#cfrp

Text

SUPER RESIN | BRAND FILM

Role | CREATIVE PRODUCE

Year | 2015

Client | Super Resin

Film | TOKYO

0 notes

Text

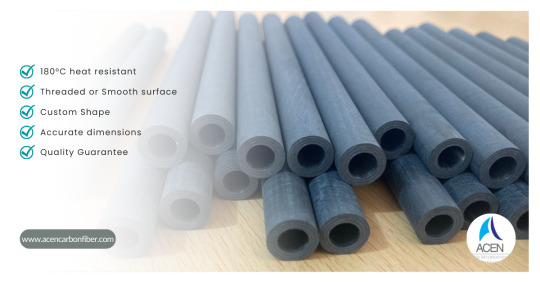

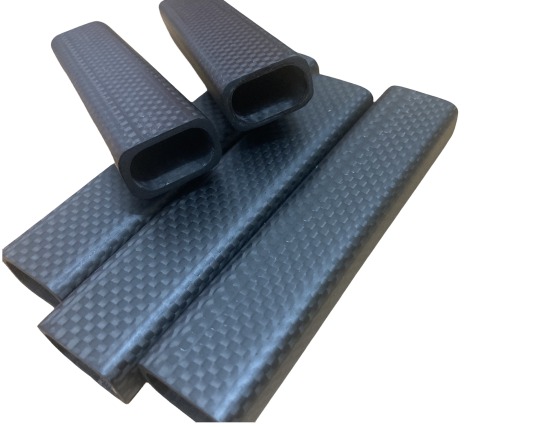

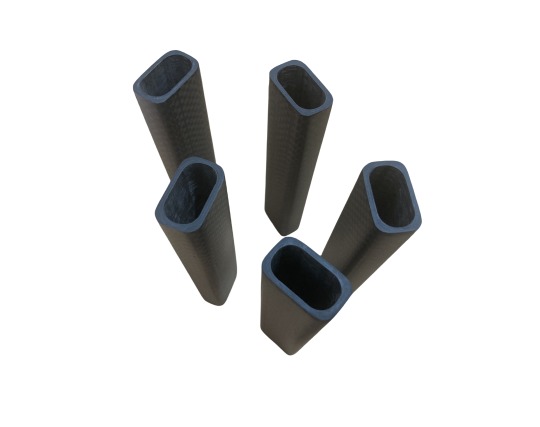

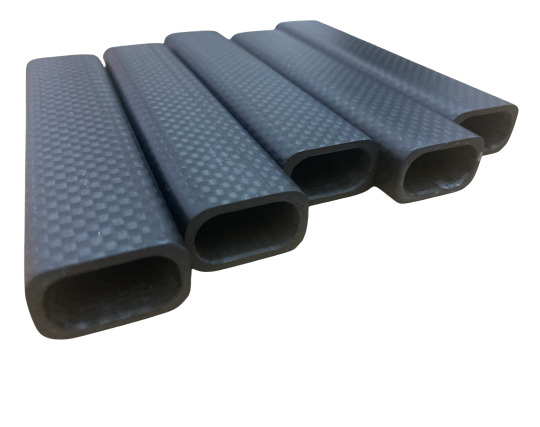

Carbon fiber tubes with a temperature resistance of 180 degrees Celsius

#cfk#cfrp#acen carbon fiber#Tubos de fibra de carbono#Tubes en fibre de carbone#Kohlefaserrohre#カーボンファイバーチューブ#탄소 섬유 튜브#Tubi in fibra di carbonio#Трубы из углеродного волокна#أنابيب الألياف الكربونية#Karbon fiber borular#Koolstofvezelbuizen#Kolfiber rör#Rury z włókna węglowego#Tuburi din fibră de carbon#Σωλήνες από ίνες άνθρακα#Ống sợi carbon#ท่อไฟเบอร์คาร์บอน#Tiub gentian karbon#Tabung serat karbon#Труби з вуглецевого волокна#Trubky z uhlíkových vláken#Hiilikuituputket#Cijevi od ugljičnih vlakana#Тръби от въглеродни влакна#Cevi od ugljeničnih vlakana#Cevi iz ogljikovih vlaken#Ogļu šķiedras caurules#Süsinikkiudtorud

0 notes

Text

Carbon Fibers (CF) and Carbon Fiber Reinforced Plastics (CFRP) Market Upcoming Trends Analysis 2023-2033

Market Definition

Carbon fiber reinforced plastics (CFRP) are a composite material made up of a polymer matrix and carbon fibers. Carbon fibers are extremely strong and lightweight materials that can be used to reinforce various polymers, such as polyesters, epoxy resins, and polyamides. CFRP is used in a wide variety of applications, from aerospace and automotive components to sporting goods and medical devices.

The carbon fibers are made from a variety of sources, such as rayon, polyacrylonitrile (PAN), and pitch-based fibers. The fibers are then formed into a yarn or fabric and then impregnated with a resin, such as epoxy or polyester. This forms a composite material that is then used to form components.

Market Outlook

Carbon fibers and carbon fiber reinforced plastics (CFRP) are increasingly being used in a wide range of industries, from aerospace to automotive and from medical to military. This is due to their unique properties, which include high strength, low weight, and excellent resistance to corrosion and fatigue. The market for these materials is growing rapidly, and there are several key trends driving this growth.

1. Increasing Demand for Lightweight Materials: As the demand for lighter and more fuel-efficient vehicles increases, so does the demand for lightweight materials such as carbon fibers and CFRP.

2. Cost Reduction: The cost of carbon fibers and CFRP has been steadily declining over the years, making them more cost-effective for a variety of applications.

3. Improved Performance: The performance of carbon fibers and CFRP has been steadily improving over the years, due to the development of new production processes and the introduction of new additives and modifiers.

Carbon Fibers (CF) and Carbon Fiber Reinforced Plastics (CFRP) are two of the most important materials used in modern-day engineering and manufacturing. They are used in a variety of industries including aerospace, automotive, and sporting goods.

Technological advances in Carbon Fibers and Carbon Fiber Reinforced Plastics have enabled the materials to be used in a wider range of applications. Carbon fibers are strong, lightweight, and can be formed into complex shapes.

Cost efficiency is another major driver of the Carbon Fibers and Carbon Fiber Reinforced Plastics Market. Carbon fibers and Carbon Fiber Reinforced Plastics are much lighter than traditional materials, which helps to reduce the overall cost of manufacturing. Additionally, Carbon Fibers and Carbon Fiber Reinforced Plastics are more durable and require less maintenance, which helps to reduce costs in the long run.

Finally, environmental sustainability is another key driver of the Carbon Fibers and Carbon Fiber Reinforced Plastics Market. Carbon Fibers and Carbon Fiber Reinforced Plastics are made from renewable resources, and they have a much lower carbon footprint than traditional materials.

To Know More: https://www.globalinsightservices.com/reports/carbon-fibers-cf-and-carbon-fiber-reinforced-plastics-cfrp-market//?utm_id=1014

Research Objectives

Estimates and forecast the overall market size for the total market, across product, service type, type, end-user, and region

Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

Identify factors influencing market growth and challenges, opportunities, drivers and restraints

Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

Thoroughly analyze smaller market segments strategically, focusing on their potential, individual patterns of growth, and impact on the overall market

To thoroughly outline the competitive landscape within the market, including an assessment of business and corporate strategies, aimed at monitoring and dissecting competitive advancements.

Identify the primary market participants, based on their business objectives, regional footprint, product offerings, and strategic initiatives

Request Sample: https://www.globalinsightservices.com/request-sample/GIS25601//?utm_id=1014

Market Segmentation

The carbon fibers (CF) and carbon fiber reinforced plastics (CFRP) market is segmented by type, end-use, application, and region. By type, the market is divided into PAN-based, pitch-based, and rayon-based. By end use, the market is bifurcated into automotive, wind energy, sporting goods, Marine electronics, and others. By application, the market is divided into aircraft components, automotive parts, wind turbine blades, and others. By region, the market is classified into North America, Europe, Asia-Pacific, and the rest of the world.

Request Customization@ https://www.globalinsightservices.com/request-customization/GIS25601//?utm_id=1014

Major Players

The global carbon fibers (CF) and carbon fiber reinforced plastics (CFRP) Market report includes players like Toray Industries, Inc. – Japan, Teijin Limited – Japan, Mitsubishi Chemical Holdings Corporation – Japan, SGL Carbon SE – Germany, Hexcel Corporation – United States, Solvay SA – Belgium, Nippon Graphite Fiber Corporation – Japan, Formosa Plastics Corporation – Taiwan, Hyosung Advanced Materials Corporation – South Korea, and Cytec Solvay Group (now part of Solvay SA) – United States

Request Discounted Pricing@ https://www.globalinsightservices.com/request-special-pricing/GIS25601//?utm_id=1014

Research Scope

Scope – Highlights, Trends, Insights. Attractiveness, Forecast

Market Sizing – Product Type, End User, Offering Type, Technology, Region, Country, Others

Market Dynamics – Market Segmentation, Demand and Supply, Bargaining Power of Buyers and Sellers, Drivers, Restraints, Opportunities, Threat Analysis, Impact Analysis, Porters 5 Forces, Ansoff Analysis, Supply Chain

Business Framework – Case Studies, Regulatory Landscape, Pricing, Policies and Regulations, New Product Launches. M&As, Recent Developments

Competitive Landscape – Market Share Analysis, Market Leaders, Emerging Players, Vendor Benchmarking, Developmental Strategy Benchmarking, PESTLE Analysis, Value Chain Analysis

Company Profiles – Overview, Business Segments, Business Performance, Product Offering, Key Developmental Strategies, SWOT Analysis

Buy your copy here: https://www.globalinsightservices.com/checkout/single_user/GIS25601//?utm_id=1014

With Global Insight Services, you receive:

10-year forecast to help you make strategic decisions

In-depth segmentation which can be customized as per your requirements

Free consultation with lead analyst of the report

Infographic excel data pack, easy to analyze big data

Robust and transparent research methodology

Unmatched data quality and after sales service

Contact Us:

Global Insight Services LLC

16192, Coastal Highway, Lewes DE 19958

E-mail: [email protected]

Phone: +1-833-761-1700

Website: https://www.globalinsightservices.com/

0 notes

Video

Carbon fiber reinforced plastics (CFRP) is a versatile material that is used in a wide range of applications, including building structures. This material is lightweight and strong, and can significantly increase the life of a structure. Its high strength-to-weight ratio eliminates the need for supporting structures and heavy construction equipment

0 notes

Photo

BMW 3.0 CSL

German automaker has unveiled a special 3.0 CSL model as a tribute to its race cars from the 1970s.

It will be limited to exactly 50 units to mark BMW’s 50th anniversary, the production of all the vehicles will take approximately 3 months and each vehicle will be created in an elaborate manufacturing process at the external location of BMW Group Dingolfing plant in Moosthenning, Lower Bavaria.

The exclusive interior carbon fibre reinforced plastic (CFRP) components will be produced by hand at the BMW Group component factory in Munich.

For the paintwork of the new BMW 3.0 CSL, a specific process was conceived, craftsmanship and high-technology was combined to provide each individual part with its characteristic colour design, a team of 30 qualified technicians worked on the vehicles and each model took upto 10 days to complete.

The racing version of the historic BMW 3.0 CSL won the European Touring Car Championship during its inaugural season in 1973 and repeated this title win five more times in succession from 1975 to 1979. The road version of the racing car was developed for homologation purposes and became a widely known symbol for inspiring driving pleasure.

The BMW 3.0 CSL is powered by the most powerful straight six-cylinder engine with direct injection ever used in a BMW model, the engine produces a maximum output power of 206 hp, the powerful drive system was combined with refined suspension technology and its unladen weight was just 1270 kgs.

#art#design#sportcars#supercars#supercar#bmw#bmw 3.0 CSL#luxurylifestyle#luxurycars#luxurycar#50th anniversary#racingcar#sportcar#collector's

155 notes

·

View notes

Text

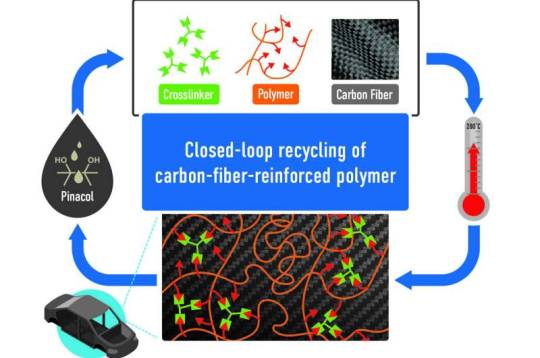

New process allows full recovery of starting materials from tough polymer composites

In a win for chemistry, inventors at the Department of Energy's Oak Ridge National Laboratory have designed a closed-loop path for synthesizing an exceptionally tough carbon-fiber-reinforced polymer, or CFRP, and later recovering all of its starting materials.

A lightweight, strong and tough composite material, CFRP is useful for reducing weight and increasing fuel efficiency of automobiles, airplanes and spacecraft. However, conventional CFRPs are difficult to recycle. Most have been single-use materials, so their carbon footprint is significant. By contrast, ORNL's closed-loop technology, which is published in Cell Reports Physical Science, accelerates addressing that grand challenge.

"We incorporated dynamic crosslinking into a commodity polymer to functionalize it. Then, we added a crosslinker to make it like thermoset materials," said ORNL chemist and inventor Md Anisur Rahman. "Dynamic crosslinking allows us to break chemical bonds and reprocess or recycle the carbon fiber composite materials."

Read more.

#Materials Science#Science#Polymers#Composites#Recycling#Fiber reinforcement#Fibers#Carbon fibers#Cross linking

9 notes

·

View notes

Text

youtube

youtube

youtube

OmniZero.13 (2011) by Takeshi Maeda, Vstone, Osaka. "I wanted speed rather than torque, so I tried removing a gear from a normal servo. Another innovation is to bake CFRP [carbon fibre-reinforced polymer] from the pre-preg. It's not a nori-maki. … A new innovation is to move the knee servo up using links, plus a spring. I tried painting it a color that would make it 3 times faster, but it doesn't seem to be much faster…" – Takeshi Maeda, Robotan Production Diary.

4 notes

·

View notes

Text

TOYOTA GAZOO Racing GRMN Yaris Rally Package

Available in Japan, the GRMN Yaris ‘Rally Package' takes the already impressive GR Yaris and adds an extra depth of rallying performance and flavour. Using the GR Yaris as its base the GRMN Yaris offers increased body rigidity, lower weight as well as fewer seats.

It features a close-ratio gear transmission and a low final gear set that has been refined in the field of motorsports. Close-ratio 1st to 4th gears make efficient use of the engine power band adding a little more urgency to the car’s performance.

In search of weight saving lightweight high-rigidity carbon (twill weave CFRP) has been used for the bonnet/hood, roof and rear spoiler. Combining these new panels with removing the rear seats has achieved weight reduction of approximately 20 kg compared to the normal GR Yaris.

To increase body rigidity the total number of spot welds has increased by 545 (compared to the GR Yaris) whilst rigidity has been yet further enhanced by applying 12m extra structural adhesive.

A rear-only roll cage also improves rigidity as well as harking back to the WRC Yaris from which this car draws its inspiration.

Both the weight savings and increased rigidity are designed to give more direct response to driver's input and enhance the performance of the GRMN Yaris.

24 notes

·

View notes

Text

assembley hole less “alloy” rims

弊所に限らずカーボン(CFRP)製のリムを使った車輪の大半がニップル組み立て用の背面孔無しになって久しいですが、アルミ合金製のリムではメジャーブランド完成車輪製品の補修パーツを除くと、背面孔が無いリムは殆んどありませんでした。

特に「アルミ合金製の背面孔が無いリム」を避けていたわけではなく、単に弊所で使用する程度の少量では入手が難しかったから、というのが理由です。

ところが最近、そう言ったちょっと変わったリムを少量でも分けていただける機会ができました。

CXやロード バイク用だけでなく、他にも色々とたくさん種類があり、全部を紹介できるといいのですが、その中から特に面白そうに感じた製品をいくつか紹介いたします。

為替レートだけでなく原材料高騰の問題もあって、何れのリムも決して安価とは言いづらいですが、その分、総じて作りも良く、ジョイントが溶接だったり、断面形状などのデザインもよく考えられています。

何れも色は黒のみ、背面孔無し仕様なので、クリンチャー型ではTL運用も楽ですし、チューブラー型の場合でもタイヤの接着が楽な上、より確実です。

また、断面形状の構造上、困難でない限り、多くのリムでブレーキ トラックの有無も選択できるので、ディスク ブレーキ用だけでなく、リム ブレーキ用の車輪も製作が可能です。

“tube-less type”

このリムは外幅は24mmくらいで大して太過ぎないのに、内幅が20mmあり、ほぼディスクブレーキでしか使えない様な幅広リム専用設計の最新タイヤがリムブレーキでも使える様になります。

メーカーの公式重量表記は450g前後、一回り断面積の小さなKinlin XR-22Tとほぼ同等の重さで作られています。

内幅20mmのリムでカーボン製だと、大抵は外幅が27~8mmくらいになるので、ブレーキトラックを付けられたとしても実質的にリムブレーキ運用がちょっと難しくなる筈ですが、アルミ製なので外幅24mmというのがいいかもしれません。

あと、TLだけでなく、熱伝導率、放熱性の良いアルミ製のリムなので、ラテックスのチューブド運用も可能です。

“tubular type”

一方で、昨今チューブラー用の車輪を希望されるのは、ガチでCX競技をされていたり、そのパフォーマンスの利点をよくご存知の方くらいだと思います。

ただ、チューブラー用のリムの選択肢は昔と比べると、完成車輪製品はもちろん、リム単体でもかなり少なくなってきました。

尤も、カーボン製のリムであれば、まだまだ色々なリム屋さんが出してはくれていますが、アルミ合金製となると本当に少なく、実際に入手が簡単なものとなると殆んど無いに近い状態です。

そんな状況の中で、こんなリムも使える様になりました。

メーカーの公式重量表記は490g前後、国内での入手性が良く軽さと引き換えに断面積が2/3未満のKinlin TB-20と比べると75gほど重たくなりますが、平均的な成人男性選手の競技用途であれば、大きな断面積から得られる剛性の高さで重さを相殺した上、更に高いパフォーマンスを得やすいのではないかと考えています。

これが更に背面孔無しの為、タイヤ接着面の確実性はもちろん、対浸水性も良くなるので、特に「泥仕合」にはオススメです。<意味が違う

これから秋に向けてCXレース用の車輪の準備を始められる方もおられると思いますが、敢えて非カーボン製のリムを希望される方には使っていただいただけるといいなぁと思っています。

もちろん他にも用途や仕様の違うアルミ合金製のリムを使った車輪デザインの提案も可能です。

興味ございましたらお問い合わせください。

よろしくお願いいたします。(^-^)

3 notes

·

View notes

Photo

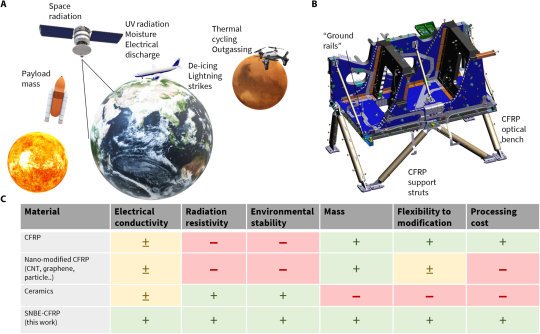

Ultra-lightweight multifunctional space skin created to withstand the extreme conditions in space A new nanobarrier coating could help protect ultra-lightweight carbon composite materials from extreme conditions in space, according to a study from the University of Surrey and Airbus Defence and Space. The new functionality added to previously developed 'space skin' structures adds a layer of protection to help maintain space payloads while traveling in space, similar to having its very own robust ultralight protective jacket. The research team has shown that their innovative nano-barrier would help drastically increase the stability of carbon fiber materials, while reducing radiation damage. Professor Ravi Silva, corresponding author of the study and Director of the Advanced Technology Institute (ATI) at the University of Surrey, said, "Current aluminum shielding is not thermally stable or fully conformal, and therefore usually undesired for stable structures. Not to mention that aluminum shielding contributes to the mass and cost of satellites. Our nano-barrier addresses these issues and is a promising upgrade to the industry standard which could become a key accessory to all space and aircraft structures that are both mobile and static." The coating is a highly dense superlattice structure applied to carbon fiber materials at room temperature which does not add over 1 μm of thickness, therefore keeping the materials lightweight. The study has been published in Science Advances. IMAGE....Challenges associated with structural materials selection for space structures.(A) Schematic illustration with environmental effects for orbiting satellites, aircrafts, and planetary science missions. (B) Image of the Sentinel-5 optical support carbon fiber reinforced polymer (CFRP) structure. (C) Comparison of simplified selection matrix for structural satellite components with superlattice nano-barrier–enhanced (SNBE)–CFRP (this work). Credit: Science Advances (2023). DOI: 10.1126/sciadv.add6947

2 notes

·

View notes

Text

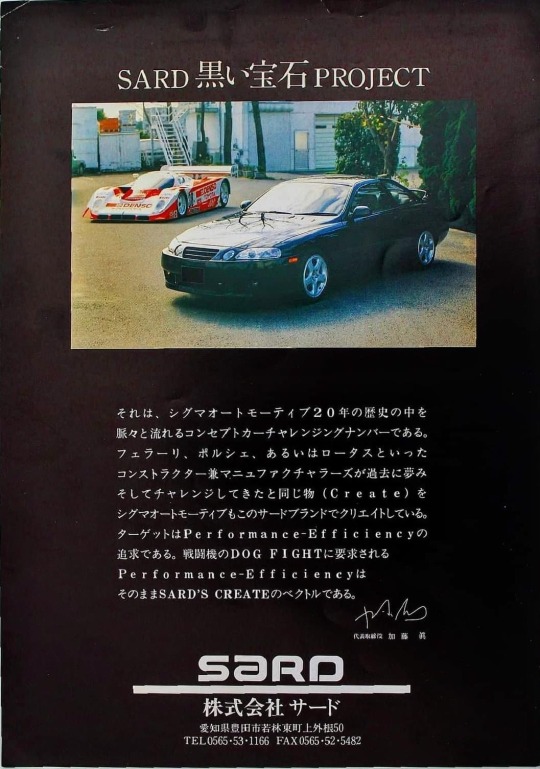

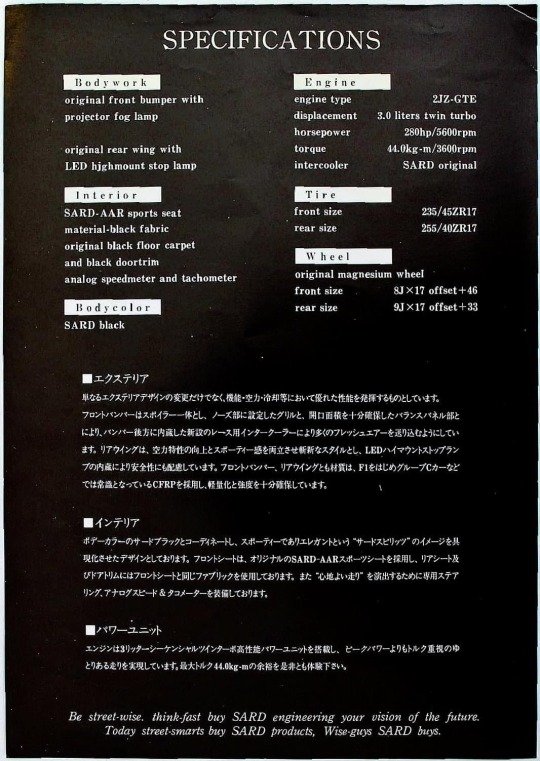

SARD Black Jewel PROJECT

It is a concept car challenging number that has flowed through the 20-year history of SIGMA AUTOMOTIVE. Sigma Automotive is also creating the same thing (Create) that constructors and manufacturers such as Ferrari, Porsche, and Lotus have dreamed and challenged in the past. The target is the pursuit of Performance-Efficiency. Performance-Efficiency required for fighter DOG FIGHT is the vector of SARD'S CREATE as it is.

Chief interrogator Kaei

SARD

SARD Co., Ltd.

SPECIFICATIONS

Engine

Bodywork

original front bumper with

projector fog lamp

2JZ-GTE

engine type displacement horsepower

3.0 liters twin turbo

280hp/5600rpm

torque

44.0kg-m/3600rpm

original rear wing with

LED highmount stop lamp

intercooler

SARD original

Interior

Tire

SARD-AAR sports seat

front size

235/45ZR17

material-black fabric analog speedmeter and tachometer

rear size

255/40ZR17

original black floor carpet and black doortrim

Wheel

original magnesium wheel

front size

8J×17 offset +46

Bodycolor

rear size

9J×17 offset +33

SARD black

■ Exterior

It is not just a change in the exterior design, but it is intended to demonstrate excellent performance in functions, aerodynamics, cooling, etc. The front bumper is integrated with the spoiler, and the grill set in the nose section and the balance panel section with a sufficient opening area are designed to send a lot of fresh air to the newly built intercooler for racing built in the rear of the bumper. The rear wing has an innovative style that combines improved aerodynamic characteristics with a sporty feel, and safety is also taken into consideration by incorporating an LED high-mounted stop lamp. The material used for both the front bumper and rear wing is CFRP, which is common in F1 and other Group C cars, ensuring both weight reduction and strength.

■ Interior

The design is coordinated with the body color of Third Black, and embodies the image of the "Third Spirits", which is sporty and elegant. The front seats use the original SARD-AAR sports seats, and the rear seats and door trims use the same fabric as the front seats. In addition, it is equipped with a special steering wheel, analog speed and tachometer to produce a "comfortable ride".

■ Power unit

The engine is equipped with a 3-liter sequential twin-turbo high-performance power unit that emphasizes torque rather than peak power for a comfortable ride. Please experience the margin of maximum torque 44.0kg-m.

Be street-wise. think-fast buy SARD engineering your vision of the future. Today street-smarts buy SARD products, Wise-guys SARD buys.

50 Kamiwone, Wakabayashihigashimachi, Toyota City, Aichi Prefecture TEL0565・53・1166 FAX 0565-52-5482

6 notes

·

View notes

Text

ShinMaywa announces inaugural flight of the unmanned amphibious 'XU-M' aircraft

Fernando Valduga By Fernando Valduga 09/22/2022 - 11:00am VANT - UAV

On September 5, ShinMaywa Industries of Japan announced the inaugural flight of its XU-M unmanned seaplane. The company stated that the inaugural flight took place on August 26.

The XU-M (EXperimental Unmanned - Marine type) is a unmanned aerial vehicle based on amphibious technology developed by ShinMaywa. It was developed with the objective of promoting research related to the sensing and control of remotely operated amphibious aircraft. The fixed-wing drone is driven by two electric motors and has a cruising speed of 60 km/h. The aircraft is 3m long, 4m wide and 0.9m high. The aircraft built with carbon fiber reinforced plastic (CFRP) has an operating weight of less than 25kg.

youtube

While the XU-M is a test aircraft, ShinMaywa will design the aircraft and provide services according to customer requirements, with the XU-M being able to form the basis for larger projects of unmanned amphibious aircraft.

ShinMaywa also developed an XU-S unmanned fixed-wing aerial vehicle, which has long-lasting flight capacity. Over the years it has been used for radio propagation tests, environmental observation and marine litter survey. This battery-powered drone is driven by two propellers in the tail.

The Japanese manufacturer ShinMaywa produces the large manned amphibious aircraft US-2, currently operated by the Japan Maritime Self-Defense Force (JMSDF). The aircraft was previously considered by the Indian Navy, for which ShinMaywa partnered with Mahindra Defence. ShinMaywa also expressed its willingness to offer US-2 for a U.S. Special Operations Command (USSOCOM) requirement for an amphibious aircraft.

JASMF ShinMaywa US-2 amphibious aircraft.

XU-M combines the technologies used in US-2 and XU-S. On September 2, the XU-M was presented during the "1st Drone Summit" held in the city of Kobe. The drone took off from the water and performed a four-minute flight demonstration. The XU-M made two automatic curves in eight before landing on the water.

Tags: amphibious aircraftDronesShinMaywa US-2

Previous news

Development of CRAIC CR2929 still continues, but should not take off by 2030

Next news

Spirit AeroSystems will provide horizontal stabilizers to keep the KC-135 in flight in the USAF until 2040

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, he has participated in several events and air operations, such as Cruzex, AirVenture, Dayton Airshow and FIDAE. It has works published in specialized aviation magazines in Brazil and abroad. He uses Canon equipment during his photographic work in the world of aviation.

Related news

BRAZIL

Embraer announces investment in XMobots, the largest drone company in Latin America

09/20/2022 - 10:31

MILITARY

Lockheed invests $100 million in its loyal wingman Speed Racer project

09/18/2022 - 11:00

MILITARY

Lithuania is acquiring $36 million in UAVs, including Switchblade drones

09/16/2022 - 08:07

COMMERCIAL

VIDEO: China's second amphibious AG600M 'Kunlong' aircraft completes the inaugural flight

09/14/2022 - 10:00

MILITARY

Iranian attack drone is shot down over Ukraine

14/09/2022 - 08:39

MILITARY

Taiwan confirms purchase of MQ-9 SeaGuardians

05/09/2022 - 14:00

homeMain PageEditorialsINFORMATIONeventsCooperateSpecialitiesadvertiseabout

Cavok Brazil - Digital Tchê Web Creation

Commercial

Executive

Helicopters

HISTORY

Military

Brazilian Air Force

Space

Specialities

Cavok Brazil - Digital Tchê Web Creation

2 notes

·

View notes

Text

Customized rectangle carbon fiber pipes, meticulously crafted to meet your unique requirements

#cfk#cfrp#acen carbon fiber#CFtubes#carbonpipes#customizedcarbon#rectanglecarbonfibertubes#carbontube#carbonfiber#CFRPcomposites#temperatureresistant#kohlefaserrohre#cfkrohregewickelt#CFK#kulfiberrør#CarbonBuis#TubeCarbone#Tubicarbonio#카본파이프#углепластикатрубы#rurawłóknowęglowe

0 notes

Text

How can new composites enhance structural strength and reduce weight in aircraft?

At present, with the development of science and technology, new composite materials play a vital role in enhancing the structural strength and reducing the weight and economic efficiency of aircraft. Here we combine the various properties of ACF artificial cartilage technology and materials, and the composite use with other materials:

Energy absorption performance and structural strength:

ACF artificial cartilage technology is known for its excellent energy absorption performance, up to 97.1%, which can effectively absorb and disperse impact energy. The use of ACF materials or ACF composites in critical areas of an aircraft, such as the landing gear, wing leading edge and fuselage bottom, can significantly improve the impact resistance of these areas, thus enhancing the overall structural strength.

At the same time, the energy-absorbing properties of ACF materials can also reduce the damage to the occupants and the internal equipment of the aircraft in an impact event.

2. Lightweight design:

ACF materials have a low density, which means that while maintaining the same strength or energy-absorbing properties, the use of ACF materials can significantly reduce the weight of the aircraft.

Lightweight design not only helps to improve the aircraft's fuel efficiency and reduce operating costs, but also improves the aircraft's maneuverability and load-carrying capacity.

3. Composite use with other materials:

Composite use of ACF materials with other high-performance composites (e.g. carbon fiber reinforced plastic CFRP) can further enhance the structural performance of the aircraft. For example, embedding ACF materials in critical parts of CFRP structures can enhance the impact resistance and durability of the structure.

The composite use of different materials can also optimize the matching of properties, such as using ACF materials to improve energy absorption while using CFRP to provide high stiffness and strength.

Multi-functional integrated design:

Multifunctional integrated design can be achieved by utilizing the energy absorption, vibration damping, and lightweighting properties of ACF materials and combining them with the functions of other materials. For example, integrating energy-absorbing regions, vibration-damping systems and heat-insulating layers in the structural design of an aircraft to improve the overall performance of the aircraft.

5. Structural optimization design:

The performance advantages of ACF materials and other composites can be further exploited by optimizing the structural design of the aircraft, such as by adopting the lightweight design of laminated structures and structural optimization design. These design methods can reduce the amount of material under the premise of meeting the performance requirements, thus realizing the goals of weight reduction and cost reduction.

It can be seen that the new composite materials can significantly enhance the structural strength and reduce the weight of aircraft through their unique performance advantages, combined with the various properties of ACF artificial cartilage technology and materials, as well as their composite use with other materials. These advantages not only help to improve the safety and reliability of aircraft, but also help to reduce operating costs and improve economic efficiency.

400-6543-699

www.acf.com

0 notes

Text

A woofer system using the largest woofer unit of Diatone developed in 1980.

The unit is equipped with PW 1600 which is a 160 cm cone type woofer. A honeycomb diaphragm is used for the diaphragm. Aluminum alloy is used for the honeycomb core and CFRP (carbon fiber reinforced plastic) is used for the skin material to realize weight reduction. The weight of the diaphragm is reduced to 3 kg even though it is a super large woofer. We have also adopted a field coil for the magnetic circuit. At the design stage, when calculated using permanent magnets, the weight exceeds 800 kg even if a strong magnet is used. Therefore, we have decided to use a field coil to reduce the weight. This coil uses electric wires for train motors, and the field coil alone weighs 400 kg.

A high heat-resistant bobbin is used for the voice coil to achieve high input resistance. Since the frame cannot be cast as a single unit, four parts are assembled with bolts. This unit weighs 600 kg as a single unit.

The enclosure uses a bass-reflex system and is made of a steel balk covered with wood.

At the Koriyama Test at the Koriyama Factory was carried out in the measurement room at first, but it was stopped because fluorescent lamps on the ceiling fell due to vibration. It seems that the characteristic test was carried out at the ground in the factory premises.

The outdoor test seemed to have a negative impact on the neighborhood. At a distance of about 100m from the speaker, it was felt as sound, but at a distance of more than that, it was transmitted as vibration and earth rumbling instead of audible sound. Within a radius of 2 km from the factory, there were damages such as vibrations like earthquakes and earth rumbling, and sound of walls and windows.

0 notes

Text

It's estimated that by 2030 carbon and glass fibre composites (CFRP), materials commonly used in wind turbine blades, hydrogen tanks, airplanes, yachts, construction, and car manufacturing, will be a key waste stream worldwide.

The annual accumulation of CFRP waste from aircraft and wind turbine industries alone is projected to reach 840,300 tonnes by 2050 -- the equivalent of 34 full stadiums -- if suitable recycling methods are not adopted.

While recycling methods do exist, most of this waste currently goes to landfill or is incinerated. The production of "virgin" composites has further implications for the environment too, including resource depletion and high energy input during production.

This is despite the existence of numerous methods to recycle carbon fibre composites which a research team at the University of Sydney says, if fully implemented, have the potential to significantly reduce energy use by 70 percent and prevent key streams of materials from going to waste.

Read more.

13 notes

·

View notes