#welding engineering inspection services

Text

Why Do Engineering Safety Inspection Services Matter in Management and Supervision?

In today’s competitive industrial world, safety is no longer a luxury; it’s a fundamental cornerstone of successful operations. Accidents not only have devastating human consequences, but they also lead to costly downtime, production delays, and potential legal ramifications. This is where engineering safety inspection services come into play — acting as a critical partner for management and supervision in ensuring a safe and productive work environment.

Proactive Risk Mitigation:

One of the most significant advantages of employing engineering safety inspection services is their focus on proactive risk mitigation. Unlike reactive approaches that address issues only after an incident occurs, these services utilize a proactive strategy to identify potential hazards and safety concerns before they develop into accidents. Through comprehensive inspections conducted by qualified professionals, these services can uncover:

Equipment malfunctions: Regular inspections can detect potential equipment failures before they happen, allowing for timely maintenance and repairs. This not only prevents accidents but also extends the lifespan of valuable equipment.

Process safety hazards: Improper procedures or deviations from safety protocols can create unseen dangers. Engineering safety inspections scrutinize existing processes and procedures, recommending modifications to eliminate these hazards.

Environmental concerns: Leaks, spills, and hazardous materials pose a significant threat to both personnel and the environment. Inspection services can identify these issues and recommend corrective actions to ensure a safe and sustainable work environment.

Improved Compliance:

Safety regulations and standards are constantly changing, and keeping pace with these changes can be a challenge for management teams. Engineering safety inspection services possess in-depth knowledge of relevant regulations and standards. Their inspections ensure your operations adhere to these requirements, minimizing the risk of compliance violations and potential legal consequences.

Enhanced Employee Morale and Productivity:

When employees feel safe and confident in their work environment, their morale and productivity naturally increase. Regular safety inspections demonstrate a commitment to worker safety, fostering an atmosphere of trust and well-being. Employees feel valued and are more likely to be engaged in their work, leading to improved efficiency and overall performance.

Reduced Operational Costs:

While the cost of engineering safety inspection services might seem like an additional expense at first glance, in the long run, it is a valuable investment. By preventing accidents, injuries, and downtime, these services lead to significant cost savings. Additionally, reduced repair costs, improved equipment lifespan, and lower insurance premiums contribute to a healthier bottom line.

Data-Driven Decision Making:

Engineering safety inspections yield valuable data and insights that empower management and supervision to make informed decisions regarding safety protocols and resource allocation. These reports can identify trends and patterns, allowing for targeted interventions and resource allocation to address priority areas.

Continuous Improvement:

The safety inspection process is not a one-time event. Regular inspections create a culture of continuous improvement within your organisation. By identifying and addressing safety concerns proactively, management can demonstrate a commitment to creating and maintaining a safe work environment. This fosters a proactive safety culture where employees feel empowered to report potential hazards, leading to ongoing improvement in safety practices.

Choosing the Right Inspection Service Provider:

When selecting an engineering safety inspection service provider, it’s crucial to choose a company with qualified professionals who have experience and expertise in your specific industry. Look for a provider that offers comprehensive inspection, use of relevant standards and regulations, and can translate complex findings into actionable recommendations.

Conclusion:

In conclusion, engineering safety and ndt inspection services are not just a tick-the-box exercise but a crucial investment in the safety, well-being, and overall success of your organization. By partnering with a reputable inspection service provider, management and supervision gain valuable insights, proactive risk mitigation strategies, and improved compliance, fostering a safe, productive, and cost-effective work environment for everyone.

To learn more contact the experts at RiskCON today.

#non destructive evaluation

#non-destructive testing

#engineering services

#welding engineer

#visual inspection

#ndt certification

#welding engineering

#mag particle testing

#ndt inspector

#testing and inspections

#ultrasonic test

#ndt inspection services

#ultrasonic inspection

#visual testing

#inspection engineer

#engineering and inspection services

#construction engineering and inspection services

#engineering & inspection services

#engineering safety inspection services

#welding engineering inspection services

#welding engineering inspection services#engineering safety inspection services#engineering & inspection services#construction engineering and inspection services#engineering and inspection services#inspection engineer#ultrasonic test#ndt inspection services#visual testing#non destructive evaluation#non-destructive testing#engineering services

0 notes

Text

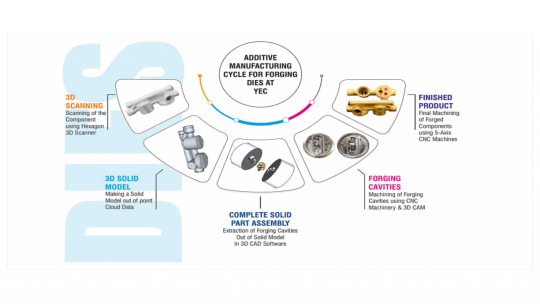

Unveiling the Potential of 3D Scanning in Reverse Engineering

In the realm of engineering innovation, the advent of 3D scanning has revolutionized traditional methodologies. Among its myriad applications, one particularly noteworthy domain is reverse engineering.

Enterprises worldwide are leveraging 3D scanning technologies to dissect and recreate intricate designs, breathing new life into legacy components and machinery. The process involves capturing detailed digital renderings of physical objects, which serve as blueprints for replication or enhancement.

In the heart of technological advancements, Yamunanagar Engineering Cluster stands as a beacon of ingenuity. Employing cutting-edge 3D scanning techniques, the cluster pioneers the restoration and optimization of industrial assets with unparalleled precision and efficiency.

Beyond restoration, 3D scanning facilitates product innovation, enabling engineers to analyze and enhance existing designs swiftly. It expedites prototyping, reduces time-to-market, and fosters a culture of continuous improvement.

As industries evolve, the fusion of 3D scanning reverse engineering propels progress, ushering in a new era of limitless possibilities and unparalleled innovation.

#Yamunanagar Engineering Cluster#mechanical testing laboratory#3d scanning reverse engineering#cnc precision testing services#robotic welding testing services#inspection equipment testing services#research and development solutions

0 notes

Text

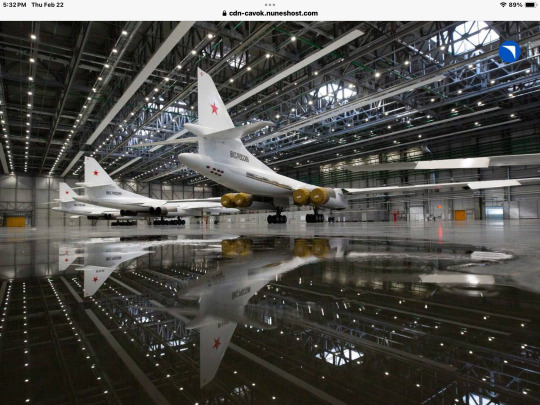

IMAGES: Russia resumes production of modernized Tu-160 bombers

Russia plans to eventually buy 50 new Tu-160M and modernize 15 existing Tu-160.

Fernando Valduga By Fernando Valduga 02/22/2024 - 08:17 in Military

Russia restarted the production of the Tupolev-160 strategic bombers, known as Blackjack, with the announcement coming from Sergey Chemezov, CEO of the state company Rostec.

"Restarting the production of the Tu-160 was quite a task for all Rostec affiliates. The project documentation was fully digitized within the tightest deadlines. The vacuum welding technique of titanium parts was restored and the production of fuselage units was resumed. Today we can safely say that we have been successful in all aspects," he said, according to the Russian state media.

The updated Tu-160M maintains the exterior design of its predecessor, but incorporates a technological base and completely new digital solutions.

The recent visit of Russian President Vladimir Putin to the S.P. aviation factory. Gorbunov Kazan, in Tartaristan, where he inspected four updated strategic bombers, drew attention amid concerns about the country's military capabilities.

The Tu-160, recognized as the largest and most powerful supersonic aircraft with wings of variable geometry in the history of military aviation, underwent an update program initiated by Putin's decision.

The government contract, signed between the Ministry of Industry and Commerce and the Tupolev design department, facilitated the digitization of the Tu-160M aircraft design documentation and the restoration of vacuum welding techniques for titanium products, leading to the resumption of the production of fuselage units.

Rostec's main industrial companies in metallurgy, aircraft design, engineering and instrument manufacturing have played crucial roles in revitalizing their cooperation for the successful resumption of production.

The first Tu-160M strategic bomber built from scratch made its first 30-minute flight on January 12, 2022. It is equipped with modern weapons, electronic warfare system, as well as on-board electronic equipment.

According to reports, the Tu-160 entered Soviet service for the first time in the late 1980s, with production until 1995. In 2015, Russian President Vladimir Putin ordered the resumption of production of the updated variant of the Tu-160M to strengthen the strategy of the Russian Air Force in the capabilities of the bombers at a time of increasing tension with the West, and to compensate for delays in the future PAK-DA bomber program.

Russia plans to eventually buy about 50 Tu-160M bombers and is upgrading 16 existing Tu-160s to the modernized standard. With the first Tu-160M scheduled to be delivered soon, series production is expected to begin in 2023, at a production rate of at least three aircraft per year. This would fit the order for 10 aircraft in the period 2023–27.

The update of the Tu-160M is being implemented in two phases, with the first phase of the Tu-160M1 comprising the new navigation system K-042K-1 and autopilot ABSU-200-1, as well as the removal of some previous systems, such as pump observation systems. This variant of the Tu-160M1 has been operational in the Russian Air Force since the end of 2014.

The second phase of the Tu-160M2 includes the new Novella NV1.70 radar, a digital glass booth, modern communications and anti-jamming equipment, updated NK-32 engines (designated NK-32-02) and modern conventional and nuclear weapons.

Tags: Military AviationROSTECRussiaTu-160 Blackjack

Sharing

tweet

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, he has participated in several events and air operations, such as Cruzex, AirVenture, Dayton Airshow and FIDAE. He has works published in specialized aviation magazines in Brazil and abroad. He uses Canon equipment during his photographic work in the world of aviation.

Related news

MILITARY

US released the F-16 to Ankara and F-35 to Athens, but with some conditions

21/02/2024 - 23:09

MILITARY

B-52 flies with Filipino fighters over the South China Sea

21/02/2024 - 22:24

MILITARY

Norway receives first C-130J-30 Super Hercules with Block 8.1 update

21/02/2024 - 21:56

MILITARY

Greece and France block supply of Turkish UAVs to Ukraine

21/02/2024 - 17:00

HELICOPTERS

Indra will develop H225M helicopter simulator for the Singapore Republic Air Force

21/02/2024 - 16:00

HELICOPTERS

Schiebel wins contract with Camcopter S-300 for the South Korean Navy

21/02/2024 - 14:00

11 notes

·

View notes

Text

The Role of MS Plate in Modern Structural Engineering

Utilising high-quality materials is essential for the safety and longevity of buildings, bridges, and infrastructure projects in the dynamic world of contemporary structural engineering. Plates made of Mild Steel (MS) serve an important role in structural engineering. MS plates for numerous construction applications are in high demand in Vadodara, Gujarat, and their significance cannot be overstated. This blog will examine the role of MS plates in modern structural engineering, with a concentration on the availability of MS plates from suppliers and distributors in Vadodara, Gujarat.

MS Plates' Evolving Form:

Structural engineering has made great strides with plates of mild steel. Initially, iron plates were employed, but they lacked the required strength and durability. As a result of metallurgical advancements, MS plates have become the material of choice for a variety of structural applications. MS plates are fabricated from low carbon steel, making them ideal for welding, bending, and forming without sacrificing structural integrity.

In structural engineering, the function of MS plates:

MS plates offer remarkable strength and durability, making them an excellent option for supporting the load-bearing components of structures. The durability of the structure is ensured by the ability of these plates to withstand large loads and adverse weather conditions.

MS plates are extremely versatile and can be used in a wide variety of structural applications, such as building foundations, bridges, and industrial structures. They are an indispensable component of modern engineering due to their adaptability.

MS plates are renowned for their excellent weldability, enabling for the creation of strong joints and connections. This characteristic is indispensable in structural engineering, where precise welding is frequently required.

MS Plates in Vadodara, Gujarat:

When sourcing high-quality MS plates in Vadodara, Gujarat, it's crucial to work with dependable suppliers and distributors who can provide the appropriate materials for your projects. Tube Trading Co. is a reputable provider and distributor of MS plates in Vadodara, Gujarat, and their dedication to quality and customer satisfaction sets them apart.

MS Plates Supplier in Gujarat's Vadodara

In Vadodara, Gujarat, Tube Trading Co. takes pride in being a dependable supplier of MS plates. To meet the diverse requirements of the construction industry, they provide a vast selection of MS plates. Whether you need MS plates for a residential project or a large-scale industrial undertaking, they have the knowledge and inventory to meet your needs.

MS Plates Distributor Vadodara, Gujarat

As a dedicated distributor of MS plates in Vadodara, Gujarat, Tube Trading Company ensures that you have convenient access to high-quality MS plates whenever you require them. Their efficient distribution network and on-time delivery services make them the preferred supplier for contractors and engineers in Vadodara and beyond.

Why Buy MS Plates from Tube Trading Co. in Vadodara, Gujarat?

Tube Trading Co. is dedicated to delivering MS plates of the highest quality, meeting or exceeding industry standards. Their products undergo stringent quality inspections to ensure their dependability.

They offer competitive pricing, which makes the use of MS plates cost-effective for projects of any size.

Expert Guidance: Their seasoned team can offer valuable guidance and recommendations to assist you in selecting the ideal MS plates for your specific project requirements.

Final Thought

MS plates are indispensable in contemporary structural engineering because of their strength, durability, versatility, and weldability. If you are in Vadodara, Gujarat and in need of high-quality MS plates, Tube Trading Co. is your reliable source as an MS plates supplier and distributor. Their commitment to quality and customer satisfaction ensures that your structural engineering projects will have access to the finest materials on the market. To ensure the success of your upcoming endeavour in Vadodara, Gujarat, select MS plates from Tube Trading Co. It is impossible to overstate the significance of MS plates in contemporary structural engineering. Their strength, sturdiness, weldability, and adaptability make them indispensable in the construction of safe, dependable, and lasting structures. Tube Trading Co. is your trusted partner when it comes to procuring premium MS plates in Vadodara, Gujarat, ensuring structural consistency and adaptability in your projects. Choose Tube Trading Co. as your MS plates supplier and distributor to enhance your construction projects and reinforce structural integrity in Vadodara and the surrounding areas. MS plates from Tube Trading Co. are the best option for your construction project's success.

#MS plates supplier in Vadodara#MS plates supplier in Gujarat#MS plates distributor in Vadodara#MS plates distributor in Gujarat#MS plates in Vadodara#MS plates in Gujarat#Jindal Pipes#Tube Trading Co.#Gujarat#Vadodara#business

6 notes

·

View notes

Text

What is Metal Fabrication?

Metal fabrication transforms raw metal materials into a final product using various cutting, bending, welding, and assembling techniques. The process typically starts with the design and engineering of a product, followed by the selection and preparation of the raw materials, and then the fabrication process itself.

Metal fabrication can create various products, from simple metal components to complex machinery and structures. Some common examples of products created through metal fabrication include metal frames, brackets, enclosures, and structural components for buildings and bridges. Metal fabrication is used in various industries, including construction, automotive manufacturing, aerospace, and consumer products.

Why is metal fabrication important?

Metal fabrication is important for several reasons:

Customisation: Metal fabrication allows for customising metal products according to specific requirements, such as size, shape, and design. This flexibility enables businesses and industries to produce products that meet their unique needs and specifications.

Durability: Metal products produced through fabrication are durable and long-lasting. They can withstand extreme temperatures, pressures, and forces, making them ideal for various industries, including construction, manufacturing, and transportation.

Cost-effective: Fabricating metal products is often more cost-effective than purchasing pre-made products. This is because fabricators can produce multiple pieces of a product using the same materials, reducing waste and keeping costs low.

Quality control: Metal fabrication ensures high-quality products through strict quality control measures. Each product is inspected and tested to meet industry standards and specifications.

Metal fabrication is important because it enables businesses and industries to produce high-quality, customised, durable metal products that meet their unique needs and requirements.

What are the benefits of metal fabrication?

Metal fabrication offers many benefits, including:

Customisation: Metal fabrication allows for custom metal products that meet each customer's needs and requirements.

Strength and durability: Metal products created through fabrication are strong, durable, and able to withstand a variety of harsh conditions, making them ideal for use in construction and manufacturing industries.

Versatility: Metal fabrication can create a wide range of products, from small components to large structures, and can be used in various industries such as automotive, aerospace, construction, and more.

Cost-effective: Fabricated metal products can be produced in large quantities at a lower cost than other manufacturing processes, making them an affordable option for businesses and consumers.

Efficiency: With advanced technology and equipment, metal fabrication can produce high-quality products with minimal waste and faster turnaround times.

Aesthetics: Metal fabrication offers a wide range of finishes and coatings that can enhance the appearance of metal products, making them visually appealing and functional.

Recyclable: Metal is a recyclable material, which makes it an eco-friendly choice for businesses and consumers who want to reduce their environmental impact.

These benefits make metal fabrication an important and valuable process for a variety of industries and applications.

When do you need to get metal fabrication services?

You may need metal fabrication services when you require custom metal parts, structures or products for various purposes. Metal fabrication can be used in various industries, including construction, automotive, aerospace, manufacturing, and more. You may need metal fabrication services when you require unique parts or components that cannot be found off the shelf or a specific metal product designed and manufactured to your specifications.

Some common examples of when you may require metal fabrication services include the production of metal frames, structures, and enclosures, creating custom metal products, fabricating metal components for machinery or equipment, and repairing or modifying existing metal structures or products.

© DDK Engineering

2 notes

·

View notes

Text

Buy MS Flanges Online – High-Quality Flanges for Your Industrial Needs

Introduction: Buy the Best MS Flanges at Udhhyog

In search of a trusted supplier to buy MS flanges online? Udhhyog provides the highest-quality mild steel (MS) flanges that are engineered for durability and efficiency. With a comprehensive selection of flanges for industrial applications, we make it easy for you to purchase the right flange, regardless of the scope of your project.

From construction to manufacturing industries, MS flanges are vital for connecting pipelines and machinery, ensuring secure and efficient operations. Udhhyog takes pride in offering cost-effective solutions that meet the requirements of both small businesses and large-scale enterprises.

Why Buy MS Flanges from Udhhyog?

Wide Selection of Flanges: At Udhhyog, you’ll find an extensive range of MS flange types, including weld neck, slip-on, and blind flanges, all tailored for different industrial needs. Our MS flanges are designed to fit seamlessly into your systems, ensuring reliable performance.

Easy Online Purchase: With Udhhyog’s user-friendly platform, you can easily browse, compare, and buy the MS flanges you need in just a few clicks. No more waiting for quotes or visiting physical stores—our seamless online shopping experience is tailored for your convenience.

Superior Strength and Durability: Manufactured from the highest-grade mild steel, Udhhyog’s MS flanges are built to withstand extreme conditions, ensuring long-lasting durability in high-pressure environments.

Expert Support and Guidance: Not sure which flange to choose? Our team of industry experts is available to guide you through the selection process, helping you make an informed decision. Simply reach out to our customer service, and we’ll ensure you buy the right MS flange for your project.

Applications of MS Flanges

Udhhyog’s MS flanges are used across multiple industries:

Oil & Gas: Reliable connections for pipelines, tanks, and vessels.

Water Supply Systems: Ensuring leak-proof joints in industrial and municipal water systems.

Chemical Industry: Suitable for high-pressure chemical processes.

Construction: Essential for constructing strong, durable frameworks in buildings and bridges.

Our flanges are tested rigorously to meet industry standards, guaranteeing performance and safety across all applications. When you buy MS flanges from Udhhyog, you are investing in quality, reliability, and long-term value.

Why Udhhyog Stands Out

At Udhhyog, we are committed to providing the best-in-class industrial procurement solutions. Here’s why you should buy from us:

Competitive Pricing: We offer the best rates on all MS flanges, ensuring you get the most value for your money.

Quality Assurance: Each MS flange is thoroughly inspected before shipping, ensuring that you only receive products that meet the highest standards.

Nationwide Delivery: We deliver across India, ensuring that your flanges reach you quickly, no matter where your project is based.

Bulk Orders and Special Discounts

Need to purchase in bulk? Udhhyog offers special pricing and discounts on large orders of MS flanges. Simply contact our sales team, and we’ll ensure you get the best deals for your requirements.

For a streamlined shopping experience and reliable MS flange solutions, visit Udhhyog’s MS Flange Section and make your purchase today!

#BuyMSFlanges#MSFlangesOnline#IndustrialFlanges#MSFlangesSupplier#FlangeManufacturing#Udhhyog#PipelineSolutions#ConstructionSupplies#MSFlangeDeal

1 note

·

View note

Text

Transforming the Future: The Positive Impact of AI in Robotics

Artificial Intelligence (AI) is revolutionizing many sectors, and one of the most significant impacts is seen in robotics. The integration of AI in robotics is not just enhancing efficiency; it's transforming industries, improving lives, and creating new opportunities. Here’s how:

1. Enhanced Automation and Efficiency

AI-driven robots can perform repetitive tasks with precision and speed that far surpass human capabilities. For instance, in manufacturing, AI robots can adapt to changes in production lines in real-time, optimizing workflows and reducing downtime. This leads to increased productivity and cost savings for companies.

2. Improved Decision-Making

AI enables robots to analyze vast amounts of data quickly. For example, in autonomous vehicles, AI processes information from sensors to make real-time decisions, ensuring safety and efficiency on the roads. This capability can be extended to drones for delivery services, agricultural robots for crop monitoring, and more.

3. Enhanced Safety

Robots equipped with AI can take on dangerous tasks in hazardous environments, reducing risks to human workers. In construction, for instance, AI robots can inspect structures and perform dangerous tasks like welding or demolition, minimizing workplace accidents.

4. Personalized Services

In the healthcare sector, AI-powered robots are assisting in surgeries and providing personalized care. They can analyze patient data to recommend tailored treatment plans, improving patient outcomes and efficiency in healthcare delivery.

5. Robotic Companions

AI is also paving the way for social robots that can assist the elderly or individuals with disabilities. These robots can engage in conversations, remind users of medications, and provide companionship, significantly enhancing quality of life.

6. Innovation and Economic Growth

The fusion of AI and robotics is driving innovation across various sectors, from agriculture to logistics. Startups and established companies alike are investing in AI robotics, contributing to economic growth and creating new job opportunities in tech and engineering fields.

7. Sustainability

AI in robotics can promote sustainability. For instance, AI algorithms can optimize resource use in agriculture, ensuring minimal waste and maximizing yield. In environmental monitoring, robots can track pollution levels and biodiversity, aiding in conservation efforts.

Conclusion

The positive impact of AI in robotics is profound and far-reaching. From enhancing productivity and safety to fostering innovation and sustainability, the future is bright. As AI technology continues to evolve, its synergy with robotics will undoubtedly lead to transformative changes that can benefit society at large.

If you have any further questions or want to discuss specific applications, feel free to ask!

#artificial intelligence#branding#devlog#business#entrepreneur#ecommerce#coding#accounting#commercial#economy

0 notes

Text

Importance of Compression Tube Fittings Manufacturer in India

Overview of Compression Tube Fittings

Compression tube fittings are a critical component in various industries, providing a reliable and leak-proof connection for tubing systems. These fittings are essential in applications where precision, durability, and safety are paramount. Whether it's in the oil and gas sector, chemical processing, or power generation, the right choice of compression tube fittings manufacturer in Mumbai, Chennai, Ahmedabad, Rajasthan, Bangalore, Vadodara, Gujarat, Ghaziabad and Delhi, it can make a significant difference in operational efficiency and safety.

Why Choose Compression Tube Fittings?

Compression fittings offer numerous advantages, such as ease of installation, reusability, and resistance to high pressures and temperatures. Unlike welded or soldered joints, compression fittings can be assembled and disassembled without specialized tools, making them a preferred choice for maintenance and repairs.

The Importance of Quality in Fittings Manufacturing

The quality of compression tube fittings is crucial. Poor-quality fittings can lead to leaks, system failures, and even safety hazards. Therefore, selecting a reputable manufacturer like We ensures that you get products that meet stringent quality standards and provide reliable performance over time.

Pedlock's History and Reputation

Pedlock has established itself as a premier manufacturer of compression tube fittings, known for its commitment to quality and innovation. With decades of experience, our company has built a solid reputation in the industry, providing top products to clients worldwide.

Commitment to Quality and Innovation

We dedication to quality is evident in its state of the art manufacturing facilities and rigorous quality control processes. The company continually invests in research and development to innovate and improve its product offerings, ensuring that customers receive the best solutions for their needs.

Global Presence and Clientele

With a global presence, we serves a diverse range of industries and clients, from small businesses to large multinational corporations. This extensive reach is a testament to the trust and confidence that customers place in our products and services.

What Are Compression Tube Fittings?

Compression tube fittings manufacturer in Bangalore, Ahmedabad, Vadodara, Mumbai, Chennai, Delhi, Rajasthan, Ghaziabad and Gujarat is mechanical fittings used to connect tubes in a secure and leak-proof manner. They are commonly used in applications involving fluids and gases, where precision and reliability are essential.

How Do They Work?

Compression fittings work by compressing a ferrule onto the tube as a nut is tightened, creating a tight seal. This mechanism allows for secure connections without the need for welding, threading, or adhesives.

Types of Compression Tube Fittings

Single Ferrule vs. Double Ferrule

Single Ferrule: Consists of one ferrule that compresses onto the tube, providing a seal.

Double Ferrule: Uses two ferrules, offering enhanced sealing and gripping performance, making them ideal for high-pressure applications.

Male vs. Female Connectors

Male Connectors: Feature an external thread, used to connect to female fittings.

Female Connectors: Have an internal thread, designed to receive male connectors.

Raw Material Selection

We carefully select high quality raw materials to ensure the durability and performance of its fittings. Materials like stainless steel, brass, and other corrosion resistant alloys are commonly used.

Precision Engineering and Machining

Advanced CNC machines and precision engineering techniques are employed to manufacture fittings to exact specifications. This precision ensures that each fitting performs reliably, even in demanding conditions.

Quality Control Measures

Every Pedlock fitting undergoes stringent quality control checks, including dimensional inspections, pressure testing, and material verification. This rigorous process ensures that only the highest quality products reach the customer.

Benefits of Using Compression Tube Fittings

Superior Leak-Proof Design

Our fittings are engineered to provide a secure, leak-proof connection, even under high-pressure conditions. This reliability makes them ideal for critical applications where leaks are not an option.

High Pressure and Temperature Resistance

Our fittings are designed to with stand extreme pressures and temperatures, ensuring long lasting performance in challenging environments.

Easy Installation and Maintenance

The design of our compression tube fittings allows for quick and easy installation, reducing downtime and maintenance costs. This user-friendly feature is particularly beneficial in industries where time is of the essence.

Applications of Compression Tube Fittings Manufacturer

Oil and Gas Industry

Pedlock fittings are extensively used in the oil and gas sector, where they provide reliable connections in pipelines and equipment used for extraction, refining, and distribution.

Chemical and Petrochemical Industry

In chemical processing plants, our fittings ensure safe and leak-proof connections in systems handling hazardous materials, maintaining the integrity of the operation.

Power Generation and Utilities

Our compression fittings are crucial in power generation facilities, providing secure connections in systems that require high pressure and temperature resistance.

Other Industrial Applications

From automotive to aerospace, our fittings find applications across various industries, proving their versatility and reliability in diverse environments.

Choosing the Right Compression Tube Fitting

Factors to Consider

When selecting a compression fitting, it's essential to consider factors such as pressure rating, temperature compatibility, and material selection to ensure optimal performance.

Compatibility and Sizing

Choosing the correct size and ensuring compatibility with existing systems is crucial to prevent leaks and maintain the integrity of the connection.

Material Selection and Corrosion Resistance

Selecting the appropriate material for your application is key to preventing corrosion and ensuring the longevity of the fitting. We offer a range of materials to suit different needs.

Pedlock's Competitive Advantage

Cutting Edge Manufacturing Technology

We use of an advanced manufacturing technology ensures the production of high-quality, precision-engineered fittings that meet the stringent demands of various industries.

Exceptional Customer Support

We pride it on providing exceptional customer support, assisting clients with product selection, installation guidance, and technical support.

Certifications and Compliance

Our fittings are certified to meet various international standards, ensuring compliance and quality assurance for customers worldwide.

Conclusion

Pedlock is a trusted name in the field of compression tube fittings manufacturer in Ahmedabad, Chennai, Mumbai, Vadodara, Gujarat, Bangalore, Rajasthan, Delhi, and Ghaziabad in India as known for its quality, innovation, and exceptional customer service. With a wide range of products and a commitment to excellence, we remain the preferred choice for industries seeking reliable and high-performance fittings.

#compression tube fittings manufacturer in Mumbai#compression tube fittings manufacturer in Chennai#compression tube fittings manufacturer in Ahmedabad#compression tube fittings manufacturer in Vadodara#compression tube fittings manufacturer in Gujarat#compression tube fittings manufacturer in Delhi#compression tube fittings manufacturer in Rajasthan#compression tube fittings manufacturer in Ghaziabad#compression tube fittings manufacturer in Bangalore

0 notes

Text

Understanding Flange Standards: ANSI, ASME, and Beyond - Metalica Forging Inc

Metalica Forging Inc, a renowned leader in Flanges Manufacturer in India, offers a wide range of industrial pipe flanges to meet various needs, from 12 inches to 48 inches in diameter. These flanges are essential for seamlessly connecting pipes to other components, such as tees, elbows, reducers, and valves, ensuring a smooth integration within piping systems.

As one of the largest Flange Suppliers in India, we have earned a reputation for its unwavering commitment to meeting the global demands of its clients, who are spread across five continents and nearly 80 countries. This remarkable achievement is a testament to the exceptional quality and durability of the company's products.

We are most trusted name in the Indian flanges market, known for producing ASTM A105 flanges that can withstand high-pressure and high-temperature conditions. As a prominent supplier of JIS Flanges, the company is continuously expanding its service offerings to cater to the changing requirements of its diverse clientele.

Flanges are crucial components in many industries, especially in piping systems. Whether in oil and gas, chemical, power plants, or water treatment facilities, the proper design of flanges can significantly affect the overall performance, reliability, and safety of the system. This blog delves into the secrets of effective flange design, as shared by industry experts, and provides invaluable tips to ensure optimal performance and longevity of flanges in various applications.

Understanding the Basics of Flange Design

A flange is a mechanical part used to connect pipes, valves, pumps, and other equipment into a complete piping system. It is a circular plate with holes for bolts, which allows for a strong connection. Flanges serve both as a structural link and, in many cases, a sealing surface for gaskets to stop leaks.

Key Flange Types

Weld Neck Flange:

This type of product is made for applications that require high pressure. The flange is attached to the pipe by welding the edges together, creating a continuous and smooth connection that spreads the stress across the pipe's wall and the flange's neck. It is well-suited for situations with significant changes in temperature.

Slip-On Flange:

Slip-on flanges are generally used for low-pressure, low-temperature applications and are simpler to install than weld neck flanges. They are positioned over the pipe and welded on the inside and outside to increase their strength.

Blind Flange:

Blind flanges are used to seal off pipelines or valves, which is crucial for testing and maintenance. These flanges have a straightforward design and can withstand high pressure.

Socket Weld Flange:

Socket weld flanges are well-suited for small pipes and high-pressure applications, as they offer exceptional resistance to fatigue.

Lap Joint Flange:

Lap joint flanges paired with stub-end fittings are well-suited for systems that need to be disassembled regularly for inspection or cleaning purposes.

Critical Design Considerations

When designing flanges, various elements must be considered, such as the material type, pressure classification, and surrounding conditions. A properly engineered flange should be capable of enduring the mechanical tensions caused by internal pressure and external forces, while simultaneously preserving a leak-free seal. Here are some expert recommendations to achieve an optimal flange design.

Flange Design Tips from Industry Experts

1. Material Selection: Compatibility is Key

Selecting the right material is crucial when designing flanges. Experts stress the need to pick materials that can withstand the substances flowing through the pipes and the surrounding environment. For example, stainless steel is highly resistant to corrosion, making it a common choice for chemical and water treatment facilities. Conversely, carbon steel flanges are more appropriate for high-temperature settings, such as power plants.

In harsh environments like offshore oil drilling, specialized metal alloys such as Inconel or Monel may be necessary to withstand the intense corrosive effects of seawater. When selecting materials, it's important to consider the temperature and pressure requirements to prevent flange failures during operation.

2. Stress Analysis: Prevent Overstressing the Flange

Analyzing stress is essential to prevent failures, particularly in high-pressure or high-temperature settings. Specialists suggest performing a finite element analysis (FEA) to verify that the flange can withstand the stresses imposed by the system. Excessive stress can result in flange distortion, bolt loosening, and potentially, leakage or catastrophic failure.

3. Flange Face Finish: Achieving a Tight Seal

The surface of a flange, called the flange face, is crucial for stopping leaks. The texture of the flange face should be carefully selected to work well with the gasket material and the specific use. Experts advise using a smoother finish for soft gaskets like rubber or PTFE to get a tight seal, while rougher textures are better with metal gaskets that need more friction to make an effective seal.

The most common finishes for flange faces are:

Raised Face: A higher surface area creates a better seal. This is often used in high-pressure settings.

Flat Face: The flange must be in complete contact with the gasket and the surface it is mating with.

Ring-Type Joint (RTJ): RTJ flanges are designed for use in systems that operate under high pressure and high temperature conditions. These flanges have a groove cut into their face to hold a metal ring gasket in place.

4. Gasket Selection: Proper Sealing is Essential

The type of gasket material and its design are crucial for creating a leak-free seal. The gasket needs to be suitable for the flange material, the substance being transported, and the operating environment, including temperature and pressure.

Metallic gaskets are suitable for high-pressure and high-temperature applications.

Non-metallic gaskets are used in lower-pressure systems and typically include materials like rubber, Teflon, or compressed fiber.

Composite gaskets combine metallic and non-metallic materials, providing a balance between flexibility and strength.

5. Bolt Torque and Tightening Patterns: Ensuring Uniform Pressure

Bolts are essential for keeping the flange assembly intact, and applying the right amount of torque is crucial to prevent uneven pressure, which can cause the gasket to fail. Experts advise using a controlled tightening technique, like a torque wrench, to apply the appropriate amount of force evenly across all the bolts.

Fasteners are essential for securely joining the flanged components, and the appropriate application of twisting force is crucial to prevent uneven pressure, which can result in gasket malfunction. Specialists suggest employing a regulated tightening approach, like a torque wrench, to apply the correct amount of force uniformly across all fasteners.

6. Temperature and Pressure Ratings: Don’t Exceed the Limits

Each flange has particular pressure and temperature limits, often called the "pressure class." These limits define the highest allowed working pressure at a given temperature. Going beyond these limits may result in severe failures.

Experts stress the need to comprehend the system's working conditions and ensure the flange's pressure rating aligns with the maximum anticipated pressure and temperature. For instance, in steam systems, temperature variations can lead to substantial expansion and contraction, necessitating flanges with higher ratings to handle the stress.

7. Corrosion Protection: Guarding Against Environmental Factors

Damage to flanges is often caused by corrosion, particularly in challenging settings like offshore rigs or chemical facilities. Experts advise applying protective coatings, like galvanization or epoxy, to prevent corrosion. In certain situations, using a corrosion-resistant alloy may be necessary to ensure long-lasting performance.

Most Trusted Manufacturer leading flanges in several Indian cities:

MS Flanges Manufacturer In Rajkot

MS Flanges Manufacturer In Ahmedabad

MS Flange Manufacturer In Surat

MS Flange Manufacturer In Pune

MS Flange Manufacturer in Bhavnagar

For More Details

Website: metalicaforginginc.com

0 notes

Text

Tips for Inspecting a Used Excavator Before You Buy

Buying a used excavator can be a great way to save money while still getting the machinery you need. However, it's crucial to inspect the machine thoroughly before making a purchase. A proper inspection can help you avoid costly repairs and ensure that you're getting a good deal.

Why Choose a Used Excavator?

Used excavators can be a cost-effective alternative to buying new. They have a lower upfront cost and can offer significant savings on depreciation. Plus, if maintained properly, they can perform just as well as a new machine.

Essential Tools for Inspection

Before you begin, gather some essential tools like a flashlight, inspection mirror, gloves, and a notepad. These tools will help you perform a detailed inspection.

Inspecting the Excavator's Exterior

Check for Structural Damage

Look for any cracks, welds, or other signs of damage on the frame and boom. Structural damage can indicate heavy use or past accidents.

Look for Signs of Rust or Corrosion

Examine areas prone to rust, such as the undercarriage and joints. Rust can weaken the machine's integrity and lead to future problems.

Examine the Paint and Bodywork

Check for paint overspray or mismatched colors, which could indicate repairs. Consistent paint suggests that the machine has been well-maintained.

Assessing the Engine and Hydraulics

Engine Condition and Oil Leaks

Open the engine compartment and inspect for oil leaks or other fluid leaks. Start the engine to listen for unusual noises like knocking or sputtering, which could indicate internal issues.

Hydraulic System Performance

Inspect hoses and cylinders for leaks, cracks, or wear. Test the hydraulic system by moving the boom, stick, and bucket to ensure smooth operation.

Fluid Levels and Quality

Check the levels of hydraulic fluid, engine oil, and coolant. Look at the fluid color and consistency; milky or discolored fluids can indicate contamination or neglect.

Evaluating the Undercarriage

Tracks and Track Tension

Inspect the tracks for wear, cracks, or missing parts. Proper track tension is crucial for the machine's stability and performance.

Rollers and Idlers

Check the condition of the rollers, idlers, and sprockets. Excessive wear on these components can lead to costly repairs.

Look for Excessive Wear

Look for uneven wear patterns, which could indicate alignment issues or improper use.

Testing the Boom, Stick, and Bucket

Check for Cracks or Welds

Inspect the boom, stick, and bucket for any cracks, dents, or welds. Repairs in these areas can be a red flag for heavy usage or damage.

Bucket Teeth and Edges

Examine the bucket teeth and cutting edges for wear. Worn teeth can affect digging efficiency and indicate the machine's overall usage.

Smoothness of Operation

Operate the boom, stick, and bucket to check for smoothness and responsiveness. Jerky movements can indicate hydraulic issues.

Inspecting the Cab and Controls

Operator Comfort and Visibility

Sit in the cab to assess comfort and visibility. A comfortable operator's seat and clear visibility are crucial for safe operation.

Control Panel and Electronics

Test all the controls and switches to ensure they are functioning properly. Check the display panel for any error codes or warning lights.

Seat Condition and Safety Features

Inspect the seat for wear and tear, and ensure that safety features like seat belts and emergency shut-offs are in good working order.

Checking the Maintenance History

Service Records and Logs

Ask for the machine's maintenance records and logs. Regular servicing is a good sign that the previous owner took care of the machine.

Past Repairs and Modifications

Review any past repairs or modifications to understand the machine's history. Major repairs could indicate underlying issues.

Testing the Excavator in Action

Functional Test Drive

If possible, take the excavator for a test drive. Pay attention to how it handles, accelerates, and brakes.

Listen for Unusual Noises

During the test drive, listen for any unusual noises like grinding or clunking, which could indicate mechanical problems.

Evaluate the Machine's Performance

Test the machine's performance in different operations, like digging, lifting, and swinging. It should operate smoothly without any delays or hesitations.

Verifying Legal and Documentation

Ownership and Title

Verify the ownership documents and title to ensure there are no liens or legal issues with the machine.

Insurance and Warranty

Check if the machine has any remaining warranty or if the previous owner had it insured. This information can add value to your purchase.

Consulting a Professional Mechanic

Even if you have some knowledge about excavators, it's always a good idea to have a professional mechanic inspect the machine. They can provide a detailed report and identify issues you might have missed.

Negotiating the Price

Use Inspection Findings for Leverage

Use the information gathered during the inspection to negotiate a better price. Point out any issues or necessary repairs to justify a lower offer.

Fair Market Value Research

Research the fair market value of similar used excavators to ensure you're getting a reasonable deal.

Conclusion

Inspecting a used excavator before buying is a crucial step to ensure you’re making a sound investment. By following these tips, you can avoid potential pitfalls and find a machine that meets your needs and budget. Remember, a thorough inspection now can save you a lot of time and money in the future.

visit - https://www.southwest-global.com/construction-equipment/used-excavators/

0 notes

Text

How Mag Particle Testing Protects Your Critical Assets?

Our world relies on a vast network of critical assets. From the towering wind turbines that harvest clean energy to the intricate pipelines that transport vital resources, these structures form the backbone of modern civilization. However, hidden beneath the surface of these assets can lurk a silent threat: cracks. These imperfections, often invisible to the naked eye, can pose a significant risk to safety, functionality, and operational efficiency. To read more visit

#welding engineering inspection services#engineering safety inspection services#engineering & inspection services#construction engineering and inspection services#engineering and inspection services#inspection engineer#visual testing#ultrasonic inspection#ndt inspection services#ultrasonic test#testing and inspections#ndt inspector#mag particle testing#welding engineering#ndt certification#visual inspection#welding engineer#engineering services#non-destructive testing#non destructive evaluation

0 notes

Text

Inspection Equipment Testing Services: Your Precision and Safety Experts

In industries, the growing competition requires optimum equipment operations that mark the paramount importance of precision and safety. This inspection equipment plays a crucial role in maintaining quality standards and preventing potential hazards avoiding any business disruption. For this reason, Inspection equipment testing services are essential for any business domain heavily dependent on machinery to ensure the accuracy and reliability of these tools.

We involve comprehensive quality checks and evaluation of various inspection tools, such as gauges, meters, scanners, and analysers, to verify their accuracy and functionality. These services are typically performed by specialized technicians who follow stringent testing protocols to test equipment on various parameters critical for the production process.

Importance of Inspection Equipment Testing Services:

Quality Assurance: Precise inspection equipment is crucial for maintaining product quality and process efficiency. It allows regular testing that guarantees that measurements will be accurate and consistent.

Safety Compliance: Industries like manufacturing, aerospace, and healthcare rely on inspection equipment for safety and compliance with best business practices. The correct functioning of devices through inspection reduces the risk of accidents and largely ensures adherence to regulations.

Cost Efficiency: Faulty inspection equipment can lead to flawed products, production downtime, and rework costs that can significantly hamper business image. Leveraging Inspection equipment testing services prevent these issues by detecting problems early, saving both time and money.

Data Integrity: Inspection equipment often generates crucial data that plays an important role in decision-making. If these instruments are inaccurate, it can lead to incorrect data conclusions which can be avoided by regular testing safeguards.

#Yamunanagar Engineering Cluster#mechanical testing laboratory#3d scanning reverse engineering#cnc precision testing services#robotic welding testing services#inspection equipment testing services#research and development solutions

0 notes

Link

Job title: WELDING INSPECTOR Company: Profile Middle East Job description: Profile Middle East is a service provider with more than 20 years of experience in the market which specializes in Technical Field and HR Consultancy Services in the Industrial Sector (Oil & Gas, Engineering, Construction, Commissioning) with our focus on the Middle East region and a worldwide presence.For our own projects, we are looking for: WELDING INSPECTORRef code: CR_2407-144_Welding InspectorJob summaryMISSION:Responsible for ensuring the supervision of welding inspection activities and verifying Quality Control Plans implementation.TASKS: Check Quality Control Plans with reference to welding activities. Check the availability and adequacy of consumables and equipment / instrumentation used for welding execution and control. Verify that material and equipment are correctly received, stored, preserved, calibrated, handled, identified and traceable. Support and check the evaluation of the qualification of inspection personnel in charge of works, verify work procedures, including those relating to special processes. Support the definition of QC Information System rules. Supervise and witness inspections, check reports and documentation issued by inspectors and verify the collection of required Quality Records. Verify that tests, controls and inspections are carried out according to Quality Control Plans / Inspection Test Plans, checking the collection of relevant documentation also for the mechanical completion approval, and that personnel have access to all required project documentation. In case of subcontracted activities, verify the correct implementation of approved Quality Control Plans / Inspection Test Plans, witnessing inspections and collecting relevant Quality Control records. Verify the collection and management of documents certifying test, controls and inspections, checking that all records are properly retrievable within the final As-Built dossier. Verify the preparation of the Quality works dossier for final handover to the Document Controller. Verify that the NCR management process is in place and effective. EDUCATION & EXPERIENCE: Bachelor's degree or a related experience; CSWIP 3.1 certification; Strong proven experience in Magnetic Particle Test, Ultrasonic Test, Liquid Penetrate Inspections 10+ years of work experience in the Inspection and NDT check task during the fabrication phase. Fluent level of written and spoken English. OTHER DETAILS: Job Location: Sharjah yard, Hamriyah Free Zone, UAE; Contract Duration: 1 year; Starting date: August 2024. Profile Middle East upholds workplace equality and diversity, assessing candidates solely on merit and potential. Expected salary: Location: Hamriyah, Muscat - United Arab Emirates Job date: Fri, 05 Jul 2024 22:50:44 GMT Apply for the job now!

0 notes

Text

Pipe Fittings Manufacturing Standards and Types

At Online Fittings, we understand the importance of reliable components in your piping systems. While pipes take center stage, the unsung heroes are the fittings that ensure a smooth flow and strong connections. Let’s talk about forged pipe fittings, exploring the standards that govern their creation and the various types available.

Built to Withstand Pressure: Forged Pipe Fitting Manufacturing Standards

Unlike cast fittings, forged fittings are crafted from solid metal blocks. Intense heat and pressure are applied, shaping the metal into the desired fitting form. This process results in exceptionally strong and resilient components, making them ideal for high-pressure applications. But how do we ensure their quality and consistency?

Several crucial standards oversee the manufacturing of forged pipe fittings. Here are the main ones:

ASME B16.11: This American Society of Mechanical Engineers (ASME) standard dictates the dimensions, tolerances, pressure-temperature ratings, material requirements, and markings for forged fittings. By adhering to ASME B16.11, manufacturers guarantee fittings that seamlessly integrate with pipe conforming to ASME B36.10 and B36.19 standards.

MSS SP-75, SP-83, SP-95: These Manufacturer’s Standardization Society (MSS) specifications supplement ASME B16.11, providing additional details on material properties, inspection procedures, and testing requirements for specific fitting types.

Choosing the Right Tool for the Job: Diverse Forged Pipe Fitting Types

Forged fittings come in a wide array of shapes and sizes, each catering to unique piping needs. Here’s a look at some of the most common types:

1. Elbows: These fittings change the direction of flow, typically at 90 or 45 degrees. They are available in threaded and socket-weld configurations.

Socket Weld: 45° Elbow, 90° Elbow, 180° Elbow.

Threaded: 45° Elbow, 90° Elbow, 180° Elbow.

2. Tees: T-shaped fittings with one inlet and two outlets, used for branching or merging pipelines. They come in equal (all three openings are the same size) or reducing (one outlet has a smaller diameter) variations.

Socket Weld: Equal Tee, Reducing Tee.

Threaded: Equal Tee, Reducing Tee, Lateral Tee.

3. Couplings: Simple straight fittings that connect two pipes of the same diameter.

Socket Weld: Half Coupling, Full Coupling.

Threaded: Full Coupling, Half Coupling.

6. Reducers: Designed to connect pipes with different diameters, allowing for smooth transitions in pipe size.

7. Unions: Three-piece fittings enabling easy disconnection of a pipe segment for maintenance or inspection.

Threaded: Union.

8. Caps and Plugs: Caps seal off the end of a pipe, while plugs screw into a threaded opening to block it.

Socket Weld: End Cap.

Threaded: End Cap, Plugs.

Material Matters: Selecting the Right Forged Fitting Material

The material used in forged fittings plays a crucial role in their performance. Here are the two most common options:

Carbon Steel (ASTM A105): This cost-effective material is widely used for moderate-pressure applications. Its versatility makes it suitable for various industries.

Stainless Steel (ASTM A182): Offering superior corrosion resistance, stainless steel finds favour in environments with harsh chemicals or high temperatures.

Finding the Perfect Fit With Quality and Reliable Forged Pipe Fittings by Online Fittings

We’re your one-stop shop for top-quality forged pipe fittings. As a leading wholesale distributor, we offer bulk quantities directly from the manufacturer at factory prices, eliminating intermediaries and ensuring competitive pricing. Our global delivery service ensures prompt and reliable shipping worldwide. With dedicated post-sales support and a secure shopping environment, you can trust us to provide exceptional service and products.

At Online Fittings, we offer a comprehensive selection of forged pipe fitting accessories online that meet the highest industry standards. By understanding the manufacturing standards and available types, you can make informed decisions to ensure the optimal performance and longevity of your piping system.

0 notes

Text

Ultrasonic Testing in Pune by Integrated NDE Solution Company: Your Trusted NDT Partner

Introduction

In the modern industrial landscape, ensuring the integrity and safety of materials and components is paramount. Non-destructive testing (NDT) plays a crucial role in maintaining these standards, with ultrasonic testing being one of the most effective and reliable methods. Integrated NDE Solution Company, based in Pune, offers a comprehensive range of ultrasonic testing services that cater to various industries. Whether you are searching for NDT testing near me or require specialized ultrasonic testing services, Integrated NDE Solutions is your go-to partner for all your inspection needs.

The Importance of Ultrasonic Testing in NDT

Ultrasonic testing is a non-invasive inspection technique that uses high-frequency sound waves to detect imperfections or changes in material properties. This method is widely used across industries such as aerospace, automotive, construction, and manufacturing due to its accuracy and ability to provide detailed information about the internal structure of a material.

Integrated NDE Solution Company excels in providing ultrasonic testing services that are critical for ensuring the safety and longevity of various components. From detecting flaws in welds to measuring material thickness, our ultrasonic testing services are designed to meet the highest industry standards.

Why Choose Integrated NDE Solution Company?

When it comes to NDT inspection and ultrasonic testing, choosing the right service provider is crucial. Integrated NDE Solution Company stands out for several reasons:

Expertise in Ultrasonic Testing: Our team of experienced professionals is well-versed in the latest ultrasonic testing techniques, ensuring accurate and reliable results every time.

Advanced Equipment: We use state-of-the-art ultrasonic testing equipment, including ultrasonic thickness testers and specialized ultrasonic NDT devices, to provide precise measurements and detect even the smallest defects.

Comprehensive Services: Whether you need ultrasonic testing in Pune or are looking for ultrasonic testing services near me, we offer a wide range of services tailored to meet the specific needs of each client.

Commitment to Quality: At Integrated NDE Solution Company, quality is our top priority. We adhere to strict industry standards and protocols to ensure that our NDT inspections are of the highest quality.

Applications of Ultrasonic Testing

Ultrasonic testing is versatile and can be applied to a wide range of materials and components. Some of the key applications include:

Weld Inspection: Ultrasonic testing is widely used for inspecting welds to detect flaws such as cracks, voids, and inclusions. This is critical in industries where the integrity of welded joints is paramount, such as in pipeline construction, shipbuilding, and aerospace.

Thickness Measurement: Using an ultrasonic thickness tester, we can accurately measure the thickness of materials, including metals, plastics, and composites. This is essential for determining the remaining life of components and ensuring that they meet the required specifications.

Flaw Detection: Ultrasonic testing is highly effective in detecting internal flaws such as cracks, voids, and inclusions in materials. This helps in preventing catastrophic failures and ensuring the safety of components.

Corrosion Mapping: Ultrasonic testing can be used to map the extent of corrosion in materials, providing valuable information for maintenance and repair decisions.

Ultrasonic Testing in Pune

As a leading provider of ultrasonic testing in Pune, Integrated NDE Solution Company is proud to serve a wide range of industries in the region. Pune is a hub for manufacturing, automotive, and engineering industries, all of which require reliable NDT inspection services to ensure the safety and integrity of their products.

Our ultrasonic testing services in Pune are designed to meet the specific needs of each industry. Whether you are looking for routine inspections or require specialized testing for critical components, our team is equipped to handle it all.

Non-Destructive Testing Near Me

If you are searching for non-destructive testing near me, look no further than Integrated NDE Solution Company. We offer a comprehensive range of NDT services, including ultrasonic testing, that are designed to provide accurate and reliable results.

Our NDT services are available to clients across Pune and the surrounding regions. We understand the importance of timely and efficient inspections, which is why we strive to provide our services with minimal disruption to your operations.

Ultrasonic NDT: A Closer Look

Ultrasonic NDT is a specialized form of non-destructive testing that uses high-frequency sound waves to inspect materials and components. This method is highly effective in detecting internal flaws and measuring material thickness, making it an essential tool for ensuring the safety and integrity of various components.

At Integrated NDE Solution Company, we offer a wide range of ultrasonic NDT services, including:

Flaw Detection: Our ultrasonic NDT services are designed to detect internal flaws in materials, including cracks, voids, and inclusions. This helps in preventing catastrophic failures and ensuring the safety of components.

Thickness Measurement: Using advanced ultrasonic equipment, we can accurately measure the thickness of materials, ensuring that they meet the required specifications.

Weld Inspection: Our ultrasonic NDT services are widely used for inspecting welds to detect flaws and ensure the integrity of welded joints.

Corrosion Mapping: We offer ultrasonic corrosion mapping services to help identify the extent of corrosion in materials, providing valuable information for maintenance and repair decisions.

Ultrasonic Testing Services Near Me

For those in search of ultrasonic testing services near me, Integrated NDE Solution Company offers a comprehensive range of services that are tailored to meet the specific needs of each client. Our team of experienced professionals is equipped with the latest ultrasonic testing equipment, ensuring accurate and reliable results every time.

Whether you need ultrasonic testing for weld inspection, thickness measurement, or flaw detection, our team is here to help. We offer our services to clients across Pune and the surrounding regions, providing timely and efficient inspections that meet the highest industry standards.

The Future of Ultrasonic Testing

As technology continues to evolve, so too does the field of ultrasonic testing. Integrated NDE Solution Company is committed to staying at the forefront of these advancements, continually investing in the latest equipment and training for our team.

One of the key trends in ultrasonic testing is the development of advanced imaging techniques, such as phased array ultrasonic testing (PAUT) and time-of-flight diffraction (TOFD). These techniques offer higher resolution images and more accurate defect detection, making them invaluable tools for NDT inspections.

In addition, there is a growing trend towards the use of automated ultrasonic testing systems, which can provide faster and more consistent results. At Integrated NDE Solution Company, we are exploring these advancements to ensure that we continue to provide our clients with the most accurate and reliable ultrasonic testing services available.

Conclusion

Ultrasonic testing is a critical component of non-destructive testing, offering accurate and reliable results for a wide range of applications. Whether you are looking for NDT inspection services, ultrasonic testing in Pune, or ultrasonic testing services near me, Integrated NDE Solution Company is your trusted partner for all your NDT needs.

With our expertise, advanced equipment, and commitment to quality, we are well-equipped to handle all your ultrasonic testing requirements. Contact us today to learn more about our services and how we can help ensure the safety and integrity of your materials and components.

#nde company#ndt inspection#ndt testing near me#non destructive testing near me#ultrasonic testing#ultrasonic testing in pune#ultrasonic testing ndt#ultrasonic thickness tester#ultrasonic ndt#ultrasonic testing services near me

0 notes

Text

Glass-Lined Water Storage Tanks: The Ultimate Low-Maintenance Solution for Reliable Water Storage

When it comes to water storage, the need for durability, safety, and cost-efficiency is paramount. Shijiazhuang Zhengzhong Technology Co., Ltd. is proud to offer Glass-Lined Water Storage Tanks, specifically designed to meet these needs while ensuring the lowest possible maintenance requirements. Our tanks are the ideal solution for industries and municipalities looking for reliable, long-term water storage with minimal upkeep.

Shijiazhuang Zhengzhong Technology Co., Ltd.’s Glass-Lined Water Storage Tanks are the ideal solution for anyone seeking a low-maintenance, durable, and reliable water storage option. With exceptional corrosion resistance, minimal maintenance needs, and a range of applications, our tanks offer the best value for long-term water storage. Invest in our glass-lined tanks to secure your water storage needs with the lowest possible maintenance requirements. Contact us today to learn more about our products and how we can help you find the perfect solution for your water storage challenges.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Why Choose Glass-Lined Water Storage Tanks?

Glass-lined water storage tanks are engineered with a unique combination of steel strength and glass corrosion resistance. This fusion creates a robust and durable storage solution that stands the test of time, making them an excellent choice for various water storage applications.

Exceptional Corrosion Resistance:

Glass-Fused-to-Steel Coating: The glass lining is fused to the steel surface at extremely high temperatures, creating a smooth, non-porous barrier that is impervious to water, chemicals, and other corrosive elements. This ensures that the tank remains rust-free and maintains its structural integrity, even in harsh environments.

Longer Service Life: The superior corrosion resistance of glass-lined tanks significantly extends their service life compared to traditional steel tanks, reducing the need for frequent replacements or repairs.

Minimal Maintenance Requirements:

Non-Porous Surface: The glass coating prevents the accumulation of sediments, algae, and other contaminants inside the tank. This non-porous surface makes the tank easy to clean and reduces the frequency of maintenance activities.

Low Wear and Tear: The durable glass lining is highly resistant to wear and tear, even under constant use. This means less frequent inspections and lower maintenance costs over the tank’s lifespan.

Resilience in Adverse Conditions: Our glass-lined tanks are designed to withstand extreme weather conditions, including high humidity, UV exposure, and temperature fluctuations. This resilience ensures that the tanks require minimal intervention to keep them in optimal working condition.

Reliable Sealing and Structural Integrity:

Leak-Proof Design: The glass-fused-to-steel process creates a seamless, leak-proof structure that ensures reliable water storage without the risk of contamination or leaks. This design feature not only protects the stored water but also reduces the need for costly repairs.

Strong and Stable: The inherent strength of the steel structure, combined with the protective glass coating, provides exceptional stability and durability, making these tanks ideal for long-term water storage solutions.

Applications of Glass-Lined Water Storage Tanks

Our Glass-Lined Water Storage Tanks are versatile and suitable for a wide range of applications, including:

Potable Water Storage: Ensure the safe storage of drinking water with minimal risk of contamination or corrosion. Our tanks meet international standards for potable water storage, providing a reliable solution for municipalities and water utilities.

Wastewater Treatment: Store treated or untreated wastewater efficiently, with the glass lining offering superior protection against corrosive substances commonly found in industrial and municipal wastewater.

Fire Protection Systems: Our tanks are ideal for storing water for fire protection systems, offering a reliable and maintenance-free solution that ensures water is always available in emergencies.

Industrial Water Storage: Whether for manufacturing, processing, or other industrial uses, our tanks provide a dependable storage solution that can withstand the rigors of industrial environments.

The Shijiazhuang Zhengzhong Advantage

At Shijiazhuang Zhengzhong Technology Co., Ltd., we are committed to delivering high-quality water storage solutions that exceed our customers' expectations. Here’s why our Glass-Lined Water Storage Tanks are the preferred choice:

Cutting-Edge Technology: We utilize advanced glass-fusion technology to create tanks that offer unparalleled durability and corrosion resistance.

Customization Options: Our tanks are available in a variety of sizes and configurations to meet the specific needs of each client. We work closely with our customers to design and manufacture tanks that fit their exact requirements.

Global Expertise: With decades of experience and a global presence, we have successfully delivered water storage solutions to clients in over 100 countries. Our expertise ensures that each tank is manufactured to the highest standards of quality and reliability.

Quality Assurance: All our tanks undergo rigorous testing and quality control to ensure they meet international standards. This commitment to quality guarantees that our tanks provide long-lasting performance with minimal maintenance.

From being a leader in the Asian GFS tank industry to becoming a diversified environmental equipment smart manufacturer in China, Center Enamel utilizes crucial core technologies to continuously iterate and upgrade equipment in research and development. This drives the sustained high-quality development of the company in the face of new challenges. Leveraging existing brand advantages, technological strengths, and team capabilities, the company will continue to focus on cutting-edge industry technologies. Adhering to a diversified development strategy, Center Enamel aims to elevate environmental business to new heights while jointly creating a beautiful picture of green hills and clear waters.

0 notes