#nema17

Text

Rocket Grant

Before I moved to Pittsburgh, I applied for a $6,000 grant. It funds Kansas-City based projects, and there's this

creepy robotic figure situated in the basement-theatre of the "Steamboat Arabia" museum.. when I took the picture, I thought it might jump out at me, like from the video-game "Five Nights at Freddy's". I know it used to be in the lobby, but now it just sits idly, and allegedly does not work.

I put together a proposal that would involve one sculptor, one installer, and a couple-others in a Schrodinger's box.. and I only say that because they might not want to work with me, although as my brother says "money makes the world go round."

Hopefully my rebooted website can convince the jury that I'm competent-enough to get something moving that can excite kids about the future. After all, they are.

0 notes

Text

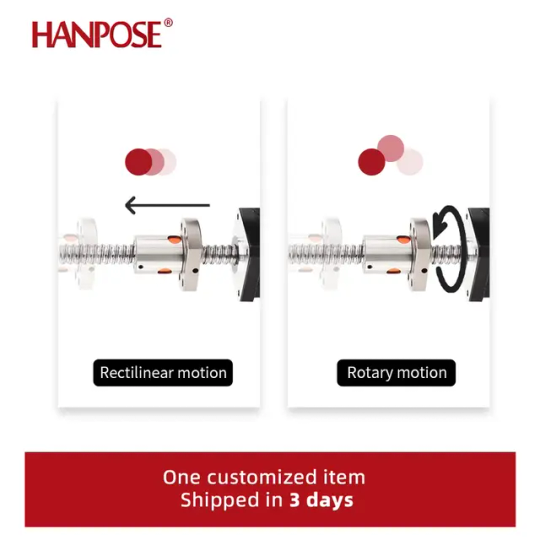

HANPOSE 17HS6401S-SFU1204 nut screw length 300mm nema17 stepper motor con riduttore CNC milling machine ballscrew stepper motor

Welcome to contact with us here!

Welcome to contact with us here!

Model

17HS6401S-1204

Motor length

60MM

Step angle

1.8°

Torque detection

70N.CM

Motor weight

450g

Rated current

1.7A

Welcome to contact with us here!

Welcome to contact with us here!

View On WordPress

0 notes

Text

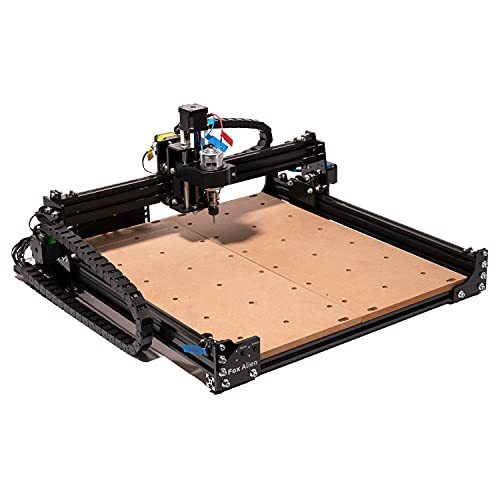

FoxAlien Masuter 4040 CNC Router Machine 3-Axis Engraving Milling

- Brand and Manufacturer: FoxAlien

Features

- Masuter 4040 is a budget-friendly CNC router with huge workspace of 400 x 380 x 55mm (15.75" x 14.96" x 2.16"). It utilizes a 60W spindle as well as NEMA17 stepper motors. Max moving rate is 2000mm/min and pin rate array is 0 ~ 10000.

- The control board is equipped with an upgraded 32-bit chip which works a lot more effective and also secure. It likewise sustains attachments such as offline controller, 300W spindle and power components. (Add-ons offered separately)

- Masuter 4040 is qualified to engrave, cut as well as pierce lots of kinds of material such as wood, MDF, acrylic and material etc. Suggested setups: speed-1000mm/ minutes; deepness per pass-0.2 mm; plunge rate-200mm/ minutes.

- House function and Emergency-Stop button are incorporated on the machine. The machine will certainly go to house with just push the button.

- Almost all are pre-assembled. It takes about 20-30mins to totally setting up. The machine works with Grbl software. It sustains Windows XP/7/10, Linux as well as Mac OS.

Maker Info

- Model: Masuter 4040

Item Info

- Size: 26.38 x 23.62 x 11.81 inches

Read the full article

0 notes

Photo

I finished everything on the Prusa Printer Enclosure v2 with MMU2S support today. I've taken the PSU of the Original Prusa i3 MK3S with MMU2S by @josefprusa and placed it outside the enclosure and the PTFE tubes are going through the workbench to the buffer. It gives the setup a nice clean look. https://www.prusaprinters.org/prints/3673-prusa-printer-enclosure-v2-with-mmu2s-support #3dprinting #3dprintingcommunity #3dp #3dprinter #prusa3d #prusaresearch #prusaprinters #prusai3mk3s #mmu2s #josefprusa #3dprinterenclosure #ikea #nema17 #ptfe #diy #makermovement #makers #additivemanufacturing #de3dprintman https://www.instagram.com/p/CAnQXsCjcc0/?igshid=1gxgfezyldpez

#3dprinting#3dprintingcommunity#3dp#3dprinter#prusa3d#prusaresearch#prusaprinters#prusai3mk3s#mmu2s#josefprusa#3dprinterenclosure#ikea#nema17#ptfe#diy#makermovement#makers#additivemanufacturing#de3dprintman

1 note

·

View note

Text

Hybrid stepper motors

Hybridstepper motors combine aspects of both permanent magnet (PM) and variable reluctance (VR) stepper motors. Like PM motors, they contain a permanent magnet in the rotor teeth. Two sets of teeth called cups ring the rotor. One ring is all south poles, and the other ring is all north poles.

Like VR motors, hybrid stepper motors have stator poles. Note that stator poles in hybrid motors are sometimes called teeth. (For more information, read FAQ: What is pole count and why does it matter?) More after the jump.

How here are the rotor and stator of a hybrid stepper motor. Two soft iron cups sport teeth to guide the flux from a permanent magnet to the rotor-stator air gap.

To illustrate how these motors work, consider a 1.8° hybrid stepper. The teeth of one ring are offset from those on the other ring by 3.6°. The stator poles are offset by 90° and these are opposite polarity, so that every 180° the stator poles are in identical polarity. The rotor poles exist in sets of four, with two being north poles and two being south poles. The rotor poles align alternately with the rotor’s teeth and cups, so that one set of rotor poles attracts fully while the other attracts and repels ¾, ½ or ¼ of a tooth. If there are 50 teeth, the pitch angle is 7.2° … so at the next step, the motor rotates to the next closest step, which is 7.2° × ¼ = 1.8°.

When the current changes, the rotor can turn a very small amount—an improvement over basic PM motors and VR motors. Newer control techniques such as half-stepping and microstepping let designers get even finer movements of rotation, which make for more exact output than that from VR stepper motors (which can’t usually be microstepped). Hybrid stepper motors also have higher torque-to-size ratios and higher output speeds than other stepper-motor types. They are also quieter than VR stepper motors.

One caveat is that hybrid stepper motors are more expensive than other step motors. So, designers should weigh the higher cost against the advantages of quiet operation, smaller steps, and torque output before making a final step-motor selection.

0 notes

Link

Our Nema Stepper Motor enhance the overall performance and profitability of today’s manufacturing facility and automation systems. We provide Nema 17 Stepper Motor to satisfy your dimensional requirements however also provide you with custom winding to satisfy your specific application wishes.

#nema11#nema14#nema17#nema23motor#nema24#nema34#nema8#steppermotor#nema17steppermotor#steppermotorwithgearbox#hightorquesteppermotor#12vsteppermotor

0 notes

Photo

A good driver that works by default as the user wants. More 🔭 @aelmaker . . #esp32 #diyelectronics #electronics #arduino #makers #украина #ukraine #diy #prototype #aelmaker #электроника #homemade #electronics #arduinomega #18650 #diyprojects ts #drv8825 #nema17 (Delhi, India) https://www.instagram.com/p/COccO51La1E/?igshid=m9iirqbhvpev

#esp32#diyelectronics#electronics#arduino#makers#украина#ukraine#diy#prototype#aelmaker#электроника#homemade#arduinomega#18650#diyprojects#drv8825#nema17

0 notes

Photo

Драйвер #tb6560 для управления шаговиком. В данной связке с #nema17. Недорогой функциональный и вполне надёжный но время покажет. Хотя это пока сборка на столе так скажем прикидочная. #ProfConnect #делаемавтоматику #наширукинедляскуки (at Moscow, Russia) https://www.instagram.com/p/BzVcRTRpfXR/?igshid=13j4pga90zsuz

0 notes

Text

Pulley & Belt Transmission

Admittedly, building a robot arm joint transmission is way more difficult than I expected. But where's the fun in a simple project? In my last post, I explained why a geared transmission doesn't work. This week I'll try a new approach.

As hinted in my last post, I'll give a timing belt and pulley transmission a go. The added benefit of using transmission pulleys in stead of gears is that I'm able to 3D print them. Since the force will be distributed over 50% of the pulley teeth, 3D printed pulleys should be able to handle the necessary torque.

I printed a small prototype to see if 3D printed pulleys would work, and although GT2 pulleys are on the limit of what is printable with a 0.5mm nozzle, they work absolutely fine. Just make sure the belt tension is sufficient.

So after my prototype had proven the possibilities of 3D printed pulleys I started working on a full fledged transmission.

The small (bought) pulleys I use are 20 teeth, so by using 80 teeth large (3D printed) pulleys, there is a 1:4 speed reduction. Since I aim for a 1:16 speed reduction, I needed to put two 1:4 reductions in series.

The "packaging" of the transmission matches the 60mm diameter pipe I'll be using fo the robot arm body.

After a few hours ... days ... of Fusion 360, the render looked extremely promising!

Of course, I need to do some real world testing before I can say anything about the accuracy, speed and torque. So fire up the Lulzbot, feed it some FormFutura HDglass, and start the printing!

Since the Lulzbot Mini has a print bed of 150x150 mm, the joint is built up by three separate pieces. Not only does this allow me to overcome the size limit, but it also helps in preserving strength and print quality by alternating the print orientation.

The 3D-printed body is provided with ball bearings which accommodates the 5mm and 8mm shafts. As a shaft, I simply use some hex head bolts. Bolts aren't precisely sized, but are very convenient to attach to a 3D printed part. Together with the ball bearing, the bolts seem to do their job.

I initially expected that I needed to add belt tensioners, but by calculation the needed pulley distance, I was able to get a perfect belt tension.

In the photo below, the large pulley on the main shaft only has one set screw. It turns out this wasn't sufficient, so I ended up redesigning this pulley to accommodate two 3mm setscrews.

The main shaft (bolt) will be attached to the matching joint part. this part might eventually get a redesign, but for now it will be used to temporarily mount a piece of 60mm pipe.

To make the test setup look a bit more impressive, I sticked an old joint prototype in the end of the pipe (and used some black electrical tape to keep it in place).

So there you have it. The one axis prototype of my robot arm. I can't wait to give it a test spin! So without further ado, I present you the first results:

youtube

It works wonders! The accuracy is impressive, there is no backlash and the torque is much higher than I expected. As a matter of fact, I wasn't able to stall the motor. The first point of failure where the slipping setscrews of the pulley. I managed to solve this, by flattening the bolt on the position of the setscrews. I'll do some actual torque tests as soon as I've manages to mount the joint in a proper way (in stead of the electrical tape).

The video also shows the acceleration and deceleration of the joint. This is not due to a spin up or spin down of the motor, but programmatically generated by the AccelStepper motor library I use. This is fully configurable (as well as the maximum speed).

The next steps on the to-do lists are properly mounting the joint and designing some nice covers to hide the pulleys and belts. But more important: getting real time absolute position feedback by using an encoder. Stay tuned!

Let me know what you think about this design in the comments down below!

#robot#robotics#engeneering#3dprinting#3ddesign#fusion360#formfutura#hdglass#lulzbot#stepper#nema17#accelstepper#arduino#video#prototype#pulley#belt#gt2#transmission#joint

4 notes

·

View notes

Link

0 notes

Text

HANPOSE motor 17HS4401S-SFU1204 300MM 1.5A 40N.CM length 40MM for Various instrument accessories NEMA17 ballscrew stepper motor

Welcome to contact with us here!

Welcome to contact with us here!

Model

17HS4401S-1204

Motor length

40MM

Step angle

1.8°

Torque detection

40N.CM

Motor weight

280g

Rated current

1.5A

NEMA17 Stepper motor

parameter

Welcome to contact with us here!

Welcome to contact with us here!

View On WordPress

0 notes

Text

Nema-17 Stepper Motor

Motors and actuators are the integral part of any automation and control application. By using different kind of motors we control our position of the controlled object. Servo motors are used in 180° Control applications and Stepper Motor is used when you need low speed but multiple rotations but in steps i.e. there are a specific number of steps in a revolution so you can control the final position of the motor by exciting the particular phase wires.

Buy this motor: https://quartzcomponents.com/products/nema17-stepper-motor

1 note

·

View note

Text

DIY Mini 1610 PRO Milling Machine 3 Axis CNC Router Kit

- Brand: CNCTOPBAOS

- Supplier: Changzhou Rattm Motor Co., Ltd

Features

- Update Version 1610 Pro Mini CNC machine tiny size, lightweight, USB user interface, GRBL control systems, excellent cnc router machine for beginers; The CNC1610 PRO machine is very easy to set up, steady structure, our parcel likewise consist of english user handbook.

- Working area 18x10x4.5 centimeters; Frame size: 30x26x25cm; Type: USB port Desktop cnc router System requirements Windows XP, win7, win8, win10; Supporting data: G-code (. nc/. txt/. tape/. gcode)

- Spindle&& Stepper Motor Diameter 45mm 10000 rpm maximum power 120W; ER11-3.175 mm (can be replaced 0-7mm ); Nema17 42 stepper electric motor 1.3 A/0.3 N.m

- Main application Can be etched plastic, timber, acrylic, pvc, pcb, timber and so forth material.soft steel like copper and aluminum and other products, however can not sculpt hard steel, jade or various other really difficult appearance of the things.

- GRBL Software GRBL control (candle); Parcel consist of 1pcs 4G USB flash drive which contains customer handbook & & GRBL software

Supplier Info

- PartNumber: 3018

Read the full article

0 notes

Photo

Just installed the @bondtech3d extruder with a nice LDO pancake NEMA 17 stepper motor for the @3d.passion NOVA hotend on the Craftbot Plus for @plasticznetherlands. Time to start working on the firmware! #3dprinting #3dprintingcommunity #3dp #3dpassion #novahotend #bondtech3d #bondtech #plasticznetherlands #ldomotors #steppermotor #hotend #nema17 #craftbot #makermovement #makergram #makerslife #de3dprintman https://www.instagram.com/p/B2RZ7MCIhdv/?igshid=1sda40b2puh7z

#3dprinting#3dprintingcommunity#3dp#3dpassion#novahotend#bondtech3d#bondtech#plasticznetherlands#ldomotors#steppermotor#hotend#nema17#craftbot#makermovement#makergram#makerslife#de3dprintman

1 note

·

View note

Link

#nema17steppermotor#nema23motor#steppermotorwithgearbox#hightorquesteppermotor#steppermotor#nema11#nema14#nema17#nema24#nema34#nema8

0 notes

Photo

Тест драйвера с обратной связью + #nema17 Отличный драйвер #tmc2130 с ценой в 10$ от @bigtreetech Использовать без охлаждения не рекомендуется . . . . Буду рад твоей подписке! @aelmaker #esp32 #diyelectronics #electronics #arduino #maker #украина #ukraine #diy #prototype #aelmaker #электроника #homemade #electronics #arduino #hobby #driver #m5stack #m5core (Zaporozhye, Ukraine) https://www.instagram.com/p/CNMbRH4LZU9/?igshid=8e5lyw3b8g9

#nema17#tmc2130#esp32#diyelectronics#electronics#arduino#maker#украина#ukraine#diy#prototype#aelmaker#электроника#homemade#hobby#driver#m5stack#m5core

0 notes