#ultrasonic test

Text

Why Do Engineering Safety Inspection Services Matter in Management and Supervision?

In today’s competitive industrial world, safety is no longer a luxury; it’s a fundamental cornerstone of successful operations. Accidents not only have devastating human consequences, but they also lead to costly downtime, production delays, and potential legal ramifications. This is where engineering safety inspection services come into play — acting as a critical partner for management and supervision in ensuring a safe and productive work environment.

Proactive Risk Mitigation:

One of the most significant advantages of employing engineering safety inspection services is their focus on proactive risk mitigation. Unlike reactive approaches that address issues only after an incident occurs, these services utilize a proactive strategy to identify potential hazards and safety concerns before they develop into accidents. Through comprehensive inspections conducted by qualified professionals, these services can uncover:

Equipment malfunctions: Regular inspections can detect potential equipment failures before they happen, allowing for timely maintenance and repairs. This not only prevents accidents but also extends the lifespan of valuable equipment.

Process safety hazards: Improper procedures or deviations from safety protocols can create unseen dangers. Engineering safety inspections scrutinize existing processes and procedures, recommending modifications to eliminate these hazards.

Environmental concerns: Leaks, spills, and hazardous materials pose a significant threat to both personnel and the environment. Inspection services can identify these issues and recommend corrective actions to ensure a safe and sustainable work environment.

Improved Compliance:

Safety regulations and standards are constantly changing, and keeping pace with these changes can be a challenge for management teams. Engineering safety inspection services possess in-depth knowledge of relevant regulations and standards. Their inspections ensure your operations adhere to these requirements, minimizing the risk of compliance violations and potential legal consequences.

Enhanced Employee Morale and Productivity:

When employees feel safe and confident in their work environment, their morale and productivity naturally increase. Regular safety inspections demonstrate a commitment to worker safety, fostering an atmosphere of trust and well-being. Employees feel valued and are more likely to be engaged in their work, leading to improved efficiency and overall performance.

Reduced Operational Costs:

While the cost of engineering safety inspection services might seem like an additional expense at first glance, in the long run, it is a valuable investment. By preventing accidents, injuries, and downtime, these services lead to significant cost savings. Additionally, reduced repair costs, improved equipment lifespan, and lower insurance premiums contribute to a healthier bottom line.

Data-Driven Decision Making:

Engineering safety inspections yield valuable data and insights that empower management and supervision to make informed decisions regarding safety protocols and resource allocation. These reports can identify trends and patterns, allowing for targeted interventions and resource allocation to address priority areas.

Continuous Improvement:

The safety inspection process is not a one-time event. Regular inspections create a culture of continuous improvement within your organisation. By identifying and addressing safety concerns proactively, management can demonstrate a commitment to creating and maintaining a safe work environment. This fosters a proactive safety culture where employees feel empowered to report potential hazards, leading to ongoing improvement in safety practices.

Choosing the Right Inspection Service Provider:

When selecting an engineering safety inspection service provider, it’s crucial to choose a company with qualified professionals who have experience and expertise in your specific industry. Look for a provider that offers comprehensive inspection, use of relevant standards and regulations, and can translate complex findings into actionable recommendations.

Conclusion:

In conclusion, engineering safety and ndt inspection services are not just a tick-the-box exercise but a crucial investment in the safety, well-being, and overall success of your organization. By partnering with a reputable inspection service provider, management and supervision gain valuable insights, proactive risk mitigation strategies, and improved compliance, fostering a safe, productive, and cost-effective work environment for everyone.

To learn more contact the experts at RiskCON today.

#non destructive evaluation

#non-destructive testing

#engineering services

#welding engineer

#visual inspection

#ndt certification

#welding engineering

#mag particle testing

#ndt inspector

#testing and inspections

#ultrasonic test

#ndt inspection services

#ultrasonic inspection

#visual testing

#inspection engineer

#engineering and inspection services

#construction engineering and inspection services

#engineering & inspection services

#engineering safety inspection services

#welding engineering inspection services

#welding engineering inspection services#engineering safety inspection services#engineering & inspection services#construction engineering and inspection services#engineering and inspection services#inspection engineer#ultrasonic test#ndt inspection services#visual testing#non destructive evaluation#non-destructive testing#engineering services

0 notes

Text

A More Specific Hearing Poll

Put on OVER THE EAR headphones, turn off background noises if possible, and go to this link.

https://mynoise.net/NoiseMachines/ultrasonicNoiseGenerator.php

Press play, press "Z" to turn the noise to zero, and then test the sliders individually.

36 notes

·

View notes

Text

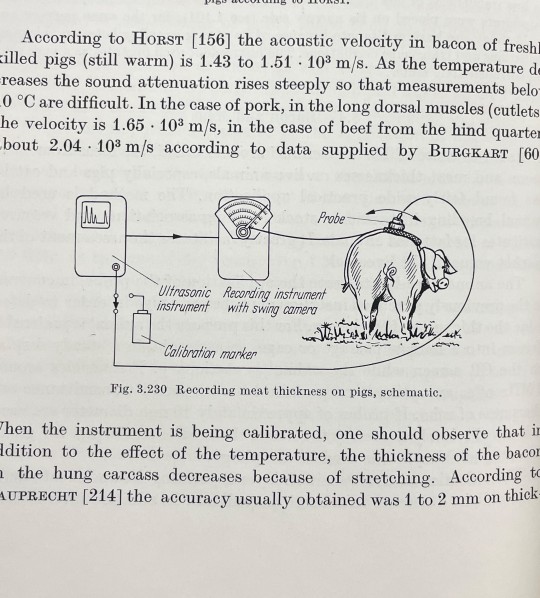

This illustration of an ultrasonic reading device to measure the fat in pigs for bacon is JUST SO WIERD.

Ultrasonic testing of materials, 1969.

25 notes

·

View notes

Text

Ultrasonic Testing in Pune: Comprehensive NDT Inspection Services by Integrated NDE

When it comes to ensuring the integrity and safety of materials and structures, ultrasonic testing stands out as one of the most reliable methods. Integrated NDE, a leading NDE company in Pune, offers state-of-the-art ultrasonic testing services designed to meet the stringent demands of various industries.

What is Ultrasonic Testing?

Ultrasonic testing (UT) is a form of Non-Destructive Testing (NDT) that utilizes high-frequency sound waves to detect flaws, measure thickness, and evaluate material properties without causing damage. This method is particularly effective for inspecting welds, castings, and forgings, making it a critical component of any comprehensive NDT inspection process.

Why Choose Ultrasonic Testing?

Ultrasonic testing is highly accurate and versatile, capable of detecting both surface and subsurface defects. It is widely used in industries such as construction, manufacturing, and aerospace, where safety and precision are paramount.

At Integrated NDE, we employ advanced ultrasonic NDT techniques and equipment, including ultrasonic thickness testers, to provide detailed assessments of materials. Our team of experts ensures that every inspection is carried out with the utmost precision, delivering reliable results that help you maintain the highest standards of quality and safety.

NDT Testing Services Near You

For businesses in Pune and the surrounding areas, finding reliable NDT testing near me is crucial. Integrated NDE offers a wide range of non-destructive testing (NDT) services, including ultrasonic testing. Our ultrasonic testing services near me are designed to meet the needs of industries looking for accurate, efficient, and cost-effective solutions.

Benefits of Choosing Integrated NDE

Local Expertise: As a leading NDE company in Pune, we understand the specific needs of our clients and provide tailored solutions to meet those needs.

Advanced Equipment: We use the latest technology in ultrasonic NDT, ensuring precise and reliable results.

Comprehensive Services: From ultrasonic testing to other forms of NDT inspection, we offer a full suite of services to cover all your non-destructive testing needs.

Conclusion

For businesses in Pune seeking reliable and accurate ultrasonic testing services, Integrated NDE is the go-to solution. With our expert team, advanced equipment, and commitment to quality, we ensure that your materials and structures meet the highest safety standards. Contact us today to learn more about how our ultrasonic testing and other NDT services can benefit your operations.

#nde company#ndt inspection#ndt testing near me#non destructive testing near me#ultrasonic testing#ultrasonic testing in pune#ultrasonic testing ndt#ultrasonic thickness tester#ultrasonic ndt#ultrasonic testing services near me

0 notes

Text

A-STAR TESTING & INSPECTION (S) PTE LTD stands at the cutting edge of Non-Destructive Testing (NDT) with our advanced solutions and technologies. We specialize in Computed Radiography (CR), an innovative imaging technique that revolutionizes material and component inspection. Our CR technology ensures precise, high-quality images, enhancing the detection of defects and ensuring the integrity and safety of your assets. Trust us for reliable, state-of-the-art NDT services that set new standards in accuracy and efficiency.

0 notes

Text

Ultrasonic Cleaner

Labnics stainless steel ultrasonic cleaner uses a powerful transducer for excellent cleaning. It's user-friendly and versatile. The cleaner has a durable stainless steel tank with a 40 KHz frequency and 150 W heating power, ensuring long-lasting, efficient cleaning for various items.

0 notes

Text

Ultrasonic Testing Market Valuation and Overview – 2024-2030

The Ultrasonic Testing Market is projected to experience significant growth from 2024 to 2030, driven by the escalating demand for non-destructive testing (NDT) techniques across various industries such as oil & gas, aerospace, automotive, and construction. Valued for its accuracy, safety, and efficiency in detecting material flaws and structural integrity issues, ultrasonic testing is increasingly being adopted to ensure compliance with stringent safety and quality standards.

Technological advancements, including the development of phased array ultrasonic testing (PAUT) and automated ultrasonic testing (AUT) systems, are expected to enhance inspection capabilities and drive market expansion. The rising focus on infrastructure maintenance, coupled with the need for extending the lifespan of aging assets, is further propelling market growth.

The global ultrasonic testing market size is projected to reach USD 4.2 billion by 2026, at a compound annual growth rate (CAGR) of 7.1% during the forecast period.

Download PDF Brochure:

https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=131229239

The ultrasonic technique (UT) is likely to be the largest contributor in the market during the forecast period

The market for the UT (ultrasonic testing) technique is projected to largest contributor in Market. It is presently the most popular NDT technique due to its ability to identify defects and accurately determine their severity. Some advanced techniques such as ultrasonic immersion testing and guided-wave ultrasonic testing can be used for critical applications in the oil & gas and aerospace industries, among many others.

Inspection services to account for the largest market size by 2021

Ultrasonic testing and inspection services are likely to account for the largest share of the market in 2021. Ultrasonic testing techniques' primary purpose is to inspect objects, materials, machinery, and structures for defects so that they can be rectified in a timely and cost-effective manner. After inspection services, training services are likely to continue to gain the second-largest market share in the coming years since training NDT technicians to keep them updated with new technological trends and make them aware of the customers' changing demands is equally essential.

The Ultrasonic testing market in APAC to grow at the highest CAGR during the forecast period

Asia Pacific is likely to be the fastest-growing region in the ultrasonic testing market due to the rapid infrastructural development and automation adoption in manufacturing industries in countries such as India and China. Countries in Asia Pacific are involved in the manufacturing of defense aircraft, which is expected to increase ultrasonic testing equipment and services in the defense & aerospace industry. Many infrastructural development projects are under construction and scheduled to be constructed in the region during the forecast period. The demand for automobiles is estimated to grow substantially by 2026.

The market was dominated by ultrasonic testing companies such as Baker Hughes(US), Olympus Corporation (Japan), MISTRAS Group (US), Intertek (UK), Sonatest (UK), Zetec, Inc. (US), T.D. Williamson Inc. (US), Bosello High Technology srl (Italy), Eddyfi (Canada), and Magnaflux (US), Fischer Technology Inc. (US), Cygnus Instruments Ltd. (UK), NDT Global GmbH (Germany), Acuren (US), and LynX Inspection (Canada).

0 notes

Text

The Power of Precision: Exploring the Benefits of PAUT in NDT

In the realm of industrial inspections, the demand for accuracy and efficiency has never been higher. Phased Array Ultrasonic Testing (PAUT) stands out as a revolutionary method that fulfills these requirements, offering unparalleled precision and speed. As an integral part of Non Destructive Testing, PAUT is widely used across various industries to ensure the integrity and reliability of critical components. Here, we delve into the intricacies of PAUT and its benefits.

PAUT is an advanced method of ultrasonic testing that uses multiple elements and electronic time delays to create beams of sound waves. These beams can be steered, focused, and scanned, providing detailed images of internal structures. Unlike conventional ultrasonic testing, which uses a single transducer to send and receive sound waves, PAUT employs an array of transducers. This allows for simultaneous collection of data from multiple angles, resulting in more comprehensive and accurate inspections.

As part of a broader suite of Non Destructive Testing Services, PAUT plays a crucial role in ensuring the safety and reliability of industrial components. Nondestructive testing (NDT) from RVS QUALITY CERTIFICATIONS PVT LTD encompasses various techniques used to evaluate the properties of a material, component, or system without causing damage. PAUT's advanced capabilities enhance the overall effectiveness of NDT services, providing detailed and reliable data that support maintenance and quality assurance programs.

Applications Across Industries

The versatility of PAUT makes it suitable for a wide range of applications. It is commonly used in the aerospace, automotive, and power generation industries for inspecting critical components such as welds, turbine blades, and composite materials. PAUT's ability to detect minute defects and irregularities ensures that even the smallest flaws are identified before they become critical issues. This level of precision is essential for maintaining safety and performance standards in high-stakes environments.

Efficiency and Accuracy Combined

One of the standout features of PAUT is its efficiency. The ability to steer and focus sound waves electronically means that inspections can be performed more quickly compared to traditional methods. This not only reduces downtime but also increases the number of inspections that can be completed within a given timeframe. Additionally, the detailed images produced by PAUT provide a clearer understanding of the inspected material's condition, allowing for more accurate assessments and decision-making.

Enhanced Tube Inspections

A specific area where PAUT excels is in Tube Inspection Services. Tubes, often found in heat exchangers and boilers, are prone to various types of degradation such as corrosion and cracking. PAUT's ability to inspect from multiple angles simultaneously makes it particularly effective for tube inspections. It can detect flaws that may be missed by conventional methods, ensuring that tubes are thoroughly evaluated for any signs of wear or damage. This comprehensive approach helps prevent failures and extends the lifespan of critical equipment.

Advancing with Technology

The continuous evolution of technology has significantly impacted PAUT. Advances in digital signal processing and software have improved the resolution and clarity of the images produced. Portable PAUT equipment from RVS QUALITY CERTIFICATIONS PVT LTD has made it possible to conduct inspections in challenging environments, further expanding its applicability. These technological advancements ensure that PAUT remains at the forefront of nondestructive testing techniques, providing industries with cutting-edge solutions for maintaining safety and quality.

In conclusion, PAUT is a powerful tool that combines precision and efficiency to deliver superior inspection results. Its ability to provide detailed images from multiple angles makes it invaluable for identifying defects and ensuring the integrity of critical components. As a key component of Non Destructive Testing, PAUT supports industries in maintaining high standards of safety and performance. Whether it's for welds, turbine blades, or Tube Inspection Service, PAUT continues to set the standard for advanced nondestructive testing methodologies.

0 notes

Text

Ensuring Weld Quality: Advanced Ultrasonic Testing Methods

In the world of welding, ensuring the quality and integrity of welds is crucial. One of the most effective ways to inspect welds is through ultrasonic testing, which uses high-frequency sound waves to detect imperfections. This blog explores advanced ultrasonic testing methods for welding inspection, highlighting their benefits and applications in the UK.

Introduction to Ultrasonic Testing

Ultrasonic testing for welding involves high-frequency sound waves to detect flaws in welds. This non-destructive testing (NDT) method effectively identifies internal and surface defects without damaging the material.

Why Ultrasonic Testing for Welding?

Accuracy: Provides precise detection of internal flaws.

Non-Destructive: Does not damage the material being inspected.

Versatility: Suitable for a wide range of materials and thicknesses.

Advanced Ultrasonic Testing Techniques

Advanced ultrasonic testing techniques have revolutionised the NDT industry, providing unprecedented levels of accuracy and efficiency. Below are some of the most advanced testing techniques used in the industry:

1. Phased Array Ultrasonic Testing (PAUT)

PAUT is an advanced technique that uses different ultrasonic elements and electronic time delays to create a sweeping beam. This method provides a detailed image of the weld, allowing for precise identification of defects.

Benefits:

High-resolution and detailed images

Faster inspection times

Improved defect characterisation

2. Time-of-Flight Diffraction (TOFD)

TOFD is another complex ultrasonic testing method that uses the time taken by sound waves to travel and diffract around defects to detect and size flaws accurately.

Benefits:

High accuracy in defect sizing

Effective for detecting both surface and subsurface defects

Reduced operator dependency

3. Automated Ultrasonic Testing (AUT)

AUT involves automated systems that perform ultrasonic inspections. This method enhances the consistency and repeatability of inspections, making it ideal for large-scale projects.

Benefits:

Consistent and repeatable results

Increased inspection speed

Reduced human error

Applications of Ultrasonic Testing in the UK

Ultrasonic testing is widely used in the UK across different industries to provide safety and integrity to critical infrastructure. Here are some key applications of ultrasonic testing in the UK.

1. Oil and Gas Industry

In the UK, the oil and gas industry rely heavily on ultrasonic testing for welding to ensure the integrity of pipelines and other critical infrastructure. PAUT and TOFD are commonly used to inspect welds in pipelines, ensuring they are free from defects that could lead to failures.

2. Aerospace Industry

The aerospace industry requires the highest levels of safety and reliability. Ultrasonic testing methods are used extensively to inspect welds in aircraft components, ensuring they meet strict safety standards.

3. Construction and Infrastructure

Ultrasonic testing plays a crucial role in the construction industry, particularly for inspecting welds in bridges, buildings, and other structures.

Advantages of Advanced Ultrasonic Testing Methods

Check out the advantages of advanced ultrasonic testing methods over traditional approaches.

1. Enhanced Accuracy

Advanced ultrasonic testing methods provide higher accuracy in detecting and sizing defects than traditional methods.

2. Increased Efficiency

Automated and advanced techniques like PAUT and AUT significantly reduce inspection times while maintaining high levels of accuracy.

3. Comprehensive Reporting

These methods offer detailed and comprehensive reporting, providing clear images and data that can be used for further analysis and decision-making.

Conclusion

Adopting advanced ultrasonic testing for welding is essential for industries aiming to maintain high quality and safety standards.

Investing in these advanced techniques enhances inspection reliability and ensures compliance with stringent safety regulations. By leveraging the benefits of advanced ultrasonic testing, industries can achieve greater efficiency, accuracy, and overall project success.

1 note

·

View note

Text

NDT equipment in UAE

Non-Destructive Testing (NDT) equipment is essential in various industries, including oil and gas, aerospace, manufacturing, and construction, to ensure the integrity and reliability of materials and structures without causing any damage. Here’s a comprehensive overview of NDT equipment available in the UAE

https://incorworld.com/products/

0 notes

Text

How Mag Particle Testing Protects Your Critical Assets?

Our world relies on a vast network of critical assets. From the towering wind turbines that harvest clean energy to the intricate pipelines that transport vital resources, these structures form the backbone of modern civilization. However, hidden beneath the surface of these assets can lurk a silent threat: cracks. These imperfections, often invisible to the naked eye, can pose a significant risk to safety, functionality, and operational efficiency. To read more visit

#welding engineering inspection services#engineering safety inspection services#engineering & inspection services#construction engineering and inspection services#engineering and inspection services#inspection engineer#visual testing#ultrasonic inspection#ndt inspection services#ultrasonic test#testing and inspections#ndt inspector#mag particle testing#welding engineering#ndt certification#visual inspection#welding engineer#engineering services#non-destructive testing#non destructive evaluation

0 notes

Text

Integrated NDE Solution in Pune: Precision in Ultrasonic Thickness Measurement

Ensuring the integrity and safety of materials and structures is crucial in many industries, and ultrasonic thickness measurement (UTM) is a key non-destructive testing method used for this purpose. Integrated NDE Solution in Pune specializes in providing comprehensive ultrasonic thickness measurement services, leveraging advanced technologies to deliver precise and reliable results. This article explores the importance of UTM, its benefits, and the state-of-the-art services offered by Integrated NDE Solution.

Understanding Ultrasonic Thickness Measurement

Ultrasonic thickness measurement is a non-destructive testing (NDT) method used to determine the thickness of a material from one side. This technique employs high-frequency sound waves to measure the time it takes for an ultrasonic pulse to travel through the material and reflect back to the transducer. By calculating the travel time, the thickness of the material can be accurately determined.

Importance of Ultrasonic Thickness Measurement

Material Integrity: Ensures that materials have the required thickness and are free from thinning or erosion.

Safety Compliance: Verifies that components meet industry safety standards, reducing the risk of failures and accidents.

Preventive Maintenance: Identifies areas of concern before they become critical, enabling timely maintenance and repairs.

Quality Control: Confirms that materials conform to the specified thickness, maintaining the integrity and quality of the final product.

Cost Savings: Prevents costly failures and downtime by ensuring the correct material thickness from the start.

How Ultrasonic Thickness Measurement Works

Ultrasonic thickness measurement involves several steps and the use of advanced equipment:

Preparation: The surface of the material is cleaned to ensure accurate readings.

Couplant Application: A couplant (gel or liquid) is applied to the surface to facilitate the transmission of sound waves.

Transducer Placement: The ultrasonic transducer is placed on the surface, emitting high-frequency sound waves into the material.

Sound Wave Reflection: The sound waves travel through the material and reflect back when they reach the opposite surface or an internal flaw.

Measurement: The time it takes for the sound waves to return to the transducer is measured.

Thickness Calculation: The material thickness is calculated based on the sound wave travel time and the known velocity of sound in the material.

Benefits of Ultrasonic Thickness Measurement

Non-Destructive: Does not damage or alter the material being tested.

Accurate: Provides precise and reliable thickness measurements.

Quick and Efficient: Delivers immediate results, enabling rapid decision-making.

Versatile: Applicable to a wide range of materials, including metals, plastics, and composites.

Portable: UTM equipment is often portable, allowing for on-site testing.

Integrated NDE Solution in Pune: Leaders in Ultrasonic Thickness Measurement

Integrated NDE Solution in Pune is a leader in non-destructive testing, offering a broad spectrum of NDT services, including ultrasonic thickness measurement. Their expertise, state-of-the-art equipment, and commitment to quality make them a trusted partner for industries requiring reliable thickness measurements.

Comprehensive NDT Services Offered

Ultrasonic Thickness Measurement (UTM)

Remote Visual Inspection (RVI)

Magnetic Particle Inspection (MPI)

Ultrasonic Testing (UT)

Radiographic Testing (RT)

Liquid Penetrant Testing (LPT)

Eddy Current Testing (ECT)

Portable Hardness Testing

Ferrite Testing

Industries Served

Integrated NDE Solution in Pune caters to a diverse array of industries, including:

Aerospace: Ensuring the safety and reliability of aircraft components.

Automotive: Inspecting critical parts to prevent failures.

Construction: Verifying the integrity of structural components.

Oil and Gas: Ensuring the reliability of pipelines and equipment.

Power Generation: Maintaining the integrity of infrastructure components.

Manufacturing: Ensuring the quality of machined parts and assemblies.

Ultrasonic Thickness Measurement in Action

Case Study: Oil and Gas Pipeline Inspection

In the oil and gas industry, the reliability of pipelines is crucial. Integrated NDE Solution was approached by a leading oil and gas company to conduct ultrasonic thickness measurement on pipeline materials. Using advanced ultrasonic equipment, the team measured the wall thickness of the pipelines, ensuring they met the specified standards for corrosion resistance and mechanical strength. The inspection helped prevent potential failures and ensured the safety and reliability of the pipeline network.

Case Study: Aerospace Component Verification

A major aerospace manufacturer required ultrasonic thickness measurement for critical components used in aircraft engines. Integrated NDE Solution employed advanced ultrasonic equipment to measure the thickness of the components. The precise measurements confirmed that the materials met the stringent specifications required for aerospace applications, ensuring the safety and performance of the aircraft engines.

Advanced Ultrasonic Thickness Measurement Equipment

Integrated NDE Solution in Pune utilizes the latest UTM equipment to ensure the highest level of accuracy and reliability in their inspections. Some of the advanced equipment includes:

Digital Ultrasonic Thickness Gauges: Portable devices that provide rapid, on-site thickness measurements.

High-Frequency Transducers: Used for measuring the thickness of thin materials with high precision.

Dual-Element Transducers: Ideal for measuring corroded materials and rough surfaces.

Through-Coating Transducers: Capable of measuring the thickness of materials through coatings and paint.

The Role of Certified Technicians

The effectiveness of ultrasonic thickness measurement largely depends on the expertise of the technicians conducting the tests. Integrated NDE Solution in Pune employs certified technicians who undergo rigorous training and continuous professional development. Their skills and knowledge ensure that clients receive the highest quality of service.

Commitment to Quality and Safety

Integrated NDE Solution in Pune is dedicated to maintaining the highest standards of quality and safety. They adhere to international standards and best practices, ensuring that all inspections are performed with utmost precision and reliability. This commitment to excellence has earned them a stellar reputation in the industry.

Customer-Centric Approach

At Integrated NDE Solution in Pune, customer satisfaction is a top priority. They work closely with clients to understand their specific needs and tailor their services accordingly. Whether it’s a small-scale inspection or a large industrial project, they provide personalized solutions that meet the highest standards of quality and reliability.

Why Choose Integrated NDE Solution in Pune?

Expertise: Extensive experience and technical know-how in NDT services.

Technology: Utilization of the latest and most advanced testing equipment.

Quality: Commitment to providing accurate and reliable results.

Customer Service: Focus on building long-term relationships through excellent service.

Compliance: Adherence to all relevant industry standards and regulations.

Conclusion

In industries where precision and reliability are non-negotiable, Integrated NDE Solution in Pune stands out as a leader in non-destructive testing, particularly in ultrasonic thickness measurement. Their dedication to quality, use of advanced technology, and customer-centric approach make them the go-to choice for businesses across various sectors. By partnering with Integrated NDE Solution, companies can ensure the integrity and safety of their materials and components, safeguarding their operations and reputation.

Integrated NDE Solution in Pune continues to set the standard for excellence in non-destructive inspection. Their expertise in ultrasonic thickness measurement and other NDT services is pivotal in industries where safety and reliability are crucial. As technology advances and industries evolve, Integrated NDE Solution remains at the forefront, offering unparalleled service and support to their clients.

In conclusion, for businesses seeking the highest standards in ultrasonic thickness measurement, non-destructive testing methods, and comprehensive NDT services, Integrated NDE Solution in Pune is the trusted partner that delivers results. Their innovative approach, advanced technology, and unwavering commitment to quality ensure that every inspection meets the stringent requirements of today’s demanding industrial environments.

#ultrasonic thickness measurement#non destructive testing method#non destructive testing#ultrasonic thickness

0 notes

Text

#𝗡𝗼𝗻 𝗗𝗲𝘀𝘁𝗿𝘂𝗰𝘁𝗶𝘃𝗲 𝗧𝗲𝘀𝘁𝗶𝗻𝗴 [𝗡𝗗𝗧] 𝐂𝐨𝐮𝐫𝐬𝐞𝐬#Level II#1. Visual Testing (VT)#2. Liquid Penetrant Testing (PT)#3. Magnetic Particle Testing (MT)#4. Ultrasonic Testing (UT)#5. Radiography Testing (RT)#6. Thermal/Infrared Testing (IR)#7. Acoustic Emission Testing (AET)#8. Eddy Current Testing (ECT)#9. Magnetic Flux leakage (MFL)#Contact Us:#Mob:#+919787872866#Email:#[email protected]#Web:#www.cosmostrg.com#WhatsApp Channel :#https://whatsapp.com/channel/0029VaHMYayGufJ45OH4Xo1n#WhatsApp Group :#https://chat.whatsapp.com/IunhDueyuLsEPc9SkB7dlK#NDT#ndtinspection#ndttraining#visualtesting#liquid#penetranttesting#Magnetic#magneticparticletesting

0 notes

Text

Ultrasonic Testing in Pune by Integrated NDE Solution Company: Your Trusted NDT Partner

Introduction

In the modern industrial landscape, ensuring the integrity and safety of materials and components is paramount. Non-destructive testing (NDT) plays a crucial role in maintaining these standards, with ultrasonic testing being one of the most effective and reliable methods. Integrated NDE Solution Company, based in Pune, offers a comprehensive range of ultrasonic testing services that cater to various industries. Whether you are searching for NDT testing near me or require specialized ultrasonic testing services, Integrated NDE Solutions is your go-to partner for all your inspection needs.

The Importance of Ultrasonic Testing in NDT

Ultrasonic testing is a non-invasive inspection technique that uses high-frequency sound waves to detect imperfections or changes in material properties. This method is widely used across industries such as aerospace, automotive, construction, and manufacturing due to its accuracy and ability to provide detailed information about the internal structure of a material.

Integrated NDE Solution Company excels in providing ultrasonic testing services that are critical for ensuring the safety and longevity of various components. From detecting flaws in welds to measuring material thickness, our ultrasonic testing services are designed to meet the highest industry standards.

Why Choose Integrated NDE Solution Company?

When it comes to NDT inspection and ultrasonic testing, choosing the right service provider is crucial. Integrated NDE Solution Company stands out for several reasons:

Expertise in Ultrasonic Testing: Our team of experienced professionals is well-versed in the latest ultrasonic testing techniques, ensuring accurate and reliable results every time.

Advanced Equipment: We use state-of-the-art ultrasonic testing equipment, including ultrasonic thickness testers and specialized ultrasonic NDT devices, to provide precise measurements and detect even the smallest defects.

Comprehensive Services: Whether you need ultrasonic testing in Pune or are looking for ultrasonic testing services near me, we offer a wide range of services tailored to meet the specific needs of each client.

Commitment to Quality: At Integrated NDE Solution Company, quality is our top priority. We adhere to strict industry standards and protocols to ensure that our NDT inspections are of the highest quality.

Applications of Ultrasonic Testing

Ultrasonic testing is versatile and can be applied to a wide range of materials and components. Some of the key applications include:

Weld Inspection: Ultrasonic testing is widely used for inspecting welds to detect flaws such as cracks, voids, and inclusions. This is critical in industries where the integrity of welded joints is paramount, such as in pipeline construction, shipbuilding, and aerospace.

Thickness Measurement: Using an ultrasonic thickness tester, we can accurately measure the thickness of materials, including metals, plastics, and composites. This is essential for determining the remaining life of components and ensuring that they meet the required specifications.

Flaw Detection: Ultrasonic testing is highly effective in detecting internal flaws such as cracks, voids, and inclusions in materials. This helps in preventing catastrophic failures and ensuring the safety of components.

Corrosion Mapping: Ultrasonic testing can be used to map the extent of corrosion in materials, providing valuable information for maintenance and repair decisions.

Ultrasonic Testing in Pune

As a leading provider of ultrasonic testing in Pune, Integrated NDE Solution Company is proud to serve a wide range of industries in the region. Pune is a hub for manufacturing, automotive, and engineering industries, all of which require reliable NDT inspection services to ensure the safety and integrity of their products.

Our ultrasonic testing services in Pune are designed to meet the specific needs of each industry. Whether you are looking for routine inspections or require specialized testing for critical components, our team is equipped to handle it all.

Non-Destructive Testing Near Me

If you are searching for non-destructive testing near me, look no further than Integrated NDE Solution Company. We offer a comprehensive range of NDT services, including ultrasonic testing, that are designed to provide accurate and reliable results.

Our NDT services are available to clients across Pune and the surrounding regions. We understand the importance of timely and efficient inspections, which is why we strive to provide our services with minimal disruption to your operations.

Ultrasonic NDT: A Closer Look

Ultrasonic NDT is a specialized form of non-destructive testing that uses high-frequency sound waves to inspect materials and components. This method is highly effective in detecting internal flaws and measuring material thickness, making it an essential tool for ensuring the safety and integrity of various components.

At Integrated NDE Solution Company, we offer a wide range of ultrasonic NDT services, including:

Flaw Detection: Our ultrasonic NDT services are designed to detect internal flaws in materials, including cracks, voids, and inclusions. This helps in preventing catastrophic failures and ensuring the safety of components.

Thickness Measurement: Using advanced ultrasonic equipment, we can accurately measure the thickness of materials, ensuring that they meet the required specifications.

Weld Inspection: Our ultrasonic NDT services are widely used for inspecting welds to detect flaws and ensure the integrity of welded joints.

Corrosion Mapping: We offer ultrasonic corrosion mapping services to help identify the extent of corrosion in materials, providing valuable information for maintenance and repair decisions.

Ultrasonic Testing Services Near Me

For those in search of ultrasonic testing services near me, Integrated NDE Solution Company offers a comprehensive range of services that are tailored to meet the specific needs of each client. Our team of experienced professionals is equipped with the latest ultrasonic testing equipment, ensuring accurate and reliable results every time.

Whether you need ultrasonic testing for weld inspection, thickness measurement, or flaw detection, our team is here to help. We offer our services to clients across Pune and the surrounding regions, providing timely and efficient inspections that meet the highest industry standards.

The Future of Ultrasonic Testing

As technology continues to evolve, so too does the field of ultrasonic testing. Integrated NDE Solution Company is committed to staying at the forefront of these advancements, continually investing in the latest equipment and training for our team.

One of the key trends in ultrasonic testing is the development of advanced imaging techniques, such as phased array ultrasonic testing (PAUT) and time-of-flight diffraction (TOFD). These techniques offer higher resolution images and more accurate defect detection, making them invaluable tools for NDT inspections.

In addition, there is a growing trend towards the use of automated ultrasonic testing systems, which can provide faster and more consistent results. At Integrated NDE Solution Company, we are exploring these advancements to ensure that we continue to provide our clients with the most accurate and reliable ultrasonic testing services available.

Conclusion

Ultrasonic testing is a critical component of non-destructive testing, offering accurate and reliable results for a wide range of applications. Whether you are looking for NDT inspection services, ultrasonic testing in Pune, or ultrasonic testing services near me, Integrated NDE Solution Company is your trusted partner for all your NDT needs.

With our expertise, advanced equipment, and commitment to quality, we are well-equipped to handle all your ultrasonic testing requirements. Contact us today to learn more about our services and how we can help ensure the safety and integrity of your materials and components.

#nde company#ndt inspection#ndt testing near me#non destructive testing near me#ultrasonic testing#ultrasonic testing in pune#ultrasonic testing ndt#ultrasonic thickness tester#ultrasonic ndt#ultrasonic testing services near me

0 notes

Text

The Future of Technical Cleaning: Why You Need an Ultrasonic Machine in Your Indian Manufacturing Facility

Introduction

In today’s competitive Indian manufacturing landscape, efficiency and precision are paramount. Traditional cleaning methods often fall short, leaving behind contaminants that can compromise product quality and lead to costly downtime. However, there’s a revolutionary technology that’s transforming the way manufacturers clean critical components: Ultrasonic Cleaning.

What is Ultrasonic Cleaning?

Ultrasonic Cleaning utilizes high-frequency sound waves to create microscopic cavitation bubbles within a cleaning solution. These bubbles rapidly collapse, generating a powerful cleaning action that dislodges even the most stubborn contaminants from intricate surfaces. Unlike traditional methods that rely on manual scrubbing or harsh chemicals, ultrasonic cleaning is gentle yet incredibly effective, reaching even the most inaccessible areas of a component.

Why You Need Ultrasonic Cleaning in Your Indian Manufacturing Facility

Enhanced Cleaning Performance: Ultrasonic Cleaning removes contaminants like grease, oil, polishing compounds, flux residues, and more, ensuring a pristine surface finish essential for optimal product performance and reliability.

Improved Quality Control: By removing microscopic contaminants that can cause defects, Ultrasonic Cleaning significantly improves quality control standards, leading to fewer rejects and higher production yields.

Reduced Downtime: Ultrasonic cleaning’s rapid and efficient cleaning process minimizes downtime associated with Traditional Cleaning Methods, allowing for increased production capacity.

Environmentally Friendly: Ultrasonic Cleaning utilizes water-based cleaning solutions, minimizing the use of harsh chemicals and reducing environmental impact.

Versatility: Ultrasonic cleaning systems are incredibly versatile, suitable for cleaning a wide range of components across various industries, including automotive, electronics, medical devices, and more.

Why Ecoclean India’s Ultrasonic Machines are the Superior Choice

At Ecoclean India, we understand the critical role ultrasonic cleaning plays in modern manufacturing. We offer a comprehensive range of state-of-the-art Ultrasonic Cleaning machines designed to meet the specific needs of Indian manufacturers.

Here’s what sets Ecoclean India apart:

Advanced Technology: Our machines are equipped with cutting-edge Ultrasonic Technology, delivering exceptional cleaning performance and unmatched efficiency.

Durability and Reliability: Built with the highest quality materials and components, our ultrasonic machines are designed for long-lasting performance and minimal maintenance.

Expert Support: Our team of experienced engineers provides comprehensive support, from initial consultation to installation and ongoing maintenance.

Competitive Pricing: We offer competitive pricing on our entire range of Ultrasonic Cleaning Machines, ensuring you get the best value for your investment.

Investing in the Future

By incorporating Ultrasonic Cleaning into your manufacturing process, you’re investing in the future of your business. You’ll experience enhanced cleaning performance, improved quality control, reduced downtime, and a more environmentally friendly operation.

Ready to Experience the Power of Ultrasonic Cleaning?

Visit Ecoclean India’s website today at: https://ecoclean-india.com/products-solutions/ to explore our comprehensive range of ultrasonic cleaning machines and discover how we can help you achieve superior cleaning results in your Indian manufacturing facility.

#Ultrasonic Cleaning#Industry#Cleaning#Cleaning Services#Manufacturing#ultrasonic cleaning machine#technical cleanliness#degreasing machine#industrial parts cleaning machine#millipore test#solvent cleaning system#component cleaning machine#durr ecoclean#ultrasonic cleaning machine manufacturers in india#manufacturer#business

0 notes

Text

Dolphitech pioneers ultrasonic technology in non-destructive testing, setting new standards with precise inspection solutions for aerospace, automotive, and manufacturing industries.

0 notes