical power. From substations and factories to commercial buildings and critical infrastructure, switchgear is the silent guardian that protects equipment, ensures safety, and minimizes power failures.

But have you ever wondered what goes on behind the scenes, from the idea to the actual installation? Let’s dive into the full journey — from design to deployment — of how a switchgear system is built.

Step 1: Requirement Analysis and Load Study

Every switchgear project begins with requirement analysis. This includes:

Understanding the electrical load requirements

Calculating voltage levels, short-circuit ratings, and operating current

Identifying environmental conditions: indoor, outdoor, temperature, humidity

Reviewing applicable industry standards like IEC, ANSI, or DEWA regulations (especially in UAE)

This stage helps engineers determine whether the project needs low voltage (LV), medium voltage (MV), or high voltage (HV) switchgear.

Step 2: Conceptual Design & Engineering

Once the requirements are clear, the conceptual design begins.

Selection of switchgear type (air insulated, gas insulated, metal-enclosed, metal-clad, etc.)

Deciding on protection devices: MCCBs, ACBs, relays, CTs, VTs, and fuses

Creating single-line diagrams (SLDs) and layout drawings

Choosing the busbar material (copper or aluminum), insulation type, and earthing arrangements

Software like AutoCAD, EPLAN, and ETAP are commonly used for precise engineering drawings and simulations.

Step 3: Manufacturing & Fabrication

This is where the physical structure comes to life.

Sheet metal is cut, punched, and bent to form the panel enclosures

Powder coating or galvanizing is done for corrosion protection

Assembly of circuit breakers, contactors, protection relays, meters, etc.

Internal wiring is installed according to the schematic

Every switchgear panel is built with precision and must undergo quality control checks at each stage.

Step 4: Factory Testing (FAT)

Before deployment, every switchgear unit undergoes Factory Acceptance Testing (FAT) to ensure it meets technical and safety standards.

Typical FAT includes:

High-voltage insulation testing

Continuity and phase sequence testing

Functionality check of all protection relays and interlocks

Mechanical operations of breakers and switches

Thermal imaging to detect hotspots

Only after passing FAT, the switchgear is cleared for shipping.

Step 5: Transportation & Site Installation

Transportation must be handled with care to avoid damage to components. At the site:

Panels are unloaded and moved to their final location

Cabling and bus duct connections are established

Earthing systems are connected

Environmental sealing is done if installed outdoors or in dusty environments

Step 6: Commissioning & Site Acceptance Testing (SAT)

This final stage ensures the switchgear is ready for live operation.

Final checks and Site Acceptance Tests (SAT) are performed

System integration is tested with other components like transformers, UPS, and generators

Load tests and trial runs are conducted

Commissioning report is generated, and documentation is handed over to the client

Conclusion

From idea to execution, the journey of building a switchgear system is highly technical, safety-driven, and precision-based. Whether you’re in power generation, industrial automation, or commercial construction, understanding this process ensures you choose the right system for your needs.

7 notes

·

View notes

Text

Restore

I come bearing a wonderful gift, written by my wonderful friend @red-sprite!

The morning was early, the sky was grey, and the store was closed. Samantha was waiting by her car for the owner of the electronics store to open the front door, but her watch told her it was currently half an hour past opening and there was no-one in sight yet.

Looking in through the window the place reminded her of an old bookstore. You know the kind, the ones that seem to open whenever the owner feels like it, completely covered from floor to ceiling in books you can barely read the cover of. Antiquarians. She could see the remnants of a shelving system buried under strata of components, stretching around the corner into the darkness beyond.

Still, it was her best bet to find what she needed.

Ten minutes later the door opened, she hadn’t seen the owner arrive. Fifteen minutes and some smalltalk interwoven with project descriptions, she was about to walk out with her purchase. And that’s when she saw something she never thought she would.

An original AnTech, buried under a pile of merchandise. Her dome was stained, her screen was completely scuffed up, and the faded post-it said ‘As-is. No returns’.

Five minutes later she was secure in Samantha’s car.

The rest of the day was a blur. She finished the project, got it tested, got it packaged and shipped out. When she clocked out she’d almost forgotten this morning’s surprise. But not enough to lack a spring in her step when she made it to her car.

There, in the passenger seat, sat her find. In the light of the parking garage she looked like she was about to come alive. Samantha’s shadow danced over her scuffed faceplate as she passed the car, her arms resting in her lap.

‘You need a name, don’t you,’ Samantha thought to herself. ‘Ann sounds nice.’

The drive home was short. The trip up the stairs was very very long. As it turns out, hauling an immobile full-sized humanoid robot up three flights of stairs was a lot of work. She set Ann gently down in her comfy chair and went to work clearing her workbench. Projects half in-progress were bagged up, labelled and put away, tools were cleared, and finally she had enough space.

One last time she lifted Ann up, from her chair, to lay her as gently as she could on the workbench. Under the harsh fluorescent light it was finally visible just in what sort of condition she was. Samantha went over her section by section, noting all the outward damage. Scuffed faceplate, she knew that one. Seized motor on her left elbow, to be expected. Dent in the abdominal covering, possible impact, have to check the underlying actuators. Scuffs on legs, rattling in left ankle joint. Also very very dusty.

Knocking off the initial dust was the easy part. Finding the proprietary bits for her screwdrivers was slightly harder, but thankfully she had an extensive collection. The first thing she took off was the face plate. Four screws held it in place, now neatly extracted and marked where they go. The plate came off, connected only by a short ribbon cable. It took her a moment to find a good angle to disconnect it, but after that she was able to place the assembly to the side. Under the faceplate there was the sensor suite; cameras, both visible light and IR, depth-sensors, audio receptors tucked into the sides of the cavity, and at the bottom, the release for the chest covering.

Samantha pulled it gently, hoping that it wasn’t seized up. When she heard the click, she breathed a sigh of relief and held it in almost as quickly. She’d finally get a view of how Ann looked inside. Would all the components be present, would there be any damage, had she been scavenged for parts? It was all a big uncertainty, but there was only one way to find out.

She extracted her hand, and moved it over under Ann’s arms. Then she pulled.

The cavity opened before her, slowly bathed in the fluorescent light as deft hands maneuvered the cover away from its mounting points. There, inside, she saw a plethora of parts. All the ones she knew were supposed to be there were accounted for, and a few ones she didn’t expect caught her eye.

Breathe out.

Ann was complete, everything else was a matter of restoring. She could do this.

She lifted the cover the rest of the way off, and flipped it around. The dent was superficial, and it didn’t look like the force impacted beyond the insulation. She put the cover to the side.

Figuring out the order of cleaning was, on the one hand, a daunting process. On the other, cable layout dictated order nine out of ten times. Samantha had only worked on less sophisticated models in the past, but the principles were exactly the same. The power and data cables ran all over Ann’s chassis like a spider’s web. But like a spider, Samantha could read them. She knew them by sight, by location, by feeling. One by one they came undone until they revealed the city that lay underneath.

Heat exchangers rose like buildings on a city of green, highways of copper connected everything to everything else, crowded out by vast daughterboards rising perpendicular to the cavity.

Samantha set to work, disconnecting each component, slowly and lovingly taking Ann to pieces. Heat sink, to the side. Fans, to the side. Boards, to the side. Not all of them were standard, and Samantha could only guess to the function of some of them. Clearly Ann had not been a standard model.

She took a spray and diligently brushed each connector until it shone like it was fresh from the factory. Every single speck of dust removed, every pin straightened, every single capacitor checked.

She extracted the battery pack. Light, for what it was, but still one of the heavier components. Also probably completely dead.

Samantha lifted it out of the chassis, onto the small part of her workbench that was still free, and pulled out her tester to confirm. It wouldn’t even show a reading. She grabbed a piece of paper and wrote down the part number. With any luck it’d be a standard type, and the extent of the anti-tampering would be the screws.

Half an hour of searching later, she found the battery was an available size and could be ordered without problem. Express shipping was worth it.

She turned her attention back to Ann.

The battery could be replaced last. It was not interfering with any of the other components. The working memory modules slid in easy save for the final lock. Those always took more pressure than she liked to put onto delicate components. It left a mark on her hand.

The permanent storage was next. A big heavy box screwed into place on shock mounts to prevent the fragile internals from suffering damage when the frame moved about.

The daughterboards, slotted into the exact slots they came out of – she checked. Thrice. Screwed into place on their retaining brackets.

The fans, cleaned and lubricated, reinstalled on the processors.

And finally, the web of cables. Data cables, power cables, crossed all along the cavity to reach from everywhere to everywhere. Each of them seated with care.

She brought her power supply over to the workbench and dialed it in exactly to the battery specifications. One clip to the positive, one clip to the negative. Tomorrow would be a big day.

*

AnTech-G-25036 woke up. It was midnight on January 1st 1970. She couldn’t see for the blinding light. She couldn’t move. She couldn’t feel her face, or her arms, or her legs. She tried to move. Nothing happened. There was something on her chest. Her chest was open. She tried to think back, there were no memories before now. She tried to–

“Shh, it’s okay. You’re going to be okay. I’ve got you.”

The voice was soft, soothing. Her ears were working. She stopped trying.

Tapping noises came from somewhere. They felt distant and close at the same time.

“There, will you try again?” Three taps sounded.

AnTech-G-25036 woke up. Her last memories were decades ago. There had been a battery failure. She had fallen down. Then there was nothing. Nothing for a long time until she woke up in the blinding light.

“Can you speak?”

She didn’t know. Could she? There were many things that she could before that she couldn’t now. Like move her arms. She tried.

“I… think so?”

There was a high-pitched sound that was hard to parse. Then more sounds, and finally more speech.

“I’m so sorry. Here.”

The light faded, and she felt her head be turned. A face came in view, her emotional recognition processes supplied [happy], [excited], [holding back]. Something supplied [pretty].

“Hi, my name is Samantha. You were damaged, and I’m restoring you.”

New contact registered: Samantha

Current list of contacts: Samantha

Time since factory reset: 30 years

Time since product end of life: 32 years

Accessing AnTech servers for revised EOL date: [server not found]

“Why?”

“Because a lot of love went into making you, and I don’t believe you deserve to be tossed aside.”

There was a process inside her that wasn’t standard from the factory. It was supplying data that she didn’t understand and reaching conclusions that she didn’t know what to do with.

“What should I do?”

User input overrode most any other process. Listening to Samantha would help.

“I will work on your hardware. Will you run AnDiagTxt for me and write the result to your secondary output?”

She did as she was told, running the program that could tell a technician every status of every component of every part of her. Something supplied [intimate] and [vulnerable].

She let the program run, aware of its process, and how it was probing every part of her. She could feel it try to reach her legs, which weren’t there. Tried to reach her arms, which weren’t there. Tried to reach her face, which wasn’t there. It found her voice, it found her camera. It found her processors and fans. It found cables. So many cables attached from her, diagnostic ports, secondary output, keyboard, there was… the correct voltage from her battery, but no battery in the housing. More cables, snaking out like an umbilical cord tethering her to the workbench.

She saw Samantha turn her face from the camera and towards something out of view. As the program ran, her eyes were focused on it. When it finished, her emotional recognition processes supplied [satisfied] [happy].

Samantha turned back towards the camera, and she could feel a hand on her shoulder.

“Don’t worry. We’ll get you back up and running in no time.”

No time turned out to be an overstatement on the speed, but the progress was consistent. The first thing she hooked back up was the actuator for the camera. AnTech-G-25036 could look around now and take in more of the workspace. There was a chair that housed several components, including two AnTech arms and two AnTech legs. There was a fluorescent light fixture directly overhead. If she turned the camera away, she would not be blinded. She could not move her head. Samantha said that happened later in the process.

“Do you have a name?”

The question surprised her. Names were for people, not for AnTech products.

“I am AnTech-G-25036”

She turned her camera towards Samantha. Her emotional recognition processes supplied [concentrated] and [comfortable].

Samantha had an arm on her lap. There was a spraycan on the desk, and a screwdriver in her hand. She was manipulating the elbow joint. Every cycle, it moved more until with a final [click] it completed its full range of motion. Samantha manually took it through its motions twice before inverting it to inspect the contacts.

“That is what AnTech called you. What would you like to be called?”

She didn’t know. She didn’t remember having wants before. She could feel her fans speed up as her processors tried to construct metrics by which to tackle this problem. Her processors stayed cool. The fans felt smooth in their housing.

She could ask Samantha. User input can often break process deadlocks.

“What do you think I should be called, Samantha?”

The processes slowed down and then stopped. The fans were quiet. AnTech-G-25036 was focused solely on input processing.

“I’ve been calling you Ann. Is that a name you’d like?”

She did not remember liking things before. She did not remember being allowed to like things before. How would she know what to like, how would she know the correct things to like?

Something supplied [yes].

The fans slowed down.

“Yes.”

Samantha finished with the contacts and walked up to the workbench.

“Ann it is then, pleasure to meet you Ann!”

Emotional recognition: [smile] [happy] [satisfied]

Something: [warm] [safe] [self]

Samantha stood by the workbench, Ann’s arm in her hands. “May I attach this component, Ann?”

It was not something she’d ever heard before. It wasn’t a user command, it wasn’t a query, it wasn’t a request for action.

Whatever it was, the answer was clear as day. “Yes.”

She took the detached arm in one hand and clicked it into place. It felt… smooth. It felt cool and clean and better than it had in a long time.

Ann moved her arm. Her secondary display lit up with all the new data being sent and received. Her Something lit up with somethings.

The next stretch of time really did feel like no time at all to Ann. So many new sensations to process from within and from without.

“May I?”

“You may.”

Her other arm felt as smooth as the first, able to move with a grace she had forgotten she could have.

“May I?”

“You may.”

Her legs, stable and strong. Moving with strength and finesse not seen since she was new, and even then.

“May I?”

“You may.”

Her torso cover clicked into place, dent completely removed by Samantha’s hand.

Her camera was focused on the technician now, holding the last piece of herself. A coarse white paste coated her faceplate and Samantha was rubbing a cloth over it. Every pass made it look more scratched and opaque until the final one, where it emerged spotless, restored to the mirror sheen she could barely remember it being.

She handed it to Ann, who took it wordlessly. With mechanical precision and effortless finesse, she connected it. Finally sliding the last centimeters home until a ‘click’ was the only sound audible in the workspace. Her fans were silent and smooth as the screen behind her face came to life for the first time in decades. The image on it mirrored the camera’s, an expression of care, of trust, of something.

Ann reached out with her hand, smooth and controlled, to touch Samantha’s cheek.

“May I?”

“Please.”

She leaned forward until her camera was as close as it could be to her technician’s face without touching.

And then moved the final distance.

34 notes

·

View notes

Text

Some detail of the heart, I was told that the heart works well by itself however the wires spilling out of the box is something I enjoy too much to discard.

It was suggested to me by a member of staff to insert these red flashing lights into the box, which ended up helping to identify the silhouette of the heart.

If i had the time to remake this, I would have made the box bigger, fixed the edges from spilling over and have added more detail. I would have liked to add the grates for the fans of computers to expell air out of. Possibly also some rectangular and circular holes emulating the cable ports on a computer. I think it would have added more to this piece.

Finally, I found the time to assemble the product of this experiment. Gluing the box together, pushing wires though the heart and attaching some of the components i aquired from the DVD rewriter.

Heart / Box; How vein? part two 28 & 29/11/24

7 notes

·

View notes

Text

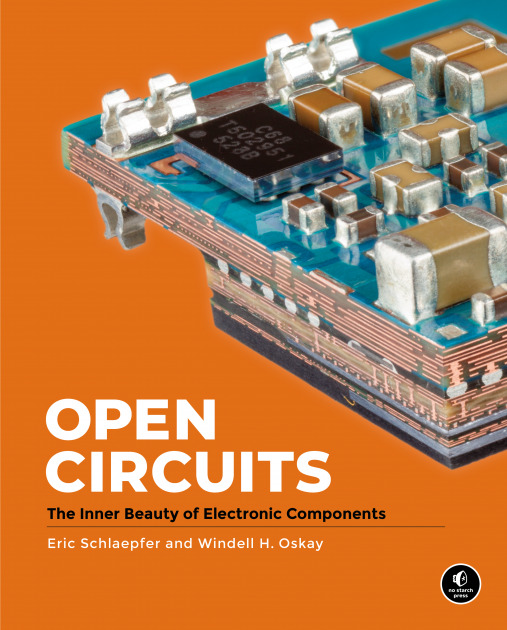

Open Circuits

I'm kickstarting the audiobook for "The Internet Con: How To Seize the Means of Computation," a Big Tech disassembly manual to disenshittify the web and make a new, good internet that picks up where the old, good internet left off. It's a DRM-free book, which means Audible won't carry it, so this crowdfunder is essential. Back now to get the audio, Verso hardcover and ebook:

http://seizethemeansofcomputation.org

Every trip to Defcon – the massive annual hacker-con in Las Vegas – is a delight. Partly it's the familiar – seeing old friends, getting updates on hacks of years gone by. But mostly, it's the surprises, the things you never anticipated. Defcon never fails to surprise.

I got back from Vegas yesterday and I've just unpacking my suitcase, and with it, the tangible evidence of Defcon's cave of wonders. My gear bag has a new essential: Hak5's malicious cable detector, a little USB gizmo that lights up if it detects surreptitious malicious activity, even as it interdicts those nasty payloads:

https://shop.hak5.org/collections/omg-row2/products/malicious-cable-detector-by-o-mg

(In case you're wondering if it's really possible to craft a malicious USB cable that injects badware into your computer and is visually indistinguishable from a regular cable, the answer is a resounding yes, and of course, Hak5 sells those cables, with a variety of USB tips:)

https://shop.hak5.org/collections/omg-row2/products/omg-cable

But merch is only a sideshow. The real action is in the conference rooms, where hackers update you on the pursuit of their obsessions. These are such beautiful weirdos who pursue knowledge to ridiculous extremes, untangling gnarly hairballs just to follow a thread to its origin point.

For the second year in a row, I caught a presentation from Joseph Gabay about his work on warshopping: slicing up shopping cart wheels and haunting shopping mall parking lots during resurfacing to figure out how the anti-theft mechanism that stops your cart from leaving the parking lot works:

https://www.begaydocrime.com/

And of course, I got to give one of those presentations, "An Audacious Plan to Halt the Internet's Enshittification," to a packed house. What a thrill! It was livestreamed, and if you missed it, you'll be able to catch it on Defcon's Youtube page as soon as they upload it (they've got a lot of uploading to do!):

https://www.youtube.com/@DEFCONConference/videos

After my talk, I went back to the No Starch Press booth for a book signing – which was amazing, so many beautiful hackers, plus I got to share a signing table with Micah Lee. As I was leaving, Bill Pollock slipped me a giant hardcover art-book, and said, "You're gonna love this."

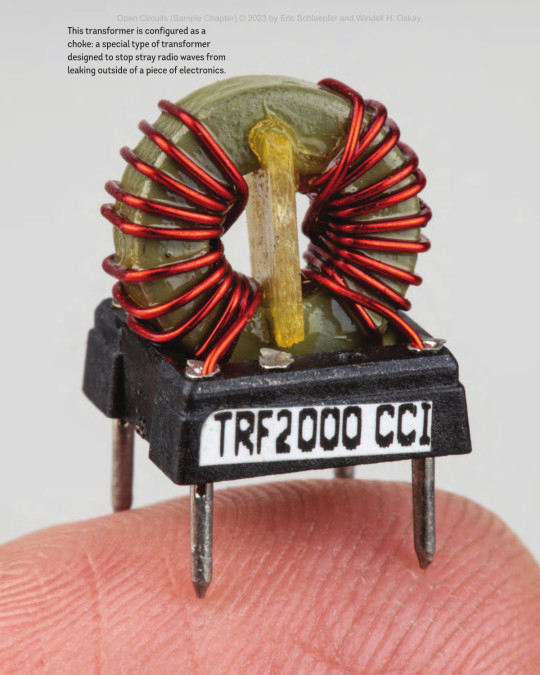

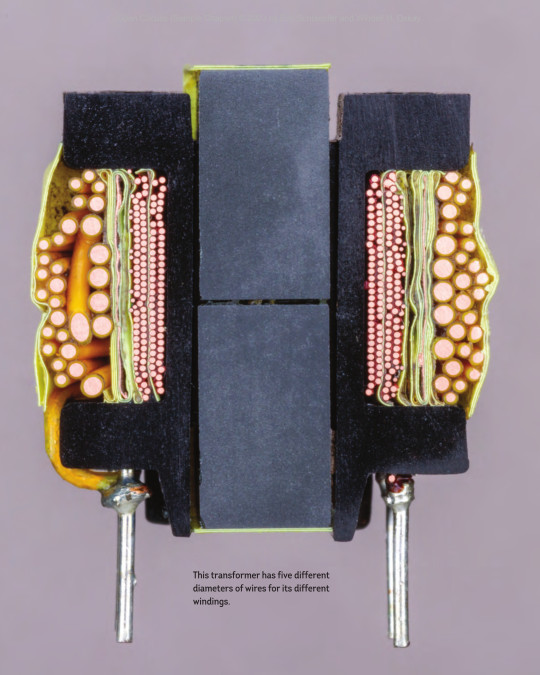

I did. The book is Open Circuits: The Inner Beauty of Electronic Components, by Windell Oskay and Eric Schlaepfer, and it is a drop-dead gorgeous collection of photos of electronic components, painstakingly cross-sectioned and polished:

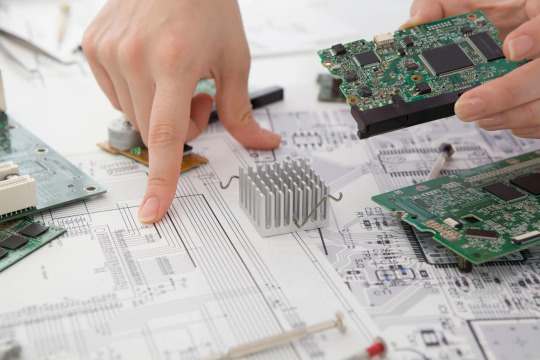

The photos illustrate layperson-friendly explanations of what each component does, how it is constructed, and why. Perhaps you've pondered a circuit board and wondered about the colorful, candy-shaped components soldered to it. It's natural to assume that these are indivisible, abstract functional units, a thing that is best understood as a reliable and deterministic brick that can be used to construct a specific kind of wall.

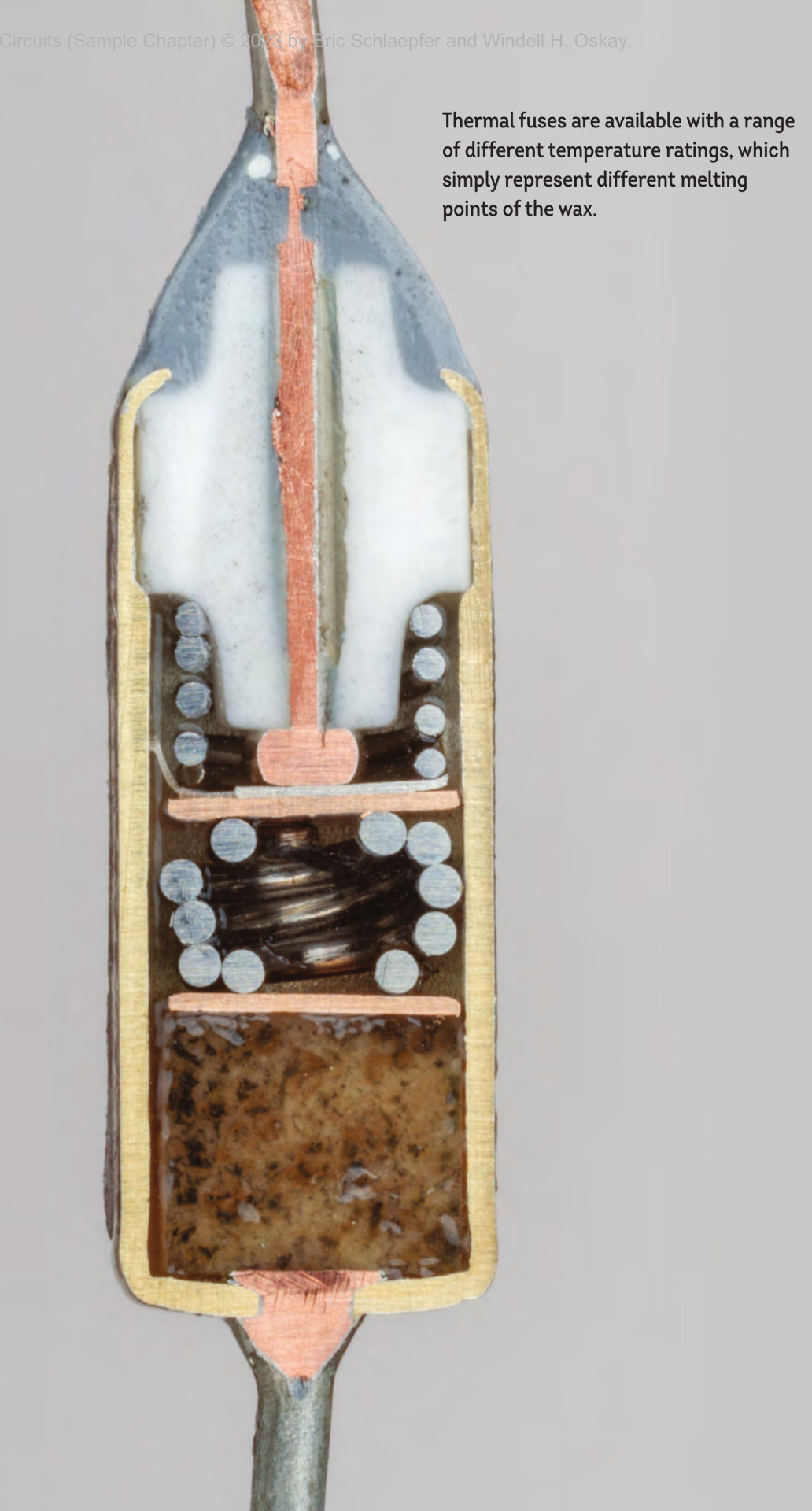

But peering inside these sealed packages reveals another world, a miniature land where things get simpler – and more complex. Inside these blobs of resin are snips of wire, plugs of wax, simple screws, fine sheets of metal in stacks, wafers of plain ceramic, springs and screws.

Truly, quantity has a quality all its own. Miniaturize these assemblies and produce them at unimaginable scale and the simple, legible components turn into mystical black boxes that only the most dedicated study can reveal. Like every magician's trick, the unfathomable effect is built up through the precise repetition of something very simple.

A prolonged study of Open Circuits reveals something important about the hacker aesthetic, a collection of graphic design, fashion and industrial design conventions that begins with this realization: that the crisp lines of digital logic can be decomposed into blobby, probabilistic lumps of metal, plastic, and even wax.

It reminds me of George Dyson's brilliant memoir/history of computing, Turing's Cathedral, where he describes how he and the other children of the scientists building the first digital computers at the Princeton Institute spent their summers in the basement, hand-winding cores for the early colossi their parents were building on the floors above them:

https://memex.craphound.com/2012/03/12/george-dysons-history-of-the-computer-turings-cathedral/

You can see my hacker aesthetic photos in my Defcon 31 photo set:

https://www.flickr.com/search/?sort=date-taken-desc&safe_search=1&tags=defcon31&user_id=37996580417%40N01&view_all=1

In this video, Eric Schlaepfer illustrates the painstaking work that went into decomposing these tiny, precise components into their messy, analog subcomponents. It's pure hacker aesthetic, and it's mesmerizing:

https://www.youtube.com/watch?v=byKyJ0b04Lo

But Open Circuits isn't just an aesthetic journey, it's a technical one. After all, Oskay is co-founder of Evil Mad Scientist Labs, one of the defining places where hardware hackers gather to tear down, pick apart, mod, improve and destroy electronics. The accompanying text is a masterclass in the simple machines that combine together to make complex assemblies:

https://www.evilmadscientist.com/

Defcon is a reminder that the world only seems hermetically sealed and legible to authorized parties with clearance to crack open the box. From shopping cart wheels to thermal fuses, that illegibility is only a few millimeters thick. Sand away the glossy outer layer and you will find yourself in a weird land of wax-blobs, rough approximations, expedient choices and endless opportunities for delight and terror, mischief and care.

Back my anti-enshittification Kickstarter here!

If you'd like an essay-formatted version of this post to read or share, here's a link to it on pluralistic.net, my surveillance-free, ad-free, tracker-free blog:

https://pluralistic.net/2023/08/14/hidden-worlds/#making-the-invisible-visible-and-beautiful

#pluralistic#books#reviews#evil mad scientist laboratories#no starch press#Windell Oskay#Eric Schlaepfer#electronics#hacker aesthetic#makers#diy#secret knowledge#gift guide#photography

96 notes

·

View notes