#electronic component distribution

Explore tagged Tumblr posts

Text

Why Choose Semikart as Your Go-To Electronic Components Distributor?

In today’s fast-paced world of electronics, finding a reliable and efficient distributor for electronic components is essential for businesses, engineers, and hobbyists alike. Semikart, a leading name in electronic component distribution, stands out as the go-to choice for sourcing quality parts. Here’s why you should consider Semikart for all your electronic component needs:

Extensive Product Range

One of the primary reasons to choose Semikart is its vast inventory. Whether you need semiconductors, resistors, capacitors, connectors, or sensors, Semikart offers a comprehensive range of products to meet the needs of diverse projects. They stock components from leading global manufacturers, ensuring you get access to genuine and high-quality parts.

Key Highlights:

A wide variety of components, including rare and hard-to-find parts.

Partnerships with top manufacturers like Texas Instruments, STMicroelectronics, and NXP.

Support for small to large orders, catering to hobbyists, stratus, and established businesses.

User-Friendly Online Platform

Sourcing electronic components online can be challenging, especially when you need specific parts for critical projects. Semikart user-friendly platform simplifies this process with advanced search features and filters, making it easy to find the exact component you need quickly.

Platform Features:

Advanced search filters by part number, manufacturer, and specifications.

Real-time stock availability and detailed product descriptions.

Secure checkout process with multiple payment options.

Competitive Pricing and Bulk Discounts

For many businesses, cost is a significant factor when buying electronic components. Semikart offers competitive pricing across its entire product range, ensuring you get the best value for your money. Additionally, they provide attractive bulk discounts for larger orders, making it an ideal choice for manufacturers and assembly lines looking to save on procurement costs.

Benefits:

Affordable pricing without compromising on quality.

Special pricing options for bulk purchases.

Regular promotions and discounts on selected components.

Reliable and Fast Shipping

Timely delivery is crucial in the electronics industry, especially when deadlines are tight. Semikart understands the importance of fast shipping and partners with reliable logistics providers to ensure your components arrive on time, no matter where you are.

Shipping Advantages:

Multiple shipping options, including express delivery for urgent orders.

Real-time tracking of orders from dispatch to delivery.

Safe and secure packaging to protect components during transit.

Exceptional Customer Support

At Semikart, customer satisfaction is a top priority. Their knowledgeable and friendly support team is always ready to assist with any queries you may have, whether it's about finding the right component, checking stock availability, or resolving order issues.

Support Services:

Dedicated customer support via phone, email, and live chat.

Technical assistance to help you choose the right components for your project.

Easy returns and replacements for defective or incorrect parts.

Quality Assurance and Authenticity

Ensuring the authenticity of electronic components is vital to prevent issues in product performance and reliability. Semikart guarantees that all components are sourced directly from reputable manufacturers and authorized distributors. This commitment to quality helps prevent counterfeit parts from entering your supply chain.

Quality Measures:

Components are inspected and verified for authenticity.

Partnerships with trusted manufacturers for genuine parts.

Clear labelling and detailed datasheets for each component.

Catering to a Wide Range of Customers

Whether you're a professional engineer, a small business, or a DIY enthusiast, Semikart caters to a diverse range of customers. Their flexible purchasing options allow you to buy in small quantities for prototyping or in bulk for mass production.

Customer Focus:

No minimum order quantity, allowing flexibility for small projects.

Bulk ordering options for large-scale production requirements.

Customized solutions for unique component needs.

Conclusion

Choosing the right electronic components distributor can make a significant difference in the success of your projects. With its extensive product range, user-friendly platform, competitive pricing, reliable shipping, and excellent customer support, Semikart stands out as a top choice for sourcing electronic components.

Whether you're working on a simple DIY project or managing a complex production line, Semikart has the expertise, inventory, and service quality to meet your needs. Make the smart choice today and partner with Semikart for all your electronic component requirements.

#semikart#electronic component suppliers#electronics#distributor for electronic components#electronic components online#electronic component distribution

0 notes

Text

#FRP Enclosures#Fiberglass Reinforced Polyester#Enclosures#TRIBOX#LT control panels#Solar Box#Metering Box#Terminal Box#Distribution Box#Junction Box#Pole & Wall mounted Box#GRP#SMC#electrical components#electronic components#ev#electricvehicles#solar#cable glands#emobility#solarsolutions#electricvehicle#exhibition

1 note

·

View note

Link

Decoding OEM: Unraveling the Mystery Behind the Acronym When it comes to the world of manufacturing and technology, the term "OEM" often pops up. OEM stands for Original Equipment Manufacturer and plays a significant role in various industries. In this article, we will delve into the concept of OEM, employing the MECE (Mutually Exclusive, Collectively Exhaustive) Framework to provide a comprehensive understanding of its implications and significance. [caption id="attachment_62824" align="aligncenter" width="800"] what does OEM stand for[/caption] Understanding OEM What Does OEM Stand For? OEM stands for Original Equipment Manufacturer. It refers to a company that produces components or products that are used in the manufacturing of another company's end product. The term "equipment" refers to the physical or digital parts, devices, or software that are integrated into the final product by the OEM. The Role of OEM in Different Industries OEM is prevalent in various industries, including automotive, electronics, software, and more. In these sectors, OEM ensures that the products manufactured by different companies meet the required quality, reliability, and compatibility standards. OEM plays a crucial role in maintaining consistency and standardization within the industry. OEM vs. Aftermarket: Key Differences OEM products are different from aftermarket products. OEM components are produced by the original manufacturer of the end product, ensuring a high level of quality, compatibility, and warranty. Aftermarket products, on the other hand, are produced by third-party manufacturers and may not meet the same quality standards as OEM products. While aftermarket products may be cheaper, they often lack the same level of reliability and compatibility as OEM products. OEM in Practice OEM in the Automotive Industry In the automotive industry, OEM components are seamlessly integrated into vehicles during the manufacturing process. These components, such as engines, transmissions, and electronic systems, are specifically designed and manufactured by the original vehicle manufacturer. Using OEM parts in vehicles ensures optimal performance, warranty coverage, and safety. OEM parts are built to the exact specifications of the vehicle, providing a perfect fit and maintaining the integrity of the vehicle's design. OEM in the Electronics Industry The electronics industry heavily relies on OEM components to create various devices. OEM electronics, such as integrated circuits, displays, and sensors, are designed and produced by the original manufacturer. These components are known for their compatibility with the devices they are intended for, ensuring reliable performance and seamless integration. Using OEM electronics in devices enhances their functionality and reliability, as they are specifically engineered to work harmoniously with the overall system. OEM in the Software Industry In the software industry, OEM software refers to software packages that are licensed by original manufacturers to be bundled with other products or services. OEM software is often pre-installed on computers, smartphones, or other electronic devices. It provides users with a legitimate and authorized version of the software, along with regular updates and technical support. OEM software is an integral part of the overall user experience, offering enhanced functionality and compatibility. FAQs: What are the advantages of choosing OEM products? Choosing OEM products comes with several advantages. OEM products are known for their high quality, as they are produced by the original manufacturer and designed to meet specific standards. They offer compatibility with the intended system, ensuring seamless integration and optimal performance. Additionally, OEM products often come with warranties, providing peace of mind to consumers. Are OEM products more expensive than aftermarket alternatives? OEM products may be slightly more expensive than aftermarket alternatives due to their higher quality and compatibility. However, it is important to consider the long-term benefits of choosing OEM, such as better performance and reliability. The cost difference is often justified by the enhanced user experience and reduced risk of compatibility issues. Can OEM parts be used to upgrade existing products? Yes, OEM parts can be used to upgrade existing products in many cases. OEM manufacturers often provide compatible upgrade options for their products, allowing users to enhance the performance or functionality of their devices. Whether it's upgrading a vehicle with OEM performance parts or upgrading a computer with OEM components, using OEM parts ensures compatibility and maintains the integrity of the original product design. However, it's important to check the compatibility and specifications provided by the OEM to ensure a successful upgrade. How can consumers identify OEM products? Identifying genuine OEM products can be crucial to ensure quality and compatibility. Here are a few tips: Check the packaging and labels for the OEM branding and logos. Look for authorized OEM retailers or purchase directly from the OEM's official website. Read product descriptions and specifications to ensure they match the OEM's official information. Verify the warranty and support provided, as OEM products usually come with manufacturer-backed warranties. Is OEM limited to physical products, or does it extend to services as well? While OEM is commonly associated with physical products, it can also extend to services. In service-oriented industries, OEM refers to companies that provide specialized services or solutions to other businesses. These OEM service providers offer expertise, resources, and support to help other companies enhance their operations or deliver specific services. For example, in the IT industry, OEM service providers may offer white-label services or customized solutions that can be resold by other businesses under their brand. Conclusion: OEM, or Original Equipment Manufacturer, is a fundamental concept in various industries. Understanding OEM helps us recognize the importance of quality, compatibility, and standardization in the products and services we use. Whether it's automotive, electronics, software, or other sectors, OEM plays a crucial role in ensuring optimal performance, reliability, and customer satisfaction. By choosing OEM products, consumers can enjoy the benefits of high-quality components and seamless integration, ultimately enhancing their overall experience. So, the next time you make a purchasing decision, consider the value that OEM brings to the table.

#appliances#assembly#Automotive#branding#components#computers#contracts#customization#devices#distribution#electronics#hardware#industry#machinery#manufacturing#OEM#Original_Equipment_Manufacturer#outsourcing#Partnerships#parts#production#products#software#specifications#suppliers#technology#telecommunications

0 notes

Text

Apple fucked us on right to repair (again)

Today (September 22), I'm (virtually) presenting at the DIG Festival in Modena, Italy. Tonight, I'll be in person at LA's Book Soup for the launch of Justin C Key's "The World Wasn’t Ready for You." On September 27, I'll be at Chevalier's Books in Los Angeles with Brian Merchant for a joint launch for my new book The Internet Con and his new book, Blood in the Machine.

Right to repair has no cannier, more dedicated adversary than Apple, a company whose most innovative work is dreaming up new ways to sneakily sabotage electronics repair while claiming to be a caring environmental steward, a lie that covers up the mountains of e-waste that Apple dooms our descendants to wade through.

Why does Apple hate repair so much? It's not that they want to poison our water and bodies with microplastics; it's not that they want to hasten the day our coastal cities drown; it's not that they relish the human misery that accompanies every gram of conflict mineral. They aren't sadists. They're merely sociopathically greedy.

Tim Cook laid it out for his investors: when people can repair their devices, they don't buy new ones. When people don't buy new devices, Apple doesn't sell them new devices. It's that's simple:

https://www.inverse.com/article/52189-tim-cook-says-apple-faces-2-key-problems-in-surprising-shareholder-letter

So Apple does everything it can to monopolize repair. Not just because this lets the company gouge you on routine service, but because it lets them decide when your phone is beyond repair, so they can offer you a trade-in, ensuring both that you buy a new device and that the device you buy is another Apple.

There are so many tactics Apple gets to use to sabotage repair. For example, Apple engraves microscopic Apple logos on the subassemblies in its devices. This allows the company to enlist US Customs to seize and destroy refurbished parts that are harvested from dead phones by workers in the Pacific Rim:

https://repair.eu/news/apple-uses-trademark-law-to-strengthen-its-monopoly-on-repair/

Of course, the easiest way to prevent harvested components from entering the parts stream is to destroy as many old devices as possible. That's why Apple's so-called "recycling" program shreds any devices you turn over to them. When you trade in your old iPhone at an Apple Store, it is converted into immortal e-waste (no other major recycling program does this). The logic is straightforward: no parts, no repairs:

https://www.vice.com/en/article/yp73jw/apple-recycling-iphones-macbooks

Shredding parts and cooking up bogus trademark claims is just for starters, though. For Apple, the true anti-repair innovation comes from the most pernicious US tech law: Section 1201 of the Digital Millennium Copyright Act (DMCA).

DMCA 1201 is an "anti-circumvention" law. It bans the distribution of any tool that bypasses "an effective means of access control." That's all very abstract, but here's what it means: if a manufacturer sticks some Digital Rights Management (DRM) in its device, then anything you want to do that involves removing that DRM is now illegal – even if the thing itself is perfectly legal.

When Congress passed this stupid law in 1998, it had a very limited blast radius. Computers were still pretty expensive and DRM use was limited to a few narrow categories. In 1998, DMCA 1201 was mostly used to prevent you from de-regionalizing your DVD player to watch discs that had been released overseas but not in your own country.

But as we warned back then, computers were only going to get smaller and cheaper, and eventually, it would only cost manufacturers pennies to wrap their products – or even subassemblies in their products – in DRM. Congress was putting a gun on the mantelpiece in Act I, and it was bound to go off in Act III.

Welcome to Act III.

Today, it costs about a quarter to add a system-on-a-chip to even the tiniest parts. These SOCs can run DRM. Here's how that DRM works: when you put a new part in a device, the SOC and the device's main controller communicate with one another. They perform a cryptographic protocol: the part says, "Here's my serial number," and then the main controller prompts the user to enter a manufacturer-supplied secret code, and the master controller sends a signed version of this to the part, and the part and the system then recognize each other.

This process has many names, but because it was first used in the automotive sector, it's widely known as VIN-Locking (VIN stands for "vehicle identification number," the unique number given to every car by its manufacturer). VIN-locking is used by automakers to block independent mechanics from repairing your car; even if they use the manufacturer's own parts, the parts and the engine will refuse to work together until the manufacturer's rep keys in the unlock code:

https://pluralistic.net/2023/07/24/rent-to-pwn/#kitt-is-a-demon

VIN locking is everywhere. It's how John Deere stops farmers from fixing their own tractors – something farmers have done literally since tractors were invented:

https://pluralistic.net/2022/05/08/about-those-kill-switched-ukrainian-tractors/

It's in ventilators. Like mobile phones, ventilators are a grotesquely monopolized sector, controlled by a single company Medtronic, whose biggest claim to fame is effecting the world's largest tax inversion in order to manufacture the appearance that it is an Irish company and therefore largely untaxable. Medtronic used the resulting windfall to gobble up most of its competitors.

During lockdown, as hospitals scrambled to keep their desperately needed supply of ventilators running, Medtronic's VIN-locking became a lethal impediment. Med-techs who used donor parts from one ventilator to keep another running – say, transplanting a screen – couldn't get the device to recognize the part because all the world's civilian aircraft were grounded, meaning Medtronic's technicians couldn't swan into their hospitals to type in the unlock code and charge them hundreds of dollars.

The saving grace was an anonymous, former Medtronic repair tech, who built pirate boxes to generate unlock codes, using any housing they could lay hands on to use as a case: guitar pedals, clock radios, etc. This tech shipped these gadgets around the world, observing strict anonymity, because Article 6 of the EUCD also bans circumvention:

https://pluralistic.net/2020/07/10/flintstone-delano-roosevelt/#medtronic-again

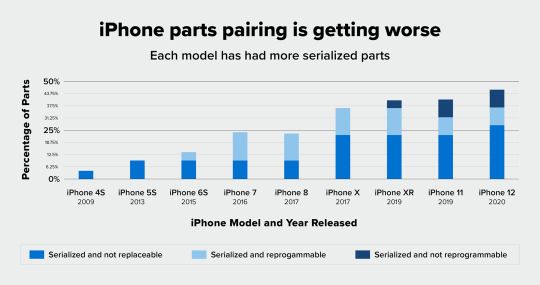

Of course, Apple is a huge fan of VIN-locking. In phones, VIN-locking is usually called "serializing" or "parts-pairing," but it's the same thing: a tiny subassembly gets its own microcontroller whose sole purpose is to prevent independent repair technicians from fixing your gadget. Parts-pairing lets Apple block repairs even when the technician uses new, Apple parts – but it also lets Apple block refurb parts and third party parts.

For many years, Apple was the senior partner and leading voice in blocking state Right to Repair bills, which it killed by the dozen, leading a coalition of monopolists, from Wahl (who boobytrap their hair-clippers with springs that cause their heads irreversibly decompose if you try to sharpen them at home) to John Deere (who reinvented tenant farming by making farmers tenants of their tractors, rather than their land).

But Apple's opposition to repair eventually became a problem for the company. It's bad optics, and both Apple customers and Apple employees are volubly displeased with the company's ecocidal conduct. But of course, Apple's management and shareholders hate repair and want to block it as much as possible.

But Apple knows how to Think Differently. It came up with a way to eat its cake and have it, too. The company embarked on a program of visibly support right to repair, while working behind the scenes to sabotage it.

Last year, Apple announced a repair program. It was hilarious. If you wanted to swap your phone's battery, all you had to do was let Apple put a $1200 hold on your credit card, and then wait while the company shipped you 80 pounds' worth of specialized tools, packed in two special Pelican cases:

https://pluralistic.net/2022/05/22/apples-cement-overshoes/

Then, you swapped your battery, but you weren't done! After your battery was installed, you had to conference in an authorized Apple tech who would tell you what code to type into a laptop you tethered to the phone in order to pair it with your phone. Then all you had to do was lug those two 40-pound Pelican cases to a shipping depot and wait for Apple to take the hold off your card (less the $120 in parts and fees).

By contrast, independent repair outfits like iFixit will sell you all the tools you need to do your own battery swap – including the battery! for $32. The whole kit fits in a padded envelope:

https://www.ifixit.com/products/iphone-x-replacement-battery

But while Apple was able to make a showy announcement of its repair program and then hide the malicious compliance inside those giant Pelican cases, sabotaging right to repair legislation is a lot harder.

Not that they didn't try. When New York State passed the first general electronics right-to-repair bill in the country, someone convinced New York Governor Kathy Hochul to neuter it with last-minute modifications:

https://arstechnica.com/gadgets/2022/12/weakened-right-to-repair-bill-is-signed-into-law-by-new-yorks-governor/

But that kind of trick only works once. When California's right to repair bill was introduced, it was clear that it was gonna pass. Rather than get run over by that train, Apple got on board, supporting the legislation, which passed unanimously:

https://www.ifixit.com/News/79902/apples-u-turn-tech-giant-finally-backs-repair-in-california

But Apple got the last laugh. Because while California's bill contains many useful clauses for the independent repair shops that keep your gadgets out of a landfill, it's a state law, and DMCA 1201 is federal. A state law can't simply legalize the conduct federal law prohibits. California's right to repair bill is a banger, but it has a weak spot: parts-pairing, the scourge of repair techs:

https://www.ifixit.com/News/69320/how-parts-pairing-kills-independent-repair

Every generation of Apple devices does more parts-pairing than the previous one, and the current models are so infested with paired parts as to be effectively unrepairable, except by Apple. It's so bad that iFixit has dropped its repairability score for the iPhone 14 from a 7 ("recommend") to a 4 (do not recommend):

https://www.ifixit.com/News/82493/we-are-retroactively-dropping-the-iphones-repairability-score-en

Parts-pairing is bullshit, and Apple are scum for using it, but they're hardly unique. Parts-pairing is at the core of the fuckery of inkjet printer companies, who use it to fence out third-party ink, so they can charge $9,600/gallon for ink that pennies to make:

https://www.eff.org/deeplinks/2020/11/ink-stained-wretches-battle-soul-digital-freedom-taking-place-inside-your-printer

Parts-pairing is also rampant in powered wheelchairs, a heavily monopolized sector whose predatory conduct is jaw-droppingly depraved:

https://uspirgedfund.org/reports/usp/stranded

But if turning phones into e-waste to eke out another billion-dollar stock buyback is indefensible, stranding people with disabilities for months at a time while they await repairs is so obviously wicked that the conscience recoils. That's why it was so great when Colorado passed the nation's first wheelchair right to repair bill last year:

https://www.eff.org/deeplinks/2022/06/when-drm-comes-your-wheelchair

California actually just passed two right to repair bills; the other one was SB-271, which mirrors Colorado's HB22-1031:

https://leginfo.legislature.ca.gov/faces/billNavClient.xhtml?bill_id=202320240SB271

This is big! It's momentum! It's a start!

But it can't be the end. When Bill Clinton signed DMCA 1201 into law 25 years ago, he loaded a gun and put it on the nation's mantlepiece and now it's Act III and we're all getting sprayed with bullets. Everything from ovens to insulin pumps, thermostats to lightbulbs, has used DMCA 1201 to limit repair, modification and improvement.

Congress needs to rid us of this scourge, to let us bring back all the benefits of interoperability. I explain how this all came to be – and what we should do about it – in my new Verso Books title, The Internet Con: How to Seize the Means of Computation.

https://www.versobooks.com/products/3035-the-internet-con

If you'd like an essay-formatted version of this post to read or share, here's a link to it on pluralistic.net, my surveillance-free, ad-free, tracker-free blog:

https://pluralistic.net/2023/09/22/vin-locking/#thought-differently

Image: Mitch Barrie (modified) https://commons.wikimedia.org/wiki/File:Daytona_Skeleton_AR-15_completed_rifle_%2817551907724%29.jpg

CC BY-SA 2.0 https://creativecommons.org/licenses/by-sa/2.0/deed.en

--

kambanji (modified) https://www.flickr.com/photos/kambanji/4135216486/

CC BY 2.0 https://creativecommons.org/licenses/by/2.0/

--

Rawpixel (modified) https://www.rawpixel.com/image/12438797/png-white-background

#pluralistic#vin locking#apple#right to repair#california#ifixit#iphones#sb244#parts pairing#serialization#dmca 1201#felony contempt of business model#ewaste#repairwashing#fuckery

1K notes

·

View notes

Text

WHAT IS THE DARK UNIVERSE??

Blog#402

Saturday, May 18th, 2024.

Welcome back,

You and me, everything that we can touch and smell, and all planets, moons and stars are made of ‘normal’ matter. Normal matter consists of the elemental particles described in the famous Standard Model of particle physics. This includes quarks and electrons, which together form atoms.

We know that normal matter attracts other normal matter, depending on how much mass it has, via gravity. This force explains why apples fall towards the Earth. It also explains why the Earth revolves around the Sun, and the Sun orbits the centre of the Milky Way galaxy.

Surprisingly, normal matter turns out to be only a small fraction of what the Universe contains. 95% of the Universe is made up of dark matter and dark energy. These are words astronomers have come up with to give a name to the mysterious, invisible side of the Universe.

By studying many different galaxies, scientists discovered that stars in galaxies move faster around their galaxy centres than what the matter we see could account for.

On its own, normal matter would not be able to create enough gravity to hold these galaxies together. It’s no small difference: a typical galaxy’s missing mass is ten times larger than the mass of its visible stars!

Scientists can also tell that there is some unknown material in the space between galaxies, because its gravitational pull influences the path of starlight travelling towards Earth. Matter can act like a magnifying glass, bending and distorting light from galaxies and clusters behind it. This effect is called gravitational lensing.

Years of extensive observations have shown that the missing gravity is not caused by hard-to-see normal matter, such as for example cold hydrogen atoms. Instead, astronomers must look beyond what is known.

We call the missing mass ‘dark matter’ because it appears that it only interacts with light and normal matter via gravity. The most precise experiments so far have not found evidence of any other interactions. And despite decades of research, we still don’t know what dark matter is made of.

Euclid will make detailed observations of the Universe to infer how dark matter is distributed. It will determine how the structure of matter in the Universe changed over time and measure gravitational lensing effects. This will teach us about the behaviour of this mysterious component and provide new clues as to its identity.

Originally published on www.esa.int

COMING UP!!

(Wednesday, May 22nd, 2024)

"IS SPACE INFINITE??"

#astronomy#outer space#alternate universe#astrophysics#universe#spacecraft#white universe#space#parallel universe#astrophotography#dark energy#dark matter#dark universe

50 notes

·

View notes

Text

How Do F1 Cars Work?: Power, Transmit, Suspend

Alright part 2 everyone. Let's go.

1.Power Units

You have probably heard lots of yammering about power unit components before. Things like 'they took on too many and now have a grid penalty' are common to hear. But what is the power unit, and what does that mean?

So the power unit refers to the engine system that helps power the car. The modern F1 car is a hybrid, a mix between a typical Internal Combustion Engine (ICE) and Energy Recover Systems (ERS). The modern F1 ICE is a 1.6 liter V6 turbocharged engine and can rev up to 15,000 RPM. It uses gasoline and generates a majority of the power. I've explained how it works in an older post, but briefly it compresses air and fuel and ignites it to create combustion which generates energy. The turbocharger is a part of the ICE that helps condense air more, in turn forcing the engine to create more energy.

The ERS has two components. The first is Motor Generator Unit-Kinetic (MGU-K), which recovers energy from braking, stores it in the battery (which stores energy from the two units), and can be used as a boost to power. The second is Motor Generator Unit- Heat (MGU-H). This unit recovers heat energy from the turbocharger and converts it to electrical energy. It can either charge the battery directly or assist the ICE.

When teams get in trouble taking too many power units it essentially means they have replaced something like the MGU-H too many times. There is a cap for how many times you can replace a power unit component, but with the addition of more races every year the FIA is under pressure to increase this limit. Almost every single car takes the penalty at some point.

2. Transmission

The transmission is the semi-automatic gear box inside of F1 cars, which for them is 8-speed. It is located at the rear of the car and connects to the power unit. This is a part of the car that is famous for having issues, and often when a drivers car retires it is due to a gear box failure. With paddle shifters located under the steering wheel, drivers can change the gear in which they are driving. Different gears effect the traction, grip, fuel economy, and speed of the car and are used strategically throughout the race. Part of the transmission is the differential. The differential distributes power between the rear wheels when cornering, allowing the inside tire to rotate slower than the outside tire. The final majorly important part of the transmission is the clutch. In F1 the clutch, which is a device that connects the engine and transmission to the car is automated and controlled by electronics. It is usually used when starting the race or leaving the pit lane.

Grip levels, cornering speeds, and straight-line speeds all play a crucial role in gear ratio calculations. The teams have to find the perfect balance between acceleration, top speed, and adaptability. The team’s engineers use advanced simulations and data analysis to calculate the optimal ratios for each gear. They also take into account factors like tire wear and fuel consumption to fine-tune their calculations. All of this information can be gathered from electronic data gatherers inside of the car, running simulations, and also the drivers reporting themselves. Its why radio communication is so important in F1. This decision can make or break a race, and we have seen drivers lose due to an incorrect gear decision.

3. Suspension

The suspension system works to keep the tires in contact with the road and helps absorb the shocks F1 cars experience. This is created through a variety of springs, shock absorbers, sway bars, etc. Without the suspension, the chassis would be experiencing the full extent of the shaking and pressure, which would do damage to the car and be very painful for the driver. Anytime you see a driver shaking like crazy in the car, it usually means there is something off with the suspension. Suspension also allows the force of the bumps and the kinetic energy to be stored by a spring, which is then compressed, absorbing the energy transferred by that bump in the road and allowing all four tires to grip the road. The biggest difference between street car suspension and F1 suspension is that in an F1 car each tire is independently sprung, which means that they move on their own, useful around corners.

In F1 cars they have a pushrod or pullrod suspension. These systems transfer pressure from the wheels to the suspension dampers and springs. In a push-rod system, the rocker arms are placed at the highest point in the car. As such, the rod is under pressure as it transfers compression forces upwards into the rocker arms. In a pull-rod system however, the rocker arms are located between the upper and lower control arms, at the center of the car This means every time it hits a bump or curb, the wheel pulls on the spring which causes the pull-rod to go up and outwards from the chassis. Both are regularly used suspension types.

Teams regularly change how their suspension is functioning, and it is by far one of the most tweaked systems on the car. Truly, a weak suspension can make any car one of the slowest cars on the grid. So next time you hear a. driver complain about how slow they are on the straights, or how much their back hurts, it usually means their suspension is not where it should be.

That's all for this post, next one should be about braking, the various electronics/sensors, cooling systems, and wrap up of how everything works together.

Cheers,

-B

20 notes

·

View notes

Text

Low Voltage Relays Explained: Types, Functions, and Applications

In the complex world of electrical systems, relays play a crucial role in ensuring safety, efficiency, and automation. Among these, low voltage relays stand out as versatile components that manage and protect circuits operating below 1000 volts. Whether in industrial automation, residential power distribution, or commercial infrastructure, these devices act as the nerve center of electrical control and protection.

In this comprehensive guide, we will break down what low voltage relays are, explore their types, explain their functions, and highlight their diverse applications across industries.

What Are Low Voltage Relays?

A low voltage relay is an electrically operated switch that uses a small control voltage (typically below 1000V AC or DC) to switch larger electrical loads on and off. These relays act as intermediaries between control circuits and power circuits, providing isolation, control, and protection.

Unlike manual switches, relays automate the process of circuit management, responding to electrical signals, fault conditions, or system commands without human intervention.

Types of Low Voltage Relays

Low voltage relays come in several forms, each tailored to specific tasks within an electrical system. Here are the main types:

1. Electromechanical Relays (EMRs)

· Use a coil and a movable armature to open or close contacts.

· Provide physical isolation between input and output.

· Common in traditional control panels and basic automation.

2. Solid-State Relays (SSRs)

· Use semiconductors (like thyristors or triacs) instead of mechanical contacts.

· Offer silent operation, faster switching, and longer lifespan.

· Ideal for high-speed applications and environments requiring low maintenance.

3. Overload Relays

· Specifically designed to protect motors and equipment from sustained overcurrent.

· Available as thermal overload relays (using bimetallic strips) or electronic overload relays (using sensors and processors).

4. Time Delay Relays

Provide a deliberate time lag between the relay receiving a signal and switching.

Used in motor control circuits, lighting systems, and sequential operations.

5. Overcurrent and Short-Circuit Relays

· Detect and react to current exceeding preset thresholds.

· Essential for system protection against faults and overloads.

6. Voltage Monitoring Relays

· Monitor voltage levels and trip when voltages fall below or rise above safe limits.

· Protect sensitive devices from under voltage and overvoltage conditions.

Functions of Low Voltage Relays

Low voltage relays serve multiple vital functions in electrical systems:

1. Switching and Control

Relays control the opening and closing of power circuits in response to low voltage signals from controllers, timers, or sensors. This enables remote and automated control of large electrical loads.

2. Protection

Relays detect abnormal conditions like overloads, overcurrent, under voltage, and phase failures. When such conditions arise, they disconnect the affected circuit to prevent equipment damage or fire hazards.

3. Isolation

They electrically isolate control circuits (usually low voltage, low current) from power circuits (high voltage, high current), ensuring safety and reducing interference.

4. Signal Amplification

A small control signal (from a PLC, sensor, or microcontroller) can trigger a relay to switch much larger loads, effectively amplifying the control power.

5. Automation and Sequencing

In complex systems, relays help sequence operations by ensuring that processes occur in the correct order and at the right time intervals.

Applications of Low Voltage Relays

Low voltage relays are the backbone of automation and protection in various industries. Here are some key application areas:

Industrial Automation

· Control of motors, pumps, conveyor belts, and production lines.

· Use in programmable logic controllers (PLCs) and distributed control systems (DCS).

Power Distribution Systems

· Protect electrical panels from overload and short circuits.

· Monitor voltage and current levels in distribution boards.

Building Automation

· Lighting control systems.

· HVAC (heating, ventilation, and air conditioning) systems.

· Elevator and escalator controls.

Renewable Energy Systems

· Manage and protect solar inverters, battery banks, and wind turbines.

· Automatically disconnect faulty sections to prevent system-wide failures.

Data Centers and IT Infrastructure

· Ensure stable power supply to servers and networking equipment.

· Protect sensitive electronics from voltage fluctuations.

Transportation

· Railways, metros, and automotive applications for control and safety circuits.

Home Appliances

· Found in washing machines, microwave ovens, and HVAC units to automate functions and provide protection.

Advantages of Using Low Voltage Relays

· Enhanced Safety: Isolate control and power circuits, reducing electrical shock risks.

· Automation Ready: Easily integrated into automated systems for smarter operation.

· Cost-Effective Protection: Safeguard expensive equipment from damage due to electrical faults.

· Versatile: Available in many forms to suit different voltage levels, currents, and response times.

· Reduced Maintenance: Especially with solid-state relays, which have no moving parts.

Future Trends: Smart Relays and IoT Integration

As industries move toward smart grids and Industry 4.0, low voltage relays are also evolving:

· Digital relays offer programmable settings, self-testing, and event recording.

· IoT-enabled relays can send status updates and alerts to centralized monitoring systems.

· Energy-efficient designs reduce power consumption while providing reliable protection.

Conclusion

Low voltage relays are indispensable in modern electrical engineering, seamlessly combining protection, control, and automation. From safeguarding your home appliances to managing the power in a sprawling industrial plant, these devices ensure that electrical systems run smoothly and safely.

Understanding the different types, functions, and applications of low voltage relays empowers system designers, engineers, and even DIY enthusiasts to build safer and more efficient electrical setups.

As technology advances, the role of these small but mighty devices will only grow, driving the future of safe, smart, and automated power systems.

8 notes

·

View notes

Text

The Role of Relays and Timers in Industrial Automation Systems

In the world of industrial automation, efficiency, safety, and precision are crucial. Among the many components that contribute to a well-functioning automated system, relays and timers play a foundational role. These devices act as control elements that manage the flow of electricity, signal processes, and coordinate timing sequences — ensuring that operations run smoothly and safely.

In this article, we’ll explore how relays and timers work, their types, applications in automation systems, and how high-quality products — like those offered by Enza Electric — can enhance performance and reliability in industrial settings.

What Are Relays?

A relay is an electromechanical or electronic switch used to control a circuit by a separate low-power signal or multiple signals. In industrial automation, relays act as a bridge between the control system and the equipment being operated — allowing machines to be turned on or off automatically.

Types of Relays Commonly Used in Automation:

Electromechanical Relays (EMRs): Use physical moving parts; reliable and easy to maintain.

Solid-State Relays (SSRs): No moving parts; faster switching, longer lifespan, and better for high-speed applications.

Thermal Overload Relays: Protect motors and equipment from overheating.

Control Relays: Designed for controlling multiple contacts simultaneously in automation systems.

What Are Timers?

Timers are devices used to delay or repeat electrical signals at predetermined intervals. They help synchronize tasks, automate sequences, and provide controlled outputs over time — critical for complex industrial processes.

Common Timer Functions:

On-delay and off-delay timing

Interval timing

Cyclic or repeat cycle operation

Flashing and sequencing operations

Types of Timers:

Analog Timers: Manual dial settings, simple and cost-effective.

Digital Timers: Offer precise programming, displays, and flexible timing ranges.

Programmable Timers: Ideal for complex automation routines requiring multiple sequences.

Key Roles in Industrial Automation Systems

1. Process Control and Sequencing

Relays and timers enable automated machines to follow a specific sequence — turning motors, lights, or pumps on and off in a logical order. For example, a conveyor system can use a relay-timer combination to control material flow with millisecond precision.

2. Safety and Protection

Relays protect systems by interrupting circuits in case of faults. Combined with timers, they can ensure delay before activating emergency stop functions, preventing false triggers and increasing worker safety.

3. Load Management

In high-demand industrial environments, relays help manage load distribution by selectively energizing or de-energizing machinery. Timers assist in staggered starts, reducing power surges.

4. Energy Efficiency

By automating start/stop functions and managing operation durations, timers help reduce unnecessary energy use. Relays ensure only the necessary loads are powered, minimizing wastage.

5. System Monitoring and Feedback

In smart automation, relays provide feedback signals to the control system. Timers assist with diagnostics by creating intervals for testing or data collection.

Benefits of Using High-Quality Relays and Timers

Choosing the right components significantly impacts system performance and longevity. Enza Electric’s relays and timers are engineered with:

High durability for tough industrial environments

Precision timing for reliable operation

Easy installation and compact designs

Compliance with international safety and quality standards

By integrating Enza’s low-voltage solutions, businesses in the GCC, MENA, and Africa regions benefit from cost-effective, scalable automation that supports both current needs and future expansion.

Common Applications in Industrial Sectors

Manufacturing Plants: Control of motors, robotic arms, and production lines.

HVAC Systems: Timed control of fans, compressors, and dampers.

Water Treatment Facilities: Sequenced operation of pumps and valves.

Packaging Machinery: Relay and timer-based coordination of packing, sealing, and labeling.

Food and Beverage Industry: Process automation with hygiene-compliant controls.

Final Thoughts

Relays and timers are the silent operators behind the success of industrial automation systems. From process optimization to enhanced safety and energy management, these components are indispensable.

When sourced from a trusted manufacturer like Enza Electric, businesses are not only investing in reliable hardware but also in the longevity, scalability, and safety of their entire operation.

Ready to Power Your Automation?

Explore Enza Electric’s wide range of relays, timers, and other low-voltage switchgear solutions designed to meet the evolving demands of modern industries. Visit www.enzaelectric.com to learn more or request a quote today.

7 notes

·

View notes

Text

First coherent picture of an atomic nucleus made of quarks and gluons

The atomic nucleus is made up of protons and neutrons, particles that exist through the interaction of quarks bonded by gluons. It would seem, therefore, that it should not be difficult to reproduce all the properties of atomic nuclei hitherto observed in nuclear experiments using only quarks and gluons. However, it is only now that physicists, including those from the Institute of Nuclear Physics of the Polish Academy of Sciences in Cracow, have succeeded in doing this.

It’s almost a century since the discovery of the main components of atomic nuclei: protons and neutrons. Initially, the new particles were considered indivisible. In the 1960s, however, there was a suggestion that, at sufficiently high energies, protons and neutrons would reveal their internal structure – the presence of quarks constantly held together by gluons. Soon afterwards, the existence of quarks was confirmed experimentally. It may therefore seem surprising that, despite the passage of many decades, no one has been able to reproduce with quark-gluon models the results of nuclear experiments at low energies when only protons and neutrons are visible in atomic nuclei. This long-standing deadlock has only now been broken, in a paper published in Physical Review Letters. Its main authors are scientists from the international nCTEQ collaboration on quark-gluon distributions, including those from the Institute of Nuclear Physics of the Polish Academy of Sciences (IFJ PAN) in Cracow.

“Until now, there have been two parallel descriptions of atomic nuclei, one based on protons and neutrons which we can see at low energies, and another, for high energies, based on quarks and gluons. In our work, we have managed to bring these two so far separated worlds together,” says Dr. Aleksander Kusina, one of the three theoreticians from IFJ PAN participating in the research.

Humans see their surroundings because they use innate detectors (eyes) to register scattered photons that have previously interacted with the atoms and molecules that make up the objects of our environment. Physicists gain knowledge of atomic nuclei in a similar way: they collide them with smaller particles and meticulously analyse the results of the collisions. For practical reasons, however, they use not electrically neutral photons, but elementary particles carrying a charge, usually electrons. Experiments then show that when electrons have relatively low energies, atomic nuclei behave as if they were made of nucleons (i.e. protons and neutrons), whereas at high energies, partons (i.e. quarks and gluons) are ‘visible’ inside the atomic nuclei. The results of colliding atomic nuclei with electrons have been reproduced quite well using models assuming the existence of nucleons alone to describe low-energy collisions, and partons alone for high-energy collisions. However, so far these two descriptions have not been able to be combined into a coherent picture.

In their work, physicists from the IFJ PAN used data on high-energy collisions, including those collected at the LHC accelerator at CERN laboratory in Geneva. The main objective was to study the partonic structure of atomic nuclei at high energies, currently described by parton distribution functions (PDFs). These functions are used to map how quarks and gluons are distributed inside protons and neutrons and throughout the atomic nucleus. With PDF functions for the atomic nucleus, it is possible to determine experimentally measurable parameters, such as the probability of a specific particle being created in an electron or proton collision with the nucleus.

From the theoretical point of view, the essence of the innovation proposed in this paper was the skilful extension of parton distribution functions, inspired by those nuclear models used to describe low-energy collisions, where protons and neutrons were assumed to combine into strongly interacting pairs of nucleons: proton-neutron, proton-proton and neutron-neutron. The novel approach allowed the researchers to determine, for the 18 atomic nuclei studied, parton distribution functions in atomic nuclei, parton distributions in correlated nucleon pairs and even the numbers of such correlated pairs. The results confirmed the observation known from low-energy experiments that most correlated pairs are proton-neutron pairs (this result is particularly interesting for heavy nuclei, e.g. gold or lead). Another advantage of the approach proposed in this paper is that it provides a better description of the experimental data than the traditional methods used to determine parton distributions in atomic nuclei.

“In our model, we made improvements to simulate the phenomenon of pairing of certain nucleons. This is because we recognised that this effect could also be relevant at the parton level. Interestingly, this allowed for a conceptual simplification of the theoretical description, which should in future enable us to study parton distributions for individual atomic nuclei more precisely,” explains Dr. Kusina.

The agreement between theoretical predictions and experimental data means that, using the parton model and data from the high-energy region, it has been possible for the first time to reproduce the behaviour of atomic nuclei so far explained solely by nucleonic description and data from low-energy collisions. The results of the described studies open up new perspectives for a better understanding of the structure of the atomic nucleus, unifying its high- and low-energy aspects.

The work of the physicists from the IFJ PAN on reconstructing the nucleonic structure using the parton model was funded by the Polish National Science Centre.

The Henryk Niewodniczański Institute of Nuclear Physics (IFJ PAN) is currently one of the largest research institutes of the Polish Academy of Sciences. A wide range of research carried out at IFJ PAN covers basic and applied studies, from particle physics and astrophysics, through hadron physics, high-, medium-, and low-energy nuclear physics, condensed matter physics (including materials engineering), to various applications of nuclear physics in interdisciplinary research, covering medical physics, dosimetry, radiation and environmental biology, environmental protection, and other related disciplines. The average yearly publication output of IFJ PAN includes over 600 scientific papers in high-impact international journals. Each year the Institute hosts about 20 international and national scientific conferences. One of the most important facilities of the Institute is the Cyclotron Centre Bronowice (CCB), which is an infrastructure unique in Central Europe, serving as a clinical and research centre in the field of medical and nuclear physics. In addition, IFJ PAN runs four accredited research and measurement laboratories. IFJ PAN is a member of the Marian Smoluchowski Kraków Research Consortium: “Matter-Energy-Future”, which in the years 2012-2017 enjoyed the status of the Leading National Research Centre (KNOW) in physics. In 2017, the European Commission granted the Institute the HR Excellence in Research award. As a result of the categorization of the Ministry of Education and Science, the Institute has been classified into the A+ category (the highest scientific category in Poland) in the field of physical sciences.

IMAGE: For the first time, quarks and gluons were used to describe properties of atomic nuclei, which until now had been explained by the existence of protons and neutrons. The temporary pair of correlated nucleons is highlighted in purple. Credit Source: IFJ PAN

12 notes

·

View notes

Text

Exclusive: Hezbollah handed out pagers hours before blasts - even after checks

BEIRUT, Sept 19 (Reuters) - Lebanon's Hezbollah was still handing its members new Gold Apollo branded pagers hours before thousands of the devices blew up this week, two security sources said, indicating the group was confident they were safe despite an ongoing sweep of electronic kit to identify threats.

One member of the Iranian-backed militia received a new pager on Monday that exploded the next day while it was still in its box, said one of the sources.

A pager given to a senior member just days earlier injured a subordinate when it detonated, the second source said.

In an apparently coordinated attack, the Gold Apollo branded devices detonated on Tuesday across Hezbollah's strongholds of south Lebanon, Beirut's suburbs and the eastern Bekaa valley.

On Wednesday, hundreds of Hezbollah walkie-talkies exploded. The consecutive attacks killed 37 people, including at least two children, and injured more than 3,000 people.

Lebanon and Hezbollah say Israel was behind the attacks. Israel's secretive military intelligence Unit 8200 was involved in the planning, a Western security source told Reuters this week. Israel, which has since stepped up airstrikes on Lebanon, has neither denied or confirmed involvement.

The batteries of the walkie-talkies were laced with a highly explosive compound known as PETN, another Lebanese source familiar with the device's components told Reuters on Friday. Up to three grams of explosives hidden in the pagers had gone undetected for months by Hezbollah, Reuters reported earlier this week.

One of the security sources said it was very hard to detect the explosives "with any device or scanner." The source did not specify what type of scanners Hezbollah had run the pagers through.

Hezbollah examined the pagers after they were delivered to Lebanon, starting in 2022, including by travelling through airports with them to ensure they would not trigger alarms, two additional sources told Reuters. In total, Reuters spoke to six sources familiar with the details of the exploding devices for this story.

The sources did not specify the name of the airports where they conducted the tests.

Rather than a specific suspicion of the pagers, the checks had been part of a routine "sweep" of its equipment, including communications devices, to find any indications that they were laced with explosives or surveillance mechanisms, one of the security sources said.

The attacks, and the distribution of the devices despite the routine sweep and checks for breaches, have struck at Hezbollah's reputation as the most formidable of Iran's allied 'Axis of Resistance' umbrella of anti-Israel irregular forces across the Middle East.

In a televised speech on Thursday, Hezbollah Secretary-General Hassan Nasrallah said the attacks were "unprecedented in the history" of the group.

Hezbollah's media office and Israel's armed forces did not immediately respond to requests for comment for this story.

Taiwan-based Gold Apollo has said it did not manufacture the devices used in the attack, saying they were made by a company in Europe licensed to use the firm's brand. Reuters has not been able to establish where they were made or at what point they were tampered with.

A batch of 5,000 of the pagers were brought into Lebanon earlier this year. Reuters previously reported that Hezbollah turned to pagers in an attempt to evade Israeli surveillance of its mobile phones, following the killing of senior commanders in targeted airstrikes over the past year.

Hezbollah's conflict with Israel dates back decades but has flared up in the past year in parallel with the Gaza war, heightening worries of a full-blown regional war.

TOO LITTLE, TOO LATE

After the pagers detonated on Tuesday, Hezbollah suspected more of its devices may have been compromised, two of the security sources, as well as an intelligence source, told Reuters.

In response, it intensified the sweep of its communications systems, carrying out careful examinations of all devices. It also began investigating the supply chains through which the pagers were brought in, the two security sources said.

But the review had not been concluded by Wednesday afternoon, when the hand-held radios exploded.

Hezbollah believes that Israel opted to detonate the group's hand-held radios because it feared Hezbollah would soon find that the walkie-talkies were also rigged with explosives, one of the sources told Reuters.

The walkie-talkie explosions left 25 people dead and at least 650 injured, according to Lebanon's health ministry - a much higher fatality rate than the previous day's pager blasts, which killed 12 and wounded nearly 3,000.

That is because they carried a higher payload of explosives than the beepers, one of the security sources and the intelligence source said.

The group's probe into precisely where, when and how the devices were laced with explosives is ongoing, three of the sources said. Nasrallah later said the same in the speech on Thursday.

One of the security sources said Hezbollah had foiled previous Israeli operations targeting devices imported from abroad by the group - from its private landline telephones to ventilation units in the group's offices.

That includes suspected breaches in the past year.

"There are several electronic issues that we were able to discover - but not the pagers," the source said. "They tricked us, hats off to the enemy."

13 notes

·

View notes

Note

What do you think of people always recommending the Singer Heavy Duty to beginners to machine sewing?

I have a lot of opinions about this. Since before I started this blog, so pre-2014, I've been saying that buying a modern Singer machine will almost always prove to be some of the worst value for your money. In the intermediate time, I actually took a job working directly for SVP, who make and distribute the machines with the Singer name. I've also modified that opinion a little bit.

Buying a modern Singer machine will almost definitely be the worst value for your money.

I want to say something about availability, and just address that before I go into my harsh critique of the brand. Not everyone has access to dealerships or a wide variety of machines. If you're looking at not a wide selection, the Singer Heavy Duty line may very well be the best option out of what is available. There's also a lot of Heavy Duty machines at various price points, so it's an easy thing to recommend people look for. If you bought a Heavy Duty, you're not wrong in using it and loving it. But I don't recommend them for a good first machine.

So the company that makes these machines also makes two different premium lines, which we'll call German Machine and Swedish Machine, since that's where they used to be made. This company's name is the first letters of the brand, so you can figure it out. The notable thing about this is that they intend for Singer to be their budget line. They sort of want Singer to be available to every household. To shorten it up in the worst way, if a Singer was good enough, it'd be sold under a different name.

The thing that the Heavy Duty really has going for it is the metal internal frame. Generally, you want your machine to have a metal frame, because it holds the main components that make the machine go. Some inexpensive machines have no frame, and they can flex and break when they run over something pretty hard. Sometimes, machines flex and they never go back to where they originally were, making the machine dead in the water. However, there's a lot of options that have a metal frame and are longer lasting than a Heavy Duty.

I'm a big fan of the Baby Lock BeGenuine collection. It's got three entry level machines that are fully mechanical. Most of these machines have been on the market for a long time, just under different names. The Baby Lock Molly has become the Zeal, and before it was a Molly it was a different name. A lot of these machines are still working today. These machines don't have all the fancy features at the same price point, meaning a $300 Singer Heavy Duty will have more bells and whistles than a $300 BeGenuine, but they have a much longer life. Most people who buy these machines replace them because their skills grow and they want more, and not because the machine breaks on them.

However, if you already know that you'll want to upgrade in three or fewer years, I guess you could say there's something to be said for buying a machine that doesn't need to last that long. It'll force you to replace it. I know people who've had a Heavy Duty last a long time, but I've seen a ton replaced because they've died on people. My general rule on these machines is to check how long the "electronics and motors" warranty lasts, and assume that if the full warranty is only three months to a year, well, there's a reason why it's not a "5 years on electronics and motors" warranty.

60 notes

·

View notes

Text

Metalenses phase characterization by multi-distance phase retrieval

Metalens is a kind of optical metasurface composed of metaatoms for manipulating incoming light's amplitude, phase, and polarization. Unlike traditional refractive lenses, metalens can modulate the wavefront from plane to spherical at an interface. It has garnered widespread attention due to its novel physical properties and promising potential applications. As a phase-modulated optical functional component, phase distributions are the key parameter of metalens. However, in the optical frequency band, it is difficult to measure the phase distribution directly. Instead of measuring phase, the mainstream measurement methods for characterizing metalens currently involve light field scanning and electron microscopy. However, these methods do not directly provide the phase response of metalens.

Read more.

7 notes

·

View notes

Text

Top 5 Must-Have Accessories for Every Electrical Panel

An electrical panel is the nerve center of any low-voltage power distribution system — responsible for delivering electricity safely and efficiently to various circuits. While the breakers and busbars often take the spotlight, it’s the accessories that enhance functionality, safety, monitoring, and reliability. Whether you��re an OEM, panel builder, or facility manager, equipping your panels with the right accessories can make all the difference.

In this article, we explore the top 5 must-have accessories for every electrical panel, based on industry best practices and real-world applications.

1. Cable Ducts and Trunking Systems

Purpose:

Cable ducts (also called wiring ducts or trunking) are essential for organizing and routing internal panel wiring. They prevent clutter, minimize the risk of short circuits, and make future maintenance more manageable.

Key Benefits:

· Improved safety through wire separation and insulation

· Neat, professional layout that meets electrical standards

· Ease of troubleshooting during inspections or servicing

Common Types:

· Slotted PVC ducts

· Halogen-free wiring ducts (for safety-critical environments)

· Flexible ducts for tight corners

Pro tip: Always select ducts with sufficient space for future cable additions — typically 20–30% free space is recommended.

2. Terminal Blocks and Marking Systems

Purpose:

Terminal blocks serve as connection points between internal and external wiring, ensuring a secure and modular setup. Combined with proper marking systems, they allow clear identification of circuits and functions.

Key Benefits:

· Safe and reliable wire termination

· Clear labeling for faster diagnostics

· Scalable for expansions and upgrades

Essential Variants:

· Feed-through terminal blocks

· Grounding terminals

· Fuse terminal blocks

· DIN-rail mounted marking strips or markers

Tip: Use color-coded terminals and labels according to IEC or local wiring codes for better clarity.

3. Panel Meters and Monitoring Devices

Purpose:

Modern electrical panels are not just passive distribution points — they are smart monitoring stations. Panel meters and current monitoring devices help track voltage, current, frequency, and power consumption.

Key Benefits:

· Real-time data for preventive maintenance

· Improved energy efficiency

· Quick response to load imbalance or faults

Popular Options:

· Digital voltmeters and ammeters

· Multi-function energy analyzers

· Load monitoring relays

Advanced choice: Consider smart monitoring units with Modbus or Ethernet communication for integration with BMS or SCADA systems.

4. Control and Signaling Devices

Purpose:

Control and signaling accessories like push buttons, selector switches, and pilot lights are critical for human-machine interaction. They allow operators to control, signal, and monitor operations within or from the front of the panel.

Key Benefits:

· Improved operator control and feedback

· Quick visual status indication

· Enhanced safety through emergency stop functions

Must-Have Components:

· Illuminated push buttons (Start/Stop)

· Pilot lights (for voltage presence or fault status)

· Emergency stop buttons

· Audible buzzers for alerts

Best Practice: Use IP65-rated front-panel devices for industrial environments to ensure durability and resistance to dust and moisture.

5. Surge Protection Devices (SPD)

Purpose:

Electrical surges — whether from lightning or switching operations — can damage panel components or connected equipment. SPDs protect against transient over voltages.

Key Benefits:

· Prevents costly downtime and equipment failure

· Increases the lifespan of electronics and controls

· Meets compliance with IEC 61643 or UL 1449 standards

Selection Tips:

· Choose SPDs according to system voltage (230V/400V) and risk level

· Type 1 for external surge protection, Type 2 for internal panel protection

· Consider combined Type 1+2 for comprehensive safety

Smart move: Pair SPDs with monitoring modules to track surge counts and SPD health.

Final Thoughts

When designing or upgrading your electrical panel, these five accessory categories are not just optional — they’re essential. They improve safety, functionality, compliance, and operational efficiency. Whether you’re building panels for industrial, commercial, or residential applications, investing in high-quality accessories will yield long-term benefits.

At Daleel Trading, we supply trusted low-voltage switchgear accessories from leading brands like Civaux — ensuring your panels are equipped with components that meet international standards.

Ready to upgrade your panel accessories?

Contact us today to learn more about our product range or request a consultation with our technical team.

4 notes

·

View notes

Text

What Is a Circuit Breaker and How Does It Work in a Switchgear Assembly?

In modern electrical power systems, reliability and safety are paramount. Whether it’s a residential building, industrial plant, or renewable energy facility, the control and protection of electrical circuits are essential. One of the most critical components used for this purpose is the circuit breaker. When integrated into a switchgear assembly, the circuit breaker plays a central role in ensuring operational continuity, preventing electrical faults, and safeguarding equipment and personnel.

This article explores what a circuit breaker is, it’s working principle, types, and its specific function within a switchgear assembly.

What Is a Circuit Breaker?

A circuit breaker is an automatically operated electrical switch designed to protect an electrical circuit from damage caused by overcurrent, overload, or short circuit. Its primary function is to interrupt current flow after a fault is detected. Unlike a fuse, which operates once and must be replaced, a circuit breaker can be reset (manually or automatically) to resume normal operation.

Key Functions of a Circuit Breaker

· Interrupt Fault Currents: Quickly breaks the circuit in the event of an overcurrent or short circuit.

· Manual Switching: Can be used to manually open or close a circuit for maintenance.

· Automatic Protection: Operates automatically in response to abnormal current conditions.

· Isolation: Ensures safe isolation of electrical equipment during servicing.

How Does a Circuit Breaker Work?

Circuit breakers operate on a simple principle: detect a fault and interrupt the current flow.

Working Mechanism

1. Detection: Internal sensors such as thermal, magnetic, or electronic trip units detect abnormalities in current.

· Thermal Trip Unit: Uses a bimetallic strip that bends with heat from overcurrent.

· Magnetic Trip Unit: Uses an electromagnet that triggers a release when excessive current flows.

· Electronic Trip Unit: Uses current sensors and a microprocessor for precise tripping.

2. Tripping: Once a fault is detected, the trip mechanism activates, causing the breaker’s contacts to open.

3. Arc Extinction: When the contacts open, an electrical arc forms. The breaker extinguishes the arc using mechanisms like:

· Air-blast

· Vacuum

· SF₆ gas

· Oil

4. Resetting: After the fault is cleared, the breaker can be reset and put back into service.

Types of Circuit Breakers

What Is a Switchgear Assembly?

Switchgear is a centralized assembly of electrical disconnect switches, fuses, or circuit breakers used to control, protect, and isolate electrical equipment. It is essential in power generation, transmission, and distribution networks.

Switchgear can be categorized by voltage level:

· Low Voltage (LV): Up to 1 kV

· Medium Voltage (MV): 1 kV to 36 kV

· High Voltage (HV): Above 36 kV

Role of Circuit Breakers in Switchgear Assemblies

Circuit breakers are core protection components within switchgear systems. Their role includes:

1. Fault Detection and Isolation

Circuit breakers detect and isolate faulty circuits to prevent system-wide failures and reduce downtime.

2. Load Control

Operators can use breakers in switchgear to safely connect or disconnect loads as required during routine operations or emergencies.

3. System Coordination

In coordinated protection schemes, different breakers in the switchgear are set with time-current characteristics to isolate faults precisely and efficiently.

4. Integration with Automation

Modern switchgear integrates circuit breakers with SCADA systems and smart relays, enabling remote monitoring and control.

Circuit Breakers in Renewable and Industrial Applications

In sectors like solar and wind energy, circuit breakers are specially designed to handle:

· Bidirectional current flow

· Rapid voltage fluctuations

· High fault levels due to DC sources

In industrial settings, breakers must handle high inrush currents, frequent switching, and harsh environments.

Maintenance and Safety Considerations

To ensure reliability:

· Regular Testing: Trip settings, insulation resistance, and contact resistance must be tested periodically.

· Visual Inspection: For signs of wear, overheating, or contamination.

· Replacement of Parts: Arcing contacts and insulation materials degrade over time and must be replaced as needed.

Safety measures include:

· Lockout/Tagout (LOTO)

· Grounding procedures

· Personal Protective Equipment (PPE)

Conclusion

Circuit breakers are indispensable for the protection and control of electrical systems. When embedded within a switchgear assembly, they offer enhanced reliability, automation capability, and system safety. Whether in a power substation, a manufacturing facility, or a renewable energy farm, the synergy of circuit breakers and switchgear ensures smooth, safe, and efficient operation.

Understanding how circuit breakers function and interact within switchgear assemblies is crucial for electrical engineers, facility managers, and anyone involved in the design, operation, or maintenance of electrical infrastructure.

4 notes

·

View notes

Text

Understanding High Voltage Columnar Resistors

High Voltage Columnar Resistors are essential components in high and medium-frequency electronic applications, designed to efficiently manage high voltage while ensuring stable performance and longevity. Their unique cylindrical (columnar) design offers superior durability and reliability, making them a preferred choice for demanding electronic systems.

Key Features of High Voltage Columnar Resistors

High Voltage Handling: These resistors are specifically designed to withstand and regulate high voltage levels, preventing system failures and enhancing operational efficiency.

Columnar Design: The cylindrical structure improves heat dissipation, ensuring consistent performance even under extreme conditions.

Superior Stability: Due to their high-quality materials and construction, these resistors offer excellent stability, minimizing fluctuations in resistance values.

Enhanced Durability: High voltage columnar resistors are built to withstand harsh environmental conditions, including high temperatures and mechanical stress.

Wide Application Range: Used in power distribution systems, medical equipment, industrial automation, and telecommunications, these resistors are vital for various high-tech applications.

Applications of High Voltage Columnar Resistors

Power Electronics: Used in power transmission and distribution systems to regulate and stabilize electrical flow.

Medical Equipment: Essential in high-frequency medical devices where precision and stability are crucial.

Industrial Automation: Supports control systems and industrial machinery by managing high voltage effectively.

Aerospace and Defense: Integral in mission-critical systems that require high reliability under extreme conditions.

Telecommunication Systems: Ensures stable performance in high-frequency communication circuits.

Advantages Over Conventional Resistors

Better Heat Dissipation: The columnar shape allows for improved cooling, reducing the risk of overheating.

Higher Voltage Endurance: These resistors can handle significantly higher voltage levels than standard resistors.

Compact Design: Their cylindrical form factor allows for space-saving integration into electronic circuits.

Longevity and Reliability: Designed to function efficiently over extended periods, reducing the need for frequent replacements.

Conclusion

High Voltage Columnar Resistors play a crucial role in modern electronics, offering superior performance, durability, and efficiency in high-voltage applications. Their robust design and advanced features make them an indispensable component in various industrial, medical, and technological fields. As technology advances, the demand for reliable and high-performing resistors like these will continue to grow, further solidifying their importance in electronic systems.

2 notes

·

View notes

Text

so I think we can all agree the retcon that matoran gender distribution was the result of the great beings being stupid and terrible wasn't that well thought out. Here's what I think would have been a more interesting alternative; vortixx cultural export

vortixx have a misandrist society and are a massive source of trade in the MU, so likely when sorting out how matoran (a genderless species) fit into their society they would distribute male/female based on what each type does, with matoran types you want to keep in good graces being dubbed female and matoran you want to keep in their station (or don't live there) dubbed male

female;

ga matoran would likely be important to handling ships and transportation, which is pretty important if you want to run a country based on heavy exporting

vo matoran would likely be electrical workers or handle electronics production and manufacturing, which are important to a high-tech industrial economy