#foundry chemicals

Link

Visit the website more information

#industrial oils & lubricants#frp raw material#foundry chemicals#Surface Preparation Abrasives#industrial-paints-suppliers-pune-kolhapur

0 notes

Text

From clanging chaos to metal marvels

https://videos.pond5.com/forging-future-industrial-process-hot-footage-249666620_main_xxl.mp4

Imagine a whirlwind of steel, where clanging metal, hammering strikes, and machinery’s hum weave an industrial symphony. This isn’t just any workshop; it’s a stage where skilled hands transform raw materials into marvels of modern engineering.

Our video takes you on a captivating journey, revealing the…

View On WordPress

#aluminium#burning#can factory#chemical#energy#fireplace#flame#foundry#furnace#Goshashka#heat#hot#industry#machinery#manufacturing#metal#Motion#petrochemical#process#production#steel

0 notes

Text

SINYE engineers at foundry site.

#engineer#foundry2022#castingmaterial#foundry#castingresin#chemicalindustry#foundrymaterials#chemicalmanufacturing#companyactivity#castingmaterials#chemical industry#chemical manufacturer#socialactivity

0 notes

Link

Airpoll Techno is recognizance by manufacturing and trading highly demanded Foundary Wet Scrubber. Our offered wet scrubbers are second to none in treating chemicals, hazardous particulate and sulfuric acids. Developed with a quality compliant scrubbing vessel and high performing pumping system, the offered scrubbers feature premium grade steel construction.

#Foundry Wet Scrubbers Manufacturer in India#Foundry Wet Scrubbers Manufacturer#Foundry Wet Scrubbers Manufacturer for Chemical Industry#Wet Scrubbers Manufacturer in India

0 notes

Text

More Factorio speculation!

Vulcanus's metallurgic science introduces the Foundry, a sort of super-smelter that can make metal plates, gears, wire, etc with an inherent +50% production bonus and five module slots.

Fulgora's electromagnetic science introduces the Electromagnetic Plant, a sort of specialized assembler that can make circuits, electrical equipment, modules, etc with an inherent +50% production bonus and five module slots.

I expect that a building like that will be present on every planet in the Space Age expansion. So what's left?

The only big category of resources that isn't touched by either the electromagnetic plant or foundry is oil/chemical stuff; plastic, sulfur, lubricant, fuel, etc. So I feel confident that the third planet's special building will be some kind of enhanced chemical plant.

Which probably means we'll be getting a novel oil processing process on planet #3. Maybe the reverse of what Fulgora's oil sands have? Something that makes heavy oil important for more things than lubricant, some resource type that gives lots of petroleum gas, and a reverse cracking recipe?

If that's true, maybe planet #3 will be something like Titan, or like Titan crossed with Europa. A barren world, cold enough that ethylene condenses into pools on the surface.

But that's just a guess built on a foundation of more guesses. It could be something completely different, like a planet whose industry focuses on weapon stuff or uranium processing or something.

We'll find out eventually. We found out about Vulcanus three months ago, and Wube estimated a release date "about a year" after almost exactly six months from now. So I'm guessing we'll see a FFF about planet #3 some time around late May, and the final frontier either right before or right after the August release. Or at least, that's what I'm guessing Wube has scheduled; time will tell whether that works out!

While I'm here I'm guessing the final planet's Special Building is either some kind of super-rocket-silo, or a way to use science packs for purposes other than science. I think it would make sense for some of the last (non-infinite) technologies unlocked to be things that make linking planets together easier—a way to get resources from planetside to space platforms more easily, or upgrades for space platforms, or maybe something wild like interplanetary teleportation.

16 notes

·

View notes

Text

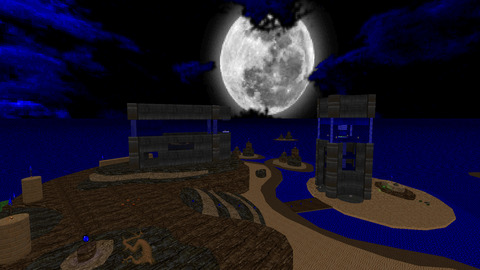

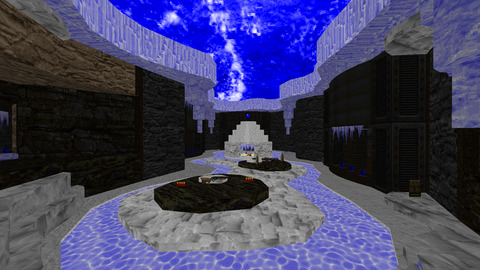

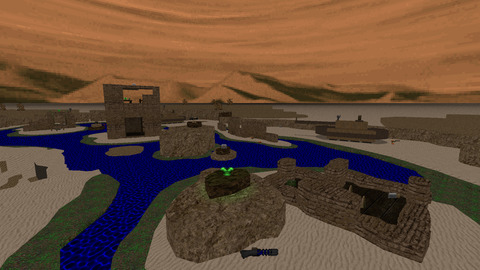

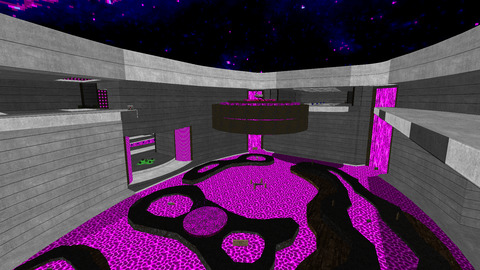

"Frantik DM 3 is a 32-map deathmatch pack that is primarily FFA focused.

I aimed for 3-6 player FFA style gameplay, but duels work just fine in this pack also. The maps are slightly larger, and much more detailed on average than those found in the previous set, Frantik DM 2.

DoomCute was also focused on heavily - as well as creating more realistic spaces. A lot of 'advanced' features are utilized in this pack, such as 3D floors, sector-linked 3D floors, slopes, jump-pads, ACS ladders, swimmable water and no-stop teleporters.

This large 32 map DM pack is split into 7 themed episodes.

I aimed for a very diverse selection of arenas, both gameplay-wise and aesthetics-wise - the locations include:

A forge, a foundry, an igloo, a froze over lake w/ ice-fishing, a winterized re-make of Frantik DM 1's MAP27, a frozen basin, a jungle w/ tree canopy, a remote island, a swamp w/ a decaying boardwalk, a watering hole in the desert, a subterranean cave system, a giant generator, a bunker, a rundown UAC-owned factory, a hydroelectric dam, a large prison, acid-melted bases, a nukage waste refinery, a chemical production lab, a nuclear reactor, a cursed crypt, a graveyard, a besieged hellish castle, and a hell-corrupted gory base - as well as a futuristic techbase w/ an alien UFO."

#doom#classic doom#id software#someone else's content#doom modding#modding#map or mapset#multiplayer

6 notes

·

View notes

Text

nidus maggot theory 2, part 1 here. Branches off this theory

The following theory is based on the presumption that Nidus utilises parthenogenesis (a form of asexual reproduction) to produce Ravenous maggots. There are mentions of typically female anatomy when referring to the masculine frame in question, as well as inferences to miscarriage and other complications of pregnancy. Proceed at your own discretion.

Anyone familiar with Nidus’ abilities knows he can summon a bunch of lil exploding maggots as a method of crowd control. It takes 3 mutation stacks to activate one instance of Ravenous (9 maggots). Looking at how Nidus gains stacks, we can guess it's possibly nutrition absorbed with his abilities.

Presuming the maggots are little underdeveloped clones of Nidus, they could develop in a sort of “womb”. Initially I imagined the maggots grew in any spare cavity within Nidus, and escaped out the open flared stacks. However the general morphology of Nidus is.. a lil scrungly once he's flaring up, possibly exposing the maggots before they're ready to attack (maybe an explosive risk to Nidus). With a womb that is flexible and can shift with Nidus’ mutating body, this can keep the maggots safe until deployment.

For example, in some species (such as dogs) the uterus is actually more intestine-like in shape. In this case, the womb is called a uterine horn.

Maybe 3 mutation stacks are needed to quickly develop a uterine horn with 9 notches for each maggot.

This is not to say Nidus develops uterine horns when he obtains stacks, but he chooses to consume them when creating the horn. As stacks are used for the Parasitic Link too, the Link is probably a malformed umbilical cord. With control over the Infestation Nidus can control if it's just to redirect damage and chemicals like cortisol, or to share positive chemicals between it.

I think for a Nidus that actually wants to raise maggots, forcibly expelling mutations is extremely draining on their body. It may be a new womb every time but having to regenerate that while juggling between feeding and fighting must be so stressful. Linking can help with the strain and give Nidus more strength but it's never long term.

If a Nidus has actually carried maggots full term, and is captured and forced to use underdeveloped maggots offensively, it could greatly traumatise them.

Without routine maintenance done by Tenno foundry and arsenals, if a Nidus is continually forced to expel maggots it may cause a buildup of internal scarring, higher pain tolerance and fatigue, as well as a constant state of depression and aggression from erratic hormonal shifts. These symptoms and damage can be reversed with regular lobotomies to the infested brain, surgical removal of scar tissue, and more stims and energy restores.

A healthy, feral Nidus is one that can grow uterine horns with no worry of conflict or energy starvation during the gestation. A Nidus carrying can continue to provide enough energy for themselves and their maggots if they have another Nidus go hunting for stacks, and sharing a Link between them. Though Nidus can create viable maggots without another progenitor, there is a preference to pair bond with any other feral Nidus diversity and the aforementioned beneficial relationship.

The maggots grown during this time will have enough information for the “blueprint” to impart on their human host when ready to metamorphosise into a new Warframe. The survival rate of a viable maggot is very low, hence Nidus’ high count for clutches and spontaneous uterine horn production.

5 notes

·

View notes

Text

ok so last week i wrote factorio dlc predictions and then the FFF wasn't about the dlc so here they are now.

some of these predictions are maybe too spicy or maybe too specific. this is on purpose.

these are based on some level of cynicism because the new sciences are the colors of the SE sciences and there is some thematic overlap between SA orange metallurgy and SE orange materials science.

i think the other two non-finale planet themes are going to be electronics/crafting and (bio?)chemistry based on both this and the fact that low density structure is made in the foundry "to make there be easier ways of getting rocket parts." and the RCU/blue chip and rocket fuel fit those themes. (it's not clear whether blue chips are replacing RCUs in the base game or just the dlc.)

also in the bz server i said that this promo image displayed one machine from each of the non-finale planets and the blue electric thingy will come from the dusty planet. the green thing looks like some kind of growth vat or chemical reactor so that fits as well.

5 notes

·

View notes

Text

On the Slow Train Passing Through

Here's Moody Furniture and the town of Moody. Also the display

for Temple Chemicals, a wire fence, some rubble and bare ground.

Privy to this endless street along the tracks, I watch

ongoing traffic move around something in the road.

It's a man on the center line lying on his back;

a woman bending down to touch him.

The cars move on. The train slides past.

And yet, in Roanoke, Virginia, in 190, when grandma's

house was on fire, the passing trolley stopped and everyone

got off and ran up the hill to help, even though there was no easy

water.

Three members of a Baptist choir endangered their whiskers,

their business attires, their waistcoats and themselves, to carry

out grandma's organ and her cherry sitting room furniture.

Although the upstairs burned through the roof and my mother's

new treadle sewing machine and her new tailored suit were

among the traumatic losses; they all did what they could.

It was the dignity of a communal disaster. No one was going

anywhere more important that that. The trolley horse had been

unhitched and loosely tethered to graze and eventually they heard

the far off sound of the approaching fire brigade. Meanwhile,

grandpa had been fetched from the foundry. Afterward, those women

who had done all they could to save my grandma's belongings,

total strangers, each in her own way commiserated with grandma.

The men washed at the pump and they all walked down the hill.

The conductor hitched up the trolley and they went on with their

regular day.

— Ruth Stone, In the Next Galaxy (2002)

#On the Slow Train Passing Through#Ruth Stone#In the Next Galaxy#poetry#writing#literature#poets on tumblr

2 notes

·

View notes

Text

Calcium Carbonate

LimeStone Granules ( Feed )

LimeStone Lumps ( Calcite )

Silica Sand ( Glass )

Foundry Sand

Frac Sand ( Proppant Sand )

Silica Flour ( Quartz Powder )

Cullet ( Broken Glass )

Glass Powder ( Cullet Flour )

Rock Gypsum

Agriculture Gypsum

Gypsum Plaster ( POP - Plaster of Paris )

Poultry Meal

Rock Phosphate

Quick Lime

Hydrated Lime

Bentonite

Barite

#calcium carbonate#raw materials#foundry sand#silica sand#limestone#Cullet#Poultry_Meal#$Silica_Sand

2 notes

·

View notes

Text

The Tea Girl's Gambit, Chapter Five

My legs were hurrying me to class but my head was a-swirl with confusion, shame and, unmistakably...envy. Not just shame at the envy, which was familiar in the way a toothache is familiar, but also shame at having been actually, actually seen committing the envy. I was reeling with the peculiar sense of having been recognized. My depths measured and plumbed and somehow known. It was terrifying. My heart was smashing frantically around like a bird trapped behind glass.

I turned down a rarely used servant’s passage, leaned against the wall and slumped down to sitting. I heaved a deep breath. I was over-reacting. There was no way that girl could actually know anything about me, right? I was fairly sure there hadn’t been any spellcraft involved. She had just looked at me.

I shook my head, bemused. Why had she looked at me? Nobody else did. People’s attention slipped off me like oil slipped off of water and I liked it that way. It was safe.

My heart was slowing down. There was no way she could have known what I was thinking when I saw her. I had never spoken my secret to another soul other than Kisma, never written it down. I knew the consequences of my yearning, even as a quiet child among the older, rougher kids of Stuhkrad.

The adults of the town hadn’t liked to talk about the small, moss-covered statues scattered in the forests and ravines around the milltown, but the older kids couldn’t gossip enough about their mingled, hybrid bodies. The town children called them kuffa. Most of them had been smashed and buried by the Imperial settlers when they’d driven out the native forest people a generation ago.

But once, exploring in the woods beyond the clear-cuts with my brother Carame and his friends, we’d found a narrow cave and slipped inside. I would have faltered, but Carame was fearless and his courage was like a drug to me. One of the boys had swiped a chemical light-stick from the Foundry. He broke it with a hiss and a sizzle of reagents mixing and the darkness flooded with brassy, white light.

I remembered the rich, earthy reds and browns and yellows of the little shrine. I remembered the little pots of unguents, the glittering quartz, the figurines and the swell of their breasts and their cocks. I remembered the older boys shouting with glee as they smashed everything and urinated on it. I remembered Carame pausing in the frenzy to turn and look at where I stood frozen against the wall, his face deep in shadow, unreadable.

I took a sharp breath and staggered to my feet, pushing down the razor-edged feeling in my throat. I was late to alchemy class.

I slipped into Advanced Principles while professor Yvell was still lecturing, my face numb and dry. I tried to concentrate but everything seemed very distant and hard to understand.

Memories continued to flood my head. The rattle of stones against brickwork around me as I ran from a gang of bullies, my whole back stinging, lungs burning. Every day, running after school. Hiding in the Foundry, a sprawling complex of workshops and labs that also contained the town’s singular, tiny, non-private library. The Foundry was Gresha’s domain, and I liked Gresha. She was a tall, stooped, squint-eyed and white-haired and gruffly kind. She gave off the smell of burnt leather and quenched iron.

Gresha was busy, because the Foundry fed the mill and the loggers with a constant supply of carefully machined new gears and cleats and plates and wheels to replace broken parts as well as chemical lights and waxes and lubricants and a hundred other things. All the same, Gresha let me read by the wood stove while she mixed powders or grumbled around in the next room, the whine of the lathe cutting on and off.

She had other staff doing piecework and delivering finished orders. Fenn had a big, calm face and limitless patience and I liked to watch his clever hands as he worked. He was mute, but he pointed carefully at each tool he used and re-positioned the light so I could see what he was doing with them. I watched him fix the boiler so many times that soon I began doing it in his stead, so he could finish his orders sooner and maybe have more time to bake a tasty treat for everyone.

Heather was a brisk, no-nonsense, ruddy-cheeked woman, Gresha’s lifelong ‘companion’, who had a sharp tongue for Gresha but a soft spot for me. She liked to rouse me from my reading nest of burlap bags by the stove to sweep or to chop onions, but always made sure I had a full belly.

The accredited town alchemist lived very handsomely in a whitestone house at the top of the hill and charged customers dearly. Gresha wasn’t officially an alchemist, had certainly never trained at a university, but she had a keen, methodical mind and she was brilliant at seeing what a thing might be able to do.

She casually nudged me towards certain books and when I came to her for more, she hmph-ed and her eyebrows, which were always growing back from being burnt off, climbed in the way they did when she tried something and it worked to her satisfaction. She asked me questions about the books—did the long-winded descriptions of how to render materials down to their basic underlying principles bore me? What about the chapter on crystalline liquids had I liked best? I found that I liked to impress her with my responses and quickly learned to see past the ways she tried to hide it.

Soon, she started dictating her notes while she was elbows deep in a project and had me scribe for her. She would look over my shoulder and poke at the page with a blunt finger and show me how, no, this is the abbreviation for sulfuric acid and that’s not how to copy a cipher correctly, try this, see? She began to check less and less often for mistakes, and I ate up the tiny signs of her satisfaction with glowing pride.

Carame had begun working in the mill and came home more and more hollow-eyed every night, ate, then slept and left again in the pre-dawn darkness. Without him to protect me, the everyday torture of school intensified and I got thrashed in the street and pelted with stones even more often. To give my bullies the slip, I began to spend more and more time at the Foundry and made fewer trips at odder hours to the shouting, crowded graybrick tenement that my older brothers and sisters and mother occupied.

My sister Kisma had started working nights at a bakery. I still risked visits to see her before her shift started and we slipped away to the roof among the flapping lines of laundry to smoke her halfpenny tobacco and giggle and watch sunset bands of pink and orange melt into the dark blue dusk. She told me about sneaking leftover dough out of work with her friends one night and stuffing it in the mouths of the vainglorious statues that lined the town square, so that all the pigeons came and ate it all and covered their strong chins and proud barrel chests with runny white streaks, so it looked, she laugh-snorted, “like they’d all been eating bird ass!”

I told her about when Gresha had set me to mixing up some bio-phosphate to dope an set of passive light emitters for the hanging walkways at the mill, I’d had some left over, and mixed the extra into the bowl of slop that Heather left at the Foundry door each night for the town’s stray cats. For a night, all the street cats of Stuhkrad had run around glowing neon blue and meowing their exasperation. Heather had such a fright she’d scolded me about it for a week.

“What! Eli! That was you?” Kisma sounded simultaneously amused and reproachful. “You’re lucky nobody started a witch-hunt. And how did you know the cats would be alright?!” She shook her head. “Maybe leave the pranks to your big sister, kid.”

My feet were hanging over the edge of the building. I kicked them, pouting. Truthfully, I wasn’t usually so daring and had only done the deed so I could impress my older sister, for once.

“I knew the cats would be alright! I did the factoring myself,” I mumbled sulkily. I knew Kisma didn’t really understand the stuff I was learning at the Foundry. But it still stung a bit, that she assumed I hadn’t known.

She raised her eyebrows at me. “You’re really smart, Eli. But you can also be really, really, really dumb, you know that?” She sighed. “Oh, I just worry about you sometimes.”

Truthfully, I was somewhat worried, too. All of my brothers were heading to the mill, or to be bargemen and cart drivers, and when I tried to imagine following them, of living that life, there was only a yawning, all-devouring blankness. I thought Gresha was training me to take her place, and at least that didn’t seem so bad. When she sat me down and told me in her gravelly voice that she was going to aim me at the Imperial merit exams, I spluttered and gaped, but in my belly a tiny circle of light opened. I could leave. I could get out.

I fed and grew that tiny light with long winter nights of obsessive reading and ciphering and memorizing tables and properties and principles until I closed my eyes to sleep and saw numbers dancing on my closed eyelids. I bent all my waking hours towards alchemy, which needed no inherited talent or gift of sorcery. I cut school and rarely went home and spent nearly all my time at the Foundry, working in the shop or studying. Lots of kids my age had already dropped out of the town school to work at the mill or on the steep slopes of the logging clear-cuts. It began to get safer for me to walk the narrow, cobbled streets without risking a beating.

Some nights, rubbing my booksore eyes, I thought guiltily of my sister Kisma sitting alone on the roof, again. But there was so, so much to do. I had seen her last week, hadn’t I? Or was that last fortnight?

And last spring, after four years of study, when the guarded wagons came to Stukrad with the merit tests locked inside, I watched them roll through the cobbled streets and up the hill biting the inside of my cheek so hard that my mouth filled with warm, metal-salty blood.

Two days later, I floated out of the testing hall, my shoulders tense and taut as lashed mill cables, my lip half-chewed through, my stomach a wreck, my eyes bloodshot, my hair a snarled bird’s nest, knowing I had demolished the test. I slept for two days on Gresha’s spare cot in one of the backrooms, waking only to piss and to drink the cold broth she’d left by my head. And cry. I hadn’t been able to cry since I was ten, but some blockage had crumbled, some rusty switch had finally slid into place inside me, and I bit Gresha’s pillow and shuddered with waves and waves of sobs that seemed to rise ceaselessly from someplace deep inside me.

Results from the exams took months to come back. In the meantime, I occupied my hands working for Gresha in the Foundry. I visited Kisma, who was getting married, and brought her a small blue dropper bottle of contraceptive—which I was ridiculously proud of, not least of all because any control by women over the reproductive power of the Democracy was frowned on by Imperial social hygienists. By teaching me how to make it, Gresha had clearly staked her trust in me. I found Carame, who was getting roaring drunk at the tavern with his mates, and brought him similar bottle but with a hangover cure in it instead. I didn’t visit Carame again.

When the results came, Heather insisted all four of us cluster around the scarred table in the kitchen before she even brought out the envelope. I tore it open, scanned it, then gasped and stumbled backwards and tripped over a chair. Heather grabbed the letter, squinted, whooped, and yanked me up and sank my head into her bosom. Gresha grunted, brought out a bottle of peach brandy and conferred upon me (when I had extracted myself from Heather) a sagacious nod. Fenn hefted a steaming, gold-crusted pie as large as wagon wheel out of the oven. I looked around at the three of them and tried to fix their faces in my memory. This is what I wanted to remember, when I thought of home. This good, glowing evening, surrounded by people who cared about me.

~ ~ ~

In the back of the lecture hall, I swallowed my emotions. My throat ached. I missed Heather, and Gresha and Fenn. Starting out at the University had been very lonely. I felt so out of place here. But hadn’t I felt so out of place in Stuhkrad, too? I woke up so many mornings full of relief that I wasn’t back there anymore, and that couldn’t be faked, right? Ididn’t think that I would ever willingly return, even though that probably made me a horrible person. I felt guilty about it, because it was ungrateful and disloyal to Gresha and Heather, Kisma and Fenn, and even Carame, wasn’t it? But when I thought of going back there, even to work with Gresha in the Foundry, I felt such a crushing suffocation. But why?

I had unpleasant memories, but so did everyone. Why did the thought of a life there, with the few and only people in the world who cared about me, fill me with a heavy and endless dread? Why did that life feel like it would be a living death?

My attention was yanked back to the lecture hall as Master Yvell finished a long, droning speech and the assembled students burst into enthusiastic applause. What was going on? Nobody applauded Yvell. Then I saw the sweep of his arm as he looked offstage and realized that he had been introducing someone.

She walked onto the lecture stage and I could only stare.

2 notes

·

View notes

Photo

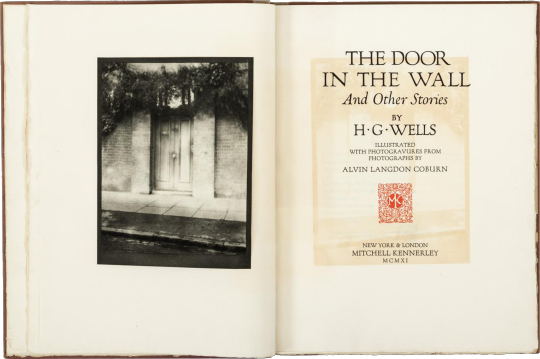

the door in the wall

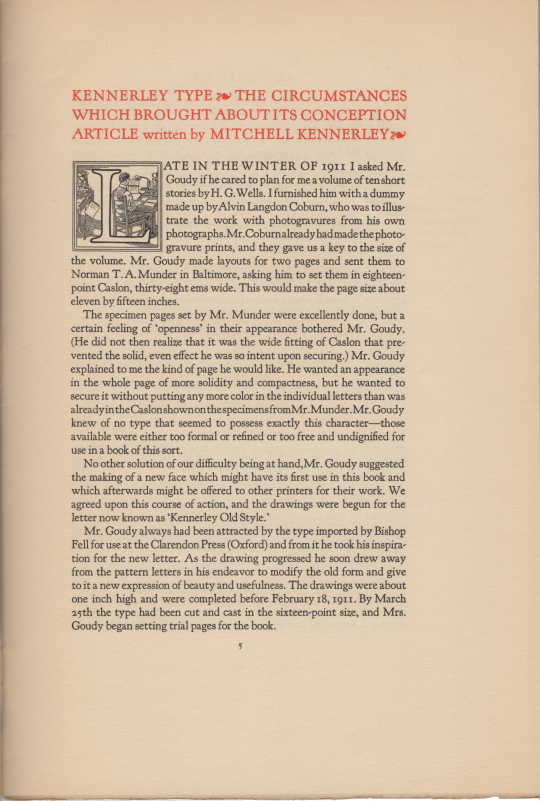

late in the winter of 1911, the english-born, nyc publisher mitchell kennerley asked his friend frederic goudy «if he cared to plan for me a volume of ten short stories by H.G. Wells.» [‘Kennerley Type, The circumstances which brought its Conception’, A Journal of Composing Room Efficiency, number 70, lanston monotype, philadelphia, 1924, p5.] matthew j. bruccoli relates: «The most typographically distinguished volume bearing Kennerley’s imprint appeared in 1911. The limited edition of H.G. Wells’s The Door in the Wall and Other Stories was proposed by Alvin Langdon Coburn as a vehicle for his photographs. Kennerley commissioned Goudy to design the book, and sample pages were printed in Caslon type by Norman T. A. Munder.» [matthew j. bruccoli, The Fortunes of Mitchell Kennerley, Bookman, hbj, 1986, p51.] bruccoli then quotes much of kennerley’s article from A Journal of Composing Room Efficiency [op. cit.].

goudy was not pleased with the type fit of the sample pages & suggested to kennerley the cutting of a new face, one that would set more tightly yet carry color as caslon. kennerley relates that goudy drew inspiration from oxford’s fell types [monotype, op. cit., p5.]; but to my eye goudy was looking at jenson (or the lettera antiche tonda of the scribes). clearly, kennerley is a 20th c. neo-venetian: canted stroke to the eye of e, serif, color, fit, canted hyphen; only, the cap-height has been brought into agreement with aldine norms.

«Goudy, who retained the rights to Kennerley, leased it to the Lanston Monotype Machine Co. [lanston monotype 268] and to the Caslon Type foundry in England. … Three days after completing Kennerley Old Style, Goudy designed an entirely new face for the title page & story titles of The Door in the Wall, inspired by the lettering in the Roman Forum and accordingly named Forum Title. [bruccoli, op. cit., p53.]

«Six hundred copies of The Door in the Wall were printed in November 1911; but publication was delayed by the spoilage of Coburn’s photogravures [photo-chemical engraving process, intaglio prints], which were to be inserted in [tipped in] the books. … Only three hundred copies were published with all ten illustrations.» [bruccoli, op. cit., p55.] of the three hundred copies not containing all ten photogravures some had at least one, but the complement was made up from aquatone prints—half-tone, relief process. [gleaned from book seller descriptions on the web, vide e.g. abebooks.com].

«As with many of the events in Kennerley’s career, it is impossible to be dogmatic about when Kennerley Old Style was actually first used in a book. The Door in the Wall is usually credited with this distinction, but it seems clear that Kennerley type was used to print 1911 books that appeared before the Wells volume. Kennerley stated that the first use of the type was in the four-page prospectus printed for The Door in the Wall.» [bruccol, op. cit., p53.]

some

settings in kennerley old style: ‹egg&dart›, ‹hommage à klaus›, ‹slender mark›.

#literature#photography#typography#h g wells#alvin langdon coburn#mitchell kennerley#frederic goudy#kennerley old style

2 notes

·

View notes

Text

We offer a range of industrial cleaning services – Ultra high-pressure (UHP) water jetting, Dry ice blasting + glass beads, Fin fan foam cleaning, and chemical cleaning to meet our customers’ requirements in different industries such as aerospace, oil & gas, automotive, food & packaging, foundry, medical, printing, marine, building & infrastructure, and more!

For more details about this service, drop us an email at [email protected] | visit us at petracarbon.com.sg

#engineering#industrial#cleaning#maintenancecare#water jets#dry ice blasting#solutions#services#oil and gas#marine#automotive

3 notes

·

View notes

Text

We Backyard Foundry

August, Tuesday, 23rd, 2022 the Museum of Making workshop team travelled to Artisan Foundry, Liverpool for a one-day course in greensand foundry practice, patternmaking and casting.

The course was taken by Art, an experienced foundry trainer and practitioner. The comprehensive course taught everything from sand moisture content and pre-moulding preparation, setting new and old patterns for moulding, ramming sand techniques, correct mould venting, sprue cutting, chemical additions to metal, heating and pouring hot aluminium and other metals such as bronze and gun metal.

Undertaking the course was preparation for commissioning the Museum of Making workshop crucible -- the final piece of equipment to be brought to life in the newly-opened museum workshop space. Post course, with the critical H&S and casting PPE regimes poured into our minds (aluminium melts at extremely high temperature) - the workshop is preparing to design courses and demonstrations in patternmaking, greensand moulding and metal casting.

Below is a selection of images in a quasi non-linear order featuring Steve, Arthur, Andy, and, of course, the mighty Art.

The green foundry student checking the ‘greensand’ which isn’t green but red. Green denotes it is damp and sticky with natural moisture and clay. Art left, Andy right.

A chicken doorstop casting repurposed as a ready-made pattern, moulded to make another slightly smaller chicken doorstop in aluminium - (all cast metal shrinks after casting, aluminium about 1mm for every 70mm 1/70 -- patternmakers use special calibrated ‘expanded’ contraction rules). Using the casting from an original pattern as the next pattern and then that cooled casting as the next pattern the chicken casting would, of course, eventually stop being there. Don’t copy copies then.

Art also runs a day course in lost wax casting. Lost wax casting as everyone knows is the oldest industrial casting process known to man. As a workshop, we will at some point be lost wax casting.

The Museum of Making is the keeper of hundreds of cast metal plaques, mostly railway related, which carry information in the form of cast text. With a crucible in workshop and the greensand training in place we intend to run courses wherein makers can create their own word signs using handmade or off-the-shelf white-metal or plastic letters, 3D text simply applied to a flat backboard.

Art is here applying a parting powder to a metal ingot pattern. A bit like talcum powder, it is kept in a traditional permeable muslin ‘pounce bag’ and the trick is to dust the pattern as if with icing sugar evenly. Parting powder stops the wet greensand sticking to the pattern and the mould sand tearing when the pattern is withdrawn after ramming. the sharpie circles denote where we are to cut riser and runner system.

We decided to cast a sign for Museum of Making workshop. The aluminium plaque pattern in the picture is ready-made and different sized letters and fonts and logos can be placed on the pattern to make varying bespoke castings. Bit Jamie Reid meets Fawlty Towers going on at this stage. The letters and logo are attached using Copydex latex glue which holds objects in place for moulding but can be pinged off - and glue residue piggled off - to clean up base pattern and let letters be used again.

Parting Powder mist

Art closing the two parts of a mould - known as ‘cope’ and ‘drag’. Cope is the upper box and has locating pins, drag the lower with accepting negative dowel holes or ‘eyes’. A mnemonic to use the moulding boxes in correct sequence is “eyes down”. You can see the down sprue and riser cut into the cope like two eyes in a strange Bruno Munari abstract face design. (Design as Art, Bruno Mari, 1966)

From this image you can see that the the ingot pattern is placed in the drag first, which is common. The pattern has no core box and is known as a shell pattern. The pattern makes its own cores which are extensions of the sand rammed up in the cope after the drag has been processed and turned over for the second-stage of sand moulding process. This ingot piece is also a good example of a ‘flat back pattern’, i.e., the pattern is placed flat on its back on a moulding board before sand is rammed (compacted) around it. * For a fuller description of different types of pattern equipment see Patternmaking Explained to Children - Steve Smith Museum of Making Tumblr).

Once a mould is completed and ‘closed up’ on its pins - and pattern of course withdrawn - the paired boxes are set on the floor ready for casting in the hot metal needed to make the required casting: iron, bronze, gunmetal or aluminium. The sprue and riser holes are then covered to prevent debris entering the mould before casting - usually a piece of wood is used. The ‘sprue’ is where the metal is poured in and the riser is usually diametrically opposite the pouring gate. The riser is there because the air within sealed mould must escape pushed out by the incoming stream of metal from the runner -- the riser also acts as a reservoir of metal and heat to feed the shrinking casting. When metal appears running up the riser to the top of the cope box the furnace pouring person realises the mould is full of hot metal and desists feeding the mould.

Art pointing out the particular sections of a ramming ‘dolly’. The tapered wedged section nearest to our instructor is designed to get into the tight corners a multiform pattern will present, the opposite flatter end - more mallet-like - is for when the pattern has been fully embedded in compacted sand and the rest of the void of the box is filled with backing greensand which provides the supporting structure of the fragile mould. Making these dollies in-house is easy and looks a good coproduction learning opportunity (how-to-turn-between-centres) for a Museum of Making volunteer. You Know who you are...

Greensand has to have just the right moisture and natural clay content to make it mouldable -- not too dense. thick sticky sand can prevent dangerous high-temperature chemical gases permeating through mould in the red-hot casting process. Here Art started to explain the properties the sand should have by demonstrating ‘by hand’ and in practice how right-damp sand should feel and behave under compression. At Ilkeston College, as apprentice patternmakers, we had to also complete City &Guilds Foundry Technology and Metallurgy examinations and empirical practice in college micro-foundry was essential. We used a closed flask - a bit like a cocktail shaker with a dial attached - to measure the moisture and chemical contents of greensand. If sand is too wet there can be gas-driven (steam powered) explosions - very dangerous - too dry and sand is friable, and casting will be a ‘scrapper-shitter’ filled with unwanted washed sand (inclusions) from decomposed mould.

Early stages of moulding: taking sand from Artisan Foundry under-bench greensand storage bin. The bin has a lid and a plastic membrane to retain moisture and keep out contaminating materials. Andy is here taking sand from the bin to start filling his wooden moulding box, the frame you can see on bench placed around the ‘Chicken Doorstop’ pattern. A sieve can be used to sift the sand that ‘faces’ against the pattern or - as here - you simply rub the sand through the palms of the hands feeling carefully to eradicate lumps and spot unwanted stones, even old cast metal amongst the essential fined-out stock material. Arthur has made a hybrid sand and moulding bench crossing Art’s bin with a foundry station he saw when a Derbyshire school D&T Technician for our workshop.

The WORKSHOP pattern is nested in the drag -’eyes down’ box - after ramming with wood dolly on moulding bench top. The welded metal moulding box has been carefully turned over and, before the cope box is located and the cope rammed to make the second section of the complete mould, excess parting powder applied to back of pattern and joint sand is removed with a pair of traditional bellows. This historical-but-still-used old-school air-making device is held away from box to avoid blasting the fragile sand with over-compressed air.

Art coached the Museum of Making team throughout our training visit to Artisan Foundry. Passing on relentless tips and dodges (’hacks’) - learnt through his own empirical practice as a jobbing foundry man and educator - in his thick scouse accent Art passed on priceless knowledge. The background has Arthur ‘sleeking off’ the top of the cope box with a moulders trowel. The next step is to then split the completed mould, withdraw the pattern and cut pouring sprues and risers, as well as vent the cope-section sand where necessary.

Small scale moulding boxes - in the sub-culture of the maverick ‘Background Foundry’ - can be made from simple homemade square section softwood. Not ideal foundry material, in all-ways, as the hot aluminium or (especially) iron can easily set alight the timber box; spot the combusted charred areas on the DIY ‘flasks’ in these images. To avoid this dramatic, though hazardous, outcome post moulding and before casting these boxes can be stripped from the sand blocks before pouring. Look closely and you can see the ‘loose-pinned’ butt hinges. Withdrawal of the thin wire pin ‘hand-grenade’ style releases the knuckle of the hinge and the box can be opened out away from sand. The box-less cope and drag can be reassembled - closed up as if with traditional moulding boxes - and the metal cast into what is termed in foundry jargon a ‘flaskless’ mould stack.

I trained at Stanton and Staveley Ironworks in Derbyshire 1977-1981. As part of our industrial education, we were exposed to the ‘real-life’ of Erewash Foundry. If you have never been inside a dark industrial dirty hot and dangerous foundry, it can seem like a kind of hell-on-earth scene. I recall monster bogeys of hot glowing spitting iron whizzing around the foundry (high in the air suspended from overhead moving cranes) glowing orange against the dark interior of the black sand-dirty foundry. In the late seventies none of the iron casting men or moulders - iron melts at 1200 degree centigrade - were equipped or supplied with regulation protective gear, except perhaps loose moulding boots which had a quick release fastening to allow leather ankle boots to be kicked off when spitted-out dangerous metal splashed inside the shoes and would burn through skin and bone until it came through the bottom of the foundry workers’ foot. Rather than wear thick fire-resistant smocks or leather aprons - as Andy is wearing here - hard Ilkeston men simply sported layers of thick wool jumpers which hopefully slowed down and cooled the ever-present flying spots of molten iron that peppered those pouring iron from oversized industrial ladles into equally oversized industrial-scale sand moulds before they hit skin. PPE advice was a topic Art majored on.

In the spirit of DIY renegade Backyard Foundrydom, Art had improvised a blast furnace from what looked like an old stainless steel camper-van oven and some square refractory bricks. The metal is heated by a propane-gas-bottle generated -flame through a hole in the contrived cupola to play on the small melt-crucible into which the raw aluminium has been placed. In this image Art is plunging a ‘de-gassing’ agent into the red-hot non-ferrous metal to chemically purify molten material before casting. A small section of a broken-up 50mm x 20mm round tablet (about the size of a walnut) is forced to the bottom of the hot melting metal until dissolved. The resulting dross (slag) is then skimmed of the surface of liquidised aluminium.

Empty moulding box awaiting pattern. In fact the dowel locating pins at the end of the fabricated-steel box indicate that this is the ‘cope’ top box. The cope pins are dropped through the receiving accurately-machined hardened-steel bushes on the base ‘drag’ box of the two-part mould which has already been rammed up with pattern in situ. Because the drag has no protruding pins the metal container which holds the green sand can be placed around the pattern on the same flat ramming board. As Art pointed out, and I pointed out above, a good aid to remembering that the drag is rammed-up first is the bingo catchphrase “eyes down”.

Here you can see the metal ‘shell pattern’ of the ingot mould bedded (post-ramming) in the drag which has been turned over ready to take the cope box and then filled with greensand compacted with the dolly so completing the two-part mould. The pattern is again dusted with parting powder as is the sand mould joint to avoid sand adherence to either surface. Facing sand is riddled onto the pattern for a finer cast finish before un-riddled sand is used to build up the back of the mould.

Sand is kept in a plastic bin covered with polythene and a tight-fitting lid to help sand remain damp and so clay-sticky for successful mould-making. Note the chalk X-X marks on both boxes. This is done to ensure mould is reassembled - post-pattern withdrawal, and pre-casting re-closing of mould - in correct position, i.e. closed in the same end-to-end ‘handed’ relation as the boxes were when rammed up.

Parting dust, like scotch mist, rising from earthy mould. (It takes your breath away.) Pretty sure in the heyday of Foundry life and Northern Soul ( early-mid1970s) them lad dancers - many of whom would’ve worked in Midland foundries-would have filched parting powder from work to save on the more infamous talcum powder sprinkled on floors of soul all-dayers and all-nighters. Art where you a Casino-Soul Star?

Andy drives the Dolly into the un-sieved greensand to ram up the cope section of mould, taking care to make sure sand is evenly rammed - but not over-rammed since over-compaction of sand leaves fewer micro apertures for hot gases and steam to rise through greensand created by hot metal poured into closed mould - Iron, Aluminium, Bronze, gun metal etcetera. (To allow gases to escape - which can blow cope and drag apart in large moulds - floor hand-moulders used/use a fine sharp rod of about 1.5mm diameter to pepper the sand above the pattern (but not hit the pattern) with vent channels. Art showed us this process using his pinched fingers holding the venting spike as a depth stop to create deep vents, but vents stopping above mould surface.

Cope and drag boxes rammed successfully, the boxes are split, pattern ‘rapped’ and lifted carefully from fragile surrounding sand revealing requisite negative impression of positive pattern into which hot molten metal will run after reclosing boxes.

Because this ingot mould is a two part mould in which the ‘cods’ or ‘cores’ which form the metal troughs of the finished ingot casting are ‘self left’ and so would ‘hang down’ if the standard Drag and Cope order had been followed, experienced Art inverted the order and so the cods are raised up from the sand by making the rammed up cope the drag. As in all forms of making there are general rules but no unbreakable ones. In making the cods stand or sit up in the mould this avoids potential situation in which unsupported cods would be suspended - merely held together and to the backing sand by moisture and sticky clay - and as such could snap off when inverted pre-casting. In Art’s right hand can be seen a short section of hollow metal pipe (Ikea wardrobe rail) he has just used, as can be seen in right aperture of mould, to bore a runner hole through the rammed sand to the top of the (upside down) cope. Hot metal will be poured (cast) through the runner - metal running downwards with gravitational forces - into the negative empty cavity of the pattern-formed ingot mould ready to shape liquid plastic metal.

Art boring out the riser through which the metal and air are expelled under diametric pressure from runner and elevated poring basin.

The runner we are to pour the metal down is approximately 20mm in diameter and exits the mould through the top of cope and is connected to underside of finished ingot casting. However, it is difficult to aim the viscous heated aluminium into such a constricted channel from an often cumbersome pouring flask. To aid filling the mould with metal and avoid hot aluminium running free and dangerously over the top of the glassy flat cope sand, down the side of the moulding box, onto the floor, potentially splashing casting-person’s boots - a pouring basin is made up with a wider tapering channel through which the hot metal can enter the narrow runner. The extra height also gives favourable downwards header pressure - like a water tank in a loft - to drive the immediately -cooling-now-unheated metal ‘faster’ into the mould and up the riser. This is often called a basin. The top reservoir of hot metal also aids the shrinkage of the casting. As the aluminium or iron cools down it dimensionally contracts, as I said. As it contracts against the cool sand of the damp mould it needs to be ‘fed’ with molten material. The basin then acts as a surplus tank supplying the hot-thirsty nascent casting with the metal feed it requires. Many larger castings require internal ‘feeders’ which are made to prevent shrinkage in a casting, which means a cast object becomes a failure or ‘scrapper’. As a first-year apprentice I was made to make feeder patterns for the first six months of my training as a patternmaker.

In the maverick spirit of the Back-yard Founder, Art has used an old pineapple ring tin as a flask for his pouring basin; the sprue cutters were crafted from truncated chrome Ikea wardrobe hanging rails.

Casting or moulding boxes don’t have to be heavy metal. This small flask has a removable pin and so the wood frame can be deconstructed and removed from sand mould leaving a ‘flask-less’ block of green or core sand that hot metal can be poured into. Working this way a backyard foundry can make multiple small moulds - and thus cast artefacts - from a single pattern and moulding box in readiness for a serial pouring and crucible firing. The box is clearly made from some simple stock softwood and hinges buyable from a DIY store but painted with red pattern varnish to avoid deterioration from wet sand.

Art and Artisan cast in a variety of materials. Plaster kept out back of workshop.

Small flask used in shrinking casting chicken doorstop with articulated flask.

Artisan foundry shop sells aluminium and bronze ingots for backyard casting community and homemade DIY foundry punks. We have spoken in workshop about the potential clever buzz around running short casting courses at Museum of Making wherein attendees bring in their own used beer cans. Post-weekend binge, smelt the used-up Brew Dog and Special Brew aluminium tins into interesting new products: chicken doorstops, nameplates or other unimagined contemporary material wants. Art cautioned against this: ‘Paint’s toxic lad’, ‘poor quality ally to be fair lads’, ‘you don’t want sticky booze-smelly ally cans hanging around a workshop do yer lad’. In the above photograph the- casting newly-knocked-out-of-steaming-hot-sand-mould is a casting poured into the mould taken from the ingot mould Art uses to cast sellable ingots, used as a pattern. Thus on the day we cast our own ingot mould for Museum of Making workshop for casting ingot bars. The ingot mould was cast from reclaimed aluminium core-wire that is used in high voltage electricity cables -- so you can use recycled ‘found’ metal. A casting course offering potential neo-backyard founders to make their own ingot mould might not grab audience. But if I modify physically the form of the ingot pattern to make a partitioned ingot-like casting and reconfigure (recast) it descriptively as a object into a pistachio-Bombay-mix-Italian caper-kimchi presentation receptacle for table top appetisers, things sound more appetising. As the Italian saying ‘L’appetito vien mangiando’ wisely advocates ‘with eating comes appetite’. I also think casting a small aluminium pie dish has potential. The silvery stems you see poking from the sand are the runner and riser connected to pouring basin.

Various tools and casting ladles needed for backyard foundries. Make your own kit if you can

Steve Smith

Workshop-Studio Manager

Museum of Making

February 2023

3 notes

·

View notes

Text

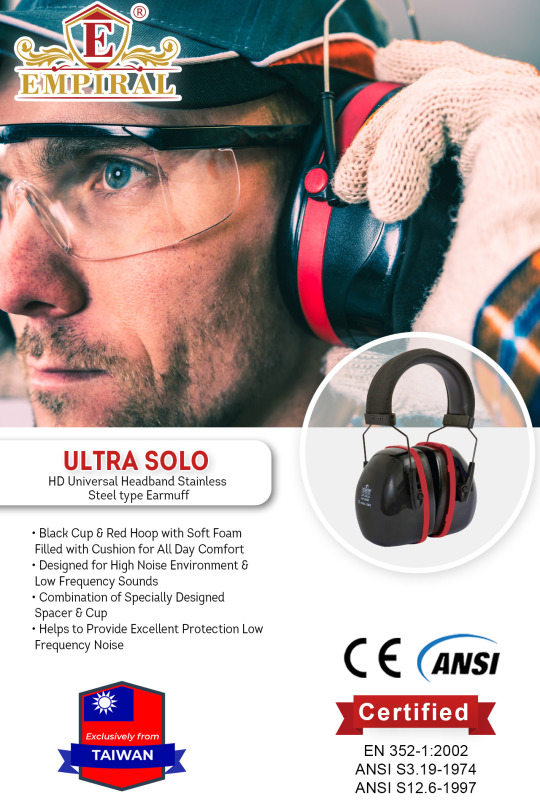

ULTRA SOLO, Ear Muff with Stainless Steel body & Universal Head Band. Hearing protection designed for high noise environment and low frequency sounds. Certified to both EN and ANSI Standards.

This earmuff is ideally designed for protection from noise arising from wide range of applications in the workplace and leisure activities

Industry Applications:

Metal processing, Automotive, Airports, Construction sites, Textile manufacturing, Cement industry, Chemical & Pharmaceutical manufacturing, Wood work, Heavy Engineering, Foundry, steel works etc.

Madi in Taiwan.

Standards:

EN 352-1:2002, ANSI S3.19-1974, ANSI S12.6-1997.

3 notes

·

View notes