#even composting is a type of fermentation

Explore tagged Tumblr posts

Note

need you to know your username and that tag paragraph you left on a reblog one time have captivated me and that's why I followed. I know nothing about fermenting. I've spoken of you to my friends. tell me a fact about fermentation

I’m going to scream, this is my first ever ask and I’m so nervous!

Let’s see, a fact about fermentation.

There are too many so here’s a few that I find interesting 🤷♂️

SCOBY (the thing most commonly associated with kombucha) stands for (S)ymbiotic (C)ulture (O)f (B)acteria and (Y)east

Vinegar can also develop a SCOBY. However, instead of being called a SCOBY, it’s more typically referred to as a MOV - (M)other (O)f (V)inegar

Hot sauces can be fermented. Many famous hot sauces are fermented. And it’s generally agreed upon that fermentation hot sauces have a better blend of flavors.

If a bread had yeast in it it’s been fermented. The difference between regular bread and sourdough bread is that with the wild yeast some bacteria will also take root which helps give that nice tart taste!

Fermentation is just the process of having smaller microorganisms digest a food before you do. The most common fermenters are fungi and yeast, bacteria, mold, and enzymes.

All vinegar starts as alcohol

Even salamis and other dried/aged meats are fermented!

There’s so much more I could talk about, but these are a spread of facts that are neat!

#Saccharomyces cerevisiae#is the most common#bakers#and#brewers#yeast#it has over 9000 variant strains and all of them taste slightly different#I’ve used my knowledge of fermentation in my anthropology classes to help date a decomposing body simulation#I’m planning one of my thesis topics on the effects fermentation had on food preservation in different cultures#you can use fresh#live#whey from cheese or yogurt to make lemonade soda#all fermentation is about keeping microbes happy#fermenters can be cult-like with their farming and tending to their little buddies#even composting is a type of fermentation

6 notes

·

View notes

Text

Open Species | MushTaurs

Q/A

Q | What is a MushTaur’s diet?

A | Things that can equate to compost or fertilizer, fermented fruits, dead leaves, or even animal remains.

Q | Do they have to be in the art style presented on the chart?

A | Not at all! Find what fits your fella.

Q | Is there a common, uncommon, or rare type of MushTaur?

A | Nope! It’s an open species.

Q | Can the mushroom type be based on a fantasy mushroom from fictional medias?

A | Certainly! Get creative with it!

Q | Where does the mushroom part of the MushTaur go?

A | The default body is like the stem of the mushroom, so anywhere you think looks good I guess. Has a cap? On the head. Has frills? Could be placed on the arms and legs. Is just a puffball mushroom? Make them chonk.

Q | Can I give them hair?

A | Sure! Might be a different fiber so get creative with the material for the hair!

42 notes

·

View notes

Note

Do trolls have anything akin to cuisine and traditional dishes? Just because you can eat just about anything doesn't mean it has to be presented with no flair. :D I suppose same question for minotaurs. Are there any foods other races go out of their way to try from either of these groups (besides minotaur milk)?

They certainly do! Trolls are in a unique position where they can eat damn near anything without consequence, even foods that are totally raw, filthy, or rotten. But what's even more unique is the fact that they like the taste of nasty, rotten food!

A troll's sense of smell and taste oppose that of most peoples'. By that I mean, smells and tastes that other peoples find pleasant are usually unpleasant to trolls, and vice versa. Taste is subjective, but we can agree that 99% of humans would retch if they put a rotten egg in their mouth. Meanwhile, the average troll can--and will--happily devour it, and enjoy it much more than a fresh egg.

Because of this, trolls have developed many unique dishes that only their species can safely eat. I will warn you, some of the following text is really disgusting. So if you get grossed out easily, consider skipping the rest of the post.

With that said, let's take a look some of these troll-specific dishes from around the world!

Redge: A rotten egg slathered in bitter herbs.

Plopslop: The manure of a herbivorous animal, boiled down into a soup with half-composted vegetables added.

Grrsi: Fresh meat is inoculated with fly eggs, which hatch and partially digest the meat over time. The meat becomes infested with the fat grubs, which are the main attraction of the dish.

Urizluuk: The urine of a male goat, fermented for months in an alcoholic fruit broth. This is a popular drink dating back to ancient times.

Akwi: Raw fish heads, left to dry in the sun until they smell putrid. Sometimes akwi is made with clams or some other sealife instead.

Dukleka: Garlic is force-fed to rats over the course of many days, then rats are fed to a pig-hawk, which has its rear-end sewn shut. The garlicky rats ferment in its GI tract until the bird dies of bloat, then its stomach and intestines are removed and eaten as a delicacy.

Zlub: This is not a meal in itself, but a sauce made from boiled slug slime and rancid onions. It's added to other foods to give it a slimy, repulsive texture that trolls love.

Volzkriz: Animal blubber (traditionally from a walrus or whale) is boiled down into a liquid and then left to cool, forming a hard block of fat. This can be eaten fresh, but it said to taste better the more rancid it gets.

There are lots more, but I'm sure you get the idea...Even ogres, who can tolerate rancid corpses, will be sickened by some of the things on this list. This gives trolls a serious survival advantage over other species.

As for minotaurs, they are a lot less tolerant of rotten foods. However, they can tolerate tough fibers which are undigestible by most peoples. This includes things like raw grass, bark, and woody vegetation. Even trolls struggle to digest these fibers unless they compost them down to a softer form, but minotaurs can eat them fresh, no preparation needed. This is also quite a big survival advantage.

Minotaurs have quite an affinity for fresh grass, and some of them can get quite snobby about it. There are many debates about which type of grass is best for taste and health, and how best to prepare it. Cooked or raw? Some insist that cooking the grass is culinary heresy, and its subtle flavors should be enjoyed in their purest form as nature intended. There are common grasses which are considered "peasant food" and other, rarer species which are enjoyed by royalty.

Grass is a big meme in Etios Nation. Even the Etiosi make fun of themselves for their apparent cultural obsession with grass, and it certainly hasn't gone unnoticed by foreigners. "Go eat some grass" is a common insult hurled towards minotaurs worldwide.

*

Questions/Comments?

Lore Masterpost

Read the Series

10 notes

·

View notes

Text

The Evolution of Drinking Straws: From Ancient Origins to Modern Innovations

Drinking straws, though often overlooked, have a rich history and have undergone significant transformations over the centuries. From their inception in ancient civilizations to the modern-day debates surrounding their environmental impact, straws have played a pivotal role in beverage consumption.

Ancient Beginnings

The concept of the drinking straw dates back to ancient Mesopotamia. The Sumerians utilized hollow reeds to consume beer, aiming to avoid the solid byproducts of fermentation that settled at the bottom of their containers. These early straws were rudimentary but served a practical purpose in daily life.

The 19th Century: A Turning Point

Fast forward to the 19th century, and the drinking straw underwent a significant transformation. In 1888, Marvin C. Stone, an American inventor, patented the first paper straw. Dissatisfied with the grassy taste imparted by rye grass straws, Stone wrapped paper around a pencil, glued it, and created a more palatable alternative. This innovation marked the beginning of mass-produced drinking straws.

Diverse Types of Straws

Over time, various types of straws have emerged to cater to different beverages and consumer preferences:

Boba Straws: Designed with a wider diameter to accommodate tapioca pearls in bubble tea. These straws often have a pointed tip to pierce sealed lids.

Thick Straws: Ideal for smoothies and milkshakes, allowing for the easy consumption of thicker liquids.

Coffee Straws: Typically, slender, these straws are used for sipping hot beverages and are often found in coffee shops.

Cocktail Straws: Shorter in length, these are used in mixed drinks, serving both functional and decorative purposes.

Chocolate Drinking Straws: Infused with chocolate flavor, these straws enhance the taste of milk and are popular among children.

Grass Straws: Made from natural grass stems, offering an eco-friendly alternative to plastic straws.

Wheat Straws: Produced from wheat stems, these biodegradable straws are gaining popularity as sustainable options.

Stir Sticks and Coffee Stirrers: Used to mix beverages, especially hot drinks, ensuring even distribution of ingredients.

Standardization and Sizes

Understanding the standard sizes of straws helps in selecting the appropriate type for specific beverages:

Standard Straw Length: Typically, around 8 inches, suitable for most drinks.

Jumbo Straws for Smoothies: Approximately 10 inches in length with a wider diameter to handle thicker beverages.

Sysco Wrapped Bubble Tea Straw Paper: These are individually wrapped straws designed specifically for bubble tea, ensuring hygiene and convenience.

The Environmental Impact

In recent years, the environmental consequences of plastic straws have come under scrutiny. A poignant example is the viral video of a sea turtle with a plastic straw lodged in its nostril, highlighting the detrimental effects of plastic waste on marine life. Such incidents have spurred movements advocating for reduced plastic straw usage.

Plastic straws are non-biodegradable and can take hundreds of years to decompose. Their lightweight nature makes them prone to being carried into oceans, where they pose threats to marine animals. The "plastic straws turtles" concern has led to increased awareness and calls for sustainable alternatives.

Modern Alternatives and Innovations

In response to environmental concerns, various alternatives to traditional plastic straws have been developed:

Paper Straws: Biodegradable and compostable, these straws decompose more quickly than plastic counterparts.

Metal Straws: Reusable and durable, metal straws are easy to clean and have become popular among eco-conscious consumers.

Silicone Straws: Flexible and reusable, suitable for both hot and cold beverages.

Edible Straws: Made from ingredients like rice or pasta, these straws can be consumed after use.

Straw Covers: Designed to protect reusable straws, ensuring hygiene and portability.

Cultural Phenomena and Trends

The "cup with a straw craze" reflects society's fascination with unique and functional drinkware. From novelty cups to customizable straw designs, consumers seek personalized experiences.

Accessibility and Considerations

While the push towards eliminating plastic straws is environmentally driven, it's essential to consider individuals who rely on straws for medical or accessibility reasons. Flexible straws, for instance, are crucial for some people with disabilities, emphasizing the need for inclusive solutions.

Conclusion

The journey of the drinking straw, from ancient reeds to modern sustainable alternatives, mirrors humanity's evolving relationship with convenience, innovation, and environmental responsibility. As we continue to seek balance between functionality and sustainability, the humble straw serves as a testament to our capacity for adaptation and change.

1 note

·

View note

Text

Horticultural Assessment of Pechay (Brassica rapa) Grown with Fish Waste-Based Organic Fertilizer Fermented with Molasses

Abstract

Nowadays, great amount of waste is being produce in the fish markets and processing industries. This study aims to find out the effect of using fish and fish waste as organic fertilizer on the growth of pechay. The study was arranged in a randomized setup with three (3) treatments and three (3) replications, each treatment has 30 samples. Among the treatments are T1– 50g/5g, T2-150g/10g and T3– 200 g/15 g). The study uses the one-way ANOVA. Results showed that T3 has the highest total mean growth of 16.4 cm and 15.77 cm in length compared to T2 and T1. The size of the leaves recorded with 14.37 cm and 7.96 cm wide. A 100% survival rate was obtained in all treatments. Significant difference was observed in the size of the leaves, other showed not significant results. The result is a good potential for adoption, especially it would benefit to the local farmers.

Introduction

In recent years, the fish industry has generated a substantial amount of fish waste. Depending on the level of processing or type of fish, 30–70% of the original fish is fish waste. Circular economy and organic farming concepts were used to evaluate the potential of producing fertilizers from captured fish. Fertilizers produced from captured fish promote the recycling of nutrients from the sea and back to terrestrial environments. The nutritional composition of fish waste is assessed to determine the potential to supply plant nutrients such as nitrogen, or a combination of nitrogen and phosphorous, or to enrich a compost. In the research of Kenhudoy (2017) on the benefits of using fish and animal wastes as fertilizer, fish waste as soil fertilizer offers an organic solution and effectively provides nutrients to the soil for a blossom harvest. Even though some of the fish products have an unpleasant smell, they do have a lot of benefits for the crop, making them a healthy food source. Native Americans showed pilgrims how to use fish to fertilize their crops. From current findings, it is proven that the Native Americans were right about the benefits of using fish fertilizer.

Production and information about processing the fish waste were illustrated in the Organic Materials Review Institute (OMRI), indicating also the fishbased fertilizers industry and research in Europe. Converting fish waste like fish entrails into liquid fertilizer can be used to water or drench the plants. This liquid fertilizer could last for up to a year. The liquid produced in the fermentation process is called fish emulsion. The two main ingredients to make the emulsion are fish guts (entrails) and molasses. If molasses is not available, brown sugar is a good substitute. It is a sucrose product with a distinctive brown color due to the presence of molasses. The methods used in the processing of fish waste to produce fish emulsion, fish hydrolysate/fish silage, fish compost, and digestate from anaerobic digestion or co-digestion are presented in the study of Ahuja et al. (2020). The accumulation of fish waste should be a source of concern because it can pollute the water (Kusuma et al., 2019). It can be turned into organic manure, which is beneficial to fish farmers and sellers who discard fish waste (Jayvardhan, 2020). It is essential to treat fish waste to minimize the environmental effects (Kusuma et al., 2019). If we can properly dispose of it so that it can decompose, we can create jobs and make money by selling the manure.

On the other hand, the culture of pechay (Brassica rapa) in the Philippines is one of the fastest-growing vegetable industries. It is an important vegetable crop and has nutritional value as well as good commercial value. One of the most popular vegetables among consumers is always available in the market at any time of the year. It is known as one of the oldest vegetables in Asia; it therefore plays an important role in the Philippines’ economy as well as in the nutrition of the Filipino people. Pechay is used mainly for its immature, but fully expanded, tender leaves. The succulent petioles are often the preferred part. It is used as the main ingredient for soups and stir-fried dishes. In Chinese cuisine, its green petioles and leaves are also used as a garnish (Gonzales et al. 2005). On the other hand, our government agencies like the Department of Agriculture encourage Filipino farmers to switch to an alternative and healthy way of marketing high-value crops to have a higher income. Several practices are being taught, like going back to basics and using organic fertilizers rather than inorganic or synthetic ones. Fermented fish entrails are another alternative medium used as a substitute for economically important and easy growing vegetables like pechay and sweet pepper in this study.

There are several studies using fermented fish entrails mixed with fish molasses (Rabia, 2022), and even decomposed seaweeds and the bark of pine trees have been documented. In the study conducted by Diaz et al. (2011) on the growth and yield response of bell pepper to fish fertilizer and fermented fish juice as organic fertilizer, they found that fish gill emulsion fertilizer is comparable to commercial or synthetic fertilizers. It may be one of the best fertilizers to utilize for growing bell peppers. The compost made from fish waste has the added benefit of containing potassium, calcium, and magnesium. Composting is a biotransformation process that involves microorganisms converting organic materials into stable and complex macromolecules. It can be used as a soil enhancement to increase the texture and fertility of the soil, reducing the need for synthetic fertilizers (Maja et al., 2019). This waste can be helpful and valuable fertilizer in agriculture (Jayvardhan, 2020). No foul odors were detected in the fish waste fertilizer (Maja et al., 2019).

Molasses is a primary by-product in the fermentation industry and can be used in the food industry, such as in distilleries, sugar production, and yeast production (Li et al., 2020). It was high in calcium, magnesium, iron, and potassium. It also contains sulfur and a host of micronutrients (Susan Patterson and Master Gardener). Molasses has been used in the past as fertilizer on sandy soil and soil with poor structure (Pyakurel et al., 2019). Using molasses as a fertilizer provides plants with a quick source of energy and encourages the growth of beneficial microorganisms. When molasses is added to organic fertilizers, it provides food for the healthy microbes in the soil (Susan Patterson, Master Gardener). Molasses supplies carbohydrates and alters the C:N ratio, which affects soil microbial ecology, lowers plant parasitic nematodes, and provides other favorable effects on plant growth (Hilty et al., 2021). Molasses improves soil aggregation and reduces surface crusting in hard-setting soils (Wynne and Meyer, 2002). Molasses plant fertilizer is a great way to grow healthy plants, and as an added benefit, using molasses in gardens can help fend off pests. The fermentation process converts the solid substrates into simple molecules with the help of microbes. It is one of the promising technologies that converts fish waste into useful organic manure, an expensive resource for agriculture, without the formation of a fusty smell.

One of the problems encountered by some farmers nowadays is their inability to harvest crops on time and the low quality of the produce, particularly some leafy vegetables. Some fishermen also encountered challenges in the disposal of fish waste, which is very abundant in the locality. Many factors cause distractions in our world today, like pollution, inadequate solid waste disposal, global warming, climate change, and many others that affect our economic and environmental aspects. Our agricultural sector is widely affected by these problems. So, most of our farmers in the country use inorganic or synthetic fertilizers to boost plant resistance and improve or multiply their yield compared to the usual or natural cycle.

Fish are consumed as food in fresh conditions. Some of them are also utilized after the preservation. During preservation and processing, some materials from fish and prawns are discarded as waste. Similarly, some trash and distasteful fish are unsuitable for human consumption. These waste materials and the above fish become an important source for producing fish by-products, which in turn are used to produce different useful fish by-products. Organic agriculture or organic farming seeks to provide good quality and healthy foods while not harming the environment, maintaining soil fertility, and using synthetic materials. There is a growing demand for organic products in both local and global markets that is likely to be significant in the future. Fertilizers produced from captured fish promote the recycling of nutrients from the sea and back to terrestrial environments. The nutritional composition of fish waste is assessed to determine the potential to supply plant nutrients such as nitrogen, or a combination of nitrogen and phosphorous, or to enrich a compost. Methods used in the processing of fish waste to produce fish emulsion, fish hydrolysate/fish silage, fish compost, and digestate from anaerobic digestion or co-digestion are presented.

With these, siganids are the most abundant fish in the locality; with the common name of rabbitfishes, they are essential to reef herbivores that browse individually or in schools over the reef or feed on plankton within the water column (Nelson, 1994; Kenhudoy, 2017). Siganids' fish waste weighs from 10 to 20 grams per fish, depending on the size of the fish. It contains the nutritional contents found in rabbit fish, which are amino acids, fatty acids, protein, vitamins, and other essential minerals. According to the International Food Research Journal in Indonesia, samples of fish filleted without skin contained 77.79% moisture, 15.93% protein, 1.01% ash, and 0.93% fat. Rabbit fish also contained nine (9) essential and seven non-essential amino acids. Glutamic acid was the most abundant amino acid with a level of 1.983 mg/100 g. The eicosatetraenoic acid (EPA), docosahexaenoic acid (DHA), and arachidonic acid (ARA) quantities were 0.54%, 6.45%, and 1.21%, respectively. So, these ideas trigger the researchers to use the fish waste as fertilizer in the culture of vegetables, particularly the pechay, which is considered an economically important crop because it is easy to grow, is available throughout the year, and is both an excellent source of different nutrients. This research study aims to determine the performance of pechay (Brassica rapa) grown in a container using fermented siganid entrails as organic fertilizer. This study also aims to determine the effects of using fish waste as organic fertilizer on the productivity of vegetable production. These could also have the potential for the replacement of other dried poultry manure from conventional farming in organic farming.

Source : Horticultural Assessment of Pechay (Brassica rapa) Grown with Fish Waste-Based Organic Fertilizer Fermented with Molasses | InformativeBD

1 note

·

View note

Text

The Evolution and Appeal of Sushi Boxes

The Evolution and Appeal of Sushi Boxes in Modern Cuisine

Sushi, a traditional Japanese dish, has gained immense popularity worldwide for its delicate flavors, artistry, and health benefits. One of the most convenient and visually appealing ways to enjoy sushi is through sushi boxes. These beautifully crafted containers have evolved over time, catering to the demands of modern consumers while preserving the essence of Japanese culinary tradition. This article explores the evolution and appeal of sushi boxes in modern cuisine, highlighting why they have become a staple for sushi lovers around the globe.Get more news about sushi box,you can vist our website!

The Evolution of Sushi Boxes Traditional Beginnings

The concept of sushi dates back to ancient Japan, where it was originally developed as a method of preserving fish through fermentation with rice. Over time, sushi evolved into an art form, with chefs meticulously preparing and presenting various types of sushi. Traditionally, sushi was served in wooden boxes known as "hako," which means box in Japanese. These boxes were used to store and transport sushi, ensuring its freshness and presentation.

Modern Innovations

With the global spread of sushi, the traditional wooden sushi boxes have evolved to meet the needs of contemporary consumers. Modern sushi boxes are made from a variety of materials, including plastic, bamboo, and biodegradable materials. These innovations have improved the convenience, portability, and sustainability of sushi boxes, making them suitable for different settings, such as takeout, delivery, and casual dining.

Appeal of Sushi Boxes Convenience

One of the primary appeals of sushi boxes is their convenience. Sushi boxes are designed to be portable and easy to carry, making them ideal for on-the-go meals, office lunches, picnics, and gatherings. The compartmentalized design of sushi boxes ensures that each piece of sushi remains intact and presentable, even during transportation.

Aesthetic Presentation

Sushi is renowned for its artistic presentation, and sushi boxes enhance this visual appeal. The neatly arranged pieces of sushi, along with garnishes and accompaniments, create a visually stunning experience. The vibrant colors and meticulous arrangement of sushi in the box add to the overall dining experience, making it not only a meal but also a feast for the eyes.

Variety and Customization

Sushi boxes offer a wide variety of sushi types and flavors, catering to diverse tastes and preferences. From classic nigiri and sashimi to creative maki rolls and fusion sushi, there is something for everyone. Many sushi boxes also allow for customization, enabling consumers to choose their favorite combinations and ingredients. This variety and customization make sushi boxes a versatile option for different occasions and dietary preferences.

Sustainability

In response to growing environmental concerns, many sushi boxes are now made from eco-friendly and sustainable materials. Biodegradable and compostable sushi boxes help reduce plastic waste and minimize the environmental impact. Additionally, some sushi restaurants have adopted reusable sushi boxes, encouraging customers to return and reuse them, further promoting sustainability.

Health Benefits

Sushi is often celebrated for its health benefits, and sushi boxes provide a convenient way to enjoy this nutritious meal. Sushi is typically low in calories and high in protein, omega-3 fatty acids, vitamins, and minerals. The inclusion of fresh fish, vegetables, and seaweed in sushi boxes offers a balanced and wholesome meal option, making it a popular choice for health-conscious consumers.

Conclusion The evolution of sushi boxes reflects the changing needs and preferences of modern consumers while preserving the essence of Japanese culinary tradition. Their convenience, aesthetic presentation, variety, customization, sustainability, and health benefits make them an appealing option for sushi lovers around the world. As sushi continues to captivate the palates of people globally, sushi boxes will remain a staple in modern cuisine, offering a delightful and convenient way to enjoy this beloved Japanese dish. Embrace the charm of sushi boxes and discover how they can elevate your sushi dining experience.

0 notes

Text

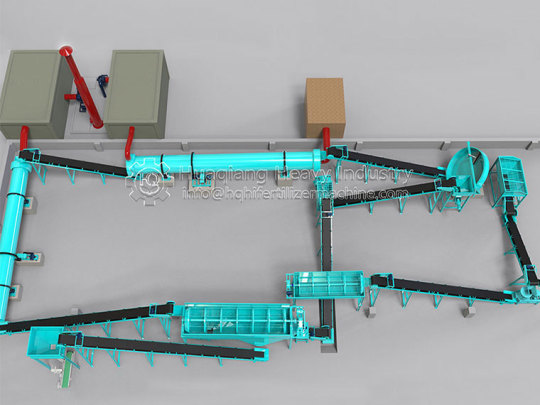

As an important auxiliary material in agricultural production, the quality and safety of organic fertilizer directly affect the growth of crops and the health of soil. In the production process of organic fertilizer, the effective control of microbial activity is the key link to ensure the quality of organic fertilizer. Here are a few key points for effective control of microbial activity:

1. Raw material pretreatment: The raw materials of organic fertilizer usually come from agricultural waste and livestock and poultry manure, which are rich in microorganisms. Turning through a Compost turning Machine (such as the Windrow Compost Turning Machine) can effectively control the activity of microorganisms, promote the growth of beneficial microorganisms, and inhibit the reproduction of harmful microorganisms.

2. Fermentation process management: In the organic fertilizer production line, fermentation is a key step, which directly affects the control of microbial activity. By adjusting the moisture, temperature and ventilation conditions in the fermentation process, the living environment of microorganisms can be optimized and the reproduction of beneficial microorganisms can be promoted. For example, maintaining the right humidity can promote microbial metabolism, while proper ventilation helps aerobic microorganisms grow.

3. Microbial inoculation: In the production process of organic fertilizer, beneficial microorganisms can be inoculated to improve the control of microbial activity. These microorganisms can be azotobacter, phosphorus solubilizer or other microorganisms that can improve soil structure and improve soil fertility. Mixing evenly through a Horizontal Ribbon Mixer ensures an even distribution of microorganisms throughout the organic fertilizer, thus enhancing its effectiveness.

4. Microbial control in the pelleting process: In the organic fertilizer pelleting process, the fertilizer pelleting Machine series (such as Flat-Die Pellet Machine) can form uniform particles, which contributes to the stable existence of microorganisms in the fertilizer. At the same time, the temperature and pressure during the granulation process also affect the activity of the microorganisms, and precise control is required to maintain the activity of the microorganisms.

5. Quality testing and monitoring: In the entire organic fertilizer production process, regular quality testing is essential. By detecting the type and number of microorganisms, the quality and safety of organic fertilizers can be assessed. In addition, the Rotary Screening Machine is used to screen the finished product, which can remove unqualified particles and ensure the uniformity of the final product and the stability of the microbial activity.

Through the above measures, we can effectively control the microbial activity in the production of organic fertilizer, produce high-quality organic fertilizer, and promote the sustainable development of agriculture.

#Windrow Compost Turning Machine#Horizontal Ribbon Mixer#Flat-Die Pellet Machine#Rotary Screening Machine

0 notes

Text

Organic fertilizer is an indispensable part of agricultural production, and every link of its production process is crucial. The correct use of organic fertilizer fermentation equipment can not only improve the quality and efficiency of fertilizers, but also ensure the safety and environmental protection of the production process. Here are a few key points to pay attention to when using organic fertilizer fermentation equipment:

Use of Uniform Feeder: In the production process of organic fertilizer, uniform feeding is an important link to ensure the quality of fermentation. By using a uniform feeder, the material can be ensured to enter the fermentation equipment continuously and evenly, avoiding the problem of incomplete or excessive fermentation caused by uneven feeding.

Selection and use of fertilizer mixer: mixer plays a role in the production of organic fertilizer. Horizontal Ribbon Mixer and Double Shafts Paddles Mixer are two common types of mixers that ensure an even mix of ingredients and improve fermentation efficiency. When using, pay attention to the mixing speed and time to avoid destroying the microbial activity in organic fertilizer.

Application of fertilizer Screening Machine: Organic fertilizer will produce materials of different particle sizes during fermentation. The Rotary Screening Machine or Vibration Screening Machine can effectively separate the fertilizer particles that meet the standard and improve the uniformity and quality of the final product.

Maintenance of Organic Fertilizer Production Line: Organic Fertilizer Production Line includes multiple links, such as raw material treatment, fermentation, drying, screening and packaging. Regular maintenance and inspection of all aspects of the equipment, such as Fertilizer Granules Compaction Machine, Flat-Die Pellet Machine, Rotary Drum Granulator, etc., can ensure the continuous and stable operation of the production line. Reduce the risk of failure.

Operation of Compost Turning Machine: compost turning machine, such as Windrow Compost Turning Machine, is the key equipment to improve the efficiency of compost fermentation. Proper operation can ensure the air permeability and temperature control inside the compost, promote the activity of microorganisms, and accelerate the decomposition of organic matter.

The rational use of fertilizer crusher: In the production process of organic fertilizer, the crushing of materials is an important step to improve the fermentation efficiency. Equipment such as Cage Crusher can crush large pieces of material into a suitable size for fermentation, but the crushing size should be adjusted to avoid excessive fine materials affecting the fermentation effect.

Environmental control: During the use of organic fertilizer fermentation equipment, the temperature, humidity and pH value of the fermentation environment need to be strictly controlled to ensure the activity of microorganisms and fermentation efficiency. At the same time, it is also necessary to pay attention to ventilation and stacking to avoid the accumulation of harmful gases.

Safe operation: When operating organic fertilizer fermentation equipment, the relevant safety procedures must be followed to ensure the safety of the operator. This includes properly wearing protective equipment, following instructions in the operating manual, and conducting regular safety training.

Through the strict implementation of these precautions, you can ensure the efficient, safe and environmentally friendly operation of organic fertilizer fermentation equipment, so as to produce high-quality organic fertilizer to meet the needs of modern agriculture.

0 notes

Text

Food Waste Composter: Turning Waste into a Valuable Resource

Food waste is a growing global issue, with millions of tons ending up in landfills every year. This waste not only occupies space but also contributes significantly to greenhouse gas emissions. To address this, food waste composters offer an eco-friendly and sustainable solution by converting food scraps into nutrient-rich compost. These devices, whether used at home or on a commercial scale, help transform what would otherwise be waste into a valuable resource for soil health and agriculture.

What is a Food Waste Composter?

A food waste composter is a device or system designed to break down organic food scraps, such as fruit and vegetable peels, coffee grounds, eggshells, and even meat and dairy, into compost. The composting process involves the biological decomposition of organic matter in the presence of oxygen, with the help of microorganisms, worms, or heat.

Food waste composters come in various forms, from simple backyard compost bins to advanced, fully automated machines used in restaurants, hotels, and even urban households. These machines make the composting process faster, easier, and more efficient, reducing the time it takes to convert food waste into usable compost.

How Does a Food Waste Composter Work?

Food waste composters vary in complexity, but the basic process remains the same. Here’s how most systems operate:

Collection: Food waste is collected and placed into the composter. Some systems require users to chop waste into smaller pieces to speed up the process.

Decomposition: Inside the composter, microorganisms break down the organic matter through a natural process of aerobic decomposition. Many modern composters provide optimal conditions, such as controlled moisture, temperature, and aeration, to accelerate the breakdown process.

Composting: Depending on the type of composter, the food waste is transformed into compost over a period of days, weeks, or months. Fully automatic machines can convert food waste into compost in as little as 24 hours.

Output: The result is nutrient-rich compost, which can be used for gardening, landscaping, or agricultural purposes, improving soil fertility and reducing the need for chemical fertilizers.

Types of Food Waste Composters

There are several types of food waste composters available, each suited for different scales and purposes:

Traditional Compost Bins: These are simple, manual composters typically used in backyards. They rely on natural decomposition, requiring users to turn the compost regularly to ensure proper aeration.

Worm Composters (Vermicomposters): These systems use worms, particularly red wigglers, to break down food scraps. Worm composters are great for indoor or outdoor use and produce high-quality compost rich in nutrients.

Bokashi Composters: This is an anaerobic composting system that uses beneficial microorganisms to ferment food waste, including meat and dairy, which are typically harder to compost. The fermented material can then be added to a traditional composter or buried in the soil.

Fully Automatic Composters: These electric machines, designed for household or commercial use, are capable of rapidly composting food waste in as little as 24 hours. They use heat, aeration, and grinding mechanisms to break down food scraps into compost efficiently.

In-vessel Composters: These large-scale composters are used by businesses, schools, or municipalities to process significant amounts of organic waste. They feature enclosed systems that control the composting environment, ensuring faster and more efficient composting.

Benefits of Food Waste Composters

Waste Reduction: One of the primary benefits of food waste composters is the significant reduction in the amount of waste sent to landfills. In fact, food waste makes up nearly 40% of landfill content, so composting can greatly reduce this volume.

Lower Carbon Footprint: By diverting food waste from landfills, composters reduce methane emissions, a potent greenhouse gas that is released when organic waste decomposes anaerobically in landfills.

Improves Soil Health: The compost produced from food waste is rich in essential nutrients like nitrogen, phosphorus, and potassium, which help improve soil structure and fertility. This organic compost also promotes healthier plant growth and increases soil’s water retention capacity.

Cost Savings: Businesses, restaurants, and households that produce large amounts of food waste can save on waste disposal costs by processing waste onsite using a food waste composter. The compost produced can also be used for landscaping or sold, further offsetting costs.

Promotes Sustainability: Composting food waste aligns with sustainability goals by closing the loop in the food system, turning waste into a valuable resource rather than allowing it to pollute the environment.

Odor Control: Advanced food waste composters are designed with odor control features, allowing food scraps to be processed indoors without the typical smell associated with compost piles. This is especially important for urban settings, restaurants, or apartments.

Commercial and Industrial Applications

While food waste composters are valuable at the household level, their impact is most significant when applied in commercial and industrial settings. Restaurants, hotels, schools, and other institutions generate vast amounts of food waste daily. By installing food waste composters, these establishments can reduce their environmental impact, lower disposal costs, and promote sustainability.

In some cases, municipalities are adopting large-scale composting initiatives, installing centralized food waste composters that process organic waste from entire communities. This helps cities manage waste more efficiently while creating compost for parks, gardens, and public spaces.

Challenges and Considerations

While food waste composters offer numerous benefits, there are also challenges that need to be addressed:

Initial Cost: Some types of composters, particularly fully automatic or large-scale systems, can be expensive to install. However, the long-term savings from reduced waste disposal often justify the investment.

Waste Segregation: Proper waste segregation is crucial for successful composting. Non-organic materials like plastic, glass, and metals must be kept out of the composter to avoid contamination and equipment damage.

Space: Traditional compost bins and larger systems may require significant space, which can be a challenge for urban dwellers or businesses with limited space.

Maintenance: Composters, particularly automated machines, require regular maintenance to ensure optimal performance. This includes cleaning, troubleshooting, and occasionally replacing parts.

Conclusion:

Food waste converter a critical tool in the fight against food waste and environmental degradation. By converting food scraps into valuable compost, they not only reduce landfill burden but also enrich soil and promote sustainable agriculture. Whether at home, in a business, or at the community level, adopting food waste composters represents a practical and impactful step toward a greener future.

0 notes

Text

In the production equipment of organic fertilizer and biological organic fertilizer, Compost Turning Machine is the first essential equipment. So, what is the important role of Compost Turning Machine in the production of organic fertilizer? What are the benefits of using Windrow Compost Turning Machine for the production and fermentation of organic fertilizer?

Tipping machine sorting

Stacking machines are divided into two types: the type of stacking machine that can walk on the ground and the trough type stacking machine that works on the fermentation tank.

Application and benefits of ground type pile tilter

The raw materials for the production of organic fertilizer are more extensive, and the more common ones are chicken manure, pig manure, cow manure, sheep manure and other livestock and poultry manure. Such raw materials need to undergo biological fermentation, and then let it reach the standard of harmless treatment, so as to further produce into commercial organic fertilizer.

The specific operation of the pile turning machine:

Determine the fermentation site, the ground fermentation site needs to be open, the site needs to be smooth, so that it can be convenient for large-scale fermentation production.

Under normal circumstances, the water content of raw materials is large, and a certain proportion of dry materials need to be added for water adjustment, such as straw powder, mushroom residue, etc. Take the sheep manure as an example, pile the sheep manure on the ground, sprinkle the fermentation agent for sheep manure compost on the surface of the raw material, according to the size of the water, add the appropriate amount of dry material/auxiliary materials, the general ratio of raw materials: auxiliary materials are 3:1, the width and height of the pile are determined according to the respective pile model number.

Taking the Wheel Type Windrow Compost Turning Machine as an example, the width and length are determined according to the length of the field. Then the pile turning machine itself walks on top of the material pile, evenly turning, stirring and crushing the raw materials, so that the sheep manure and dry materials and bacteria are fully stirred and evenly, the pile turning machine has the crushing function, even if the sheep manure or dry materials and accessories are large, under the action of the pile turning machine, the large materials can be crushed and decomposed to facilitate full fermentation.

After turning the pile, a new flat material pile is formed, and the new pile body is fluffy and loose, creating a favorable aerobic state for material fermentation, which is very conducive to the production and fermentation of organic fertilizer. In this state, the overturned reactor can rise to the fermentation high temperature within 24 hours, and the reactor can maintain the high temperature for 2-3 days, and then the reactor can be turned. This state has basically become fat in 7 days. At high temperatures, bacteria, grass seeds, and eggs in sheep dung will be killed, and large molecular proteins will be broken down into small molecular proteins that are conducive to crop absorption. In the process of biological fermentation, it can effectively prevent the production of harmful and odorous gases such as hydrogen sulfide, amine gas and indole in feces, and completely remove the odor in feces.

With the high temperature, turning the pile, the moisture in the raw material will gradually decrease, and the general fermentation cycle is 12-15 days. Can continue the next step of deep processing, screening, crushing, granulation, etc. As long as the early fermentation work is done well, the quality of organic fertilizer will be better, and the late deep processing will be easier to carry out, such as granulation, there will be no problems such as not easy to form balls.

In summary, it can be seen that the role played by the turnover machine in the production and application of organic fertilizer is very critical, and it is crucial to choose the right high-quality and inexpensive Organic Fertilizer Compost Turning Machine.

Stack turning machine compared with other products

Some customers want to save costs, with a forklift instead, in fact, the role of the forklift is far less than a special organic fertilizer turning equipment, and the cost will not be reduced.

Fermented organic fertilizer semi-finished products are brown, dark brown, no odor, there will be a little ammonia smell.

Such organic fertilizer applied to the field, do not worry about will produce soil-borne diseases, will not burn the roots, organic fertilizer in nitrogen, phosphorus and potassium and other nutrients are rich and comprehensive, more easily absorbed by crops, long-term application, will completely improve the soil dry crack, the situation of compaction, so that the soil water retention performance is enhanced, so that crop increase and income, quality is further improved!

#Organic Fertilizer Compost Turning Machine#Wheel Type Windrow Compost Turning Machine#Windrow Compost Turning Machine

0 notes

Text

When producing organic fertilizer, is it necessary to use a fermentation compost turning machine?

In the production of organic fertilizer, the use of a fermentation compost turning machine is a common practice, but this does not mean that it is necessary. In fact, whether the organic fertilizer production line needs to use a fermentation rollover machine mainly depends on the production scale, process selection and specific conditions.

First of all, the main role of the fermentation flipping machine is to help the material mix evenly, break the material caking, and promote the propagation of microorganisms and fermentation process. For small or home-scale organic fertilizer production, manual operation or simple mechanical mixing may be sufficient. However, for large-scale production, the use of a fermentation toss machine can greatly improve efficiency and ensure an even mix of raw materials.

Secondly, organic fertilizer production also involves the collection, treatment and storage of raw materials. This includes the collection of organic waste such as crop residues, animal waste and plant residues, as well as the proper crushing, crushing and drying of these raw materials. In this process, some traditional process methods, such as composting or aerobic fermentation, can also be used for organic fertilizer production.

However, for certain types of organic waste or raw materials, it may be more appropriate to use a fermentation dump machine. For raw materials that contain a lot of fiber, for example, flipping machines can help break up fiber clumps and promote microbial decomposition and fermentation processes.

In general, whether the production of organic fertilizer needs to use fermentation flipping machine mainly depends on the production scale, process selection and specific conditions. For small or home-scale organic fertilizer production, manual operation or simple mechanical mixing may be sufficient. However, for large-scale production, the use of fermentation toss machines can improve efficiency and ensure a uniform mix of raw materials.

0 notes

Text

Maximizing Waste Diversion: An Overview of Food Waste Compost Machines

The increasing focus on sustainability and waste reduction has led to the innovation of food waste compost machines, an essential technology for maximizing waste diversion. These machines serve a critical function in the recycling of kitchen scraps and leftovers into nutrient-rich compost, suitable for agricultural and horticultural use. This overview highlights how these compost machines operate, their benefits, and their role in waste management strategies.

1. Introduction to Food Waste Compost Machines

Food waste compost machines are designed to handle organic waste materials, particularly from kitchens, and transform them into compost. These devices range from small, household units to large-scale industrial machines. They are engineered to accelerate the decomposition process through controlled temperature, aeration, and moisture levels, effectively turning food waste into compost in a matter of hours or days, compared to weeks or months with traditional composting methods.

2. The Technology Behind Composting Machines

These composters utilize various technologies such as:

Aerobic Digestion: Introducing oxygen to speed up the breakdown of organic material by aerobic bacteria.

Anaerobic Digestion: Limiting oxygen to allow anaerobic bacteria to thrive and break down waste.

Bokashi Fermentation: Using an inoculated bran to ferment kitchen waste, including dairy and meats, before it's fully composted.

Vermicomposting: Employing worms to aid in the composting process.

Advanced models may also include features such as bio-filters to mitigate odors, automated turning for aeration, and easy-to-use interfaces for monitoring progress.

3. Environmental Benefits of Food Waste Composting

Reduced Landfill Reliance: By diverting food waste from landfills, these machines minimize the production of methane gas, a significant contributor to climate change.

Recycling of Nutrients: The compost produced returns valuable nutrients to the soil, promoting the growth of healthier plants and reducing the need for chemical fertilizers.

Water Conservation: Compost has excellent water-retention properties, reducing the need for frequent irrigation and conserving water resources.

4. The Role in Waste Management

Food waste compost machines are an integral component of waste management for:

Homes: Encouraging homeowners to take responsibility for their waste.

Businesses: Helping companies, especially in the food industry, to manage their organic waste efficiently.

Municipalities: Supporting local governments in achieving sustainability targets.

5. Cost and Economic Implications

While there's an upfront cost to acquiring a compost machine, the long-term savings can be substantial:

Reduction in Waste Disposal Fees: Less food waste means lower costs for waste collection and disposal.

Production of Compost: The end-product can reduce or eliminate the need to purchase commercial soil amendments.

Green Branding: Businesses using compost machines can enhance their brand's appeal to environmentally conscious consumers.

6. Considerations for Implementation

Before investing in a food waste compost machine, several factors should be considered:

Scale: The size of the machine should match the volume of waste produced.

Type of Waste: Different machines handle various types of food waste, so select one that fits your waste profile.

Location: Some machines are designed for indoor use, while others are more suited to an outdoor setting.

7. The Future of Food Waste Composting

Innovation in composting technology is ongoing, with new designs and methods constantly emerging. The future may see smart compost machines integrated with IoT technology for remote monitoring and control, making them even more user-friendly and efficient.

Conclusion

Food waste compost machines play a pivotal role in our growing commitment to sustainable waste management. They not only aid in diverting waste from landfills but also contribute to the restoration and maintenance of soil health. For households, businesses, and communities looking to reduce their environmental footprint, these compost machines offer a practical and impactful solution. By embracing this technology, we take a significant step towards a more sustainable and resource-efficient future.

0 notes

Text

Bio-plastic Industry's Surge: US$ 1,353.3 Billion Target by 2033

The global bio-plastic industry is anticipated to reach a valuation of US$ 96.6 billion in 2023, driven by consumer education and awareness. The trend is likely to open up new prospects for the market, resulting in a projected CAGR of 30.2% between 2023 and 2033, with a total valuation of over US$ 1,353.3 billion by 2033.

The reduction of greenhouse gas emissions is one of the primary factors driving the growth of the bio-plastic market. Bio-plastics have a lower carbon footprint than ordinary plastics, which helps to cut greenhouse gas emissions and battle climate change.

Access Your Sample Report for Valuable Insights! https://www.futuremarketinsights.com/reports/sample/rep-gb–69

Bio-plastics are being used in novel packaging solutions, such as edible packaging, which can reduce food waste while also providing consumers with convenience. The automobile sector is looking into bio-plastics for interior and exterior components in order to reduce vehicle weight and increase fuel efficiency, which represents a substantial potential opportunity.

Biotechnology and genetic engineering advances are making it possible to produce bio-plastics from modified microbes and agricultural feedstocks, potentially boosting scalability and cost-effectiveness. Bio-plastics’ growth into a broader range of applications, such as 3D printing, electronics, and toys, broadens market potential.

The development of clear and widely accepted certification standards for bio-plastics can increase customer trust and enable business growth. Governments and organizations may offer economic incentives, such as subsidies or tax breaks, to encourage the use of bio-plastics and foster a circular economy.

Public-private collaborations and activities targeted at reducing plastic waste and promoting sustainable materials can help to establish an environment conducive to the emergence of bio-plastics. Scalability in bio-plastic manufacturing techniques such as fermentation and chemical synthesis can reduce production costs while increasing availability.

Because bio-plastics can be integrated into municipal composting systems, the demand for effective waste management solutions, particularly in metropolitan areas, may boost their adoption. Bio-plastics are being investigated as a sustainable alternative for numerous applications by the film industry, which includes the manufacturing of agricultural films and plastic wraps.

Advanced bio-plastic materials research, such as lignin-based and algae-based polymers, opens up possibilities for even more sustainable and diverse products. Consumers are actively looking for environmentally friendly products, which may fuel demand for bio-plastic packaging, disposable utensils, and other everyday items.

Key Takeaways from the Market Study

Global bio-plastic market was valued at US$ 74.2 billion by 2022-end.

From 2018 to 2022, the market demand expanded at a CAGR of 28.8%.

The market in China is expected to expand at a CAGR of 29.4% through 2033.

By material type, the PLA and PLA blends segment to expand at a CAGR of 30.1% through 2033.

From 2023 to 2033, bio-plastic market is expected to flourish at a CAGR of 30.2%.

By 2033, the market value of bio-plastic is expected to reach US$ 1,353.3 billion.

Collaborations between bio-plastic manufacturers and recycling facilities can help streamline the recycling and reuse of bio-plastics, enhancing their sustainability credentials, remarks an FMI analyst.

Competitive Landscape

Prominent players in the bio-plastic market are BASF SE, NatureWorks LLC, Toray Industries Inc, Evonik Industries, E. I. du Pont de Nemours and Company, DSM N.V, Arkema, Techno Polymer Co. Ltd, and RTP Company, among others.

Recent Developments:

In 2023, Danimer Scientific (US) announced the launch of its new bio-plastic product, Nodax PHA. Nodax PHA is a biodegradable bio-plastic that is made from renewable resources. The product is expected to be used in a variety of applications, including food packaging, single-use plastics, and agricultural products.

In 2022, ADM (US) announced the launch of its new bio-plastic product, Enviva PLA. Enviva PLA is a biodegradable bio-plastic that is made from renewable resources.

In the same year, Novamont (Italy) announced the expansion of its production capacity for bio-plastic at its plant in Italy. The expansion is expected to meet the growing demand for bio-plastic in Europe and other regions.

More Valuable Insights Available

Future Market Insights offers an unbiased analysis of the global bio-plastic market, providing historical data for 2018 to 2022 and forecast statistics from 2023 to 2033.

To understand opportunities in the bio-plastic market, the market is segmented on the basis of material type (bio-PET, bio-PE, bio-PA, bio-degradable polyesters, PLA & PLA blends, starch blends, PHA, and others ), and applications (bottle, packaging, food-services, agriculture/horticulture, consumer products, and automotive), across seven major regions (North America, Latin America, Western Europe, Eastern Europe, South Asia & Pacific, East Asia, and Middle East & Africa (MEA)).

The chemicals & materials team at Future Market Insights offers expert analysis, time-efficient research, and strategic recommendations with the objective to provide authentic insights and accurate results to help clients worldwide. With a repertoire of over 100+ reports and 1 Million+ data points, the team has been analyzing the industry lucidly in 50+ countries for over a decade. The team provides a brief analysis on key trends including competitive landscape, profit margin, and research development efforts.

0 notes

Text

The Art of Brewing: A Guide to Making the Perfect Cup of Tea with Tea Bags

When it comes to a hot cup of comfort, nothing quite compares to the soothing embrace of a perfectly brewed tea. New Zealanders have a particular affinity for tea, the soothing aroma of a freshly brewed cup of tea is enough to brighten even the dreariest of days. And in the modern world, where convenience often takes precedence, tea bags have become the go-to choice for many tea lovers. But why choose tea bags over loose leaf teas? In this blog post we’ll discuss the tea bag universe, and the best tea bags to try from three of New Zealand’s most renowned loose leaf and tea bag brands - T Leaf T, Harney & Sons, and Tea Total. So, steep yourself in knowledge as we embark on this tea-rrific journey into the world of tea bags.

The Tale of Tea Bags

1. The Rise of Tea Bags

Tea bags have an interesting history. Many people think they were invented in the early 20th century in the United States but there is evidence that as early as the 8th Century, during the Tang dynasty in China, folded and hand sewn square paper bags were being used to conserve teas. Today, tea bags are popular because of their convenience. They come in various shapes, sizes, and materials to cater to different tastes and preferences. They act as a simplified infuser, often on a string for easy removal.

2. Types of Tea Bags

a. Empty Tea Bags for Loose Tea: For the Creative Tea Enthusiast

If you're a purist who loves loose tea leaves but you crave the convenience of tea bags, you can always make your own. Fill empty tea bags with your favourite loose tea leaves, and voilà! You have the best of both worlds. Empty tea bags are a blessing for those who love to experiment with loose tea leaves. They allow you to create your unique blends and control the strength of your brew.

b. Best Tea Bags: T Leaf T, Harney & Sons, and Tea Total

Let's talk about the best tea bags available in New Zealand, starting with three renowned brands

c. T Leaf T

T Leaf T use pyramid tea bags, which include a tag and string. They are made from polylactic acid (PLA). The PLA material used by T Leaf T is derived from corn starch and does not contain any polypropylene. The tea bags are sealed using a transducer which applies pressure at an exact temperature - this cuts and seals each bag without the addition of any other materials. While compostable, PLA products generally take a number of months to degrade in a commercial composting facility. It is not known if the heat required can be achieved in home composting set-ups. Some of T Leaf T’s best teas are available in tea bags. Our picks for the top three best tea bags from T Leaf T are Jasmine Dragon Pearls, New Zealand Breakfast, and Honeyed Chamomile with New Zealand Kawakawa.

d. Harney & Sons

This US-based brand has made its mark worldwide, and its tea bags are no exception. They recently released a statement about their progress in transitioning away from nylon based tea bags. As at 14 June 2023 91.3% of their tea bags (Harney & Sons call them “sachets”) are now using a sugarcane based material. The list of teas that are not using the sugarcane material are:

1. Hot Cinnamon Spice, Decaf Hot Cinnamon Spice, Green Hot Cinnamon Spice, Herbal Hot Cinnamon Spice

2. Hot Apple Spice

3. Chamomile

4. Yellow & Blue

5. Peppermint

6. Organic Green w/ Citrus and Ginkgo

7. Organic Turmeric & Ginger

8. White Peach Matcha, Very Berry Matcha, Roasted Buckwheat Matcha

They have plans to convert the remaining products, but adaptation of machinery is required. The plant-based material Harney & Sons use comes from sugarcane grown in Thailand. The sugarcane is fermented and bacteria eats the fermented sugar making lactic acid which is converted into a fiber that creates the mesh that holds in the tea but allows the liquid tea to flow to you. So all sugar is converted and none remains in your sachets material, making it safe for diabetics and those concerned with sugar intake.

Our top picks for Harney & Sons products available in Tea Bags are English Breakfast Tea,Japanese Sencha, and Paris Tea

e. Tea Total

Tea Total, is truly a Kiwi tea brand. Based in Auckland, is a haven for tea lovers. Their tea bags come in various flavours, and their commitment to organic teas is commendable. Explore their offerings to enjoy the pure, unadulterated taste of tea. Tea Total’s tea bags are made of NON-GMO sugarcane bioplastic which is biodegradable and industrially compostable. They are safe for brewing and sealed using heat, not glue.

Tea Total uses pyramid shaped tea bags because this allows them to provide the same quality of tea they use for their loose-leaf teas (unlike many tea bags that use a lesser grade as it’s easy to disguise in tea bags).

3. Organic Tea Bags: Sip with a Clear Conscience

Organic tea bags are gaining popularity due to their eco-friendly and health-conscious appeal. Brands like T Leaf T and Tea Total offer organic options that are free from harmful pesticides and chemicals. By choosing organic tea bags, you're not only benefiting your health but also supporting sustainable farming practices.

4. Plastic vs. Paper: The Tea Bag Material Dilemma

The material of your tea bag matters. While traditional paper tea bags are biodegradable, some tea bags contain plastic elements that may not break down as easily. Brands like Harney & Sons are moving towards plastic-free tea bags to reduce their environmental footprint, while Tea Total and T Leaf T are arguably already there.

5. Tea Bag Packaging: Aesthetics and Functionality

Tea bag packaging not only keeps your tea fresh but also adds to the overall experience. Many brands, including Harney & Sons, invest in elegant and practical packaging that enhances the pleasure of tea drinking. Tea Total say they use pyramid shaped tea bags so they don’t have to skimp on the quality of their teas just because they are provided in a tea bag.

6. Bulk Tea Bags: For the Avid Tea Drinker

If you're a frequent tea drinker, buying in bulk can save you money and reduce packaging waste. Look out for bulk options from Tea Total and other brands to keep your tea stash well-stocked.

7. Metal Tea Bags: A Reusable Alternative

For those who want to avoid disposable tea bags altogether, metal tea bags are a sustainable option. They are designed for multiple uses and allow you to enjoy loose tea without the waste.

8. Best Tea Bag Brands: The Final Sip

In the world of tea bags, quality matters. Each of the brands mentioned - T Leaf T, Harney & Sons, and Tea Total - has carved a niche for itself by delivering exceptional tea experiences. Choose your favourite and let your taste buds embark on a delightful journey.

9. Used Tea Bags: Beyond the Brew

Don't discard your used tea bags just yet. They have some surprising uses beyond brewing a second cup of tea. From natural skincare to cleaning solutions, used tea bags are versatile household allies.

10. Large Tea Bags: Brewing for a Crowd

Sometimes, a regular-sized tea bag just won't cut it. Large tea bags are perfect for brewing a pot of tea to share with friends or enjoy on your own when you need a little extra comfort.

11. Tagless Tea Bags: Simplicity in Brewing

Tagless tea bags are designed for those who prefer a fuss-free tea experience. No tags, no strings, just pure tea enjoyment.

Sip Your Way to Tea Bag Bliss

In the world of tea, the convenience and variety offered by tea bags are hard to beat. Whether you're exploring the rich, traditional flavours of T Leaf T, the global offerings of Harney & Sons, or the organic delights of Tea Total, there's a tea bag for every tea lover in New Zealand.

Remember to choose eco-friendly options when possible, and consider trying empty tea bags for a more personalised tea experience. Explore the diverse range of tea bags available at floweringherb.com to elevate your tea-drinking ritual.

So, go ahead, brew a cup of your favourite tea, and let the comforting warmth of your chosen blend embrace your senses. Cheers to the world of tea bags and the endless possibilities they bring to your tea journey.

Disclaimer: The information provided by The Flowering Herb is intended as general information for entertainment purposes only. We are not healthcare providers and we do not hold any healthcare qualification.

The content contained on this site is in no way intended as medical advice or as a substitute for medical treatment and we are not making any recommendations for your personal situation. We therefore strongly recommend and encourage you to consult with your primary health practitioner prior to making any changes to your diet/consumption habits or purchasing any of our products with the intent of manage any health condition.

Source: Perfect Cup of Tea with Tea Bags

0 notes

Text

In modern agriculture, large-scale composting production has become an important means to improve soil fertility and promote sustainable agricultural development. In this green revolution, the compost turning machine has become an indispensable equipment in the compost fermentation process with its unique advantages. So, why do we use a flip machine for large-scale composting? Let's unravel the mystery of it.

First, the Turning Machine, especially the Windrow Compost Turning Machine, ensures an even distribution of oxygen during the composting process through its powerful turning capacity. In large-scale composting production, the volume of the material pile is huge, and if the lack of effective turning, the internal anaerobic environment is easy to form, affecting the microbial activity and reducing the fermentation efficiency.

The use of flipping machine not only solves this problem, but also promotes the uniform propagation of microorganisms, accelerates the decomposition and transformation of organic matter, and lays a solid foundation for the production of high-quality organic fertilizer. Naturally, this is closely related to the Organic Fertilizer Production Line, because high-quality compost is a prerequisite for subsequent granulation, screening and other processes.

Secondly, the turning machine also helps to regulate the humidity and temperature of the compost. In the early stage of compost fermentation, the material humidity is high and the temperature rises rapidly. Regular operation of the tilting machine can effectively reduce the temperature of the pile, prevent excessive evaporation of water, and maintain a suitable fermentation environment. With the deepening of the fermentation process, the tilting machine can also mix the partially decomposed material in the outer layer with the insufficiently fermented material inside to further improve the uniformity of fermentation. This process, echoing the working principle of the Disc Granulator or Rotary Drum Granulator in the Fertilizer Granulating Production Line, both emphasize the importance of material uniformity to the quality of the finished product.

Moreover, the use of the turning machine has greatly improved the efficiency and automation level of composting production. Compared with the traditional manual turning method, the turning machine not only saves the labor cost, but also reduces the influence of human factors on the quality of compost. Especially when dealing with a large amount of organic waste, such as urban sludge, agricultural straw, etc., the application of the rollover machine is indispensable. It not only speeds up the conversion of waste to Fertilizer, but also provides a reliable guarantee for the production of Organic-Inorganic Fertilizer Compound Fertilizer.

Finally, it is worth noting that the selection and operation of the rollover machine also need to be adjusted according to the characteristics of the compost raw materials, production scale and expected objectives. Whether it is a bar type, wheel type or large wheel disk overturning machine, it has its applicable scenes and advantages. The correct selection and rational use of turning machine will bring greater economic and ecological benefits for large-scale composting production.

In summary, the use of large-scale composting machine is not only an inevitable choice to improve fermentation efficiency and ensure fertilizer quality, but also an important measure to promote the green transformation of agriculture and achieve sustainable development. In the future development of agriculture, the turning machine will continue to play its irreplaceable role, leading the composting production to a more efficient and environmentally friendly new chapter.

#Windrow Compost Turning Machine#Organic Fertilizer Production Line#Disc Granulator#Rotary Drum Granulator

0 notes

Text

The daily maintenance method of Organic Fertilizer equipment is particularly important, because once we do not operate at will according to precautions, even a small failure may cause big problems in production and use, and ultimately affect production.

First of all, let’s understand the Organic Fertilizer equipment process

It is mainly divided into the following two parts: Organic Fertilizer Compost Turning Machine, Compost Crusher, Rotary Screening Machine, And the Organic Fertilizer Granulator, Disc Granulator, Rotary Drum Granulator, Fertilizer Granules Compaction Machine, Rotary Dryer Machine, Rotary Cooler Machine, grading screen, Powder/Granules Fertilizer Packing Machine, and Belt Conveyor in the middle link.

Secondly, since we want to understand the daily maintenance methods of Organic Fertilizer fermentation equipment – ground Compost Turning Machine, let me briefly introduce the following two commonly used Compost Turning Machine types:

One, Wheel Type Windrow Compost Turning Machine is a special machine used to produce Organic Fertilizer and turn over viscous materials such as animal manure, sludge, distiller’s lees and furfural using strip compost fermentation process. The power is diesel engine. The stacking width of the material is 2 meters, the stacking height is about 0.8 meters, and the maximum processing capacity is 380m³/h. This machine can not only turn and gather the material evenly, but also effectively loosen the clumps in the fertilizer base after fermentation. It is an indispensable machine for harmless treatment of livestock and poultry manure and fertilizer making operations. Two, the use of Windrow Compost Turning Machine is very common, and it is a special machine for turning, crushing, oxygen supply and stacking of materials. This machine is mainly composed of four parts: turning auger power part, walking power part, hydraulic lifting part, control part.

The ground-type Compost Turning Machine produced by Zhengzhou Huaqiang Heavy Industry is designed according to the principle of aerobic fermentation, so that the fermentation bacteria have the space to give full play to their functions. Its machinery and equipment has the obvious advantages of less investment, low energy consumption, fast fertilizer production, and large output, saving a lot of civil construction and human and material resources.

Finally, let Xiaobian focus on the maintenance and maintenance of Compost Turning Machine

1.Com Maintenance and maintenance of post Turning Machine Daily maintenance:

The Compost Turning Machine should be maintained once a week when it is not often operated, and the Compost Turning Machine should be maintained once a day when it is often operated. Its maintenance content:

(1) Half maintenance inspection (after 10 hours of work), check whether the connection bolts, nuts and oil drain plugs are loose.

(2) Check all parts of the latch, cotter pin for defects, and timely replacement (cotter pin shall not be replaced with other things).

(3) Check whether the tilting knife is defective and whether the fastening bolts are loose, and if necessary, fill, tighten or replace the new knife.

(4) Check whether the electrical joints are tight, whether the insulation of the wire is good, and repair or replace it in time if necessary.

(5) Check whether the fastening screws of diesel engine, gearbox, bearing seat and other components are loose.

(6) Clean the bonded attachments on the Compost Turning Machine.

(7) Check the surplus of the fuel tank and water tank.

(8) Wheel Type Windrow Compost Turning Machine Should also pay attention to whether the tire pressure is normal.

2.Compost Turning Machine maintenance and maintenance Compost Turning Machine regular maintenance

(1) After working for a season, replace the gear oil of the reducer, check the bearings of all parts, apply new butter after disassembling and cleaning, and install it. If the wear is serious, it should be replaced.

(2) Remove the dust cover on the equipment, check and tighten the bolts on each transmission rod. Prevent the bolts on the transmission rod from loosening, resulting in the parts not being driven in place and causing the parts to wear and scrap.

(3) Remove the cab seat and cover plate under the seat and check to tighten the bolts on the drive shaft. Prevent the shaft body from being inclined and broken due to the loosening of the bolts on the drive shaft seat.

(4) Antifreeze should be added to the water tank when used in winter. If no antifreeze is added, warm water should be added to the water tank, body and cooler before operation, and the water in the water tank, body and cooler should be discharged after operation to prevent freezing.

(5) Check whether the electrical appliance is working normally, whether the circuit insulation performance is good, and replace the connected wire if necessary.

(6) It is necessary to regularly check the tension of the drive belt, adjust the tension if necessary, and check whether the belt is broken, worn or has other signs of aging, and replace the belt if necessary. Check the belt path and make sure there is no obstruction between the other parts of the engine and the belt. After replacing the belt, the new belt should be re-adjusted after two or three weeks of use to eliminate slack.

(7) When Compost Turning Machine is operated for a long time, the exposed parts should be coated with oil to prevent rust, and should be covered when placed outdoors.

3.Compost Turning Machine maintenance and maintenance of important components of compost Turning Machine

(1) Diesel engine maintenance and maintenance please follow the diesel engine manufacturer’s operating instructions for maintenance and maintenance.

(2) The maintenance of the car air conditioner (if equipped) see the operation and maintenance manual of the air conditioner.

(3) Compost Turning Machine battery maintenance:

Make the battery firmly fixed.

Terminals and connecting parts should be kept clean and firm.

If Compost Turning Machine starts frequently for a short time, the battery may not be supplemented by the electric energy on the generator. Please check the battery memory power frequently and charge the battery in time to prevent the battery from being scrapped due to power loss.

If the vehicle is not used for a long time, the battery wiring should be separated.