#micro linear servo actuator

Explore tagged Tumblr posts

Text

0 notes

Text

Automated Production and Testing Processes of Rocker Switches

1. Introduction

With the rapid development of industrial automation, the manufacturing process of rocker switches has undergone a transformation from traditional manual production to highly automated, precision-controlled production lines. This shift not only improves production efficiency and product consistency but also enhances the competitiveness of enterprises in the market. This article will provide a comprehensive overview of the automated production and testing processes of rocker switches, including automated terminal insertion, automated spot welding, automated LED placement, as well as contact resistance testing, travel and pressure testing, continuity time measurement, and industrial vision-based appearance inspection. These technologies represent a high degree of integration between mechanical systems, electronic control, and intelligent algorithms.

2. Automated Assembly Processes in Rocker Switch Production

2.1 Automated Terminal Insertion

Terminal insertion is one of the most critical steps in rocker switch production. Traditional manual insertion is prone to positional deviation and insertion force instability, which may cause defective contact or product rejection. Modern production lines adopt servo-controlled automated terminal insertion systems, which use multi-axis manipulators to position terminals precisely. High-precision optical sensors ensure insertion depth and orientation consistency.

For instance, the system automatically picks the copper terminal from the feeder, precisely aligns it with the switch base, and inserts it at a controlled speed and pressure. This ensures the mechanical integrity of the assembly and avoids micro-damage to the plastic shell, laying a solid foundation for subsequent spot welding.

2.2 Automated Spot Welding

Spot welding ensures the electrical connection between terminals and leads. The automated welding station uses resistance spot welding controlled by pulse current and time curves to precisely fuse metal interfaces.

Advanced systems are equipped with closed-loop current monitoring and displacement sensors, allowing real-time compensation for contact surface changes, thus ensuring stable and low-resistance welded joints. Additionally, the system is integrated with fume extraction and safety monitoring modules, improving the working environment and overall safety.

2.3 Automated LED Placement

Rocker switches with indicator lights require precise LED placement. Automated LED placement machines use high-speed pick-and-place heads and machine vision calibration to accurately position the LED within the switch cavity. The polarity and brightness are verified in real time during the process to ensure optical performance and visual consistency.

This process ensures that the LED does not shift during encapsulation or welding, maintaining long-term reliability and aesthetic appeal of the final product.

3. Automated Testing Systems for Rocker Switches

To ensure product reliability, each rocker switch must undergo comprehensive electrical and mechanical performance tests before leaving the factory.

3.1 Contact Resistance Test

The contact resistance test evaluates the resistance value across the conductive path under rated pressure. Modern automated testing equipment uses a 4-wire Kelvin method to eliminate lead resistance influence. The system can test multiple switches simultaneously, display resistance distribution curves in real-time, and automatically classify unqualified products.

Typical requirement: contact resistance < 50 mΩ (depending on the application scenario).

3.2 Travel and Pressure Test

Travel and pressure tests ensure the rocker switch provides the correct tactile feedback. High-precision linear actuators simulate human finger pressing motion, while pressure sensors and displacement encoders collect force-displacement data.

This allows evaluation of stroke range (e.g., 1.8–2.5 mm), actuation force (e.g., 300–600 gf), and pressing smoothness. Abnormalities such as mechanical jamming, misalignment, or inconsistent feedback can be identified and rejected automatically.

3.3 Continuity Time Measurement

Continuity time refers to the response speed of the switch after actuation. The test system uses high-speed data acquisition cards to detect signal transition points and calculate the time difference between actuation and circuit conduction.

This indicator is especially important for automotive and industrial control applications, where millisecond-level response times are required.

4. Visual Inspection and Intelligent Defect Detection

4.1 Industrial Vision System Introduction

Visual inspection replaces traditional manual quality checks, using high-resolution cameras, lighting modules, and image recognition algorithms to inspect every rocker switch.

It can detect:

Missing parts

Scratches or deformation on the housing

Logo misalignment or blurring

Incorrect assembly (e.g., misaligned rockers, LED offset)

4.2 High Efficiency and Accuracy

For example, a dual-camera system combined with a rotary conveyor can inspect 120 pieces per minute. The system achieves a detection accuracy of 0.05 mm, capable of identifying minute cracks or flash edges on plastic parts.

Deep learning algorithms further enhance recognition ability by learning from real production defects, continuously optimizing detection logic.

5. Traceability and Data Integration

All testing data and inspection results are integrated into the MES (Manufacturing Execution System), enabling full traceability. This helps:

Identify root causes of quality issues quickly

Analyze yield trends

Refine production parameters in real time

By applying barcode/QR code identification to each unit, data from insertion, welding, testing, and inspection can be correlated with the specific product batch, greatly enhancing quality control and accountability.

6. Conclusion

The automated production and testing processes of rocker switches represent the future trend of smart manufacturing in the electromechanical components industry. From terminal insertion to visual inspection, each step is carefully controlled and monitored, improving production efficiency, product quality, and cost-effectiveness. With continued development in industrial AI and robotics, the production of rocker switches will become even more intelligent, flexible, and scalable, helping enterprises meet the diverse and demanding needs of global markets.

en.dghongju.com

0 notes

Text

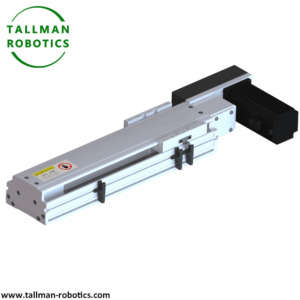

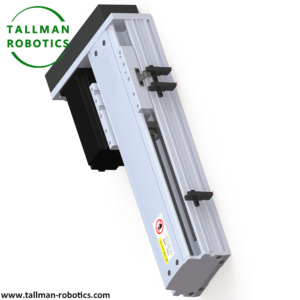

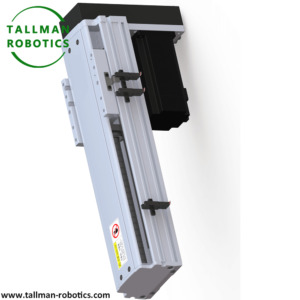

Linear Actuators Robots

Linear Actuators Robots are a pivotal technology in modern robotics due to their versatility, precision, and scalability. They have a broad range of applications in various fields. Here's an overview of how Linear Actuators Robots are integrated into robotic systems and their benefits: Classification and Mechanisms: Types: Linear Actuators Robots can be driven by different mechanisms including screw type, belt drives, and linear motors. Each mechanism offers unique advantages; for instance, screw-based actuators driven by stepping motors are highly suitable for precise positioning but may be underpowered for certain applications requiring servo motors. Motion and Force: These actuators provide both horizontal and vertical motion. They can handle travel distances up to 500 feet and speeds up to 600 inches per second, and manage loads up to 10,000 pounds, making them suitable for a variety of industrial applications. Applications: Manufacturing Automation: Linear Actuators Robots are prominently used in automation for repetitive, tedious, or dangerous tasks. They help in streamlining processes and maintaining high precision and consistency in manufacturing, greatly reducing production costs. Prosthetics: The introduction of micro linear actuators has revolutionized prosthetics, enabling more natural and powerful motions in prosthetic hands. These tiny actuators offer significant strength and precision, essential for driving individual fingers directly. Drones and Aerospace: In drones, actuators are used for functions such as camera gimbals, retractable landing gear, and arms for manipulating objects. They are also incorporated into aerospace applications, such as the International Space Station, demonstrating their reliability and precision in high-stakes environments. In conclusion, Linear Actuators Robots are vital components in the development of robotic systems, offering a broad spectrum of applications from industrial automation to advanced prosthetics and space exploration. Their adaptability, precision, and robustness make them indispensable in advancing robotics technology into the future. Here, we introduce our Screw drive linear modules by model TMS45 semi-closed type for general environment.

You are welcome to watch more projects or visit our website to check other series or load down e-catalogues for further technical data. Youtube: https://www.youtube.com/@tallmanrobotics Facebook: https://www.facebook.com/tallmanrobotics Linkedin: https://www.linkedin.com/in/tallman-robotics Read the full article

#ActuatorsinCartesianRobot#AutomationandRoboticswithElectricLinearActuator#Cartesianrobotic#Electriclinearactuators#IndustrialRobotslinearactuators#inearActuators#LinearActuator#Linearactuatorrobots#LinearActuatorsforRobotics#LinearMotionandActuatorsforSurgicalRobotics#Linearmotorsingleaxisrobots#LinearMotors&Actuators#Linearrobots#MicroLinearActuators#MultiStationBeltLinearActuator2AxisRobot#PrecisionLinearActuators#RobotActuators#RobotLinearActuators#RoboticArmwithLinearActuators#roboticslinearactuator#SingleAxisRobotLinearActuators#SingleAxisRobots#XYActuator(SingleRail)

0 notes

Text

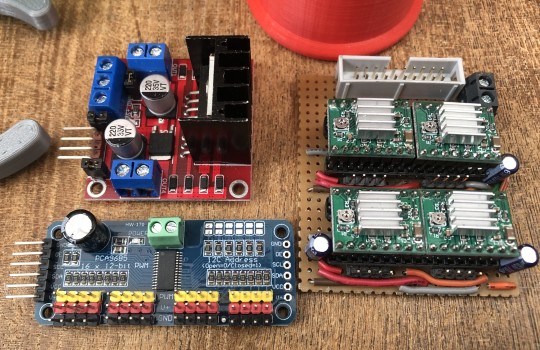

8-Dec-2023

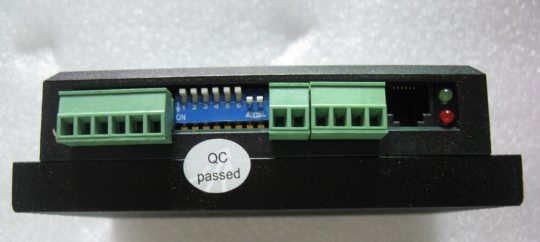

Now a little bit about extra electronic modules, that are readily available off the shelf. The modules shown in the picture and the reasons for using them is described below. There will be an update at some point showing a homemade hat to plug onto the top of the Pi, which is still having circuitry added to it and probably a Teensy Microcontroller to accurately measure the four distances from ultrasonic transducers plus the robot battery level. It might even do the PWM's aswel instead of the 16-Channel PWM board but we haven't decided on that yet.

4x Micro-Stepping motor driver modules mounted on a piece of FR2 Matrix Stripboard, for convenience of connecting to the RPi and the individual Short body Nema-17 Stepper motors. This way the motors can be controlled more accurately with direction and step pulse. These modules also provide current limiting and as stated, Micro-stepping which can provide smoother and better movement accuracy.

1x 16-channel PWM board to drive servos and probably LED’s to make the Robot a bit more flashy (Yet to be confirmed). The use of such a module is mainly because it is impossible to get a stable PWM from the Raspberry Pi. Most likely because the RPi PWM is a software generated pulse and not from a dedicated hardware counter, compounded by the Real time OS that is pulled in all manner of directions by higher priority level interrupts. It causes the PWM from the Pi OS to jitter like crazy, which in turn causes a servo to twitch rather a lot. So if you want accuracy and stability then a separate dedicated module is needed, as the RPi cannot provide either.

1x Dual H-Bridge. One of the channels is to drive the Boom’s 12V linear actuator. The second channel is spare in case we need it for some other hardware that we haven’t thought of yet.

0 notes

Link

The IR Robot mightyZAP is an All in One solution having a built-in drive circuitry. It can be applied in various fields such as factory automation, medical devices, robotics etc.

#micro linear servo actuator#mightyZAP micro linear servo actuator#IR Robot Mini Linear Servo Actuator#IR Robot mightyZAP#mightyZAP micro linear#Micro Linear Servo Actuator mightyZAP#mightyZAP

0 notes

Text

Buying Guide for Linear Actuators

Linear Actuators are electromechanical or mechanical devices that produce straight-line motion. This motion is used for many tasks, from aircraft-control actuating to precision-assembly positioning. Although ordinary hydraulic and pneumatic cylinders are linear actuators, for the most part, they are simply called “cylinders.” This article will focus on electromechanical forms that produce either direct linear motion or convert rotary motion to linear motion through some combination of motor and power transmission element. It will also discuss rodless pneumatic linear actuators, as they are one step beyond ordinary air cylinders.

The following types are discussed here:

Electric Rod-Style Linear Actuators Pneumatic Rodless Linear Actuators Electric Rodless Linear Actuators Precision Electric Linear Actuators Compared with cylinders, electric linear actuators are costlier to purchase. Specifying them requires closer engineering evaluation than specifying cylinders because oversizing electric actuators can greatly affect their cost. Among the necessary considerations for selecting electric linear actuators:

Static and dynamic loading matched to peak and continuous load capabilities Duty cycle Force and velocity Pneumatic actuators will share some of the same attributes without the same penalty for upsizing.

Rod Style Electric Linear Actuators These actuators, sometimes called electric cylinders, are intended as replacements for hydraulic and pneumatic cylinders in motion control systems. Most actuators use lead- or ball-screws driven either directly (in-line) by stepper motors or servomotors or through toothed-belt transmissions (reverse-parallel). The envelopes of these actuators do not exactly match the outlines of cylinders but the attachment styles for the actuator bodies and rod ends are similar. The reverse-parallel design can often be fitted with a clevis at the cap-end and closely approximate the length of an air cylinder, with some space needed for the motor which lies parallel to the actuator body. In-line designs are necessarily longer than air cylinders of equal stroke since the motors sit behind the cap-ends. This is not necessarily a problem for fixed mounts. Apart from their higher initial costs, rod-style actuators count positioning capability and motion profiling as advantages over air cylinders (where needed). Maintenance is less, too. Another advantage over cylinders is the ease with which their strokes can be shortened, with changeover for various production scenarios handled by the machine controls.

Rodless Pneumatic Linear Actuators

These actuators, sometimes called rodless cylinders, use traditional pistons and air cylinders but forgo cylinder rods. Instead, a sliding carrier rides the exterior housing of the cylinder and is coupled to the piston by either magnets or cables, or directly to it through a flexible band/seal. These arrangements produce more compact linear-motion systems than can be achieved with ordinary cylinders and slides. Manufacturers offer them in a variety of carrier-support configurations, such as sintered bushings or linear bearings. They can be specified for horizontal and vertical loads.

Rodless Electric Linear Actuators These actuators are the electromechanical equivalents of their pneumatic cousins. Generally driven by timing belts, ball screws, or lead screws, the design eliminates sealing concerns associated with the pneumatic versions. Depending on the applications, motors may be either stepper or brushless DC servo. Belt drives are preferred for long-stroke applications with high speed/acceleration requirements. Ball screws are preferred where accuracy is important and stroke lengths are shorter. They also provide higher thrust than belt drives. Lead screws are less expensive but also inefficient and prone to heat build-up at high speeds/loads. An advantage of lead screws is they are self-locking. As with rod-style actuators, these electric versions offer positioning, motion profiling, and pain-free changeover for motion systems that warrant them.

Precision Linear Actuators This group of actuators employs a range of motor styles to produce linear motion over generally short spans but with very high positional accuracy, often in the micro- and nano- ranges. In addition to stepper and servomotors, which often drive through gearheads to produce fine movement, precision actuators employ linear motors, piezoelectric motors, voice coils, etc. whose positioning accuracies are suited to the demands of semiconductor manufacture, optics control, etc.

0 notes

Text

Anubis write up part1

Before I get into the write up of the Pharah Anubis armor, I want to give a quick shout out to a few cosplayers that basically inspired me to do this build:Before I get into the write up of the Pharah Anubis armor, I want to give a quick shout out to a few cosplayers that basically inspired me to do this build: Germia, Kuma Cosplay , and JusCosplay & Props. These guys basically kept me going when I felt it was too difficult to do and wanted to give up. Also depending where you are reading this there are video clips showing off certain parts of the armor or giving a demonstration of it that will be included on my website within the write up or you could either look for the video on my instagram winterstormcosplay or on my website Winterstormcosplay. I will be uploading this in segments to make it easier on myself.

All right for a quick run down of the materials I used here is a list of the supplies

TntCosplay 4, 6, and 8mm Foam

Plastidip

Rustoleum flat Gray Primer, Flat black, and Gold spray paint

Airbrush black, red, gold, and silver

Gold and silver paint marker

CosplaySupplies Transparent worbla

Standard black zippers

Nylon cord/ elastic

Barge contact cement

Angle brackets

CONDOR Ronin Chest Rig

Climbing Harness

Wood

Flexbond

Corrugated plastic

Electronic portion(this list will be changing some time in the future since I am upgrading certain elements)

Adafruit 16-Channel 12-bit PWM/Servo Shield

ELEGOO UNO R3 Board

DC Momentary Reversing Rocker Switch

16 AWG Gauge Stranded Hook-Up Wire Kit

High Speed Linear Actuator, 12V, 6″ Stroke

Quick Wire Splice Taps and Insulated Male Quick Disconnect Terminals

Wire Terminal Crimp Connectors

Cordless screwdriver 12v battery

Heat shrink tubing

5v AA battery holder

Simple RF M4 Receiver – 315MHz Momentary Typ

Keyfob 4-Button RF Remote Control

Micro Servo Motor 9G

Adjustable Buck Converter

Standard servo – TowerPro SG-5010 – 5010

LED strips

Panel Toggle Switch

For crafting the armor itself I decided I wanted to have the wings and missile flaps move, so with those pieces I had to keep that in mind with a way to mount them for the power and other various cables. I will go more in depth later on, but something I should bring up is the torso portion of the armor. Basically if you have the game files and want to work off of that go for it, but you will most likely run into some issues due to Pharah having such a thin waist. No need to fret, there are various people online that have modified it to be worn by real people of sizes and JusCosplay & Props made modified set that will help you out immensely (well it did for me). Or you can freestyle it and hand make the patterns on a mannequin which if you can, I respect you since I am horrible at that.

Anubis Helmet/Omnic head

It was made of all foam varying from 4mm to 8mm in thickness. The difficulty of making it would be around medium, there are small pieces that have to be cut on various angles which can be annoying if you don’t have a sharp enough blade. For sealing it I first heat sealed it and went with flexbond instead of plastidip, since there are crevices that plastidip could not reach it was easier to just use a brush and apply it directly. When painting I primed it with some flat gray until I could not see the color of the foam. When painting the helmet I used airbrush paint for better control of the area, I started off with the gold areas first so when they dry I could just put some painters tape on them then color the remaining areas in black then sealed it up when everything dried thoroughly. At a certain part of the build I decided to not to do a genderbend of Pharah but an omnic squad member from her military days.

Shoulder Pauldrons

They were around medium difficulty to complete, unlike the helmet there is a lot of angular cuts on this to get its form, for certain areas on the foam I used a wood burner to burn certain designs into it if they were too big for the cut and heat method. On Pharahs armor the shoulder pieces have a flap that would open showing missiles. To have the flap move I 3d printed a hinge to the servo mount that I modified it to fit inside of the armor piece, for the cable connected to the servo I made a small hole on the underside of the armor piece so it would have a straight shot getting connected to the board. The missiles instead of using foam I made in fusion 360 that were printed on my 3d printer giving it a solid look. I made a modification where the missiles are so they can be removed in case I needed to get to the servos. For the underside of the missiles I added a strip of black 2mm foam holding them in place. This time I used plastidip to seal it instead of flexbond, but I did tape off an area where I attached a buckle so I could be hooked up to the harness i was wearing so I didn’t need to worry about it falling off. Painting was pretty straight forward, for the areas that had the designs with the wood burner I used a paint marker that matched the gold paint for fine detail painting.

Forearms

The forearms were one of the easiest parts to make besides the armor around the boots, as long as you scaled the right length of your arm there would be no real problems. Though you may need to cut away foam to have your arm pass through it easier. The right forearm that does not hold the wrist rocket that Pharah is able to launch is where I added a control unit for power. In my whole armor build I had multiple things getting powered that were located on the jetpack where the battery was. Now I did have an extra battery to replace it incase it died but being able to take off the jetpack to replace would be more work than it needs to be. So i decided to have a control unit where I can simply turn on and off the different parts of the electronics when I needed to use them. To get this done I used a Panel Toggle Switch that is meant for cars. What I liked about this it has a kill switch controlling all the power for the sub accessory switches, plus it just looked cool on the armor too. I had the power control of the whole suit suit so I had wires running up my arm to the jetpack and a rocker switch running to my hand which controlled the actuator for the wings.

For the other forearm which houses the wrist rocket, unfortunately I could not make it fireable like some other cosplayers had. So with that being that I modeled a rocket with some text on it saying, “To Whom It May Concern” in cursive. I also wanted to try having it in hieroglyphics but it did not work out so I just kept it in english.

Torso

For the torso this was kinda a pain in the butt for me, I tried making custom patterns with a torso mannequin I modded to be similar to me, but I could not achieve it. So I turned to the in game patterns and hit a wall since my body shape is no where near Pharas. Either the waist was fine, but it would be way too big everywhere else or have a way too small waist to make the rest fit, with that I gave up. So I did some research and found a cosplayer I listed in the beginning of this write up and bless him with the holy cosplay gods for making a male torso version of Pharahs torso. This thing helped so much and wasn’t too bad making, I did make custom modification to it to make it easier putting it on. To actually wear it I did not make it a closed piece, I have the opening of the torso in the back where the spine is located having it close with some buckles connected to elastic bands.

The next part to be uploaded will be the foam armor from the waist down and the type of harness I used to connect the pieces to it so they stay in place.

0 notes

Photo

Established in 1998 LANDING PLANETARY GEARBOX LIMITED is an ISO 9001 registered as a professional manufacturer of precise Planetary Gearbox ,Gearmotor and Actuator so on. Our company is active in research & development, production and worldwide distribution of Gearbox,Gearmotor and Actuator. We provide products to the commercial, industrial, medical, aerospace and defense markets. LANDING is the only one factory which can produce the high-end planetary gearbox mass-produced in China. And we fill the blank of micro planetary gearbox in the field of domestic. LANDING is a small but effective team operating in the special project design and motion control industry. We can provide: Planetary Gearbox Design And Production; Planetary Gearmotor Design And Production; Linear Actuator Design And Production; Servos System Supporting; Drive System Supporting; Related Product Design And Production. Many years experience engineer,Precise design according to your demand,Professional sales team, High quality and warranty products to save your time and cost.We are always willing to do win-win business. Let us be another member of your team! Welcome visit our website at www.landing-gearbox.com or send email:[email protected] And we are always here looking forward to support you and your company anytime. Thank you! https://www.instagram.com/p/BvyRuQDACnh/?utm_source=ig_tumblr_share&igshid=1w7t4xv8wband

0 notes

Text

Gravity: D3 Kit - A Comprehensive Kit for Education

An Arduino learning kit based on DFRduino Mega 2560 (Arduino Mega 2560 compatible) combined with 34 components such as sensor modules, shields, actuators, and optional I / O modules that will facilitate your learning process. In each module contained in this kit, there are already examples of hardware connections along with examples of source code / coding which will certainly spoil you in learning each sensor / module IO / actuator function. Everything you need is on the wiki page that has been provided. It is suitable for you who are just starting to learn Arduino or for you teachers who want to teach Arduino to their students.

Product Equipments

DFRduino Mega 2560 x1

Mega IO Expansion Shield V2.3 x1

I2C LCD1602(Arduino Compatible) x1

Relay Module V2 x1

LM35 Analog Linear Temperature Sensor x1

Analog Ambient Light Sensor x1

Digital Vibration Sensor x1

Digital Tilt Sensor x1

Digital Push Button x1

Capacitive Touch Sensor x1

Digital piranha LED light module-White x1

Digital piranha LED light module-RED x1

Digital piranha LED light module-BLUE x1

Digital Buzzer Module x1

Digital magnetic sensor x1

Analog Sound Sensor x1

Analog Rotation Sensor V2 x1

Joystick Module (DFR0061) x1

Flame sensor (DFR0076) x1

DIGITAL IR Transmitter Module(Arduino Compatible) x1

Light Disc with 7 SMD RGB LED x1

IR Kit For Arduino x1

DFRduino Ethernet Shield (Support Mega and Micro SD) x1

Triple Axis Accelerometer MMA7361 x1

URM37 V3.2 Ultrasonic Sensor x1

Digital Infrared motion sensor x1

Adjustable Infrared Sensor Switch x1

Analog Gas Sensor(MQ5) x1

9g micro servo (1.6kg) x1

Micro DC Geared Motor with Back Shaft x2

USB Cable A-B for Arduino x1

2A Motor Shield For Arduino x1

Water Sensor x1

Soil Moisture Sensor x1

LSM303 Breakout Board x1

https://ift.tt/2TqXCVM May 21, 2020 at 08:36PM

0 notes

Text

[Full-time] Blood Analyzer Repair Technician - Baltimore, MD at Jobisite

Location: Maryland URL: www.jobisite.com Description: Looking to hire candidates with experience servicing Abaxis, Abbott, Bayer, Beckman, Becton Dickinson, Biomerieux, Mindray, NovaBio, Drucker Co, T2Biosystems, OR Thermofisher blood analyzers, including installation and repairs as needed. Activities: Conduct equipment testing and validation in prior to installation in customer facilities. Author Standard Operating Procedures, training manuals, and service guides, and provide training to client operators regarding equipment operation and basic troubleshooting. Perform preventative maintenance, and respond to service calls to troubleshoot and make repairs as necessary. Document and communicate to Management recurring technical problems and equipment failures, and make recommendations for product improvements or enhancements. Should have experience with some of the following subcomponents: Fittings, Bearings; Pistons; Rotors; Gear Drives; Mounting Plates, Filters; Microplates & Pipettes; Reaction Wells; Valves; Sensors; Storage Tanks; Reaction Chambers; Micro-Fluid Pumps; Vacuum Pumps; Cameras; Stepper Motors; Motor Drives; Servo Drives; Linear and Rotating Actuators; Heaters; Thermisters; Chillers; Incubators; Fluid Reservoirs; Fluid Dispensers; Reagent Dispensers: Aspirators: Mixers; Injectors; Vibrators; Conveyors; Shakers; Spinners; Centrifuges; Probes; Bioreactors; DC Power Supplies; Control Boards; Image Processors; Photo Multipliers: Signal Processors & Transmitters; Digital Displays; Automatic Wash Systems; Automatic Suction Systems; Metering Systems; Reflectometers; Spectrophotometers; Chromatographs; Microscopes; Cytometers; Luminometers; Potentiometers; Magnetic Resonance Systems; Radiographs; Integrated Dry and Wet Chemistry Systems; PCR Systems; Sample Supply; Reagent Supply; etc. Generous base + overtime comp and bonus program for technicians who limit equipment failure and malfunctions in the field. Call on your years of experience and allow for earnings potential in excess of 6 figures as well as employee benefits including Medical, Dental, Health and others. For complete details contact James Franco at: (609) 584-9000 ext 283 Or, submit resume online at: dmc9.com/jef/app.asp Or email to: 1000038653_10007335 AT jobbank301.com Please reference #38470365 when responding. Education Requirements: Some College Minimum Experience Requirements: 2-5 years Job City Location: Baltimore Job State Location: MD Job Country Location: USA Salary Range: $70,000to $120,000 Diedre Moire Corporation, Inc. Diedremoire_dot_com WE ARE AN EQUAL OPPORTUNITY EMPLOYER and our employment decisions are made without regard to race, color, religion, age, sex, national origin, handicap, disability or marital status. We reasonably accommodate individuals with handicaps, disabilities and bona fide religious beliefs. Jobs Career Position Hiring. CONSIDERED EXPERIENCE INCLUDES: Field Service Technician Application Specialist FSE Installations Repair Field Service Engineer Blood Chemistry Analyzers Albumin Analyzers, Automated Biochemical Analyzers, Blood Gas Analyzers, Automated Blood Gas Systems, Blood Bank Systems, Blood Lactate Testers, Clinical Chemistry Analyzers, Hemoglobin Analyzers, Hematology Analyzers, Hemostasis Analyzers, Immunoassay Analyzers, Immunochemistry Analyzers, Blood Glucose Analyzers, Blood Component Separators, Coagulometers, Centrifuges, Blood Cell Counters #DiedreMoire #FieldServiceJobs #DiagnosticAnalyzers #JobSearch #JobHunt #JobOpening #Hiring #Job #Jobs #Careers #Employment #jobposting DISCLAIMER: We will make every effort to consider applications for all available positions and shall use one or more of the contact methods and addresses indicated in resume or online application. Indicated location may be proximate or may be desirable point of embarkation for paid or unpaid relocation to another venue. Job descriptions may fit single or multiple presently available or anticipated positions and are NOT an offer of employment or contract implied or otherwise. Described compensation is not definite nor precise and may be estimated and approximate and is negotiable depending on market conditions and candidate availability and other factors and is solely at the discretion of employers. Linguistics used herein may use First Person Singular and First Person Plural grammatical person construction for and with the meaning of Third Person Singular and Third Person Plural references. We reserves the right to amend and change responsibilities to meet business and organizational needs as necessary. Response to a specific posting or advertisement may result in consideration for other opportunities and not necessarily the incentive or basis of the response. Nothing herein is or may be considered a promise, guarantee, offer, pledge, agreement, contract, or oath. If you submit an application or resume which contains your email address, we will use that email address to communicate with you about this and other positions. We use an email quality control service to maintain security and a remove and dead address filter. To cancel receiving email communications, simply send an email from your address with the word "remove" in the subject line to pleaseremove_AT_candseek4.com Or, visit the website at jobbankremove_dot_com. If you have further concern regarding email received from us, call (609) 584-5499. Reference : Blood Analyzer Repair Technician - Baltimore, MD jobs Apply to this job from America Jobs http://www.america-jobs.net/job/29637/blood-analyzer-repair-technician-baltimore-md-at-jobisite/

0 notes

Text

Linear movement with Arduino and 3D printing

Arduino boards are great for controlling small servo motors, but what if you need something to provide linear travel? As spotted on Reddit, while the answer here is a little less straightforward, YouTuber Potent Printables has a great solution. It uses 3D-printed components, along with a dab of epoxy and fastener hardware to convert either a micro or standard continuous rotation servo into a rack-and-pinion mechanism.

The project can be seen in the video below with an Arduino Uno and motor shield, though any Arduino capable of PWM output should have no problem with this setup. Since the servos used here are meant for continuous rotation, travel distance is based only on timing. Depending on the application, you may want add a simple microswitch or other sensing mechanism for feedback.

This is a general purpose linear servo actuator (pusher style). Two sizes have been designed, for different space constraints and force outputs.

These use continuous rotation servos which helps keep the cost very low. Off the shelf actuators of this type can cost around $70 USD.

The “mini” version will fit in smaller spacers, but has a much lower force output. The “large” version has a higher force output, but is…larger in size than the “mini.”

youtube

Linear movement with Arduino and 3D printing was originally published on PlanetArduino

0 notes

Text

200PCS Heat Shrink Butt Connectors Terminals Insulated Waterproof Marine Automotive Electrical Kits 3 colors 3 sizes

200PCS Heat Shrink Butt Connectors Terminals Insulated Waterproof Marine Automotive Electrical Kits 3 colors 3 sizes

200PCS Heat Shrink Butt Connectors Terminals Insulated Waterproof Marine Automotive Electrical Kits 3 colors 3 sizes

200pcs Heat Shrink Butt Connectors Terminals, Eventronic Insulated Waterproof Marine Automotive Cop 200PCS Heat Shrink Butt Connectors Terminals Insulated Waterproof Marine Automotive Electrical Kits 3 colors 3 sizes 200pcs Heat Shrink Butt Connectors Terminals. Beetrie 260pcs Insulated FemaleMale Bullet Butt Connector wire Crimp Termin. Sopoby Solder Seal Heat Shrink Butt Connectors, crimp free connectors with built in low melt solder. 250 PCS Insulated Heat Shrink Electrical Wire Terminals Crimp Connectors Spade Set. Solder Seal Heat Shrink Butt Connectors. Heat Shrink Butt Connectors Kit JACKYLED 200pcs Waterproof. No solder? No problem! Butt Connectors!. 200PCS Electrical Crimp Butt Connector Insulated Terminals. Sealey Heat Shrink With Solder. Heat Shrink Butt Connectors Terminals. Find great deals on eBay for wiring butt connectors. 200Pcs Heat Shrink Insulated Butt 100 3M Heat Shrink Butt Connectors Marine Electrical Wiring Waterproof. . 560PCS Heat Shrink Tubing 2-1, Eventronic Electrical Wire Cable Wrap Assortment Electric Insulation. РекламаЛицензия The Connector. Доставка на Email. · пн-пт 10:00-18:00. . Solder vs. Butt connector ohms. 200pcs Heat Shrink Butt Connectors Terminals, Eventronic Insulated Waterproof Marine Automotive Copper Wire Electrical Kits (3 …. . Free delivery and returns on all eligible orders. Shop 200PCS Heat Shrink Butt Connectors Terminals, Aribest Insulated Waterproof Marine Automotive Copper Wire. . Heat Shrink Connectors & Terminals. electrical training heat shrink high voltage underground connection. РекламаБолее 30 тысяч това��ов: одежда, товары для дома и др. Заходи на сайт и выбирай! · круглосуточно. . Free delivery and returns on all eligible orders. Shop 200PCS Heat Shrink Butt Connectors Terminals, Eventronic Insulated Waterproof Marine …. . Wirefy Solder Seal Wire Connectors Review | Is It Worth It?. amazon heat shrink review 612. Butt connector compound injector and capping machine. Find great deals for 200pcs Heat Shrink Butt Connectors Terminals Insulated Waterproof Marine AU N4m3. Shop with confidence on eBay!. . URLWALL 900PCS Mixed Electrical Wire Connector Crimp Insulated Spade Butt Splice Male Female Termina. 200pcs Heat Shrink Butt Connectors Terminals, Eventronic Insulated Waterproof Marine Automotive Cop. Heat Shrink Butt Connectors. Electralink Heat Shrink Connectors. 50pcs Solder Seal Wire Connector, Sopoby Solder Seal Heat Shrink Butt Connectors Terminals Electrical Waterproof Insulated Marine Automotive Copper(23Red 12Blue. . How to Use Heat Shrink Butt Splices.

200PCS Heat Shrink Butt Connectors Terminals Insulated Waterproof Marine Automotive Electrical Kits 3 colors 3 sizes

New Leadshine DM556 2-phase Digital Stepper Drive work 36-60 VDC 2.1A to 5.6A for Associated products NEMA23 motor

New Leadshine DM556 2-phase Digital Stepper Drive work 36-60 VDC 2.1A to 5.6A for Associated products NEMA23 motor

120Pcs Waterproof Butt Terminal Connectors Heat Shrink Solder 1.5/3/5/6mm Set Tinned Copper Four Sizes Heat Shrink Connector Kit

120Pcs Waterproof Butt Terminal Connectors Heat Shrink Solder 1.5/3/5/6mm Set Tinned Copper Four Sizes Heat Shrink Connector Kit

HGM1750 Genset Controller

HGM1750 Genset Controller

10/20M high temperature PT100 compensation wire PT100 PTFE silver plated shielded wire 3 core 4 Core 6core cable for sensor

10/20M high temperature PT100 compensation wire PT100 PTFE silver plated shielded wire 3 core 4 Core 6core cable for sensor

ET6415BND 60A solar control mppt charge, 48V solar charge controller, 60A 24V solar control

ET6415BND 60A solar control mppt charge, 48V solar charge controller, 60A 24V solar control

Free shipping 21in = 525mm stroke 24v electric linear actuator, the maximum load 1000N 12v linear actuator

Free shipping 21in = 525mm stroke 24v electric linear actuator, the maximum load 1000N 12v linear actuator

Promotion! Red Wire White Screw Type Cap Inline 6mm x 30mm Tube Fuse Holder 5Pcs

Promotion! Red Wire White Screw Type Cap Inline 6mm x 30mm Tube Fuse Holder 5Pcs

Free Shipping DC 12V / 24V 5inch / 125mm Linear Actuator, 1000N / 100kgs / 225lbs Thrust Load Line Actuator Actuator

Free Shipping DC 12V / 24V 5inch / 125mm Linear Actuator, 1000N / 100kgs / 225lbs Thrust Load Line Actuator Actuator

100Pcs Reusable Hook and Loop Fastening multifunction PC TV Computer Wire Cable Ties Organizer (5 color)

100Pcs Reusable Hook and Loop Fastening multifunction PC TV Computer Wire Cable Ties Organizer (5 color)

ECMA-C31010ES+ASD-A1021-AB DELTA 1kw 3000rpm 3.18N.m ASDA-AB AC servo motor driver kits with 3m power and encoder cable

ECMA-C31010ES+ASD-A1021-AB DELTA 1kw 3000rpm 3.18N.m ASDA-AB AC servo motor driver kits with 3m power and encoder cable

China 2 Phase NEMA34 86mm 4.8NM Closed Loop Stepper Motor & Driver kits Encoder 10000P/R 40~70VDC 5.6A 86SMA-HA+86SDA-H

China 2 Phase NEMA34 86mm 4.8NM Closed Loop Stepper Motor & Driver kits Encoder 10000P/R 40~70VDC 5.6A 86SMA-HA+86SDA-H

Fast free shipping, 2848A278 Skid Steer Diesel Solenoid CAT 246 Fuel Shutoff Stop Shut Off

Fast free shipping, 2848A278 Skid Steer Diesel Solenoid CAT 246 Fuel Shutoff Stop Shut Off

Aiyima 68KTYZ AC220V Synchronous Motor High Toque Permanent Magnet Gear Reduction Motors Reversible Controllable Micro Moteur

Aiyima 68KTYZ AC220V Synchronous Motor High Toque Permanent Magnet Gear Reduction Motors Reversible Controllable Micro Moteur

0 notes

Text

Medium Load H-825 6-Axis Hexapod comes with absolute encoders.

Medium Load H-825 6-Axis Hexapod comes with self-locking load capacity up to 30 kg. Unit offer linear motion up to 55 mm and up to 38 degrees rotation. Product features actuator resolution of 8 nanometers and provides position repeatability of ±0.1µm and ±2µrad. H-825 is equipped with state-of-the-art controllers and software tools. Hexapod is employed with parallel-kinematic design and is incorporated with brushless servo motors. from HVAC /fullstory/medium-load-h-825-6-axis-hexapod-comes-with-absolute-encoders-40007659 via http://www.rssmix.com/

0 notes

Text

Medium Load H-825 6-Axis Hexapod comes with absolute encoders.

Medium Load H-825 6-Axis Hexapod comes with self-locking load capacity up to 30 kg. Unit offer linear motion up to 55 mm and up to 38 degrees rotation. Product features actuator resolution of 8 nanometers and provides position repeatability of ±0.1µm and ±2µrad. H-825 is equipped with state-of-the-art controllers and software tools. Hexapod is employed with parallel-kinematic design and is incorporated with brushless servo motors. from Air Conditioning /fullstory/medium-load-h-825-6-axis-hexapod-comes-with-absolute-encoders-40007659 via http://www.rssmix.com/

0 notes

Text

Radiation Tolerant Motor Drive Market : Market Development, Overview and Forecast upto 2026

Radiation tolerant is the property of making a device or system resistant to damage and make a device to tolerate high-energy electromagnetic radiation till the certain limit. The radiation tolerant motor drive provides flexible I/O that allow designs to be used in various applications, and standard logic level inputs to enable design implementation.

Moreover, the motor drive is used for various applications such as servo control, linear actuator servo control, and stepper motor driver.

Obtain Report Details @

http://www.transparencymarketresearch.com/radiation-tolerant-motor-drive-market.html

Radiation tolerant motor drive market is witnessing maximum growth owing to an innovative advance circuit, logic protection with high efficiency to the motor, eliminate shoot-through conditions, and constant output performance.

Moreover, it is used for servo-amplifiers & speed controls in various applications, reduces the weight & board area in space satellites, high reliability, provides advanced circuits and logic protection to ensure the fail-safe operation, aids in power management, data converter, interface and high system efficiency are some of the factors that can boost the demand for radiation tolerant motor drive over the forecast period.

Radiation tolerant motor drive market revenue is expected to grow at a rapid growth rate, over the forecast period. The market is anticipated to perform well in the near future owing to increase in requirement for radiation immunity & high-performance signal processing devices for satellite and spacecraft electronic systems, and rising advanced technology for more capability for civilian and government applications.

Moreover, expanding demand for power management devices, radiation tolerant MOSFETs, and transistors in space applications are some of the factors that can accelerate the market revenue growth of radiation tolerant motor drive during the forecast period.

Make an Enquiry @

http://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=22832

Depending on the geographic region, radiation tolerant motor drive market is divided into seven key regions: North America, Eastern Europe, Latin America, Western Europe, Japan, Asia-Pacific, and the Middle East & Africa. North America dominates the radiation tolerant motor drive market followed by Europe, and Japan owing to advance technology, presence of established key players, high demand for communication satellites, advanced multicore processor technology, and research & development facilities in these regions.

Some players of radiation tolerant motor drive market are Data Device Corporation, Microsemi Corporation, BEI Kimco, Atmel Corporation, Texas Instruments Incorporated, BAE Systems, Xilinx, Inc., STMicroelectronics NV and Linear Technology Corporation.

About Us

Transparency Market Research (TMR) is a market intelligence company, providing global business information reports and services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insight for thousands of decision makers. We have an experienced team of Analysts, Researchers, and Consultants, who us e proprietary data sources and various tools and techniques to gather, and analyze information. Our business offerings represent the latest and the most reliable information indispensable for businesses to sustain a competitive edge.

Each TMR Syndicated Research report covers a different sector – such as pharmaceuticals, chemical, energy, food & beverages, semiconductors, med-devices, consumer goods and technology. These reports provide in-depth analysis and deep segmentation to possible micro levels. With wider scope and stratified research methodology, our syndicated reports thrive to provide clients to serve their overall research requirement.

Contact

Transparency Market Research 90 State Street, Suite 700 Albany, NY 12207 Tel: +1-518-618-1030 USA – Canada Toll Free: 866-552-3453 Email: [email protected] Website: http://www.transparencymarketresearch.com

0 notes

Text

Established in 1998 LANDING PLANETARY GEARBOX LIMITED is an ISO 9001 registered as a professional manufacturer of precise Planetary Gearbox ,Gearmotor and Actuator so on. Our company is active in research & development, production and worldwide distribution of Gearbox,Gearmotor and Actuator. We provide products to the commercial, industrial, medical, aerospace and defense markets.

LANDING is the only one factory which can produce the high-end planetary gearbox mass-produced in China. And we fill the blank of micro planetary gearbox in the field of domestic.

LANDING is a small but effective team operating in the special project design and motion control industry.

We can provide:

Planetary Gearbox Design And Production;

Planetary Gearmotor Design And Production;

Linear Actuator Design And Production;

Servos System Supporting;

Drive System Supporting;

Related Product Design And Production.

Many years experience engineer,Precise design according to your demand,Professional sales team, High quality and warranty products to save your time and cost.We are always willing to do win-win business.

Let us be another member of your team!

Welcome visit our website at www.landing-gearbox.com or send email:[email protected]

And we are always here looking forward to support you and your company anytime.

Thank you!

0 notes