#powertrain components

Explore tagged Tumblr posts

Text

Structural and Functional Aspects of Selecting Power Shift Transmissions

If you are using modern time vehicles, then you are already aware of the Power-Shift Transmission. These are very much similar to the manual type of transmission, but with a minor shift. One major benefit is that they offer safe powershift.

This ensures that it gets better power from the engine drive. During a power shift, the driver have to use the accelerator pedal for generating more power.

When using Powershift and automatic transmission the driver will also have to engage the clutch pedal so more power can be generated for the vehicle

It eliminates the chance of damaging the engine and the vehicle.

This type of power shift is more reliable, especially when driving on uneven terrains.

Distinct gear ratio

One major advantage of using Powershift and automatic transmission is that a very distinct gear ratio can be expected. The transmission is used for directly connecting the drive shaft with the vehicle engine. This simple task will offer the driver to make use of the gear ratio factor when powering.

Consistent power

The moment you are making use of power shifts, it is certain that your vehicle gets a consistent supply of power. This ensures that you can expect high power output even at varying driving speeds. This, in turn, allows the wheels to relax, even on uneven terrains

The benefit of twin camshafts

The traditional type of transmissions made use of a single camshaft. But the moment you are using Powershift and automatic transmission you can ensure that the vehicle is provided with twin camshafts. This is one of the features that prove beneficial for offering the vehicle with much better control.

Offers better uplift

As the vehicles are provided with twin camshafts, so it means that while driving, the vehicles are offered with a high uplift factor. So the moment you are driving on uneven terrains, it is certain that you may not have to worry about shifting gears very often.

In modern time vehicles, powershift type of transmission is always considered as more beneficial.

#auto components manufacturers in india#automatic transmissions#transmission components#transmission parts manufacturer#powershift transmissions#transmission gears and shafts#powertrain manufacturer in india#powertrain components

0 notes

Text

How does an engine contribute to a car's powertrain?

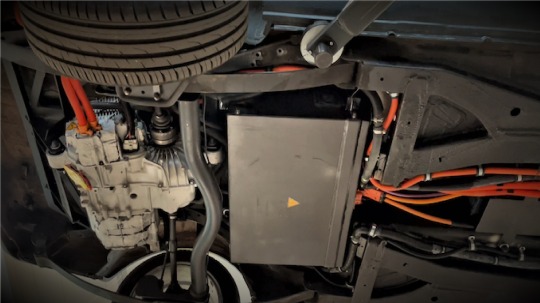

The powertrain in a vehicle is the system responsible for generating power and delivering it to the wheels to propel the vehicle forward. The operation of a powertrain can vary depending on whether the vehicle is powered by an internal combustion engine (ICE) or an electric motor (in the case of electric vehicles). Here's a general overview of how a powertrain works in both types of vehicles:

Internal Combustion Engine (ICE) Vehicle - Combustion Process: In an ICE vehicle, the powertrain starts with the combustion process in the engine. Fuel (gasoline or diesel) mixes with air in the combustion chamber and is ignited by spark plugs (in gasoline engines) or compression (in diesel engines).

Power Generation: The combustion process generates energy in the form of mechanical power, causing pistons to move up and down within the cylinders of the engine. This motion drives the crankshaft, converting linear motion into rotational motion.

Transmission: The rotational motion from the crankshaft is transmitted to the transmission, which consists of gears that allow the driver to select different ratios (speeds). This enables the engine to operate efficiently across a range of vehicle speeds.

Drivetrain: The transmission sends power to the drivetrain components, including the driveshaft, differential, and axles, which transfer power to the wheels. The differential allows the wheels to rotate at different speeds, enabling smooth turns.

Wheel Movement: The power transmitted through the drivetrain causes the wheels to rotate, propelling the vehicle forward or backward depending on the gear selection and throttle input from the driver.

Electric Vehicle (EV) -

Battery Pack: The primary source of power for the EV, storing electricity in chemical form.Powers the electric motor and provides electricity for all electronic devices within the EV.

Battery Management System (BMS): Monitors battery cell conditions, including voltage, current, temperature, and state of charge (SoC).It protects the battery against overcharging, deep discharging, and overheating and helps balance the charge across cells. Ensures optimal performance and longevity of the battery by regulating its environment.

Inverter: Converts DC from the battery pack into AC to drive the electric motor.Adjusts the frequency and amplitude of the AC output to control the motor’s speed and torque. Critical for translating electrical energy into mechanical energy efficiently.

Onboard Charger: Facilitates the conversion of external AC (from the grid) to DC to charge the battery pack. Integrated within the vehicle, allowing for charging from standard electrical outlets or specialized EV charging stations. Manages charging rate based on battery status to ensure safe and efficient charging.

DC-DC Converter: Steps down the high-voltage DC from the battery pack to the lower-voltage DC needed for the vehicle's auxiliary systems, such as lighting, infotainment, and climate control. Ensures compatibility between the high-voltage battery system and low-voltage electronic components.

Electric Motor: Converts electrical energy into mechanical energy to propel the vehicle. It can be of various types, such as induction motors or permanent magnet synchronous motors, each offering different efficiencies and characteristics. Typically provides instant torque, resulting in rapid acceleration.

Vehicle Control Unit (VCU): The central computer or electronic control unit (ECU) that governs the EV's systems. Processes inputs from the vehicle’s sensors and driver inputs to manage power delivery, regenerative braking, and vehicle dynamics. Ensures optimal performance, energy efficiency, and safety.

Power Distribution Unit (PDU): Manages electrical power distribution from the battery to the EV’s various systems. Ensures that components such as the electric motor, onboard charger, and DC-DC converter receive the power they need to operate efficiently. Protects the vehicle's electrical systems by regulating current flow and preventing electrical faults.

In both ICE vehicles and EVs, the powertrain's components work together to convert energy into motion, enabling the vehicle to move efficiently and effectively. However, the specific technologies and processes involved differ significantly between the two propulsion systems.

#electric powertrain technology#conventional powertrain#Electric vehicle components#revolo hybrid car kit#ev powertrain development services#software (SW) platforms for all Electric vehicles components#Battery Management Systems#Inverter#Smart Charger#VCU solutions

5 notes

·

View notes

Text

Explore the world of forged automotive parts and discover why they are the gold standard for strength, durability, and performance in the automotive industry. Learn about their manufacturing process, key applications, and benefits in this concise audio segment. Perfect for enthusiasts and professionals alike!

#Forged Automotive Parts#gear#curvic gear experts#Automotive Powertrain Forging#Forged Mechanical Components

0 notes

Text

The Forgotten Mach 2: Ford's 1967 Mid-Engined Mustang Prototype

The Forgotten Mach 2: Ford's 1967 Mid-Engined Mustang Prototype

In the Swinging Sixties, Ford's promotional photo featured a stylish couple beaming with joy as they prepared to take a ride in the Mach 2, essentially a mid-engined Mustang. This sleek, closed coupe boasted a 289 V8 engine, ZF 4-speed transaxle, and amenities like a radio and heater.

"Wait a minute", you may be thinking, if you're old enough to remember the Sixties, or if you've been reading this blog for awhile. "Wasn't there a mid-engined Mustang before there was any other kind?" Well, yeah, there was a drivable concept car based on the front-drive German Ford Taunus V4 powertrain, the Mustang 1*, but that was in 1962, and the roofless projectile seemed to be aimed mostly at SCCA racers ...

The Mach 2's story began in 1966, when Ford's Total Performance program aimed to infuse the GT40's mid-engined glamour into a production car. A Mustang convertible chassis was transformed into a concept chassis by Kar Kraft, incorporating Mustang front suspension, front disc brakes, and Galaxy rear drums. The independent rear suspension was borrowed from engineer Klaus Arning's patented multi-link design for Mustang 1.

Two running prototypes were built, with fiberglass bodies styled by Gene Bordinat's team. The first, a white car intended as an SCCA-ready weekend racer, suffered from chassis flex, while the second, a red example, had a reinforced chassis. The red Mach 2 was showcased at auto shows and featured in car magazines.

With a 107-inch wheelbase, similar to the new Corvette C8, and a weight of around 2,600 pounds, the Mach 2's performance was lively. Ford envisioned pricing it around $7,500, slightly above the Shelby AC 427 Cobra.

However, the Mach 2 program was ultimately scrapped. Ford's success with the Mustang and Shelby's modified versions meant that the Mach 2 was relegated to the sidelines. The white test car was crushed, and the red prototype was returned to Kar Kraft, disappearing from public view.

Rumors of the red Mach 2's fate have persisted, with some speculating that it may still be hidden away, waiting to be rediscovered. The possibility of finding this forgotten prototype has captivated car enthusiasts, offering a glimpse into an alternate history of American automotive innovation.

1967 Ford Mach 2

1967 Ford Mach 2

1967 Ford Mach 2

1967 Ford Mach 2

The 1967 Ford Mach 2 was a mid-engine sports car concept that was never mass produced. It was a two-seater with a GT style, low-sloping hood and front fenders, with a body made of fiberglass. Ford built the first one which was based on a shortened version of the 1966 Mustang convertible floor pan. Two more were built by Kar Kraft based on 1967 Mustangs and powered by a 289ci high performance engine mounted in the middle of the car. It had a five-speed manual transmission, independent rear suspension, and adjustable pedals derived from the 1962 Mustang-I.

Two fully functional prototypes were built:

• Red prototype: The production car candidate, with a revised engine cradle, adjustable Koni shocks, and a redesigned front end

•White prototype: A development mule for racing, with a modified 289, competition-spec components, and a lighter fiberglass body.

The Mach 2 was extensively tested, but the results were not encouraging. The road car handled well, but generated too much body roll at high speeds. The race car's chassis was not stiff enough, distorting under heavy loads. By the fall of 1967, Ford's designers had shifted their focus to the Mach 2A, and the three Mach 2 prototypes were left with Kar Kraft for disposal.

208 notes

·

View notes

Text

AMG S63 E PERFORMANCE „The Boss“.

Mercedes-AMG S63 E PERFORMANCE (combined fuel consumption, weighted: 4.4 l/100 km; combined CO2 emissions, weighted: 100 g/km; combined power consumption, weighted: 21.4 kWh/100 km)[1] with AMG hybrid technology once again sets the benchmark in the segment. The E PERFORMANCE model combines the AMG 4.0-litre V8 biturbo engine with the AMG-specific hybrid powertrain and a new expansion stage of the AMG high-performance battery.

The focus of the powertrain, however, is less on electric range and more on best-in-class performance. With 590kW (802hp) of system output and 1430Nm of system torque, the saloon sets new standards in the segment. The acceleration of 3.3 seconds to 100km/h and the optional top speed of 290km/h underline the superior, dynamic driving performance. Systems such as the AMG RIDE CONTROL+ suspension, AMG ACTIVE RIDE CONTROL roll stabilisation and rear-axle steering as standard ensure a wide spread between driving dynamics and comfort.

A central component of the P3 hybrid powertrain is the AMG 4.0 V8 biturbo engine, in this case producing 450kW (612hp). It provides a maximum torque of 900Nm, which is available over a wide speed range. The engine’s most important design features include the two twin-scroll turbochargers, which are located in the hot inner-V. The position between the two cylinder banks shortens the paths of the exhaust gases to the turbocharger and the compressed fresh air to the combustion chamber.

The result is a very immediate response. Another important feature is the belt-driven starter-generator (RSG), which is integrated into the 400-volt electrical system. This combines the starter and alternator into one unit, and has sufficient power to always start the V8 at once.

Mercedes-AMG One man, one engine Handcrafted by Michael Kübler @f1mike28 in Germany Affalterbach. Driving Performance is our Passion!

Mercedes-AMG the Performance and Sports Car Brand from Mercedes-Benz. Mercedes-AMG Handcrafted by Racers.

#amg#sclass#s63#s63amg#s63amgeperformance#s63eperformance#eperformance#mercedesamg#mercedes#mercedesbenz#affalterbach#onemanoneengine#pagani

8 notes

·

View notes

Text

F1's DC/AC: Assault & Battery

Formula 1 teams source batteries for their power units, specifically the Energy Store (ES) component, from specialized manufacturers and in-house development, driven by the sport’s stringent performance and safety requirements. The disposal of used batteries follows strict regulations to ensure environmental responsibility, given their hazardous materials. Below is a detailed breakdown:

Sourcing of Batteries for Formula 1 Power Units

Specialized Battery Manufacturers:

Companies like Saft, a leader in high-performance batteries, have historically supplied F1 teams with lithium-ion batteries for the Energy Recovery System (ERS). Saft’s experience, including work on defense projects like the Lockheed Martin F-35, has been adapted for F1’s extreme conditions.

About:Energy, a battery testing and software specialist, collaborates with F1 teams to develop and optimize battery performance through simulation and testing, focusing on power density and degradation.

Other suppliers, such as Marelli, provide components like the Motor Generator Unit (MGU) and associated battery systems, tailoring designs to team specifications.

In-House Development by Power Unit Manufacturers:

Major power unit suppliers—Mercedes, Ferrari, Honda, Audi, and Red Bull Powertrains (with Ford)—often develop batteries in-house or in close partnership with specialists. For example:

Mercedes High Performance Powertrains (HPP) in Brixworth, UK, integrates battery development into its power unit program, leveraging expertise from the turbo-hybrid era.

Ferrari designs its own batteries in Maranello, aligning with its power unit strategy to supply its factory team and customers like Haas and Cadillac.

Honda has advanced lightweight battery designs, achieving significant weight reductions (up to 5kg) for performance gains.

These manufacturers work with advanced lithium-ion chemistries, optimizing for high power density (up to 350kW in 2026 regulations) and energy recovery (up to 9MJ per lap).

Collaborative Innovation:

Teams and suppliers push boundaries in battery chemistry and design, exploring formats like cylindrical, pouch, or prismatic cells to balance energy density, weight (20-25kg regulatory limit), and packaging within the chassis.

Emerging technologies, such as solid-state batteries, are under consideration for future F1 applications, offering potential improvements in lifetime and energy density.

Partnerships with academic institutions, like Imperial College London, aid in refining battery performance for motorsport.

Regulatory Compliance:

Batteries must meet FIA safety standards, including UN38.3 for lithium-ion transport and crash test requirements to prevent dangerous reactions. These regulations influence sourcing decisions, as only certified suppliers can meet such demands.

The FIA’s 2026 regulations, emphasizing a 50/50 power split between internal combustion and electric systems, have spurred investment in battery development, attracting new manufacturers like Audi and Ford.

Disposal of Used Batteries

Regulatory Limits on Battery Usage:

FIA rules limit teams to a set number of Energy Stores per season (currently four, reducing to two in future seasons) to control costs and environmental impact. Exceeding this incurs grid penalties, incentivizing durable designs.

Batteries are designed to withstand intense charge-discharge cycles (10-15 per lap, depending on the circuit), but degradation over a season necessitates replacement.

Recycling and Disposal Processes:

Hazardous Material Handling: Lithium-ion batteries contain chemicals that pose environmental risks if mishandled. F1 teams, operating under EU and international regulations, partner with certified recycling facilities to manage disposal. The EU Battery Directive (2006/66/EC) mandates recycling to recover materials like lithium, cobalt, and nickel.

Specialized Recycling Partners: Companies like Umicore and Redwood Materials (common in automotive sectors) recycle lithium-ion batteries, extracting valuable metals for reuse in new batteries or other applications. While F1-specific partnerships are not publicly detailed, teams likely use similar services given the high-value materials involved.

Closed-Loop Systems: Some manufacturers, like Saft, integrate recycling into their supply chains, repurposing materials from used batteries to reduce waste and costs. This aligns with F1’s push for sustainability, including 100% sustainable fuels by 2026.

Repurposing: Degraded F1 batteries, which no longer meet the sport’s performance demands, may be repurposed for less demanding applications, such as energy storage systems or testing rigs, before final recycling. This practice is common in motorsport and automotive industries.

Environmental Considerations:

The FIA and F1 emphasize sustainability, with initiatives like sustainable fuels and increased hybrid efficiency reducing the sport’s carbon footprint. Battery disposal is part of this, with teams required to adhere to strict environmental protocols.

The high energy density and specialized chemistry of F1 batteries (100-275Wh/kg) make recycling complex but critical to avoid landfill waste and comply with regulations.

Challenges and Innovations:

The 2026 regulations, increasing battery power to 350kW and energy recovery to 9MJ per lap, will intensify battery wear, raising disposal frequency. Teams are exploring chemistries that minimize degradation to extend battery life and reduce waste.

Research into fast-charging and durable batteries aims to lower the environmental impact by reducing the need for oversized batteries, which add weight and disposal burdens.

Critical Notes

Limited Public Data: Exact suppliers and disposal partners for each team are closely guarded due to F1’s competitive nature. Information is often proprietary, with teams like Ferrari and Mercedes only broadly acknowledging in-house or specialist involvement.

Sustainability Push: F1’s commitment to net-zero by 2030 drives innovation in battery recycling and sustainable sourcing, but the sport’s high-performance demands create unique challenges compared to road-car battery systems.

Speculative Future: Solid-state batteries or alternative chemistries could reduce disposal issues by offering longer lifespans, but these are not yet standard in F1.

In summary, F1 teams source batteries from elite suppliers like Saft and through in-house programs at manufacturers like Mercedes and Ferrari, focusing on cutting-edge lithium-ion technology. Used batteries are recycled through specialized facilities to recover materials, aligning with environmental regulations and F1’s sustainability goals. The lack of specific team-by-team disposal data reflects the sport’s secrecy, but industry-standard practices provide a reliable framework.

3 notes

·

View notes

Photo

Piper GTT

Before the dominance of the big conglomerate car manufacturers took hold in the late 1960s, there was room in the market for niche companies whose products fulfilled the demands of a few drivers who wanted something a little different to the everyday, somewhat bland mainstream offering. Some companies such as Lotus thrived and are still with us while the likes of TVR have come and gone (several times), hopefully to return. Others had their day in the sun but ultimately disappeared after a relatively brief but bright life; Piper sits firmly in the later camp. Though the end results were fairly diverse, these companies’ approaches had remarkable commonality with cheap to produce fiberglass bodies (no need for expensive tooling which required high production volumes to amortise its costs) sitting on bespoke chassis while their running gear, which was financially impossible for a small business to develop and manufacture, was sourced from the industry’s major players.

Piper were kept pretty busy trying to build cars so production records are sketchy to say the least and it is thought that just eighty road cars and some twenty racers were built making them rare beasts today, though their survival rate is undoubtedly higher than that of propriety sports car such as say MGBs. Formed in 1966 by ex-racer George Henrotte, owner of Campbell’s Garage (hence the Scottish Piper logo and company name) in Hayes, Kent with the able assistance of engineer Bob Gayler (ex Harry Weslake), machinist Ken Packham and artist come designer Tony Hilder who had been responsible for the McLaren M1A, their first ‘whole car’ effort started as an evenings and weekends project until a customer, Gerry Hall, showed an interest in buying one. With his role as Works Gemini Formula Junior team manager winding up, Henrotte gave the green light for a limited production run of the pretty sports racers with four being completed for customers to add their powertrain of choice to; Hall put an Alfa Twin Cam in his, Bobby Bell a Lotus Twin Cam while racer Jerry Titus opted for a Buick V8. With a Mallite (balsawood/alloy sandwich) monocoque F3 car another Piper product, the company was building a reputation as a hotbed of outside the box thinking and a road-usable GT car was the next project. Approached by some Austin Healey Sprite racers who were looking for a light and sleek home for their running gear, a mock-up of what was to become the Piper GTT was shown at the 1967 Racing Car Show, apparently yielding an impressive seven hundred enquiries.

With Henrotte being kept busy with the tuning side of the Piper business, there was a timely intervention by Clubman racer Brian Sherwood who had not only bought a Piper GT but as the Sprite guys gradually fell by the wayside, was instrumental in more suitable Ford components being introduced at the expense of the BMC kit. With Sherwood now very much hands on, the Company was split with car production moving to his Wokingham premises while Henrotte concentrated on the aftermarket components business, though the companies remained closely linked both financially and practically. Through the late 1960s production increased from a drip to a trickle until Bill Atkinson, an enthusiastic GTT owner who had joined the company in the summer of 1969 as Works Manager, and Tony Waller (Sherwood Holdings’ Company Secretary) made great strides getting the GTT into some sort of series production. Instrumental in saving Piper’s car business, Sherwood was at heart a racer and he took them on an ultimately ill-fated foray to Le Mans in 1969 with the ultra-low, mid-engined GTR, an ambitious project that is thought to have cost £250,000. His untimely death late that year coupled with strikes at Ford ultimately resulted in the company being wound up in June 1971, despite the strong progress being made by Atkinson and Waller on the car production and development front (the longer wheelbase P2 was eventually launched in early 1971). However, this was not quite the end of the road for Piper; reborn as Emmbrook Engineering under the same management team, the Piper P2 remained in production until 1974.

41 notes

·

View notes

Text

Ferrari unveiled the '296 Challenge' at the Finali Mondiali race at Mugello Circuit. The car is scheduled to debut in the Ferrari Challenge in the 2024 season and is the ninth model in the history of the single-make championship hosted by Ferrari. The Ferrari Challenge is currently in its 32nd season.

As riders around the world became more skilled and competitive, the 296 Challenge attempted to make bigger changes than the original model. The 296 Challenge continues Ferrari's long tradition of developing cars for gentleman drivers, but draws on the expertise accumulated in the '296 GT3' more than any other model. The 296 Challenge is a vehicle for drivers who are passionate about future GT racing. During the development of the 296 Challenge we made significant changes, not just minor changes to the model of the production car, but to make it a vehicle optimized for track driving. An extreme form of the vehicle was developed that improves overall performance while maintaining consistency and repeatability for testing and competition.

The 296 Challenge is the first car in Ferrari's single-brand range to be equipped with a V6 engine. So far, all models participating in the Challenge have been equipped with V8 engines. The biggest change compared to the 296 GTB is the elimination of the hybrid powertrain like the 296 GT3. As a result, while reducing the weight of the vehicle, the power output was increased to 700 horsepower (cv), setting a new record in this segment with an output of 234 horsepower per liter. In terms of aerodynamics, solutions derived from the 296 GT3 were taken and pushed to the extreme to achieve unprecedented downforce figures. These include the "S-shaped duct" (which draws air into the central radiator and exhausts it through the vents on the bonnet), the "swan-neck rear wing layout (another element inspired by the development of the 296 GT3)", and the A device that maximizes the stability of downforce generated in different trim conditions.

The braking system has also been completely redesigned. It's the first to feature the new "CCM-R PLUS" disc, which features technology derived from extreme track applications. New Pirelli tires developed specifically for the 296 Challenge also contributed significantly to improved performance. After its debut at the "2019 Finali Mondiali", the 296 Challenge set a record at the Mugello circuit approximately 2 seconds faster than its predecessor "488 Challenge Evo" which debuted in the 2020 season. From the early stages of development, the 296 Challenge discussed removing all hybrid components from the V6 powertrain, as in the 296 GT3. The electric motor and high-voltage battery have been eliminated, and the output of the twin-turbo V6 engine has been increased to 700 cv. This approach helps limit vehicle weight and overall unit complexity, which are fundamental factors in track driving.

Ferrari unveils '296 Challenge' race car with F1 technology

#cars#ferrari#ferrari f1#formula 1#scuderia ferrari#formula one drivers#formula one#296 Challenge#car

10 notes

·

View notes

Text

Kickstarter Project: The Thelen drive train: Powerful electric conversion:

A state-of-the-art, flexible and eco-friendly powertrain for high performance electric conversion for all kinds of vehicles.

Game Geeks News is proud to bring you another exciting new project currently live on Kickstarter. Darian Thelen (Mayen, Germany) has a workshop near Koblenz and a Bachelor's degree. The conversion of his classic car from 1988, which was converted into a high-performance and future-oriented electric car, was successfully completed. Darian's goal with the help of Kickstarter is to use the high-performance powertrain for as many vehicles as possible. For a quieter and more environmentally friendly future.

Sustainable, powerful, and flexible powertrain by Thelen Electric Conversion.

The product is a powertrain with state-of-the-art technology that can be used flexibly. In addition, it is the most environmentally friendly way to convert vehicles and thus cause fewer emissions when driving in the future.

Thelen is a German manufacturer, located in the Eifel region, close to the heart of German motorsport, the Nürburgring Nordschleife. Thelen has started to manufacture a flexible powertrain for a large number of different vehicles. This was successfully used in a test vehicle, tested and proved its worth. With this powertrain, existing resources can be further utilized.

In order to demonstrate and test the enormous performance capability of the powertrain, the initial focus was on the conversion of classic cars and sports cars. This is what can be seen in the video below to demonstrate what the Thelen drive train is capable of. This is best shown in motorsports or sports cars. As well as with highly individual vehicles like classic cars. However, the drive train has been designed and developed from the ground up to be flexible, so that a number of different vehicles can be converted.

But why convert vehicles to electric drive? Millions of cars, buses, and trucks are on the road every day, emitting pollutants with every kilometer they travel. Scrapping all these vehicles in order to build new ones cannot be the most sensible solution. Many of the vehicles on the road still have excellent substance. Conversion saves far more emissions here than disposing of the old car and rebuilding the new one.

youtube

But what makes the powertrain and the conversions special? The highly complex components used were developed by the manufacturer for perfect functionality in the vehicles intended for this purpose. and this is exactly where Thelen comes in. With a control unit including its own software from the professional supplier ESDI EV, also from Germany, the components are strapped in such a way that the functionality in the powertrain is exactly as in the original vehicle. This means that as soon as the components are installed in your new vehicle, the cooling, power control, and safety functions work exactly as the manufacturer intended.

By supporting this crowdfunder Darian wishes to continue to improve and expand the successfully tested drive train so that it can be integrated into all vehicles. You can read more in-depth on Kickstarter. Rewards include a virtual meeting, consultation, and feasibility study of your project, a test drive in a vehicle in which a version of the high-performance powertrain has been used, and a step-by-step guide to build a drive-train outside Germany, with detailed step-by-step instructions.

For more information visit Kickstarter and help support this project.

Source

10 notes

·

View notes

Text

How To Find And Work With Precision Auto Components OEMs?

The world is changing is a faster face so do the demands of the customers, there are many new vehicles and cars in the market, you as an automotive brand must make sure that you have the best cars and for that, you need to have the right components.

If you have been looking for using Precision Auto components manufacturer in India, then you are doing it right but the thing is that you need to be looking for the best OEMs for it, and here is what you need to look for when you are looking for OEMs.

Go for experienced and reputed OEMS:

You need to ensure that you are going for the right and experienced OEMs of the automotive industry; here you need to make sure that you are looking at their client list and there you can find out what brands they work with and that will also give you a fair idea about their capability and quality.

The second thing is that when you are looking at their reputation, you are making sure that you are going for people who know technicalities of auto tech as they would have worked on a project earlier.

Other things to look for:

The thing that you must make sure is that make a visit to their facility and you need to be looking for a company that has a global presence because, in that way, you can get a better idea about how good they are

The most important thing is that you need to make sure that Precision Auto components manufacturer in India makers follow strict quality standards and you have to also look at how good they are when it comes to service

Good manufacturing for precision components will get you smart quality and cist alike, you need to follow the suggestions here to spot a good company that can make parts and components that you need.

#auto components manufacturers in india#powertrain components#powershift transmissions#transmission components#automatic transmissions#precision auto components#engine parts manufacturers in india#powertrain manufacturer in india

0 notes

Text

Saturn Aura XR Mid Sized Sedan Concept

What if... Saturn returned to the automobile market and brought back the Aura midsized sedan? In this scenario, the Aura would be above the ION series sedans but below the Celeste Full sized sedan (showing later in this blog). While being an independent company, it still has collaborated efforts from others to include Toyota as well as Chevrolet. The Aura would share some components with Toyota, mainly from a chassis perspective. The engine would be an in house built V6 as well as Turbo 4 cylinder equipped with 8-speed automatic transmission as well as a 6-speed manual transmission. Unfortunately, this will be offered as a front wheel drive powertrain, and maybe later in an all wheel drive powertrain.

#autos#cars#automotive#classic car#sedan#luxury car#sports cars#chevrolet#saturn ion#general motors#toyota#toyota cars

3 notes

·

View notes

Text

Discover why forged powertrain components are crucial for improving the durability and efficiency of modern vehicles. Learn how precision forging strengthens key parts like crankshafts and connecting rods, ensuring long-lasting performance under demanding conditions.

Contact:

Address: Unit 8, Atley Way, North Nelson Industrial Estate, Cramlington

Client Email: [email protected]

Contact: 7956729465

Website: cpfl-tvs.com

0 notes

Text

Elon Musk hasn’t been sighted at the picket lines in Missouri, Ohio, or Michigan, where autoworkers are striking against the Big Three US carmakers. Yet the influence of Musk and his non-unionized company Tesla have been everywhere since the United Auto Workers called the strike last week. In some ways, Tesla—the world’s most valuable automaker by market capitalization—set the whole thing in motion.

Tesla’s pioneering electric vehicles kicked off a new era that has turned the entire auto industry on its head. In a scramble to compete with Tesla and make that transition, the legacy automakers targeted by the current strike, General Motors, Ford, and Stellantis, have each pledged billions in global investment and have begun dramatically restructuring their operations. For workers, the “green jobs” being created can be scarcer and worse paying. Electric vehicle powertrains have many fewer moving parts than conventional gas-powered ones, and so they require 30 percent fewer vehicle assembly hours, according to one estimate. Plants that make EV batteries are generally outside the core, unionized auto supply chain. The United Auto Workers has seen a dramatic drop in membership due to jobs moving outside the US—it lost 45 percent of its members between 2001 and 2022. A future with more electric vehicles could mean fewer union jobs overall. “This strike is about electrification,” says Mark Barrott, an automotive analyst at the Michigan-based consultancy Plante Moran.

The new assembly plants that the legacy automakers need to pull off the transition have been stood up mostly in US states hostile to union organizing, such as Kentucky, Tennessee, and Alabama. And because many of these plants are joint ventures between automakers and foreign battery companies, they are not subject to previous union contracts.

The UAW did not respond to a request for comment, but UAW president Shawn Fain told CNBC last week that the electric transition can’t leave workers behind. “Workers deserve their share of equity in this economy,” he said.

Tesla’s rise over recent years has also put ever-ratcheting pressure on the legacy automakers to cut costs. Including benefits, Musk’s non-unionized EV company spends $45 per hour on labor, significantly less than the $63 per hour spent in the Big Three, according to industry analysts.

Musk’s willingness to upend auto manufacturing shibboleths has also forced his legacy competitors to seek new efficiencies. Tesla led the way in building large-scale car casts, stamping out very large metal components in one go rather than making a series of small casts that have to be joined together. And it pioneered an automotive chassis building process that can be easily adapted to produce different makes and models.

Tesla’s Silicon Valley roots also helped it become the first automaker to envision the car as a software-first, iPhone-like “platform” that can be modified via over-the-air updates. And the company aims to automate more of its factories, and extract more of the materials it needs to build its batteries itself.

Tesla’s novel production ideas could soon lead the company to put even more pressure on legacy automakers. Musk said earlier this year that Tesla plans to build a new, smaller vehicle that can be made for half the production cost of its most popular (and cheapest) vehicle, the Model 3.

Musk says a lot of things, and many don’t come to pass. (The world is still waiting for the 1 million Tesla robotaxis promised by the end of 2020.) But Tesla has been disruptive enough to leave legacy automakers, including Detroit’s Big Three, “in a quest for capital,” says Marick Masters, who studies labor and workplace issues at Wayne State University's School of Business. Detroit’s automakers have made good money in the past decade—some $250 billion in profits—but also paid a significant chunk of it out in dividends. Pressure from Tesla and the EV transition it catalyzed has left them feeling as if they need every penny they can corral to keep afloat as the industry changes.

“They have little money to concede for union demands,” says Masters. The UAW’s wants include significantly higher wages, especially for workers who have joined the companies since their Great Recession and bankruptcy-era reorganizations, which left some with less pay and reduced pension and health benefits.

So far, the UAW has shown little patience for the idea that the automakers it is pressuring are cash-strapped and under competitive pressure. “Competition is a code word for race to the bottom, and I'm not concerned about Elon Musk building more rocket ships so he can fly into outer space and stuff,” UAW president Fain told CNBC last week when asked about pressure from Tesla. He has argued that production workers should receive the same pay raise received by auto executives over recent years.

When automakers have taken the opposite tack, insisting that they’re well capitalized and making plans to put them ahead of the electric car maker—well, that set up conditions for this strike too. The three American automakers are forecasted to make $32 billion in profits this year, a slight dip from last year’s 10-year high. “The more they toot their own horns about profitability, the more the union looks at them and says, ‘We want our rightful share,’” says Masters.

Tesla did not respond to a request for comment, but Musk has, in typical fashion, chimed in. He posted on X last week to compare working conditions at his companies with the competition, apparently seeking to turn the dispute he helped foment into a recruiting pitch. “Tesla and SpaceX factories have a great vibe. We encourage playing music and having some fun,” he wrote. “We pay more than the UAW btw, but performance expectations are also higher.” A UAW attempt to organize Tesla workers in 2017 and 2018, as the company struggled to produce its Model 3, failed. The National Labor Board ruled that Tesla violated labor laws during the organizing drive; the carmaker has appealed the decision.

5 notes

·

View notes

Text

1969 Holden Hurricane Concept

1969 Holden Hurricane Concept

1969 Holden Hurricane Concept

1969 Holden Hurricane Concept

1969 Holden Hurricane Concept

Holden has gone back to the future, restoring its very first concept car - the 1969 Holden Hurricane Concept.

The futuristic research vehicle described as an experiment "to study design trend, propulsion systems and other long range developments" has been restored to its former glory as a labour of love by a dedicated group of Holden designers and engineers.

Code named RD 001; the Holden Hurricane is a mid-engined, rear-wheel drive, two-seater sports car which incorporates a remarkable array of innovative features and technology, much of it way ahead of its time.

Features such as electronic digital instrument displays, station-seeking radio, automatic temperature control air conditioning, rear vision camera and an automated route finder were all showcased in this ground-breaking vehicle 42 years ago. Many of these technologies have only recently made their way into mass production, demonstrating Holden's remarkable foresight into both design and engineering technology.

The Holden Hurricane stole headlines and dropped jaws nationwide when it debuted at the 1969 Melbourne Motor Show.

Michael Simcoe, Executive Director GMIO Design, said it was fantastic to see such a significant vehicle restored.

"At Holden we have always prided ourselves on our ability to look into the future through our concept cars," Mr Simcoe said.

"It's amazing to think that the features we take for granted today were born out of creative minds over 40 years ago."

As its code name suggests, the RD 001 was the first product of the GMH Research and Development organisation, staffed by a small squad of engineers working in conjunction with the Advance Styling Group at the Fishermans Bend Technical Centre in the 1960s.

The team that designed and built the original Holden Hurricane employed some advanced technologies and techniques when it came to the powertrain. Powered by an experimental 4.2-litre (253 cubic inch) V8, this engine was a precursor to the Holden V8 engine program which entered production in late 1969.

The Holden Hurricane's V8 engine featured many advanced design components such as the four-barrel carburettor - a feature which wouldn't be seen on a production 253ci Holden V8 until the late 1970s. The end result was approximately 262hp (193kW), a towering power output in 1969 and one that ensured the Holden Hurricane had the go to match its show.

But perhaps the two most innovative features were the "Pathfinder" route guidance system and the rear-view camera.

The "Pathfinder", essentially a pre-GPS navigation system, relied on a system of magnets embedded at intersections along the road network to guide the driver along the desired route. A dash-mounted panel informed the driver of which turn to take by illuminating different arrows, as well as sounding a warning buzzer.

The rear-view camera was also a ground-breaking innovation.

Engineers using a Closed Circuit Television (CCTV) system with a camera mounted in the rear bumper feeding vision to a small black-and-white TV mounted in the centre console.

Former Holden Chief Studio Engineer Rick Martin led the modern-day Hurricane team in researching the vehicle's components, systems and history in order to restore it.

"There are some genuinely remarkable ideas and technology in the Hurricane," said Mr Martin.

"From the automatic air-conditioning and magnet-based guidance system, to the inertia-reel seat belts and metallic paint, this was a car that was genuinely ahead of its time.

"The hand-picked team of engineers and designers who built the original Holden Hurricane worked in strict secrecy and began Holden's now proud tradition of ground-breaking concept cars."

RD 001 stands just 990mm high and has no doors in the conventional sense. A hydraulically-powered canopy opens upwards and forward over the front wheels, combined with twin "astronaut type" power-elevating seats which rise up and pivot forward, along with the steering column for ease of access. Occupants are then lowered to a semi-reclining position before the roof closes over them.

The wind tunnel-tested fibreglass body consists of three segments; the canopy, the engine hood and body shell and was finished in an experimental aluminium flake-based metallic orange paint.

Safety innovations included a foam-lined fuel tank, integrated roll-over bar, digital instrument readouts, ignition safety locks, interior padding and a fire warning system.

The project to restore RD 001 began in 2006 and has been a genuine labour of love for some very dedicated Holden employees. The entire restoration process has been driven primarily by volunteer labour from Holden designers and engineers in their spare time.

But the Hurricane first entered Holden Design in less than immaculate condition. RD 001 had a residency in a trade school where apprentices practised their welding on the priceless concept.

After being returned to Holden in 2006, the Hurricane restoration project has taken many thousands of painstaking man hours to lovingly restore RD 001 to concourse condition.

Holden's Manager for Creative Hard Modelling, Paul Clarke, has been largely responsible for managing the restoration of RD 001. He ensured as many of the original parts as possible have been used or remade using modern techniques to 1969 specification, in order to preserve the authenticity of this hugely important Holden.

"The entire team has done a fantastic job in bringing this beautiful concept back to life," Mr Clarke said.

"The talent we have within the Holden organisation is simply outstanding. Every time we take on a project I'm constantly amazed by the passion and talent in this company, making it a genuine pleasure to work on these projects.

"The Hurricane plays a crucial role in Holden's story and the company has such a great sense of history and heritage that it was very important to bring RD 001 back to life. It's been a challenging but incredibly rewarding process."

Since the debut of the Holden Hurricane Concept in 1969, Holden has continued to build a global reputation for envisioning and executing world-class concept vehicles. Holden is recognised globally within General Motors as a centre of excellence for concept vehicle and show car development and is one of only three GM design studios that is capable to design and build concept cars.

Michael Simcoe added that the Hurricane holds a particularly special place in Holden's history as it kick-started Holden's long love affair with concepts that has since seen the likes of the iconic GTR-X, Torana TT36, Coupe 60, the GMC Denali XT (which was requested specifically by GM for the North American market) and the award-winning Efijy.

Holden Hurricane Concept (1969)

58 notes

·

View notes

Text

AMG S63 E PERFORMANCE „The Boss“.

Mercedes-AMG S63 E PERFORMANCE (combined fuel consumption, weighted: 4.4 l/100 km; combined CO2 emissions, weighted: 100 g/km; combined power consumption, weighted: 21.4 kWh/100 km)[1] with AMG hybrid technology once again sets the benchmark in the segment. The E PERFORMANCE model combines the AMG 4.0-litre V8 biturbo engine with the AMG-specific hybrid powertrain and a new expansion stage of the AMG high-performance battery.

The focus of the powertrain, however, is less on electric range and more on best-in-class performance. With 590kW (802hp) of system output and 1430Nm of system torque, the saloon sets new standards in the segment. The acceleration of 3.3 seconds to 100km/h and the optional top speed of 290km/h underline the superior, dynamic driving performance. Systems such as the AMG RIDE CONTROL+ suspension, AMG ACTIVE RIDE CONTROL roll stabilisation and rear-axle steering as standard ensure a wide spread between driving dynamics and comfort.

A central component of the P3 hybrid powertrain is the AMG 4.0 V8 biturbo engine, in this case producing 450kW (612hp). It provides a maximum torque of 900Nm, which is available over a wide speed range. The engine’s most important design features include the two twin-scroll turbochargers, which are located in the hot inner-V. The position between the two cylinder banks shortens the paths of the exhaust gases to the turbocharger and the compressed fresh air to the combustion chamber.

The result is a very immediate response. Another important feature is the belt-driven starter-generator (RSG), which is integrated into the 400-volt electrical system. This combines the starter and alternator into one unit, and has sufficient power to always start the V8 at once.

Mercedes-AMG One man, one engine Handcrafted by Michael Kübler @f1mike28 in Germany Affalterbach. Driving Performance is our Passion!

Mercedes-AMG the Performance and Sports Car Brand from Mercedes-Benz. Mercedes-AMG Handcrafted by Racers.

#amg#sclass#s63#s63amg#s63amgeperformance#s63eperformance#eperformance#mercedesamg#mercedes#mercedesbenz#affalterbach#onemanoneengine#pagani

9 notes

·

View notes

Text

Royal Enfield Meteor 350 Gets Aurora Colour Variant At Rs 2.20 Lakh

Royal Enfield has widened the Meteor 350 range by launching the new Aurora variant of the cruiser.

It gets a couple of changes over other variants of the bike and comes with a price tag of Rs. 2,19,900 (ex-showroom, Chennai) which places it between the Stellar and Supernova trims of the Meteor 350.

RE Meteor 350 Thoroughly Overhauled

The new Aurora variant of the Meteor 350 comes equipped with spoke wheels and tube tyres, unlike other versions which get alloy wheels and tubeless rubbers.

Moreover, the engine case, exhaust system, and a few other components have been bestowed with chrome finishing. All of this is done to enhance the retro appeal of the bike.

You may like it : Best Bikes in India 2023

Royal Enfield Meteor 350 Aurora continues to receive the same J-series underpinnings, the 349 cc air-cooled, long-stroke engine, with 20.2 bhp and 2.75 kgm of torque, mated to a five-speed transmission.

What’s new with Aurora trim?

The trim introduces three new colourways and also debuts LED headlights to the range. Royal Enfield might make the latter feature standard with this range in the future.

You may like it : Royal Enfield Himalayan 452 Production Starts

As opposed to black treatment on all other trims, Aurora trim stands out in its classic appeal. RE is also giving Aurora LED headlights, a deluxe touring seat, aluminium switch cubes, a Tripper display for navigation and more.

Feature additions

Apart from adding Aurora trim, Royal Enfield has fettled with Meteor 350’s trim-wise features list too. Top-spec Supernova trim now gets LED headlights and aluminium switchgear, taking it a notch higher than before. Astral trim now gets Royal Enfield’s Tripper screen for navigation as standard fitment.

You may like it : RE Himalayan 452 Easily Clocks Over 140 km/h – VIDEO

With base Fireball trim, Royal Enfield has added a new Black stock colour which is both elegant and standard. Powering RE Meteor 350 is a 349cc J-series single-cylinder, air-cooled motor that kicks out 20.2 bhp at 6100rpm and a peak torque of 27 Nm at 4000rpm.

This unit is paired with a 5-speed gearbox. The same powertrain is found on newly launched Bullet 350 too.

Meteor 350 is underpinned by a dual-cradle J-series chassis which is suspended on 41mm RSU telescopic suspension at the front and twin shocks at the rear. Anchorage duties are handled by a 300mm front disc and a 270mm rear disc which are aided by a dual-channel ABS as standard.

In terms of features, it comes with a semi-digital instrument console, a USB charger, circular LED DRL and a side-stand engine inhibitor, among many.

You may like it : Best Electric Bikes in India Words from the manufacturer

Speaking about the new range and enhancements on the Meteor 350, B Govindarajan, CEO – Royal Enfield said, “As we reflect on the remarkable success of the Meteor 350 in India and international markets it is evident that the Meteor has struck a chord with many long distance riders and motorcycling enthusiasts. Its dynamic cruising ability and dependable performance have resonated deeply with our riders.

The Aurora range is a result of our constant interactions with our community of riders, where we witnessed a strong inclination towards retro-inspired cruisers. The new colourways and features are sure to elevate the pleasure of pure retro-cruising among our customers.”

#Meteor #Overhauled

2 notes

·

View notes