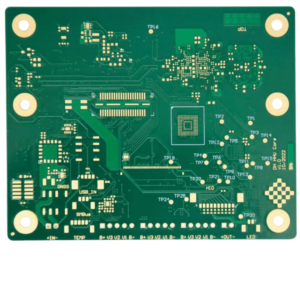

#double side pcb

Explore tagged Tumblr posts

Text

As a top China PCB manufacturer, Hitech Circuits has a lot of experience and skill in every part of PCB production, from layout and design to manufacturing, testing, and after-sales support. All our work is done in our ISO-certified factory, ensuring high quality at every step. We focus on excellence, with each circuit board going through strict quality control before delivery. We make a wide range of printed circuit boards, including PCB prototypes, FR4 PCB, double-sided PCB, aluminum PCB, RF PCB, ceramic PCB, high-frequency PCB, and HDI PCB. If you need a reliable PCB manufacturer in China, contact us today! Just send email to [email protected] . For more information, please visit https://hitechcircuits.com/

#pcb manufacturer#pcb assembly#ceramic pcb#hdi pcb#PCB prototypes#fr4 pcb#double-sided PCB#multilayer pcb#aluminum PCB#pcb factory#pcb fabrication#RF PCB#high frequency

0 notes

Text

A double-sided PCB is a printed circuit board that has two copper layers on top and bottom sides. So copper pads and copper traces are available on both sides of the PCB, and the two copper layers are connected by plated through holes. Inner layers are not present in double-sided PCBs.

0 notes

Text

double-sided PCB manufacturer in india

sb electronics is one of the best manufacturer of double sided pcb in gandhinagar, gujarat. Our Double-Sided PCBs offer the perfect balance between complexity and versatility, making them suitable for a wide range of applications where space and functionality are critical.

#double sided pcb#double sided pcb manufactures#double sided pcb supplier#double sided pcb in gujarat#double sided pcb in gandhinagar#double sided pcb in india

0 notes

Text

It is called "3OZ Double-Sided PCB with HASL",if you just engage in or somehow need this product or custom another new one,welcome contact me to know more details

#3OZ Double-Sided PCB with HASL#3OZ Double-Sided PCB#3OZ Double-Sided with HASL#3OZ PCB with HASL#Double-Sided PCB with HASL#PCB with HASL

0 notes

Text

The Role of Double-Sided PCBs in Multilayered Circuitry

In the rapidly evolving world of electronics, staying abreast with design and architectural advancements is paramount for maintaining the edge in efficiency and performance. Among the various technological marvels that have graced the industry, double-sided Printed Circuit Boards (PCBs) stand out prominently. Acting as the backbone for many contemporary electronic applications, these components are particularly crucial when it comes to the construction of sophisticated multi-layered circuitry.

This era is marked by an insatiable thirst for electronic gadgets and devices. As this demand grows, so does the call for intricate, yet compact, device components. PCB technology, while rooted in time-tested principles, has had to adapt and morph to cater to these demands. In this transformational journey, double-sided PCBs have proven to be instrumental. Delving deep into their structure and functionality reveals their indispensable nature.

The Essential Components of Double-Sided PCBs

At a glance, a double-sided PCB might seem just like its single-sided counterpart but with components on both its sides. However, this seemingly simple design alteration serves a multitude of purposes:

Space Utilization: The quest for miniaturization in electronics is unending. As gadgets shrink, there's a pronounced emphasis on using every millimeter of space efficiently. Double-sided PCBs address this challenge head-on. By allowing components to be mounted on both sides, they drastically increase the potential for component placement, ensuring that devices remain compact.

Connectivity Enhancements: A remarkable feature of these PCBs is the capability to connect circuits on both faces through small holes known as 'vias'. This not only results in a more compact design but also leads to increased circuit density, fostering improved connectivity and signal transmission.

The Integration in Multilayered Circuitry

In the realm of PCBs, multi-layered designs are the epitome of complexity and innovation. Comprising more than two layers of conductive tracks, these PCBs have each layer meticulously isolated by an insulating substrate. Here's where double-sided PCBs become integral:

Enhanced Functionality: The multi-layered architecture can often seem daunting. However, with double-sided PCBs serving as a foundational layer, the process of integrating multiple layers becomes more systematic. This invariably results in devices that can perform a wider range of functions efficiently.

Complexity Management: Handling intricate circuits is no easy feat. But, thanks to the double-sided PCB's ability to manage connections on both of its surfaces, this complexity is significantly tamed, leading to devices that are both reliable and efficient.

Thermal Management: Electronic devices generate heat, and multi-layered circuitry, due to its dense component placement, exacerbates this challenge. Double-sided PCBs, with their dual-faced design, facilitate better heat distribution and dissipation, ensuring the devices remain cool and function optimally.

Advantages of Modern Electronics

The benefits of incorporating double-sided PCBs in multi-layered circuitry are manifold. While some advantages are immediately apparent, others become evident over prolonged use:

Reduced Size: Their ability to house components on both sides plays a significant role in achieving device miniaturization. This not only meets the consumer demand for smaller gadgets but also paves the way for innovative device designs.

Cost Efficiency: It's a common misconception that more advanced components invariably lead to escalated costs. While the upfront expenditure on double-sided PCBs might be marginally higher, the long-term gains in terms of device durability, reduced maintenance, and enhanced functionalities translate to substantial cost savings.

Reliability: Entities like Vishal International are a testament to the unparalleled quality and longevity that double-sided PCBs offer. Their meticulous construction and design, coupled with stringent quality checks, ensure that devices have fewer system glitches, ensuring minimal downtimes and extended device life.

To say that double-sided PCBs play a pivotal role in the realm of multi-layered circuitry would be an understatement.Double sided PCB manufacturers in Bangalore such as Vishal International silently power the seamless operations of a myriad of modern electronic devices. As the technological landscape marches forward, PCBs' significance is poised to grow exponentially. Designers, manufacturers, and tech aficionados must recognize and leverage the unmatched potential of double-sided PCBs in the intricate world of multi-layered circuitry.

#double sided pcb manufacturers in bangalore#double sided pcb manufacturers in India#pcb manufacturers in bangalore

0 notes

Text

double sided pcb manufacturer

Techno Advance System is a largest PCB Assembly Company in India. We offer PCB Assembly, LED PCB Assembly, double sided pcb, and LED Assembly in Ahmedabad, India.

#double sided pcb#double sided pcb manufacturer#double sided pcb in india#pcb soldering manufacturer#double sided pcb manufacturing#double sided pcb in gandhinagar

0 notes

Text

Updating organization at the Adabench for the New Year This coming year, we wanted to update our storage and organization: with about 700 original designs, a couple dozen in progress, and thousands of items in the shop, it's hard to keep track of all the components and devboards we need to test various combinations. Historically, we've used double-sided totes

, which are good, but the double-sidedness is a bit annoying, or the little divider boxes for small breakouts

, and snap-top boxes for SMT components

But all these cases were sort of swimming around, and it was getting unwieldy. We're going to try to use the large IKEA ALEX drawers

- we like them cause they're wide and thin - and maybe use something like gridfinity

to make a flat storage surface so we can quickly find any PCB or part we need.

#organizationgoals#newyearupdate#storagesolutions#adabench#electronicsworkshop#ikeaalex#gridfinity#pcbdesign#electronicsorganization#diysetup#makerspace#storageideas#workspacegoals#creativesolutions#tidyworkspace#storagehacks#diyorganization#electronicsprojects#smallpartsstorage#modularstorage#ikeahack#makersgonnamake#storagetips#workshopsetup#designworkflow#electronicslab#tidyup#workspaceinspo#makerslife#organizedworkshop

18 notes

·

View notes

Text

In my quest to build my chief assistant the ultimate gamer gf setup, I decided to include a keyboard with new parts I had lying around but never got around to using myself. Built to my taste, it was only this morning I realized it's Vertin-coded LOL so I thought I might share since I haven't posted anything artistic in awhile.

From 4 years ago, this is a NK65e Blumen (named because it's blue and glows in the dark) with modded stabilizers. I used the bandaid mod on the PCB, as well as brushed the stabilizer stems with Super Lube 92003 Silicone grease.

The switches are Glorious Lynx (linear) I hand-lubed with Krytox 205g0 one year ago. The light blue housing with the translucent white stem is super cute, too bad it can't be seen from underneath.

As for the keycaps: I actually picked these up a few weeks ago after wracking my brain for hours deciding between different profiles and colors. I finally went with this set because I love pastel colors, especially blue/lavender (the three-tone was a plus). The keycaps are Womier double-shot PBT Cherry-profile (side-printed Shinethrough legends) with a Rainy colorway.

Synthwave series Pastelwave deskmat groupbuy dropped in early 2021.

Altogether, this board has a solid and low sound profile akin to steady rain falling on a roof. I'm proud that it's going to a happy home :) <3

10 notes

·

View notes

Text

R-8 backlight DIY

I picked this up off the Yahoo Flea Market app. It's seen better days but works fine. I had a Mk II aaaaaaaaaaages ago. I forgot how goddam huge these things are. I was killing time on YouTube and saw someone doing Autechre style stuff with an R-8 and was like OH YEAH! That was right around when I had one and I was doing similar stuff, though I was shit at putting actual tracks together. Oh well. Anyway so yeah tharr she blows! As I mentioned, I had the Mk II version and that one has a backlit screen, which the first version does not have, so I thought hmmmm inverters are probably super small to drive that tiny of an EL sheet, and a step-up power converter probably won't be too big, and I can probably find an el-cheapo made in china deal for peanuts on Jamazon or AliExpress, so let's do this! I got the step up converter from Jamazon. I think I had to buy a set of 8 and it was like ten bucks. I tapped the legs of the 7805 +5V regulator for the power source and ground. Set the pot on the step up thing to output +12V, ran that out to the inverter for the EL sheet, cut the sheet to size, wired it all up, plugged it in, turned it on and hoped for the best. Worked fine first time.

Went with "red" for no real reason. If I get sick of it I'll just buy a blue or blue-green sheet. They're like ten bucks for a sheet. The inverter was about fifteen bucks? I got those from Kyohritsu, a major electronics parts supplier in Osaka. I always use them or Akidzuki. In this case it was Kyohritsu because they make the backlight screen kits themselves, and I've always used them for EL sheets. Here's what the business end looked like when done.

I used double-sided tape to secure the step-up converter there on the right, but because of me forgetting to trim the legs off the inverter components (not done at the factory, tsk tsk) I used a set of clippers but that didn't work 100% so I hot glued the inverter pcb there on the left. LOTS of free space on that PCB in the R-8. I had to cut a small hole in the metal noise shielding sheet that goes between the main PCBs and the keypad/drumpad PCBs to feed the EL sheet power wires through, but yeah no big deal. I also checked the voltage on the battery while I was in there. It's still fine. Something that surprised me was that there is NO whine at all with this inverter. Super easy job. Yay!

6 notes

·

View notes

Text

Double Sided PCB Manufacturers In Gujarat

Sb electronics is a manufacturer and supplier of double sided pcb, single sided pcb, aluminium pcb. it is widely used in various electronics applications in india.

#double sided pcb#double sided printed circuit board#double sided pcb manufacturer#double sided pcb supplier#double sided pcb manufacturer in gujarat

0 notes

Text

Understanding Circuit Board Electronic Components: A Comprehensive Guide

In today's digital world, electronic devices have become an essential part of our daily lives. But what makes these devices tick? At the heart of every electronic device lies a circuit board—a masterpiece of tiny electronic components working together to perform complex tasks. In this article, we’ll dive deep into the fascinating world of circuit board electronic components, exploring each element’s role and how they contribute to the overall functionality of the device.

What is a Circuit Board?

A circuit board, often referred to as a PCB (Printed Circuit Board), is a flat board used to mechanically support and electrically connect various electronic components. These components work in unison to perform a specific task. Think of the circuit board as the skeleton and nervous system of an electronic device—it holds everything together and allows communication between parts.

Types of Circuit Boards

Single-sided PCB: Has one layer of conducting material.

Double-sided PCB: Contains two layers for components and connections.

Multi-layer PCB: Complex boards with multiple layers for advanced applications.

The Role of Electronic Components on a Circuit Board

Every electronic device you interact with is powered by a carefully designed circuit board filled with various components. These components might be tiny, but each one has a critical role in the operation of the device. Here's a breakdown of the most important electronic components you’ll find on a typical circuit board.

1. Resistors

Resistors are fundamental components that control the flow of electrical current. They resist the flow of electrons, hence the name "resistor." Their primary function is to reduce current flow, adjust signal levels, and divide voltages in a circuit. Without resistors, circuits would allow too much current to flow, potentially damaging other components.

Types of Resistors

Fixed resistors: Have a set resistance value.

Variable resistors: Allow adjustment of the resistance.

2. Capacitors

Capacitors store and release electrical energy in a circuit. They are often compared to small rechargeable batteries that quickly charge and discharge. Capacitors help smooth out fluctuations in voltage, filter noise, and store energy for future use.

Common Uses of Capacitors

Energy storage

Signal filtering

Voltage stabilization

3. Inductors

Inductors are components that store energy in a magnetic field when electrical current flows through them. They resist changes in current and are typically used in circuits to filter signals, manage power, and store energy.

Applications of Inductors

Power supplies

Radio frequency circuits

Noise suppression in circuits

4. Diodes

A diode is like a one-way valve for electricity, allowing current to flow in only one direction. They are vital in circuits to prevent reverse currents, which can damage components.

Types of Diodes

Light-emitting diodes (LEDs): Produce light when current flows through.

Zener diodes: Regulate voltage within a circuit.

5. Transistors

The transistor is a versatile component used to amplify or switch electronic signals. In essence, transistors are like tiny switches that turn signals on and off rapidly, making them essential in modern electronics.

Types of Transistors

NPN transistors: Allow current flow when a small voltage is applied to the base.

PNP transistors: Conduct when the base is negatively charged.

How Circuit Board Components Work Together

In a circuit, each component has a specific role, and together they form a cohesive system. For example:

Capacitors and resistors may work together to filter signals or smooth out voltage fluctuations.

Transistors and diodes ensure that signals are amplified or directed properly.

Integrated circuits handle the complex tasks, processing data, and controlling the overall system.

Choosing the Right Components for Your Circuit Board

When designing or repairing a circuit board, choosing the correct components is crucial. Some factors to consider include:

Voltage requirements

Power consumption

Signal type and frequency

Physical size and compatibility

Conclusion

Circuit boards are an integral part of any electronic device. The various components on the board each play a specific role in ensuring the device functions as intended. Understanding these components, from resistors to integrated circuits, is essential for anyone working with electronics, whether you're designing a new system or troubleshooting an existing one.

2 notes

·

View notes

Text

Circuit Board, PCB assembly & electronics manufacturing service provider from China (hitechcircuits.com)

What is a prototype PCB assembly?

PCB prototyping is the experimentation pilot stage of the product which is to be mass produced at a later stage. This is more of an experiment which is done after the initial discussions and the design. This offers a pre-production analysis of the boards that are to be manufactured, reducing the possible number of errors in the PCB design. PCB prototypes help the manufacturer analyze the strengths as well as weak areas of their proposed circuit boards. Prototypes also serve as a reference point for future versions of the same product. At Hitechpcba, we handle PCB prototype assembly in quantities from one to hundred printed circuit boards.

We have acquired capabilities that enable us to serve our clients better. All these years, we have worked on many complex prototype PCB assembly projects, and we believe the following capabilities have helped us serve our clients better.

Prototype PCB Assembly Services: We specialize in the following prototype printed circuit board assembly services.

SMT: We can provide single-sided and double-sided surface mount PCB assemblies in different specifications.

Plated Through Hole: We offer plated through hole assembly with selective soldering.

Mixed Assemblies: We often work on projects involving mixed assemblies – through-hole and SMT and electromechanical assemblies.

PCBA Testing: All the PCBA functional testing is performed in-house. Over the years, we have invested in various test fixtures and equipment, which helps us ensure the quality of PCBA. Currently, we provide the following types of PCBA testing services:

Flying probe testing for PCB

Functional testing including system and board-level testing

General PCB Assembly Capabilities: Our general PCB assembly capabilities are not limited to these:

RoHS, leaded or lead free, clean and no chemistries

PCB components including various types of QFNs, BGAs, 0105, 0201, 0804, and press fit components in small quantities.

What are the benefits of a prototype PCB assembly?

Prototype PCB assembly comes with several advantages. These benefits play a major role in the facilitation of your PCB manufacturing. Some of these benefits include:

Detection of Flaws Early

With prototype PCB, you will easily detect whatever flaws are present during the product’s development stages. This will allow you to solve the issues thereby saving you some money if you had gone ahead to make the production having the flaws in them.

If you go ahead to make changes during the production, there may be a need for more technicalities, and this may be expensive.

Testing of Each Component

With a prototype, you will be able to test all your system’s elements individually before you go ahead to set it up. You should do this because it is important especially for very complex projects composed of several parts that are PCB based.

When you validate each of these components, you will be able to identify those areas having issues that you should look into. This is the only way the project can function the right way.

Reduction in Total Costs

Utilizing the prototype bare PCB for any of your projects could go a long way in reducing what you’ll have spent in total for the project. With prototyping, you will be able to notice those errors in your project and then make corrections before you start the real production.

As soon as these flaws have been checked and rectified, then you may continue with the manufacturing of your Printed circuit boards in large quantities, thereby saving you unnecessary costs.

High-Quality PCBs

Why prototyping your PCB is important is to help you test if your project will function effectively. When we talk of testing, it involves the identification of errors present and then rectifying and making corrections to them.

Therefore, the eventual PCB after the prototyping will be of high quality that surely meets standards set internationally.

Less Turnaround Time

With prototype PCB assembly, you will be able to reduce the total time used in producing your printed circuit board. While making use of prototype printed circuit boards, you’ll be able to see the errors and then make corrections before you start the actual production.

Therefore, the eventual prototype will be free of defects. This implies that your PCBs will be produced quickly by your manufacturer.

What are the different types of prototype PCB assembly services you offer?

With years of market presence and experience, we specializes in the following prototype PCB assembly services.

Plated through-hole (PTH): We can provide the through-hole assembly with selective soldering.

Surface mount technology (SMT): We offer single-sided as well as double-sided SMT board assemblies in varied specifications.

Mixed Assemblies: Our experts often work on projects involving both PTH and SMT assemblies.

What are the types of testing Hitechpcba use for prototype PCB assembly?

Automated Optical Inspection (AOI): This is performed before and after the soldering to identify the component placement, presence, and solder quality.

X-ray Testing: In this type of testing, the operator relies on the X-ray images of the PCB to check the solder joints and lead-less components such as Quad Flat Packs and ball grid arrays, which are generally not visible to naked eyes.

In-Circuit Testing (ICT): This method is used to detect manufacturing defects by testing the electrical properties in the SMT Assembly.

These techniques help us ensure the reliability and accuracy of the circuit boards. In addition to this, it ensures a long operational life of equipment, minimal production losses, streamlined processes, and much more.

What are the capabilities Hitechpcba offer for prototype PCB assemblies?

We specialize in offering IPC compliant, and quick turn PCB assemblies. We are very particular about our scheduled deliveries and timelines, and we deliver without compromising the quality. Our PCBA capabilities are not limited to these. Here are some capabilities we offer through prototype PCB assemblies.

RoHS compliance

Stringent testing procedures

Device encapsulation

Full turnkey, partial turnkey, and kitted/consigned services

Assemblies using Surface Mount (SMT), Thru-hole, Mixed Technology (SMT/Thru-hole), Single and double-sided SMT/PTH, Large parts on both sides, BGA on both sides.

Do you perform a component analysis for prototype PCB assemblies?

Yes, we check the quality and performance of components before mounting them on the circuit boards. This is because a malfunctioning component can affect the performance of the entire circuit board assembly and also pose risks.

What is your standard turnaround time for a prototype PCB assembly?

Our turnaround time for standard applications is two weeks. This timeframe varies depending on the complexity of the applications. However, we are committed to offering quick turnaround times without compromising on quality, functionality, and accuracy, which offers our client a competitive advantage and reduced time to market. You can also request any emergency assistance or queries related to any type of PCB assembly. Our experts will assist you in all possible ways.

How is the cost of prototype PCB assembly estimated?

PCBA costing varies based on the different factors, such as PCBA parts, type of materials to be used, order quantity, and much more. We can also offer quotes and customization options once you share the detailed requirement with us.

We focus on quality and customer satisfaction over anything else. This has helped us build a long list of happy and satisfied customers. So, if you wish to partner with a manufacturer of prototype PCB assembly in China, then don’t hesitate to reach us. Our experts will assist you through all the phases of the prototype PCB assembly process. We look forward to making your experience with us better and memorable.

How to choose prototype pcb assembly manufacturer?

Our pcb prototype assembly service includes the sourcing of components. This allows you to concentrate on what you do best: layout design. We have a dedicated sourcing staff that coordinates with multiple suppliers and distributors to purchase electronic parts as per client requirements, and our staff completes these purchasing particulars in a most efficient manner. We have advanced processes for optimal selection of packaging (cut tape, tube, bulk, etc.) to reduce the total cost. Furthermore, we are capable of cross-referencing parts and even locating hard-to-find and obsolete parts. Customers can be rest assured that when Hitech Circuits substitutes components that they are high quality: we only use the electronic component numbers and manufacturers specified in the BOM. We will not modify your original layout design. Part substitutions take place only with your permission.

The final pcb prototype assembly service cost includes assembly labor charges, bare circuit board rates, and part costs. We understand the importance of prompt delivery. The sooner the components are sourced, the sooner we can begin circuit board fabrication. We thoroughly evaluate engineering inquiries and concerns related to the related parts with our clients before commencing circuit board assembly. The average time taken for pcb manufacturing assembly is about two weeks, which can be further reduced if there are no hard-to-locate components or documentation mistakes.

We have specialized experts to deliver fast turnarounds for prototype circuit board assembly with surface-mount (SMT), through-hole (THT) and mixed-technology components.

Anyone interested in electronics and electronic circuit boards needs to understand the various stages of developing and producing a printed circuit board. It can come in handy when you are seeking a top prototype smt assembly provider. The various production stages of printed circuit boards entail design, prototyping (prototype PCB development and rapid prototyping pcb assembly), and PCB high volume production. Different entities will always seek part of the whole production process depending on their electronic circuit board needs.

However, this article seeks to help you understand everything about prototype PCB assembly, a fundamental aspect of the PCB production process.

Rapid prototyping pcb assembly represents a fundamental phase of the printed circuit production process. It is also inferred as PCBA prototype assembly, SMT or surface-mount technology PCB prototype, PCB sample assembly, etc. From these alternative names, the meaning of prototype assembly regarding printed circuit boards becomes apparent. So what is assembly prototype?

PCB prototype assembly service is a fast prototype printed circuit board assembly primarily used to test fresh or new electronic designs. Consequently, it assists with checking and ensuring quality assurance of the PCB. For instance, it verifies that no bug exists in the test PCB, updates the design, and finds bugs. In most instances, prototype assembly of an electronic project will require two or three iterations to ensure everything is perfect.

Why Choose Hitech Circuits PCB Assembly for Your Prototype PCB Assembly Projects?

There are several PCB manufacturers specializing in prototype PCB assembly services. However, Hitech Circuits stands out owing to the following:

1.Strong Supply Chain: Over the years, we have built strong supply chain relationships in the industry, which helps us fulfill the requirements of turnkey prototype assembly services easily.

2.Fastest Turnaround Times: Our engineering expertise coupled with our understanding of industry requirements and a well-equipped facility enables us to assure the fastest turnaround times of 24-48 hours.

3.Reliability: All the printed circuit boards that we produce are IPC compliant, which helps us assure reliability.

4.Competitive Pricing and Quick Quote: Our supply chain relationships enable us to assure competitive prices. The cost of the PCB prototype assembly will be made available within 24-48 hours.

2 notes

·

View notes

Text

The Rise of Sustainable Circuitry: Exploring Eco-Friendly Practices in PCB Manufacturing

In recent years, there has been a growing global concern regarding the environmental impact of various industries. One sector that has gained significant attention is the electronics industry, particularly in the manufacturing of printed circuit boards (PCBs). PCBs are integral components of electronic devices, ranging from smartphones and laptops to industrial machinery and medical equipment. As the demand for electronics continues to rise, it becomes crucial to explore eco-friendly practices in PCB manufacturing. This article delves into the emerging trend of sustainable circuitry and highlights the importance of adopting environmentally conscious approaches in the production of PCBs.

I. The Environmental Impact of Traditional PCB Manufacturing:

The conventional methods of PCB manufacturing have significant environmental consequences. The production processes involve the use of hazardous chemicals, such as lead, mercury, and brominated flame retardants (BFRs), which pose risks to human health and the ecosystem. Additionally, the energy consumption and carbon emissions associated with PCB manufacturing contribute to climate change. These factors have spurred the need for alternative practices that prioritize sustainability.

II. The Principles of Sustainable Circuitry:

Sustainable circuitry aims to minimize the environmental impact of PCB manufacturing through various principles:

a) Material Selection: One of the fundamental aspects of sustainable circuitry is choosing eco-friendly materials for PCB production. Opting for lead-free solder, recyclable substrates, and non-toxic coatings reduces the ecological footprint of the manufacturing process.

b) Waste Reduction: Sustainable circuitry emphasizes the reduction of waste generated during PCB manufacturing. Implementing efficient production techniques, recycling solder and unused materials, and proper disposal of hazardous waste are crucial steps in achieving this objective.

c) Energy Efficiency: Energy consumption plays a significant role in the environmental impact of PCB manufacturing. Sustainable practices focus on optimizing energy efficiency through process improvements, equipment upgrades, and the utilization of renewable energy sources.

d) Lifecycle Considerations: Sustainable circuitry takes into account the entire lifecycle of PCBs, including their disposal. Designing for disassembly and recyclability ensures that the materials used in PCBs can be recovered and reused, reducing the need for virgin resources.

III. Innovations in Sustainable Circuitry:

The pursuit of sustainable circuitry has driven innovations in PCB manufacturing. These advancements not only reduce environmental impact but also enhance the performance and longevity of electronic devices.

a) Green Chemistry: Green chemistry principles are being applied to develop eco-friendly alternatives to traditional PCB manufacturing chemicals. This includes the use of water-based fluxes and solder masks, as well as the development of halogen-free flame retardants.

b) Renewable Materials: Researchers are exploring the use of renewable materials, such as bioplastics and bio-based resins, as substitutes for conventional PCB substrates. These materials offer reduced environmental impact and can be derived from renewable resources.

c) Closed-Loop Manufacturing: Closed-loop manufacturing systems aim to minimize waste and resource consumption by recycling materials within the production process. This approach reduces the reliance on virgin materials and contributes to a more circular economy.

d) Life Cycle Assessment (LCA): LCA is a methodology used to evaluate the environmental impact of a product throughout its entire lifecycle. Applying LCA to PCB manufacturing allows for the identification of areas with the highest environmental impact, enabling targeted improvements and informed decision-making.

IV. The Role of Vishal International in Sustainable Circuitry:

Vishal International is at the forefront of promoting sustainable circuitry in PCB manufacturing. The company recognizes the importance of minimizing environmental impact and has implemented several eco-friendly practices.

a) Lead-Free Manufacturing: Vishal International utilizes lead-free solder in its PCB manufacturing processes. This eliminates the use of toxic materials and reduces the potential harm to both human health and the environment.

b) Energy Efficiency Measures: The company has invested in energy-efficient machinery and production techniques, reducing energy consumption and greenhouse gas emissions.

c) Waste Management: Vishal International emphasizes proper waste management, ensuring that hazardous materials are disposed of in compliance with environmental regulations. Additionally, the company actively promotes recycling and reuse of materials whenever possible.

d) Sustainable Material Choices: Vishal International prioritizes the use of eco-friendly materials in PCB manufacturing, such as recyclable substrates and non-toxic coatings. These choices contribute to the overall sustainability of their products.

Conclusion

As the demand for eco-friendly electronics grows, Vishal International's dedication to sustainable practices positions it as largest multilayer pcb manufcturers in India. By supporting companies like Vishal International, we can drive the transition toward a more sustainable and greener future in the electronics industry.

#multilayer pcb manufacturers in India#double sided pcb manufacturers in india#pcb suppliers in India

0 notes

Text

GIGABYTE Introduces AMD Radeon RX 7600 XT 16GB GPU

GIGABYTE TECHNOLOGY releases an AMD RDNA 3 graphics card today. GIGABYTE’s best-in-class WINDFORCE cooling system comes with the AMD Radeon RX 7600 XT GAMING OC 16G graphics card. Its superior performance, stunning visual effects, and efficiency make it ideal for 1080p gaming and streaming.

GIGABYTE AMD Radeon RX 7600 XT Gaming Performance

With its three distinct blade fans that spin alternately, its composite copper heat pipes that come into direct contact with the GPU, its three 3D active fans, and its screen cooling, the GIGABYTE WINDFORCE cooling system is designed with gamers in mind. By rotating the central fan in the opposite direction from the side fans, the Alternate Spinning technology directs airflow in the same direction, doubling air pressure and lowering turbulence. This design improves overall cooling performance by efficiently dissipating heat from the graphics card’s top and bottom.

Using graphene nano lubricant, three of the WINDFORCE fans have a 2.1-fold longer lifespan than the double ball bearing design, with a quieter operation that nevertheless yields nearly the same durability. The protective back plate keeps the PCB from bending or getting damaged in addition to strengthening the graphics card’s overall structure. With customizable LED lighting on the side that can be displayed in a personalized manner using software, the graphics card boasts a gaming-style design.

The graphics card’s superior performance can be attributed to its power design and utilization of ULTRA DURABLE certified components. With their superior computational performance and extended lifespan, ULTRA DURABLE certified high-quality materials like metal chokes, all-solid capacitors, and low-resistance MOSFETs allow gamers to fully immerse themselves in 1080p gaming and vivid virtual worlds.

The 16GB of GDDR6 memory and next-generation technologies that enable a smoother, better-looking, and ultra-fast gaming experience at 1080p and beyond give the GIGABYTE AMD Radeon RX 7600 XT GAMING OC 16G graphics card the promise of great gaming for years to come. You can adjust your game settings to achieve the highest level of immersion and responsiveness, and in certain crucial situations, you can even increase the resolution to 1440p, thanks to next-generation technologies like AMD FidelityFX Super Resolution 3 and AMD HYPR-RX with AMD Fluid Motion Frames.

With 16GB of lightning-fast RAM, games will be ready for years to come, and workloads involving creation and Al can be completed with greater freedom and inventiveness. Future-ready performance and next generation technologies are what gamers care about most, and the GIGABYTE AMD Radeon RX 7600 XT GAMING OC 16G graphics card delivers on both fronts.

Read more on Govindhtech.com

#GIGABYTE#AMDRadeonRX7600XT#16GBGPU#AMDRDNA3#graphicscard#WINDFORCE#RAM#technews#technology#govindhtech#gpu

2 notes

·

View notes

Text

Leopold FC980m

Custom PCB (source)

Aflion Melody and Runner switches

Deadline Studio AirR PC keycaps

Lightblue painted stock aluminium plate

Stock plate-mounted clip-in stabilizers

More under the cut.

This build took well over a year to actually get it to it's current state and it's technically not done yet, considering I still have to tune and lube the stock stabilizers.

Issue number 1 before everything else was getting the cherry mx brown switches out of the old PCB to be able to remove the plate because I didn't want to order a custom plate or go plateless. The solder used on the original PCB has a stupid melting point so not only did I have to dilute the solder with my own that melts at roughly 320°c, but my soldering iron was set to 410°c (or more for specific spots, more on that later). A good chunk of the extracted switches were simply not usable anymore afterwards from being slightly molten. The plate has a few hooks and the PCB has holes for them to hook into, one of which is a PTH (plated through hole) hole that goes to the PCB's ground and the corresponding hook lacks paint and is soldered into this hole. This cursed and damned hook was the reason for a lot of frustration as it took quite literally half an hour (maybe more) to de-solder at 435°c while constantly adding and removing solder to slowly chip away at this literal mountain of solder they used.

My next problem was simply getting the new PCB(s). Back then I was a bit tight on money from expenses out of my other hobbies and various mundane things I needed, so it took a month or two to be able to finally order them. Except JLCPCB, the service that was recommended for this PCB by this keebtalk thread, ran out of the MCUs I needed, so I researched if they had any alternatives, but by the time I read enough of the documentation of various alternatives and found one, that one ended up being out of stock as well. So another couple of months passed basically just waiting.

After ordering, an engineer of JLCPCB contacted me because some of the NPTH (non-plated through hole) holes were too close to each other and would be at risk of breaking while drilling and the best option seemed to be just making them PTH holes, because the hook holes aren't connected to anything and the plate's paint makes it non-conductive anyways so it should be fine. Right?

FORESHADOWING IS A LITERARY DEVI-

I eventually get the new PCBs and of course immediately scratch one of the 5 I ordered (it still works), tested 2 of them and went to work. Across a couple months (I was preoccupied, blah blah lazy excuses) I slowly chipped away at soldering in the MillMax sockets.

Couldn't have 4 minutes without problems though, now can we? Trying to install the switches and PCB didn't work because the MillMax sockets add roughly a millimeter of distance between PCB and plate and you can already guess that this doesn't play nice with the plate's hooks. I trimmed off the hooks but left them as little poles for aligning the PCB and so everything would be alright. Right?

I assemble the keyboard fully and plug it in to see... it not working. I assumed due to the extra millimeter from the hotswap sockets messing with the tolerances, there may be a short to the daughter board, so I took it apart again and taped any contacts and it still didn't work after reassembly. Now I was getting quite annoyed so I took off the top of the casing and tested it like that and surprisingly it worked. Kinda.

As soon as I snapped the top of the case back on, or pressed down on the plate in the bottom left corner, the keyboard would fire A bunch of keys at the same time.

Seeing this set of keys led me to the right path. I double checked this side of the PCB and saw that the hole for the PCB hook next to caps was PTH rather than NPTH and connected to one of the contacts for caps. Remember when I said one of the hooks was connected straight to ground? Or how I had to remove part of the plate hooks, thus removing the paint that prevents it from conducting electricity? Yeah. One strip of tape later and everything is fixed and works perfectly fine.

That's basically it. It was a pain, but it looks, sounds and types nicely. I'm happy with how it turned out.

2 notes

·

View notes

Text

grab yourself a drink and some popcorn for this one, this is by far my longest post yet and youre gonna want to be prepared :P

nina's thoughts on Touhou 11 - Subterranean Animism

Subterranian Animism is probably one of my favourites in the series so far, it has a ton of really cool aspects both in gameplay and story. the majority of the big changes to gameplay come in the playable characters themselves, but theres a few system changes too. faith comes back from MoF but now it only goes down if you die, resetting to the initial value, which may sound broken with how many points you'd get, but lives are different now. lives now are gained by collecting 5 'life pieces', little pink stars that drop from mid-bosses, boss fights, and the occasional strong fairy whenever you beat one of their phases without dying or timing out. life gains are much more consistent now, but the fact you only get life pieces if you dont get hit is a bit strange, as it means a player having trouble will get even less lives to help while a good player has tons of lives that they dont need since they dont get hit. bombs are handled the same way as MoF, sacrificing a weapon option (which you now only get 4 of instead of 5), but unique bomb effects are back depending on your moveset.

speaking of those movesets, SA again only has Reimu and Marisa with 3 movesets each, but with a twist! instead of being simple weapons, each of the movesets represents a youkai from a previous game teaming up with Reimu/Marisa, reminiscent of Imperishable Night. each combo has unique weapon mechanics not seen before, a bonus skill, and unique dialogue through the story, making for a lot of variety based on your choice. all 6 are really cool and i wanna talk about them all, so prepare for a big wall of text here :P

Reimu + Yukari: Reimu's first combo is with her old partner from IN, the gap youkai Yukari. This moveset is somewhat reminiscent of Reimu's typical needle attacks, but with some unique elements. Yukari's needle-shooting options are constantly orbiting Reimu, and if the option would go off the left or right edge of the screen, it instead wraps around and keeps shooting on the other side. the special skill of this combo allows Reimu to do the same, if you double-tap a direction into the side of the screen you will zoop in and come out on the other side! its a really funny move, and probably has some insane use cases, but i never could make good use of it myself. their bomb is pretty nuts, having Reimu slip into another dimension where shes completely unaffected by bullets for a few seconds, and then fully clearing the screen when she reappears in reality.

Reimu + Suika: Reimu's next partner is the drunk oni Suika who debuted in one of the fighting games iirc. Suika's weapon acts as this games homing option, although the actual homing aspect is pretty weak. interestingly though, her bullets are also piercing in addition, which makes her great at punching through crowds of enemies. her special technique is that if you let go of every button on the controller it magnetizes every item on screen to you no matter where you are, which is a pretty huge QoL buff and is really helpful for grabbing life pieces without putting yourself in danger. her bomb creates a circle of protection on your position like the MoF ones, but any enemy bullet that enters is turned against the enemy instead of simply being negated, which can deal some nasty damage. i played Suika's combo the least, but it actually ended up being my 1cc somehow lmao.

Reimu + Aya: Reimu's third partner is the high-speed newpaper tengu Aya! this was my favourite of Reimu's partners. her weapon is reminiscent of Sakuya's B set from PCB, where the direction of Aya's shots is tied to the direction Reimu is moving in, with focusing locking the angle in place. unlike that set though, Aya shoots both in front of and behind Reimu, and can spin full 360 degrees, which gives her great versatility and surprising utility against certain bosses. Aya's special ability is also really fun, if you let go of the shoot button Aya lets you absolutely schmoove around the screen. this combos really well with her bomb, which surrounds Reimu with a circle of destruction that stays locked to her as she moves and negates any bullets that enter. popping a bomb and then rocketing all around the screen deleting enemies is insanely fun, and if used at the right times can even give you a full power refund through the enemies you defeat with it!

Marisa + Alice: like Reimu, Marisa's first partner is her IN companion Alice. Alice's weapon is fairly simple, a collection of lasers that either shoot in a inward angle or an outward fan depending on if you're focused or not. the interesting part comes from Alice's special ability, which is that you can stack weapon options up to 8 instead of just 4. at full power, if you hit an enemy with all the beams at once it can deal nutty damage, although at the risk of moving unfocused. plus, 8 options means 8 potential bomb uses before you need to refill! it sounds great, but as a compensation Alice's bomb is pretty bad. one of her dolls shoots a thin line forward from Marisa's position for a second, dealing damage and destroying any bullets that touch it. the damage isnt bad, but the screen clearing is abysmal. at least you get the universal i-frames for a bit after activating.

Marisa + Patchouli: more magicians! Marisa's second partner is the library witch of the Scarlet Devil Mansion. her weapon is a very technical one, and inherently tied to her special ability. instead of one weapon, Patchouli has 5 different shot variants that fire at different angles, that you toggle through by pressing the shot and focus buttons simultanously. there's a lot of potential in Patchouli's moveset, and much like Aya her ability to fire in almost any direction is surprisingly useful against some bosses. unfortunately, her bomb is pretty basic, being pretty much exactly a MoF bomb but slightly larger and dealing good damage if something gets hit by it. the bigger problem though is that pressing the button combo to switch firing modes gets tiring on the hand once you're deep into a run. very ironic that Patchouli of all people has the most physically exhausting special move :P

Marisa + Nitori: Marisa's last partner is the kappa nerd from MoF, the outlier of the group as shes not a magic user. probably the most basic moveset of the game, Nitori's attack is shooting high-power missiles that slowly fly up the screen. her special ability ties into her bomb: when you use your bomb initially, a shield appears around Marisa. the shield lasts for a few seconds, and if you're hit at any point then the shield breaks and fully clears the screen. if the shield fully wears off though, instead you get a 50% refund on the power you used to activate the bomb in the first place. returning the resources for a bomb that you didn't need is a neat concept, but the fact that her bomb deals no damage at all is a hard sell, and ideally you aren't using a bomb unless you really need to anyways, making her a pretty weak choice if you already know what youre doing.

if it wasn't clear by all that, the movesets in SA are really cool both flavor-wise and in their actual mechanics, and its hard to pick a favourite. i love all the different character interactions that take place in the dialogue across different runs, and theres one more bonus thing related to your moveset choice that ill get to later. its about time to talk about the new characters!

i have to start with Yamame, the earth spider youkai. you love to see another bug-type youkai show up! unfortunately, much like Wriggle, she has stage 1 boss syndrome. barely any relevance to the story, and pretty much never shows up again in the games. sad! bug youkai getting the short end of the stick again. i sure hope this doesnt happen to another buggy character like 5 games from now. #justice4bugyoukai!

the real standout characters of SA are the Komeiji sisters, Satori and Koishi. Satori is a mind reader, using her third eye to see into the heart of others, look through their memories, and discern what theyre thinking. its a pretty freaky power, which has made her a complete outcast, living alone in her mansion with her two pets. her ability makes holding a conversation awkward, as Satori already knows what you're thinking before you say it, and unfortunately she can't stop herself from knowing how you really feel about her. she seems to genuinely not Want to constantly be reading people, even apologizing to Reimu about it after their fight. speaking of the fight though, Satori has probably one of the coolest moves in the series. partway through her fight, Satori will look into Reimu or Marisa's mind, and copy moves from their memory. Specifically, she copies old moves that your chosen youkai partner used against you in previous games! its such a sick concept integrating story and gameplay together, and honestly this moment is one of the reasons i wanted to start writing out my thoughts about these games cause it was so cool to me i HAD to talk about it somewhere. also while im at it, i havent really mentioned the music much in this series cause its pretty common knowledge that touhou music is good, but Satori's theme in particular is an absolute banger, please give it a listen. man, what a good fight, and she's not even the final boss! she's stage 4!

Koishi is another great character from SA, who is unfortunately flanderized a LOT in fanon, often being depicted as either a head-empty goofball or occasionally an edgy serial killer. its a shame, because Koishi's actual character and backstory is honestly heartbreaking. like her sister Satori, Koishi is a mind reader. or, more accurately, Koishi WAS a mind reader. reading the minds of anyone and everyone she talked to, being hated for her powers, and being forced to Know that everyone hated her, even if their words said the opposite, broke her. she decided to try and turn off her powers by closing her third eye, and she succeeded, but not without a cost. Koishi became a creature of the subconcious mind, with others not being able to percieve her existence unless she's directly in vision, often forgetting about her as soon as she's gone. despite it all, she seems happier after closing her third eye, being very cheery and free-spirited, and trying her best to make friends even if she's liable to be forgotten shortly after. adorable and tragic.

wow that was a lot! i had a surprising amount to say about Subterranean Animism, which i guess makes sense as this one took me the longest time to finish of them so far. it took me almost 2 weeks of attempts to finally clear SA, compared to most previous usually taking a week at most. there's a lot of stuff to like in SA, and as i mentioned way back at the start im tempted to call it my favourite entry in the series at the moment. the characters, the mechanics, the music, its all really good and they come together to make a real home run after the slight disappointments of MoF. now if only Wriggle came back as one of the youkai partners, then it would be the perfect game :P

to those of you who read all the way here, thanks so much for reading! i dont plan on making future posts quite this long again, but i cant make any promises. the fact that you care enough about a random girl's touhou ramblings to still be reading now is greatly appreciated, and i hope you have a great day! :>

3 notes

·

View notes