#microfluidic

Explore tagged Tumblr posts

Text

New microfluidic device brings affordable kidney testing to the point of care

Chronic kidney disease (CKD) affects over 800 million people globally and is often diagnosed too late for effective intervention. Early detection depends on accurate measurement of biomarkers such as creatinine and the urine albumin-to-creatinine ratio (uACR). While urine testing is non-invasive and informative, standard methods are time-consuming, costly, and require specialized facilities.…

View On WordPress

0 notes

Text

SciTech Chronicles. . . . . .May 16th, 2025

#iCares#microfluidic#biomarker#prediction#amber#deformation#“fluorescence imaging”#flame-shaped#MSR#Thorium#modular#cartridge#scalable#recyclable#degradability#durability#cis-urocanic#urocanase#microbiome#“UV radiation”

0 notes

Text

Microfluidic technologies for cell separation

Microfluidic technologies for cell separation in the biomedical field are booming in the recent 15 years. Benefitted from the microscale features approaching a single cell, microfluidic cell sorting devices have shown many attractive advantages compared to their forerunners (e.g., fluorescence-assisted cell sorting (FACS) and magnetic-assisted cell sorting (MACS)). With the advance in diagnostic and therapeutic medicine for point-of-care tests, the need for cell separation has been greatly expanded nowadays. In this context, microfluidic-based cell separation and cell sorting technologies have shown excellent performance.

0 notes

Text

Choosing the Right Homogenizer: Valve-Type vs. Microfluidic Jet High-Pressure Homogenizer?

High-pressure homogenization is widely used in industries like pharmaceuticals, biotechnology, food processing, and cosmetics for tasks such as achieving uniform particle sizes, forming stable emulsions, and producing consistent suspensions. Two commonly used technologies for this purpose are valve-type and microfluidic jet high-pressure homogenizers. Understanding how each one works and their…

View On WordPress

0 notes

Text

Microfluidic: Advances in Microfabricated Systems Open Doors to New Scientific Discoveries

Microfabricateds refers to the behavior, precise control and manipulation of fluids that are geometrically constrained to a small, typically sub-millimeter, scale. At this scale, fluid flow is governed by low Reynolds number fluid flow dynamics and is amenable to precise analytical description. By leveraging microfabrication techniques originally developed for the microelectronics industry, microfabricated systems can be manufactured with precise microscopic features to control flows on sub-millimeter length scales. Early Development of Microfluidic Technology

The roots of microfabricateds can be traced back to the late 1980s and early 1990s. Researchers worked to develop new specialized fabrication techniques, adapted from microelectromechanical systems (MEMS) technology, that would allow the precise construction of microscopic fluid flow channels and reservoirs. Initial applications focused on developing "lab-on-a-chip" micro total analysis systems (μTAS) that could perform routine analytical techniques like chromatography, electrophoresis and chemical reactions on a single integrated microchip. This promised to enable miniaturization, automation, reduced sample/reagent consumption and cost advantages over traditional benchtop instruments. Biological and Medical Applications Emerge

As fabrication techniques advanced, new applications emerged in areas like biotechnology, biological assay development and medical diagnostics where tight control over fluid flows and precise fluid handling was paramount. Microfabricated systems enabled controlled culturing and analysis of cells at the single-cell level. Integrated "organ-on-a-chip" systems that model human organ and body functions using tissue-engineered "microphysiological systems" also began emerging. Notable applications include "lung-on-a-chip" and "liver-on-a-chip" models to study disease pathogenesis and perform drug testing. Portable microfabricated POC (point-of-care) diagnostic devices for applications like glucose monitoring, infectious disease detection, and environmental monitoring were also developed. Enabling Technologies Drive Continued Growth

Advances in enabling technologies like soft lithography, 3D printing, contact/contactless handling of liquids at the Microfluidic and new detection schemes are continually expanding the frontiers of microfabricateds. Soft lithography allows rapid, inexpensive manufacture of elastomeric microfabricated devices and enables novel applications like lipid bilayer formation. 3D printing enables custom, on-demand fabrication of complex microfabricated device designs. Optical tweezers, dielectrophoresis and acoustic manipulation techniques provide contactless control over fluids and particles in microfabricated chips. These techniques are unlocking new applications in domains like stem cell engineering, molecular biology and biomanufacturing. Microfabricateds in Drug Development and High-throughput Screening

Microfabricated systems are becoming valuable tools in pharmaceutical R&D. Their abilities to perform highly-parallel chemical and biological assays at micro-volume scales has enabled ultra high-throughput screening of thousands to millions of compounds per day in the search for new drug leads. Microfabricated assays allow much smaller volumes of expensive reagents to be used compared to standard microtiter plate-based assays. Complex 3D tissue models and organs-on-chips are also being used to more accurately mimic in vivo drug responses during pre-clinical testing, potentially reducing late-stage drug failures. Continuous microfabricated processing also enables inline analysis and characterization of drug structures, screens and interactions with targets. These capabilities are accelerating drug discovery timelines and reducing costs. Applications in Chemical Synthesis and Process Intensification

Beyond biomedical uses, microfabricateds is finding applications in diverse chemical fields including flow chemistry, process intensification and materials synthesis. Controlled, rapid mixing at the microscale enables unique reaction conditions and kinetics leading to enhanced or unprecedented chemical transformations. Continuous flow microreactors show advantages over batch reactors by enabling reactions under extreme conditions like high temperature/pressure. Microreaction technology enables scalable, modular “factory-on-a-chip” systems for production of commodity and fine chemicals. Microchannels may also serve as micro- and nano-scale templates or scaffolds for manufacturing novel structured materials with complex hierarchical architectures. Intensified mass and heat transfer in microchannels creates opportunities for more efficient chemical processing and separations.

Since the early demonstrations of microfabricated “lab-on-a-chip” concepts in the 1980s/90s, the field has grown exponentially as fabrication methods have matured and new applications have emerged. Today, microfabricateds is a vibrant multidisciplinary research area spanning physics, engineering, materials science, chemistry and biology. Commercialization of microfabricated-based POC diagnostic devices, high-throughput screening systems and continuous microreaction technologies has begun in sectors like healthcare, pharmaceuticals, chemicals and more.

further integration of micro/nano-scale manipulation and sensing components with fluidics promises to revolutionize fields like synthetic biology, tissue engineering and environmental monitoring. Microfabricateds will likely play an increasing role in sectors from personalized medicine to high-value manufacturing. Its capabilities for controlling fluids and interfaces at the smallest scales will continue enabling new scientific discoveries across many domains.

Get more insights on Microfluidic

Vaagisha brings over three years of expertise as a content editor in the market research domain. Originally a creative writer, she discovered her passion for editing, combining her flair for writing with a meticulous eye for detail. Her ability to craft and refine compelling content makes her an invaluable asset in delivering polished and engaging write-ups.

(LinkedIn: https://www.linkedin.com/in/vaagisha-singh-8080b91)

#Microfluidic#Microfabrication#Fluid Dynamics#Miniaturization#Microchannels#Biomedical Engineering#Microfluidic Devices

0 notes

Text

Blood Flow in a Fin

This award-winning video shows blood flowing through the tail fin of a small fish. Cells flow outward in a central vessel, then split to either side for the return journey. (Video and image credit: F. Weston for the 2023 Nikon Small World in Motion Competition; via Colossal) Read the full article

624 notes

·

View notes

Text

Rooting for You

Deep underground, bargains are made between living things. Symbiotic relationships allow fungi to weave their whisker-like hyphae among the roots of plants. This is mutually beneficial: the fungus is rewarded with nutrients while expanding the plant’s thirsty root system. But this biological bonding might benefit us too. Here, researchers grow a plant in a pit of sandy silica nanoparticles. Its roots burrow tunnels in the particles which then harden after a blast of extreme heat, a process known as sintering which leaves a network of tiny channels behind in the transformed glass. A blue liquid is sucked through the tunnels via capillary action, similar to how chemicals move into and around our tissues. Such techniques might allow tissue engineers to explore new designs for microfluidic devices, using plants and fungi as tiny biodegradable scaffolds.

Written by John Ankers

Clip from a video from work by Tetsuro Koga, Shota Nakashima & Fujio Tsumori

Department of Aeronautics and Astronautics, Graduate School of Kyushu University, Fukuoka, Japan

Video originally published with a Creative Commons Attribution – NonCommercial – NoDerivs (CC BY-NC-ND 4.0)

Published in Scientific Reports, September 2024

You can also follow BPoD on Instagram, Twitter, Facebook and Bluesky

11 notes

·

View notes

Text

Collective synchronized magnetic oscillations enable micropillar arrays to manipulate fluids and act as soft robots

Researchers from Hanyang University have developed an innovative micropillar array capable of collective and rapid magnetic oscillations, demonstrating strong potential for advanced applications in robotics, fluid transport, and dynamic surface control. In nature, many organisms exhibit collective movements to accomplish tasks that would be challenging for individuals alone. A prominent example is the coordinated motion of marine cilia, which collectively regulate fluid flow, facilitate locomotion, or enhance adhesion to surrounding surfaces. Although artificial micropillar structures have been explored to manipulate surface functionality, achieving dynamic actuation with both rapid response and sufficiently large deformation remains a significant challenge.

Read more.

9 notes

·

View notes

Text

I can't remember when I last spend a whole day going wow like this, the research has got so much further than I'd have expected!

Matt Gray is Trying: Biomedical Research

youtube

49 notes

·

View notes

Text

Microfluidic organ chip replicates human cervix, addressing critical gap in women's health research

- By InnoNurse Staff -

Bacterial vaginosis (BV) affects over 25% of reproductive-aged women, causing severe health complications, and is inadequately treated by current antibiotics, prompting researchers at Harvard and UC Davis to develop a microfluidic "Cervix Chip" that models the cervix's complex environment to better study BV and improve treatments.

Read more at Harvard University/Medical Xpress

Header image credit: DALL·E 3

3 notes

·

View notes

Text

Microfluidic contact lenses emerge as next generation tools for eye care

The tear film coating the eye offers a window into a person’s systemic and ocular health, carrying biomarkers such as glucose, electrolytes, and proteins. Yet, existing diagnostic approaches-like tonometry or tear sampling-are often invasive, infrequent, and impractical for daily monitoring. Likewise, standard eye drop treatments suffer from poor drug retention due to blinking and drainage,…

View On WordPress

0 notes

Photo

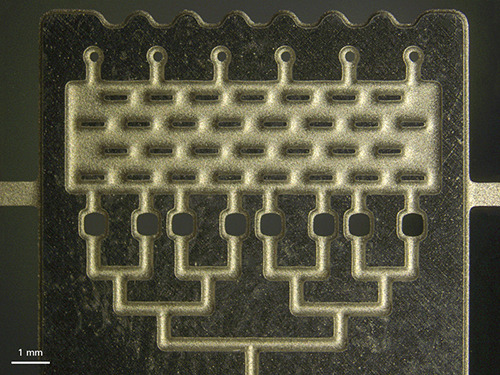

Microfluidics under the ZEISS Stemi 508 microscope.

7 notes

·

View notes

Link

🧪💡 Tiny tech, massive impact! Micro pumps are powering precision in drug delivery, diagnostics & wearables 📦

1 note

·

View note

Text

An electrospray engine applies an electric field to a conductive liquid, generating a high-speed jet of tiny droplets that can propel a spacecraft. These miniature engines are ideal for small satellites called CubeSats that are often used in academic research. Since electrospray engines utilize propellant more efficiently than the powerful, chemical rockets used on the launchpad, they are better suited for precise, in-orbit maneuvers. The thrust generated by an electrospray emitter is tiny, so electrospray engines typically use an array of emitters that are uniformly operated in parallel. However, these multiplexed electrospray thrusters are typically made via expensive and time-consuming semiconductor cleanroom fabrication, which limits who can manufacture them and how the devices can be applied.

Read more.

7 notes

·

View notes

Text

3D-printed collagen scaffolds mimic living tissues and may replace animal testing

- By Nuadox Crew -

Engineers at the University of Pittsburgh have developed a groundbreaking method for 3D printing collagen-based scaffolds—called CHIPS—that support the growth and self-organization of living cells into functional tissues.

Led by Daniel Shiwarski in collaboration with Adam Feinberg from Carnegie Mellon, this innovation combines natural biomaterials with advanced microfluidic design to mimic real organ environments.

Unlike traditional synthetic models, these collagen structures allow cells to grow, interact, and function as they would in the body, including responding to stimuli like glucose.

Integrated with a custom bioreactor system (VAPOR), the platform enables complex 3D vascular networks and offers a more human-relevant alternative to animal testing.

All designs are open-source, with the long-term goal of modeling diseases like hypertension and replacing animal studies in biomedical research.

Header image: Online cover of Science Advances, April issue. Credit: Daniel Shiwarski.

Read more at University of Pittsburgh Swanson School of Engineering

Scientific paper: “3D bioprinting of collagen-based high-resolution internally perfusable scaffolds for engineering fully biologic tissue systems” by Daniel J. Shiwarski, Andrew R. Hudson, Joshua W. Tashman, Ezgi Bakirci, Samuel Moss, Brian D. Coffin and Adam W. Feinberg, 23 April 2025, Science Advances. DOI: 10.1126/sciadv.adu5905

Related Content

Scientists achieve the milestone of being the first to successfully 3D-print functional human brain tissue

Other Recent News

Household washing machines may leave behind harmful pathogens on clothing.

Facial and eye biomarkers reveal new insights into tinnitus severity, offering potential for treatment testing.

Uncovered mechanisms improve understanding of advanced AI memory devices.

One molecule significantly enhances both the efficiency and durability of perovskite solar cells.

0 notes

Text

Negative Photoresists: Tailored Solutions for Complex Designs

Explore how negative photoresists deliver precision, durability, and high aspect ratio patterning for electronics, MEMS, photonics, and PCB manufacturing. Discover tailored solutions for microfabrication excellence with A-Gas Electronic Materials. Contact us today to learn more.

#negative photoresists UK#microfabrication photoresists#high aspect ratio photoresists#photolithography resists#PCB photoresist materials#microfluidic device photoresists#optical device photoresists#advanced microfabrication solutions#A-Gas Electronic Materials

0 notes