#ndt certification

Explore tagged Tumblr posts

Text

How Mag Particle Testing Protects Your Critical Assets?

Our world relies on a vast network of critical assets. From the towering wind turbines that harvest clean energy to the intricate pipelines that transport vital resources, these structures form the backbone of modern civilization. However, hidden beneath the surface of these assets can lurk a silent threat: cracks. These imperfections, often invisible to the naked eye, can pose a significant risk to safety, functionality, and operational efficiency. To read more visit

#welding engineering inspection services#engineering safety inspection services#engineering & inspection services#construction engineering and inspection services#engineering and inspection services#inspection engineer#visual testing#ultrasonic inspection#ndt inspection services#ultrasonic test#testing and inspections#ndt inspector#mag particle testing#welding engineering#ndt certification#visual inspection#welding engineer#engineering services#non-destructive testing#non destructive evaluation

0 notes

Text

NDT Training and Certification Courses in Singapore| Best NDT Inspection

Are you trying to growth in your Non-Destructive Testing (NDT) career? Best NDT Inspection specific NDT Training and Certification courses in Singapore are designed to equip professionals with the skills and identifications required in fabrication and manufacturing industries.

Why Choose Us?

Comprehensive Training Modules: Covering UT, MT, PT, RT, and VT techniques.

Internationally Recognized Certifications: Compliant with ASNT and ISO 9712 standards.

Expert Trainers: Learn from certified and experienced NDT professionals.

Hands-On Practical Sessions: Access to advanced equipment and real-world testing scenarios.

Flexible Learning Options: Weekend and evening batches available.

Who Should Enroll?

Quality Control Inspectors

Engineers & Technicians in Manufacturing

Fresh Graduates in Engineering

Professionals seeking career advancement in NDT

Key Benefits: ✔ Enhance job prospects globally ✔ Stay updated with cutting-edge NDT methodologies ✔ Network with industry peers

Don’t miss the opportunity to grow your expertise. Enroll today!

Contact Us Now:

Visit: https://www.bestndtinspection.com/ndt-training-certification/

Phone no: 65-84797783

0 notes

Text

NDT Testing in Perth: Ensuring Safety and Quality with Cossack Inspections

NDT Testing plays a crucial role in the safety, maintenance, and longevity of industrial infrastructure, machinery, and materials. In Perth, Cossack Inspections stands out as a trusted provider of NDT testing services. Their comprehensive range of testing methods and their commitment to quality ensure that industries in Perth can maintain the integrity of their operations and safeguard against potential hazards.

Non-Destructive Testing (NDT) refers to a series of techniques used to evaluate the properties, structure, and integrity of materials, components, or systems without causing any damage to them. These tests are critical for detecting internal or surface defects that might not be visible to the naked eye, allowing for early identification of issues before they become serious problems.

0 notes

Text

The Value of Advanced NDT Techniques in Tube Inspection

Ensuring the optimal performance and safety of industrial equipment is a top priority across various sectors. One critical aspect of maintaining such performance is through Tube Inspection Services from RVS QUALITY CERTIFICATIONS PVT LTD. These services are indispensable for industries that rely on the efficient functioning of tubes, such as in heat exchangers, boilers, and condensers. Here, we explore the importance of Inspection Services and how they contribute to the overall health of industrial systems.

Preventive Maintenance e Precision

Inspection Services are fundamental to preventive maintenance strategies. By regularly inspecting tubes, potential issues can be identified before they lead to significant failures or costly downtime. This proactive approach not only enhances the longevity of the equipment but also ensures that it operates at peak efficiency. Regular inspections help detect early signs of wear and tear, corrosion, and other forms of degradation, allowing for timely interventions that can prevent more severe damage.

Advanced Inspection Techniques

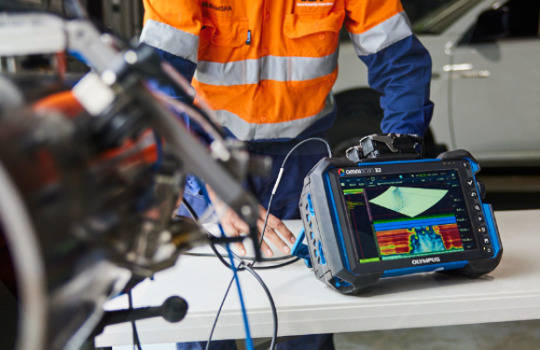

The effectiveness of Inspection Services is greatly enhanced by advanced non-destructive testing (NDT) methods. Techniques such as eddy current testing, ultrasonic testing, and remote visual inspection are commonly employed to assess the condition of tubes without causing any damage. Inspectors with NDT Level 2 Certification Courses from RVS QUALITY CERTIFICATIONS PVT LTD are trained to use these advanced methods to accurately identify defects, including cracks, pitting, and wall thinning. This high level of precision ensures that even the smallest issues are detected, enabling precise maintenance planning and execution.

Optimizing System Efficiency

The performance of systems that rely on tubes, such as heat exchangers and boilers, directly impacts the overall efficiency of industrial operations. Any compromise in the integrity of these tubes can lead to reduced heat transfer efficiency, increased energy consumption, and higher operational costs. By employing comprehensive Inspection Services, organizations can maintain optimal system performance. These inspections help ensure that the tubes are free from blockages, corrosion, and other issues that could impede their functionality, thereby sustaining efficient and cost-effective operations.

Safety and Compliance

Ensuring the safety of industrial operations is paramount, and Inspection Services play a crucial role in this regard. Faulty tubes can lead to catastrophic failures, posing serious risks to personnel and equipment. Regular inspections help mitigate these risks by identifying and addressing potential issues before they escalate. Furthermore, industries are often required to comply with stringent safety and regulatory standards. Third-party Third-Party Inspection Services from RVS QUALITY CERTIFICATIONS PVT LTD provide an additional layer of assurance, validating that the equipment meets all necessary compliance requirements. This external validation not only enhances safety but also boosts the organization's credibility and reliability.

Cost-Effective Maintenance

While some may view Inspection Services as an added expense, they are, in fact, a cost-effective maintenance strategy. Early detection of issues through regular inspections can prevent costly repairs, extensive downtime, and loss of productivity. The ability to plan maintenance activities based on accurate inspection data allows organizations to allocate resources more efficiently and avoid unexpected breakdowns. In the long run, the investment in Inspection Services pays off by reducing the total cost of ownership and maximizing the return on investment for industrial equipment.

Training and Expertise

The effectiveness of Inspection Services is highly dependent on the expertise of the inspectors. Professionals trained through NDT Certification Courses possess the necessary skills and knowledge to perform thorough and accurate inspections. Their expertise ensures that all potential issues are identified and appropriately addressed. Continuous training and certification updates are essential to keep inspectors abreast of the latest advancements in inspection technologies and methodologies, thereby maintaining high standards of service quality.

In conclusion, Inspection Services are essential for ensuring the optimal performance, safety, and efficiency of industrial systems. By incorporating advanced non-destructive testing techniques and leveraging the expertise of certified professionals, organizations can proactively manage the health of their equipment. Regular inspections help prevent costly failures, ensure compliance with safety standards, and enhance overall operational efficiency. For industries striving to maintain high-performance standards and minimize risks, investing in Inspection Services is a prudent and necessary decision.

0 notes

Text

Carbon Steel Flanges ADNOC Approved Stockiest in Ajman

When it comes to high-pressure and high-stress pipeline systems, especially in oil and gas transmission, ASTM A694 F65 Flanges have emerged as a reliable and high-performance solution. These flanges are manufactured from high-yield carbon steel and are specifically designed for severe service conditions, including high-pressure fluid transmission and sour service environments.

This article explores the key characteristics, types, applications, and advantages of ASTM A694 F65 Carbon Steel Flanges, providing insights into their role in modern industrial systems.

What is ASTM A694 F65?

ASTM A694 is a standard specification established by ASTM International for forged or rolled carbon and alloy steel flanges, fittings, valves, and parts intended for high-pressure transmission service. The F65 grade indicates a minimum yield strength of 65,000 psi (450 MPa), ensuring the flange can withstand high stress and pressure conditions without deformation or failure.

Key Features of ASTM A694 F65 Flanges

Material: Forged high-strength carbon steel (Grade F65)

Yield Strength: ≥ 65,000 psi (450 MPa)

Tensile Strength: ≥ 77,000 psi (531 MPa)

Service Environment: Suitable for sour gas (H2S), high pressure, and high-temperature applications

Heat Treatment: Normalized, quenched and tempered, or normalized and tempered

Types of ASTM A694 F65 Carbon Steel Flanges

These flanges are available in various configurations to support different system requirements:

Weld Neck Flanges (WN)

Ideal for high-pressure pipelines and critical stress environments.

Slip-On Flanges (SO)

Economical and suitable for moderate pressure applications.

Blind Flanges (BL)

Used to seal piping ends or pressure vessels for inspection or closure.

Socket Weld Flanges (SW)

Used for small-diameter, high-pressure pipework.

Threaded Flanges (TH)

Used in systems where welding is not feasible or preferred.

Lap Joint Flanges (LJ)

Ideal for systems requiring frequent assembly and disassembly.

Ring Type Joint Flanges (RTJ)

High-performance sealing in high-pressure and high-temperature systems.

Standards and Classifications

Specifications: ASTM A694 / ASME SA694

Size Range: ½″ to 60″ Nominal Bore (NB)

Pressure Ratings: ANSI Class 150 to 2500

Design Standards: ASME B16.5, ASME B16.47 (Series A & B), MSS-SP-44

Face Types: Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ)

Sour Service Compatibility: Available upon request as per NACE MR0175 / ISO 15156

Applications of ASTM A694 F65 Flanges

Thanks to their high strength and pressure-handling capabilities, ASTM A694 F65 carbon steel flanges are extensively used in:

Oil & Gas Pipelines

Petrochemical Refineries

Natural Gas Distribution Networks

LNG Plants and Terminals

Offshore Drilling and Subsea Equipment

High-Pressure Steam and Water Lines

Power Generation Facilities

These flanges are ideal for severe service conditions, including high flow rates, corrosive fluids, and extreme pressure differentials.

Advantages of ASTM A694 F65 Flanges

✅ High Yield Strength: Supports high-pressure fluid transport ✅ Superior Durability: Withstands mechanical stress and temperature fluctuations ✅ Good Weldability: Easy to fabricate and assemble on-site ✅ Cost-Effective Performance: Offers strength and reliability without resorting to exotic alloys ✅ Sour Service Compatibility: Can be customized for H2S resistance with proper testing and certification

Testing and Quality Assurance

To ensure optimal performance, ASTM A694 F65 flanges undergo rigorous quality control procedures, including:

Chemical Composition Verification

Tensile and Yield Strength Testing

Charpy V-Notch Impact Testing (for low-temp or sour service)

Hardness Testing

Non-Destructive Testing (NDT): Ultrasonic, Magnetic Particle, Radiographic (as required)

Hydrostatic Pressure Testing

Conclusion

ASTM A694 F65 Carbon Steel Flanges are built for excellence in strength, toughness, and pressure resistance. In industries where reliability under high-pressure, high-stress, and corrosive conditions is non-negotiable, these flanges deliver consistent and safe performance. Their widespread adoption in the global energy and processing sectors underscores their importance in critical infrastructure and pipeline engineering.

#ASTM A694 F65 Flanges Manufacturers in UAE#ASTM A694 F65 Flanges Suppliers in UAE#ASTM A694 F65 Flanges Stcokists in UAE#ASTM A694 F65 Flanges Exporters in UAE#carbon steel flanges stockist in uae#carbon steel flanges in uae#wmass carbon steel flanges manufacturers in uae#cs flanges in uae

0 notes

Text

Underwater Work Isn’t Just a Job—It’s a Life Below the Surface Diploma in Commercial Diving: Where Tough Meets Transformative

Not every career path begins in a classroom. Some begin in saltwater. Some start with steel-toe boots, gear that weighs more than you do, and a mask that cuts off the world above. This is the world of commercial diving—and for those drawn to deep water and hard work, it’s more than just a job. It’s a calling.

If you've ever felt that tug toward something raw, physical, and powerful—commercial diving might be it. And the Diploma in Commercial Diving is where the journey begins.

This isn't about casual dives or holiday certification cards. This is real, high-pressure, underwater labor in industries that depend on skilled divers to keep things running, safe, and standing.

So… What Is Commercial Diving Really?

Commercial diving is one of those careers that flies under the radar for most people. You don’t hear about it often, but it’s behind a surprising amount of infrastructure and industry. Divers inspect offshore rigs, repair pipelines deep below the ocean, weld broken steel under bridges, salvage sunken vessels, and even handle dangerous tasks in murky, hazardous environments.

It’s gritty. It’s tough. It’s dangerous at times. And that’s exactly why it requires precision training, mental focus, and solid teamwork.

The Diploma in Commercial Diving is built to prepare you for that kind of environment. It’s more than a crash course. It’s an introduction to a whole different world—one where being underwater is your workday, and your gear is your lifeline.

What You’ll Learn in the Program

The diploma isn’t just about how to dive. It’s about how to do hard things under pressure—literally.

Here’s some of what’s covered:

Diving physics and decompression science – Understand how depth, pressure, and timing affect the human body.

Underwater welding and cutting – Learn to manipulate metal and flame in an environment where nothing is simple.

Heavy tool handling – From hydraulic drills to grinders, you’ll train with tools that get the job done below the surface.

Non-destructive testing (NDT) – Learn how to inspect and test underwater structures without damaging them.

Diving system operations – Familiarize yourself with helmets, umbilicals, compressors, and communication tools—your link to the surface.

Safety protocols – Because underwater, safety isn’t optional—it’s everything.

It’s a curriculum built to mold working divers. It won’t coddle, but it will prepare.

Where You Train Matters

Theory is one thing, but real learning happens when your feet leave the platform and your vision goes dark in open water.

Training takes place in modern, purpose-built environments that mimic the real-world chaos and conditions of commercial diving sites. You’ll spend time in deep pools, confined spaces, and controlled offshore-style settings. You’ll sweat. You’ll freeze. You’ll work hard in places that are loud, cold, and unfamiliar.

And that’s exactly the point.

With small class sizes and one-on-one mentorship, this program doesn’t leave you to figure it out alone. You get direct, honest feedback from instructors who’ve actually lived the job—people who know what it means to dive for a living, and what it takes to make it back safely every time.

It’s Not Just About the Cert—But You’ll Get That, Too

Let’s talk credentials.

By the end of the diploma program, you’ll be prepared for certifications recognized globally—like IMCA and ADCI. These aren’t just pieces of paper. They’re proof to employers across oceans that you know your stuff.

Whether you’re applying for work in the Middle East, Southeast Asia, Australia, or the North Sea—these certs open doors. They say: “This person knows how to handle themselves down there.”

The Real Reasons People Choose This Path

Yes, the pay is good. And yes, it’s in demand.

But most commercial divers will tell you: they didn’t choose it just for the paycheck. They chose it because they wanted to feel something. Something physical. Something raw. Something most people will never understand unless they’ve been 30 meters deep, with a job to finish and only their training to rely on.

This line of work isn’t for everyone. It asks for a lot—your time, your strength, your focus. But it gives back something even more rare: purpose. Adventure. And the respect that comes with doing something few others can.

Is This the Start of Something Bigger?

For a lot of folks, the Diploma in Commercial Diving isn’t just job prep—it’s a personal transformation.

It builds:

Discipline – You can’t fake your way through this. You show up. You push through.

Confidence – Knowing you can function under pressure (literally) changes the way you see the world.

Brotherhood – You train as a team. You dive as a team. You look out for each other.

Opportunity – Whether offshore, in ports, or in support industries, skilled divers are always needed.

And once you’re in, the field is surprisingly broad. From energy and shipping to underwater film work or marine research—commercial diving is a strong foundation that leads to a wide range of careers.

Ready to Take the First Step?

If all this sounds less like a job and more like something you’ve been craving without having the words—follow that instinct. This isn’t ordinary work. But maybe you’re not looking for an ordinary life.

You can get full details, course structure, and enrollment info right here: 👉 https://scuba-career.com/commercial/diploma-commercial-diving/

Because some people are made to go deeper. Literally.

0 notes

Text

Affordable ASNT Training and course | TryIn Solution

Boost your career with Affordable ASNT Training and Courses from TryIn Solution. Our expert-led programs offer practical knowledge and certification in non-destructive testing (NDT), designed to meet industry standards without breaking your budget. To learn more, visit www.tryinsolution.com today.

0 notes

Text

How BS Group Ensures Quality Control in Every Pipe Manufactured in Raigarh

In the rapidly developing industrial region of Raigarh, Chhattisgarh, BS Group has emerged as a reliable name in the pipe manufacturing sector. Known for its consistent quality and dependable performance, BS Group ensures that every pipe manufactured in its Raigarh facility meets the highest standards. From sourcing raw materials to the final delivery, the company follows a strict quality control process that sets it apart from others in the industry.

End-to-End Quality Control Starts with Raw Materials

The quality journey at BS Group begins with the careful selection of raw materials. Only premium-grade steel and iron are used for manufacturing pipes. Each batch of raw material undergoes testing for chemical composition, strength, and purity. This initial step ensures that the foundation of the product is strong and reliable.

BS Group sources these materials from trusted suppliers who follow national and international quality standards. Once the materials reach the Raigarh facility, they are inspected again before being approved for production. This double-checking process is a vital part of maintaining product integrity.

Precision Manufacturing with Advanced Machinery

Modern, high-tech equipment at the Raigarh production facility guarantees accuracy and consistency in each pipe manufactured. To function at their best, this equipment undergoes routine maintenance and calibration. A significant portion of the production process is automated, which lowers the chance of human error and guarantees consistency in thickness, size, and finish.

Every pipe is constantly checked for irregularities during manufacture. To ensure consistency, variables including rolling speed, pressure, and temperature are carefully regulated. Delivering pipes that satisfy project needs and industry specifications is greatly aided by this emphasis on accuracy.

In-Process and Final Inspections

To ensure every product leaving the factory is of top quality, BS Group implements multiple levels of inspection during and after the production process. In-process checks are conducted at different stages of manufacturing, such as welding, shaping, and cooling. These checks help in identifying any defects early and fixing them before the next step.

Once the pipes are ready, a final inspection is carried out. Each pipe is checked for:

Dimensions (length, diameter, wall thickness)

Surface finish

Weld quality

Strength and durability

Leakage resistance

BS Group also uses non-destructive testing (NDT) methods to detect internal flaws without damaging the product. Pipes that pass all tests are approved for packaging and delivery, while any sub-standard item is rejected or reprocessed.

Testing Labs and Certifications

BS Group has dedicated quality control labs within its Raigarh facility. These labs are equipped with tools and instruments for mechanical and chemical testing. Every batch of pipes is tested for tensile strength, yield strength, elongation, and corrosion resistance.

Moreover, BS Group’s manufacturing process complies with various national and international certifications, including ISO standards. These certifications not only validate the company’s commitment to quality but also build trust with clients across sectors such as construction, agriculture, water supply, and industrial infrastructure.

Skilled Workforce and Quality Culture

The BS Group, quality involves both people and machines. The business makes investments in ongoing training for its employees, guaranteeing that each technician, engineer, and quality inspector is knowledgeable about the newest procedures and advancements in technology.

Every team member takes responsibility for their part in upholding high standards when there is a strong internal quality culture in place. This shared accountability enables BS Group to continuously produce goods that function dependably in the field.

Conclusion

Quality control is not a one-time task—it’s a commitment that BS Group upholds every day at its Raigarh BS pipe manufacturing facility. By combining advanced machinery, skilled manpower, and rigorous testing protocols, the company ensures that every pipe it produces lives up to customer expectations and industry demands.

0 notes

Text

Behind the Scenes: How Ali Yaqoob Ensures Quality Control in Valve Supply Across the UAE

When UAE industries need the best valves, they use Ali Yaqoob Trading—Dubai valve suppliers in UAE that are among the most reliable valve suppliers in Dubai. From oil and gas to water treatment plants and petrochemical industries, our quality standards speak volumes. Here's an insider's look at how our stringent quality control process makes all the difference in the valve-supply market.

1. Stringent Vendor Selection & Product Standards

Our quality journey begins with selecting the right partners. We deal only with internationally certified manufacturers that adhere to API and ASME standards. These relationships enable us to provide an extensive variety of valves—gate, globe, ball, butterfly, check, pressure relief, needle, solenoid, and others—intended for industrial use.

Prior to onboarding a vendor, we perform extensive audits of their manufacturing process to ascertain if they are up to our material traceability, quality of welding, and dimensional accuracy standards.

2. Detailed Stock Management in Dubai

Located at Dubai Investment Park, Ali Yacoob Trading's warehouses are optimized for efficiency and management. We hold a wide stock of valves in several sizes, pressure classes, and materials—carbon steel, stainless steel, alloys—to meet quick delivery commitments to clients throughout the UAE.

Our facility has organized storage, humidity control, and FIFO procedures to maintain material integrity. Every batch is labeled and recorded electronically, correlating to source documents for complete traceability.

3. Technical Verification by Experienced Engineers

Every incoming valve has a comprehensive technical check. Our experts verify:

Physical dimensions versus specification sheets

Material certificates and heat-number tracking

Visual inspection for defects like burrs or corrosion

Pressure or seat tests to identify leaks

Our engineering staff, with decades of experience, guarantees each valve meets Ali Yaqoob's reputation for reliability.

4. Third-Party Testing for Critical Applications

For mission-critical applications—such as petrochemical or offshore—third-party testing is crucial. We collaborate with accredited laboratories to perform hydrostatic pressure testing, non-destructive testing (NDT), and performance testing. Test reports are included, with every shipment of valves, giving clients confidence to move forward.

5. Customized Testing and Certification

Realizing that industries are specific in their needs, we provide proprietary test packages that suit your project:

Specialized pressure tests

Control valve endurance cycling

Certification according to international specifications (ATEX, PED, NACE, etc.)

These extra tests confirm compatibility with operating conditions and regulatory compliance.

6. Order-Fulfilment: Precision, Packaging, and Shipping

When the customer orders, our personnel remove the specified valves, check batch and traceability, and package them safely—especially for overseas shipments that need export packing standards.

Our efficient logistics chain from our headquarters in Dubai facilitates timely despatch in the UAE and GCC.

7. Longevity and Post-Sale Support

Our dedication does not end with delivery. Customers enjoy:

Technical installation guidance

Maintenance instructions and inspection intervals

Field assistance for repair or replacement

This support maximizes valve performance throughout their lifespan.

8. Continuous Improvement Through Feedback

Ali Yaqoob Trading sees each delivery as a chance to get better. Feedback loops give visibility into field performance, warranty claims, and aftermarket behavior. This information allows us to optimize vendor selection, inspection techniques, and product assortment—bringing more value to customers.

Final Thoughts

Supplying valves is not enough—having each unit meet stringent quality standards is what really differentiates Ali Yaqoob Trading. As Dubai's and the UAE's top valve suppliers, we don't merely supply valves—we provide engineered assurance and peace of mind. Our strict quality control—from vendor qualification to field service—guarantees customers only the highest. Searching for a trusted valve supplier in UAE? Taste the difference of Ali Yaqoob Trading's unmatched quality and service.

0 notes

Text

How Matters Testing Lab UAE Helps Businesses Meet International Standards? | +971 554747210

In today’s globalized economy, businesses operating in the UAE are increasingly expected to comply with stringent international standards to remain competitive and trustworthy. Whether manufacturing consumer goods, industrial products, or high-tech equipment, adherence to globally recognized quality and safety benchmarks is essential for market access, regulatory compliance, and brand reputation.

This is where Matters Testing Lab UAE plays a pivotal role. As a premier accredited testing laboratory, Matters Testing Lab provides comprehensive testing and certification services that help UAE businesses meet and exceed international standards. In this blog, we will explore how Matters Testing Lab UAE supports companies across industries to achieve compliance, enhance product quality, and succeed in global markets.

Why Meeting International Standards Matters for UAE Businesses

With its strategic location as a trade hub, the UAE attracts businesses aiming to export to markets in Europe, North America, Asia, and beyond. International standards — such as ISO (International Organization for Standardization), ASTM (American Society for Testing and Materials), IEC (International Electrotechnical Commission), and EN (European Norms) — define the technical and quality requirements that products must fulfill.

Meeting these standards helps businesses:

Ensure product safety and reliability for end-users.

Gain market access and regulatory approvals across countries.

Reduce risks of recalls, legal penalties, and reputational damage.

Improve manufacturing processes and innovation through standardized benchmarks.

Build consumer confidence and brand equity worldwide.

However, navigating the complex web of international standards requires expertise, precision, and reliable testing services — all of which Matters Testing Lab UAE delivers.

Accredited Testing Services Tailored to International Standards

1. ISO/IEC 17025 Accreditation

Matters Testing Lab UAE is accredited under ISO/IEC 17025, the global benchmark for testing and calibration laboratories. This accreditation guarantees that the lab meets rigorous requirements for technical competence, impartiality, and consistent test result quality.

For businesses, this means that all testing, analysis, and certifications provided by Matters Testing Lab are recognized and accepted internationally, which is crucial for export certification and regulatory submissions.

2. Comprehensive Testing Capabilities Across Multiple Standards

Matters Testing Lab UAE offers a wide range of testing services aligned with international standards, including but not limited to:

Material Testing: Evaluations for metals, plastics, textiles, and composites as per ASTM, ISO, and EN standards.

Mechanical Testing: Tensile strength, hardness, fatigue, and impact testing according to ASTM and ISO protocols.

Electrical and Electronic Testing: Safety, EMC, and performance testing compliant with IEC and UL standards.

Environmental Testing: Simulating extreme conditions like temperature, humidity, and corrosion in line with ISO and ASTM standards.

Chemical Testing: Identification and quantification of hazardous substances following REACH, RoHS, and other regulations.

Non-Destructive Testing (NDT): Ultrasonic, radiographic, magnetic particle, and dye penetrant inspections to detect flaws without damaging products.

By aligning testing services with recognized international standards, Matters Testing Lab UAE ensures businesses receive valid, globally accepted test reports.

3. Customized Testing Programs for Industry-Specific Compliance

Different industries face unique regulatory challenges. Matters Testing Lab UAE collaborates closely with manufacturers, exporters, and importers to design customized testing plans that address specific industry requirements, such as:

Construction and building materials conforming to ASTM and EN standards.

Automotive parts tested according to ISO/TS and SAE norms.

Electronics and appliances complying with IEC and FCC regulations.

Food contact materials tested for chemical safety per FDA and EU standards.

This tailored approach ensures that every product undergoes relevant testing that supports certification and compliance for its target markets.

Supporting Regulatory Approvals and Certification Processes

1. Facilitating Product Certification and Market Entry

International standards are often prerequisites for obtaining certifications required by regulatory authorities worldwide. Matters Testing Lab UAE not only performs necessary testing but also assists businesses in compiling technical documentation and test reports that meet the requirements of certifying bodies such as:

Emirates Authority for Standardization and Metrology (ESMA)

Gulf Cooperation Council (GCC) Standardization Organization

European Conformity (CE) marking agencies

U.S. Federal Communications Commission (FCC)

Underwriters Laboratories (UL) and other global bodies

By providing precise, accredited test reports, Matters Testing Lab UAE smooths the path to product certification and market approval.

2. Compliance with Environmental and Safety Regulations

Global consumers and regulators increasingly demand environmentally friendly and safe products. Matters Testing Lab UAE supports compliance with key regulations such as:

REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) — limiting hazardous substances.

RoHS (Restriction of Hazardous Substances) — ensuring electronics and electrical products are free from specific toxins.

WEEE (Waste Electrical and Electronic Equipment) directives.

Food safety standards for packaging and contact materials.

By conducting chemical and toxicology testing aligned with these regulations, Matters Testing Lab helps businesses avoid fines, import restrictions, and consumer backlash.

Leveraging Advanced Technology and Expert Insights

To maintain alignment with evolving international standards, Matters Testing Lab UAE continuously invests in advanced testing equipment and highly trained professionals. This investment translates into:

Accurate and reproducible test results validated by stringent quality control.

State-of-the-art testing methodologies in mechanical, chemical, environmental, and electrical domains.

Consultative services offering guidance on compliance strategies and standard interpretation.

Rapid turnaround times allowing businesses to stay agile and meet launch deadlines.

This expertise empowers UAE businesses to confidently navigate complex global regulations and deliver products that meet or exceed market expectations.

Real-World Impact: Success Stories of Compliance and Growth

Many UAE businesses have leveraged Matters Testing Lab’s expertise to gain international certifications, expand their global footprint, and improve product quality. For example:

A UAE-based electronics manufacturer achieved IEC compliance for a new line of appliances, enabling export to European and North American markets.

A construction materials company passed rigorous ASTM testing for fire resistance and mechanical strength, leading to adoption by major infrastructure projects in the GCC.

A textile exporter met OEKO-TEX and REACH chemical safety standards, opening doors to eco-conscious buyers in Europe.

These success stories highlight how Matters Testing Lab UAE’s accredited testing and consulting services transform compliance challenges into business opportunities.

Why Partner with Matters Testing Lab UAE for International Standards Compliance?

Choosing the right testing partner is crucial. Matters Testing Lab UAE stands out because:

Accredited and internationally recognized test reports support smooth certification.

Wide-ranging testing services meet diverse industry and product needs.

Customized testing programs focused on relevant international standards.

Experienced technical team with in-depth knowledge of global regulations.

Fast and reliable service ensuring timely market entry.

Comprehensive compliance support beyond testing, including documentation and advisory services.

For businesses striving to enhance quality, safety, and market access, Matters Testing Lab UAE is an invaluable ally.

Conclusion

In a competitive global marketplace, meeting international standards is not optional — it’s essential. For UAE businesses seeking trusted, accurate, and comprehensive testing solutions, Matters Testing Lab UAE offers the expertise, accreditation, and service excellence necessary to achieve full compliance with global benchmarks.

By partnering with Matters Testing Lab, businesses can ensure their products meet rigorous international standards, unlock new markets, build consumer trust, and foster sustainable growth.

0 notes

Text

Industrial Cabineted X-ray Market Key Growth Drivers Fueling Expansion in the Global Systems Market

Industrial Cabineted X‑Ray Market Drivers

1. Surge in Non‑Destructive Testing (NDT)

One of the primary factors fueling the demand for industrial cabineted X‑ray systems is the escalating need for non‑destructive testing (NDT). Sectors like aerospace, automotive, electronics, and machinery heavily rely on precise inspection tools to ensure structural integrity and detect defects without damaging critical components. Cabineted X‑ray systems deliver high-resolution imaging, enabling the identification of flaws such as voids, inclusions, cracks, or assembly errors—essential for maintaining quality standards in high‑stakes industries.

Regulatory frameworks and industry standards increasingly mandate stringent quality control protocols. The ability of cabineted X‑ray systems to conduct detailed inspections while ensuring compliance with safety regulations makes them indispensable. Regulatory pressure — particularly in aerospace and pharmaceuticals — further amplifies their adoption.

2. Technological Advancements: Digital Imaging & AI Integration

Robust growth in digital radiography (DR) and computed tomography (CT) technologies has revolutionized X‑ray inspection. DR systems, equipped with advanced detectors and imaging software, significantly enhance image quality and operational efficiency. They offer faster acquisition, improved clarity, and decreased radiation exposure—advantages that are increasingly prioritized by industrial manufacturers.

Beyond DR, the advent of artificial intelligence (AI) and machine learning (ML) marks a transformative shift. These systems can automatically detect defects with high precision, reducing manual inspection errors. AI enhances throughput and consistency and can even predict maintenance needs to reduce system downtime.

3. Broadening Applications Across Industries

While traditional industrial sectors—electronics, aerospace, automotive—continue to drive demand, cabineted X‑ray systems are finding new use cases:

Electronics: Miniaturization in semiconductors and surface‑mount technology necessitates high-precision inspection to detect hidden defects in microcomponents.

Pharmaceuticals: X‑ray cabinets ensure tablet integrity, detect contaminants in packaging, and verify labeling accuracy—critical in compliance‑driven environments.

Food & Beverage: Safety concerns demand reliable contaminant detection (e.g., metal shards, glass, stones) in packaged foods; X‑ray systems provide non‑destructive inspection without opening containers.

Security & Logistics: Heightened global security demands have led to widespread use of cabineted X‑ray systems at airports, ports, customs, and government facilities to detect contraband and ensure safe shipments.

4. Safety and Regulatory Mandates

Strong regulatory emphasis on radiation safety is pushing organizations to adopt enclosed cabineted X‑ray solutions. These systems are equipped with shielding to protect personnel and comply with stringent international standards and certifications.

In sectors like pharmaceuticals, aerospace, and defense, thorough inspection is legally required to guarantee safety. Cabineted X‑ray systems offer the reliability and traceability needed to satisfy audits and certification bodies—making the technology a must-have in highly regulated environments.

5. Industry 4.0 & Automation Integration

The shift toward Industry 4.0-driven smart manufacturing favors X‑ray systems that integrate with automated production lines and IoT platforms. Automated conveyor-fed cabineted X‑ray systems provide real-time defect detection and feedback, enabling manufacturers to halt or adjust defective workflows instantly—minimizing waste and improving operational efficiency.

These systems not only detect issues but can also predict maintenance needs through embedded AI and analytics tools, reducing unplanned downtime and extending equipment life.

6. Portable, Compact, and Eco‑Friendly Solutions

Manufacturers are engineering more compact and mobile cabineted X‑ray units, ideal for on-site inspections—particularly in industries like construction, oil & gas, and field service operations.

Moreover, there is a growing emphasis on eco-friendly solutions. Advancements in energy-efficient emitters and green sourcing of components are aligning X‑ray systems with sustainability objectives—an increasing consideration for industrial buyers aiming to reduce carbon footprints.

7. Geographical Market Expansion

North America and Europe remain dominant players due to mature sectors and strict compliance regimes. Meanwhile, Asia‑Pacific—led by China and India—is rapidly catching up thanks to booming industrialization, stronger healthcare infrastructure, and heightened security concerns.

Initiatives like India’s “Make in India” are boosting domestic manufacturing quality standards, driving demand for advanced inspection technologies. Similarly, airport expansions, customs modernization, and healthcare upgrades across the Asia-Pacific region present substantial market opportunities.

Conclusion

The industrial cabineted X‑ray market is experiencing strong, sustained growth, fueled by several interrelated drivers:

A rising need for non‑destructive testing across critical industries

Breakthroughs in digital imaging, AI, and automation

Expanded applications in electronics, healthcare, food safety, and security

Regulatory pressures around quality control and radiation safety

Integration with Industry 4.0 protocols for smart manufacturing

Development of portable, energy‑efficient systems

Rapid industrial expansion in Asia‑Pacific

Together, these factors not only point to increasing adoption—but also signal that cabineted X‑ray technology is becoming integral to quality assurance, safety standards, and operational efficiency in modern manufacturing and inspection landscapes.

0 notes

Text

PrimeInspection Dubai – The Gold Standard in Inspection & Certification Services

PrimeInspection Dubai stands as a leading authority in the field of professional inspection, certification, and quality assurance services across the UAE. Renowned for its unmatched precision, expertise, and commitment to international standards, PrimeInspection is the trusted choice for businesses seeking safety, compliance, and operational excellence.Prime inspection is considered among the top home inspection companies in dubai

With a team of highly trained inspectors, engineers, and industry experts, PrimeInspection offers a wide range of services including third-party inspections, lifting equipment certifications, non-destructive testing (NDT), safety audits, and quality management system consulting. Whether you're in construction, oil & gas, manufacturing, marine, or logistics, PrimeInspection ensures your equipment, systems, and processes meet the highest regulatory and safety standards.

What sets PrimeInspection apart is its dedication to customer satisfaction, fast turnaround times, and the use of cutting-edge technology. Backed by ISO accreditations and a strong reputation in the UAE market, PrimeInspection is not just a service provider — it's your partner in building safer, more reliable, and more compliant operations.

0 notes

Text

Top Structural Audit Company & Services in Dubai for Safe Buildings Ensure building safety and compliance with the top structural audit company in Dubai. Expert services include detailed inspections, risk assessment, and certification for residential, commercial, and industrial properties. For more information Contact Us: 📞 +91-8469769160 🌐 https://structuralauditcertification.com

0 notes

Text

Seeing the Unseen: How Infrared Thermography Services Can Save You Time and Money

In the modern world, maintaining efficiency and reducing costs are paramount for businesses across various industries. One powerful tool that has emerged to help achieve these goals is infrared thermography. Infrared Thermography Services are revolutionizing how companies manage maintenance, detect issues, and ensure safety. At RVS Quality Certifications Pvt Ltd., we understand the value of advanced diagnostic tools and offer comprehensive training and consultancy services to help you harness these technologies.

Understanding Infrared Thermography

Infrared thermography is a non-invasive, non-contact method of detecting heat patterns and temperatures on surfaces. By using infrared cameras, technicians can visualize and measure thermal energy emitted by objects. This technology allows for the identification of anomalies that might indicate underlying problems, such as electrical faults, mechanical failures, or insulation deficiencies.

Employing Infrared Thermography provides significant advantages over traditional inspection methods. It enables the detection of issues before they become critical, allowing for preventive maintenance and reducing the likelihood of unexpected downtime. This proactive approach can save businesses substantial amounts of time and money by avoiding costly repairs and ensuring optimal operational efficiency.

Applications Across Industries

Infrared thermography is versatile and applicable in various industries, including manufacturing, construction, energy, and automotive. In manufacturing, it helps in monitoring equipment conditions, detecting overheating components, and ensuring the integrity of electrical systems. In construction, it is used for inspecting building envelopes, identifying moisture intrusion, and verifying insulation performance.

For energy companies, infrared thermography is essential in monitoring power lines, transformers, and substations. It aids in detecting hot spots that could indicate potential failures, thereby preventing power outages. In the automotive industry, it is used for quality control and ensuring the safety of electrical systems in vehicles.

Training and Certification

To effectively utilize infrared thermography, proper training and certification are crucial. At RVS Quality Certifications Pvt Ltd., we offer NDT Level 2 Certification Courses that equip professionals with the necessary skills and knowledge to perform accurate and reliable thermographic inspections. Our courses cover the principles of thermography, equipment handling, data analysis, and report generation.

Achieving NDT Level 2 certification signifies a high level of competence in non-destructive testing methods, including infrared thermography. This certification not only enhances the skill set of professionals but also increases their value in the job market. Companies benefit from having certified personnel who can conduct thorough inspections and contribute to improved maintenance strategies.

Enhancing Safety and Reliability

One of the primary benefits of infrared thermography is its contribution to safety. By identifying potential issues early, businesses can mitigate risks and prevent accidents. For example, detecting overheating electrical components can prevent fires, while identifying structural weaknesses can avoid catastrophic failures in buildings and machinery.

RVS Quality Certifications Pvt Ltd. emphasizes the importance of Non Destructive Testing Services in maintaining safety and reliability. Our comprehensive training ensures that professionals are equipped to perform accurate assessments, thereby contributing to safer work environments and more reliable operations.

Cost Savings and Efficiency

Implementing infrared thermography can lead to significant cost savings. By identifying problems before they escalate, businesses can plan maintenance activities more effectively, reduce unplanned downtime, and extend the lifespan of equipment. This proactive approach minimizes the need for emergency repairs, which are often more expensive and disruptive.

For industries that rely heavily on the integrity of their equipment, such as energy and manufacturing, the cost savings from avoiding major failures are substantial. Additionally, by optimizing maintenance schedules and reducing downtime, companies can enhance their overall productivity and operational efficiency.

Specialized Services for Specific Needs

In addition to general applications, infrared thermography is also valuable for specialized inspections. For instance, Tube Inspection Services utilize infrared technology to assess the condition of tubes in boilers, heat exchangers, and other critical equipment. This type of inspection can detect issues such as blockages, corrosion, and leaks, which can significantly impact the performance and safety of the equipment.

#Infrared Thermography Services#NDT Level 2 Certification Courses#Non Destructive Testing Services#Tube Inspection Services

0 notes

Text

Comprehensive Guide to Lifting Equipment Inspection in the UAE

When it comes to workplace safety and operational efficiency, Lifting Equipment Inspection Services play a crucial role in ensuring that lifting devices are functioning safely and effectively. In the UAE’s fast-paced industrial and construction sectors, regular inspection and maintenance of cranes, hoists, slings, shackles, and other lifting devices is not just a safety measure—it’s a legal requirement.

Why Lifting Equipment Inspection is Critical

In industries like construction, oil and gas, logistics, and manufacturing, lifting equipment is used daily. Wear and tear from frequent usage can lead to mechanical failures if left unchecked. Lifting equipment inspection in the UAE is mandated under various safety regulations to reduce workplace hazards, avoid downtime, and maintain compliance.

Routine inspections help detect potential issues early, preventing accidents, equipment failure, and costly delays. By hiring certified professionals for lifting inspections, businesses not only protect their workforce but also extend the lifespan of their equipment.

What’s Included in Lifting Equipment Inspection Services?

Professional Lifting Equipment Inspection Services typically involve:

Visual and functional assessments

Load testing

Certification and compliance checks

Non-destructive testing (NDT)

Documentation and reporting

These services ensure that the equipment meets UAE’s safety and operational standards, including local municipality requirements and international norms such as LOLER and OSHA.

Choosing the Right Inspection Partner in the UAE

Selecting a reliable inspection service provider is essential. One trusted name in the industry is Darlsco, a company recognized for its expertise in safety and technical services across the UAE.

Darlsco provides certified lifting equipment inspection in the UAE, delivering tailored solutions for various industries. With experienced inspectors, cutting-edge tools, and a strong commitment to safety and compliance, Darlsco ensures that your lifting operations meet both local and global standards.

Explore more about their services here: Darlsco Lifting Equipment Inspection Services

Final Thoughts

Lifting operations carry significant risks, but these can be minimized with the help of regular and professional Lifting Equipment Inspection Services. If you're operating in the UAE, partnering with experienced providers like Darlsco can ensure that your equipment is safe, certified, and compliant with regulations. Don’t compromise on safety—make inspections a core part of your operational routine.

0 notes

Text

Industrial Vessels Manufacturer: Driving Industrial Efficiency and Safety

An industrial vessels manufacturer plays a vital role in supporting a wide range of industries by providing high-quality, custom-engineered containers designed to hold, mix, or process liquids, gases, and solids under controlled conditions. These vessels are essential to sectors such as chemical processing, oil and gas, pharmaceuticals, food and beverage, water treatment, and power generation.

What Are Industrial Vessels?

Industrial vessels include a variety of specialized containers used in manufacturing and processing environments. Common types include:

Pressure Vessels – Designed to hold materials at high or low pressure.

Storage Tanks – Used for holding raw materials or finished products.

Reactors – Used for chemical reactions under specific temperature and pressure conditions.

Mixing Vessels – Designed to blend different components uniformly.

Heat Exchangers – Facilitate heat transfer between fluids in a process.

Each vessel must meet stringent industry standards to ensure safety, reliability, and performance.

Core Services Offered by an Industrial Vessels Manufacturer

1. Custom Design and Engineering

A leading manufacturer provides tailored solutions based on process requirements, including vessel dimensions, pressure ratings, material compatibility, insulation needs, and internal configurations.

2. Material Selection and Fabrication

Depending on the application, vessels may be fabricated from stainless steel, carbon steel, or corrosion-resistant alloys. Precision welding, cutting, and assembly ensure structural integrity and compliance with relevant codes.

3. Standards Compliance and Certification

Manufacturers must comply with global standards such as:

ASME (American Society of Mechanical Engineers)

API (American Petroleum Institute)

PED (Pressure Equipment Directive – Europe)

ISO (International Organization for Standardization)

Vessels undergo thorough testing, including hydrostatic testing, X-ray inspection, and non-destructive testing (NDT), to ensure safety and durability.

4. Installation, Commissioning, and Support

Many manufacturers offer full lifecycle support, including on-site installation, start-up assistance, operator training, preventive maintenance, and emergency repair services.

Industries Served

An industrial vessels manufacturer typically caters to a wide range of sectors, such as:

Chemical & Petrochemical – Handling corrosive substances and pressurized gases.

Pharmaceutical – Requiring sterile, cleanable vessels for hygienic processing.

Food & Beverage – Needing sanitary design with easy-to-clean surfaces.

Oil & Gas – Involving extreme temperature and pressure conditions.

Water Treatment – For filtration, sedimentation, and storage applications.

Why Partner with a Trusted Manufacturer?

Choosing the right industrial vessels manufacturer ensures:

Safe operation in high-risk environments

Reduced downtime and maintenance

Compliance with local and international regulations

Tailored solutions that improve process efficiency

Long-term operational reliability

Conclusion

A skilled industrial vessels manufacturer is more than a supplier—they’re a strategic partner in your production and process chain. Their expertise in engineering, fabrication, and compliance ensures that your operations run smoothly, safely, and efficiently.

0 notes